Packaging method for high-capacity polymer lithium ion cells

A lithium-ion battery and packaging method technology, applied in the field of lithium-ion batteries, can solve the problems that the battery thickness cannot exceed 12mm, limit the geometric volume of the battery, etc., and achieve the effects of ensuring electrical performance, reducing length requirements, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Take a 100Ah lithium iron phosphate polymer lithium-ion battery, the size of which is: length 330mm, width 460mm, thickness 8.5mm; the battery packaging method specifically includes the following steps:

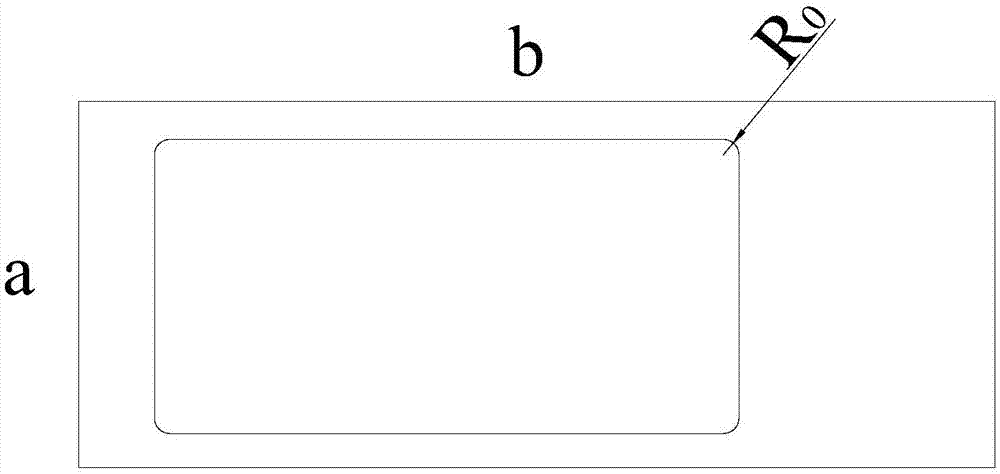

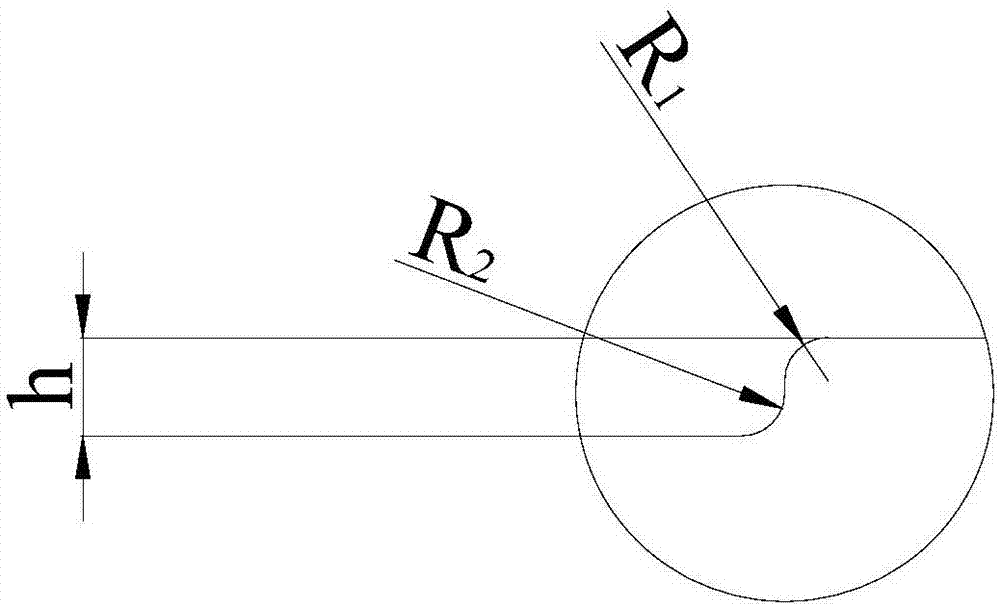

[0066] (1) Punching bags: Punching two aluminum-plastic films with a length of 480mm, a width of 660mm and a thickness of 0.152mm with the same punching die, the depth h of the punching bag is 4.1mm, and the 4 plane corner R 0 The radius of the punching bag is 8mm, and the fillet R on the punching bag 1 and fillet under punching bag R 2 The radius is 2mm.

[0067] (2) Packing: put the battery into the pocket of one piece of aluminum-plastic film, and cover another piece of aluminum-plastic film on the top of the pocket.

[0068] (3) Top heat sealing: Since the length of the top edge of the battery is greater than 500mm, the top heat sealing is performed several times. A top sealing machine with a head length of 500mm and a width of 8mm is used to heat the head to 22...

Embodiment 2

[0072] Take a 200Ah ternary lithium polymer lithium-ion battery, the size of which is: 500mm in length, 700mm in width, and 5.5mm in thickness; the battery packaging method specifically includes the following steps:

[0073] (1) Punching bags: Take two aluminum-plastic films with a length of 540mm, a width of 1200mm, and a thickness of 0.152mm. Since the thickness of the battery is less than 6mm, only one of them is punched with a stamping die. The depth of the punching bag is h is 5.2mm, and the four plane corners R of the punching bag 0 The radius is 10mm, and the fillet R on the punching bag 1 and fillet under punching bag R 2 The radius is 1mm.

[0074] (2) Bagging: put the battery into the mouth of the aluminum-plastic film with a punched bag, and cover another piece of aluminum-plastic film over the mouth of the bag correspondingly.

[0075] (3) Top heat sealing: Since the length of the top sealing side of the battery is greater than 500mm, the top heat sealing is per...

Embodiment 3

[0079] Take a 300Ah ternary lithium polymer lithium-ion battery. The size of the battery is: 435mm in length, 780mm in width, and 10.5mm in thickness; the battery packaging method specifically includes the following steps:

[0080] (1) Punching bags: two aluminum-plastic films with a length of 480mm, a width of 1200mm and a thickness of 0.152mm are punched with the same punching die, the depth h of the punched bag is 5.1mm, and the 4 plane corner R 0 The radius of the punching bag is 20mm, and the upper fillet R of the punching bag 1 and fillet under punching bag R 2 The radius is 3mm.

[0081] (2) Packing: put the battery into the pocket of one piece of aluminum-plastic film, and cover another piece of aluminum-plastic film on the top of the pocket.

[0082] (3) Top heat sealing: Since the length of the top side of the battery is greater than 500mm, the top heat sealing is performed several times. A top sealing machine with a head length of 500mm and a width of 8mm is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com