Preparation method of releaser for alkali metal releasing agent

A release agent and releaser technology, which is applied in the field of preparation of releasers used in alkali metal releasers, can solve the problems of releaser consistency and stability to be improved, so as to improve performance consistency and stability, ensure consistency and Stability, the effect of ensuring the consistency of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

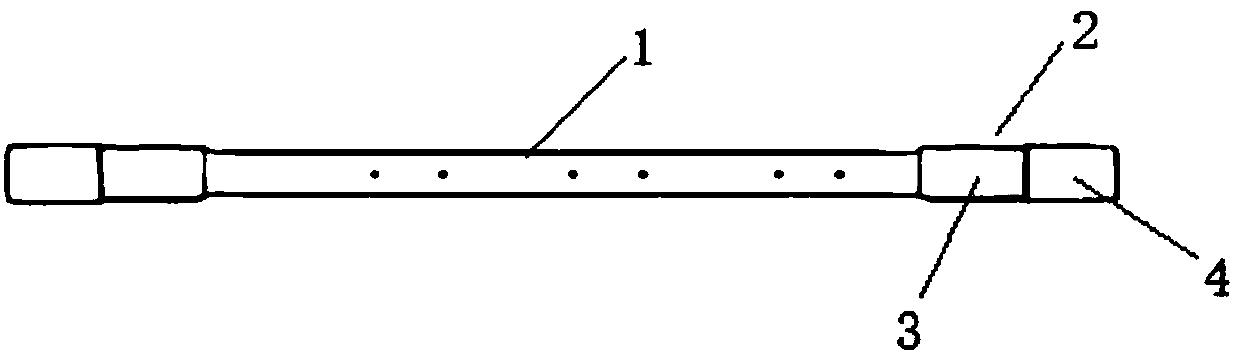

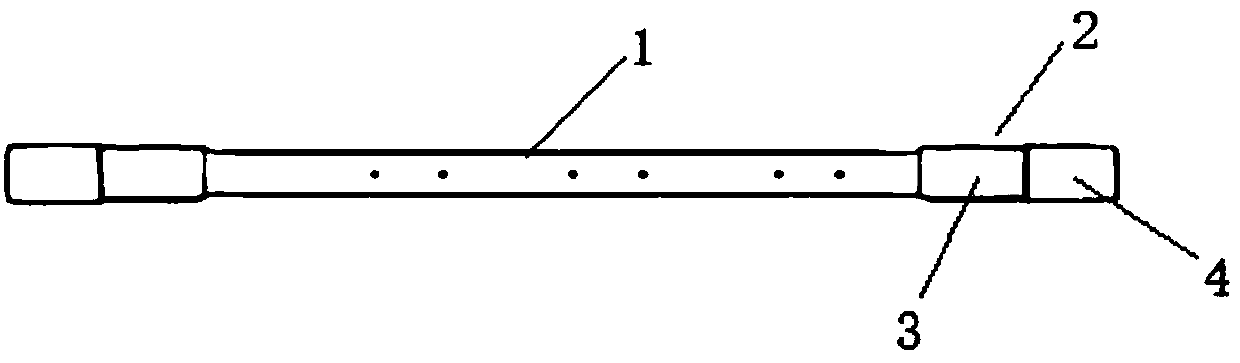

Embodiment 1

[0034] Select ZrAl16 getter as the reducing agent, the selected cesium salt is cesium chromate, and the particle size of the reducing agent powder is 10-40 μm; the atomic ratio (Cs / Zr) of Cs in the cesium salt and Zr in the reducing agent in the mixed powder is 0.7. Put the mixed powder into a nickel-chromium alloy tube with an outer diameter of 5.0mm and a wall thickness of 0.05mm, and when it is drawn to an outer diameter of 1.05mm and a wall thickness of 0.04mm, the number of passes required is 23, and the drawing speed is 10mm / s ~30mm / s. The powder loading amount of the finally obtained releaser is 50±1mg, the sample mass is 80±1mg, and the resistance is 0.3±0.02Ω. Put the prepared releaser into the low-light night vision device to test the alkali metal release performance. The results show that the cesium vapor release current of 6 releasers used in series in different batches is 1.8±0.1A, and the corresponding cesium releaser works The heating power is 4.5±0.2W.

Embodiment 2

[0036] Select ZrAl16 getter as the reducing agent, the selected cesium salt is cesium chromate, and the particle size of the reducing agent powder is 10-40 μm; the atomic ratio (Cs / Zr) of Cs in the cesium salt and Zr in the reducing agent in the mixed powder is 0.7. Put the mixed powder into a nickel-chromium alloy tube with an outer diameter of 7.0mm and a wall thickness of 0.06mm, and draw it to an outer diameter of 1.15mm and a wall thickness of 0.05mm. The required passes are 28 times, and the drawing speed is 35mm / s~ 70mm / s. The final powder loading of the Cs releaser was 55±1mg, the sample mass was 95±1mg, and the resistance was 0.23±0.02Ω. Put the prepared releaser into the low-light night vision device to test the alkali metal release performance. The results show that the cesium vapor release current of 6 releasers used in series in different batches is 2.1±0.1A, and the corresponding cesium releaser works The heating power is 4.9±0.2W.

Embodiment 3

[0038] The ZrAl16 getter is selected as the reducing agent, and the selected rubidium salt is rubidium chromate. In order to facilitate the contact of the rubidium compound and the reducing agent, the material in powder form is used for mixing. The particle diameter of the reducing agent powder is 10-40 μm; the atomic ratio (Rb / Zr) of Rb in the cesium salt in the mixed powder to Zr in the reducing agent is 0.6. Put the mixed powder into a nickel-chromium alloy tube with an outer diameter of 6.0mm and a wall thickness of 0.05mm, and draw it to an outer diameter of 1.2mm and a wall thickness of 0.035mm. The required passes are 28 times, and the drawing speed is 20mm / s~ 50mm / s. The final powder loading of the Rb releaser was 48±1.0mg, the sample mass was 79±1.0mg, and the resistance was 0.29±0.02Ω. Put the prepared releaser into the low-light night vision device to test the alkali metal release performance. The results show that: the rubidium vapor release current of 6 releaser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com