Gas injection device of semiconductor heat treatment equipment and semiconductor heat treatment equipment

A technology of heat treatment equipment and gas injection, which is applied in semiconductor/solid-state device manufacturing, electrical components, gaseous chemical plating, etc., can solve the problems of inability to guarantee the uniformity of gas distribution, poor process results, and uneven gas volume, etc., to achieve guaranteed Consistency of process results, guarantee of thickness uniformity and process result consistency, effect of guarantee of thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

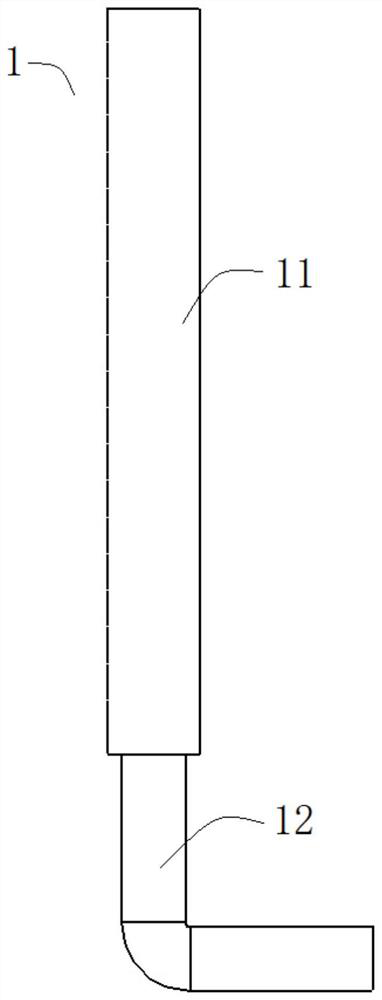

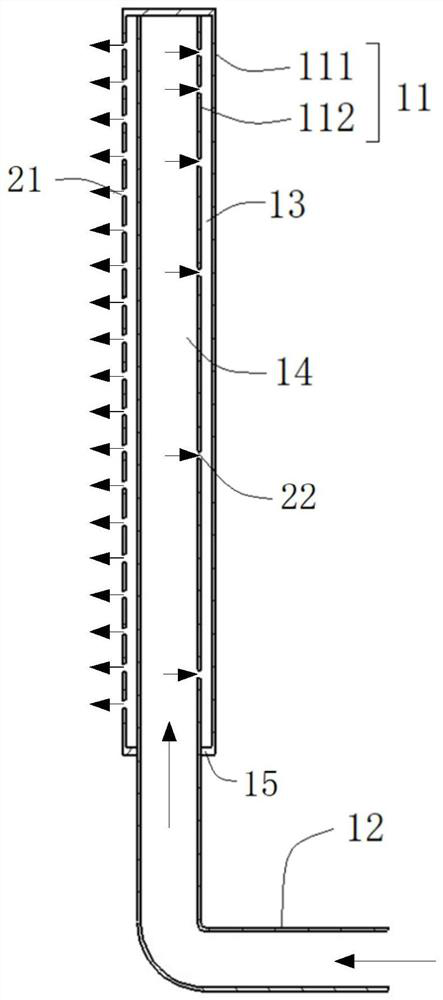

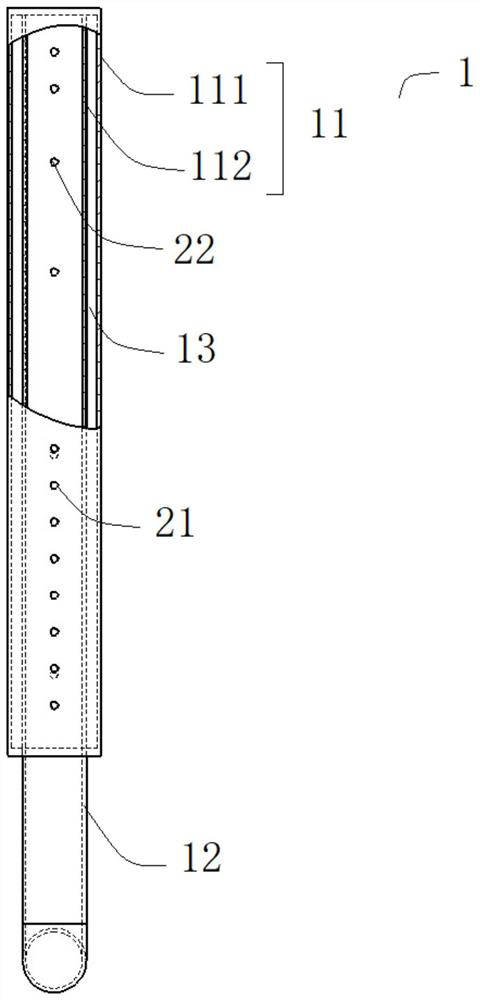

[0034] see figure 1 , the gas injection device provided in this embodiment is applied to semiconductor heat treatment equipment, especially vertical heat treatment equipment, the gas injection device includes an inlet pipe 1 for delivering process gas to the process chamber of the semiconductor heat treatment equipment, the The inlet pipe 1 comprises a first pipe section 11 and a second pipe section 12, wherein the first pipe section 11 is vertically arranged in the process chamber, and the upper end of the first pipe section 11 is closed, and the lower end of the first pipe section 11 is connected to the second pipe section 12 is connected to the upper end, and the lower end of the second pipe section 12 is connected to a gas source (not shown in the figure) for supplying process gas. Optionally, the lower end of the second pipe section 12 runs through the chamber wall of the process chamber, extends to the outside of the process chamber, and is connected to an external gas s...

no. 2 example

[0054] Please also refer to Figure 4 and Figure 5 , the gas injection device provided by this embodiment, compared with the above-mentioned first embodiment, also includes an air inlet pipe 3, and the air inlet pipe 3 includes a first pipe section 31 and a second pipe section 32, wherein the first pipe section 31 is vertically arranged In the process chamber, and the upper end of the first pipe section 31 is closed, the lower end of the first pipe section 31 is connected with the upper end of the second pipe section 32, and the lower end of the second pipe section 32 is connected with the gas source for providing process gas (in the figure not shown) connection.

[0055] Moreover, the first pipe section 31 adopts a double pipe wall structure, that is, the first pipe section 31 includes a first pipe wall 311 and a second pipe wall 312 nested in the first pipe wall 311, and the inner wall of the first pipe wall 311 A buffer space 33 is formed between the outer wall of the se...

no. 3 example

[0061] see Figure 6 , the gas injection device provided in this embodiment, compared with the above-mentioned first embodiment, also includes an air inlet pipe 5, and the air inlet pipe 5 includes a first pipe section 51 and a second pipe section 52, wherein the first pipe section 51 is vertically arranged In the process chamber, and the upper end of the first pipe section 51 is closed, the lower end of the first pipe section 51 is connected with the upper end of the second pipe section 52, and the lower end of the second pipe section 52 is connected with the gas source for providing process gas (in the figure not shown) connection.

[0062] Moreover, the first pipe section 51 adopts a double pipe wall structure, that is, the first pipe section 51 includes a first pipe wall 511 and a second pipe wall 512 nested in the first pipe wall 511, and the inner wall of the first pipe wall 511 A buffer space 53 is formed between the outer wall of the second pipe wall 512 , and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com