Hot melt adhesive preparation and coating integrated equipment and method

A hot-melt adhesive and coating technology, which is used in devices for coating liquids on surfaces, coatings, and final product manufacturing. and other problems to achieve the effect of avoiding the risk of scalding, saving material costs, and saving operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Goal: It is necessary to obtain 5 patches of molding specifications with a coating thickness of 0.1mm, a width of 170mm, and a length of 350mm.

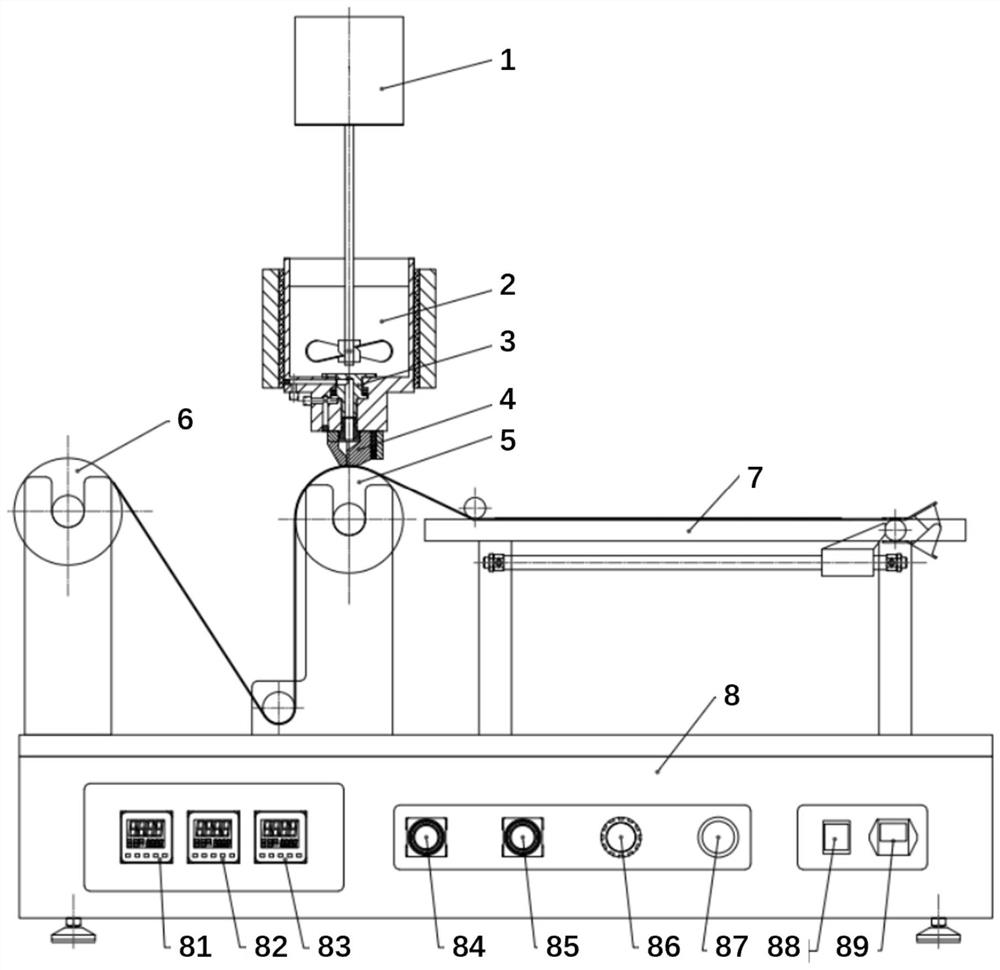

[0114] use Figure 1 to Figure 7 equipment shown.

[0115] Methods include:

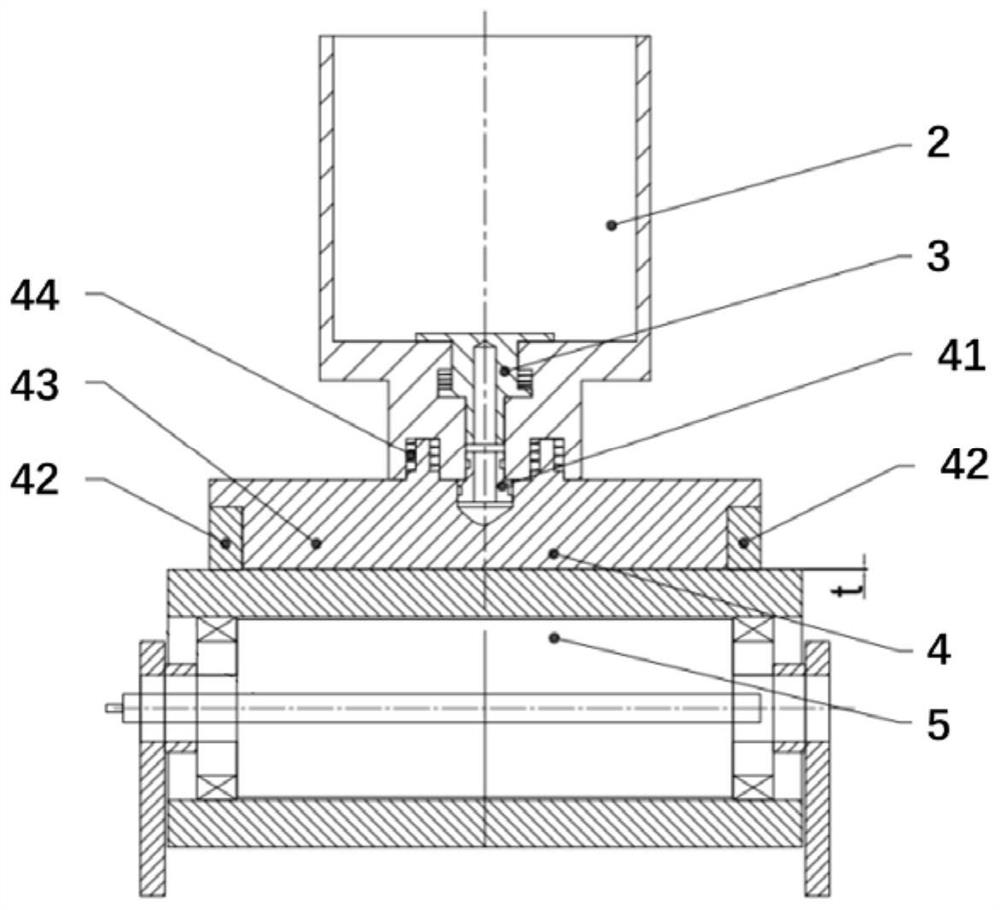

[0116] 1. In the hot-melt adhesive container 2 with a temperature control of 150°C, add the materials, and stir with the agitator 1 continuously for a long time. The color of the stirred materials is evenly mixed, and the glue reaches a molten state;

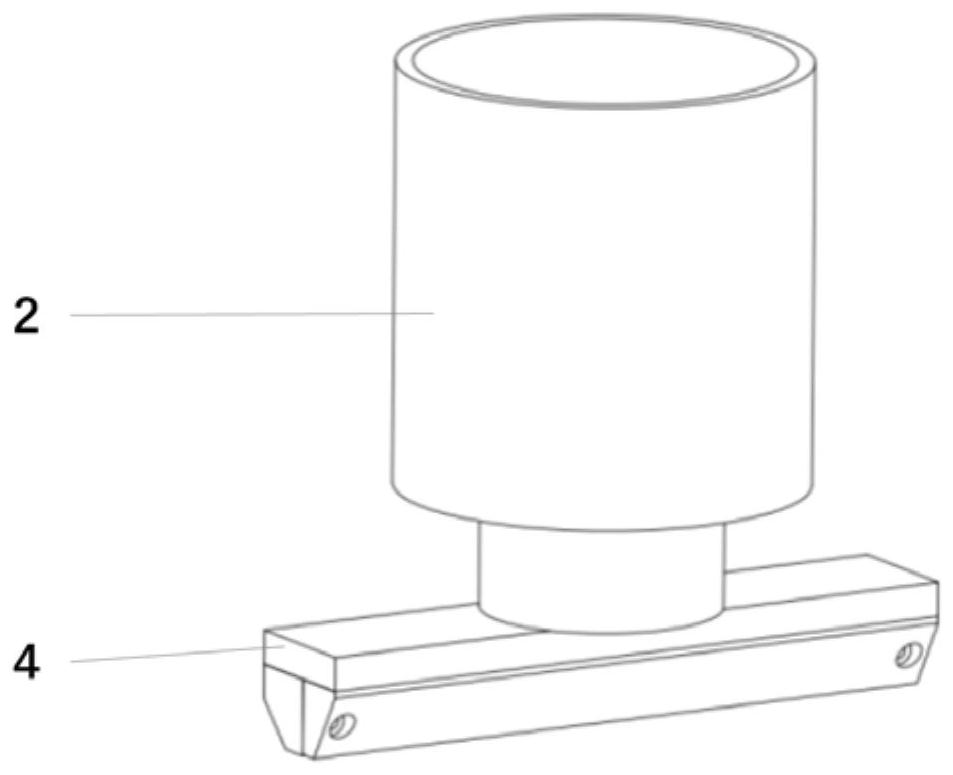

[0117] 2. Set the temperature of the flat nozzle slit coating cutter head 4 and the adhesive coating support roller 5 at 150°C, adopt a digital temperature controller, and the temperature control stability accuracy is ±0.5°C;

[0118] 3. Open the pneumatic switch 3 for ventilation, and after 3 minutes rely on the gravity of 5.95ml glue flow into the coating cutter head 4, then close the pneumatic switch 3;

[0119] 4. Adjust the pressure value of the precision pressure reducing valve 86 to 0.1bar, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com