Manufacturing method of large-diameter thick-wall flange cylinder

A manufacturing method and cylinder technology, applied in manufacturing tools, arc welding equipment, welding equipment and other directions, can solve the problems of welding deformation, large error, large plate thickness deviation, etc., and achieve small welding deformation, small error, and small thickness deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

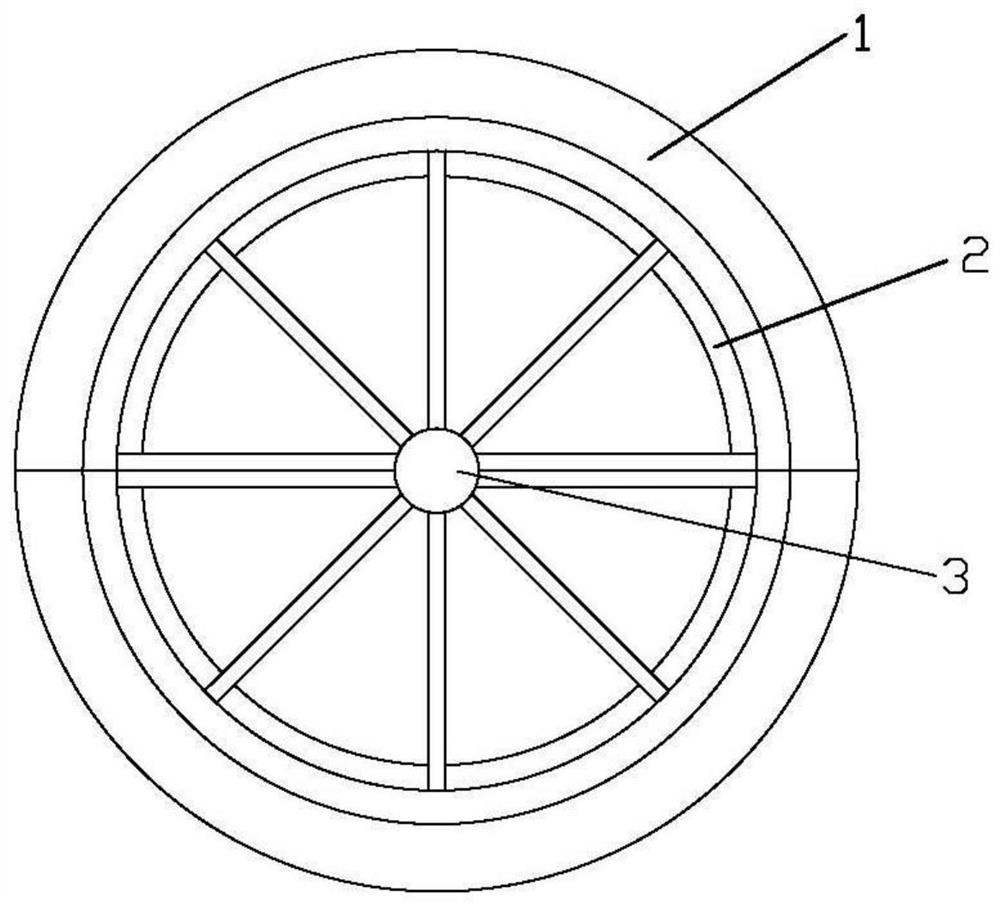

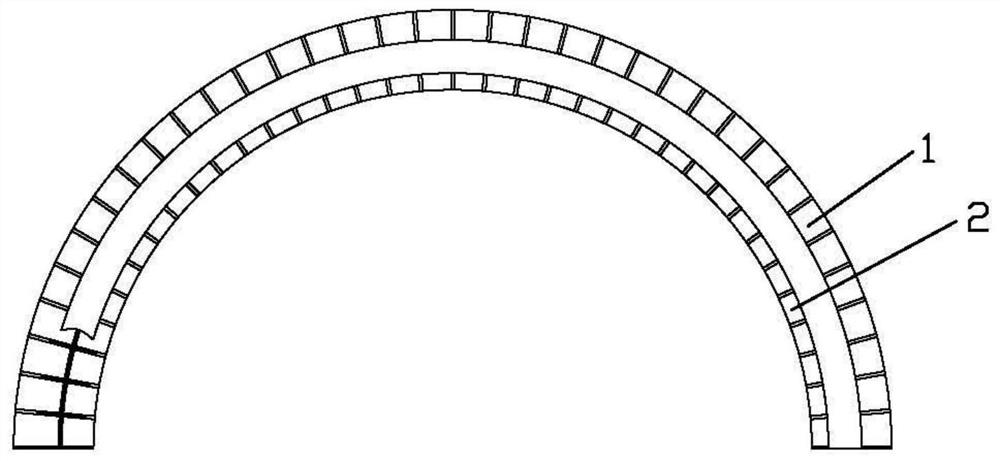

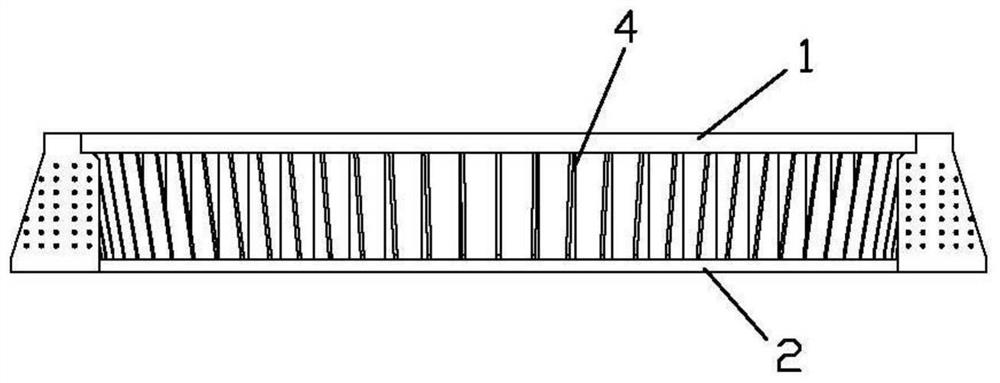

[0010] Depend on Figure 1-3 Given, the present invention comprises the following steps:

[0011] 1) Cutting

[0012] The upper ring 1 and the lower ring 2 adopt 1 / 6 blanking, considering welding shrinkage and heat treatment deformation. When blanking, the diameter of the steel plate is +10mm. Because the outer circle needs to be processed, the blanking width of the ring is +3mm, and the thickness direction of the steel plate is cut vertically. The straightness is not greater than 1.5mm to ensure the machining allowance; the cylinder body 3 adopts 1 / 2 blanking, and the height is 780±3mm. In order to ensure the assembly clearance, it is required that the straightness of the whole length is not greater than 1.5mm, and both sides are grooved at 0K45 degrees to strengthen 116 pieces of rib plate 4 are blanked. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com