Epitaxial wafer manufacturing method and epitaxial wafer

A manufacturing method and epitaxial technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reduced productivity and increased cost, and achieve high productivity, improved productivity, and excellent film thickness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

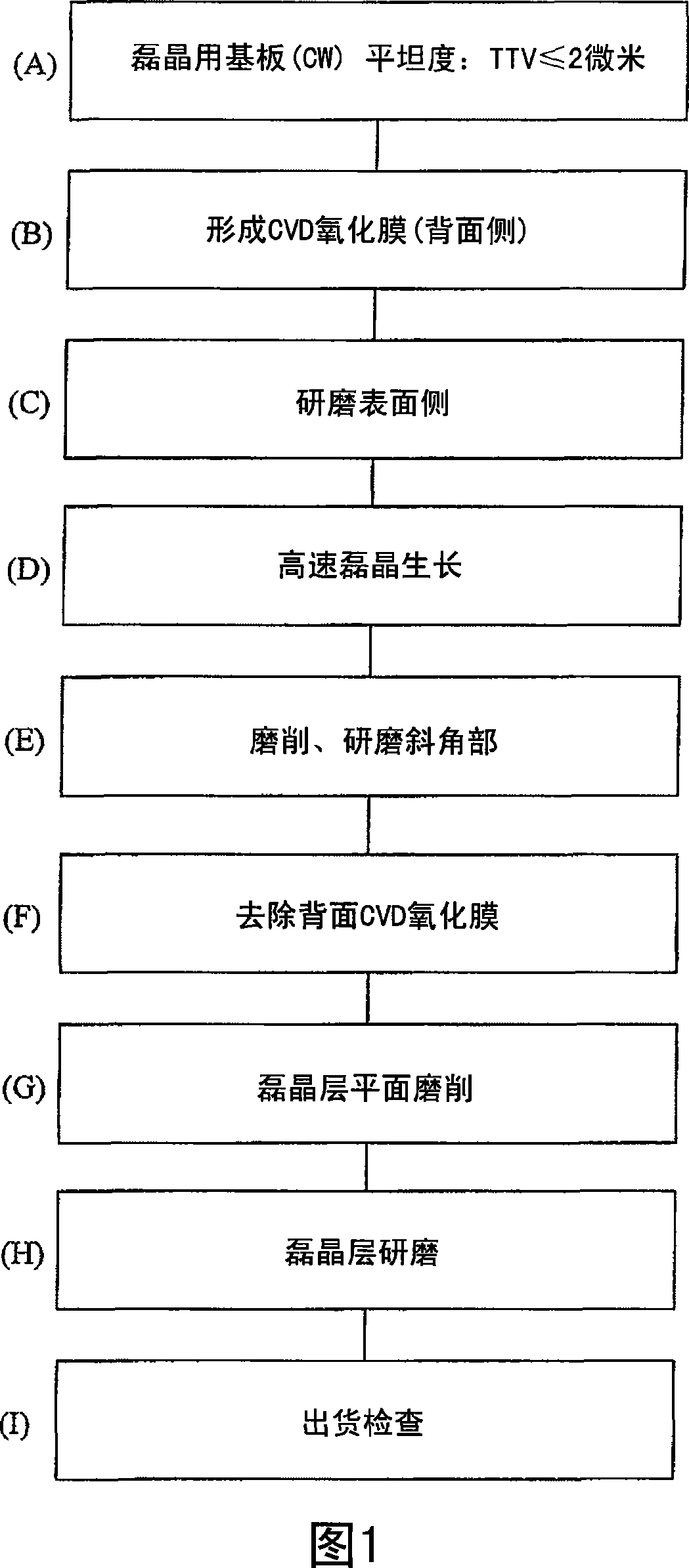

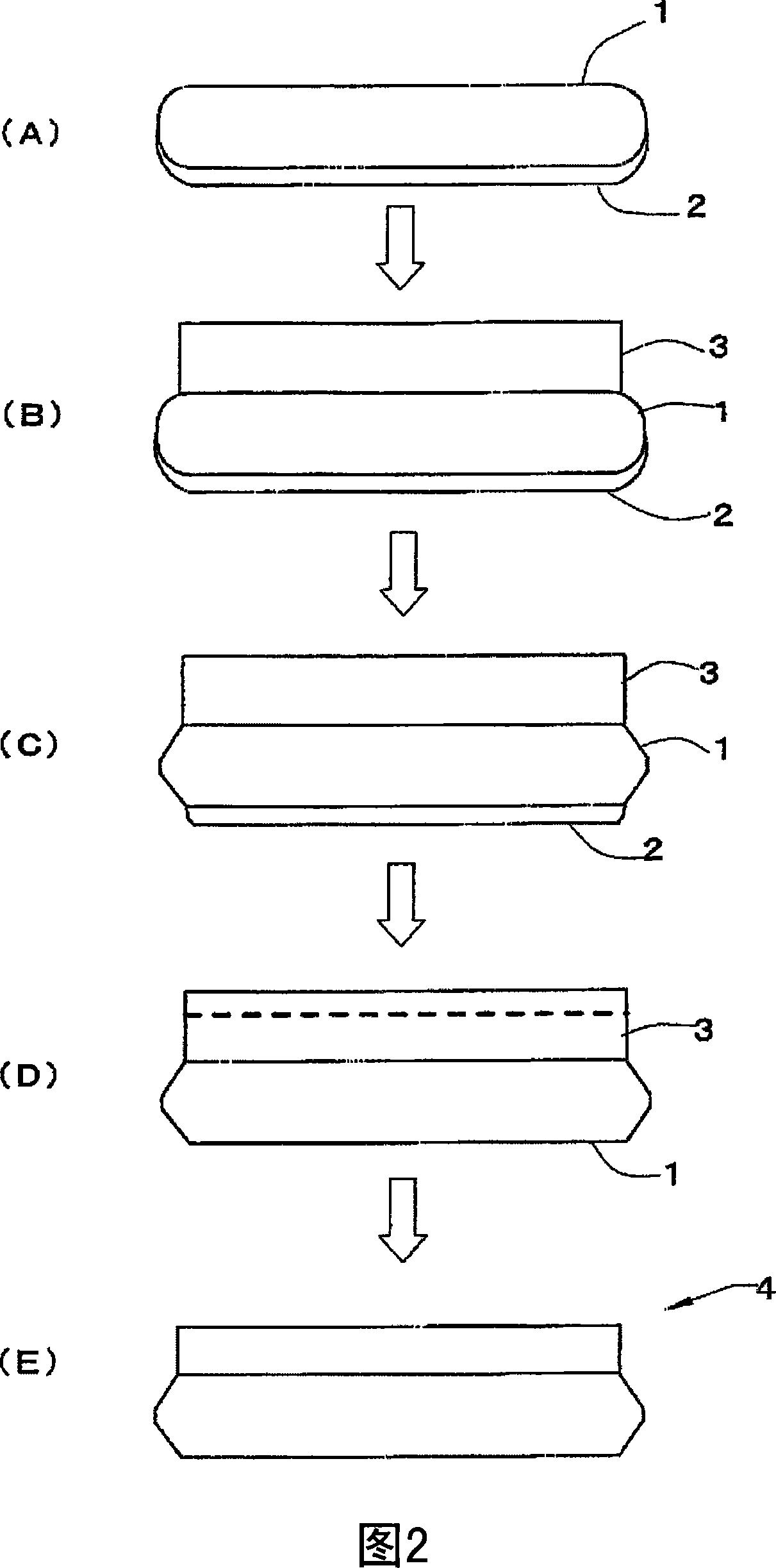

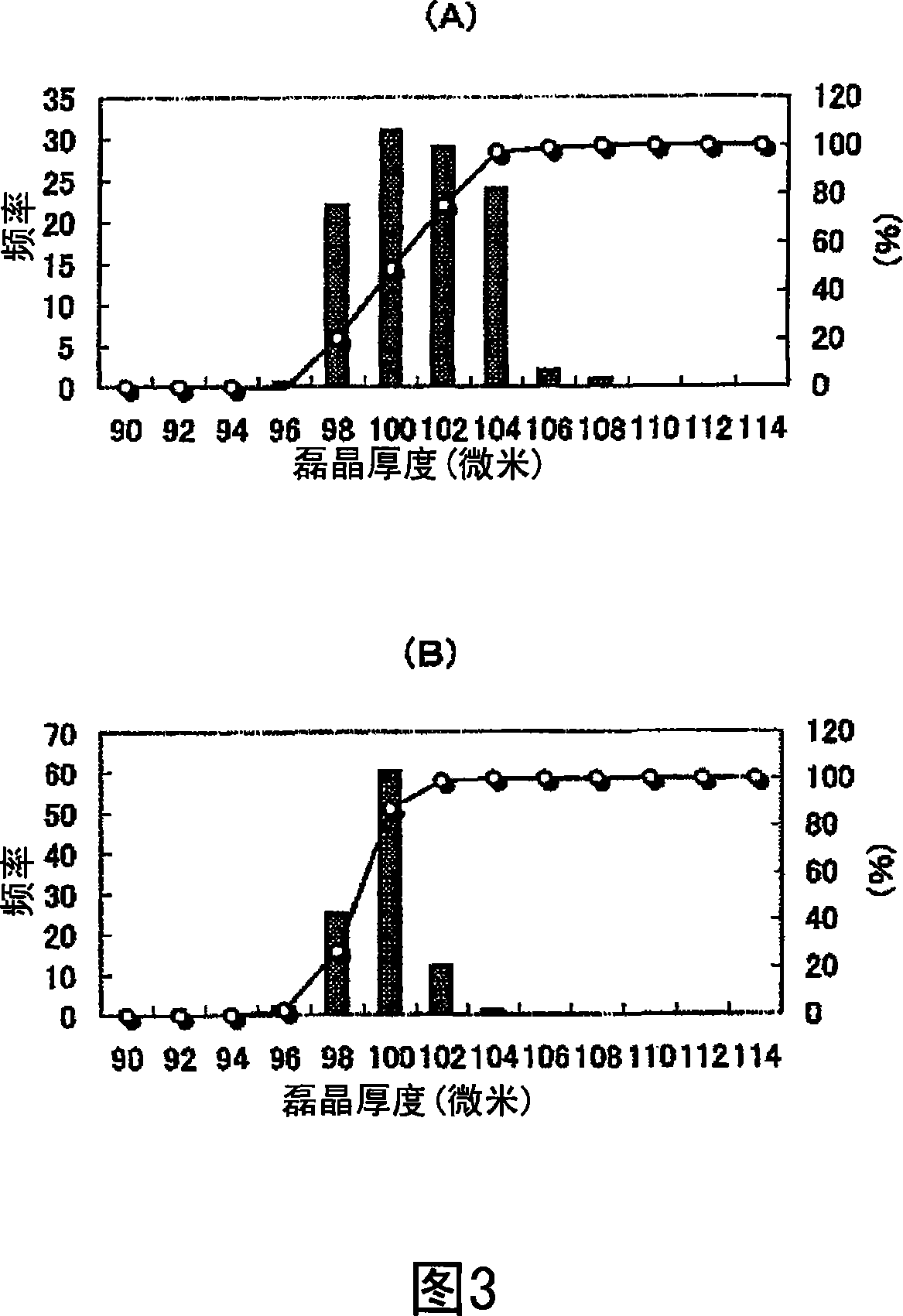

[0098] Prepare 200 silicon wafers with a diameter of 200 mm, a thickness specification of 625 μm, a P type, a resistivity of 5 to 10 mΩcm, and a TTV (flatness specification) of 2.0 μm or less as substrates for epitaxy. An oxide film (SiO 2 ). In addition, the thickness (initial thickness) of each wafer was measured before forming the CVD oxide film, and an ID number was added to each wafer by laser marking.

[0099] Epitaxial growth is a vertical epitaxial growth device that uses high-frequency heating. The epitaxial growth thickness is 120 microns as the target, the source gas is trichlorosilane, and the carrier gas is H 2 Gas, adjust the supply rate of trichlorosilane so that the growth rate is 4 μm / min. The epitaxial growth temperature (pedestal temperature) was set at 170°C. Also, the resistivity of the target epitaxial layer is N-type, 30Ωcm.

[0100] In addition, in order to suppress the bridge connection during epitaxial growth, a base is used, the base is formed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com