Patents

Literature

48results about How to "Guaranteed thickness consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging method for high-capacity polymer lithium ion cells

InactiveCN107394279AControl thicknessGuaranteed electrical performanceFinal product manufactureElectrolyte accumulators manufactureLithiumBreakage rate

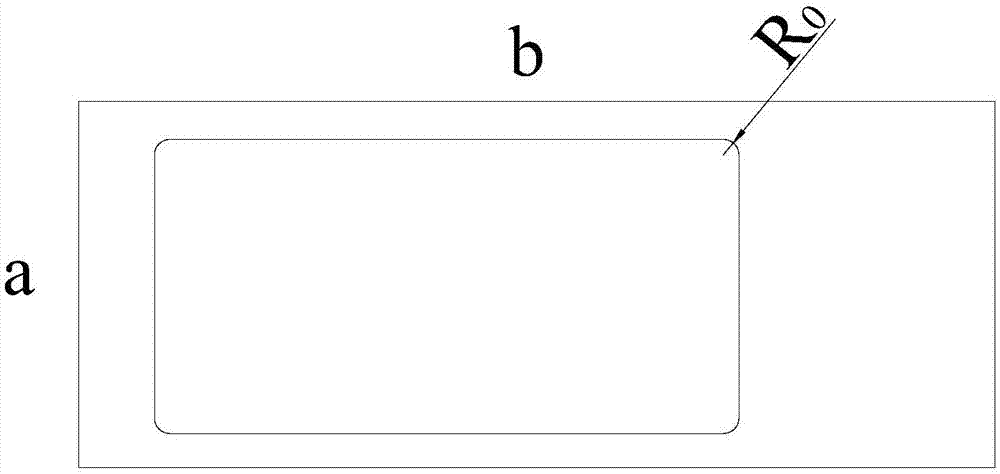

The invention discloses a packaging method for high-capacity polymer lithium ion cells. The packaging method comprises the following steps: (1) a bag is formed from at least one of two aluminum plastic films by stamping; when the thickness of a cell is smaller than 6 mm, one bag is formed from one aluminum plastic film by stamping, and when the thickness of a cell is larger than or equal to 6 mm, bags are formed from the two aluminum plastic films by stamping; (2) the cell is loaded into an opening of the bag formed from one aluminum plastic film by stamping, and the opening of the bag is correspondingly covered with the other aluminum plastic film; (3) three edges of the cell are sealed in a hot manner with seal heads. With adoption of the packaging method for the high-capacity polymer lithium ion cells, the breakage rate of the aluminum plastic films is reduced, the aluminum plastic film use efficiency is increased, and electrical performance of the high-capacity polymer lithium ion cells can be guaranteed effectively; the packaging method is simple to operate.

Owner:海口博澳国兴新能源科技有限公司

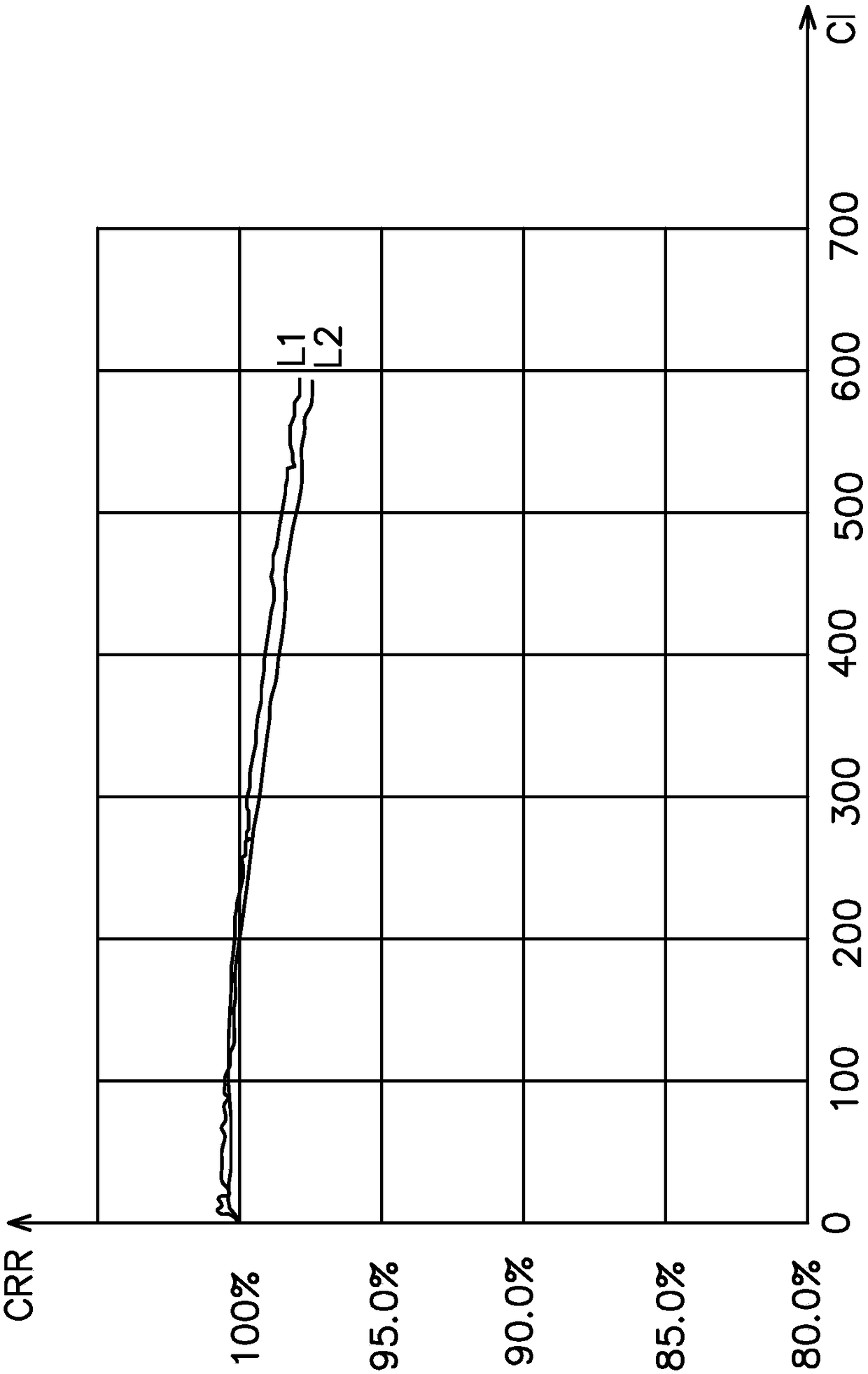

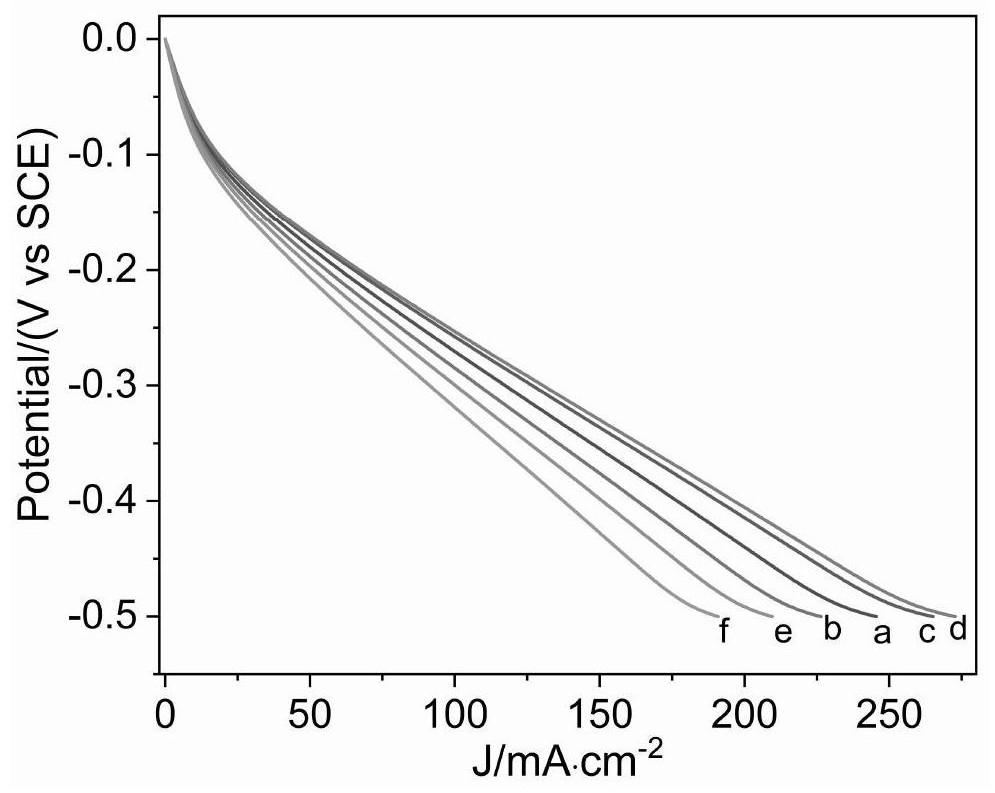

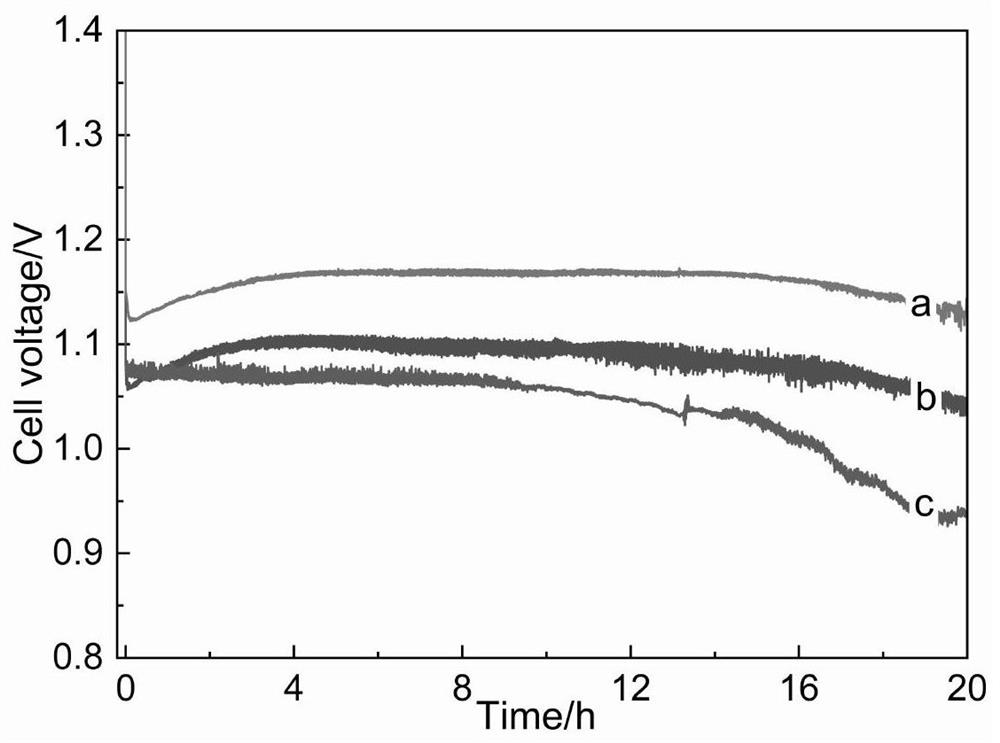

Formation method of soft package lithium ion battery

ActiveCN108598581AClosely spaced and consistentGuaranteed shuttle distanceFinal product manufactureElectrolyte accumulators manufactureElectrical batteryHigh energy

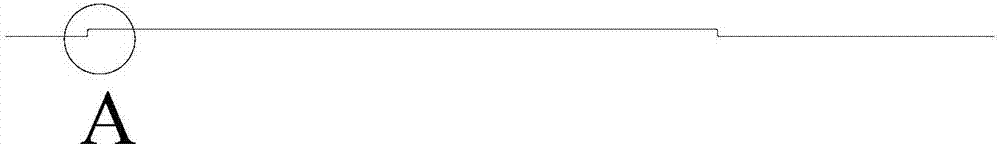

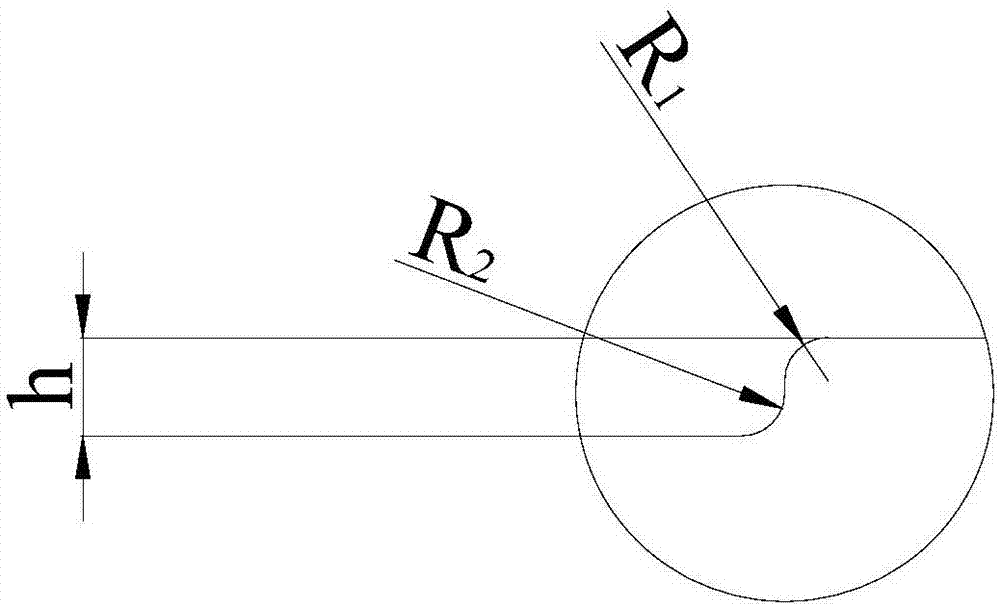

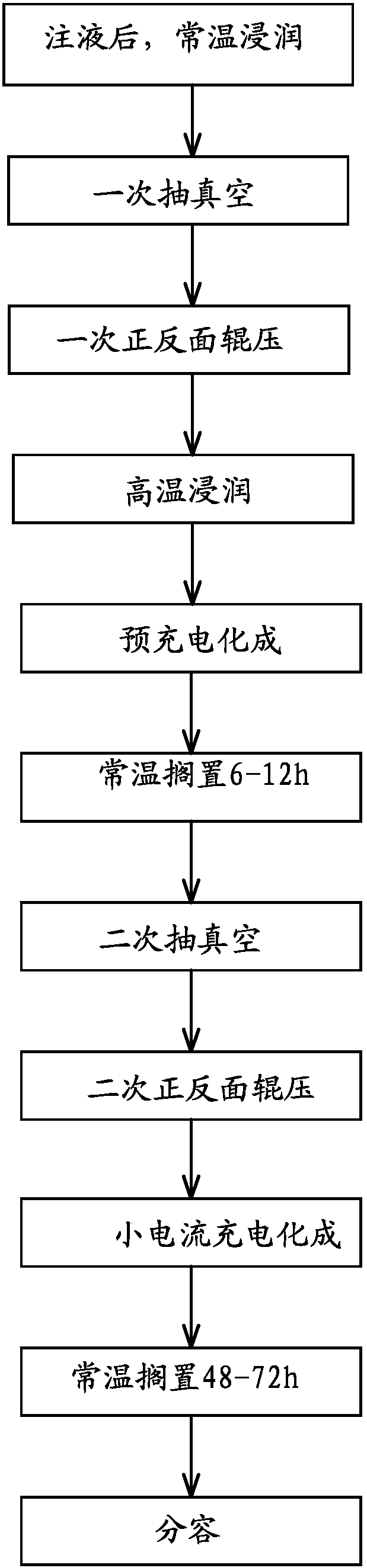

The invention provides a formation method of a soft package lithium ion battery, and belongs to the technical field of lithium ion battery manufacturing. By the formation method, the problems that howgas in the soft package lithium ion battery is effectively discharged and the formation of a more compact and stable SEI film is facilitated are solved. The formation method of the soft package lithium ion battery comprises the steps of performing pre-charging formation, secondary vacuumizing and small-current charging formation on the lithium ion battery, before pre-charging formation, performing primary vacuumizing on the lithium ion battery subjected to liquid injection and being immersed at a normal temperature to preset vacuum, performing vacuum thermal package, performing primary front-surface and back-surface rolling on the lithium ion battery after vacuum hot sealing by a rolling device, performing high-temperature immersion, reducing a temperature to a room temperature, and performing secondary front-surface and back-surface rolling on the lithium ion battery after vacuum hot sealing by a rolling device between secondary vacuumizing and small-current formation. By the method,the more compact and stable SEI film is formed on a surface of a lithium ion battery negative electrode in a high-energy consumption mode in a more stable and safer environment, so that the performance of all aspects of the lithium ion battery is improved.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

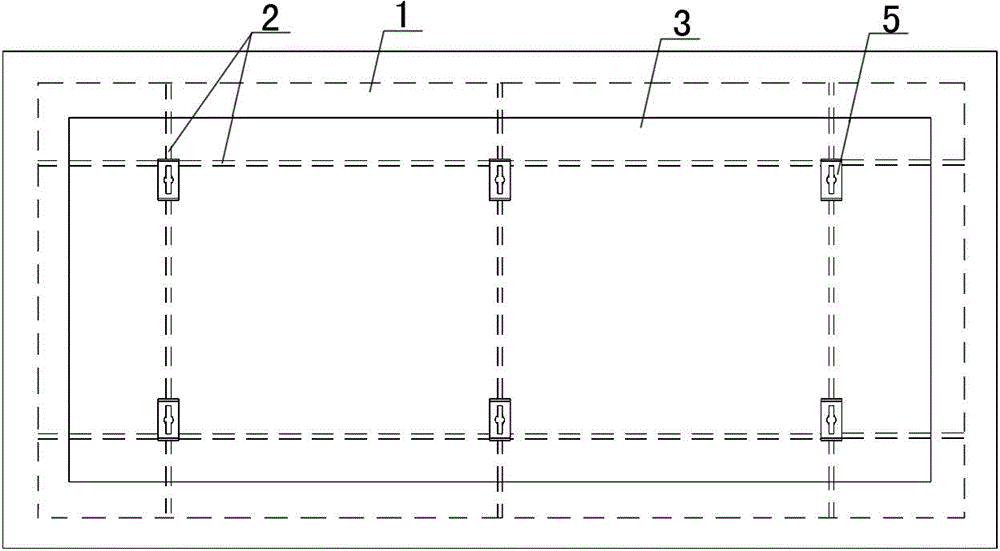

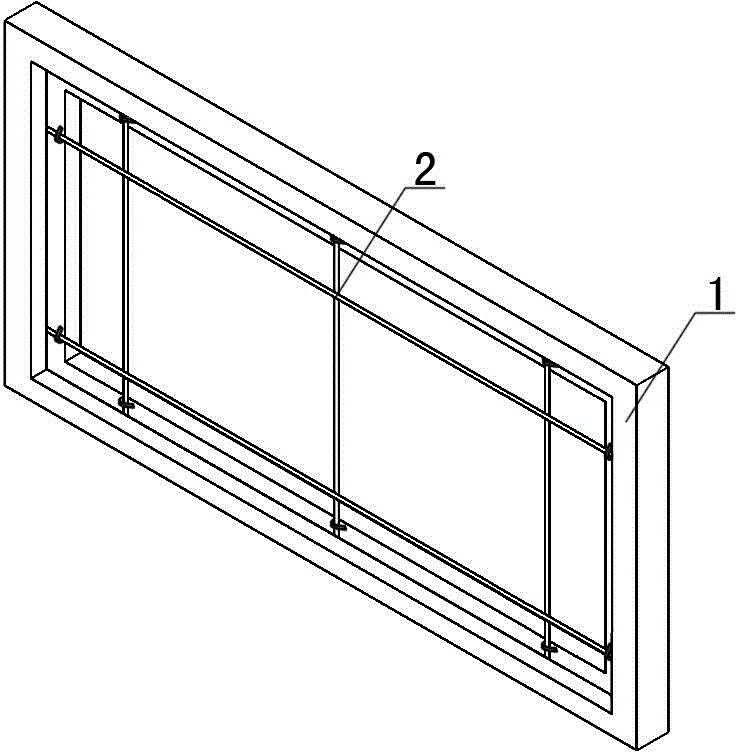

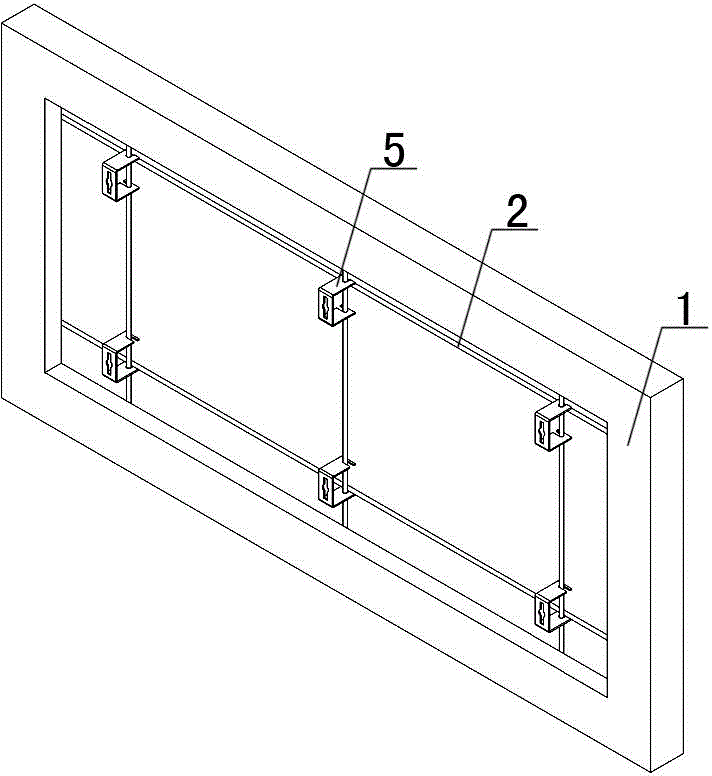

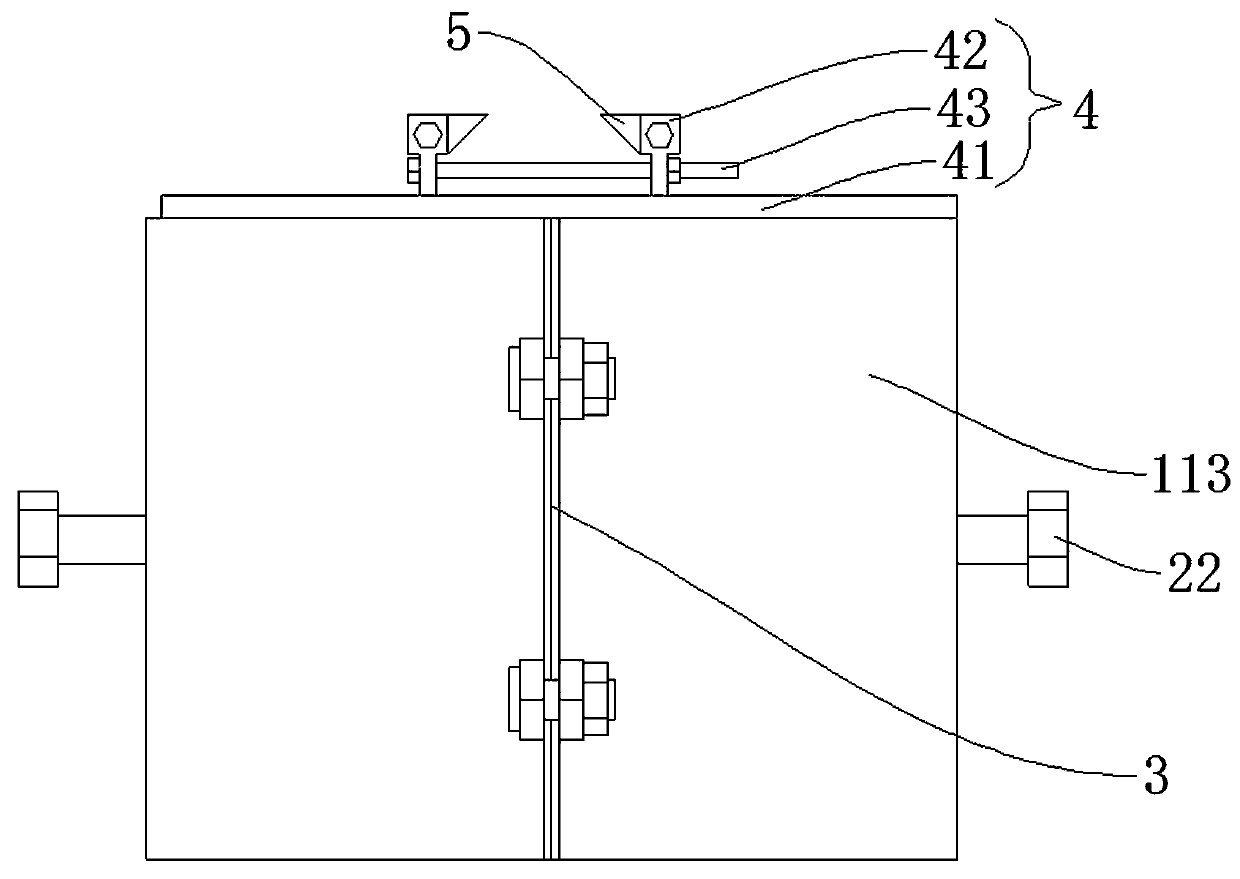

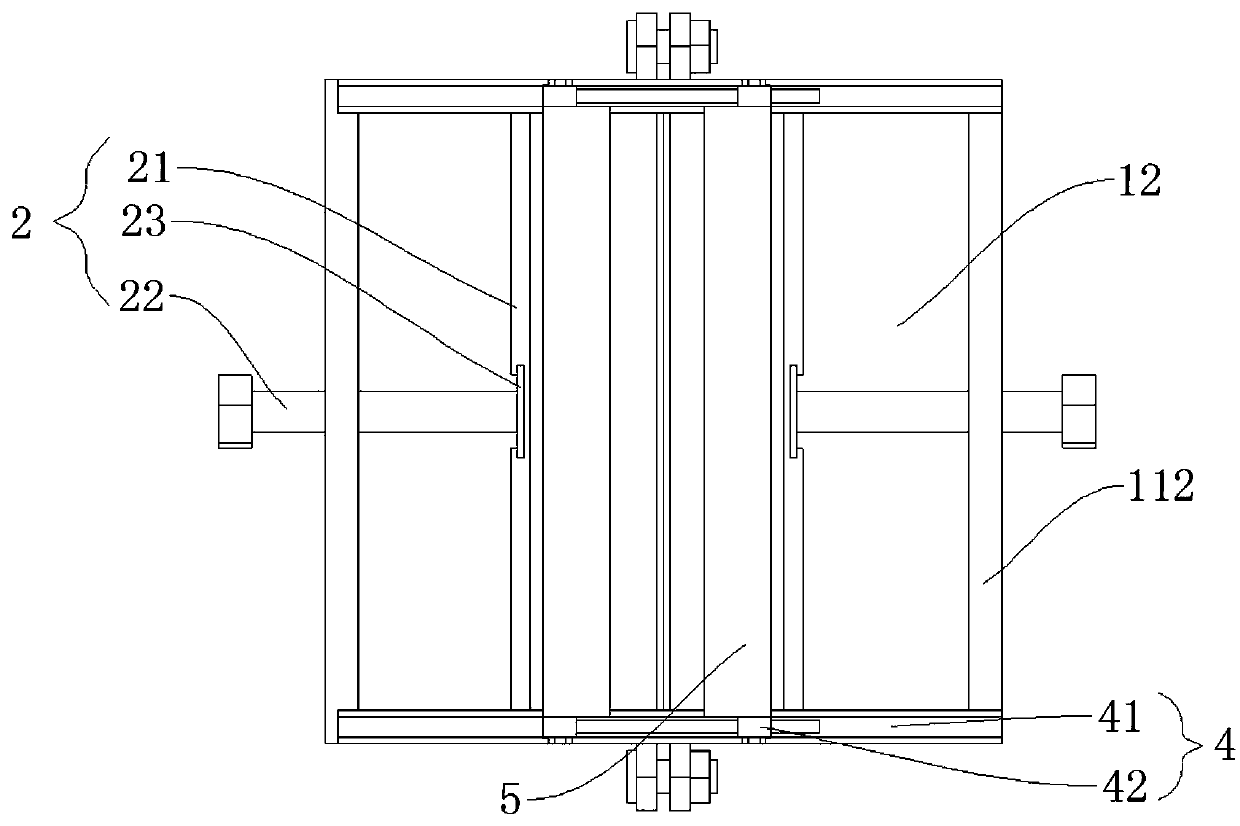

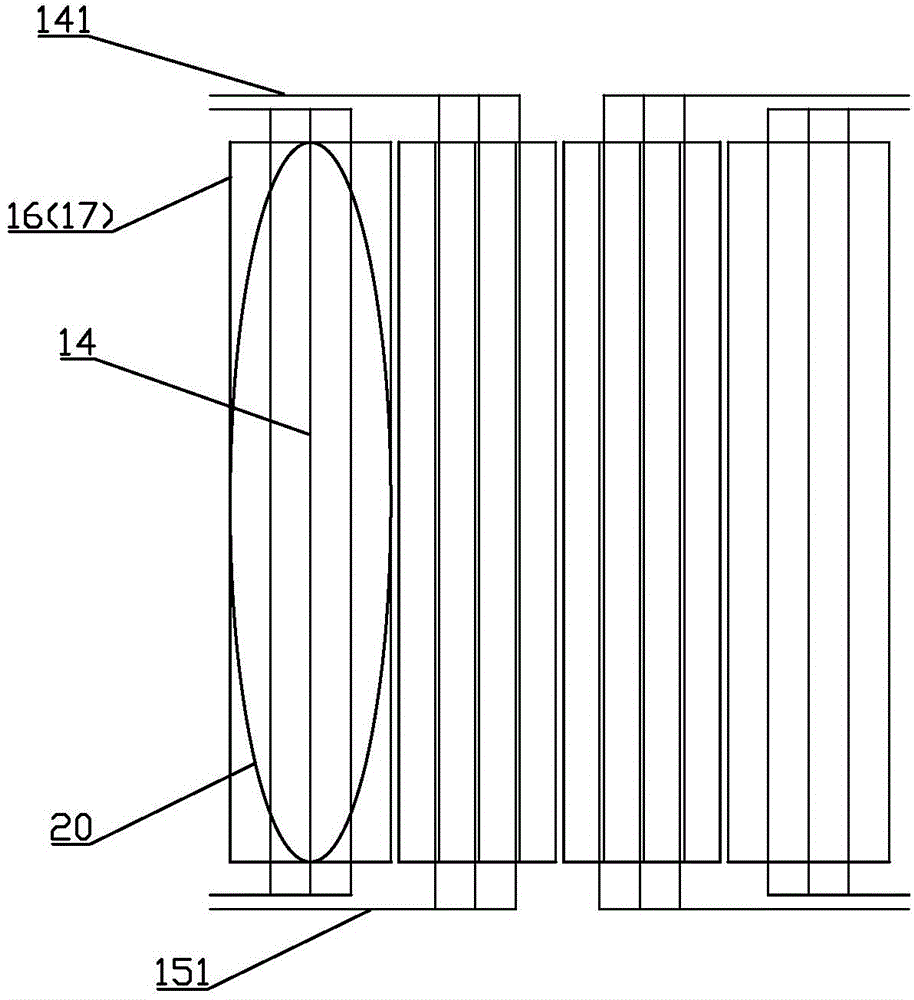

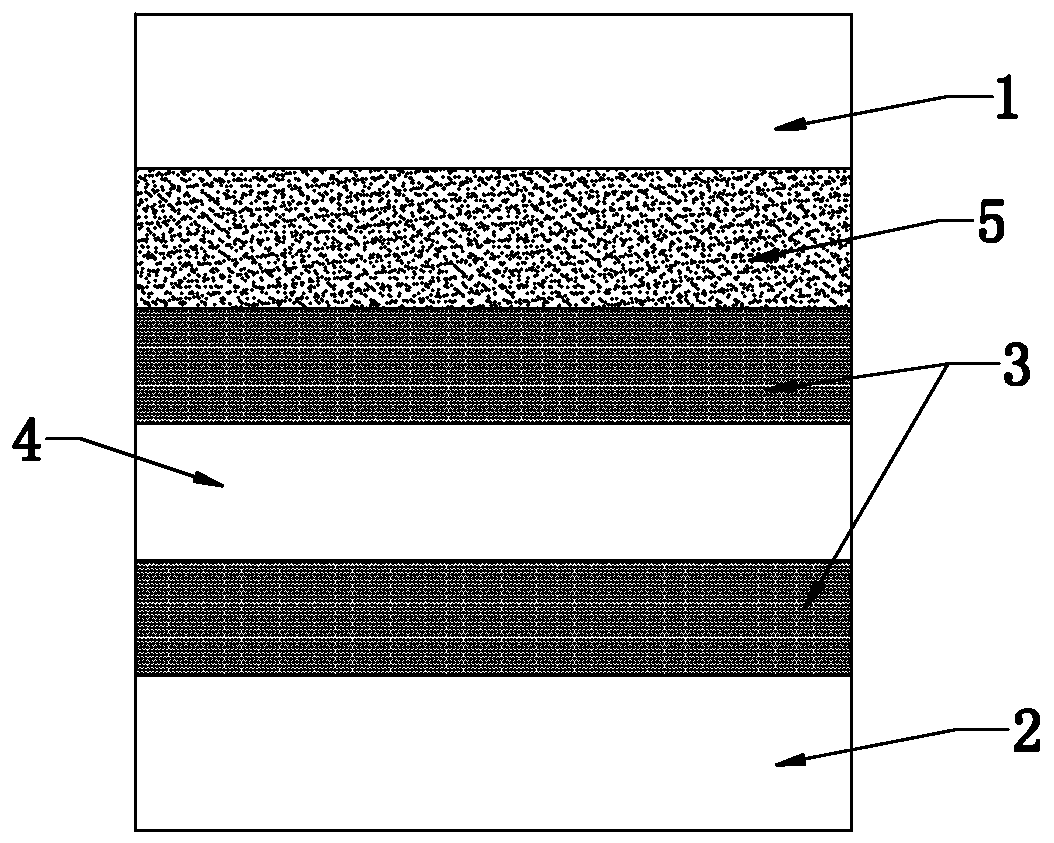

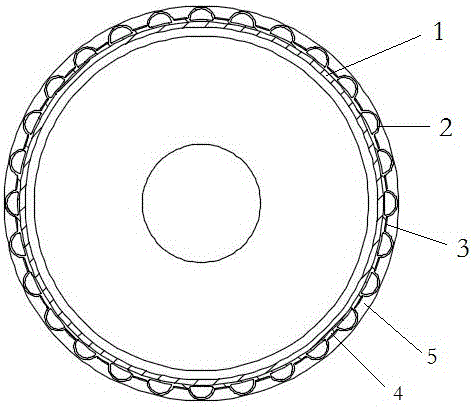

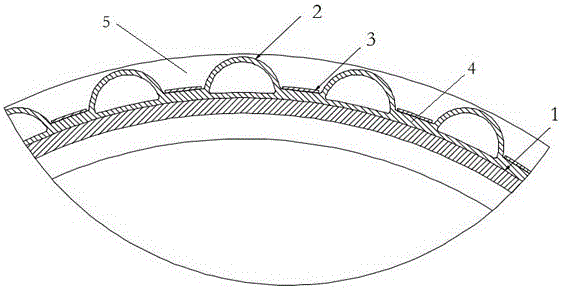

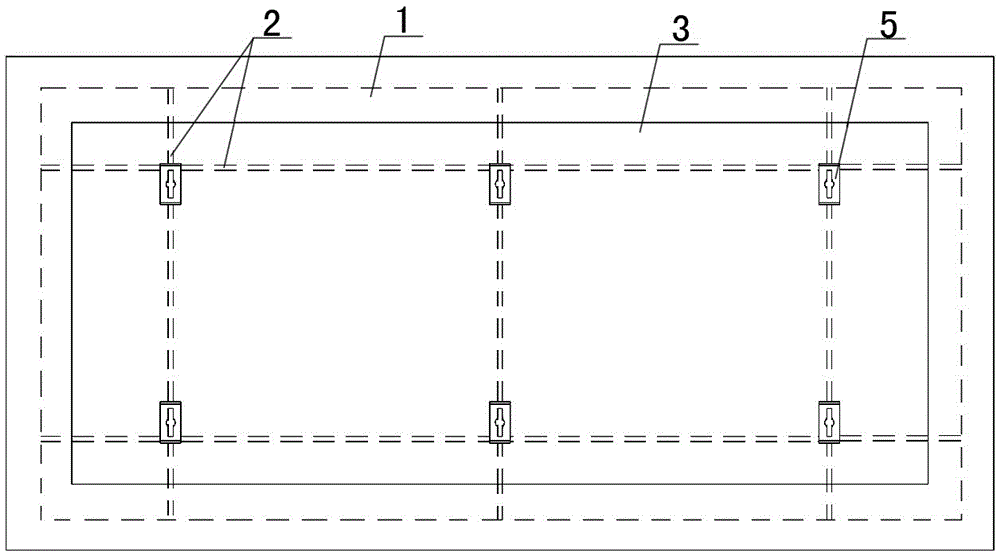

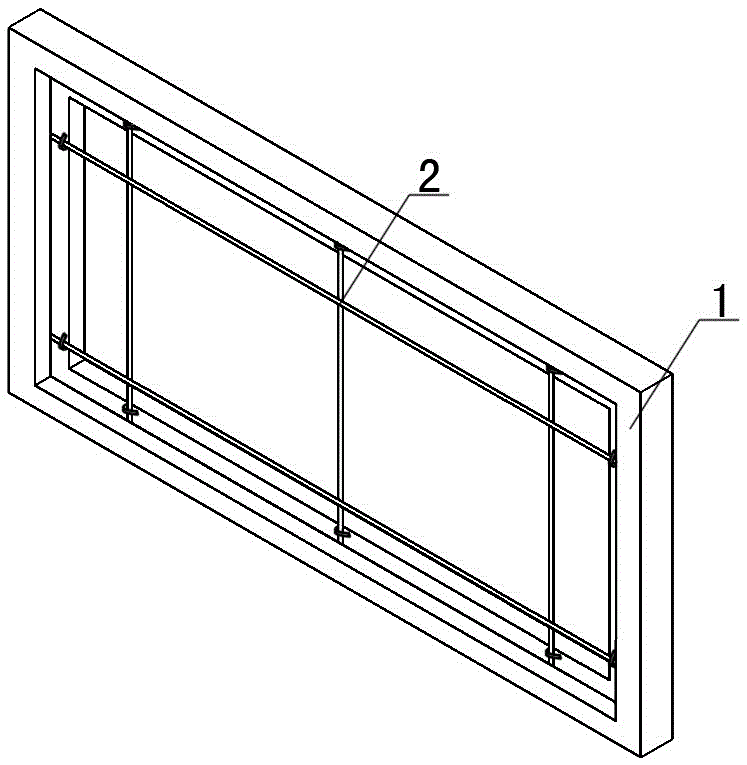

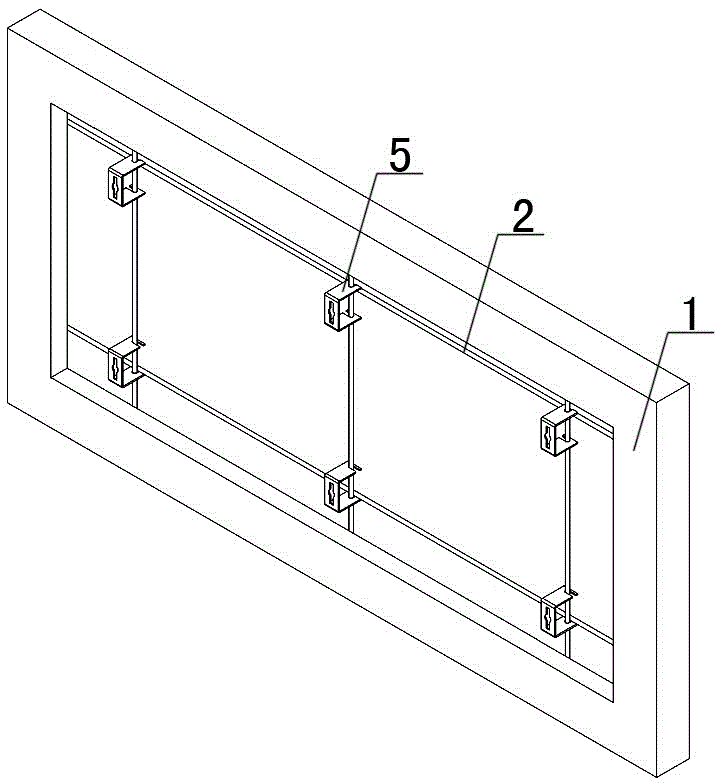

Non-dismantling die cast-in-place lightweight thermal insulation wall formboard, thermal insulation wall and construction method thereof

ActiveCN104674985AReduce the amount of constructionFast constructionWallsThermal insulationDie casting

Disclosed are a non-dismantling die cast-in-place lightweight thermal insulation wall formboard, a thermal insulation wall and a construction method thereof. The formboard comprises an inner formboard unit, an outer formboard unit and opposite-drawing connectors connecting the formboard units; the inner formboard unit comprises a formboard frame, steel bar grid frames connected between inner circles of the formboard frame, steel bar clamps connected to the cross points of the steel bars of the steel bar grid frames and a formboard core filling the inner side of the formboard frame; the inner formboard unit and the outer formboard unit are the same in structure and are connected at two ends of the opposite-drawing connector symmetrically; the steel bar clamps of the inner formboard unit and outer formboard unit are corresponded horizontally and are connected through the opposite-drawing connectors. The thermal insulation wall is simple in structure, by means of the double-layer wall formboard, the wall thickness consistence is guaranteed, the strength performance requirements are met, the thermal insulation wall is convenient to construct, the matching bar, core column and tie beam arrangement procedures are omitted, construction cost is lowered, constructing efficiency is improved, and the formboard can widely applied to wall construction.

Owner:北京振利节能环保科技股份有限公司

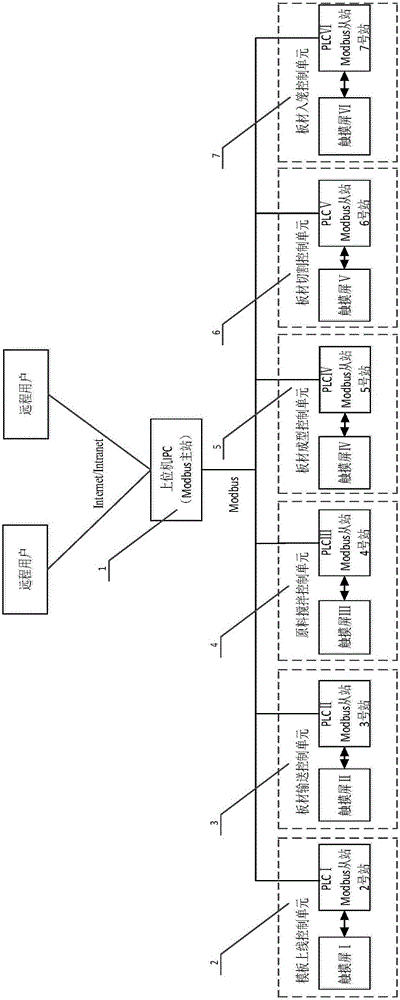

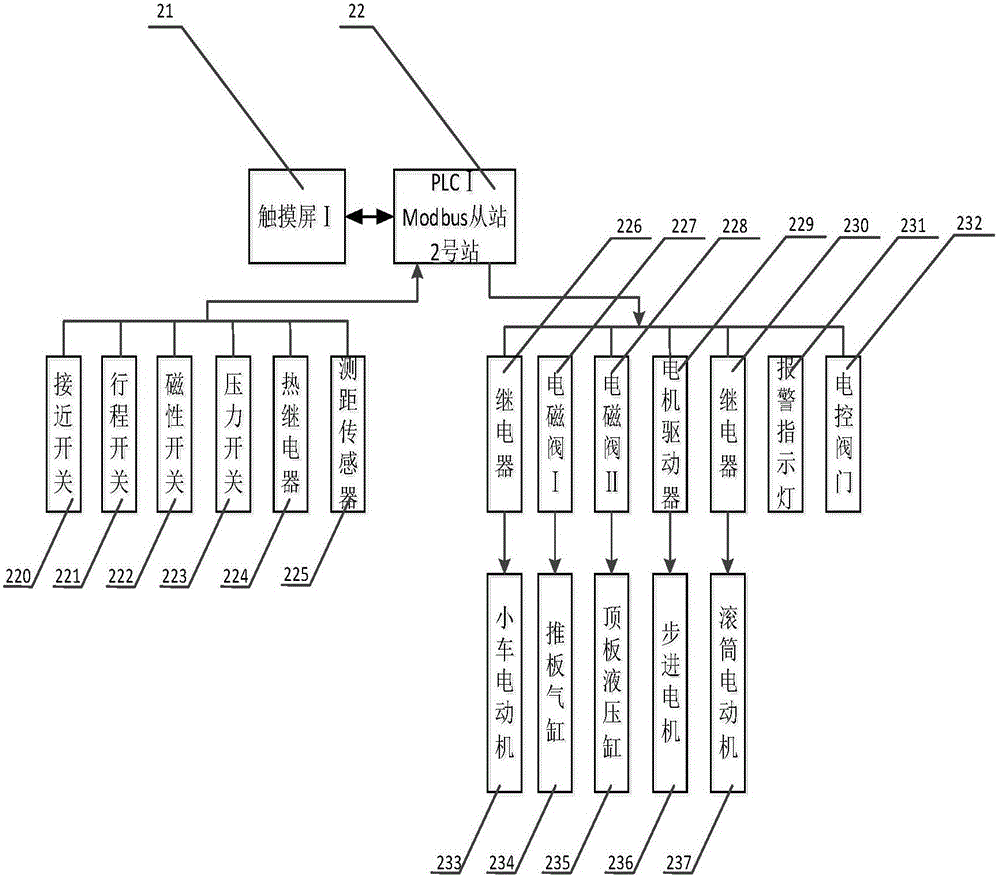

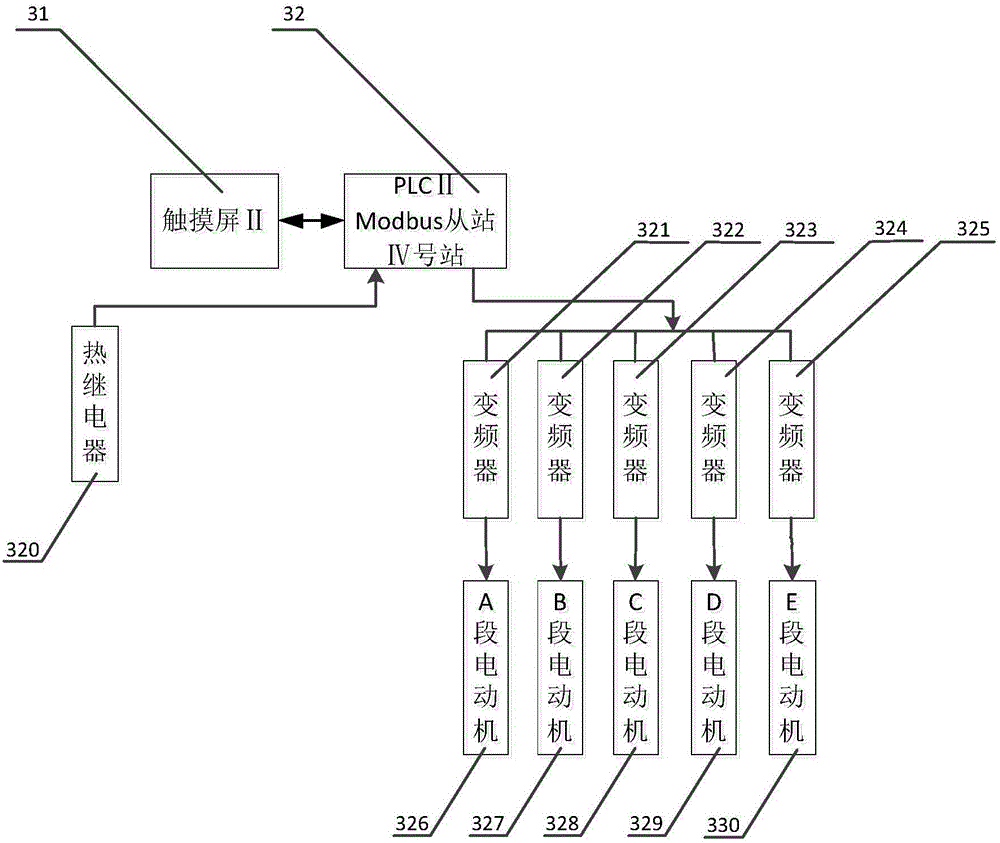

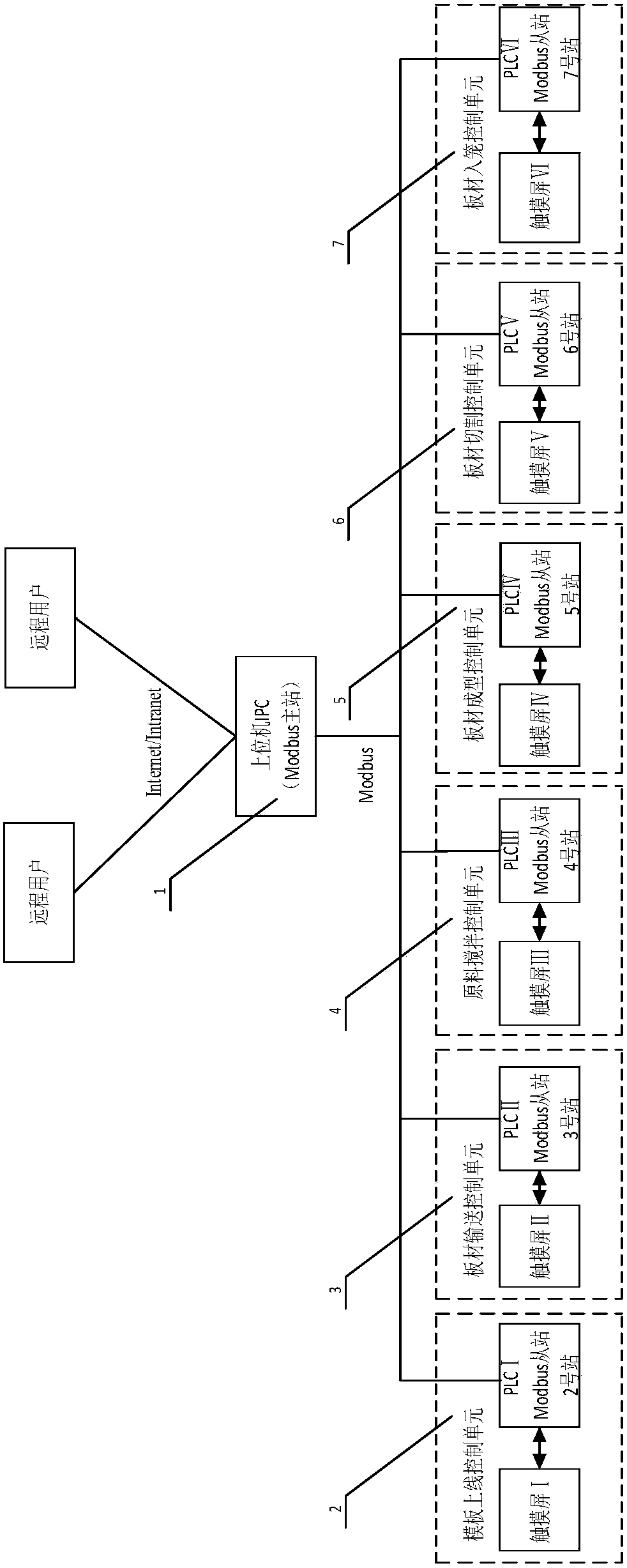

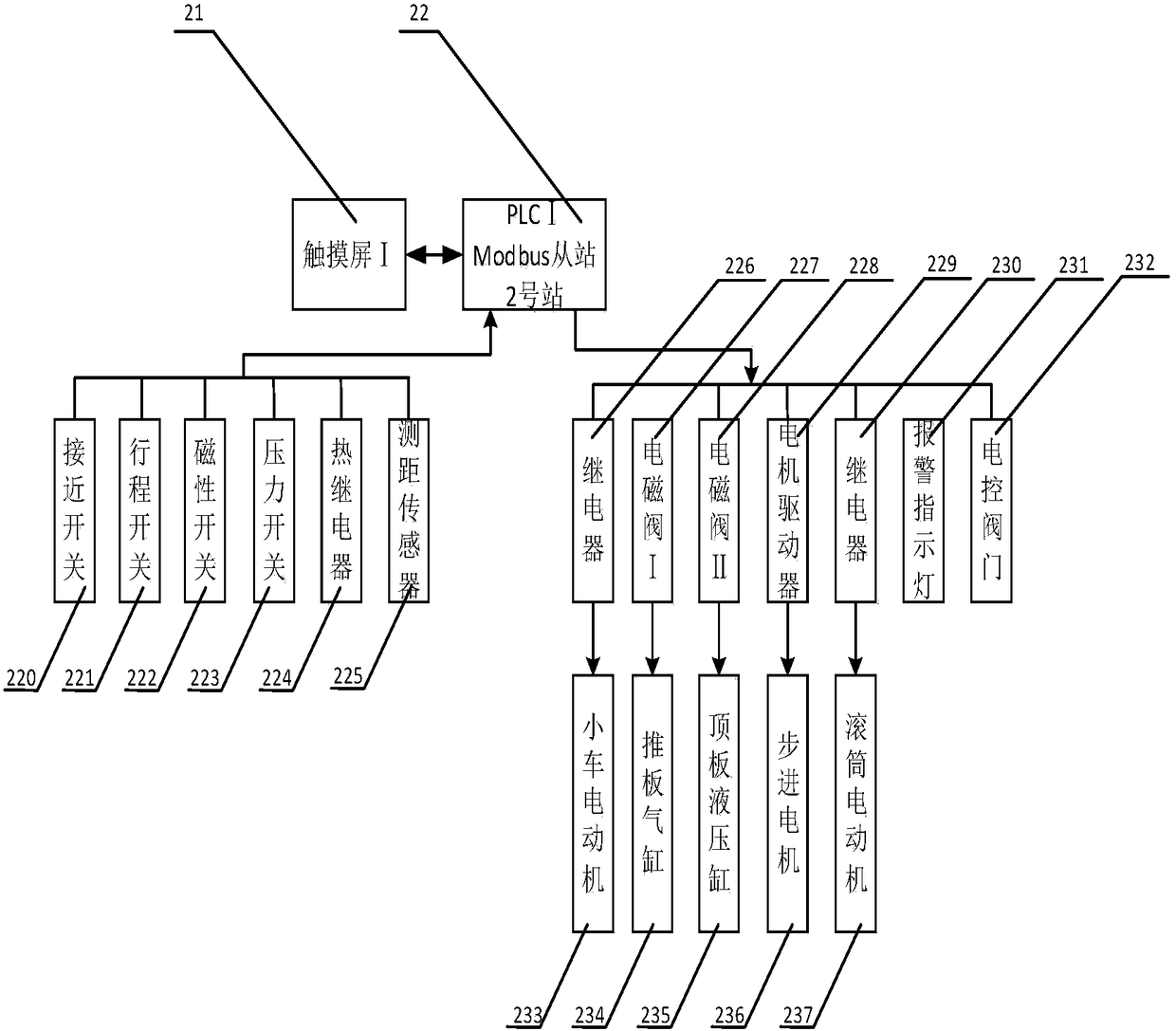

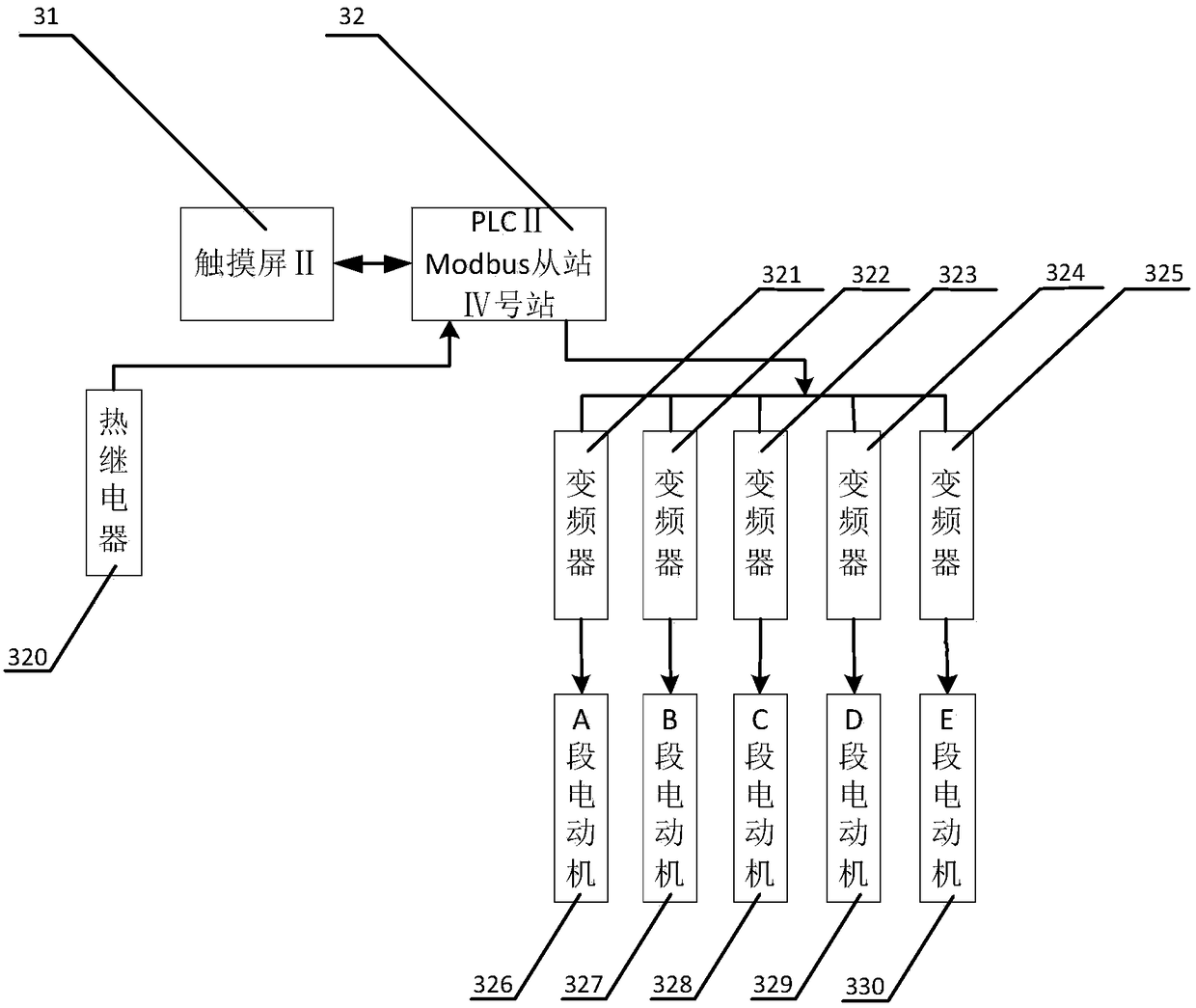

Distributive control system and control method thereof for glass magnesium board production line

ActiveCN106020143AImprove reliabilityHigh degree of automationTotal factory controlProgramme total factory controlProduction lineControl system

The invention discloses a distributive control system and control method thereof for a glass magnesium board production line. The system includes an upper computer IPC, a template application control unit, a board conveying control unit, an accessory stirring control unit, a board forming control unit, a board cutting control unit and a board caging control unit. The upper computer IPC is a main station of a Modbus while the control units are the slave stations of the Modbus, so that a distributive control system for the glass magnesium board production line is formed. The upper computer IPC takes charge of data exchange among the control units and ensures the work coordination of the control units. Each control unit includes a PLC and a touch screen achieving unit control under the coordination of the upper computer IPC. According to the invention, by adopting distributive control, an industrial bus technology, an advanced sensor technology, a PID technology and a remote monitoring technology and the like are integrated into the control system. The automation degree is high.

Owner:JIANGSU UNIV OF SCI & TECH

Method for continuously coating high-viscosity sizing agent used for preparing positive pole piece of lithium-manganese primary cell

InactiveCN103357557AGuaranteed thickness consistencyEnsure uniformityLiquid surface applicatorsElectrode manufacturing processesElectrolysisPrimary cell

The invention provides a method for continuously coating a high-viscosity sizing agent used for preparing a positive pole piece of a lithium-manganese primary cell, wherein thermally treated electrolyzed manganese dioxide is mixed with a conductive black, then deionized water or distilled water containing a polar alcohol solvent is added for continuous mixing to obtain a wet mixture, then an aqueous solution of a binder commonly used by a lithium battery is added for continuous mixing to obtain the high-viscosity sizing agent, the high-viscosity mixed sizing agent is prepared into particles, is rolled by a coating roller into a continuous piece, and is bonded on the two sides of a current collector after being rolled, so that a positive pole material piece with uniform thickness is continuously prepared, and the required positive pole piece can be obtained after the processes of drying, rolling, cutting and clearing the powder. According to the method for continuously coating the high-viscosity sizing agent used for preparing the positive pole piece of the lithium-manganese primary cell, the production efficiency and the production consistency are improved, the uniformity of the thickness of the material piece is guaranteed, and the performance of the pole piece is improved.

Owner:中国兵器工业第二一三研究所

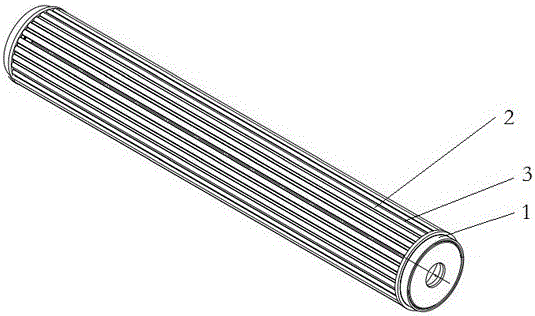

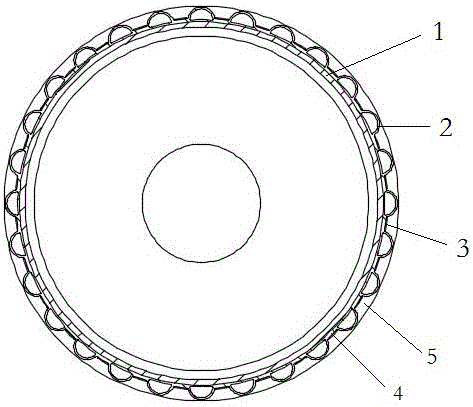

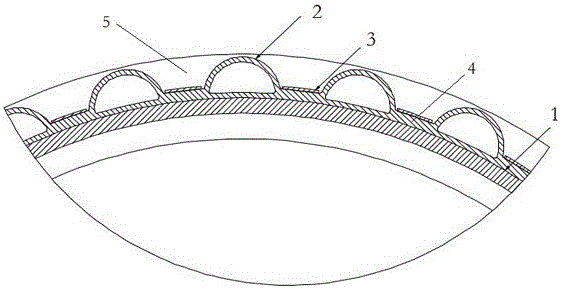

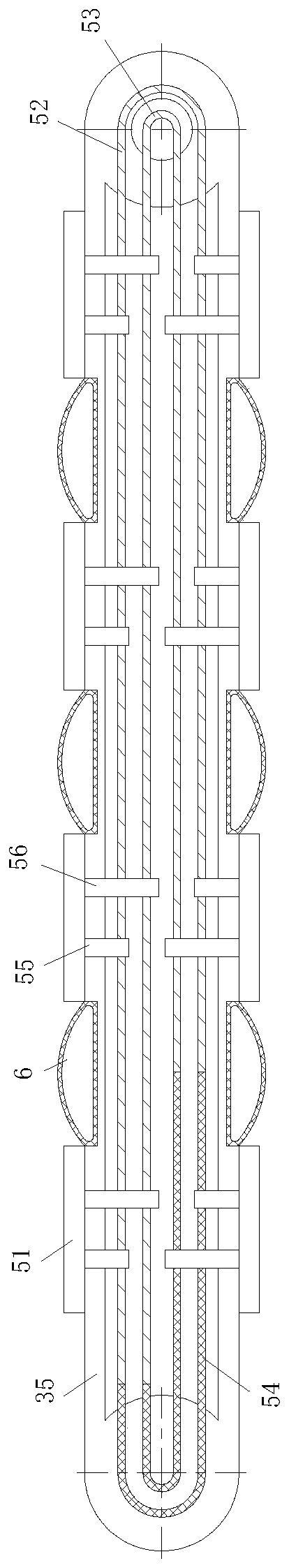

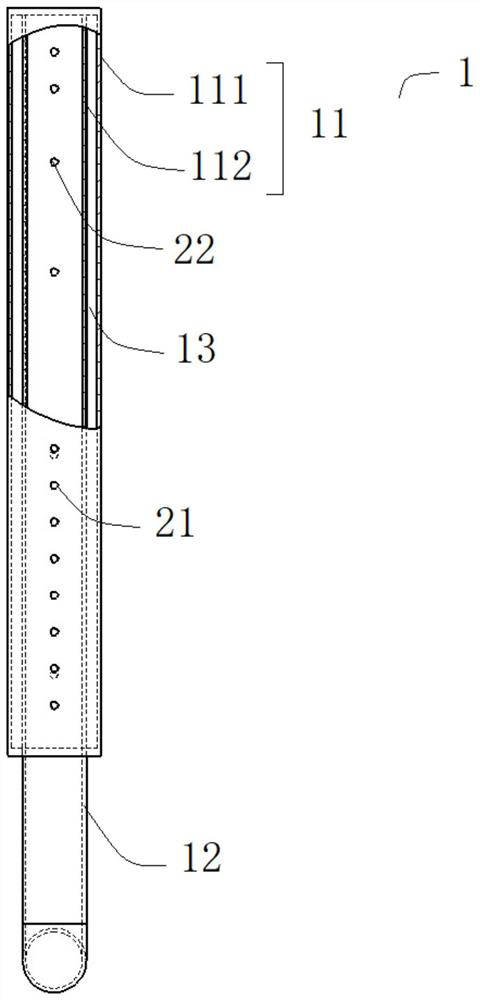

Membrane rolling roller

ActiveCN106081747AQuality is not affectedGuaranteed thickness consistencyEngineeringMechanical engineering

The invention provides a membrane rolling roller. The membrane rolling roller comprises a roller body. A plurality of air bags are arranged on the peripheral face of the roller body. Peripheral faces used for rolling a membrane are formed by the outer side faces of the air bags. The air bags communicate with air inflow and outflow openings provided with air valves. By usage of the membrane rolling roller, the problem that tension in the membrane on the rolling roller cannot be smoothly released can be solved.

Owner:河南天工膜材新能源科技有限公司

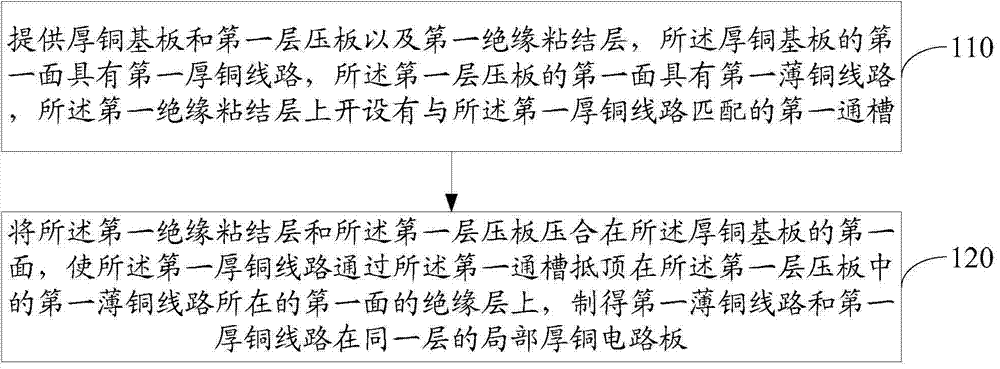

Method for manufacturing local-thick-copper circuit board and local-thick-copper circuit board

InactiveCN104717849ALow costGuaranteed thickness consistencyPrinted circuit aspectsMultilayer circuit manufactureEtchingCopper

The invention discloses a method for manufacturing a local-thick-copper circuit board and the local-thick-copper circuit board. The problems that an existing copper embedding technology is too high in cost, and an existing local-thick-copper technology is prone to film clamping, over etching or insufficient etching can be solved. The method includes the steps of etching the first face of a metal layer, wherein a non-circuit-pattern part of a thick copper circuit area and a thin copper circuit area are etched to be thinned; pressing an insulating layer on the first face of the metal layer; etching the second face of the metal layer, wherein a non-circuit-pattern part of the thin copper circuit area is etched to be removed to form a thin copper circuit, and the non-circuit-pattern part of the thick copper circuit area is etched to be removed to form a thick copper circuit.

Owner:SHENNAN CIRCUITS

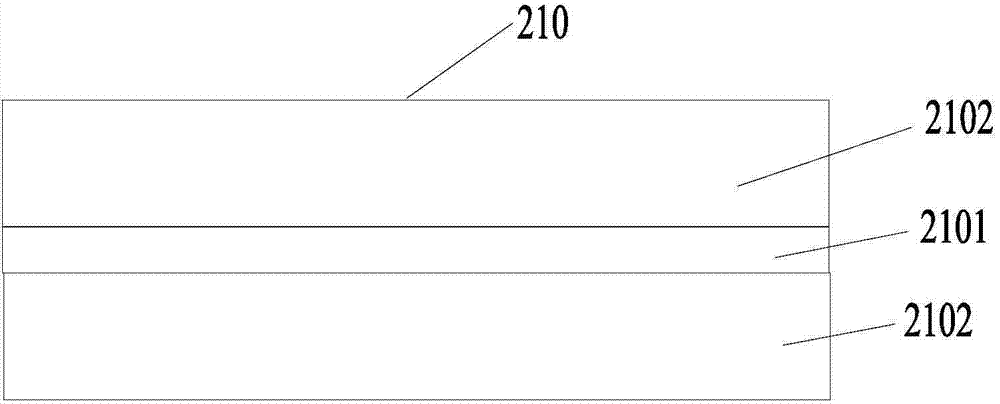

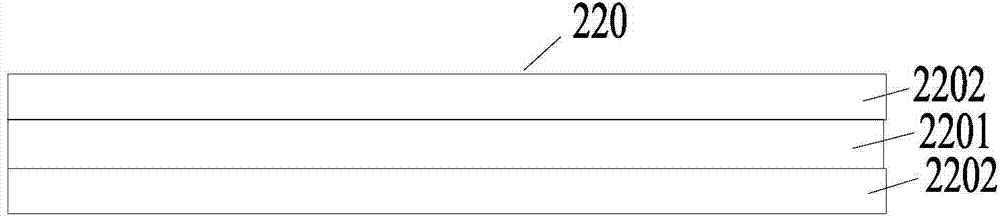

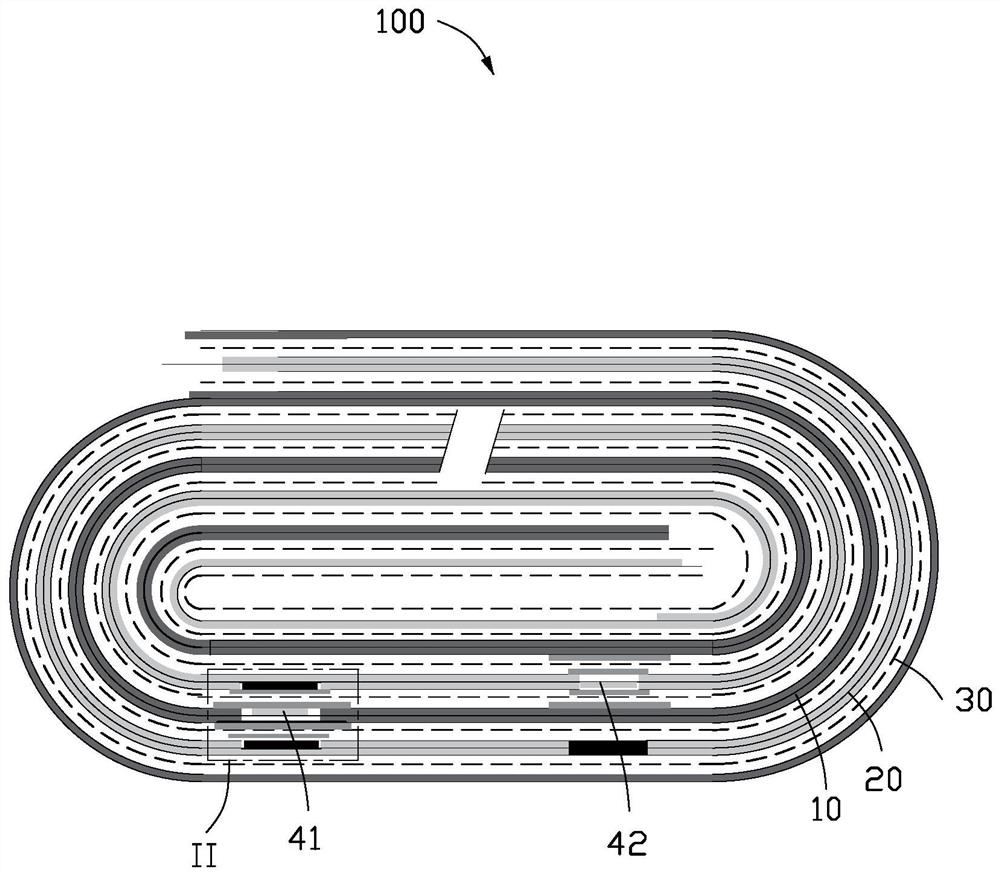

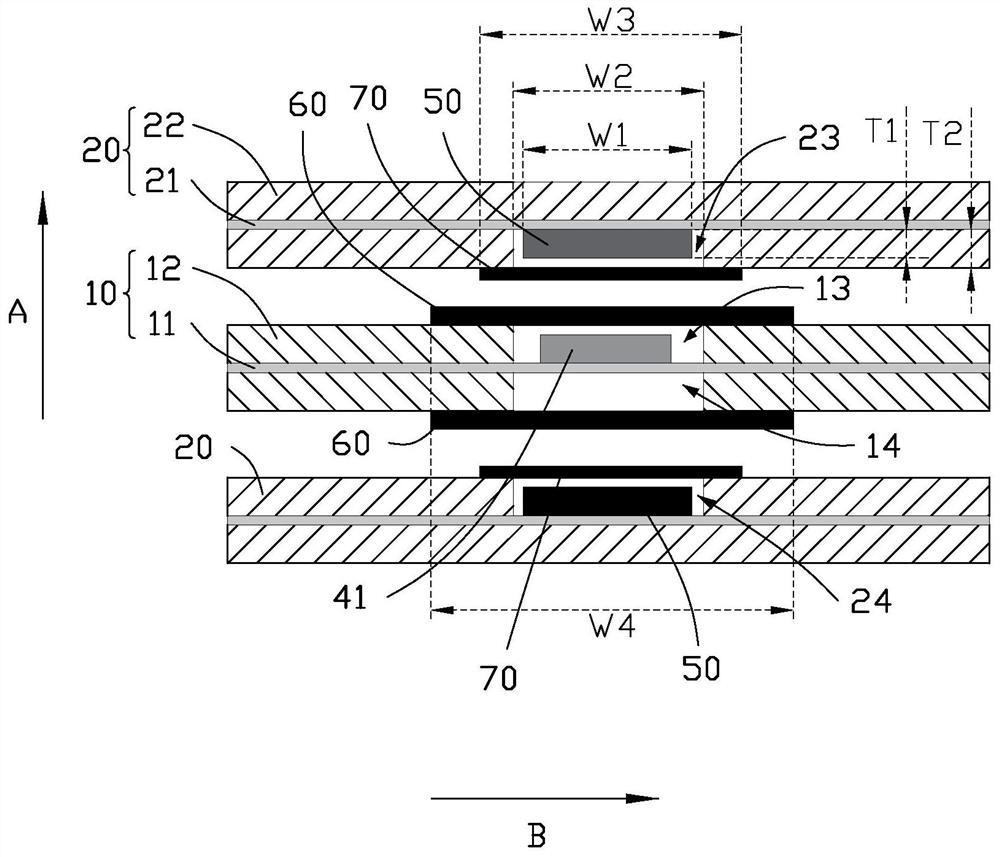

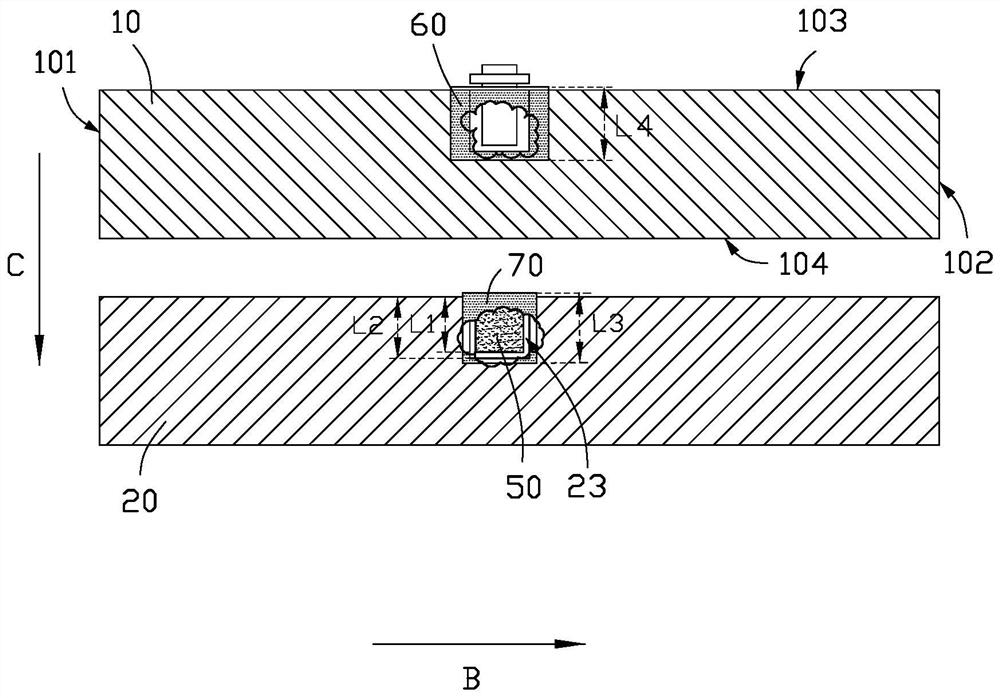

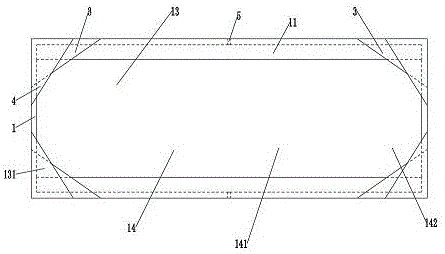

Electrode assembly and electrochemical device

PendingCN113826240AImprove undervoltage problemReduce the risk of Lithium analysis problemsFinal product manufactureNon-aqueous electrolyte accumulator electrodesChemistryComposite material

The invention provides an electrode assembly. The electrode assembly comprises a positive plate, a negative plate, an isolating membrane and a positive tab, the positive plate comprises a positive current collector and a positive active material layer arranged on the surface of the positive current collector, the negative plate comprises a negative current collector and a negative active material layer arranged on the surface of the negative current collector, and the isolating membrane is arranged between the positive plate and the negative plate. A first groove is formed in the positive electrode active material layer, and one end of the positive electrode tab is arranged in the first groove and is electrically connected with the positive electrode current collector. The negative active material layer is provided with a second groove, the second groove corresponds to the first groove, the second groove extends to the negative current collector along the thickness direction of the electrode assembly, and first protection glue is arranged in the second groove, so that the thickness consistency of the groove and the pole piece main body area is ensured; the under-voltage problem at the tab position is improved, and the short-circuit risk is reduced. The invention further provides an electrochemical device with the electrode assembly.

Owner:NINGDE AMPEREX TECH

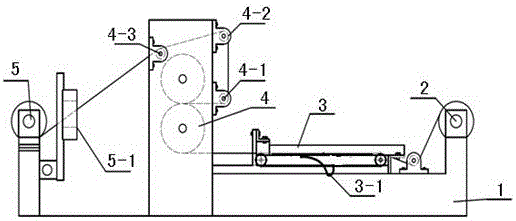

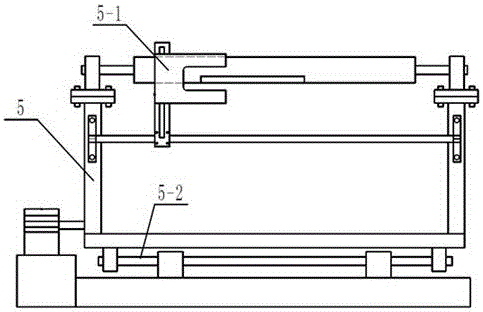

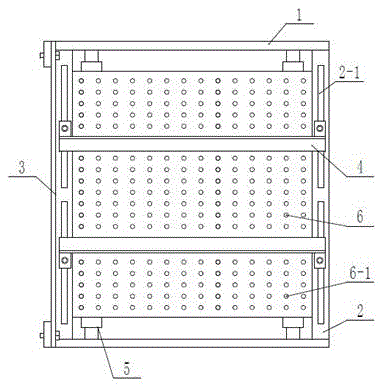

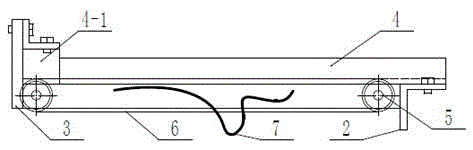

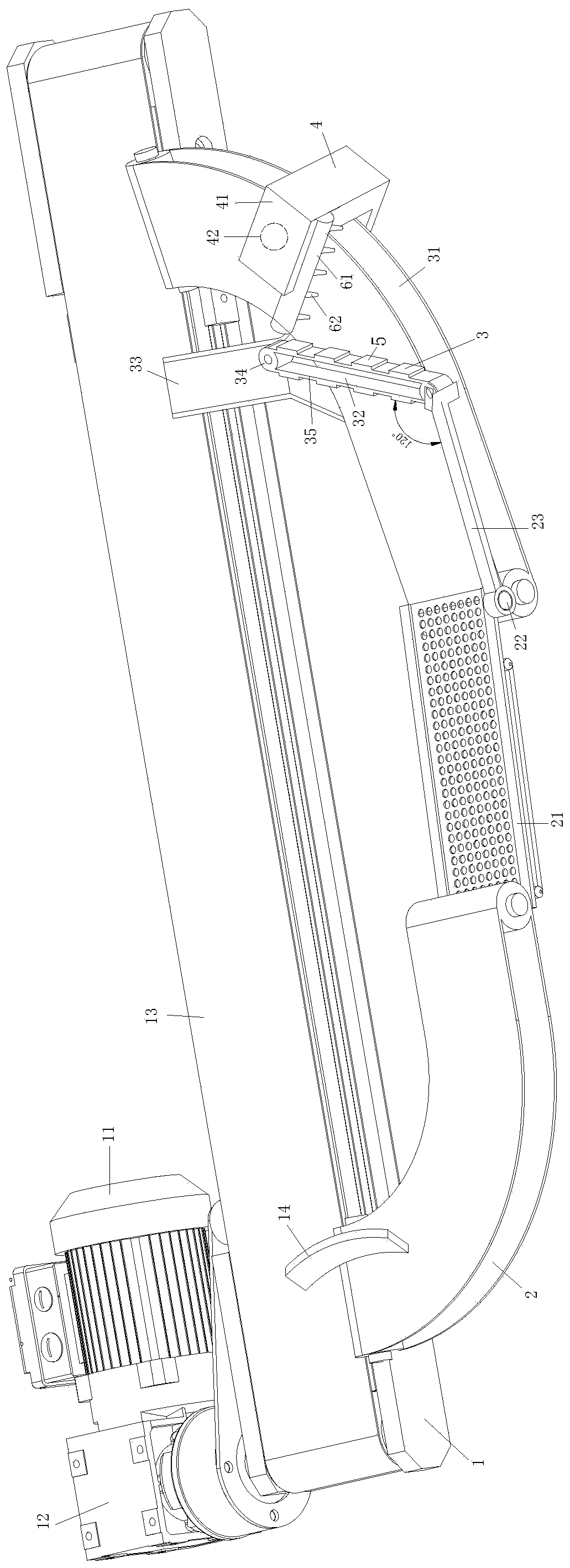

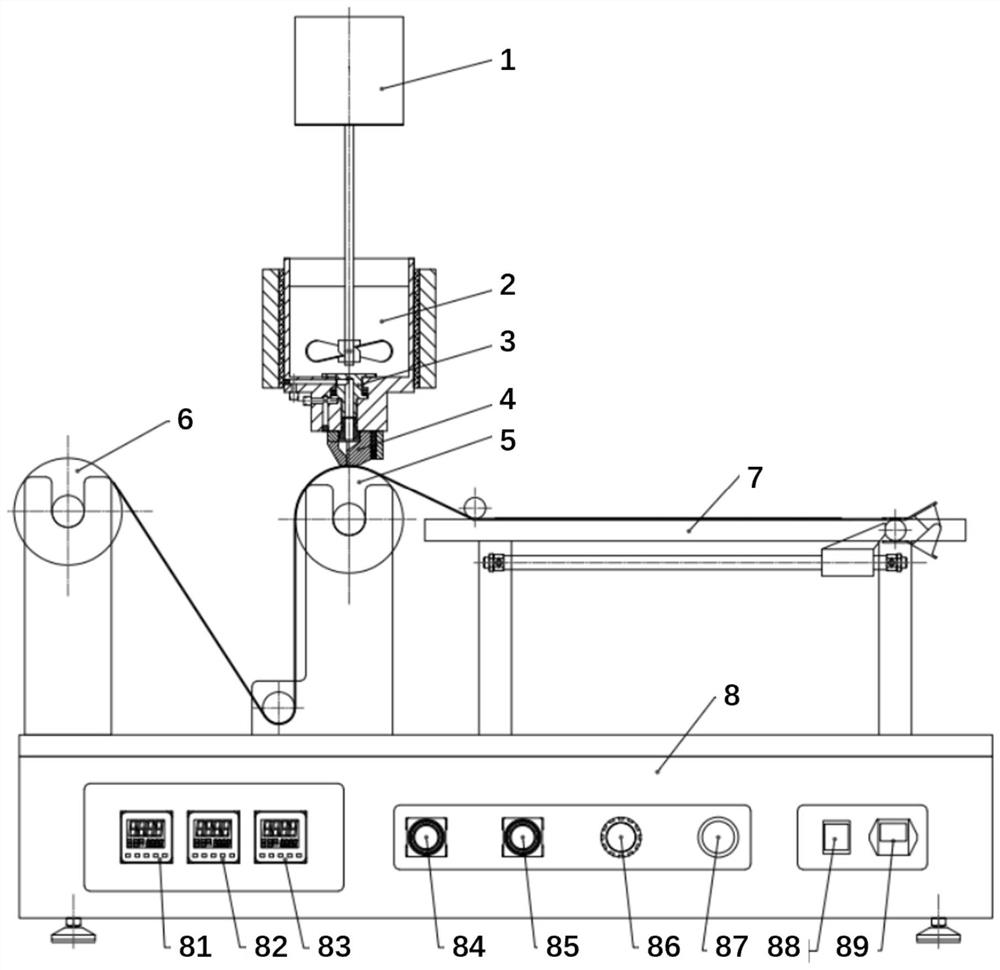

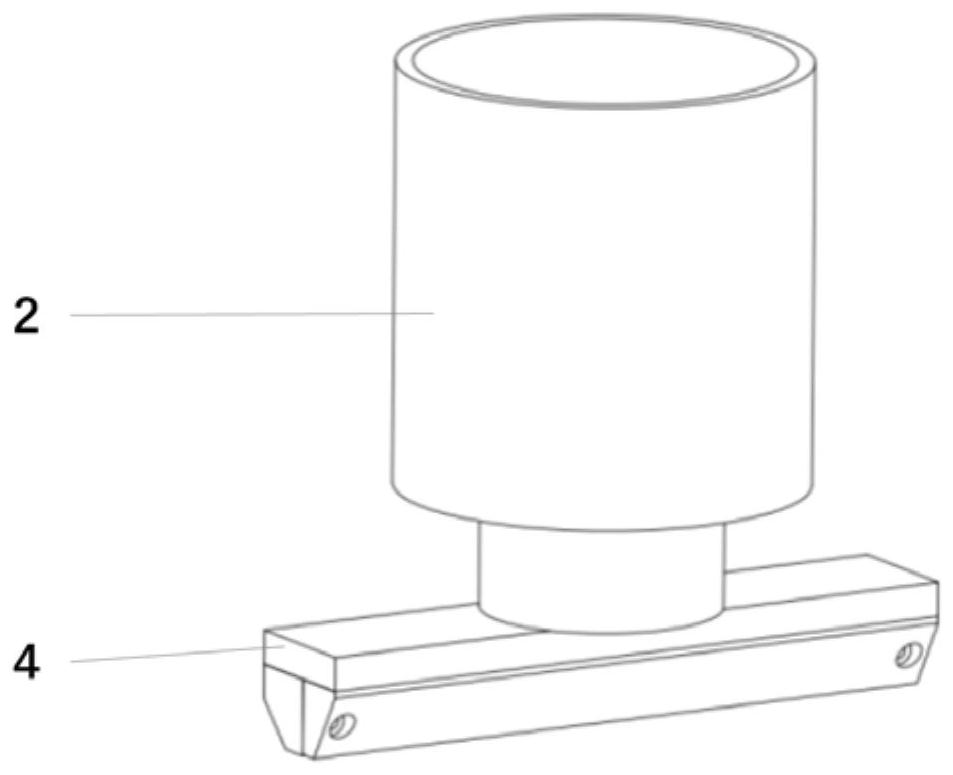

Graphite film calendaring machine

A graphite film calendaring machine comprises a main support (1), a film conveying roller component (2), a conveying belt component (3), powered roller components (4) and a recovery roller component (5), wherein the film conveying roller component (2) is installed at the right most end position on the main support (1); the conveying belt component (3) is installed above the main support (1) and located at the left side of the film conveying roller component (2); and the upper surface of the conveying belt component (3) is lower than the lower surface of the film conveying roller component (2). The graphite film calendaring machine is characterized in that an air suction component (3-1) is arranged at the bottom of the conveying belt component (3), a graphite film can be sucked to the upper portion of the conveying belt component (3). According to the graphite film calendaring machine, the stability of the graphite film during the conveying process is guaranteed by means of the interaction of a ventilation opening arranged on a conveying belt and an exhaust opening located within the conveying belt, and the thickness uniformity of the graphite film during the calendaring process is guaranteed.

Owner:ZHENJIANG BROWAH TECH

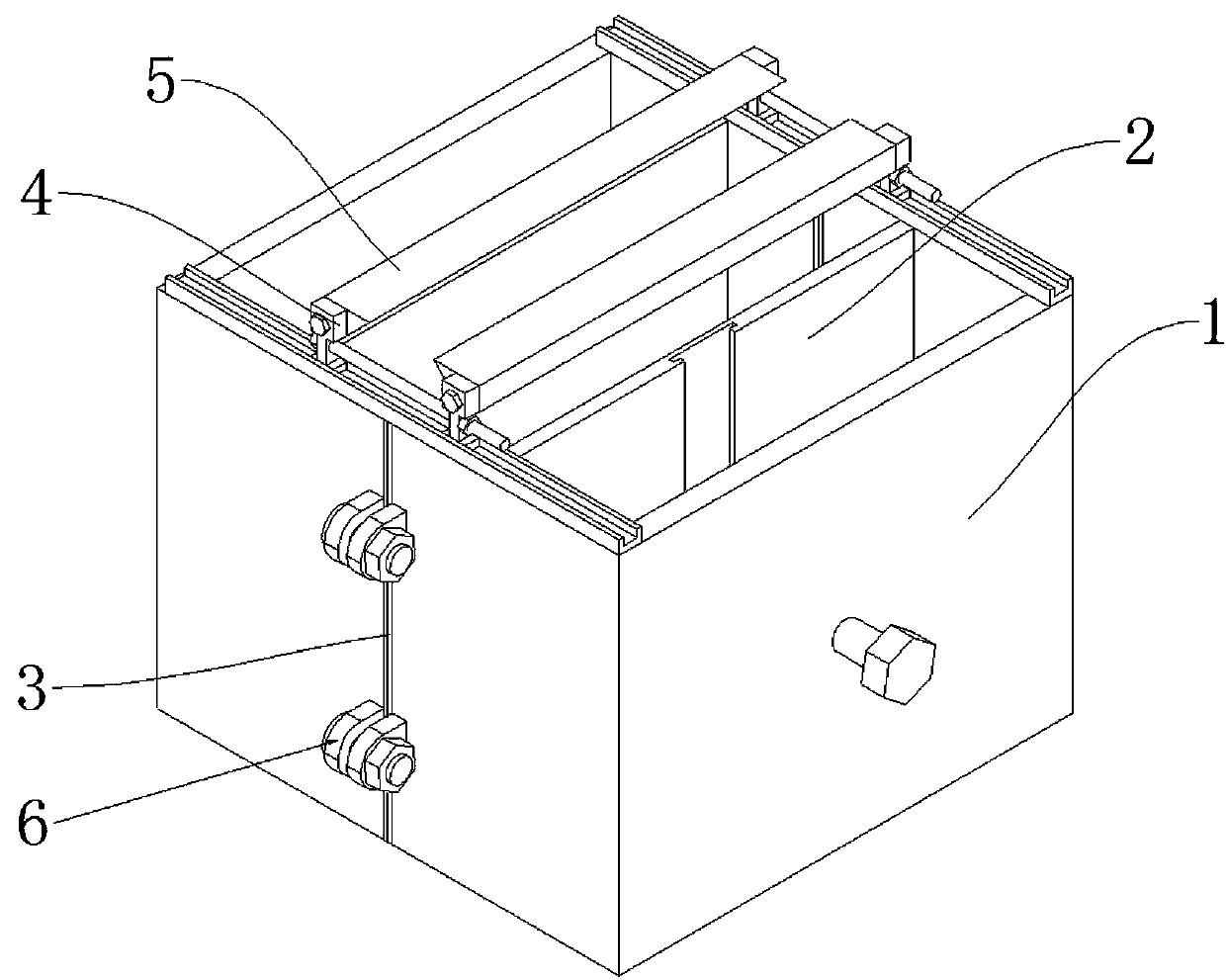

Adjustable paste box

ActiveCN110653121AGuaranteed tightnessGuaranteed liquid levelLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses an adjustable paste box, and belongs to the field of coating method research. The adjustable paste box comprises a shell, material collecting mechanisms, two rubber pads, an adjusting mechanism and two scrapers; the shell is in a cuboid shape, a concave cavity is formed in the top surface of the shell, the shell comprises two identical sub-shells, each sub-shell comprises abottom plate, side plates and two mutual paralleled vertical plates, wherein the side plates and the two vertical plates are vertically arranged on the bottom plate, the side plates are vertically connected with any vertical plate, and a clamping mechanism is arranged between the two vertical plates forming the side faces of the shell; the material collecting mechanisms are arranged inside the shell; the two rubber pads are arranged, the cross sections of the rubber pads are in U shapes, and the two rubber pads are arranged between the two sub-shells; the adjusting mechanism is provided withguide rails and sliding blocks, and the guide rails are fixedly arranged at the top of the shell; and the two scrapers are symmetrically arranged on two sliding blocks, and the scrapers are arranged in parallel with the middle section parts of the rubber pads. The adjustable paste box is simple in structure and convenient to operate, the contact area between paste liquid and a pole piece can be ensured, and then the coating quality of the pole piece is guaranteed.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Conveying belt of graphite film rolling equipment

InactiveCN105621134AAchieve stabilityGuaranteed thickness consistencyWebs handlingEngineeringGraphite

The invention discloses a conveying belt of graphite film rolling equipment. The conveying belt consists of horizontal frames (1), longitudinal frames (2), a vertical bracket (3), adjustable transoms (4), driving shafts (5), a conveying belt (6) and an air suction hole (7), wherein two horizontal frames (1) and two longitudinal frames (2) are mutually connected to form a rectangular frame structure; the vertical bracket (3) is arranged over one longitudinal frame (2); two adjustable transoms (4) are horizontally and symmetrically arranged between the two longitudinal frames (2); two driving shafts (5) are arranged under the horizontal frames (1) and are connected with the horizontal frames (1); the conveying belt is characterized in that the conveying belt (6) does rotational motion along the driving shafts (5) under the effect of the driving shafts (5). The conveying belt disclosed by the invention has the advantages of achieving stability of a graphite film during a conveying process by interaction of a ventilation opening and the air suction hole formed in the conveying belt and realizing stable product quality.

Owner:ZHENJIANG BROWAH TECH

Curing process for solder mask ink surface of LED light source board

InactiveCN108882548AShorten production timeImprove production efficiencyNon-metallic protective coating applicationSolder maskReflectivity

The invention discloses a curing process for a solder mask ink surface of a LED light source board. The curing process comprises the following steps: 1) surface treatment of the processing board: cleaning the surface of the processing board to ensure that a first ink layer is printed under the condition of no impurity oxidation; 2) printing the first ink layer : pressing and applying the ink ontothe clean processing board by the pressure of a squeegee; 3) curing the first ink layer: curing the first ink layer by the ultraviolet light fixing lamp with energy parameter of 650-750 mj / cm2, wherein adhesion and considerable hardness should be ensured, and over curing should be avoided; 4) printing the second ink layer : pressing and applying the ink onto the clean processing board cured with the first ink layer by the pressure of a squeegee; 5)curing the second ink layer: curing the second ink layer by the ultraviolet light fixing lamp with energy parameter of 950-1100 mj / cm2, wherein adhesion and considerable hardness should be ensured. The process method has the advantages that production time is short, yield efficiency is high, product precision is high, processing is smooth and reflectivity of ink surface is high.

Owner:ZHEJIANG LEUCHTEK ELECTRONICS

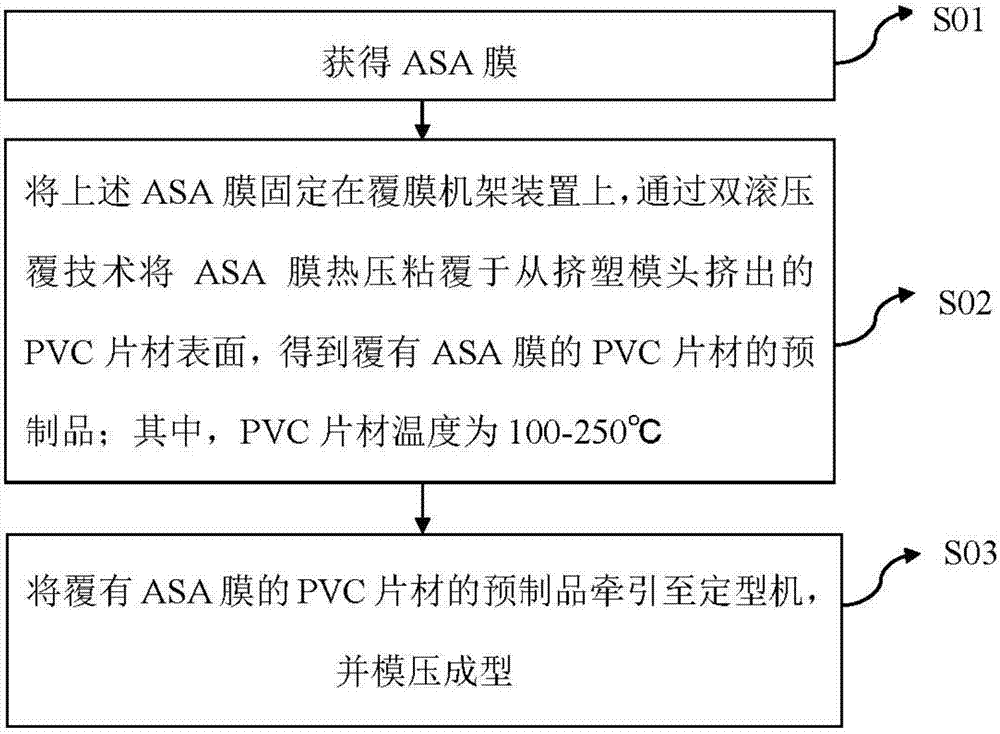

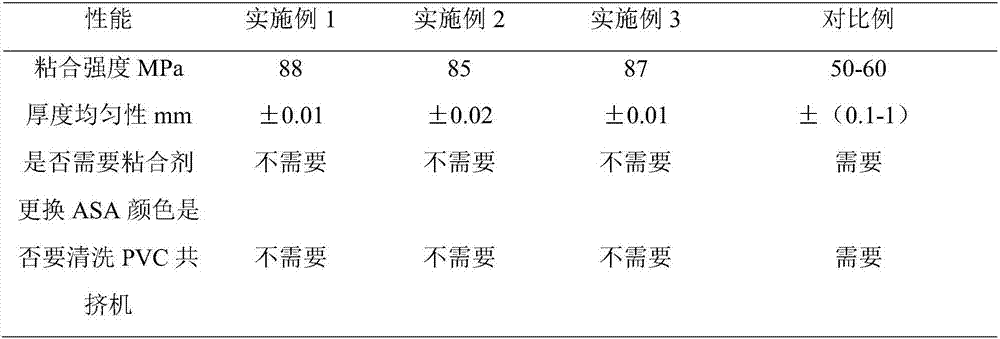

PVC (Polyvinyl Chloride) sheet coated with ASA (Acrylonitile Styrene Acrylate) film and film coating method

InactiveCN107443857AGuaranteed thickness consistencyExtended service lifeSynthetic resin layered productsLaminationAcrylateEngineering

The invention belongs to the technical field of plastic processing and forming, and particularly relates to a PVC (Polyvinyl Chloride) sheet coated with an ASA (Acrylonitile Styrene Acrylate) film and a film coating method. The method comprises the following steps: acquiring the ASA film; fixing the ASA film on a film coating rack device, using the double-roller pressing and coating technique to thermally press and adhere the ASA film to the surface of the PVC sheet extruded from an extruding die head, and obtaining a prefabricated product of the PVC sheet coated with the ASA film, wherein the temperature of the PVC sheet is 100-250 DEG C; and dragging the prefabricated product of the PVC sheet coated with the ASA film to a forming machine, and conducting compression molding. The ASA film is firmly adhered to the PVC sheet through the temperature of the just extruded PVC sheet, the double-roller embossing and the subsequent compression molding pressure, so that the consistency and the evenness of the thickness of the ASA film are guaranteed effectively, the service life of the product is prolonged, and moreover, the time is saved, the production efficiency is improved, and the purposes of saving energies and reducing consumption are fulfilled.

Owner:SHENZHEN YICAIHONGXIANG NEW MATERIALS TECH CO LTD

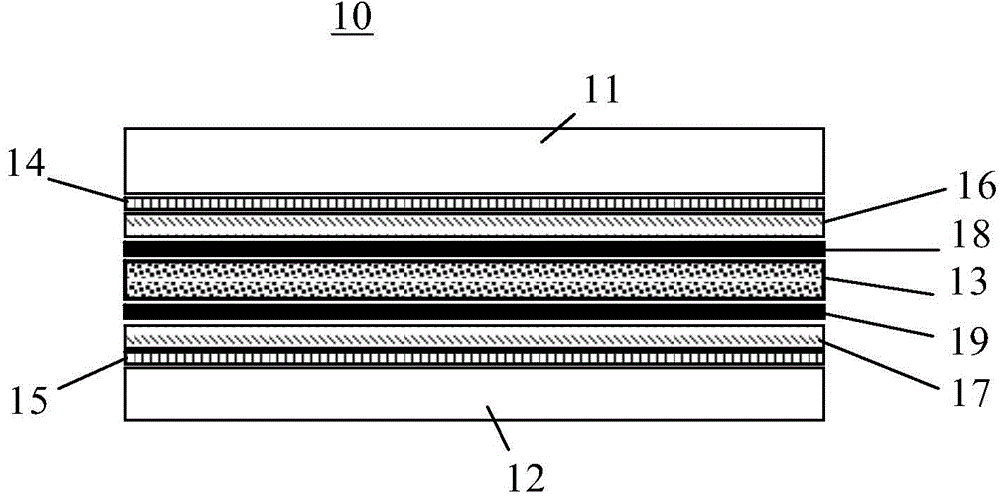

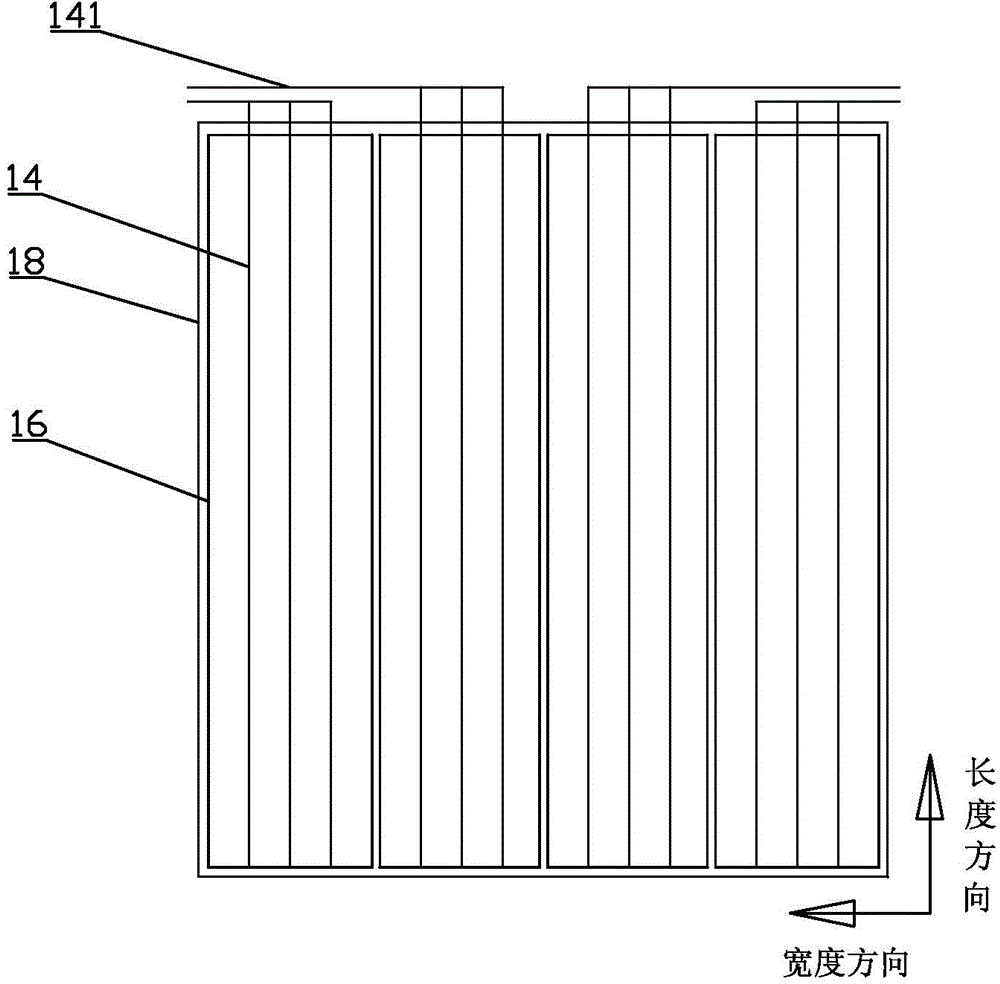

Improved smectic phase light dimming glass

PendingCN105717713AReduce energy lossGuaranteed driving abilityNon-linear opticsHigh energyEngineering

The invention discloses improved smectic phase light dimming glass which comprises a first substrate layer, a liquid crystal mixed layer and a second substrate layer in an overlapped manner, wherein a surface, facing to the liquid crystal mixed layer, of the first substrate layer, and a surface, facing to the liquid crystal mixed layer, of the second substrate layer are both plated with flaky and long-strip shaped transparent electrodes; a plurality of electrode wires of which the resistance is smaller than that of the transparent electrode and current rapidly flowing through the electrode wires self can be rapidly spread to the transparent electrodes are uniformly distributed on the transparent electrodes; all electrode wires of each transparent electrode are connected with an extraction electrode; protecting layers are arranged on two surfaces of the liquid crystal mixed layer. Due to arrangement of the low-resistance electrode wires and design of the protecting layers, the problem of high-energy consumption of large-size high-resistance light dimming glass in the driving signal transmission process can be effectively solved, the problem of electrochemical corrosion in image display is solved, the image display effect of the light dimming glass is improved, and the service life of the light dimming glass is prolonged.

Owner:重庆汉朗精工科技有限公司

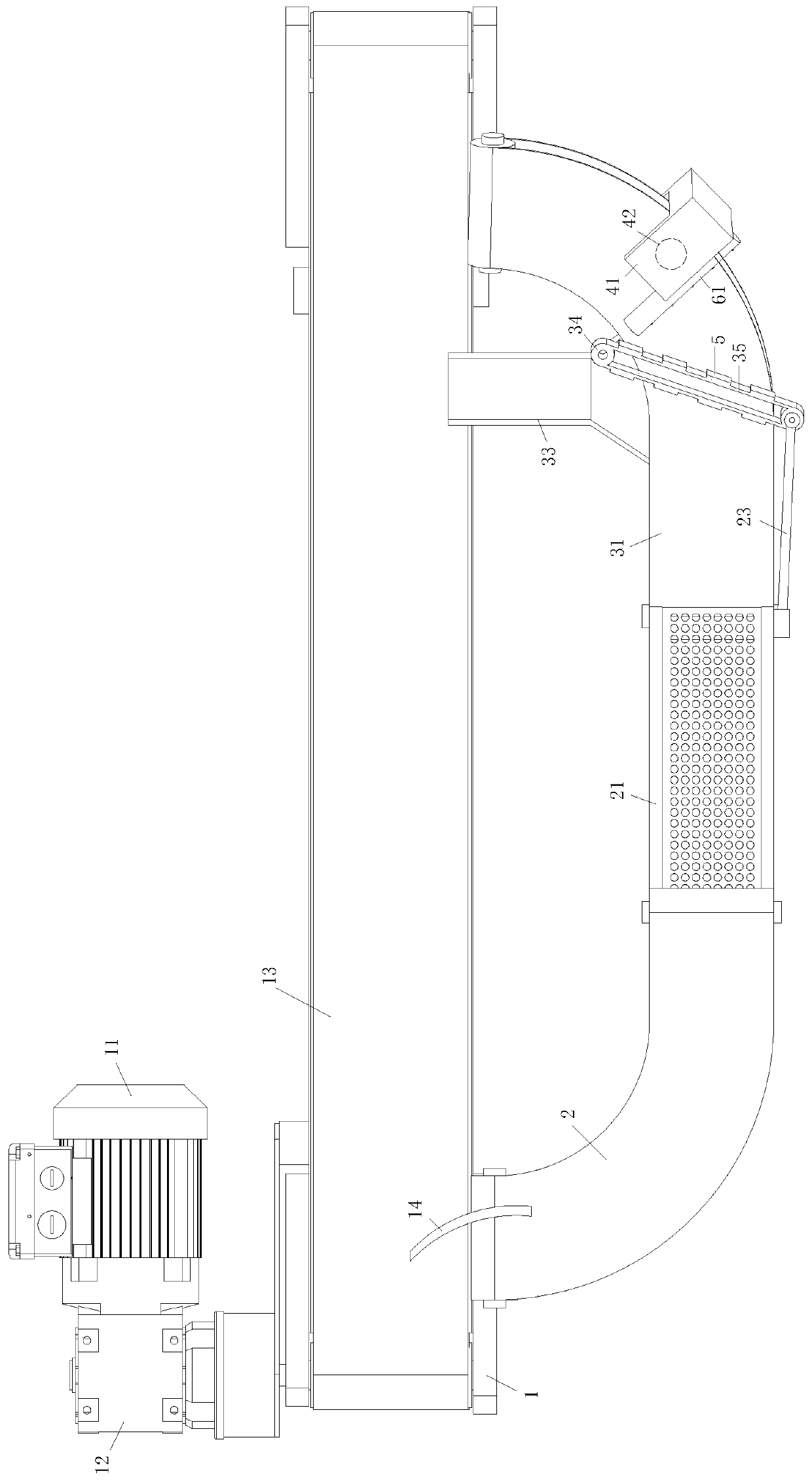

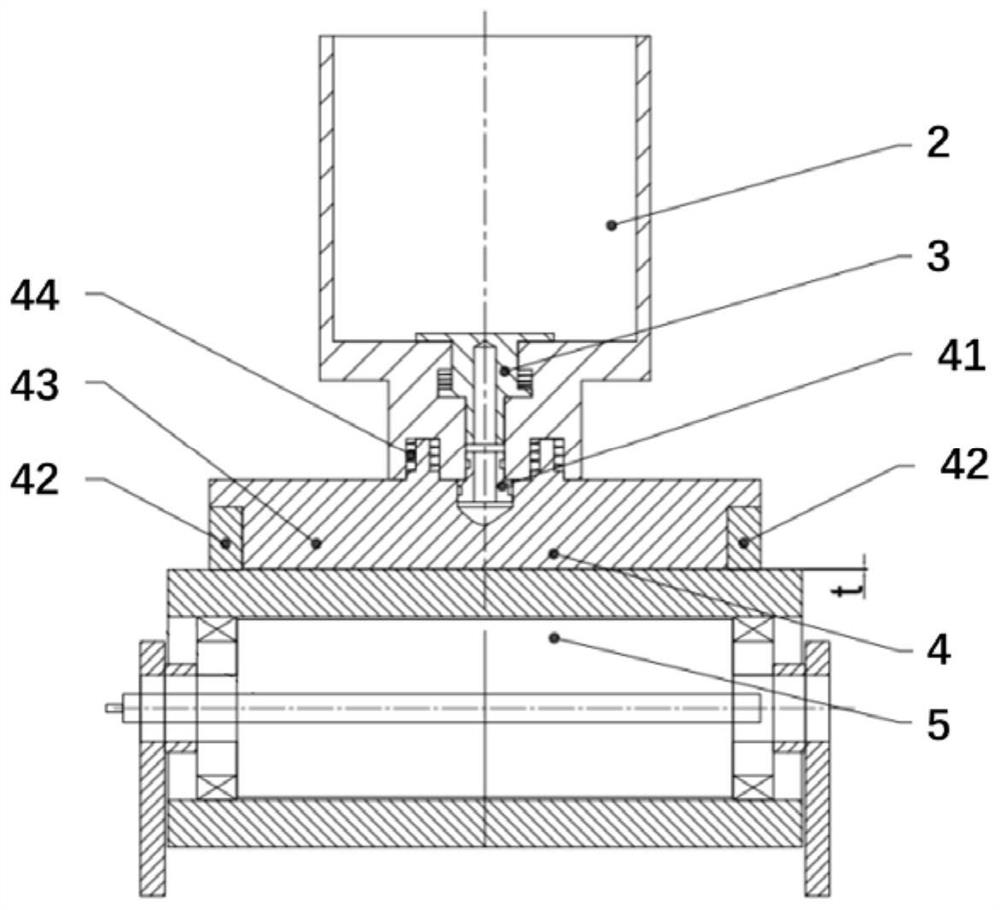

Microwave type intelligent grain moisture detector

InactiveCN110261412AImprove detection accuracyGuaranteed thickness consistencyPreparing sample for investigationMoisture content investigation using microwavesMotor driveMicrowave

The invention belongs to the field of moisture detection instruments, and particularly relates to a microwave type intelligent grain moisture detector. The microwave type intelligent grain moisture detector comprises a rack, a motor, a gearbox, a No.1 conveying belt, a guide plate, a No.2 conveying belt, a leveling unit and a measuring unit; the motor is arranged at the rear portion of the rack; the No.1 conveying belt is arranged on the rack; the motor drives the No.1 conveying belt to rotate through the gearbox; one side, far away from the motor, of the No.1 conveying belt is provided with the No.2 conveying belt; the arc-shaped guide plate is arranged between the No.1 conveying belt and the No.2 conveying belt; the right side of the No.2 conveying belt is provided with the leveling unit which is used for leveling the grain thickness; and the right side of the leveling unit is provided with the measuring unit, and the measuring unit is used for measuring the grain moisture content. According to the invention, the grains on the No.1 conveying belt are divided onto the No.2 conveying belt and a No.3 conveying belt through the guide plate, a scraping plate scrapes redundant grains off the No.3 conveying belt, the thickness consistency of the grains detected by the measuring unit is guaranteed, and the grain moisture detection precision is improved.

Owner:安徽天德智能装备制造有限公司

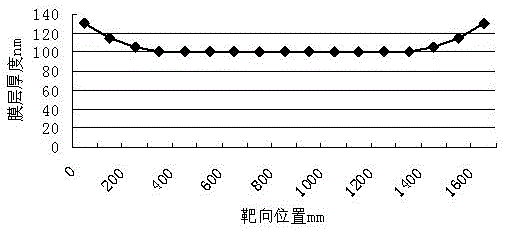

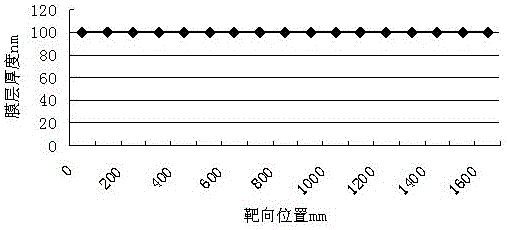

Method and device for improving uniformity and production efficiency of X-ray reflector thin film

PendingCN108203808AGuaranteed thickness uniformitySimple structureVacuum evaporation coatingSputtering coatingX-rayOptoelectronics

The invention relates to a method and a device for improving the uniformity and production efficiency of an X-ray reflector thin film. According to the method, a linear magnetron sputtering target gunis used for carrying out reflector coating, film thickness uniformity in the length direction of the thin film on a reflector is adjusted by arranging a mask plate in a sputtering direction of the target gun, and meanwhile, the film thickness of the reflector and the uniformity in the width direction of the thin film on the reflector are adjusted by controlling the speed at which the reflector passes the target gun. Compared with the prior art, the thickness uniformity deviation of the multiple reflectors at different positions within 2% can be realized, the film thickness uniformity is ensured, and meanwhile the production efficiency is improved.

Owner:TONGJI UNIV

Hot melt adhesive preparation and coating integrated equipment and method

ActiveCN113798130ASmall thickness deviationUniform widthLiquid surface applicatorsFinal product manufactureManufacturing engineeringMedical equipment

The invention relates to the field of medical equipment, in particular to hot melt adhesive preparation and coating integrated equipment and hot melt adhesive preparation and coating method. The equipment comprises an agitator, a melt coating assembly, a coating film assembly and a control assembly, wherein the melt coating assembly comprises a hot melt adhesive container, a pneumatic switch and a flat nozzle slit coating tool bit; the bottom surface of the hot melt adhesive container is provided with a material outlet, the material outlet is communicated with the flat nozzle slit coating tool bit, and the pneumatic switch is arranged on a communicated channel; and the coating film assembly comprises a back glue coating supporting roller used for bearing a coating film, and the coating film is clamped between the back glue coating supporting roller and the flat nozzle slit coating tool bit. According to the hot melt adhesive preparation and coating integrated equipment, small-batch and customized manufacturing of medical patches can be met.

Owner:江苏集萃新型药物制剂技术研究所有限公司

Ultrahigh molecular weight polyethylene plate production method

PendingCN110370520AGuaranteed thickness uniformityGuaranteed thickness consistencyFlat articlesPolymer scienceMetal sheet

The invention discloses an ultrahigh molecular weight polyethylene plate production method. Two metal sheets are placed between an upper mould pressing cover and a lower mould pressing cover on a mould pressing machine, a high-temperature-resistant elastic rubber layer plate is placed between the two metal sheets at the same time, a mixture containing ultrahigh molecular weight polyethylene powderis filled between the upper mould pressing cover and the metal sheet on the upper layer so as to be pressed, and the elasticity of the elastic rubber layer is utilized for improving the extrusion stress of the mixture in the pressing process, so that the extrusion stress on the ultrahigh molecular weight polyethylene powder is consistent, and finally an ultrahigh molecular weight polyethylene plate with uniformly distributed powder is obtained through pressing. By adopting the method, a product blank is effectively prevented from deviating and a sheet material is prevented from becoming warped during production, so that the thickness uniformity and the density consistency of the sheet material are ensured, the product has a high physical property, meanwhile, the mould pressing process conditions and parameters of the ultrahigh molecular weight polyethylene thin plate are improved, and the defects that the ultrahigh molecular weight polyethylene thin plate products are non-uniform in thickness and inconsistent in density, and dark and light spots appear under light are effectively overcome.

Owner:江苏明珠硅橡胶材料有限公司

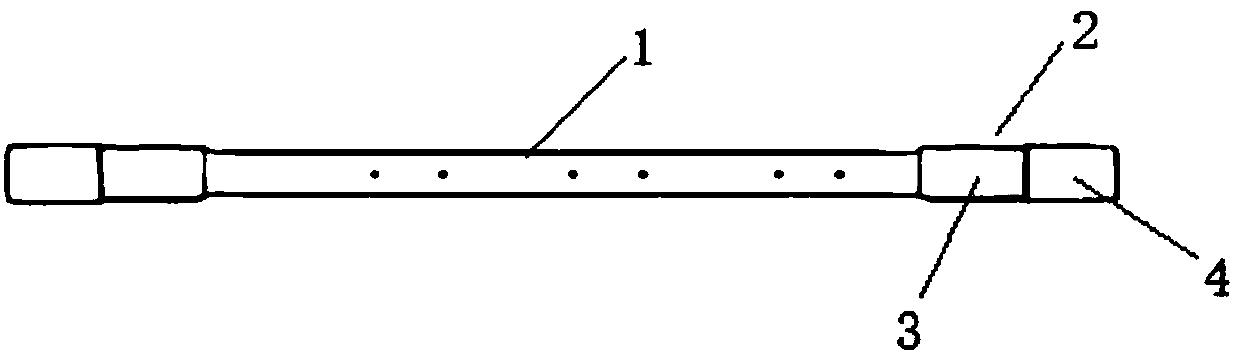

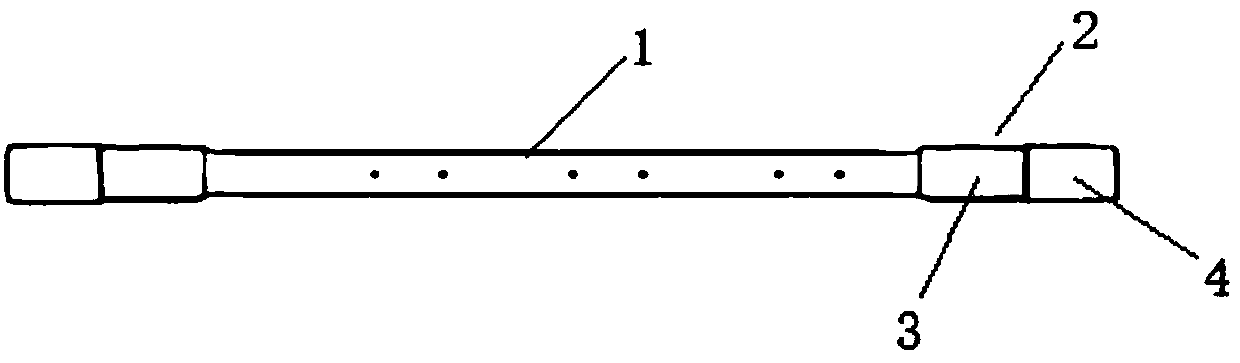

Preparation method of releaser for alkali metal releasing agent

ActiveCN109920711AIncrease productivityImprove consistencyPhoto-emissive cathodes manufactureCold cathode manufacturePhotocathodeNickel Chromium Alloys

The invention discloses a preparation method of a releaser for an alkali metal releasing agent, which comprises the following steps: (1) cleaning and drying a nichrome tube, wherein the outer diameterof the nichrome tube is 4.0-7.0 mm, and the wall thickness is 0.05-0.10 mm; (2) uniformly mixing high-purity alkali metal salt and reducing agent powder by using a powder mixing device, and filling the mixed powder into a nickel-chromium alloy tube; (3) cold drawing the nickel-chromium alloy tube after filling powder, and drawing the nickel-chromium alloy tube until the outer diameter is 1.0-1.5mm and the wall thickness is 0.03-0.06 mm, and the required pass is 8-40; (4) laser drilling under the protection of inert gas; (5) cutting the main body part of the releasing agent; (6) connecting the two ends of the main body part with end electrodes; (7) and vacuum packaging the prepared releaser. The preparation method of the releaser for the alkali metal releasing agent can improve the production efficiency of the releaser used by the alkali metal releasing agent, and significantly improve the performance consistency and the stability of the releaser of the releasing agent, thereby ensuring the thickness consistency of the releasing agent film on the surface of the photocathode and the consistency and the stability of the performance of the photocathode.

Owner:GRIMAT ENG INST CO LTD

Automatic glue spraying device for shaped charge liner of perforating charge

InactiveCN103657953AConsistent thicknessReduce scrap rateLiquid surface applicatorsCoatingsAdhesiveShaped charge

The invention discloses an automatic glue spraying device for a shaped charge liner of a perforating charge in embodiments. The automatic glue spraying device comprises a shell, a covering plate disposed at the opening of the shell, and a bearing tray propped at the lower end of the cover plate and used for bearing the shaped charge liner of the perforating charge, wherein a support is disposed in the shell, a rotation platform is disposed on the support, the rotation platform is driven to rotate by a motor which is fixed to the support by the fixed end of the rotation platform, the cover plate is provided with an anaerobic adhesive spraying gun, and when the covering plate lowers to a preset distance, the rotation platform holds up the bearing tray. The automatic glue spraying device guarantees consistency of the glue thickness outside the shaped charge liner and largely reduces the rejection rate of the perforating charge.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP

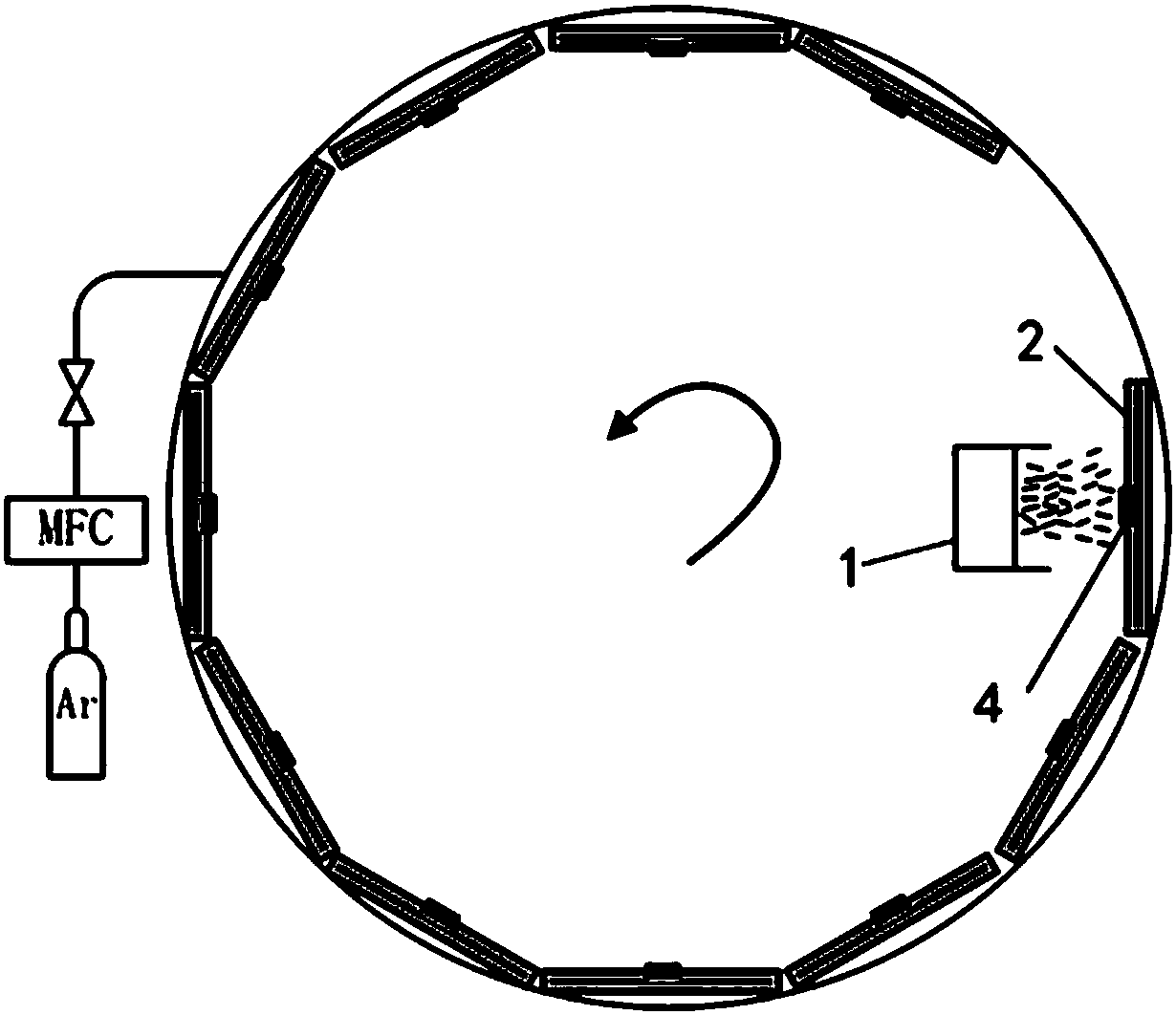

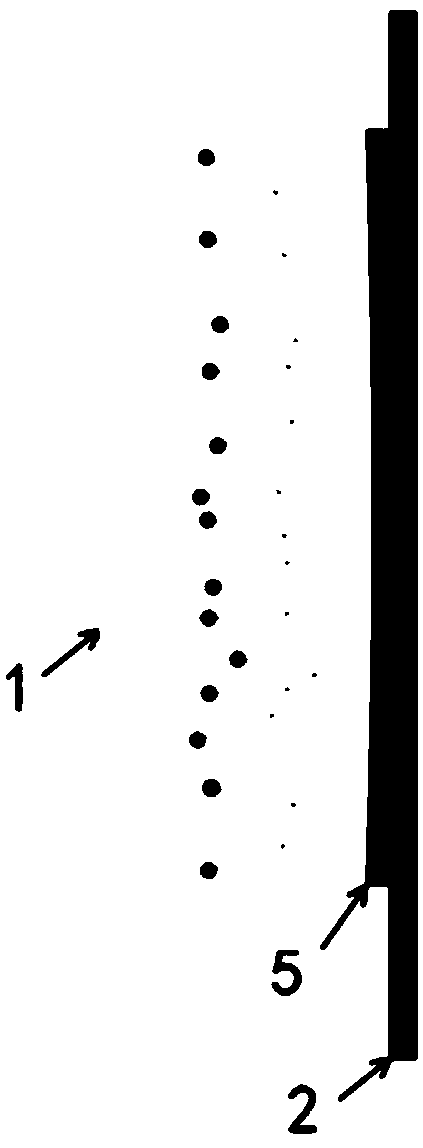

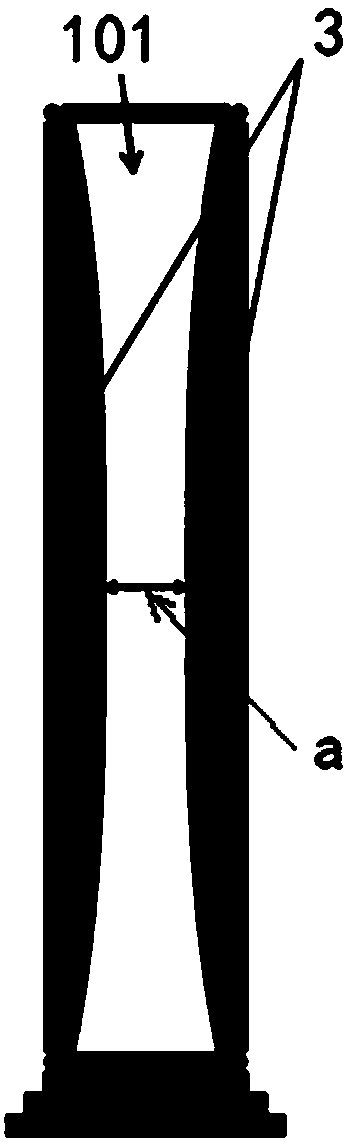

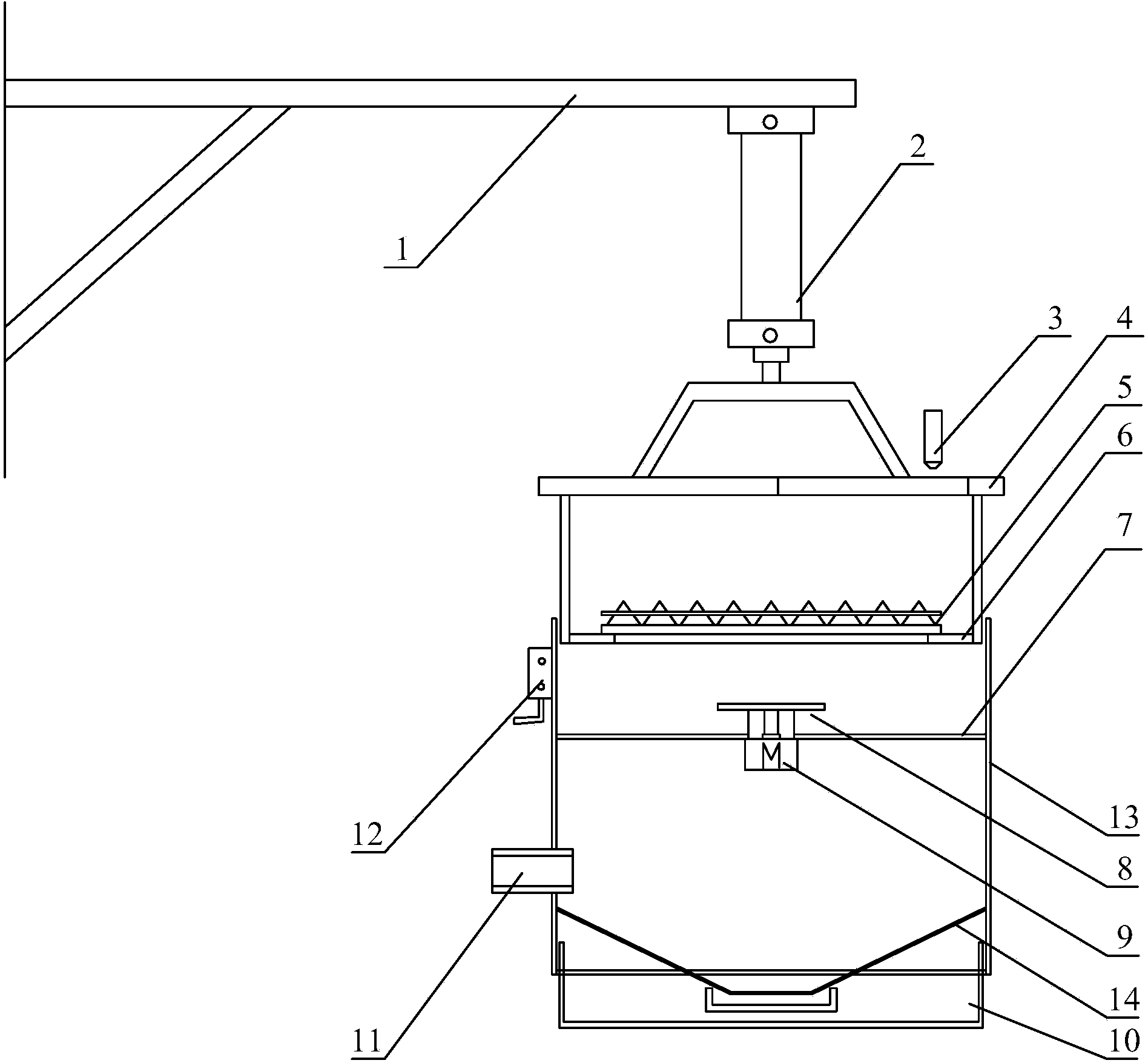

Magnetron sputtering cathode surface gas density distribution control device and method

ActiveCN105714259AUniform distribution of gas densityUniform density distributionVacuum evaporation coatingSputtering coatingDensity distributionKidney

The invention provides a magnetron sputtering cathode surface gas density distribution control device. Cathode surface gas density distribution can be even, and then it is guaranteed that the thickness of a coating film is basically the same in the length direction of a cathode target. The device comprises the cathode target located in a shielding cover, a kidney-shaped sputtering hole is formed in a shielding cover panel exactly facing the cathode target, the width of the middle of the kidney-shaped sputtering hole is consistent, and the widths of the two ends of the kidney-shaped sputtering hole are gradually reduced. The length direction of the kidney-shaped sputtering hole is consistent with that of the cathode target.

Owner:高邮市汇金新材料科技有限公司

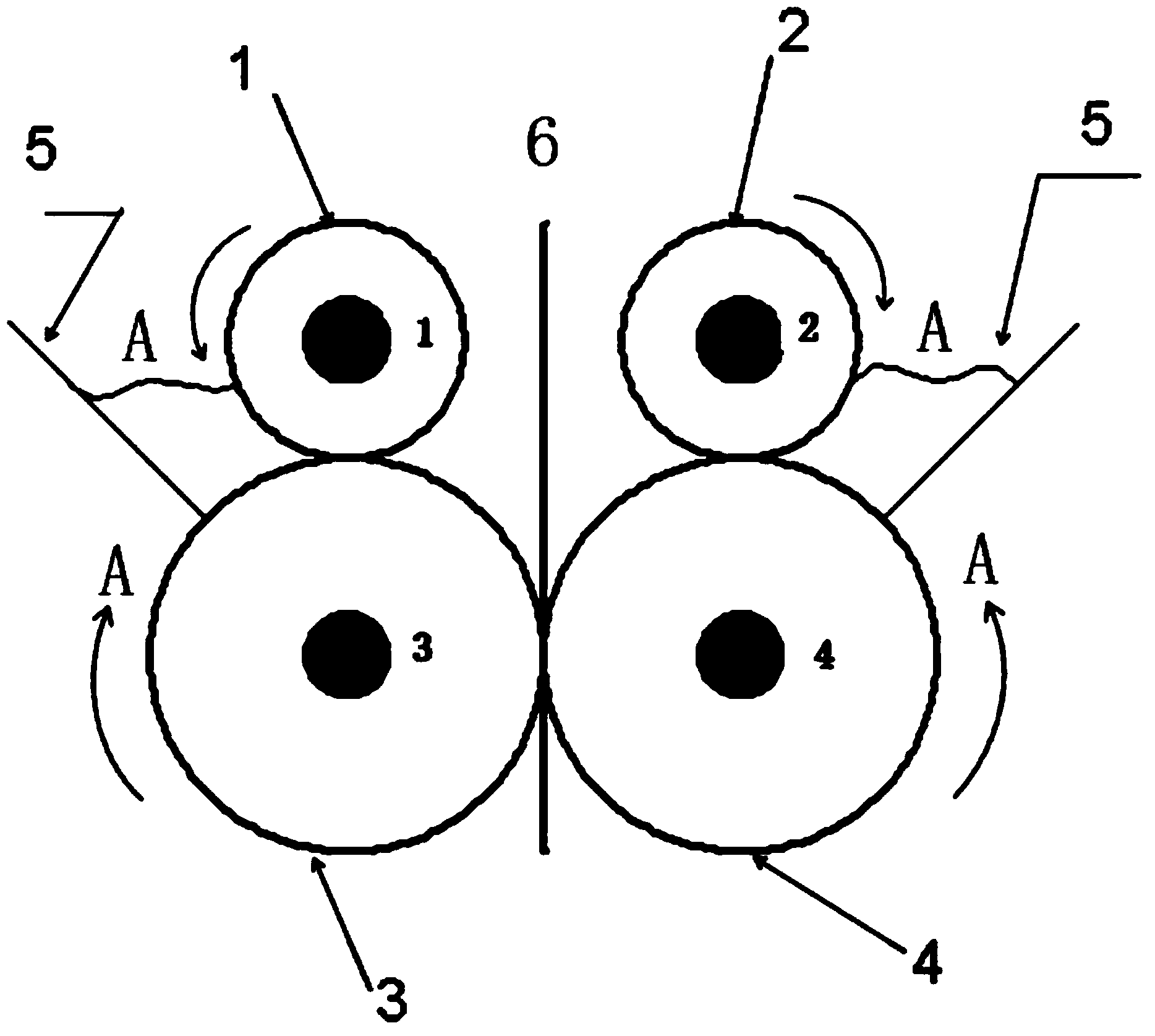

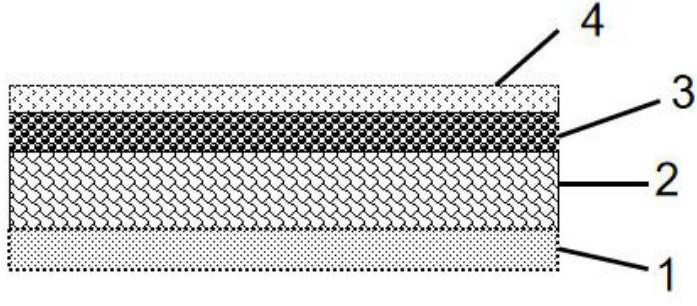

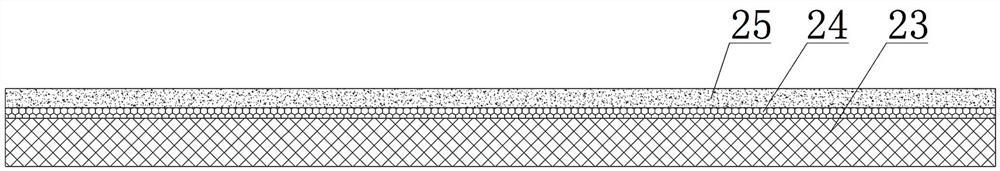

Positive electrode material of magnesium metal air battery and continuous coating preparation method thereof

InactiveCN112687888AGuaranteed uniformityGuaranteed thickness consistencyFuel and primary cellsFuel and secondary cellsFuel cellsElectrical battery

The invention relates to metal fuel cell materials in the fields of new energy and new materials and to the technical field of processing, in particular to a positive electrode material of a magnesium metal air battery and a continuous coating preparation method thereof. The positive electrode material comprises a current collector, a catalytic layer, a waterproof breathable layer and a sizing material layer, wherein the catalytic layer and the waterproof breathable layer respectively coat two sides of the current collector, and the sizing material layer coats the waterproof breathable layer. The positive electrode material can improve the waterproof effect of the waterproof breathable layer, slow down the permeation of water in the battery electrolyte, ensure that enough gas enters the catalyst layer to participate in the reaction, and effectively prolong positive electrode discharge time.

Owner:CHANGSHA XUNYANG NEW MATERIAL TECH CO LTD +1

Metalized slurry of power battery sealing connector and preparation method of metalized slurry

InactiveCN110120275AWell mixedFully brokenNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveActive agent

The invention discloses metalized slurry of a power battery sealing connector and a preparation method of the metalized slurry. The metalized slurry comprises a metalized raw material and an organic adhesive, and the mass ratio of the metalized raw material to the organic adhesive is 8-9 : 1-2. The metalized raw material comprises a metal oxide active agent, and the metal oxide active agent comprises the following components in percentage by mass: 10-15% of aluminum oxide powder, 8-15% of silicon dioxide, 1-2% of titanium dioxide and 1-2% of tantalum pentoxide. The organic adhesive comprises ethyl cellulose, terpene alcohol, organic silicon defoamer and an organic silicon flatting agent, and the mass ratio of the ethyl cellulose to the terpene alcohol to the organic silicon defoamer to theorganic silicon flatting agent is 10-15 : 1000-1199 : 3 : 5. The roughness of the metalized surface of the sintered battery sealing connector is reduced to be less than or equal to 1.0 [mu]m, and themetalized sealing strength is improved to be more than or equal to 120Mpa.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

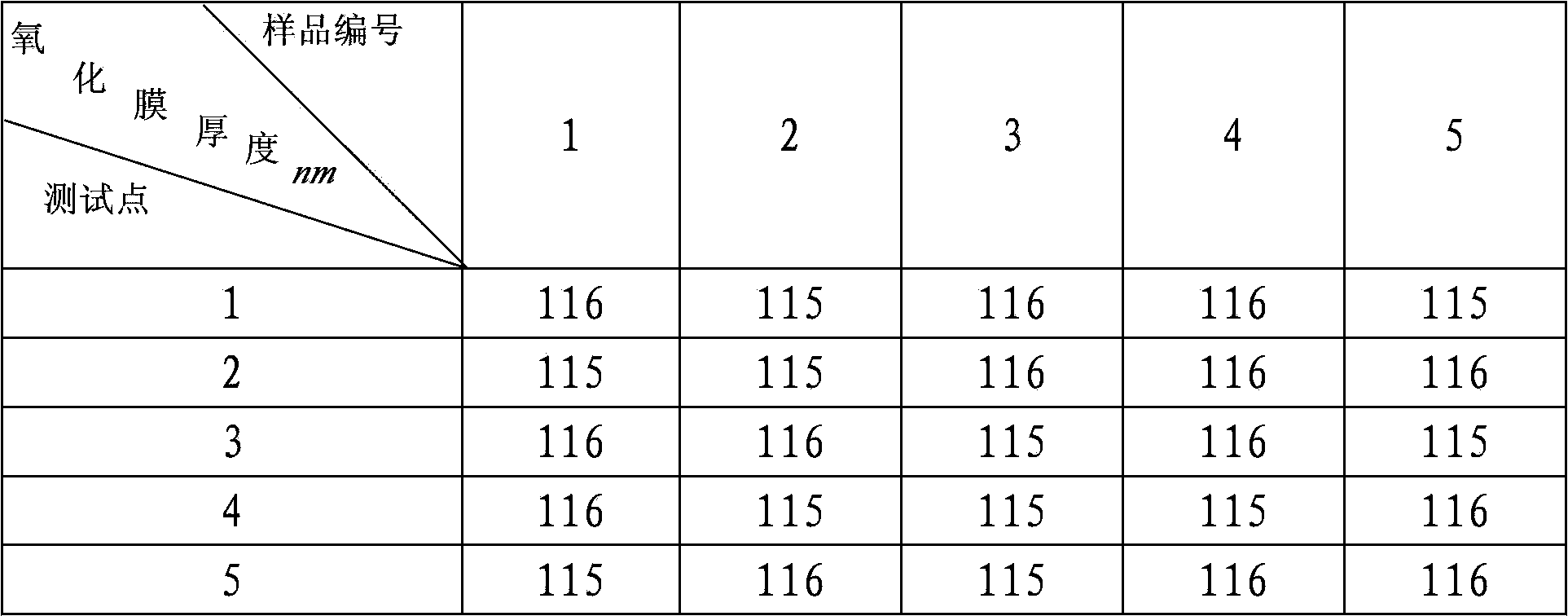

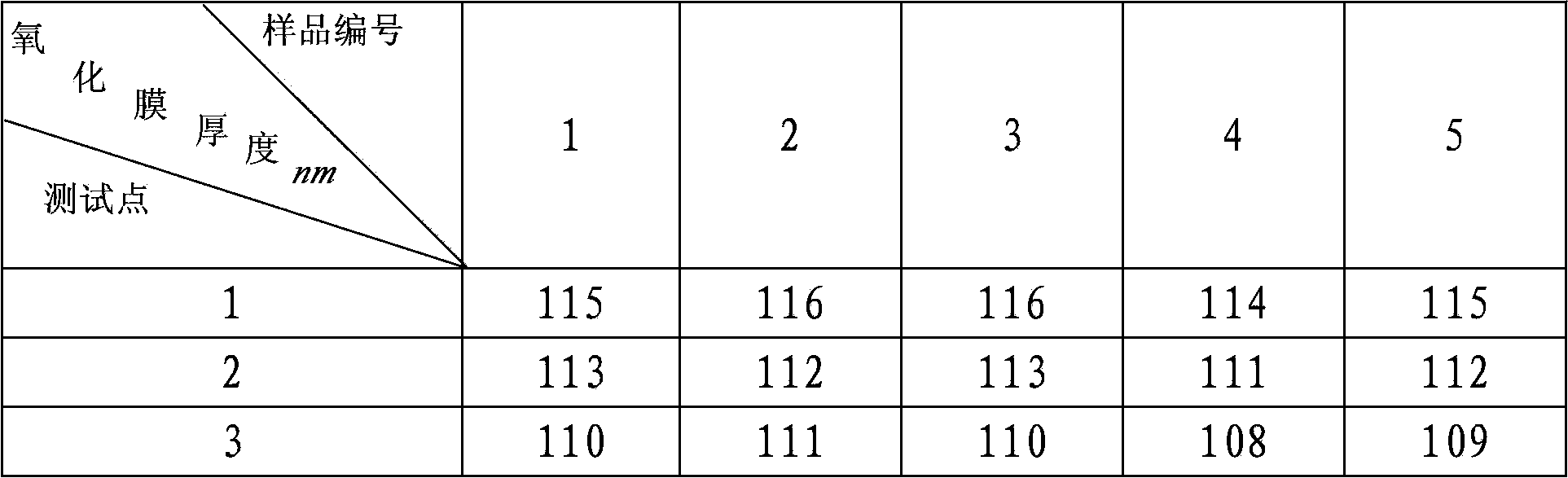

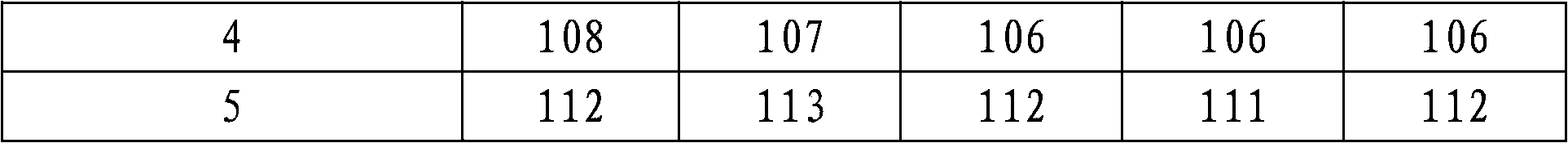

Technology for forming oxidation films with consistent thickness

ActiveCN103572350AReduce differential pressureGuaranteed thickness consistencySurface reaction electrolytic coatingElectrical field strengthMaterials science

The invention discloses a technology for forming oxidation films with consistent thickness. The technology comprises the following steps: (1) uniformly spot-welding a sintered tantalum anode block on a conductive metal bar; (2) placing a bracket with the conductive metal bar in an electrolytic cell; (3) manufacturing a lead frame in a shape of a Chinese character 'wang'; (4) placing the lead frame in the shape of the Chinese character 'wang' on the bracket in a superposed manner and compactly contacting with the metal bar spot-welded with the tantalum anode block; (5) connecting the anode of a power supply to the central position of the lead frame in the shape of the Chinese character Wang, and connecting the cathode of the power supply to the electrolytic cell; and (6) connecting the power supply for medium film forming treatment. The technology provided by the invention has the beneficial effects that the lead frame is manufactured by using a lead, so that the voltage difference between the output end of the power supply and the metal anode block of a valve is effectively reduced, the voltage applied to the anode block is guaranteed, and meanwhile, a current is applied from a terminal of a center shaft of the lead frame in the shape of the Chinese character 'wang', so that the paths of the current flowing to all directions are same, the electric field intensity is uniform, and the consistency of thickness of the generated oxidation films is guaranteed.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

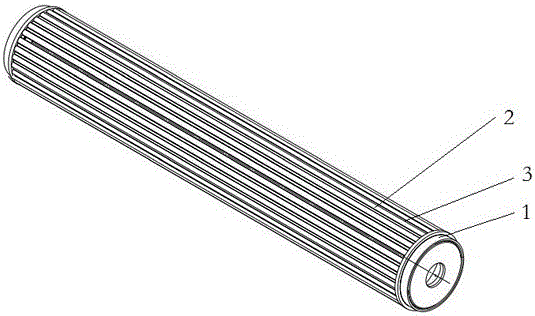

A diaphragm winding roller

ActiveCN106081747BQuality is not affectedGuaranteed thickness consistencyEngineeringMechanical engineering

The invention provides a membrane rolling roller. The membrane rolling roller comprises a roller body. A plurality of air bags are arranged on the peripheral face of the roller body. Peripheral faces used for rolling a membrane are formed by the outer side faces of the air bags. The air bags communicate with air inflow and outflow openings provided with air valves. By usage of the membrane rolling roller, the problem that tension in the membrane on the rolling roller cannot be smoothly released can be solved.

Owner:河南天工膜材新能源科技有限公司

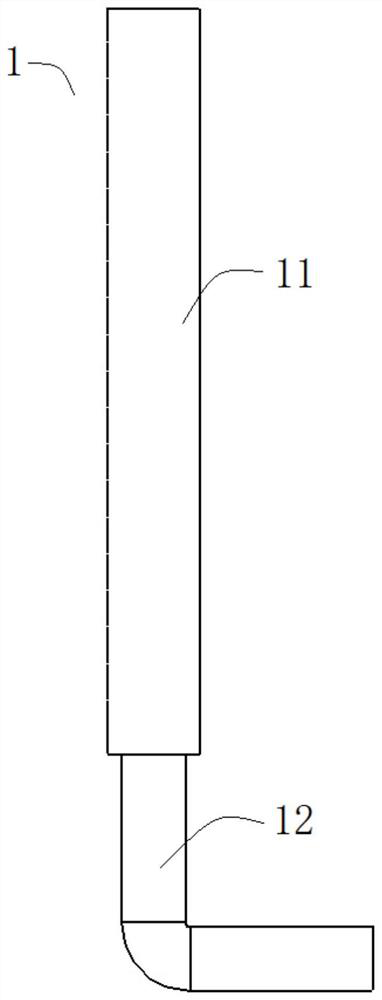

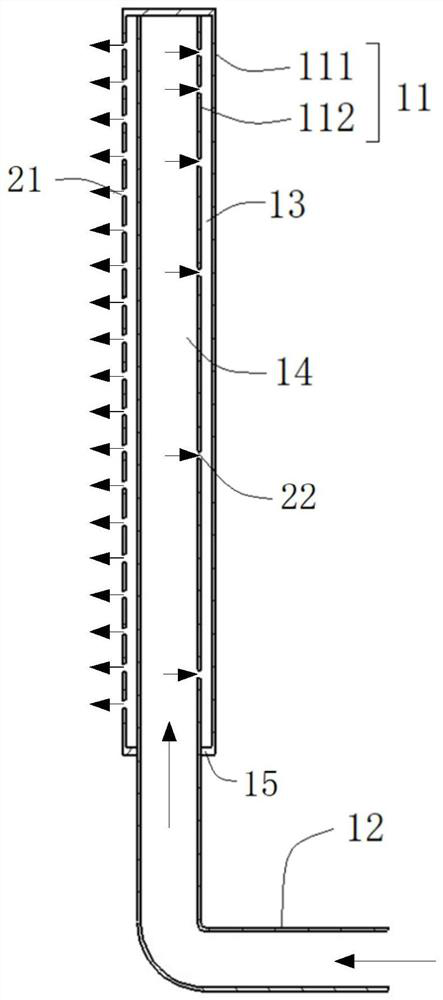

Gas injection device of semiconductor heat treatment equipment and semiconductor heat treatment equipment

PendingCN113755823AImprove uniformityGuaranteed thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermodynamicsEngineering

The invention provides a gas injection device of semiconductor heat treatment equipment and the semiconductor heat treatment equipment. The device comprises a gas inlet pipe, wherein a first pipe section comprises a first pipe wall and a second pipe wall nested in the first pipe wall, and a buffer space is formed between the inner wall of the first pipe wall and the outer wall of the second pipe wall; a plurality of first gas holes are uniformly distributed in the first pipe wall in the vertical direction, and the first gas holes are communicated with the buffer space and a process chamber respectively; a plurality of second gas holes are formed in the second pipe wall, and the second gas holes are communicated with the interior of the second pipe wall and the buffer space respectively; and the change rule of the inner diameter of the second pipe wall in the vertical direction and / or the arrangement rule of the plurality of second gas holes meet the requirement that the gas output of process gas flowing into the buffer space through the plurality of second gas holes at different positions in the vertical direction is the same. According to the technical scheme, different wafers can obtain uniform gas amount, and then the thickness uniformity of wafer film forming and the consistency of process results can be guaranteed.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

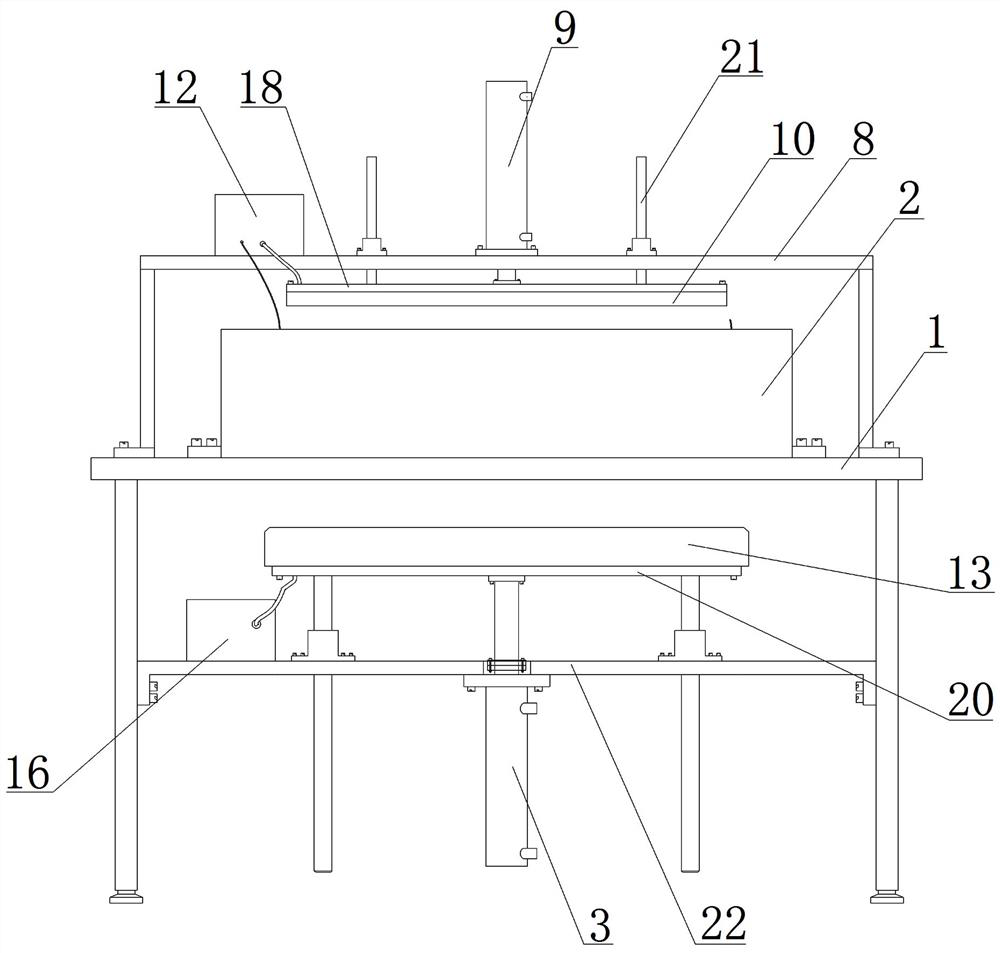

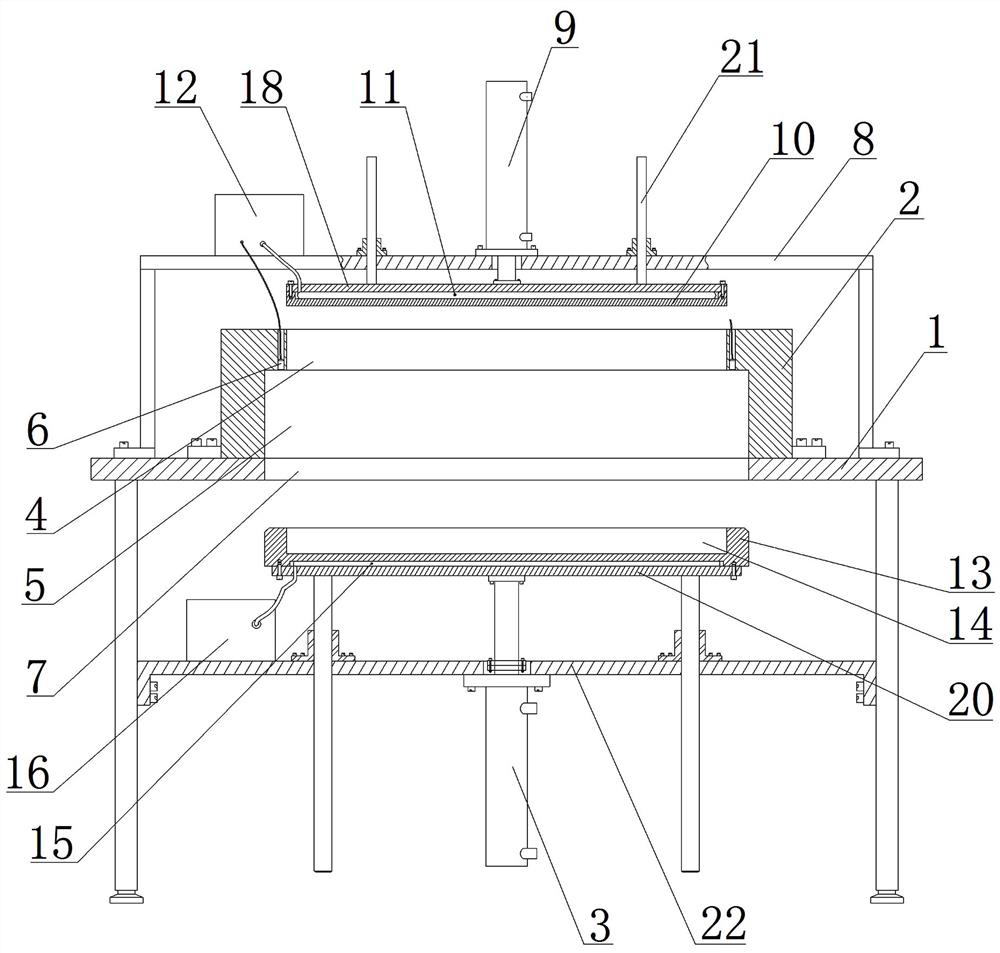

A production equipment and method for forming a conductive layer on the solder-resisting surface of a circuit board

ActiveCN113709994BReduce labor intensityGuaranteed thickness consistencyCircuit precursor manufactureSolderingWorkbench

The invention discloses a production equipment and method for forming a conductive layer on the solder-resisting surface of a circuit board, which comprises a workbench (1), a base (2) fixed on the workbench (1), and a (1) The lifting cylinder (3) below, the top surface of the base (2) is provided with an upper through groove (4) and a positioning groove (5) in sequence along its axial direction, and the positioning groove (5) is connected with the upper through A shoulder is formed between the grooves (4), and a lower through groove (7) connected to the positioning groove (5) is opened on the table surface of the workbench (1), and an extrusion cylinder ( 9), the piston rod of the extrusion cylinder (9) is set through the beam, and the extension end is provided with a pressure plate (10). The beneficial effects of the invention are: compact structure, reducing labor intensity of workers, ensuring uniform thickness of the conductive layer, improving the forming quality of the conducting layer, and improving the forming efficiency of the conducting layer.

Owner:四川英创力电子科技股份有限公司

Distributed control system and control method of glass magnesium board production line

ActiveCN106020143BImprove reliabilityHigh degree of automationTotal factory controlProgramme total factory controlControl cellTouchscreen

Owner:JIANGSU UNIV OF SCI & TECH

Formwork-free cast-in-place lightweight thermal insulation wall formwork, thermal insulation wall and construction method thereof

ActiveCN104674985BLight weightReduce construction difficultyWallsThermal insulationMesh reinforcement

Disclosed are a non-dismantling die cast-in-place lightweight thermal insulation wall formboard, a thermal insulation wall and a construction method thereof. The formboard comprises an inner formboard unit, an outer formboard unit and opposite-drawing connectors connecting the formboard units; the inner formboard unit comprises a formboard frame, steel bar grid frames connected between inner circles of the formboard frame, steel bar clamps connected to the cross points of the steel bars of the steel bar grid frames and a formboard core filling the inner side of the formboard frame; the inner formboard unit and the outer formboard unit are the same in structure and are connected at two ends of the opposite-drawing connector symmetrically; the steel bar clamps of the inner formboard unit and outer formboard unit are corresponded horizontally and are connected through the opposite-drawing connectors. The thermal insulation wall is simple in structure, by means of the double-layer wall formboard, the wall thickness consistence is guaranteed, the strength performance requirements are met, the thermal insulation wall is convenient to construct, the matching bar, core column and tie beam arrangement procedures are omitted, construction cost is lowered, constructing efficiency is improved, and the formboard can widely applied to wall construction.

Owner:北京振利节能环保科技股份有限公司

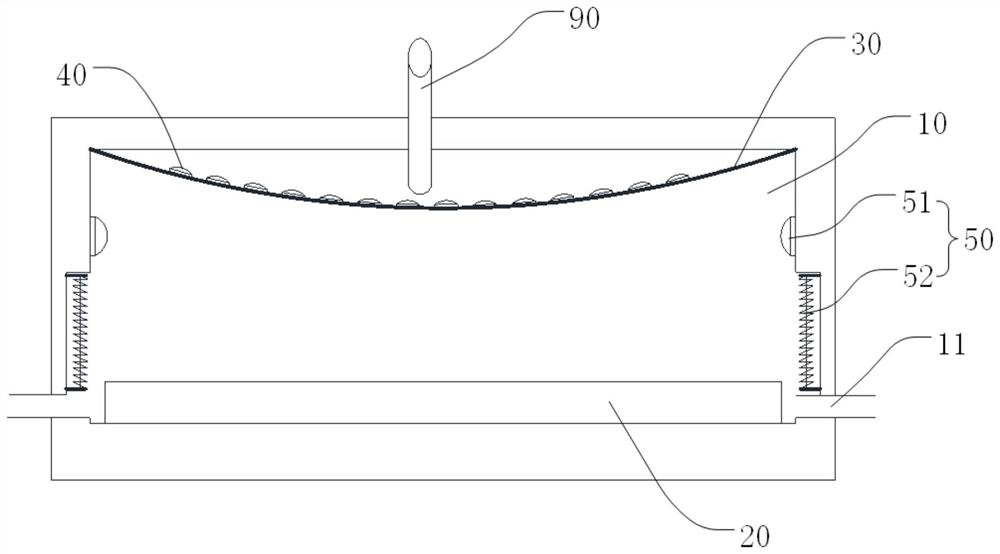

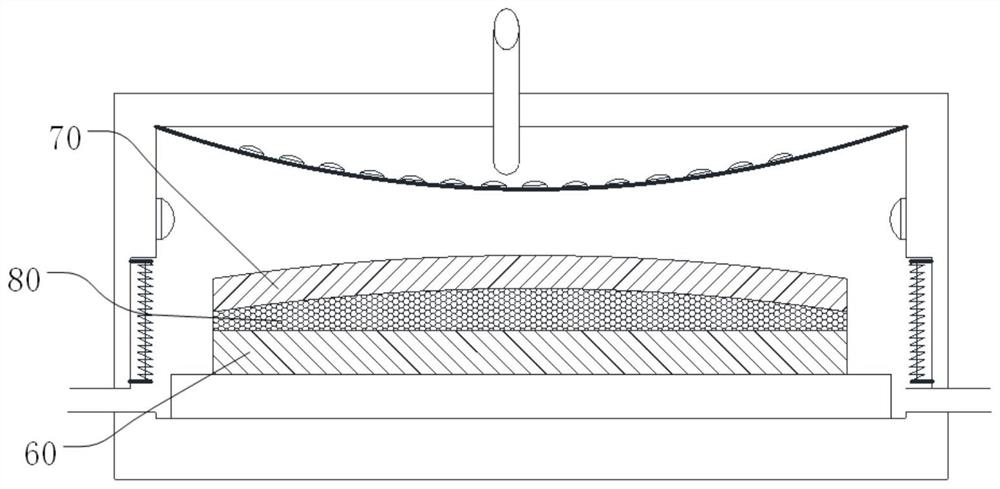

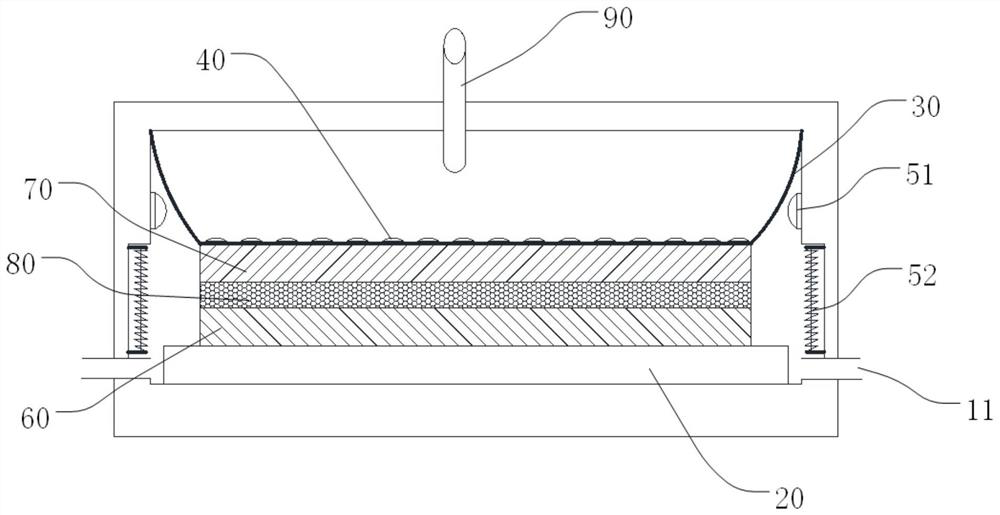

Vacuum bonding curing device and curing method for panel components

ActiveCN112855684BThickness real-time monitoringReduce the chance of reworkMaterial gluingDistance detectionAirbag

Owner:ANHUI HONGCHENG OPTO-ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com