Distributed control system and control method of glass magnesium board production line

A distributed control, glass magnesium board technology, applied in the control field, can solve the problems of poor system flexibility, high labor intensity, signal dispersion, etc., and achieve the effects of high system reliability, high degree of automation, and accurate spacing adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following will be combined with Figure 1-7 , the technical solution of the present invention will be described in detail.

[0077] At present, the commonly used glass magnesium board production line consists of several parts: template loading device, board conveying device, ingredient mixing device, board extrusion molding device, board automatic cutting device, and board entering cage device.

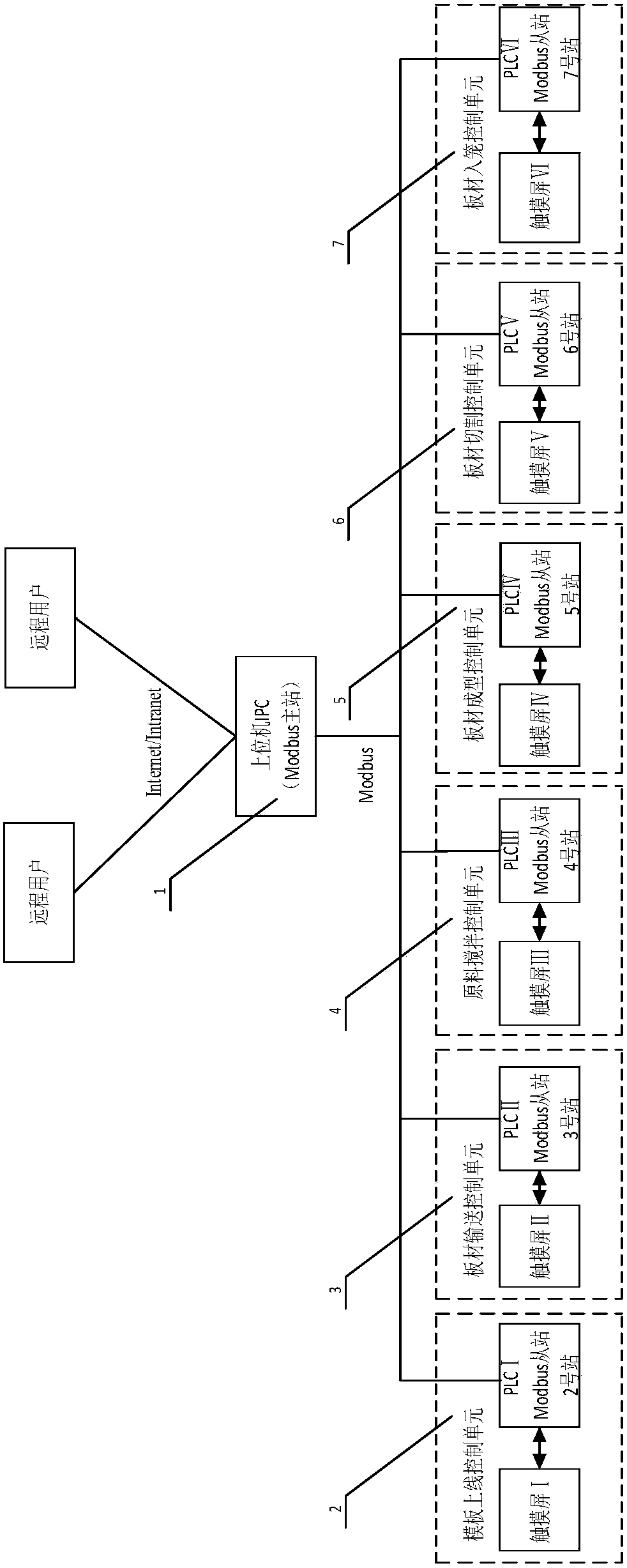

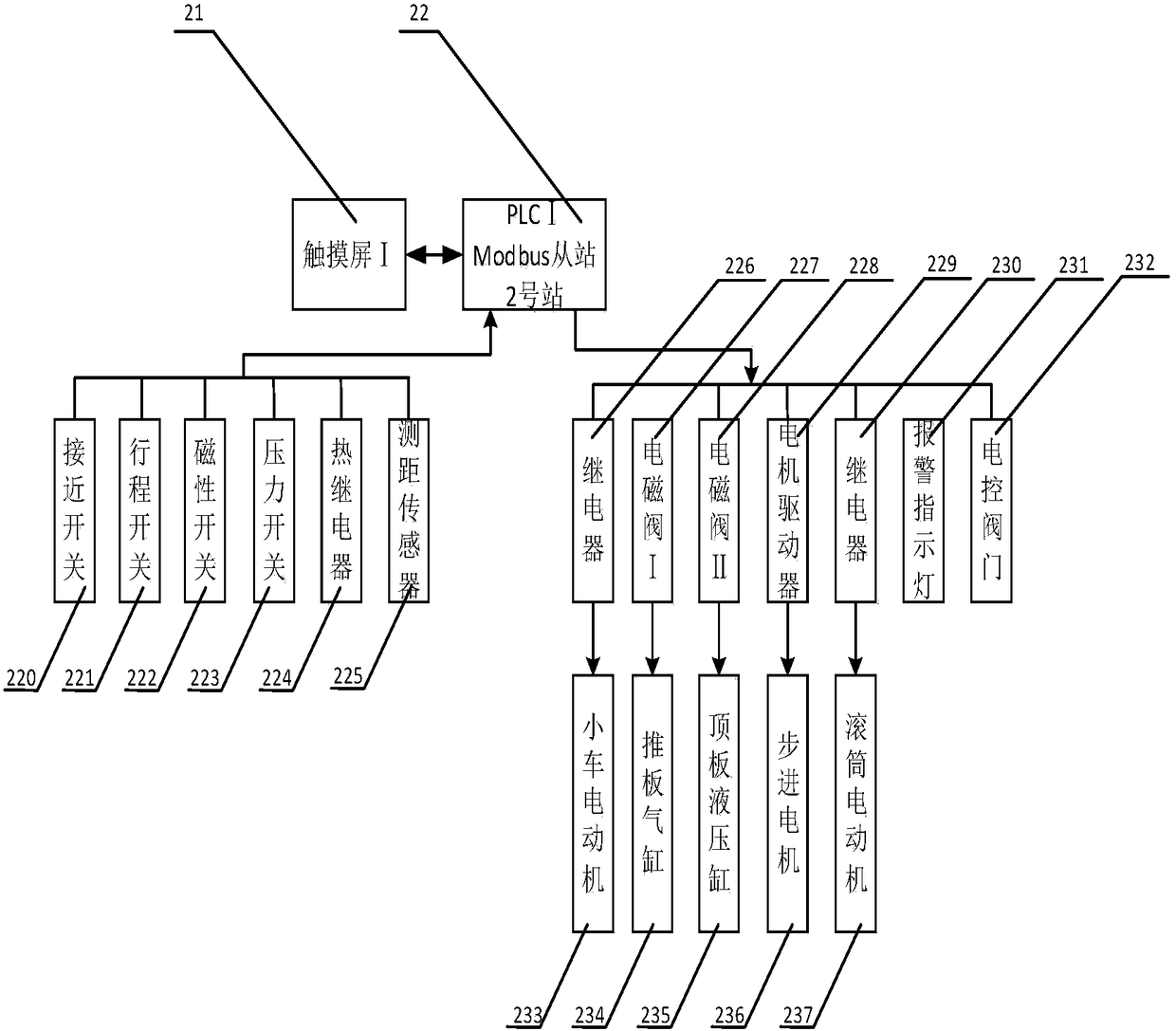

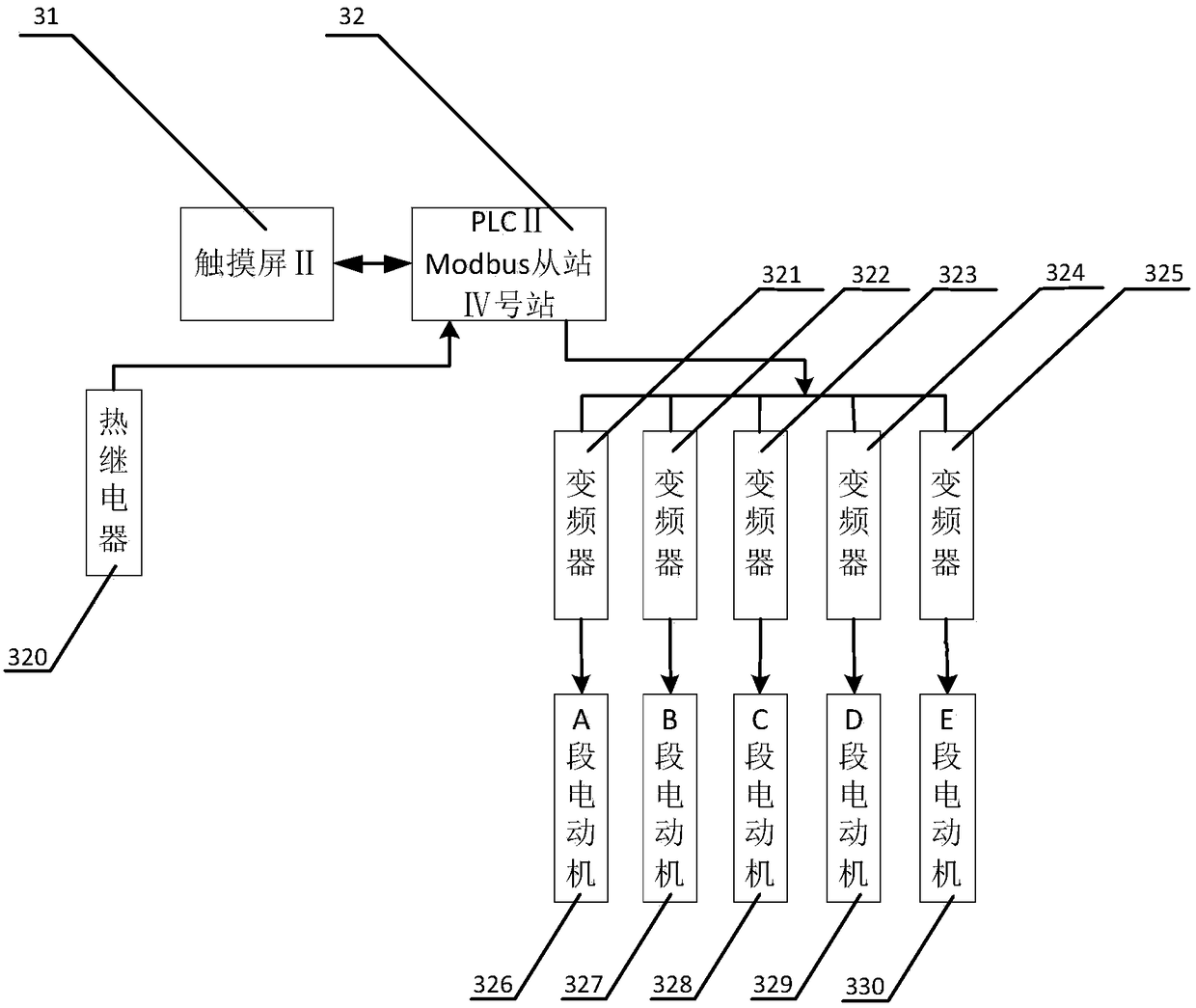

[0078] The technical purpose of the present invention is to provide a kind of distributed control system applicable to the above-mentioned glass magnesium board production line, such as figure 1 As shown, it includes host computer IPC1, template on-line control unit 2, plate conveying control unit 3, ingredient mixing control unit 4, plate forming control unit 5, plate automatic cutting control unit 6 and plate entering cage control unit 7. The upper computer IPC1 acts as the master station of Modbus, and each control unit acts as the slave station of Modbus, which jointly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com