Patents

Literature

60results about How to "Realize cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

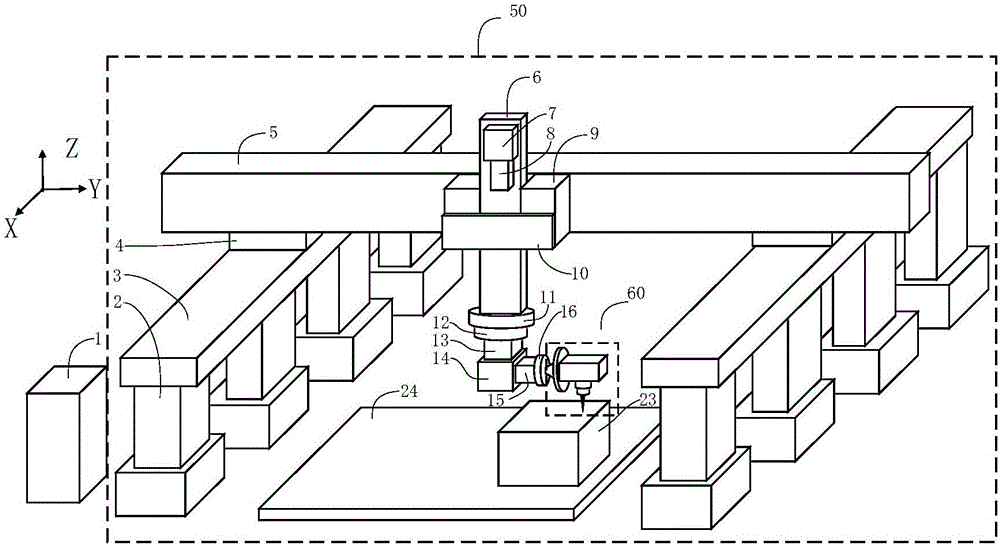

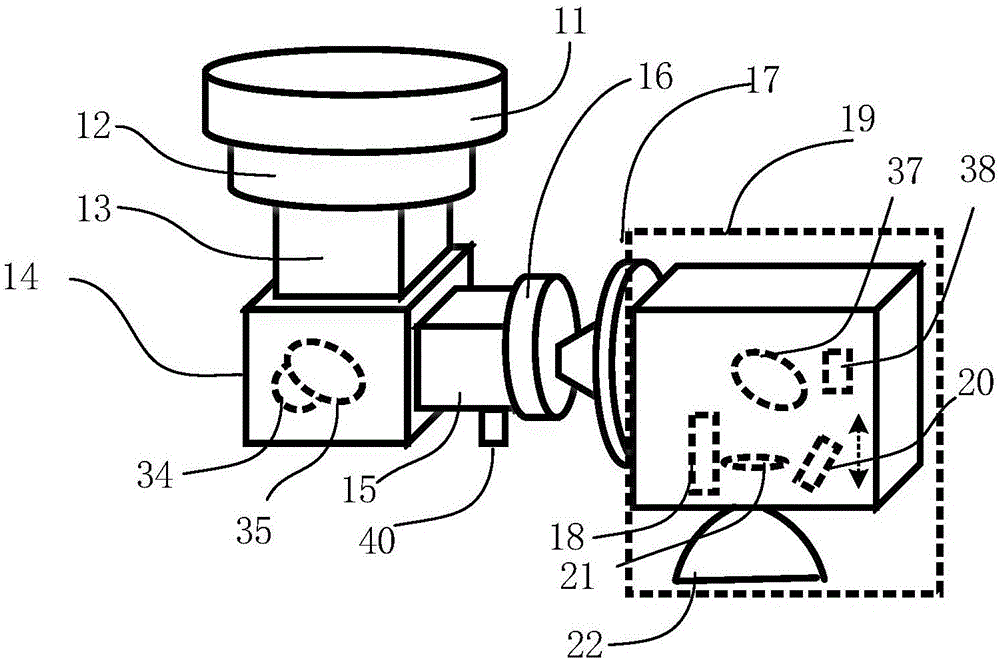

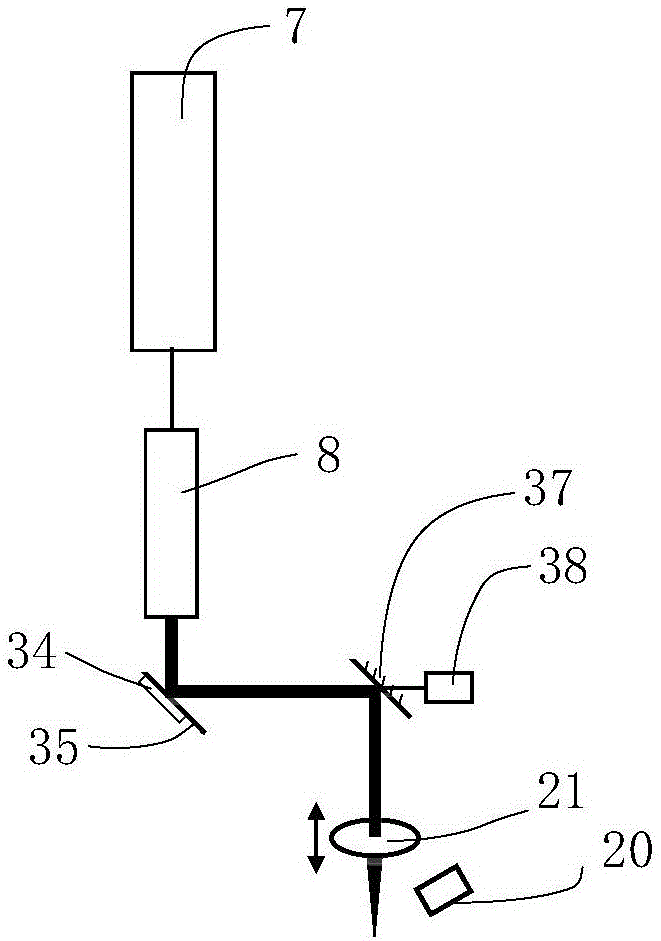

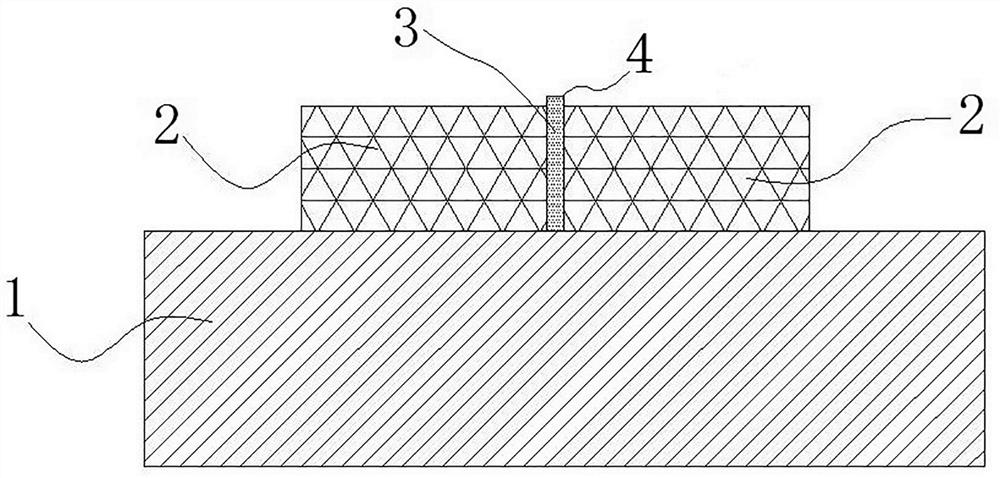

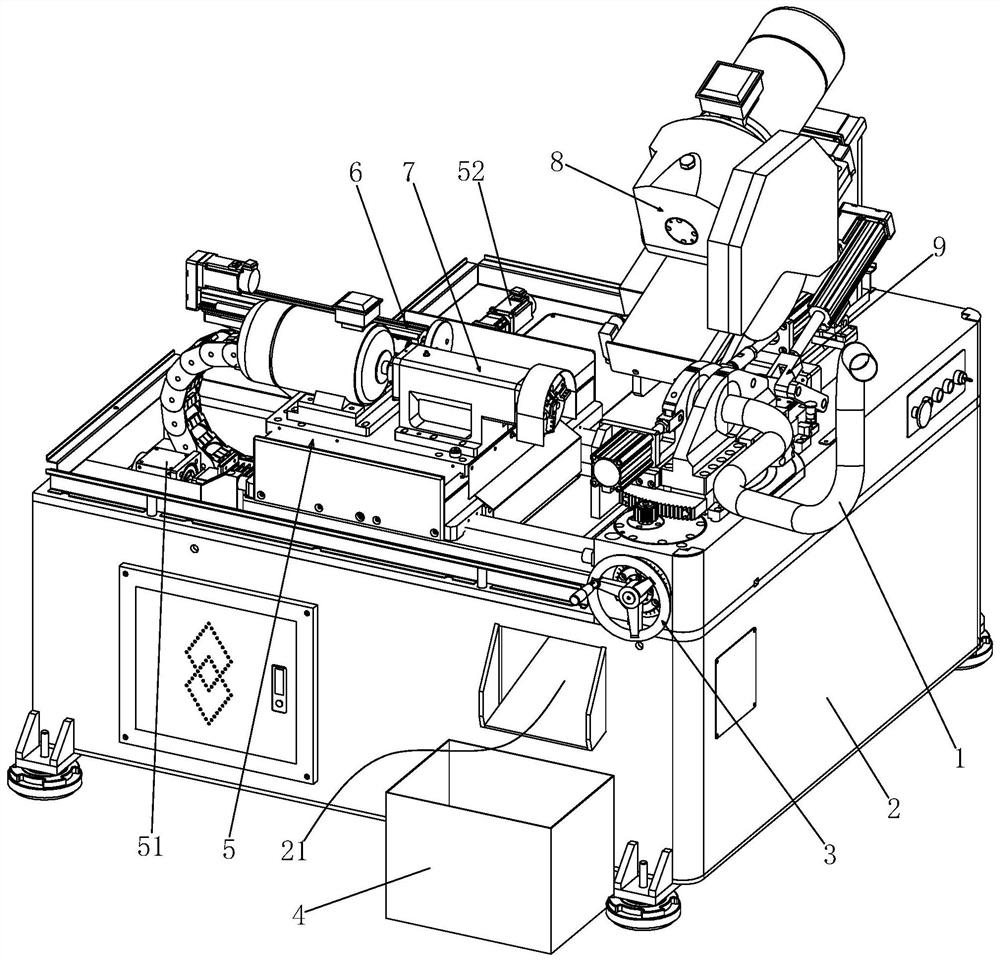

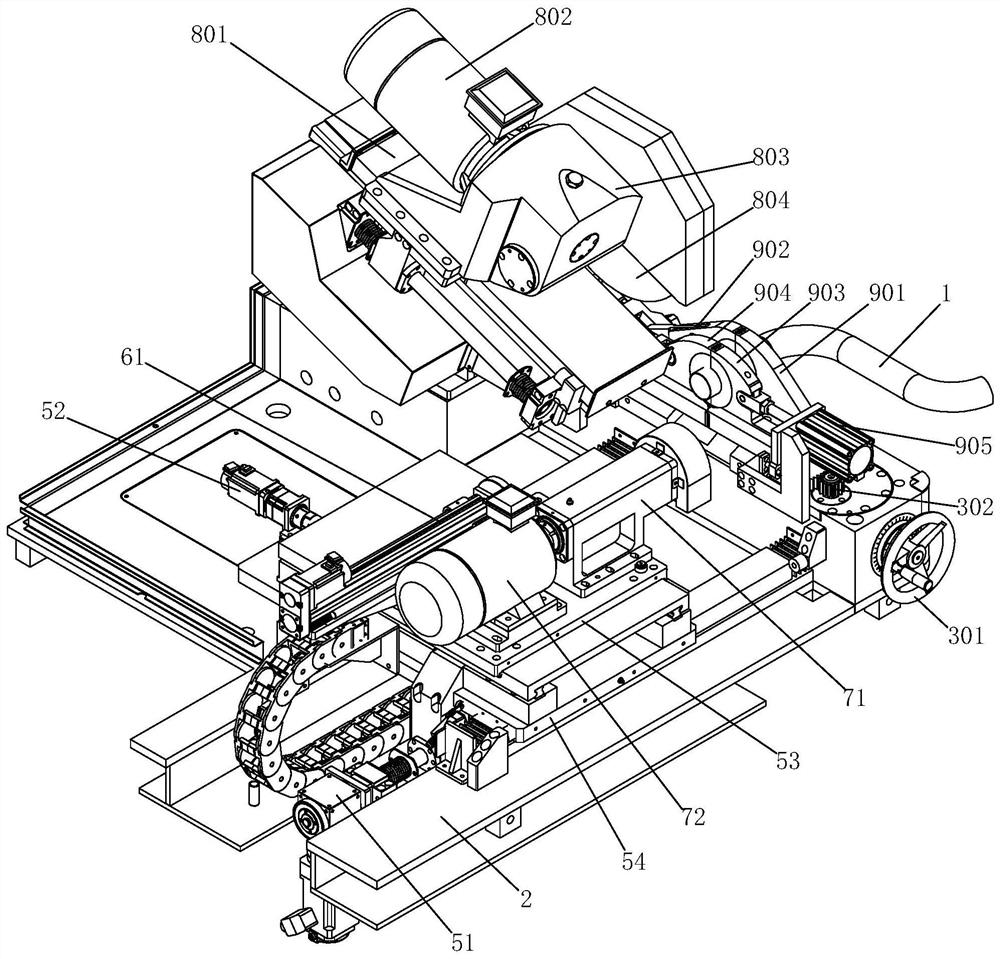

Multi-light source, multi-function and multi-axis laser processing head and apparatus

ActiveCN106563880AAchieve laser fine etchingRealize cutting processLaser beam welding apparatusNumerical controlEngineering

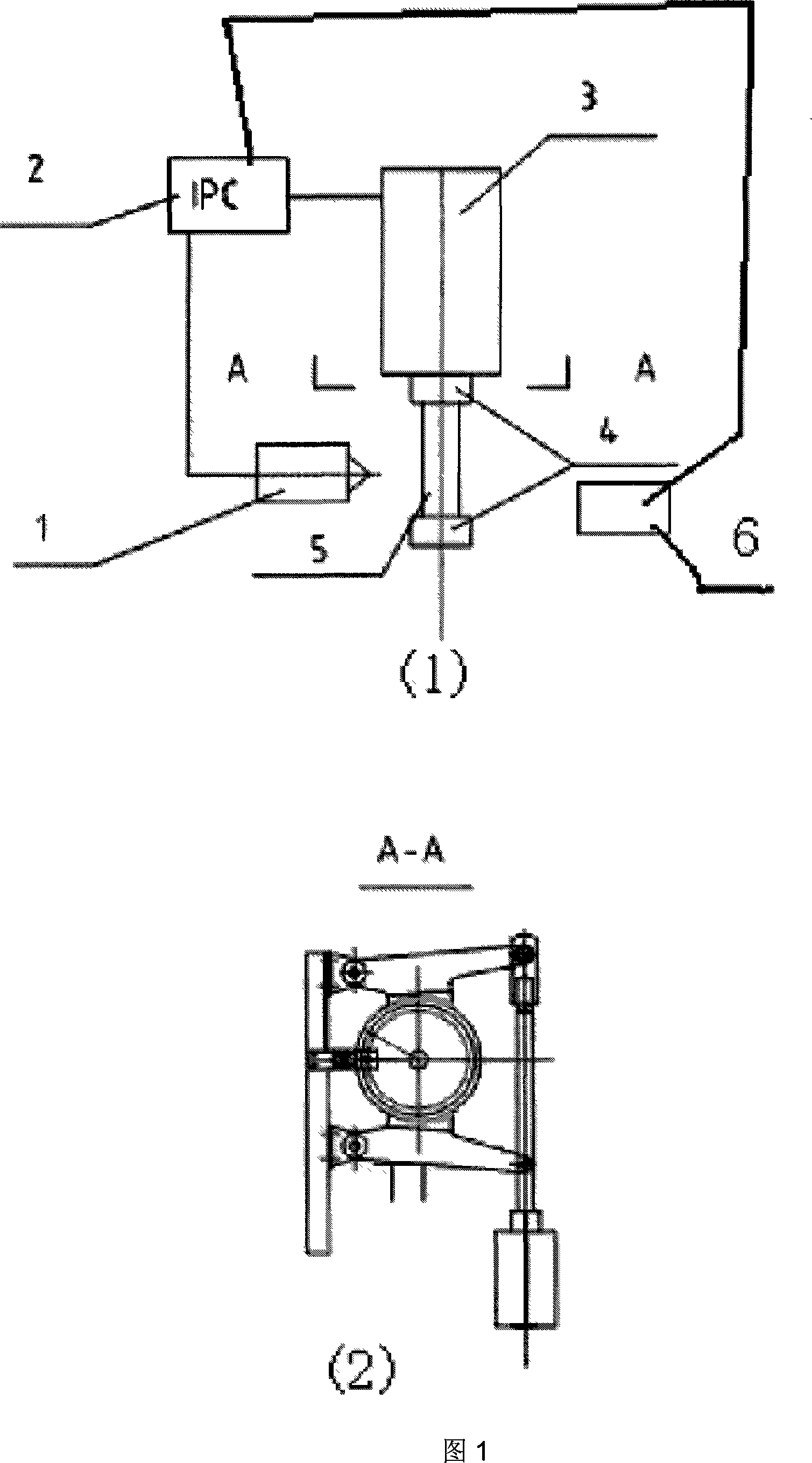

The present invention discloses a laser processing head and a multi-light source, multi-function and multi-axis processing apparatus comprising the same. The laser processing head includes a shell, an optical path system, a locating conical disk-shaped connecting mechanism, a laser range finder, a motor driving mechanism and a dust collection protection cover. The laser processing head has the advantages of a plurality of processing modes, flexibility in laser selection and easiness in replacement. The multi-light source, multi-function and multi-axis processing apparatus includes an apparatus control and operation system platform, a multi-axis linkage numerically-controlled machine tool and the laser processing head; the laser processing head is fixed on a high-precision multi-axis linkage machine tool through a blade handle type positioning cone device; and large-breadth and cross-scale laser fine processing only requires the switching of a laser light source, a laser optical path and the laser processing head, so that at least three kinds of large complex component fine surface processing application can be realized. The multi-light source, multi-function and multi-axis processing apparatus is especially for the aerospace field. The laser processing head and the multi-light source, multi-function and multi-axis processing apparatus comprising the same of the invention have the advantages of low manufacturing cost, wide application range, convenience in mass production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

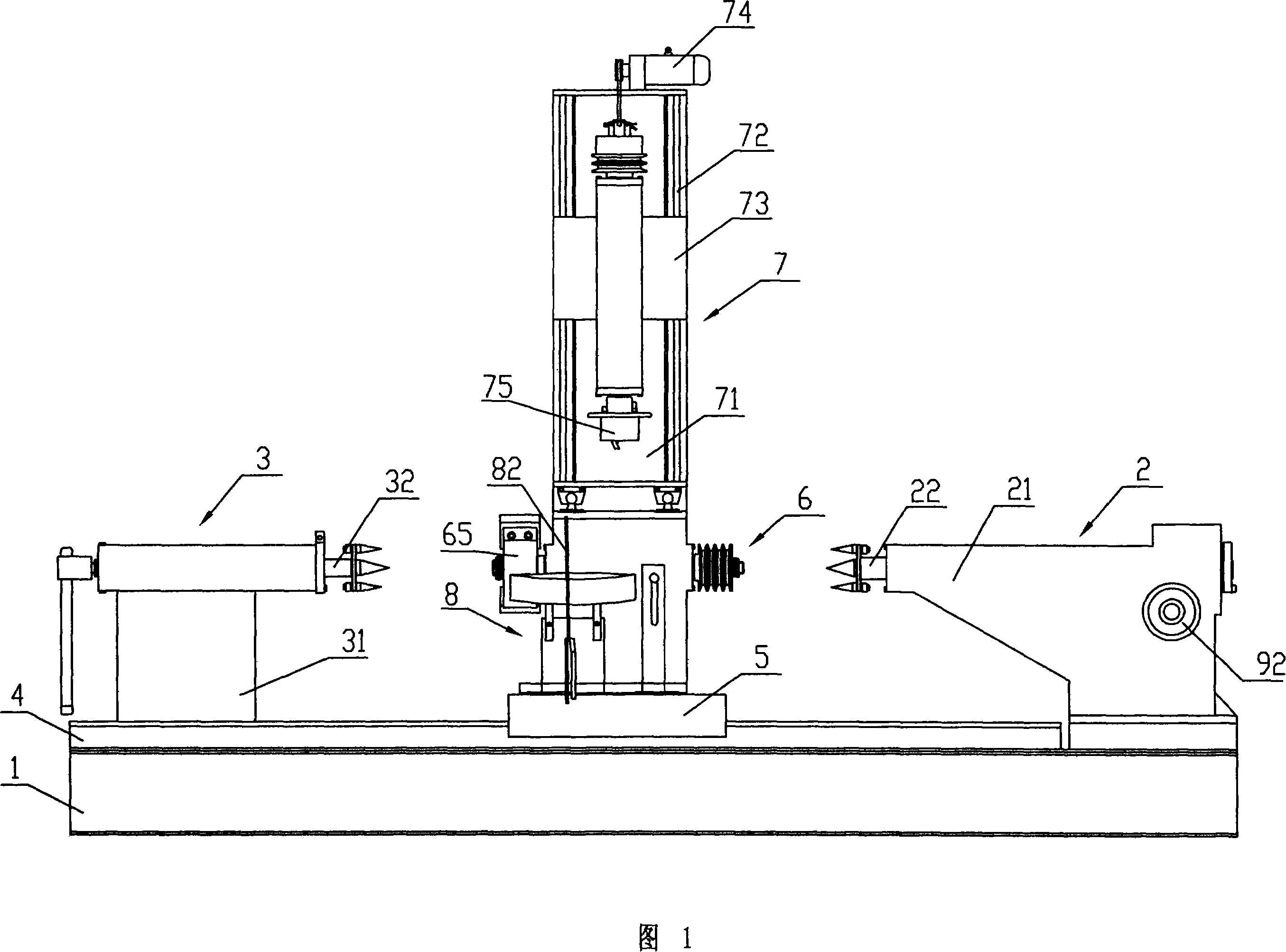

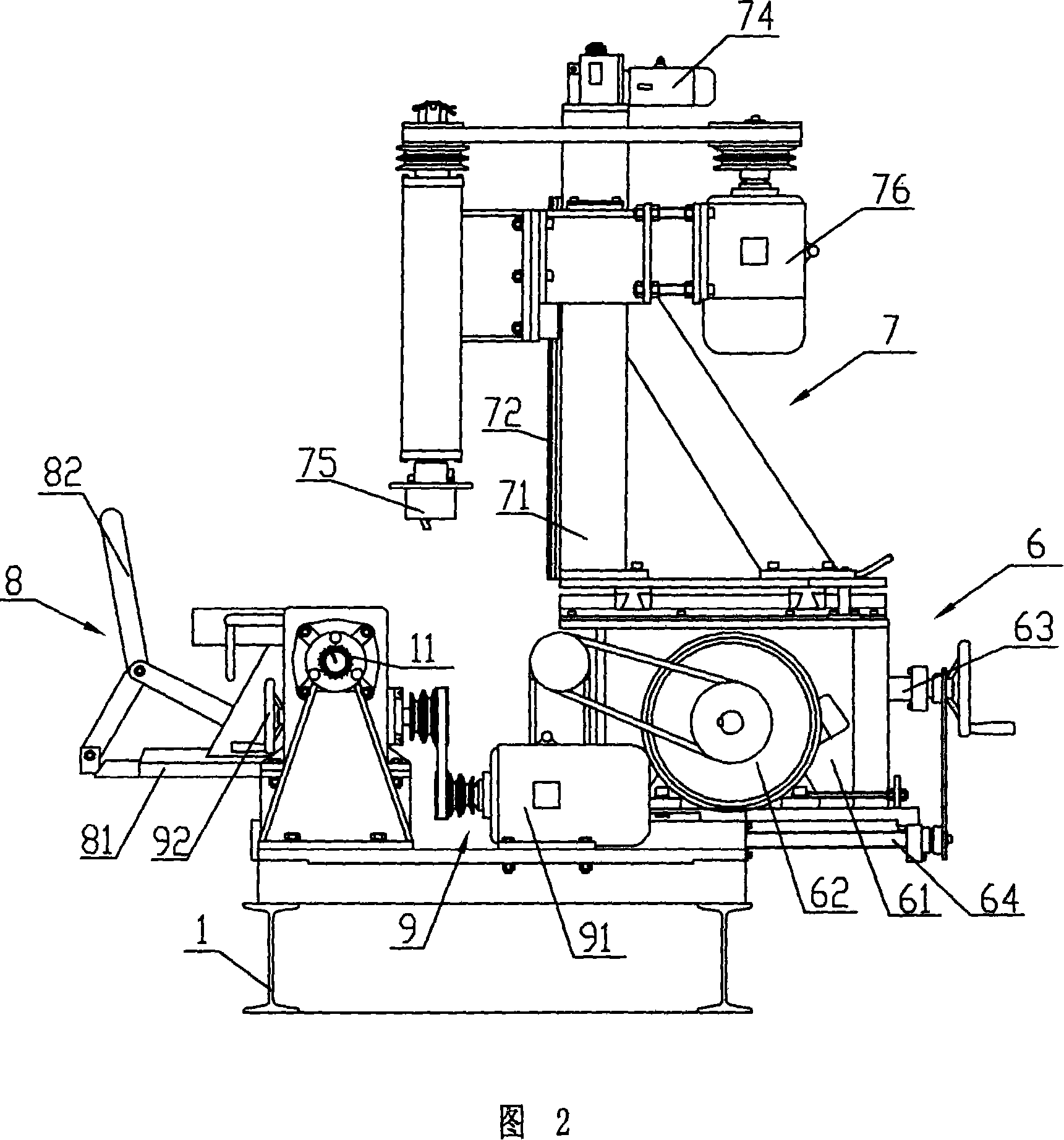

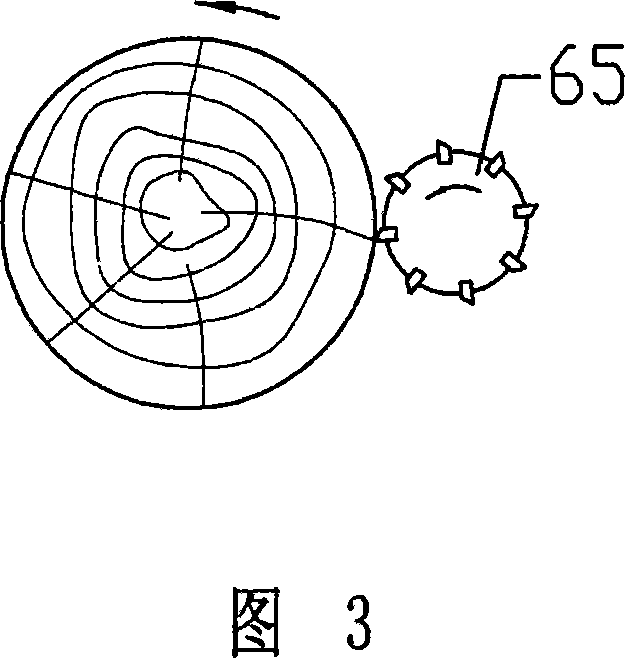

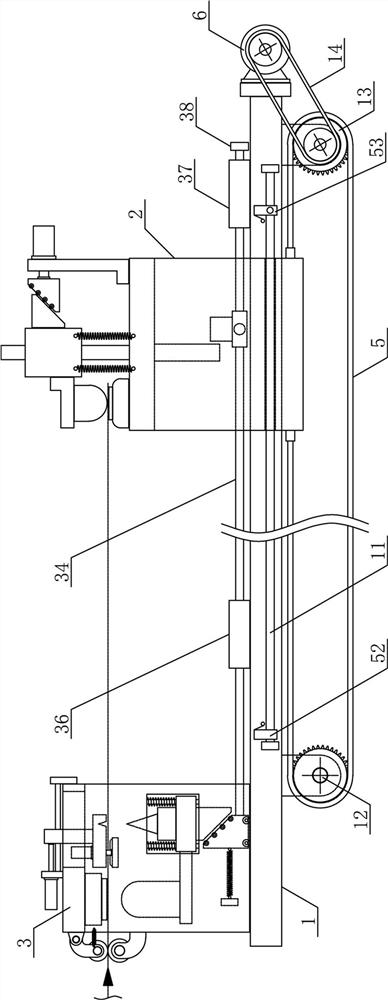

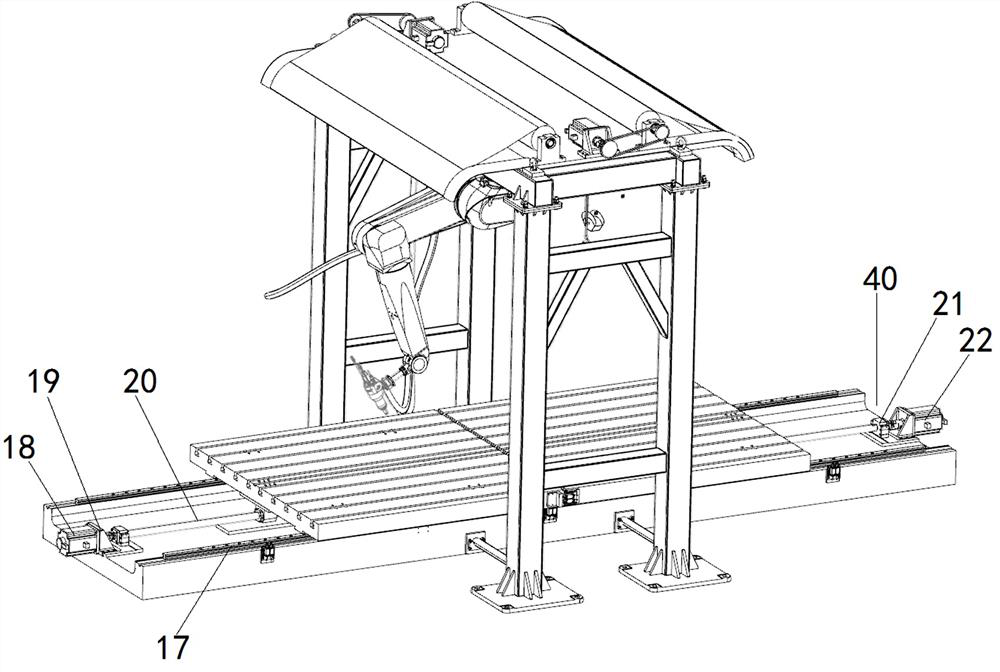

Carpentry machine tool used for log processing

InactiveCN101058196AImprove processing efficiencyEasy to stackProfiling/shaping machinesWood-turning machinesCircular discEngineering

The invention relates to a woodworking tool machine for original wood processing that comprises the vertical track base with both ends sticking the original wood and driving its motor tail base and support tail base, sliding base between them and being able to move along the vertical track, horizontal milling and cutting device for the original wood with vertical milling device installed on the horizontal milling base. The woodworking machine is not only able to process original wood with high efficiency, but also be able to vertical concave slot, horizontal concave slot and vertical sawing seam processing on the wood. It is multifunctional, with convenience for wood transportation, usage and storage.

Owner:杜明干

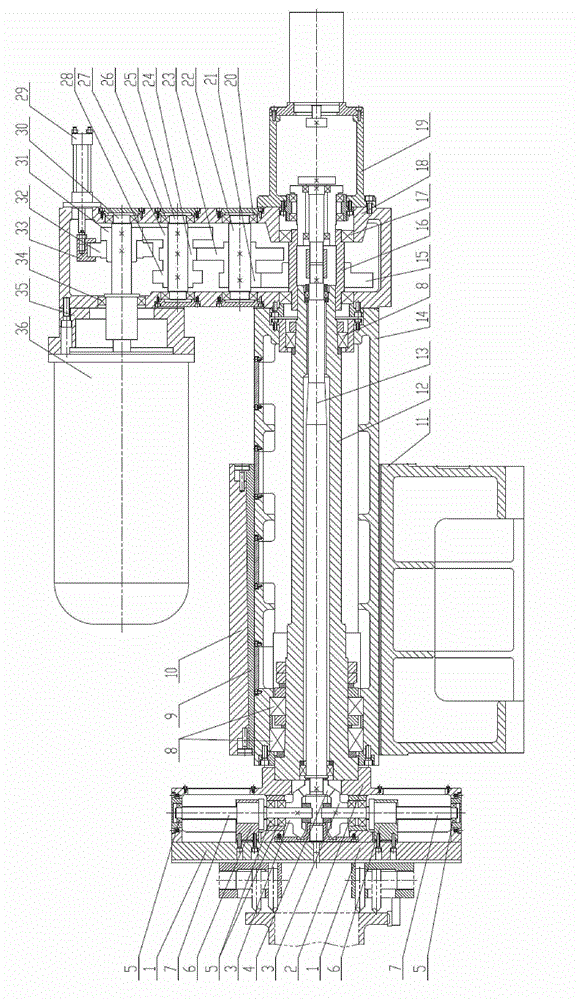

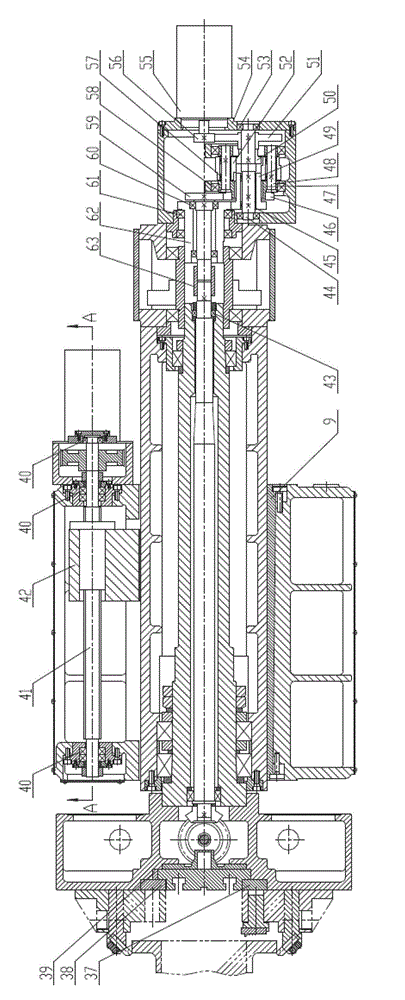

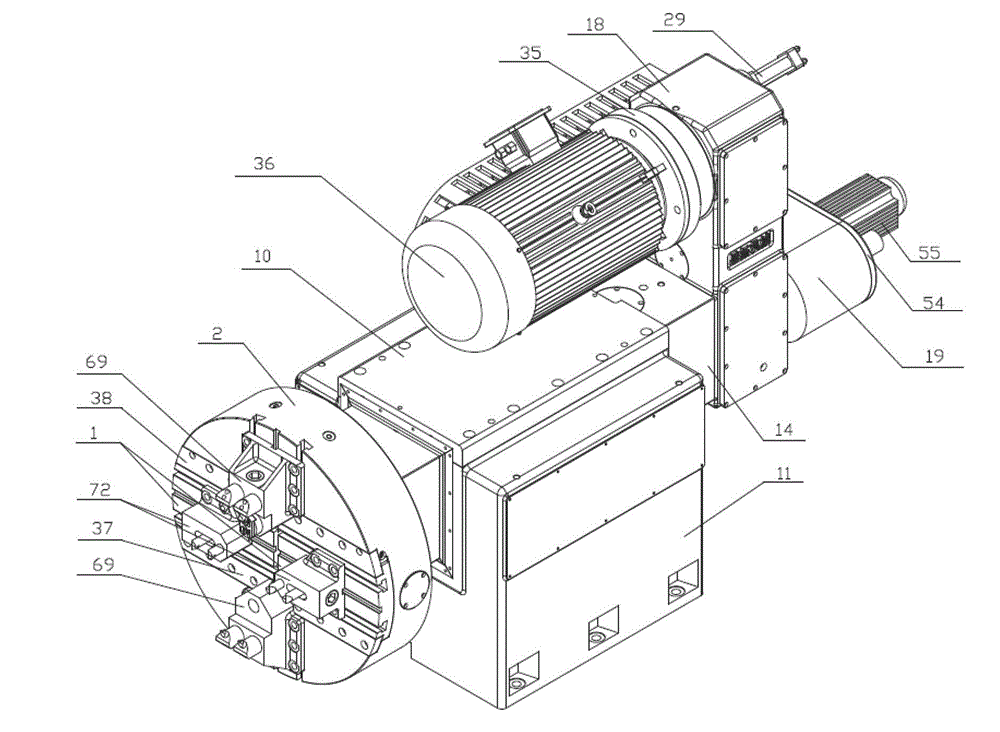

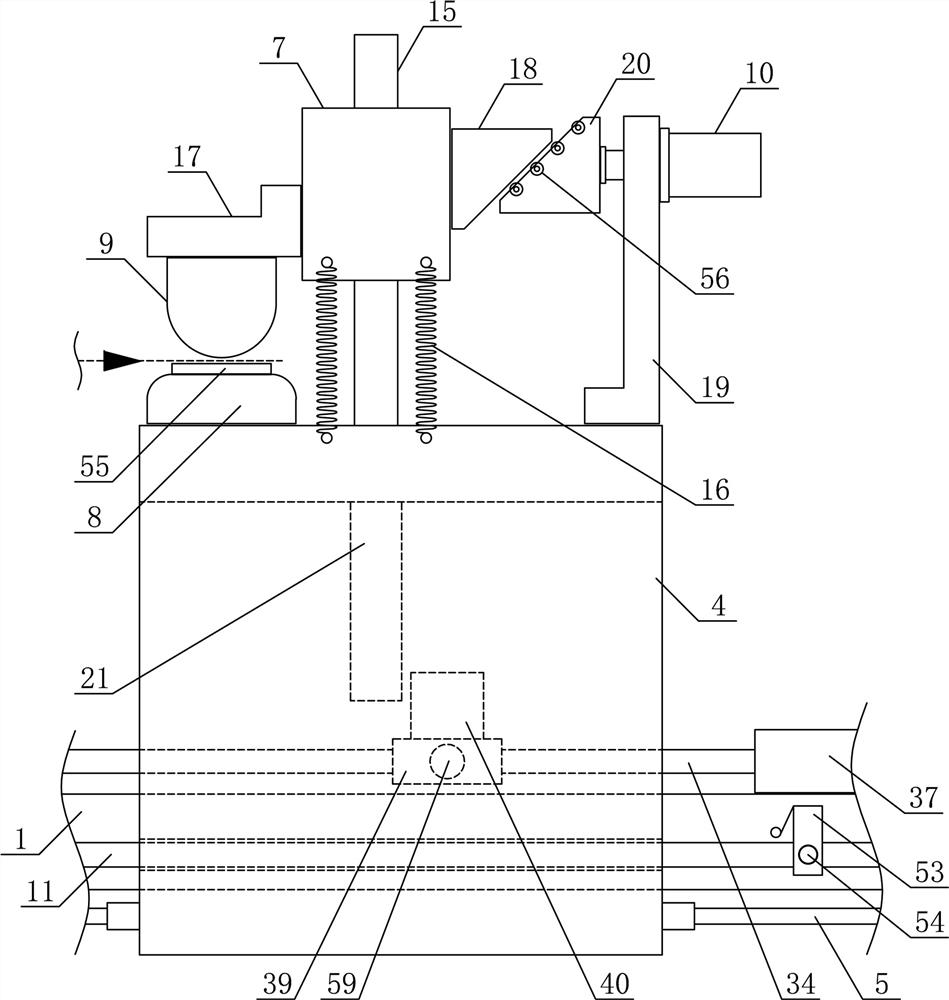

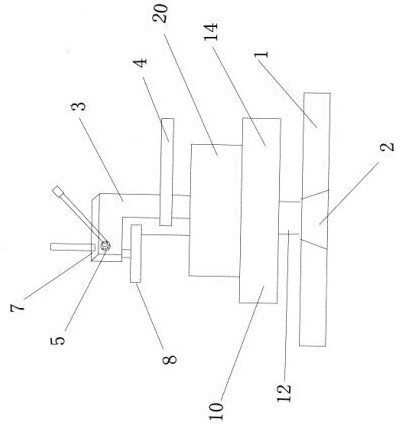

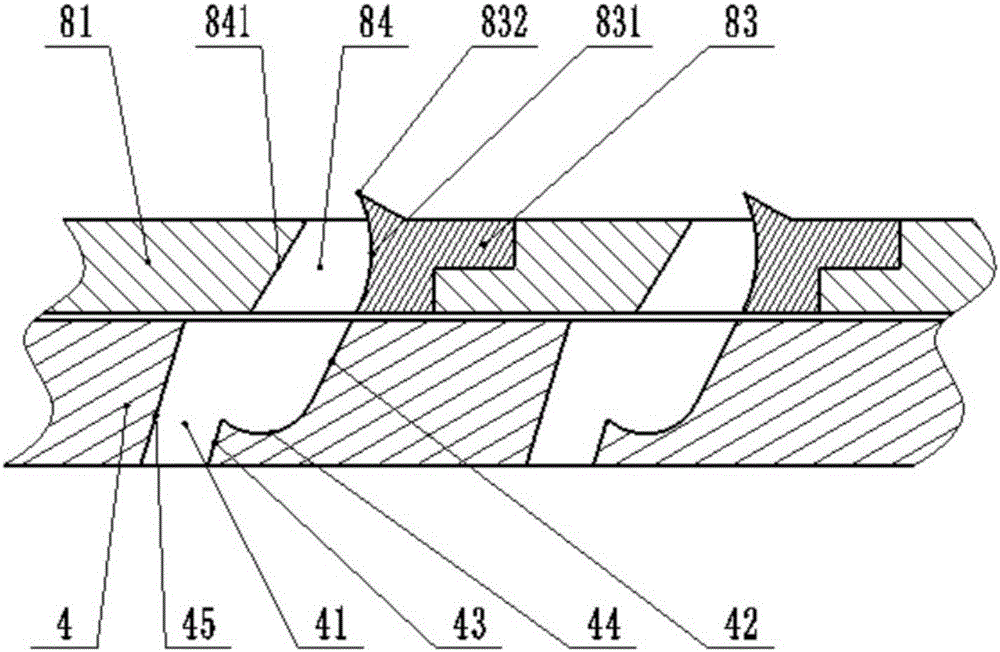

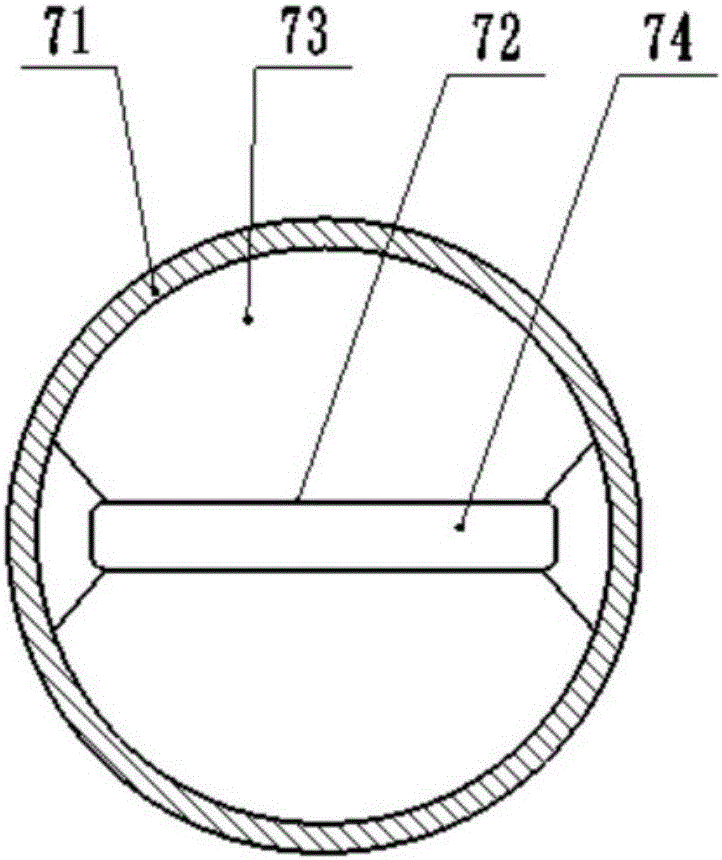

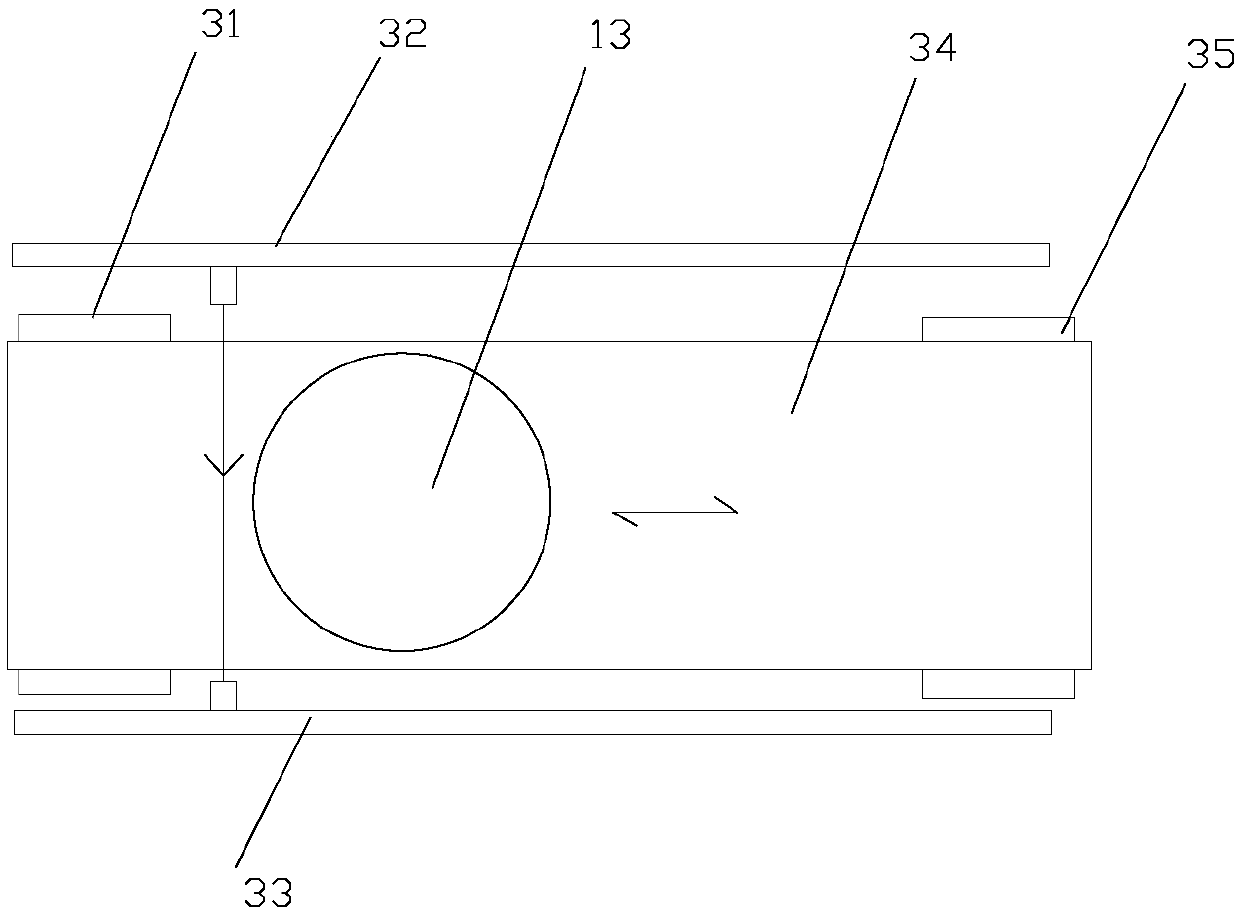

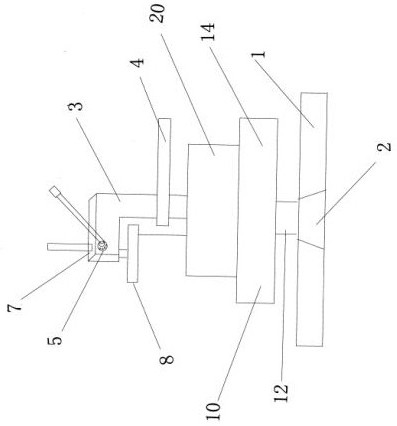

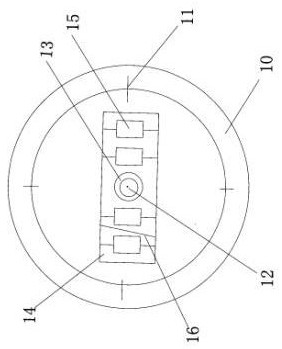

Multi-cutter processed numerically-controlled double-slider power head of valve body

ActiveCN103182655AEasy to assembleEasy to detectFeeding apparatusDriving apparatusEngineeringAlternating current

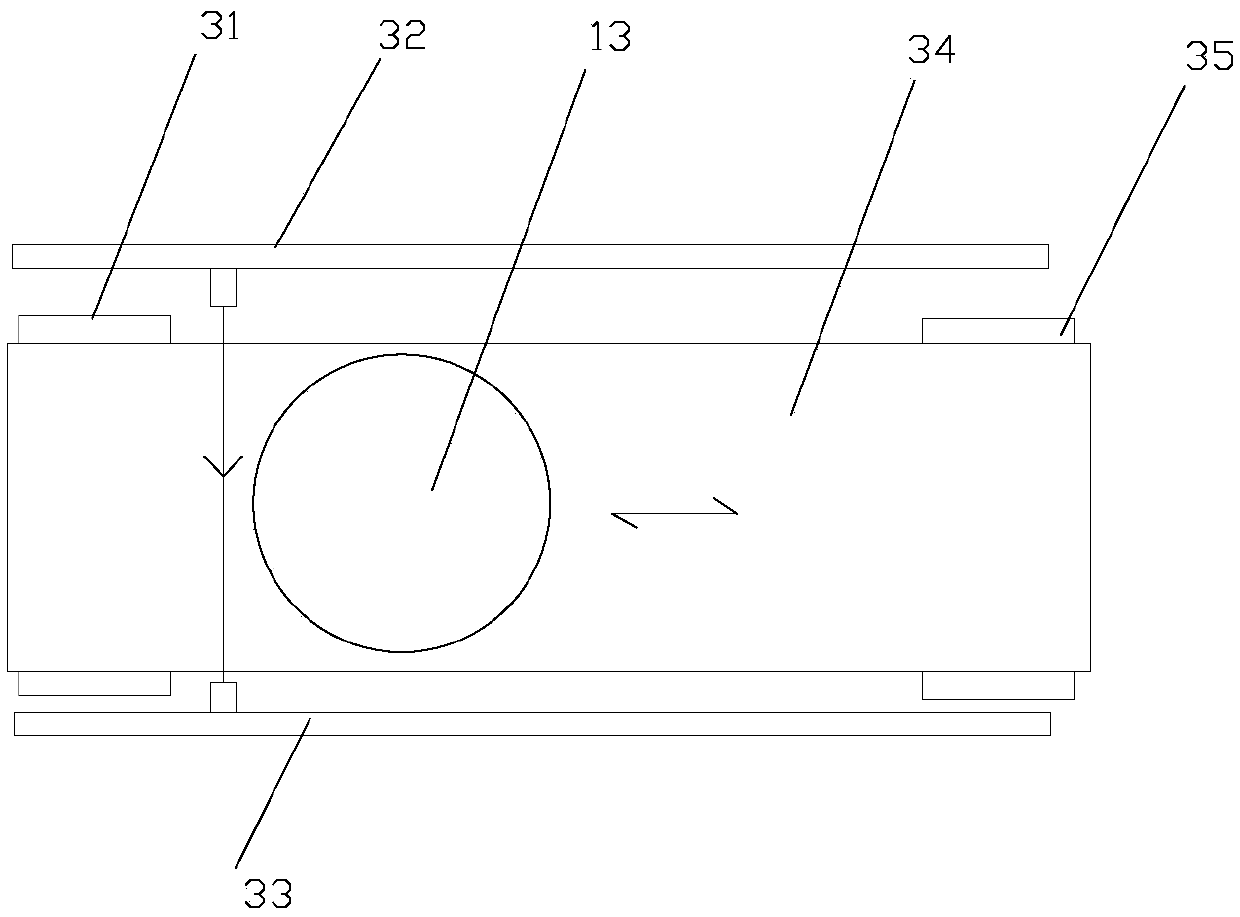

The invention relates to a multi-cutter processed numerically-controlled double-slider power head of a valve body. The power head comprises a ram seat, a square ram, a flat turning disc, sliders, a main spindle box, a differential feeding box, a tool rest mechanism and the like, wherein the square ram is mounted on the ram seat; the flat turning disc is connected to the front end of the square ram; the two sliders are mounted on the flat turning disc; tool rests are symmetrically fixed on the flat turning disc; the main spindle box is connected to the rear end of the square ram; the differential feeding box which is connected with a servo motor is connected to the other end of the main spindle box; a main spindle alternating current variable frequency motor is connected to the upper end of the main spindle box through a connector; a shifting fork oil cylinder on one side opposite to the motor is connected onto the main spindle box; and a main spindle penetrates through the square ram, one end of the main spindle is connected onto the flat turning disc, the other end is connected into the main spindle box, and a mandrel is connected to the center of the main spindle in a sleeving manner. The multi-cutter processed numerically-controlled double-slider power head of the valve body has high processing accuracy, reduces the labor intensity of workers, and improves the production efficiency and the product qualification rate.

Owner:浙江名匠智能装备股份有限公司

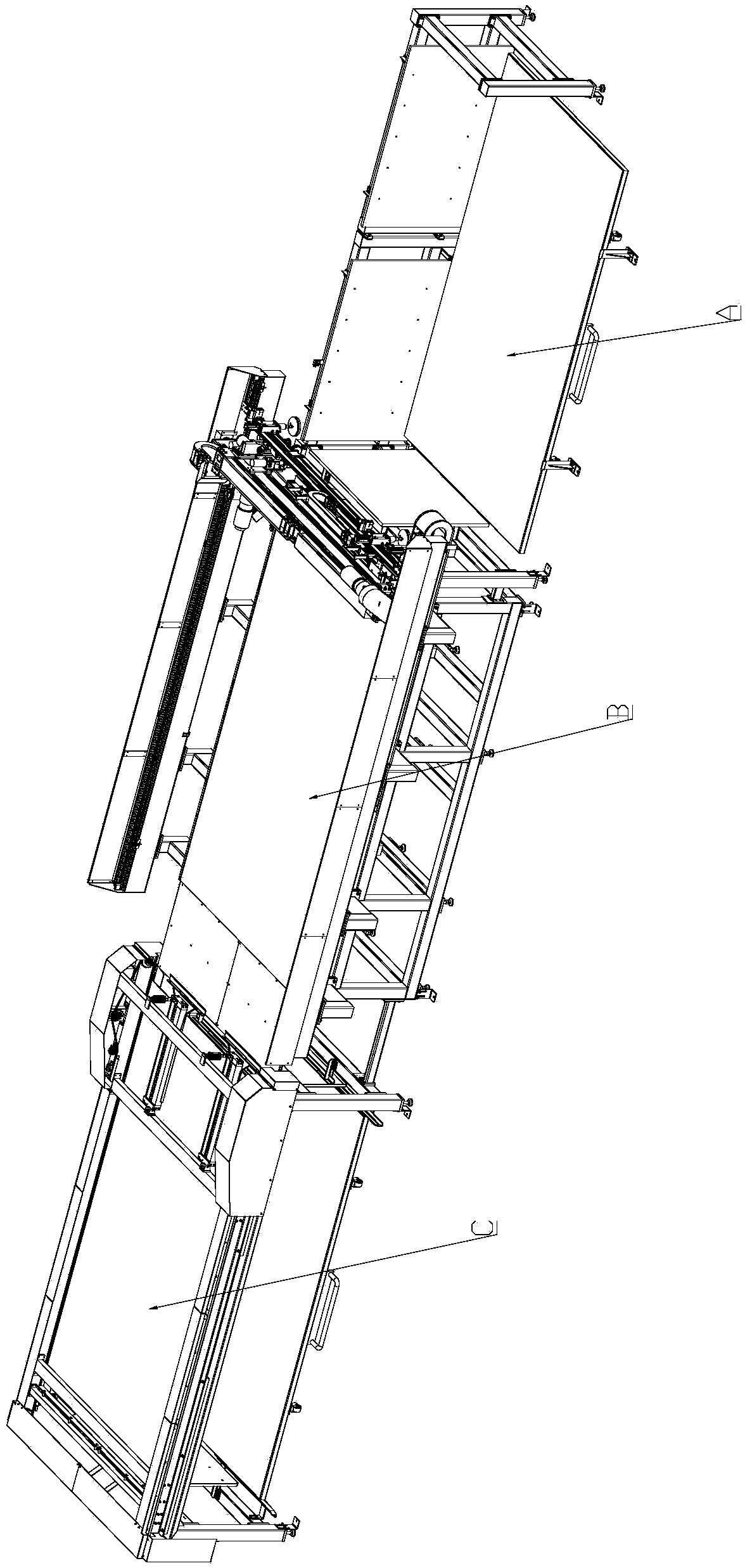

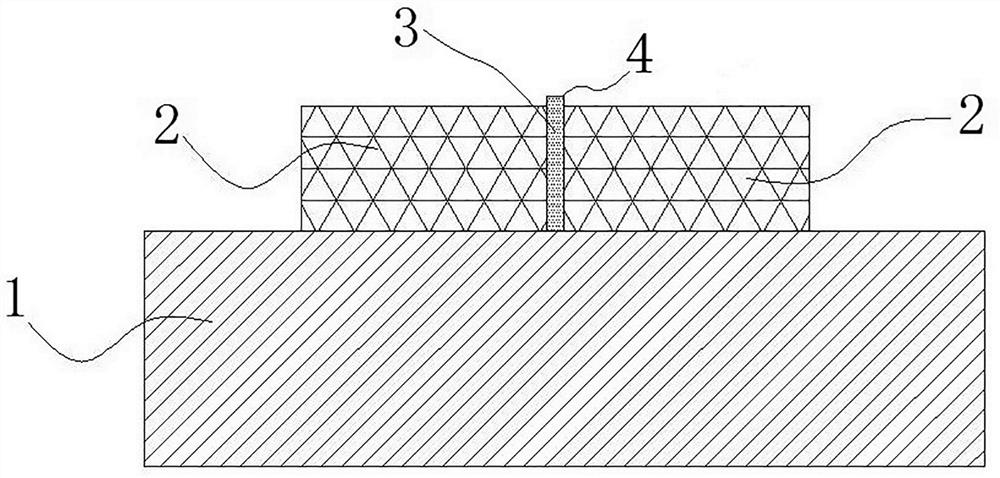

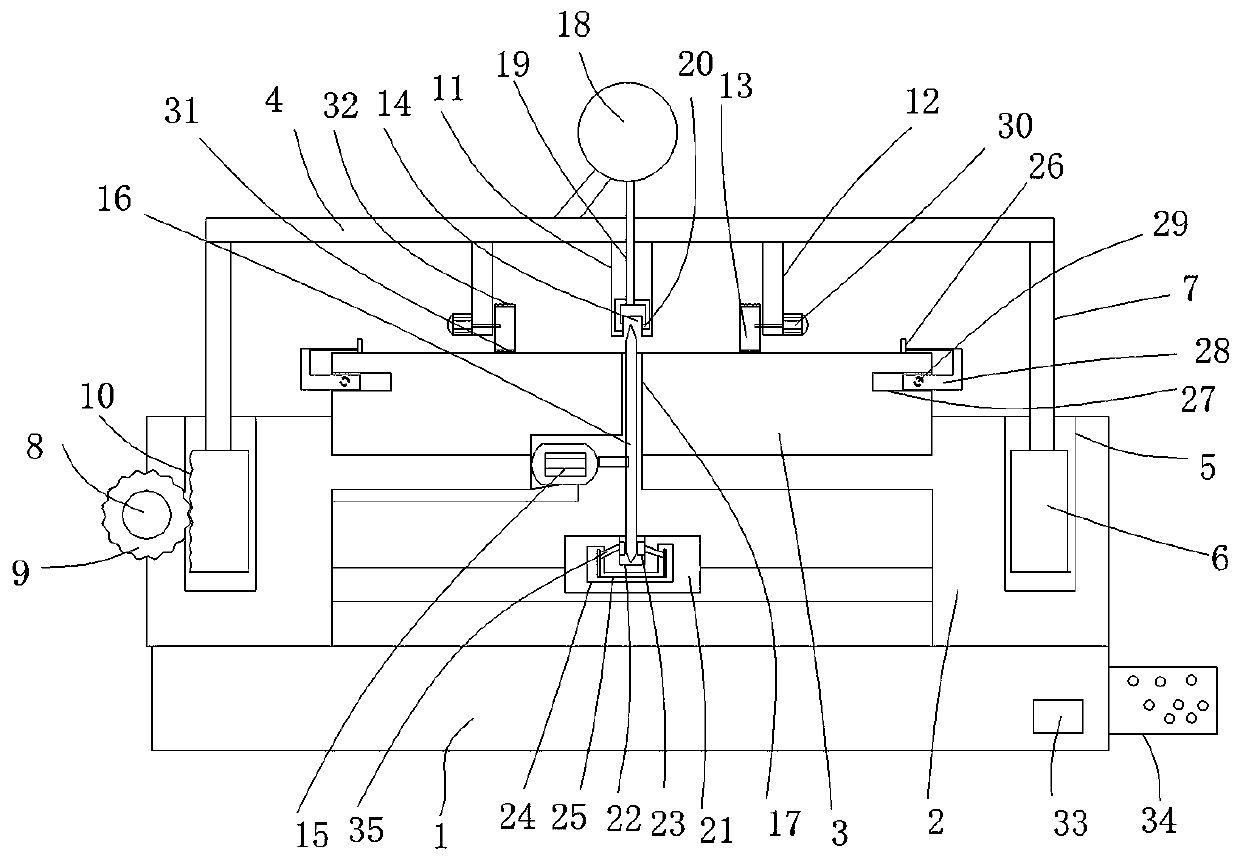

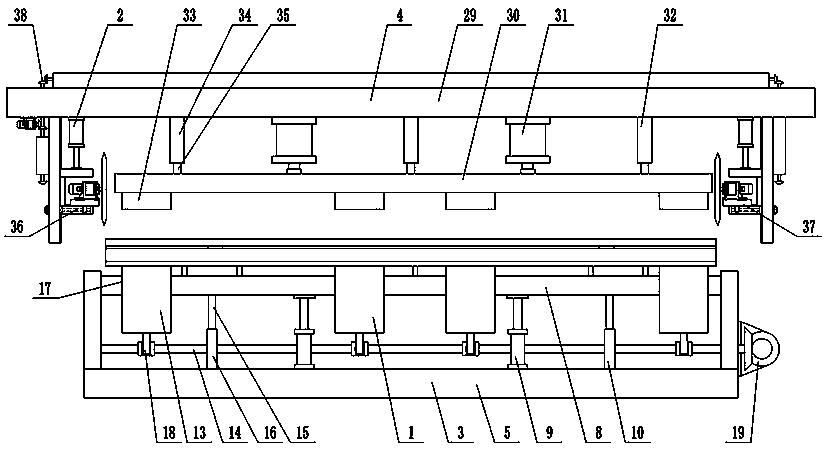

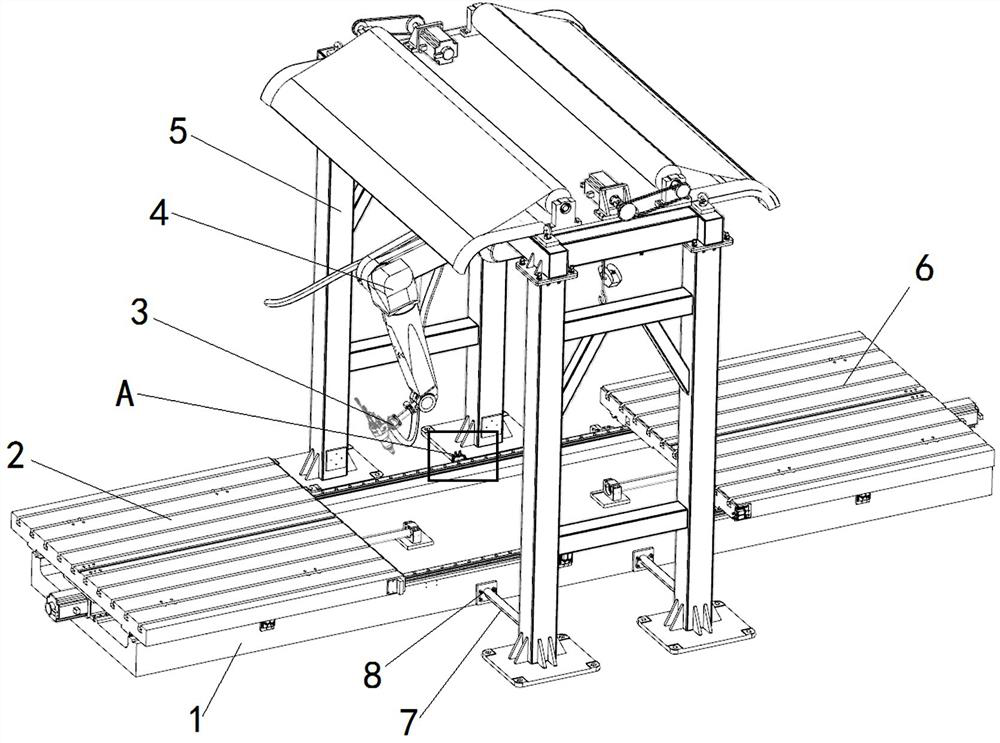

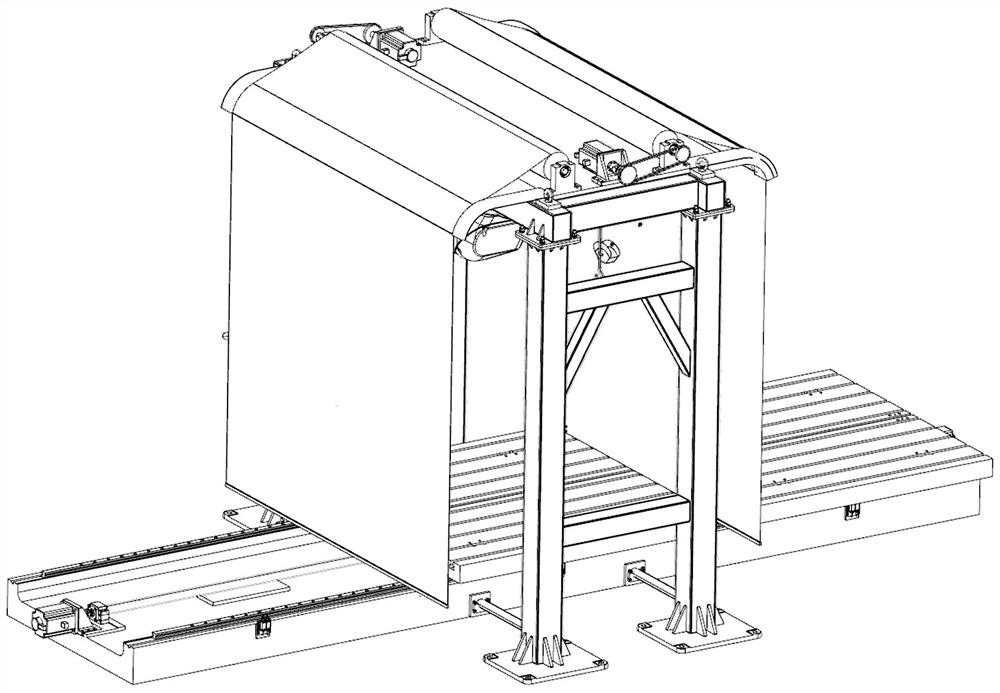

Corrugated board full-automatic cutting system for high precision instrument

ActiveCN108994941ARealize cutting processRealize the automation of cutting and processingBox making operationsPaper-makingCardboardOblique cutting

The invention discloses a corrugated board full-automatic cutting system for a high precision instrument. The corrugated board full-automatic cutting system for the high precision instrument comprisesa first movable lifting platform, a cutting device and a discharging device, and the first movable lifting platform, the cutting device and the discharging device are successively arranged along thesame straight line, wherein the cutting device includes a cutting support frame, a cutting platform is arranged on the cutting support frame, a cardboard lifting mechanism, an indentation mechanism, astraight cutting mechanism and an oblique cutting mechanism are further arranged on the cutting support frame, and the cardboard lifting mechanism, the indentation mechanism, the straight cutting mechanism and the oblique cutting mechanism can move freely in the length and width directions of the cutting platform so as to complete cutting of a cardboard; and the discharging device comprises a discharging linear transmission mechanism, a discharging push mechanism is arranged on the front part of the discharging linear transmission mechanism, and a material receiving assembly is arranged belowthe discharging linear transmission mechanism. According to the corrugated board full-automatic cutting system for the high precision instrument, the indentation mechanism, the straight cutting mechanism and the oblique cutting mechanism for processing cardboards are organically combined together, automatic feeding, cutting and discharging of the cardboards are realized, and the current market gap in this field is filled.

Owner:重庆梦马致新科技有限公司

Microspring laser processing method

InactiveCN101025211ARealize cutting processMaintain material propertiesWound springsLaser processingFacula

The invention belongs to the field of laser machining technique, relating to a method of machining micro springs by laser, firstly making cylindrical or conical moulds or moulds of other shapes with micron or milimeter radius, then using film forming method to make film on the mould surface with micro spring material; then making the mould advance axially and rotate round axis, focusing laser-emitted laser spot on the micro spring material or making the mould only rotate to make the focused spot of the laser advance along the axis of the mould, controlling the output power amplitude and focused spot size of the laser, and thus carving spiral hollowed-out lines with a certain width on the micro spring material; and finally removing the internal mould to be able to obtain the required spring. And it can make 3D spiral machining, and machine high-rigidity materials and low plasticity materials, able to keep body material characteristic of micro spring and making the materials not change body characteristics because of melting and stretching operations and other operations.

Owner:JILIN UNIV

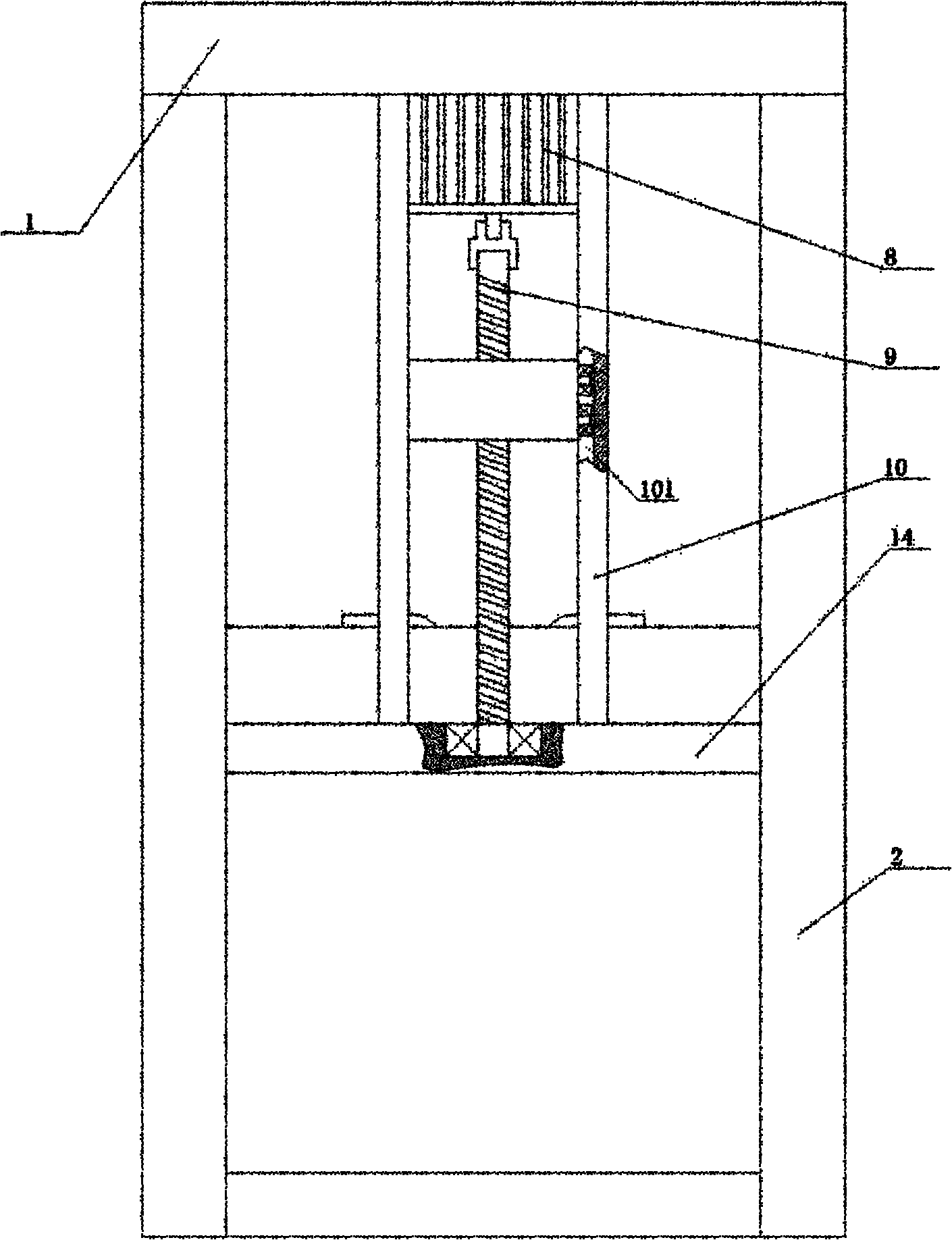

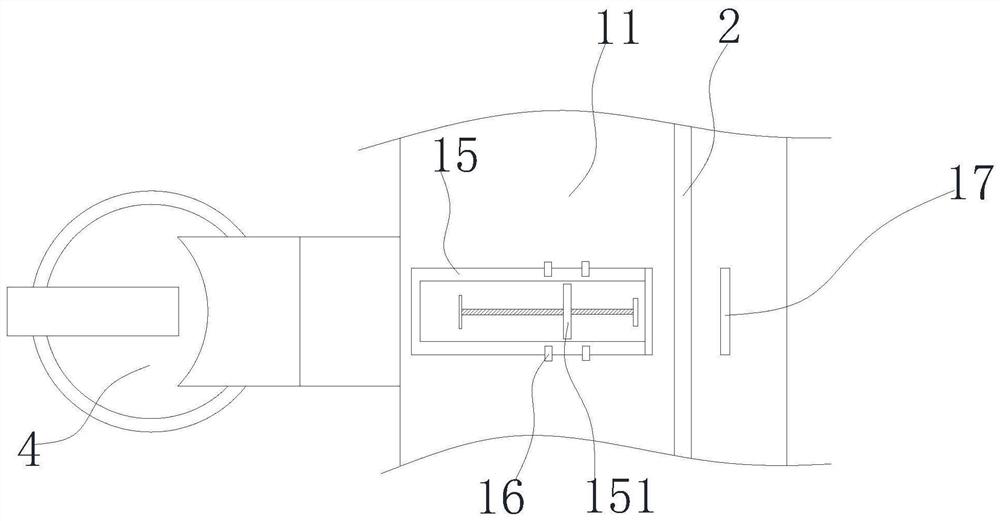

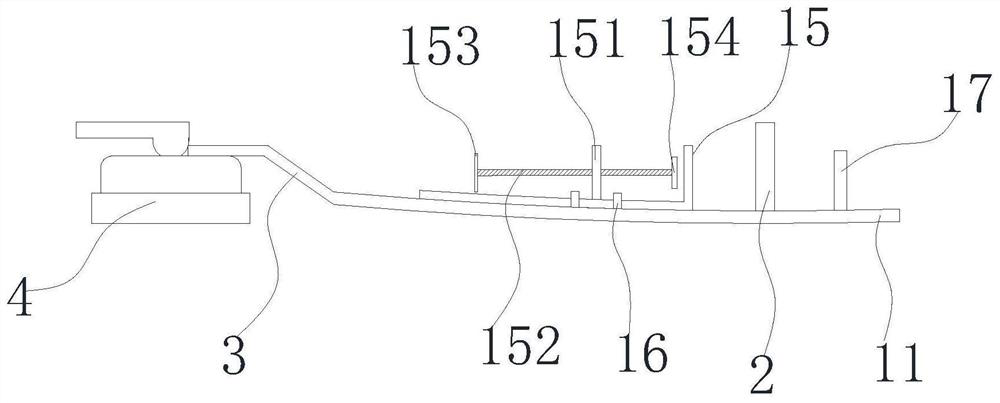

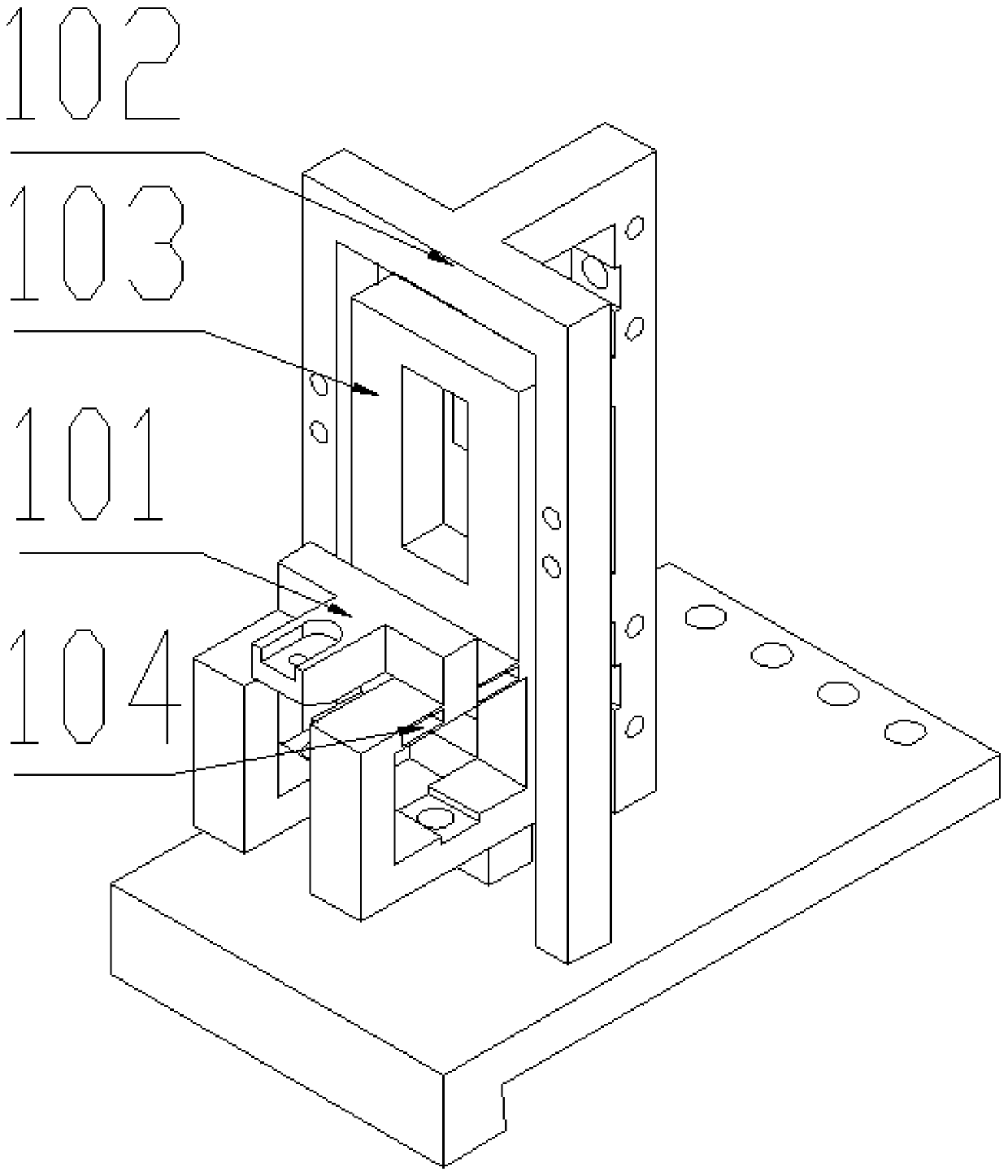

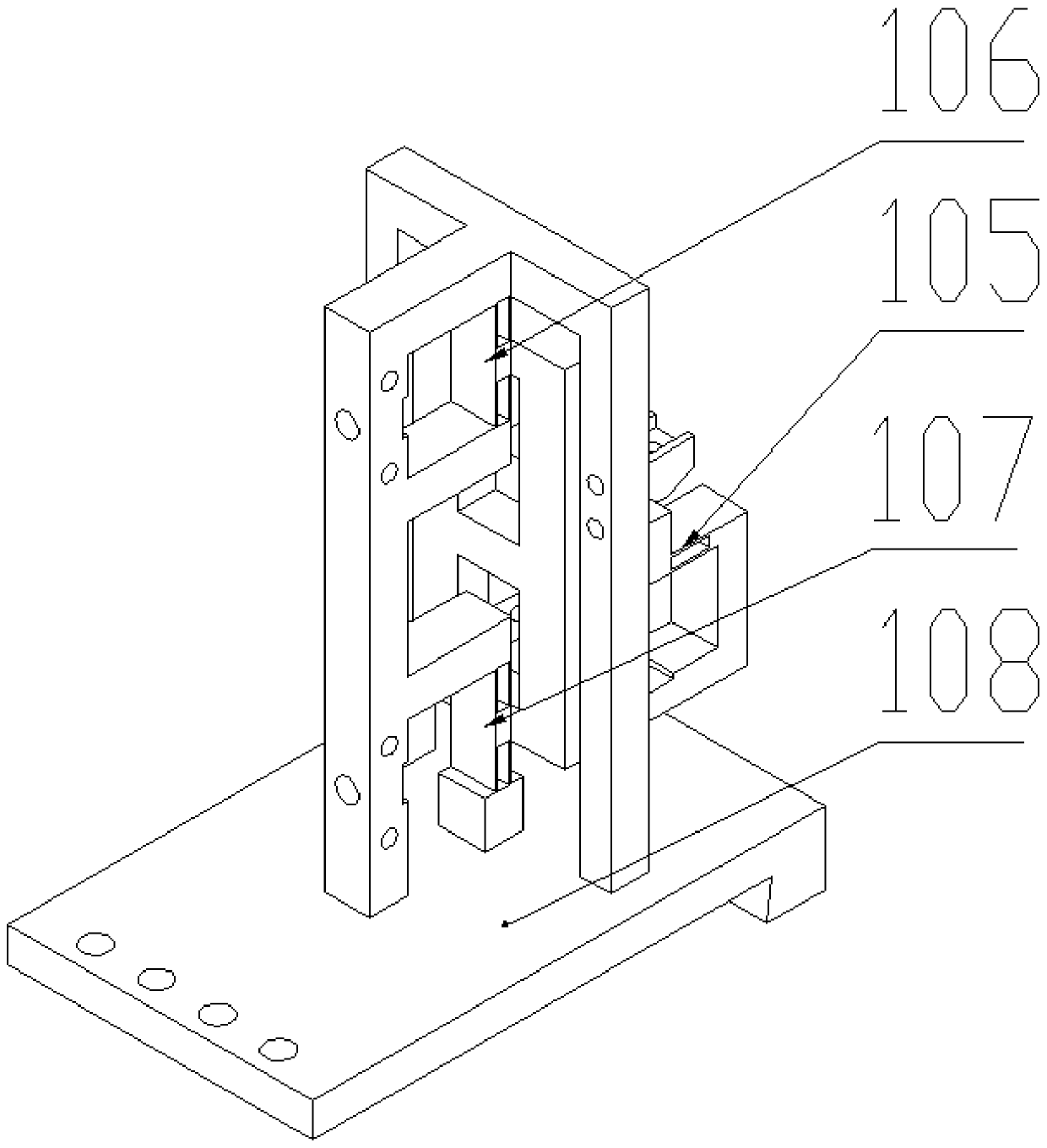

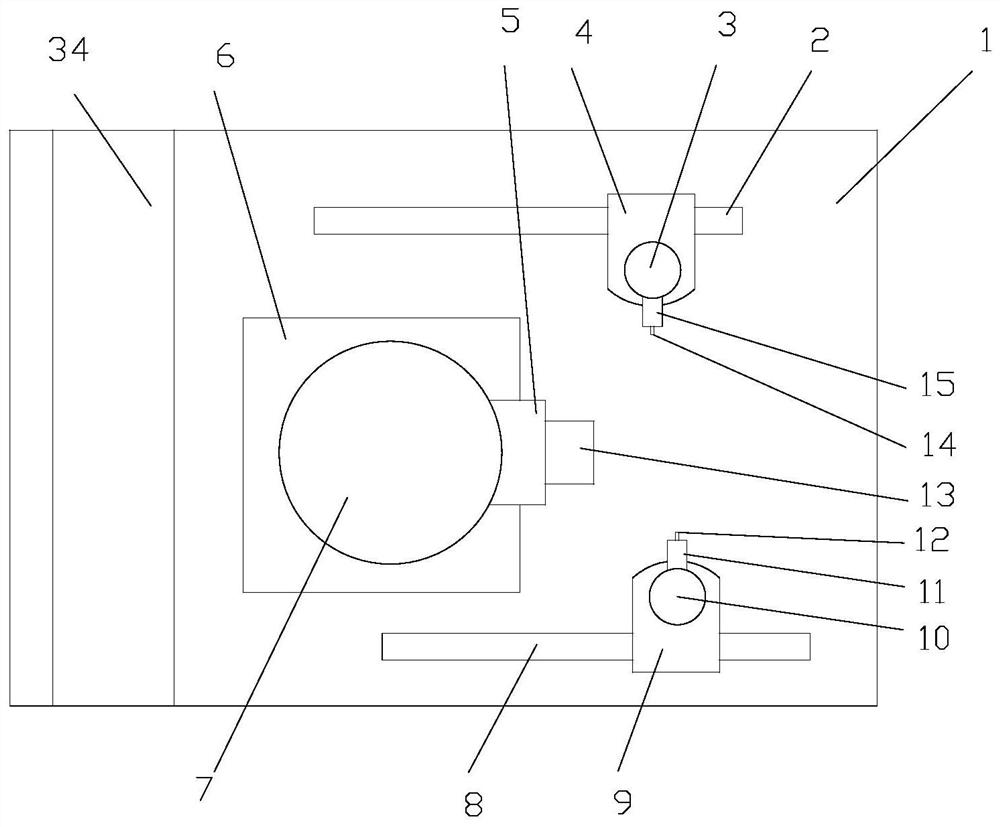

Numerical control machine control system

ActiveCN109531261AVersatileIncrease flexibilityAutomatic control devicesMeasurement/indication equipmentsNumerical controlMachine control

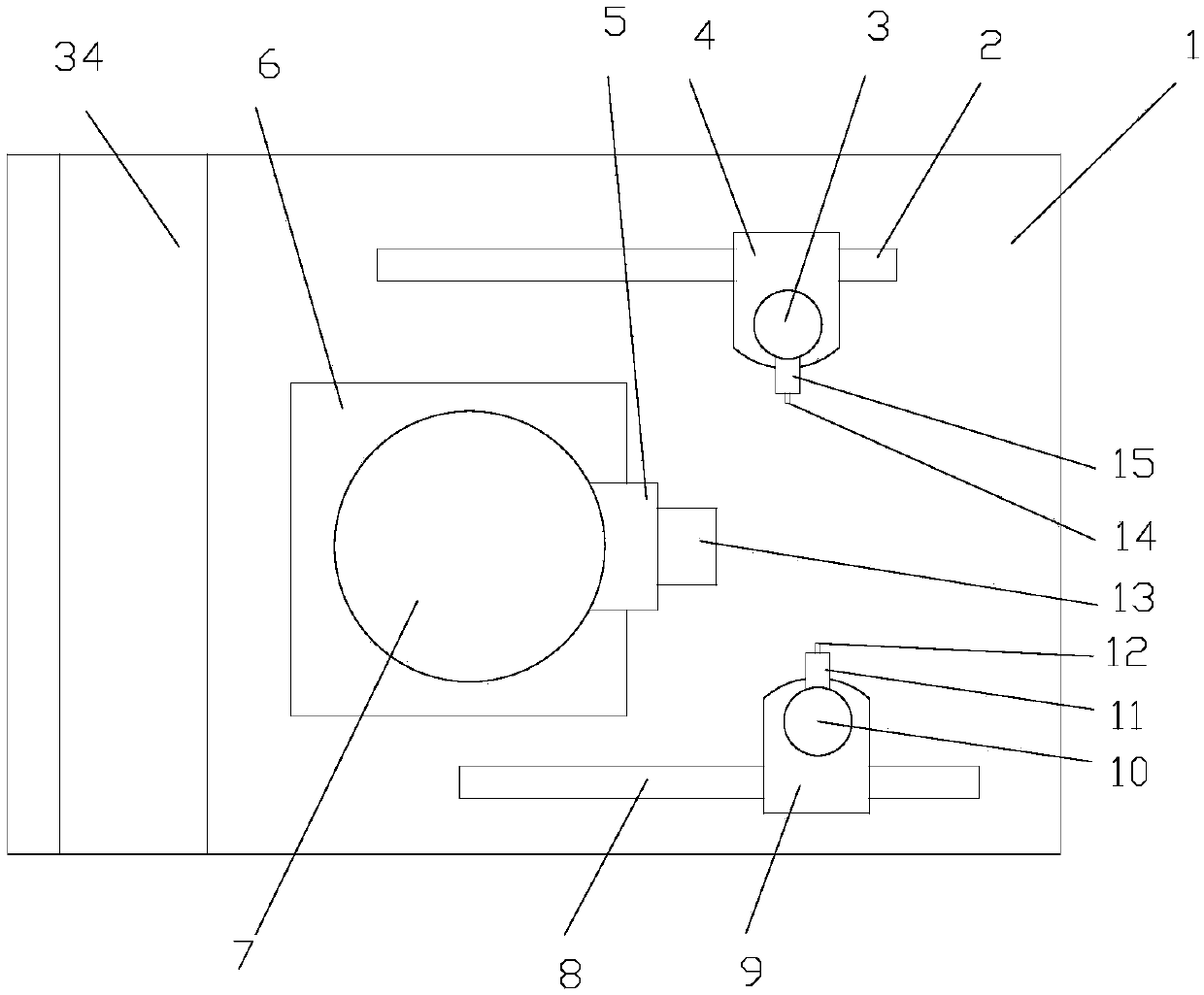

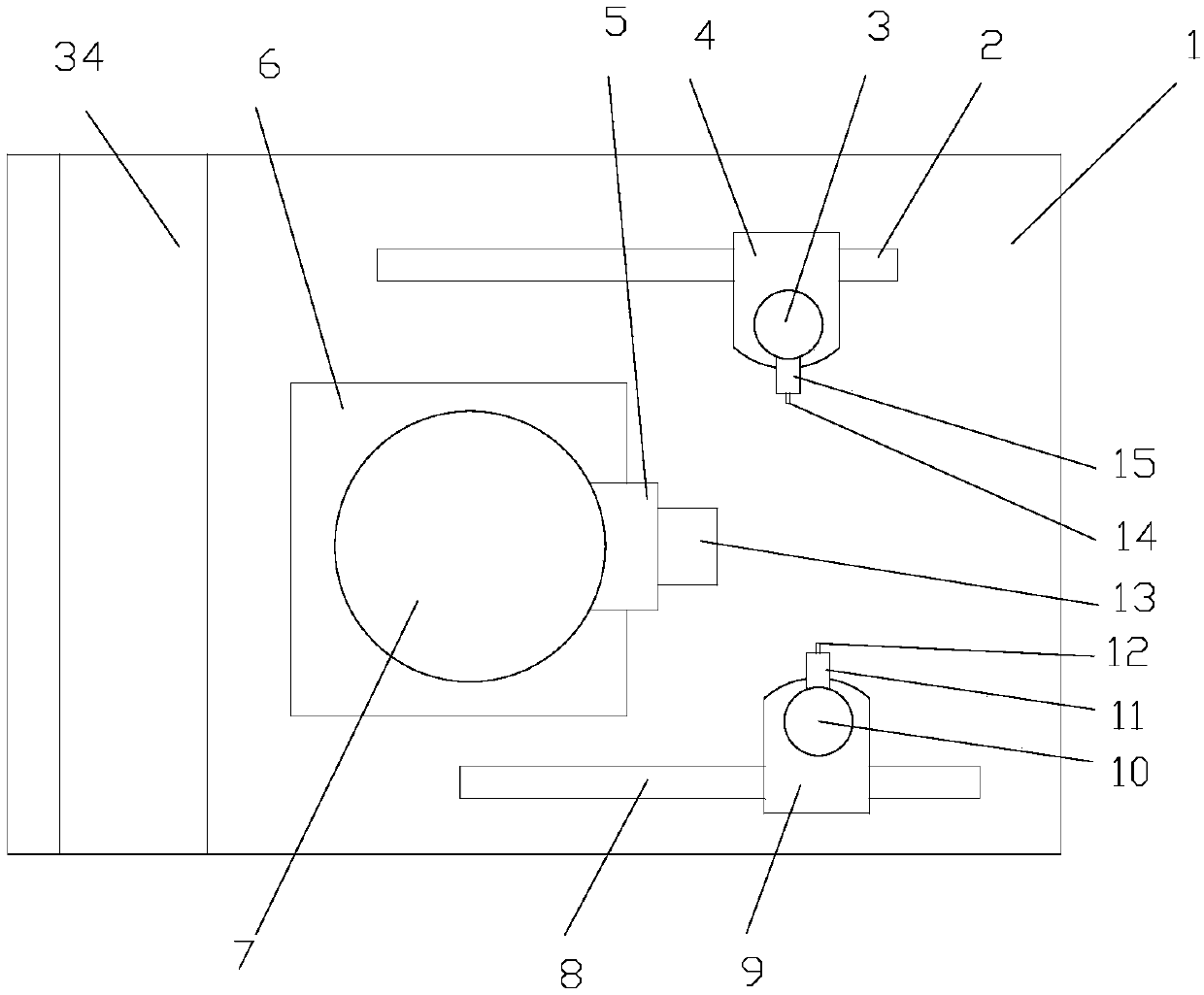

The invention discloses a numerical control machine control system. The numerical control machine control system comprises a base (1), and a workpiece clamping device and a first cutter clamping device which are arranged on the base, wherein the workpiece clamping device is provided with a workpiece chuck (5) for clamping a workpiece; the first cutter clamping device comprises a first guide rail (2), a first sliding block (4), a first rotary platform (3), a first cutter chuck (15) and a first machining head (14); the first sliding block is arranged on the first guide rail and can slide along the first guide rail under the action of a sliding driving motor; the first guide rail is arranged in the X-axis direction; the first rotary platform is arranged on the first sliding block and can spinaround the Z-directional axis on the first rotary platform under the action of a driving mechanism; the first cutter chuck is fixed on the first rotary platform; the first cutter chuck is a retractable type chuck; and the first cutter clamping device is provided with the driving mechanism for driving the retractable type chuck to rotate. The numerical control machine control system has the advantages of compact structure, high integration levels, good flexibility and abundant functions.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

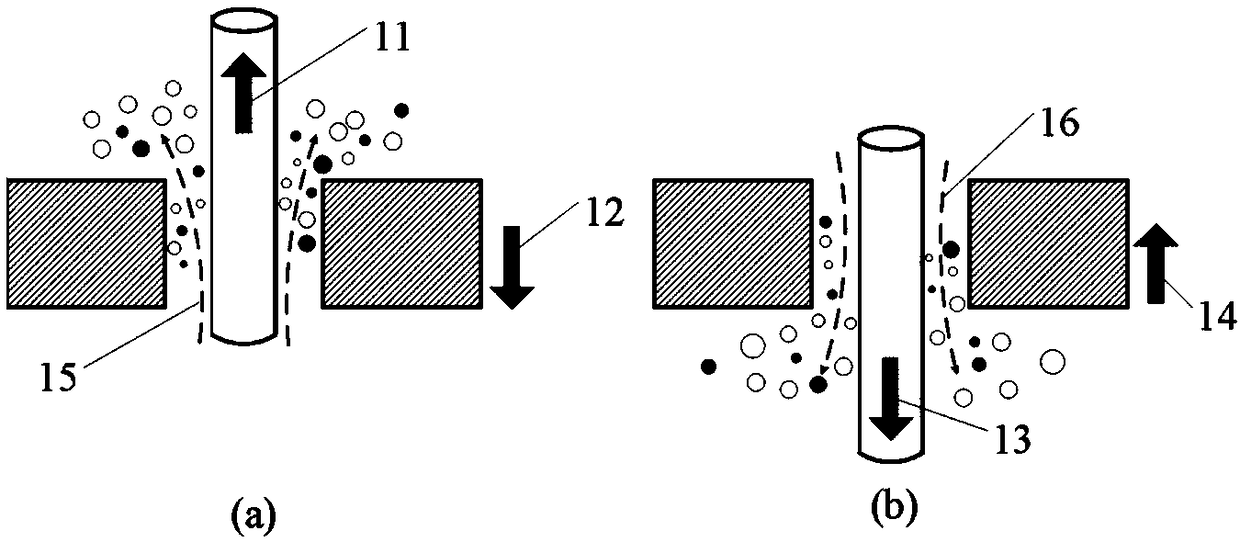

Production method of ceramic chips for ceramic packaging base

ActiveCN112589976AHigh dimensional accuracyMeet the precision requirementsCeramic shaping apparatusComposite materialGreen body

The invention relates to a production method of ceramic chips for a ceramic packaging base. The method comprises the following steps of: 1, manufacturing a ceramic green body plate, and dividing the plate-shaped ceramic green body plate into a plurality of ceramic chip green bodies; 2, cutting and trimming process edges of the ceramic chip green bodies; and 3, sintering and hardening the ceramic chip green bodies trimmed in the step 2 to obtain the ceramic chips. In the production process, the ceramic chip green bodies are produced firstly, and the process edges of the ceramic chip green bodies are cut and trimmed based on the characteristic that the hardness of the ceramic chip green bodies is relatively low, so that the size of the produced ceramic chips can conveniently meet the precision requirement.

Owner:瓷金科技(河南)有限公司

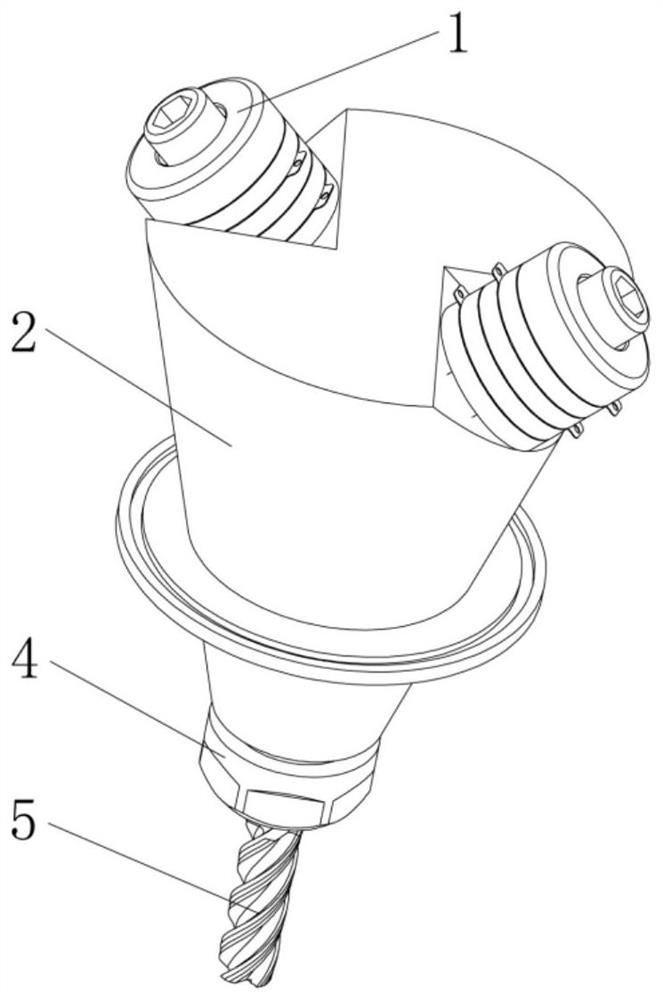

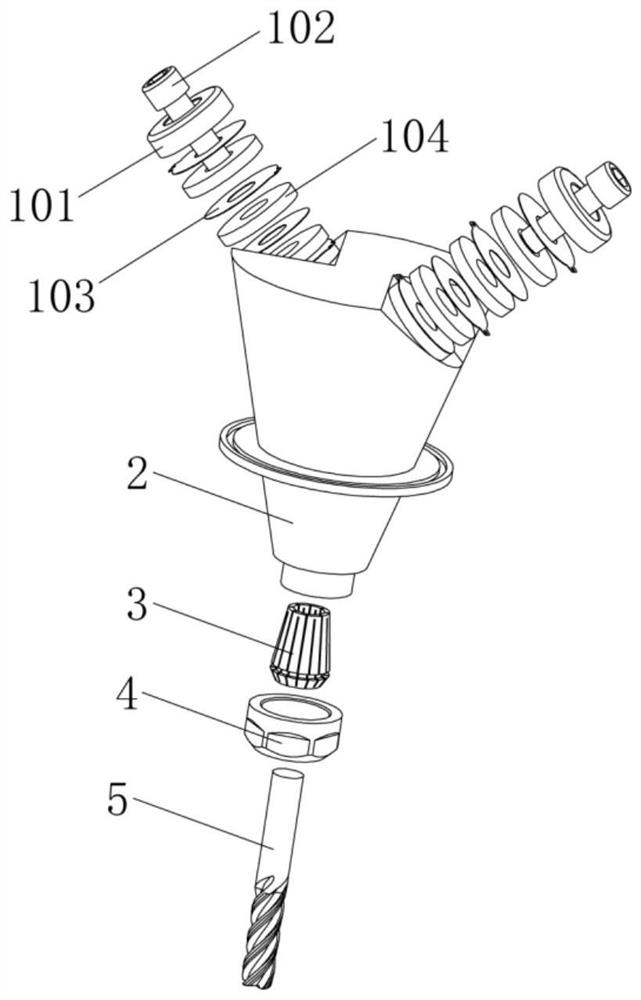

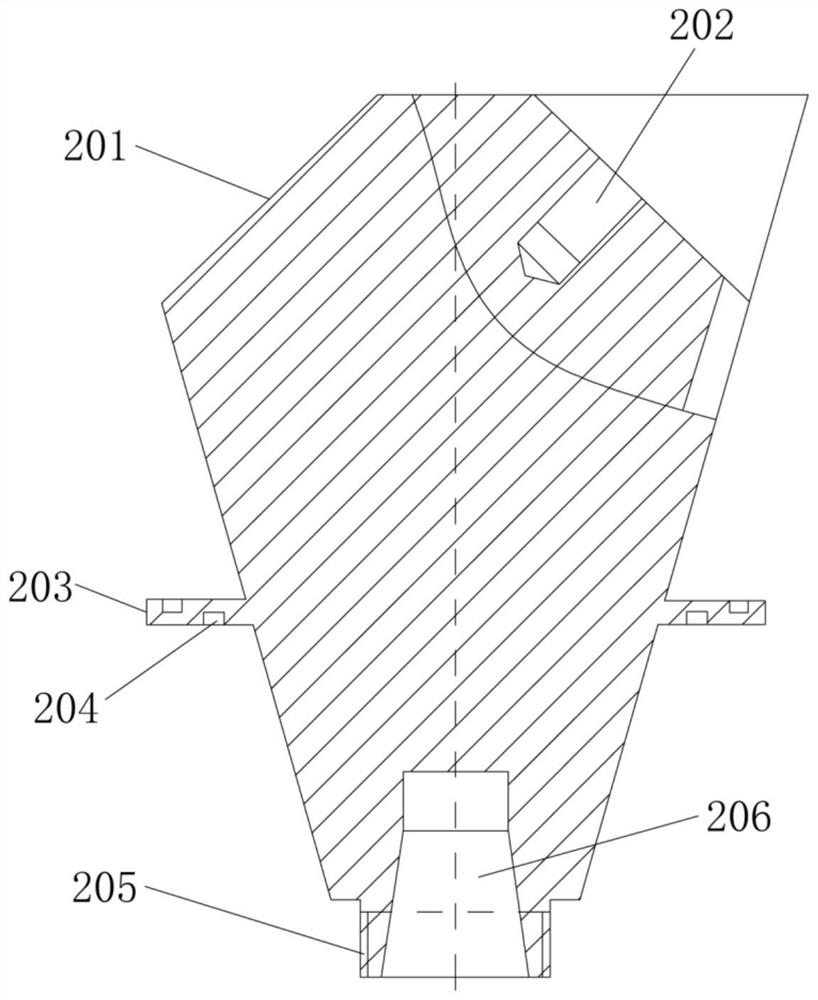

Double-excitation longitudinal-torsional combined ultrasonic vibration device

PendingCN113477496ARealize cutting processEasy to replaceMechanical vibrations separationDriving apparatusUltrasonic vibrationLongitudinal vibration

The invention relates to the technical field of ultrasonic vibration machining, in particular to a double-excitation longitudinal-torsional combined ultrasonic vibration device. The device comprises two ultrasonic vibrators used for generating longitudinal ultrasonic vibration, an amplitude-change pole used for converting the longitudinal ultrasonic vibration generated by the two ultrasonic vibrators into longitudinal-torsional combined vibration, and a cutter used for cutting materials. The two ultrasonic vibrators are fixedly installed on the two sides of the upper end of the amplitude-change pole in the modes that the angle inclination exists, and the two ultrasonic vibrators are staggered with each other. The lower end of the amplitude-change pole is fixedly connected with the cutter. By the adoption of the structural arrangement, when the longitudinal ultrasonic vibration generated by the ultrasonic vibrators is transmitted to the amplitude-change pole at a certain angle, an axial component and a radial component can be generated, the axial component enables the lower end of the amplitude-change pole to conduct longitudinal vibration, the radial component enables the lower end of the amplitude-change pole to conduct torsional vibration, waveforms transmitted to the amplitude-change pole are mutually overlapped, the longitudinal-torsional combined vibration can be generated at the lower end of the amplitude-change pole and acts on the cutter, so that cutting machining of the materials is achieved, the cutting force is reduced advantageously, the machining efficiency is improved advantageously, and the machining quality is improved.

Owner:深圳市青鼎装备有限公司

Fabric cutting device for silk quilt production

InactiveCN112850312AStable cutting processEfficient and stable cuttingArticle deliveryStructural engineeringMechanical equipment

The invention discloses a fabric cutting device for silk quilt production, and belongs to the field of home textile processing mechanical equipment. A fabric pressing and cutting mechanism and a fabric pulling and conveying mechanism of the fabric cutting device are arranged on the two sides of a fabric processing support, the two sides of the upper side of a reciprocating pulling chain are fixedly connected with the two sides of the lower side of a fabric pulling and conveying support correspondingly, a pressing plate mounting connecting plate and a lifting fixing wedge plate are horizontally and fixedly arranged on the two sides of the upper side of a lifting reciprocating guide plate correspondingly, a fabric pulling and conveying lower bearing plate is horizontally and fixedly arranged on the fabric pulling and conveying support on the lower side of a fabric pulling and conveying upper pressing plate, a pressing and cutting fixing wedge plate is horizontally and fixedly arranged on the lower side of a pressing and cutting lifting plate, a translation pressing and cutting wedge plate matched with the pressing and cutting fixing wedge plate is horizontally arranged on the fabric processing support on the lower side of the pressing and cutting fixing wedge plate, and a fabric pressing cutter is horizontally and fixedly arranged on the upper side of a cutter mounting base. The fabric cutting device for silk quilt production is reasonable in structural design, silk quilt fabric can be efficiently, stably, continuously and accurately cut in a sectional mode, the processing automation degree is high, and the requirements of production and use are met.

Owner:桐乡市诺创信息科技有限公司

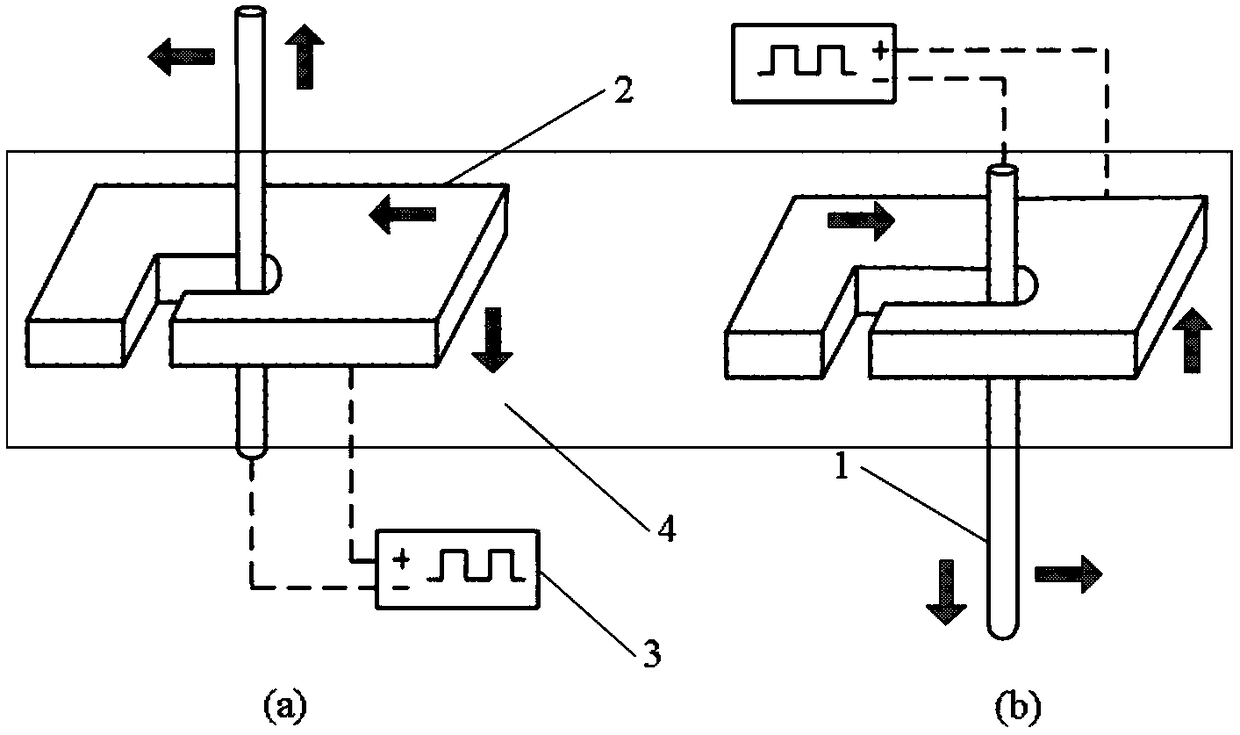

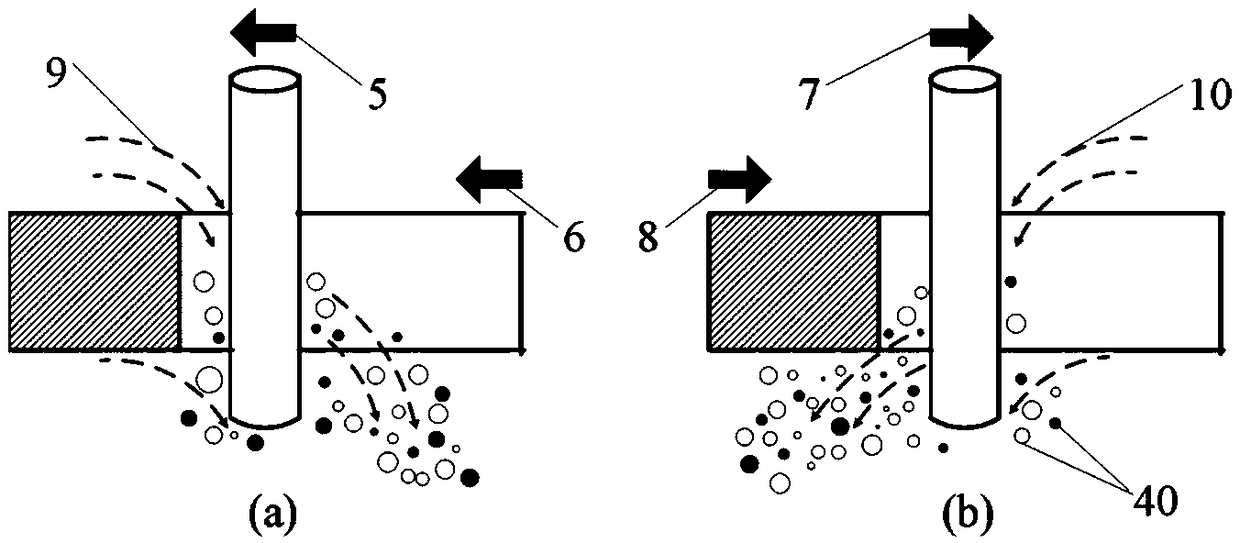

Line electrode workpiece different-speed compound motion micro electrolytic line cutting machining method

ActiveCN108788352AFast relative flowEnhanced update flowElectrical-based auxillary apparatusElectrolytic agentEngineering

The invention relates to a line electrode workpiece different-speed compound motion micro electrolytic line cutting machining method, and belongs to the field of precision micro electrochemical manufacturing. In the machining direction, the line electrode and the workpiece perform relative cutting motion at different speeds, and stationary electrolyte flows reversely and rapidly to flush out products in a gap. In the direction perpendicular to the machining direction, the line electrode and the workpiece move alternately in a reciprocating mode to assist mass transfer in the gap. By using thecompound motion in different directions, the position change of a machining area is realized, the electrolyte in the machining gap is driven to rapidly renew and flow, and the differential motion micro-electrolysis line cutting machining is carried out under the state of high-efficiency mass transfer. The line electrode workpiece different-speed compound motion micro electrolytic line cutting machining method remarkably improves the precision, efficiency and stability of micro-electrolysis line cutting machining, and has important significance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of production method of ceramic sheet for ceramic package base

ActiveCN112589976BMeet the precision requirementsHigh dimensional accuracyCeramic shaping apparatusComposite materialGreen body

The invention relates to a method for producing ceramic sheets for ceramic packaging bases, comprising the following steps: step 1, making ceramic green sheets, and dividing the plate-shaped ceramic green sheets into a plurality of ceramic green sheets; step 2, making ceramic green sheets for each The ceramic green sheet is cut and trimmed during the process; step 3, the ceramic green sheet trimmed in step 2 is sintered and hardened to obtain a ceramic sheet. In the production process, the ceramic green sheet is produced first, and based on the relatively low hardness of the ceramic green sheet, the ceramic green sheet is cut and trimmed during the process, so that the size of the produced ceramic sheet can easily meet the accuracy requirements .

Owner:瓷金科技(河南)有限公司

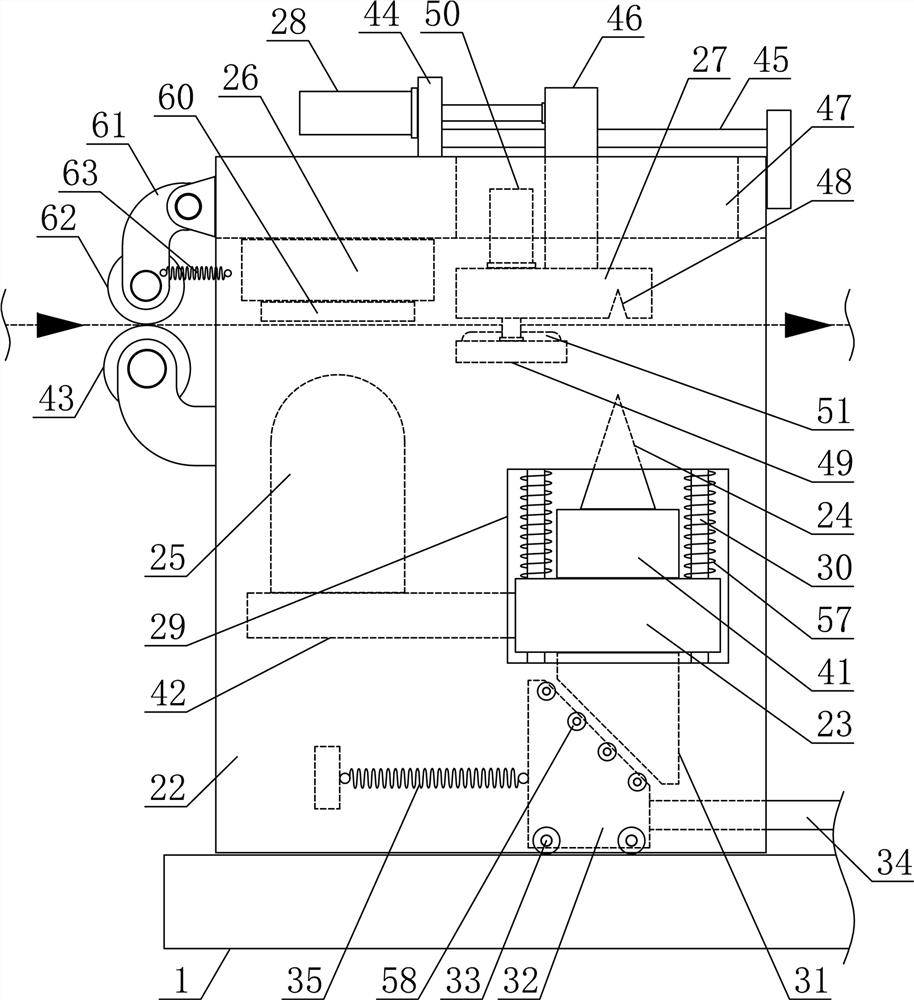

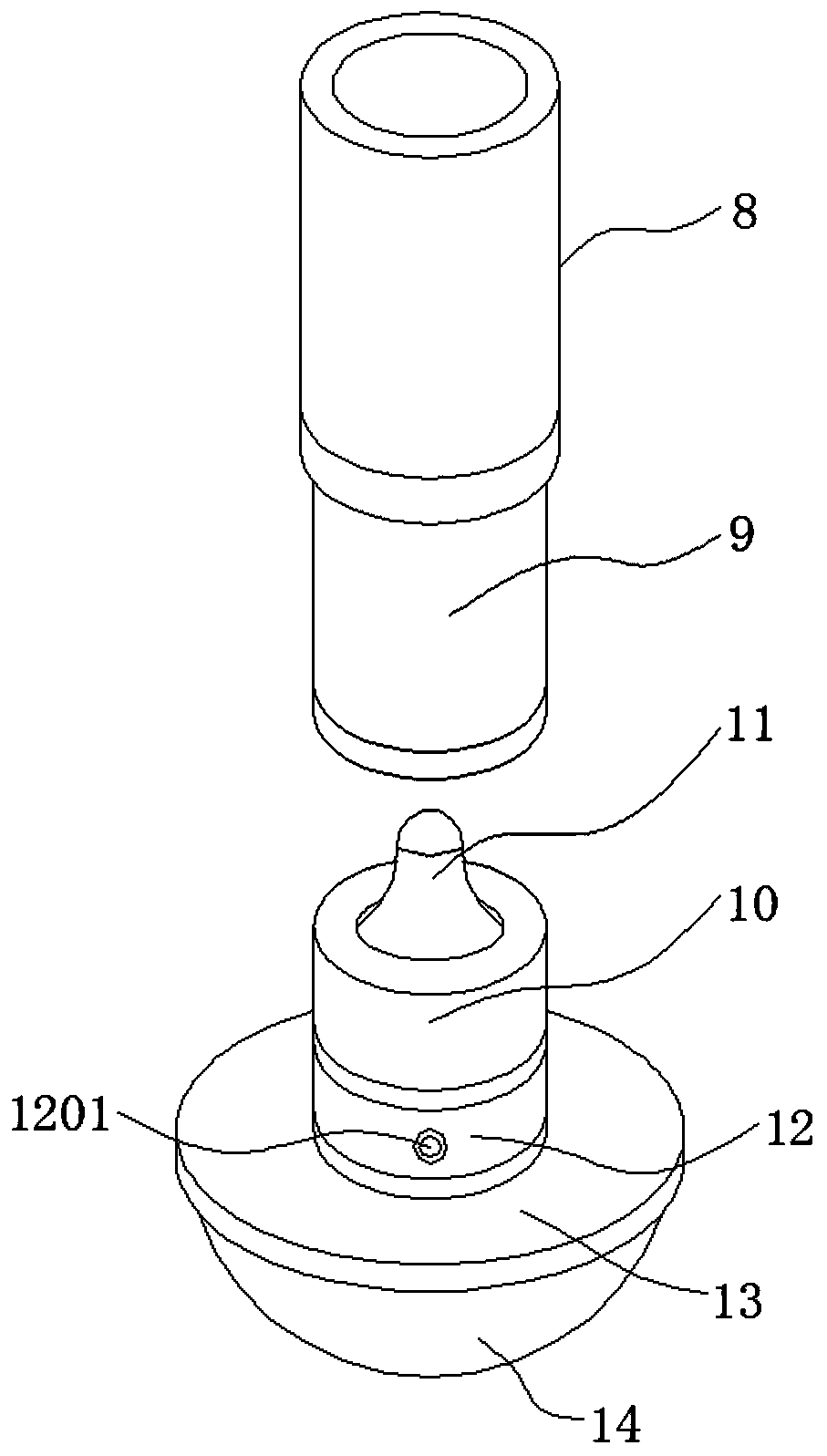

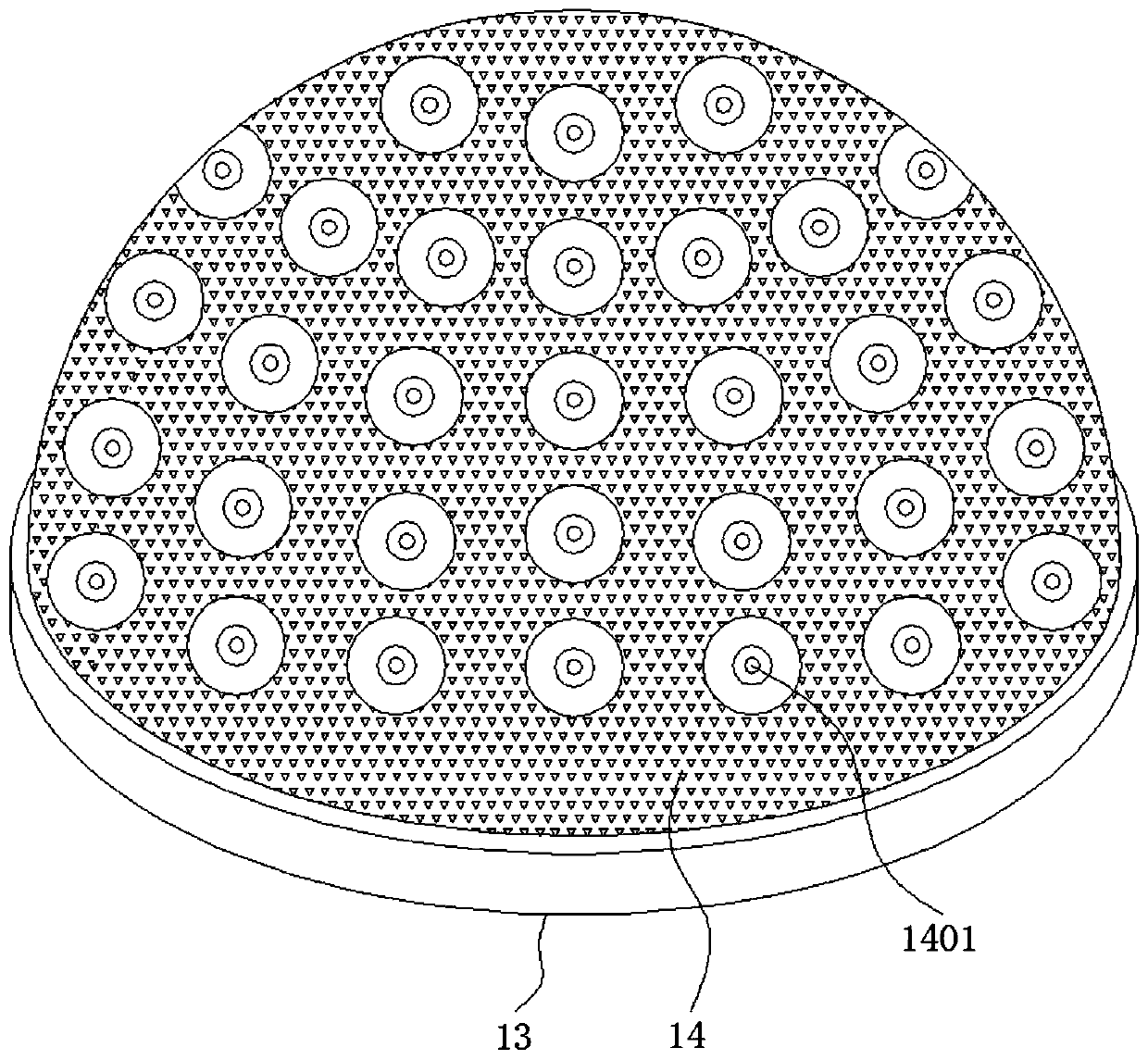

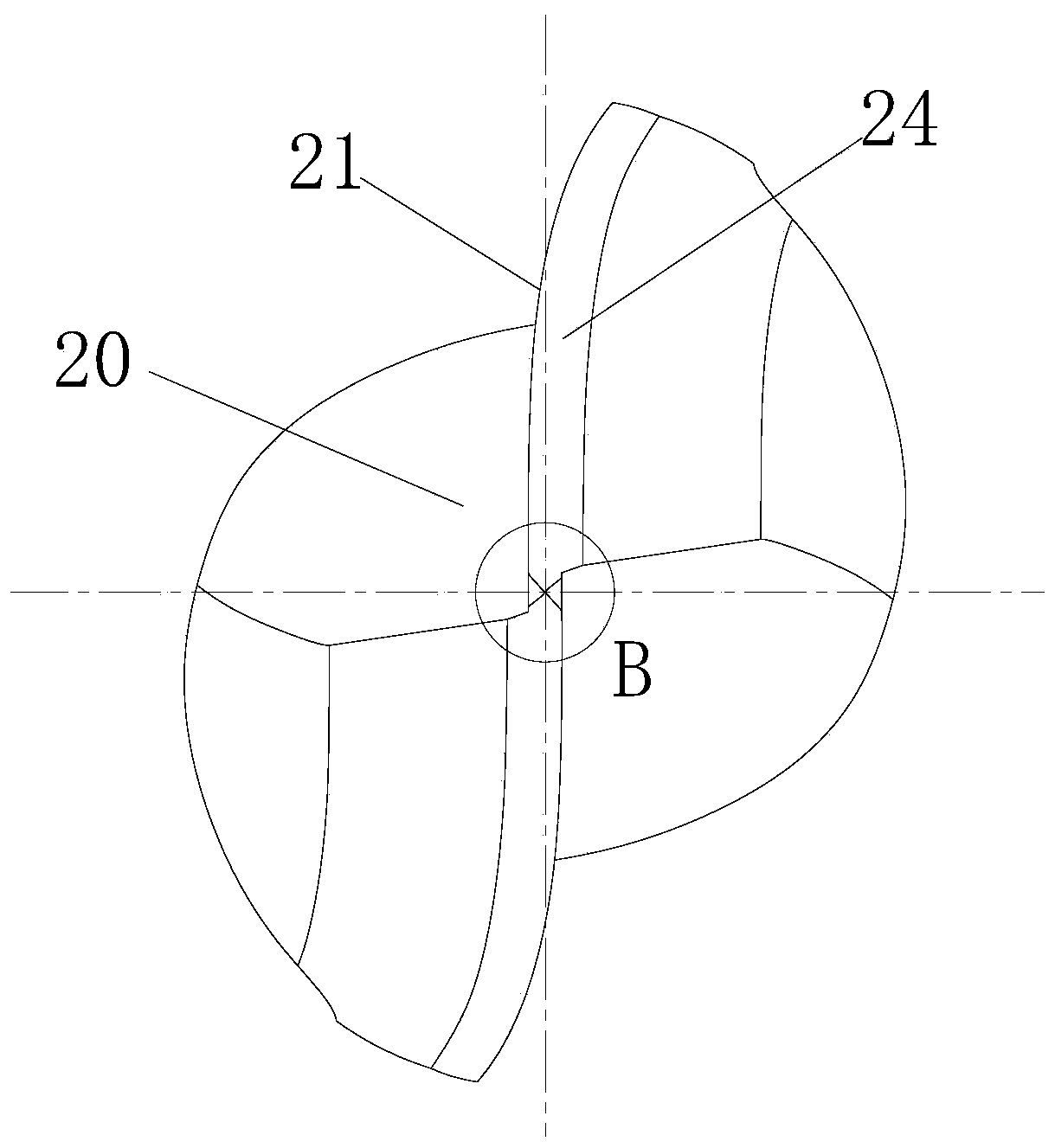

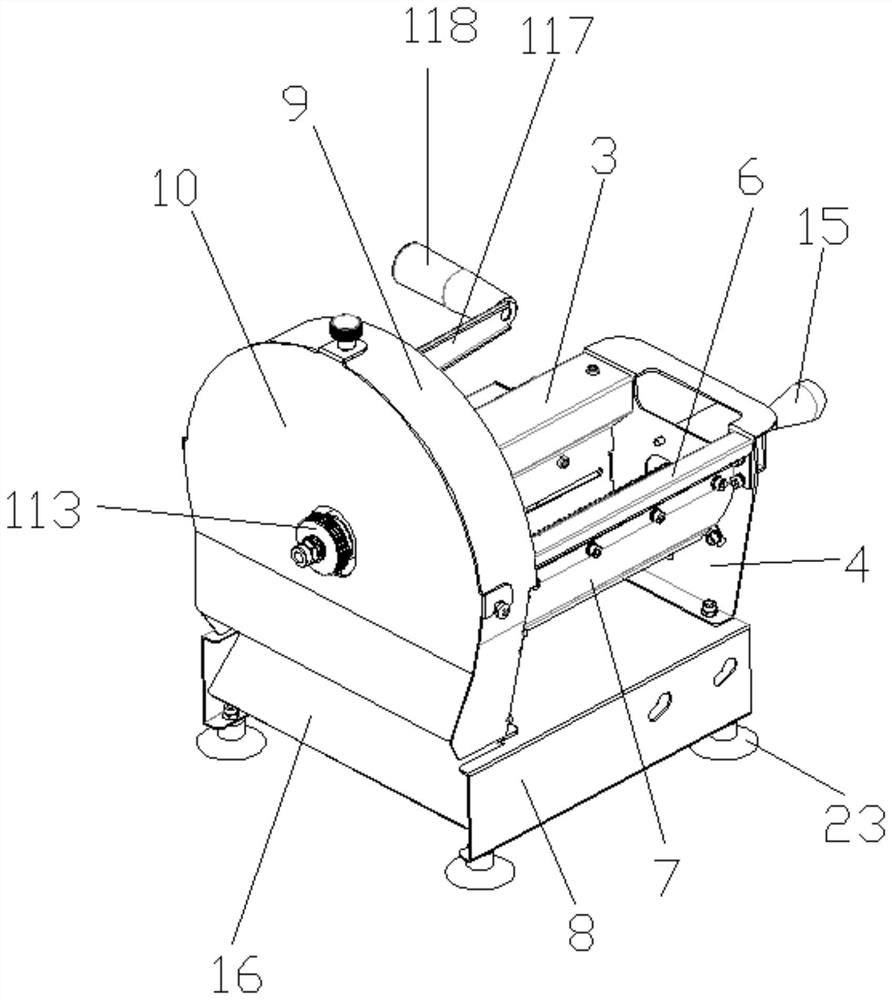

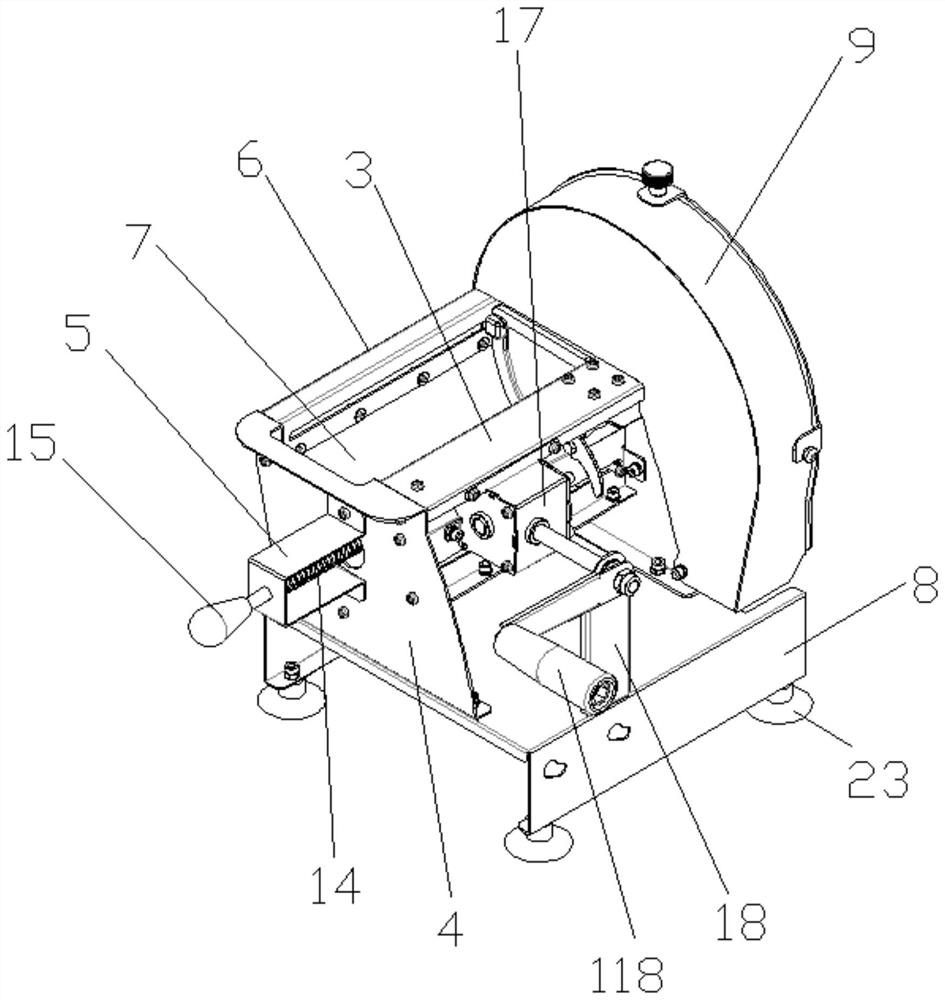

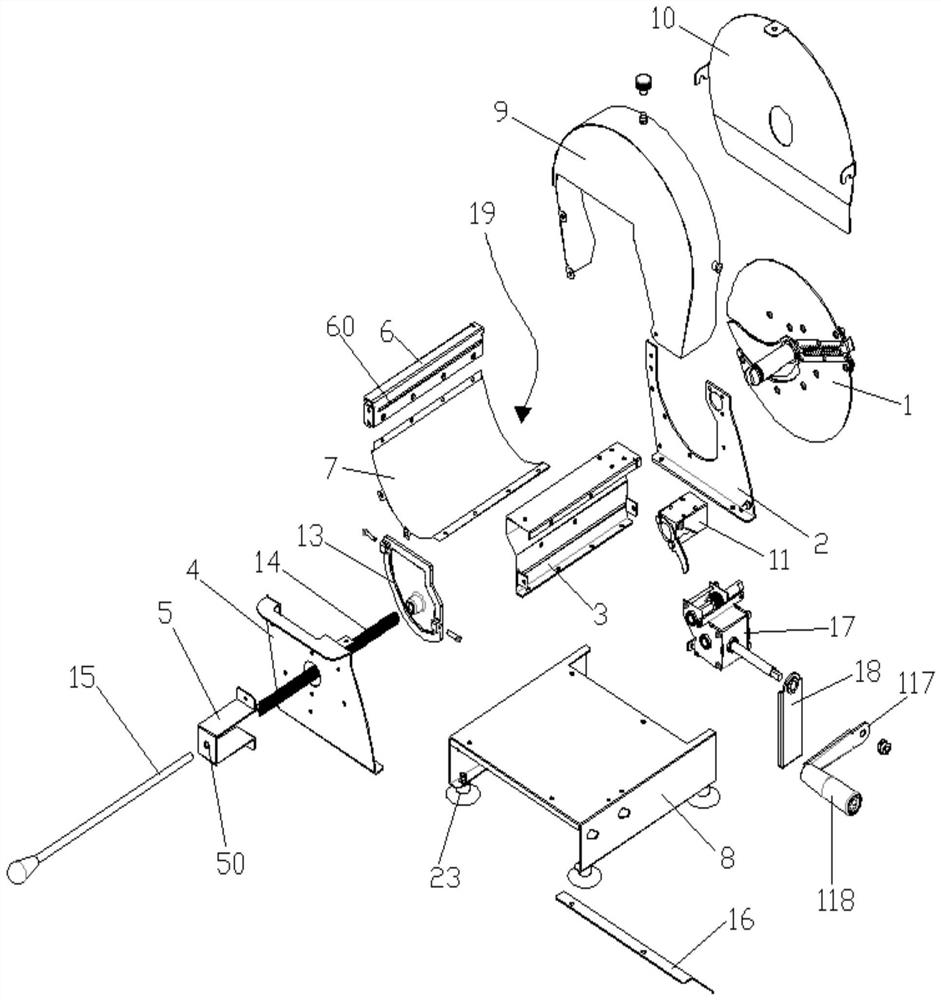

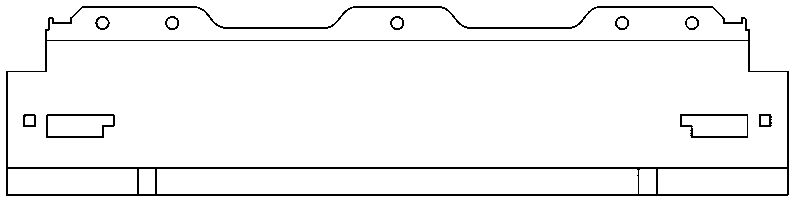

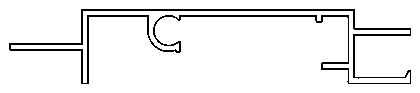

Copying cutting machine for medical retainer and cutting process

ActiveCN111531376AGuarantee processing qualityImproved profileFeeding apparatusPositioning apparatusEngineeringMachining

The invention discloses a copying cutting machine for a medical retainer and a cutting process, and relates to the technical field of medical retainer machining. The copying cutting machine specifically comprises a bottom plate, pressing mechanisms, cutter mounting mechanisms, cutter holding devices and a clamping mechanism, wherein supporting plates are vertically fixed to the two sides of the upper surface of the bottom plate, mounting plates are fixed into a top plate, the pressing mechanisms are mounted below the mounting plates at equal intervals, cutter shifting grooves and auxiliary grooves are formed in the front side surface of a vertical plate, the cutter mounting mechanisms are mounted inside the cutter shifting grooves, the cutter holding devices are slidably mounted inside theauxiliary grooves, and a clamping mechanism is mounted in the middle of the upper surface of a supporting plate. According to the copying cutting machine for the medical retainer and the cutting process, the cutter shifting grooves and the auxiliary grooves are formed, so that the cutter mounting mechanisms can move on the vertical plate according to an arc track and can stably, accurately and continuously move on the vertical plate according to the arc track under the support of the cutter holding devices.

Owner:WUXI YITONG PRECISION MACHINERY

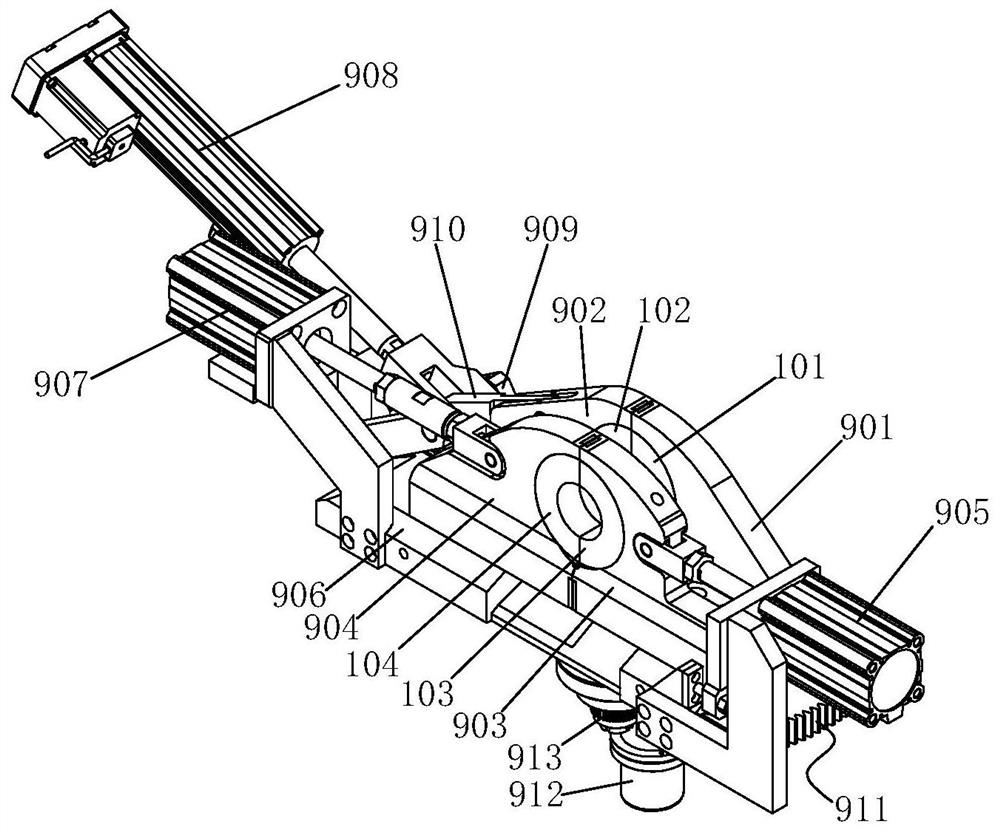

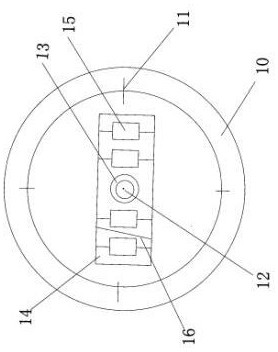

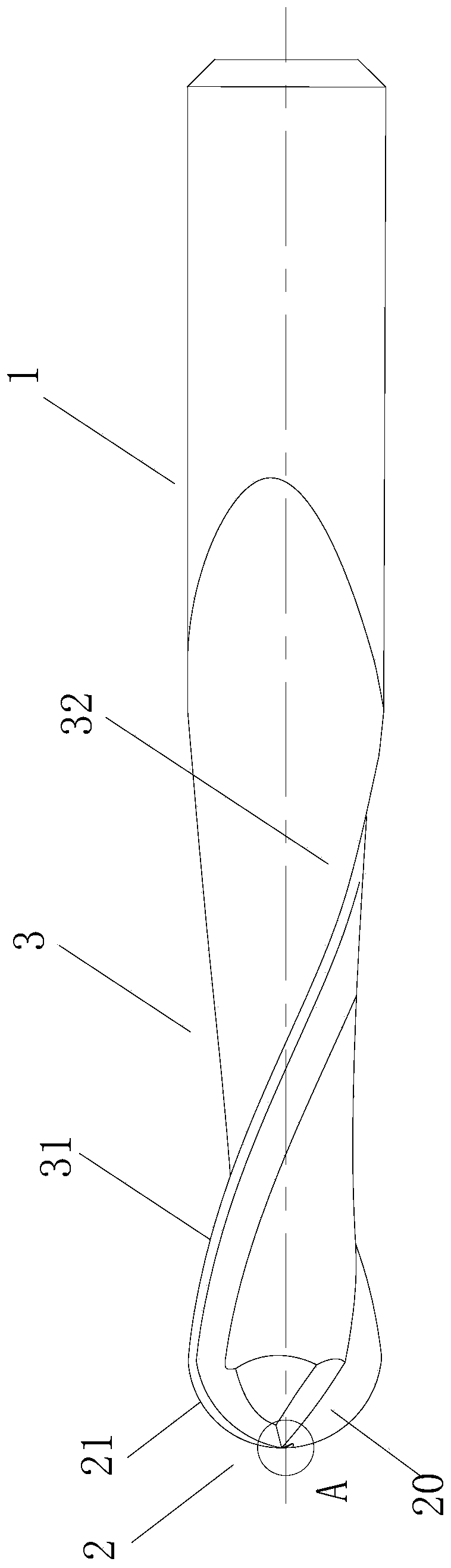

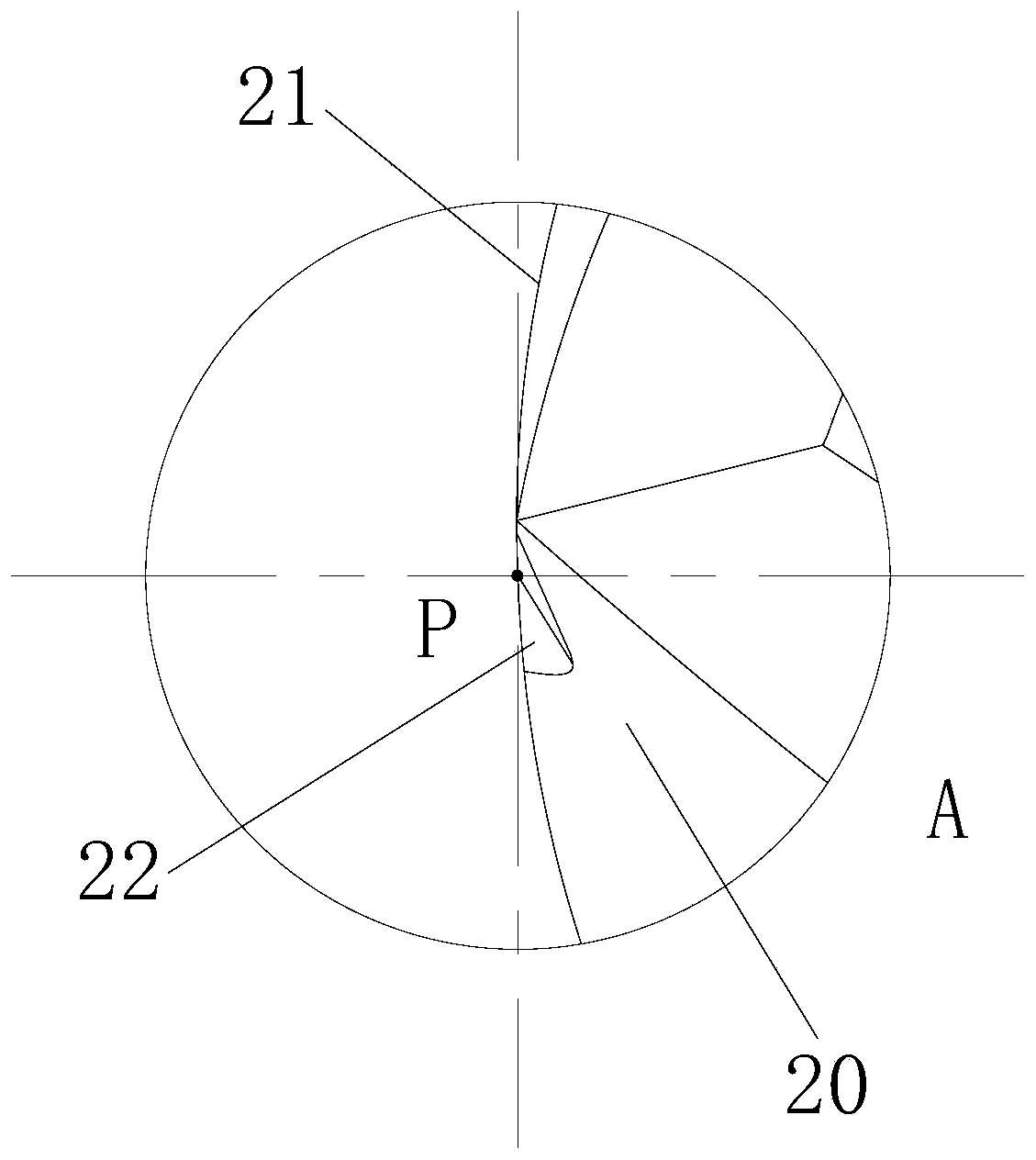

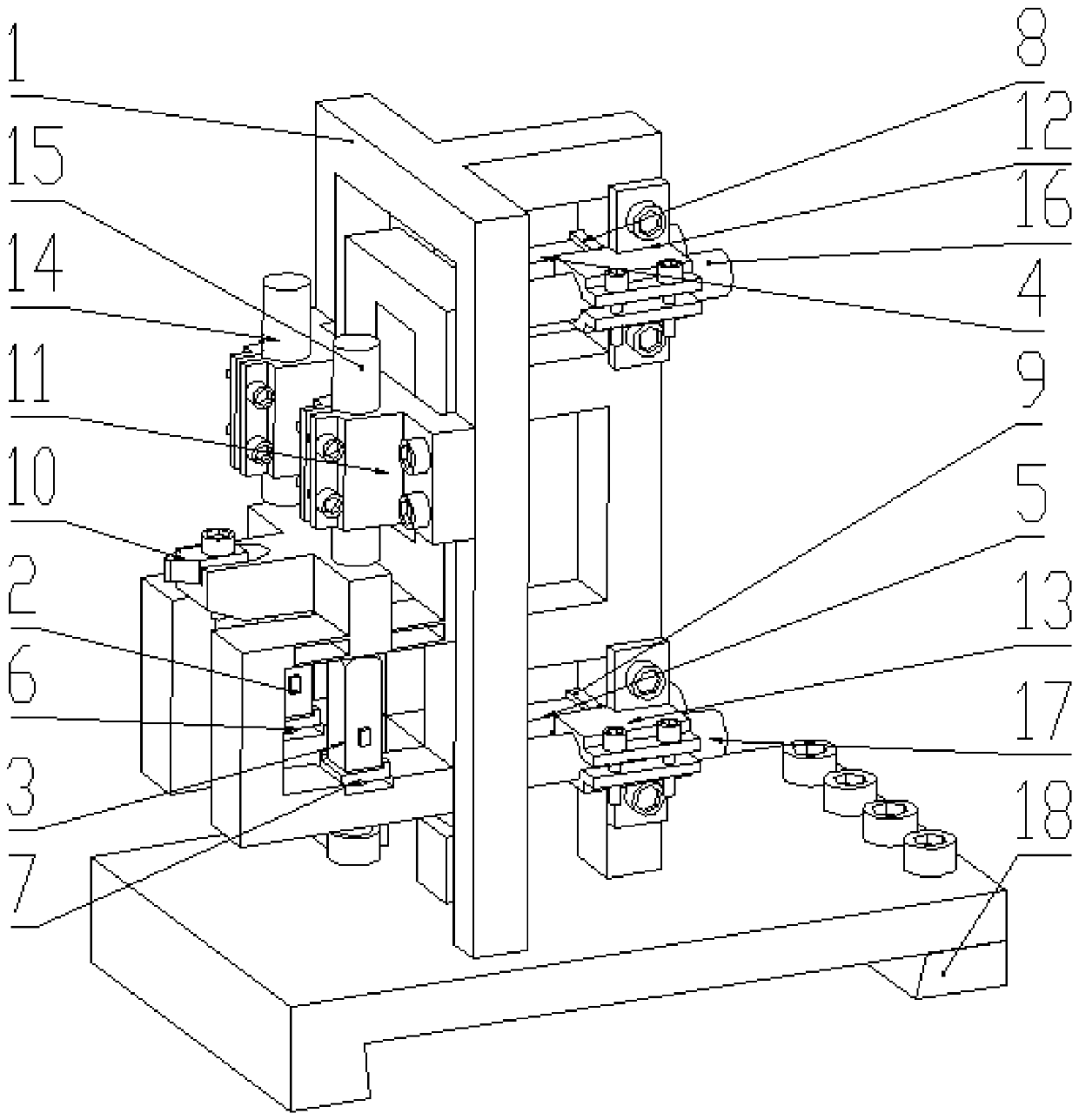

Pipe fitting cutting device and horseshoe opening cutting method adopting same

ActiveCN111673466APrecise positioningEasy to holdOther manufacturing equipments/toolsPositioning apparatusPipe fittingElectric machinery

The invention discloses a pipe fitting cutting device and a horseshoe opening cutting method adopting the pipe fitting cutting device. The pipe fitting cutting device comprises a machine body, a cutting device and a conduit clamping device are installed on the machine body, the conduit clamping device comprises a first clamping base, a second clamping base and a clamping device base, the first clamping base and the second clamping base are oppositely arranged on the clamping device base front and back and are matched front and back to clamp a conduit, the first clamping base is fixed to the clamping device base, the second clamping base is driven by a clamping motor or a third clamping air cylinder to slide on the clamping device base front and back, the clamping device base is installed on the machine body through a rotating shaft and can be driven by a rotation driving device to rotate, the cutting device feeds front and back, the axis of the rotating shaft is located on a feeding cutting face of the cutting device, and after the first clamping base and the second clamping base clamp the conduit, the axis of the straight line section of the conduit end of the conduit intersects with the axis of the rotating shaft. According to the scheme, a horseshoe opening can be rapidly and accurately formed through cutting.

Owner:ZHEJIANG KING MAZON MACHINERY +1

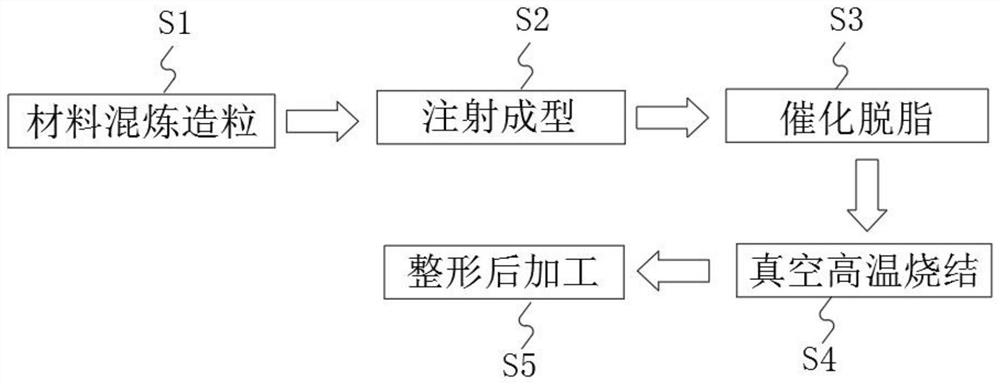

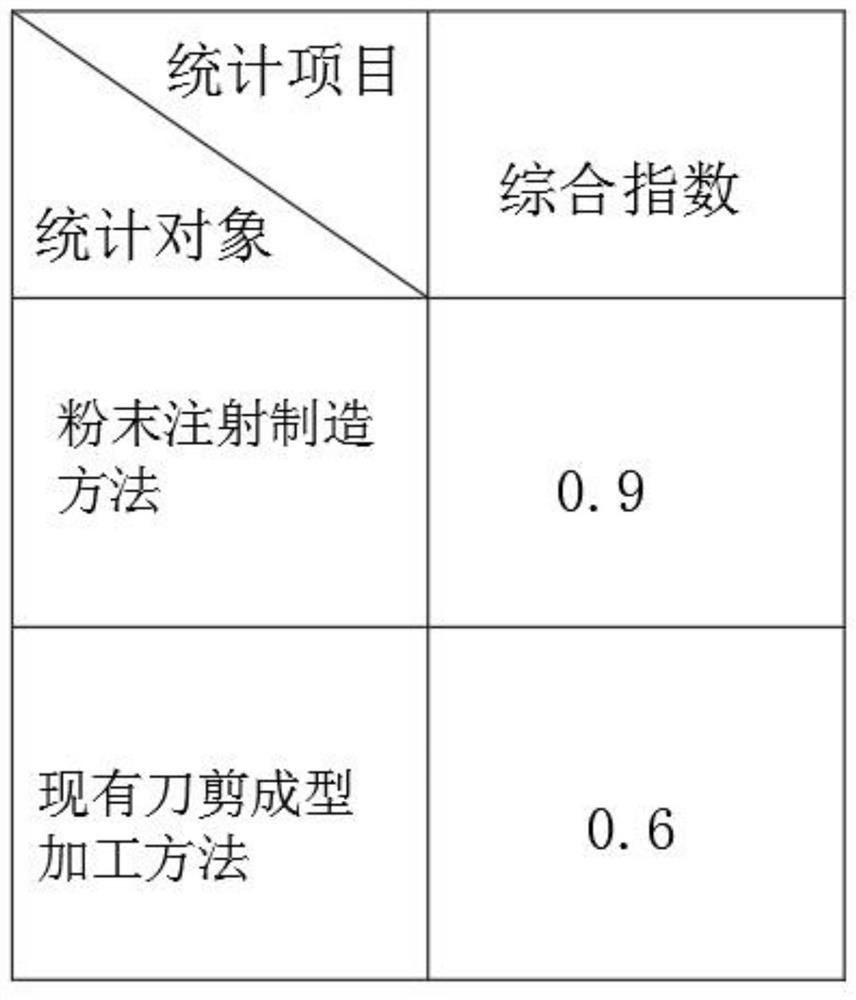

Powder injection manufacturing method for producing high-precision and high-quality knives and scissors

PendingCN113634750AImprove uniformityHigh precision castingTurbinesOther manufacturing equipments/toolsMixed materialsPowder injection

The invention discloses a powder injection manufacturing method for producing high-precision and high-quality knives and scissors. The method comprises the following steps: S1, material mixing and granulation: firstly, alloy powder and a binder are put into an internal mixer for uniform mixing, stirring and internal mixing, then a mixed material after internal mixing is put into a granulator for granulation, and then a prepared feed is collected and stored. The method relates to the technical field of powder metallurgy. According to the powder injection manufacturing method for producing the high-precision and high-quality knives and scissors, most binders are removed through catalytic degreasing in the acid atmosphere, the shape maintaining performance of blanks is good, a finished product obtained after follow-up high-temperature sintering is high in structure uniformity, good in compactness, reliable in physical performance and high in precision, meanwhile, the overall machining cost of the finished product is obviously reduced, the whole manufacturing process is shortened, the effects that the precision of the finished product is higher than that of casting, the surface treatment cost is low, and the material selectivity is high are achieved, and personnel and equipment are greatly reduced.

Owner:TIANJIAO HOUSEHOLD MFG LTD GUANGDONG

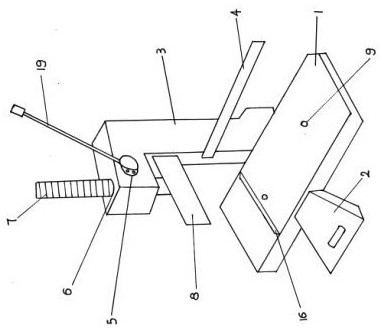

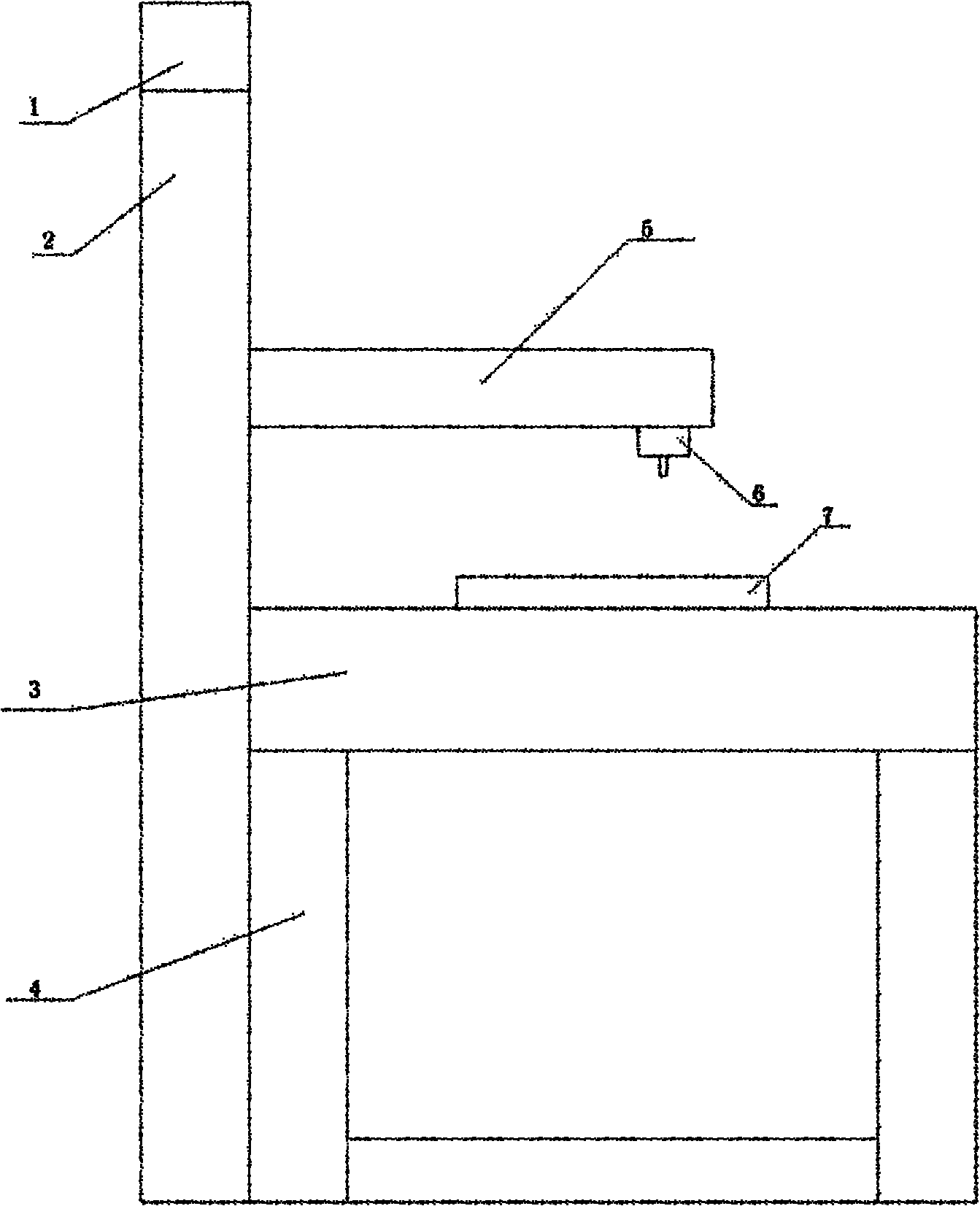

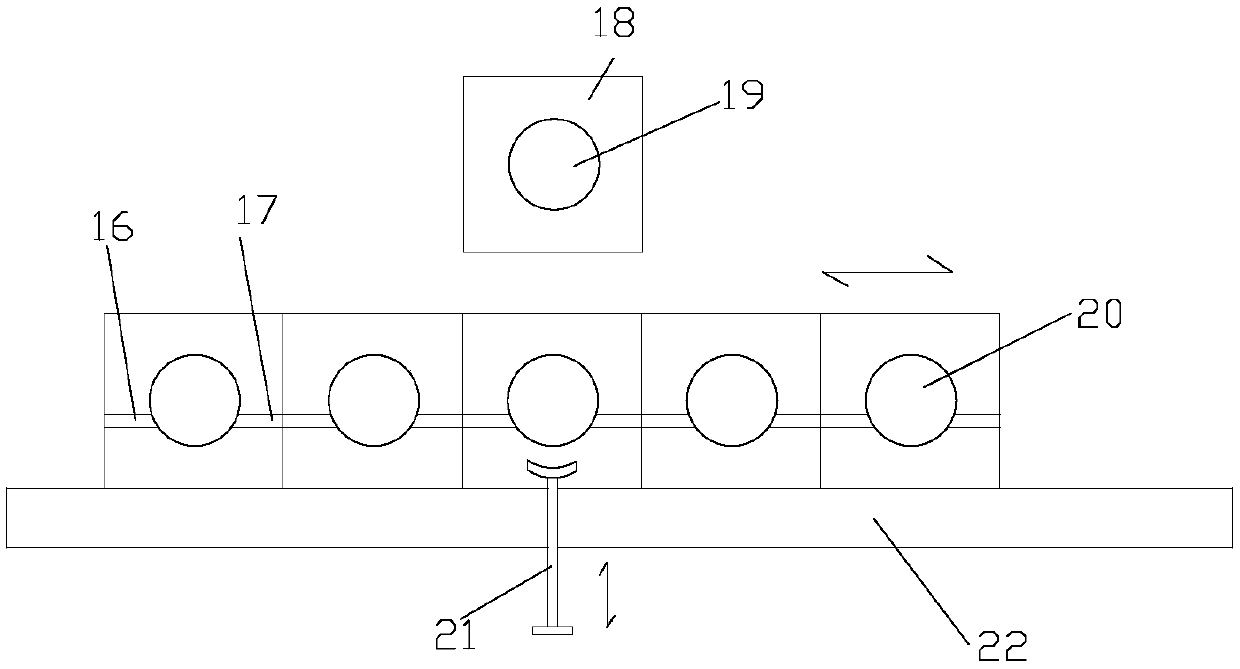

Portable cutting device for aerated concrete blocks

PendingCN112372857ARealize cutting processReduce volumeStone-like material working toolsGear wheelArchitectural engineering

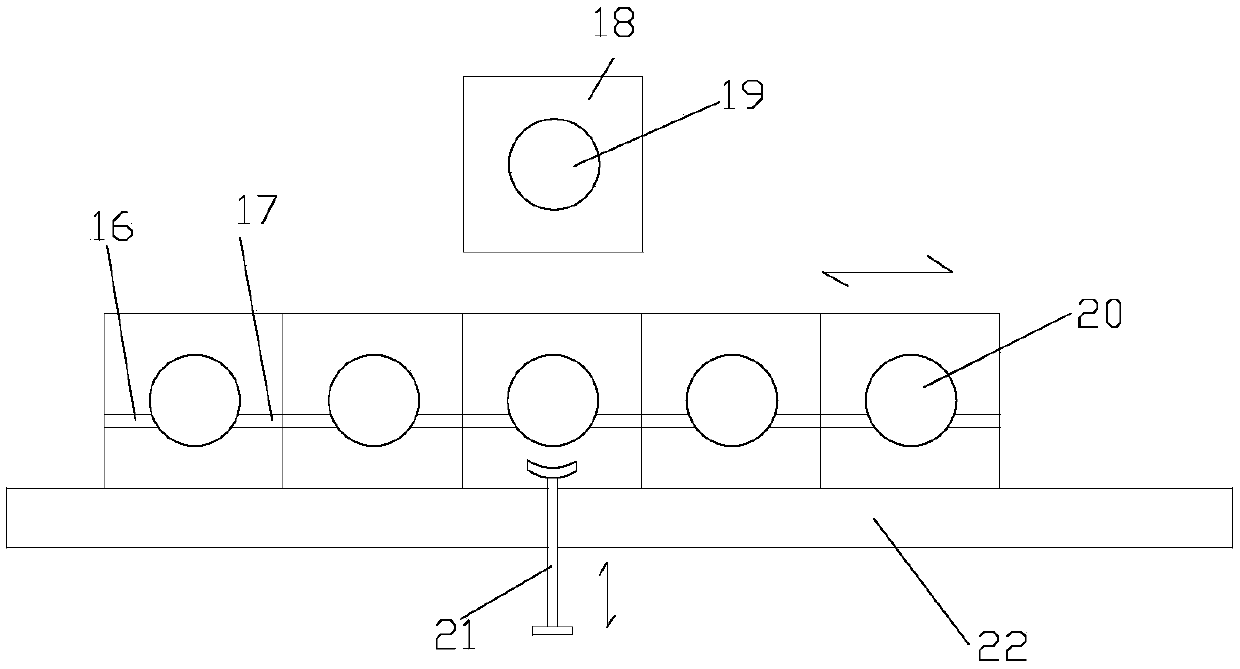

The invention discloses a portable cutting device for aerated concrete blocks, and solves the problems of serious material waste and poor cutting quality in the field cutting of existing aerated concrete blocks. A pedal tongue plate (2) and an inverted-L-shaped support (3) are connected to a rectangular base plate (1), a pair of supporting bearings (5) of a gear center shaft is arranged on a horizontal cantilever at the top end of the inverted-L-shaped support (3), a gear is arranged in the pair of supporting bearings (5) of the gear center shaft, a rack (7) movably penetrates through the position, on the left side of the gear, of the horizontal cantilever at the top end of the inverted-L-shaped support (3), the rack (7) is engaged with the gear, the lower end of the rack (7) is connectedwith a building block cutting upper blade (8), the outer side end of the gear shaft is connected with a gear rotating manual rocker (19), and a building block cutting positioning lower blade (16) is movably arranged on the top end face of the rectangular base plate (1). The cutting processing of building blocks with special shape requirements is realized.

Owner:SHANXI NO 3 CONSTR ENG

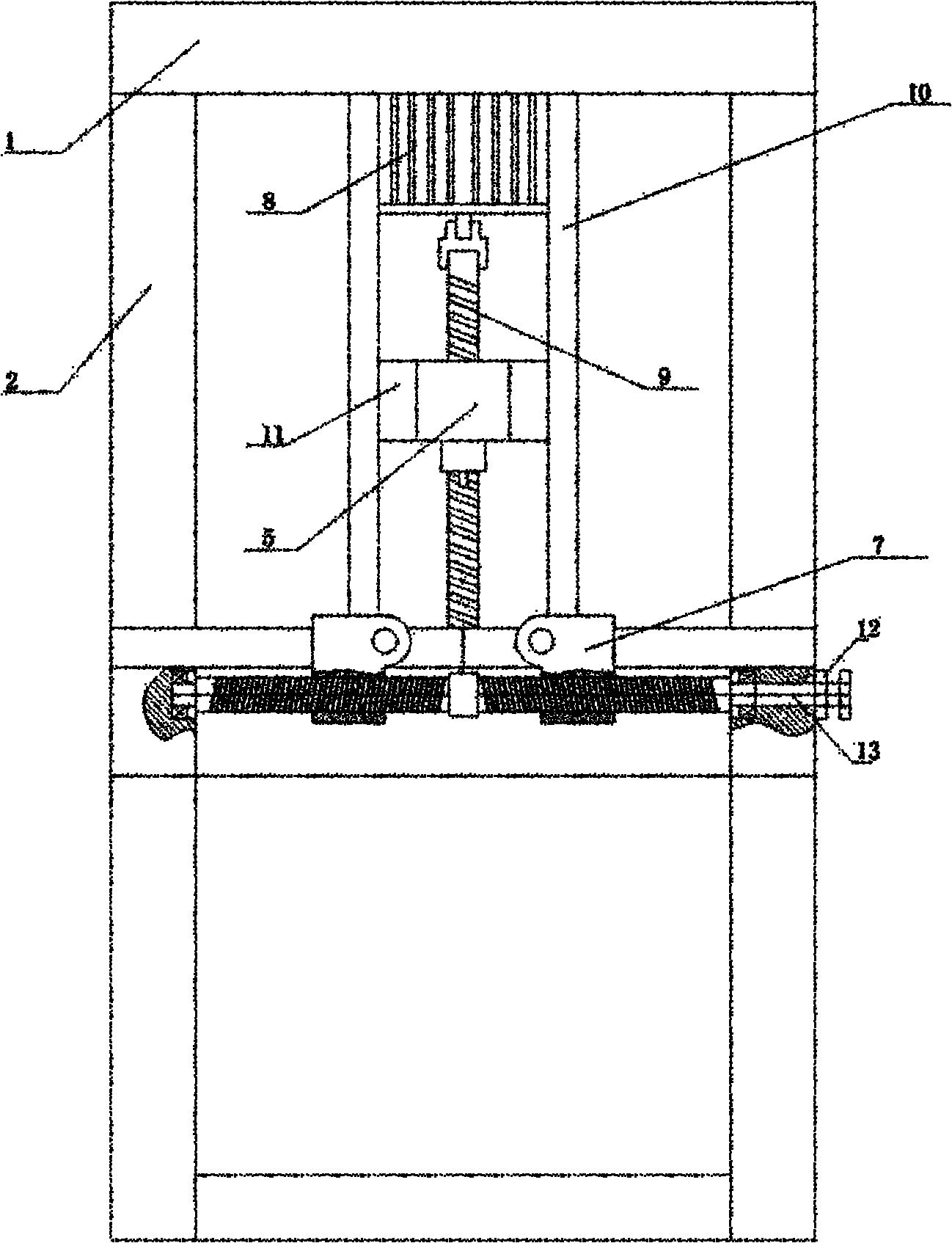

Automatic inner hole chamfering machine

InactiveCN102029415ASave electricityFully automatedAutomatic control devicesFeeding apparatusMachinePhysics

The invention relates to the field of cutting tools, in particular to an automatic inner hole chamfering machine for chamfering hole edges. The automatic inner hole chamfering machine comprises a base, support pillars and a worktable, wherein the two sides of the left side of the base are vertically provided with the support pillars which are higher than the base; the top parts of the two support pillars are provided with an upper beam; a lower beam is arranged on the middle lower part between the two support pillars; the upper part of the base is provided with the worktable which is higher than the lower beam; a height adjustment mechanism is arranged between the upper beam and the lower beam and is provided with a beam; the lower part of the beam is provided with a cutting device; in addition, the worktable is provided with a positioning mechanism. The machine also comprises a control device for controlling the mechanisms. The machine realizes automatic inner hole chamfering to facilitate mass production, and also improves the inner hole chamfering quality to facilitate subsequent assembly.

Owner:潘旭

Medical material slitter

ActiveCN106217446ARealize cutting processRealize processing into stripsMetal working apparatusEngineeringMechanical engineering

Owner:贵州苗仁堂生物医药科技有限责任公司

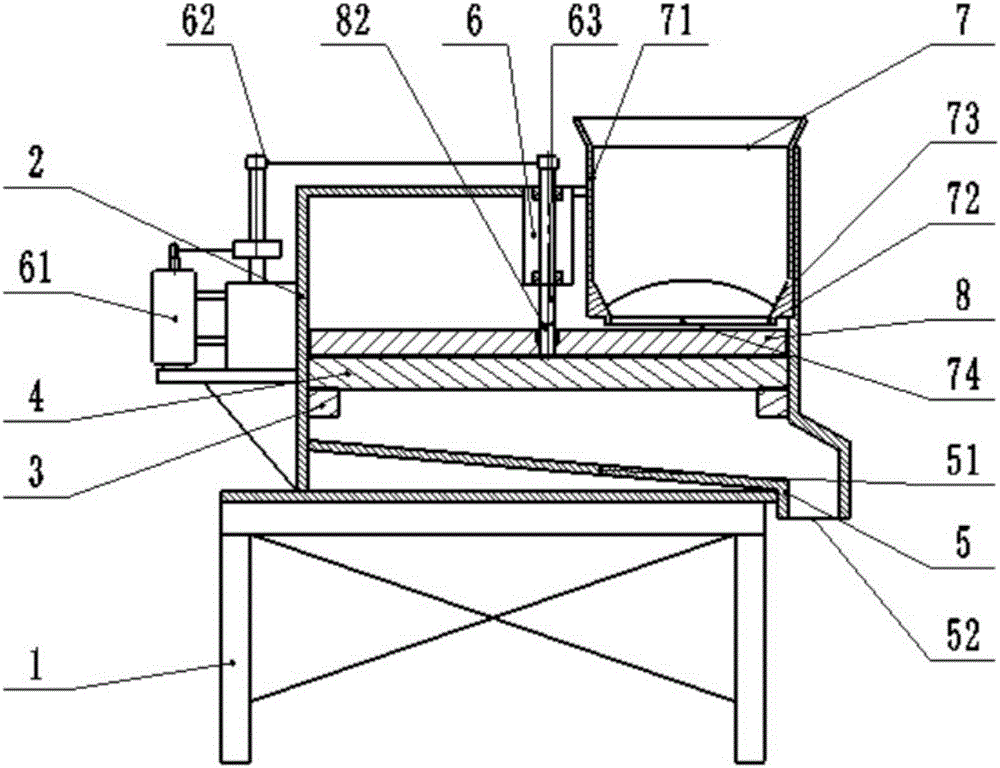

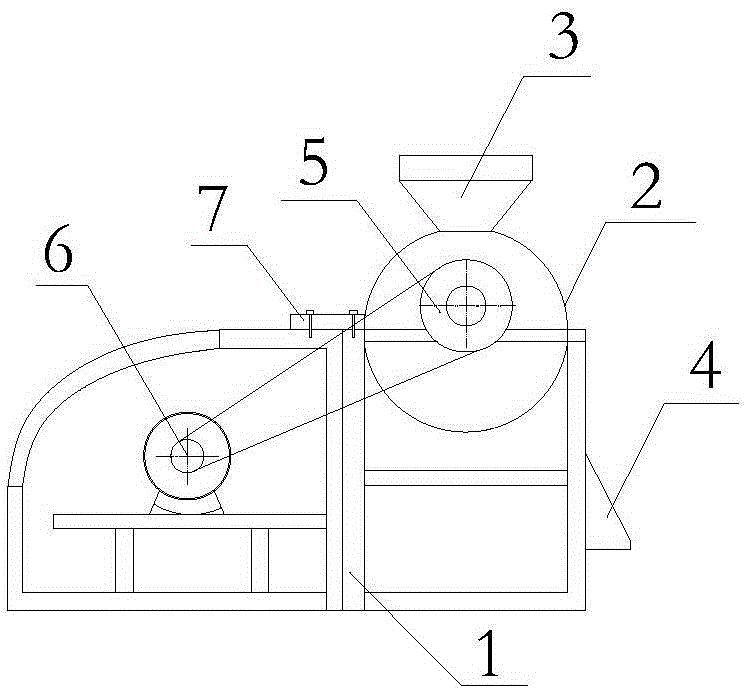

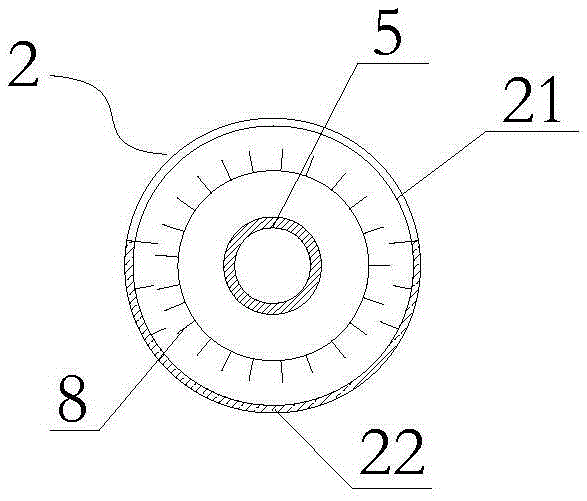

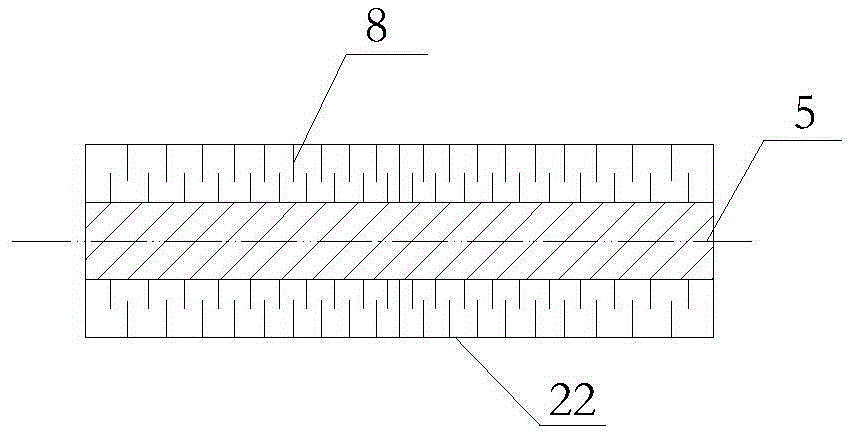

Beef back strap shredding equipment

InactiveCN106826992ARealize cutting processCompact structureMetal working apparatusEngineeringMechanical engineering

The invention discloses beef tendon shredding equipment, which comprises a frame (1), a cutting machine body installed on the front upper part of the frame (1) and a motor (7) installed on the rear lower part of the frame (1). The machine body includes a hollow cylindrical outer shell (2) and a cutting shaft (5) arranged inside it. The axis of the rotating shaft (5) is parallel to the outer shell (2) and the two ends pass through the two ends of the outer shell (2). The outer surface of the cutting shaft (5) and the inner wall of the outer casing (2) are provided with a cutting tool (8) that cooperates with each other; the cutting shaft (5) is connected with the motor (7) through a pulley; the outer casing (2) ) The upper side wall is provided with a raw material inlet (3), and the lower side wall is provided with a material outlet (4). The invention has the advantages of simple and compact structure, low price and convenient market promotion.

Owner:CHONGQING MINMAO FOODPROCESSING CO LTD

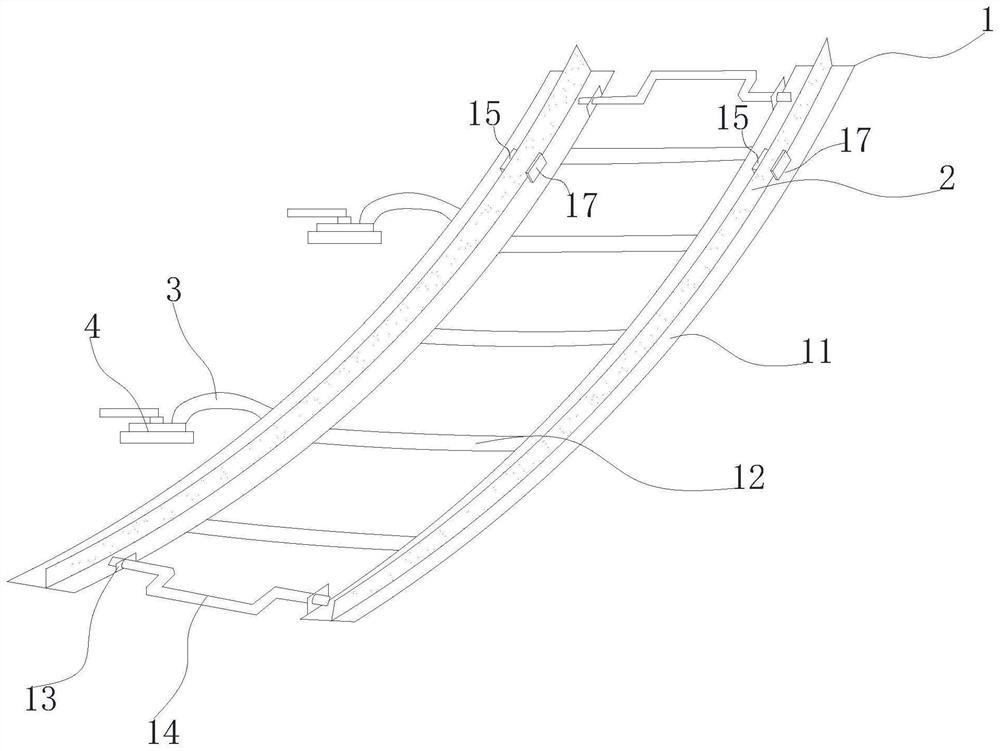

Vacuum suction cup type austenitic stainless steel spherical storage tank cutting track fixing device

InactiveCN113649647ARealize cutting processHigh cutting efficiency and stabilityLarge fixed membersMetallurgyStructural engineering

The invention discloses a vacuum suction cup type austenitic stainless steel spherical storage tank cutting track fixing device. The device comprises a track arranged on a base and used for allowing a trolley to advance, and a clamping portion used for fixing the track; the clamping portion comprises clamping plates arranged on the base and in sliding fit with the base, and baffle plates arranged on the base and correspond to the clamping plates in positions; the track is arranged between the clamping plates and the baffles; and a driving portion used for driving the clamping plates to slide towards the baffle plates are further arranged on the base so as to clamp and fix the track. According to the device, vacuum suction cups are arranged on the plate face of a spherical shell plate of an austenitic stainless steel spherical storage tank, the vacuum suction cups and the plate face of the spherical shell plate are sucked together, the vacuum suction cups are fixedly connected to the stainless steel base, and the track arranged on the stainless steel base is also fixed; and due to the fact that the base is made of stainless steel, pollution to the spherical shell plate is avoided when the base makes direct contact with the surface of the spherical shell plate, the cutting trolley can advance along the track so as to cut the surface of the spherical shell plate, and the cutting efficiency is high and stable.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Ball head milling cutter, ball head double-edged milling cutter and processing method

PendingCN111299674ARealize cutting processQuality improvementMilling cuttersMilling cutterMachined surface

The invention is suitable for the technical field of cutting tools, and discloses a ball head milling cutter, a ball head double-edged milling cutter and a processing method. The ball head milling cutter comprises a tool main body, wherein one end of the tool main body is provided with a ball head cutting part; the ball head cutting part comprises at least two ball head cutting edges which are arranged on the axial end surface of the tool main body; the ball head cutting part is provided with at least one core slot; one slot wall of the core slot is crossed with the rear cutter surface of thecorresponding ball head cutting edge to form a core edge; one end of the core edge is close to a ball head vertex of the ball head cutting part; or one end of the core edge is superposed with the ballhead vertex; the other end of the core edge is close to the corresponding ball head cutting edge; or the other end of the core edge is connected to the corresponding ball head cutting edge. The ballhead milling cutter, the ball head double-edged milling cutter and the processing method provided by the invention can effectively improve quality of a workpiece processing surface, and further can reduce heat generated while the ball head cutting part is processed.

Owner:SHENZHEN JINZHOU PRECISION TECH

Three-dimensional elliptical vibration flexible device based on metal porous material

PendingCN111408749AGuaranteed motion accuracyRealize the self-lubricating effect of the mechanismTool holdersMachine toolCapacitive displacement sensor

The invention relates to a three-dimensional elliptical vibration flexible device based on a metal porous material, and belongs to the technical field of optical part machining. The device is characterized in that a cutter is fixed in a cutter groove in the middle of a T-shaped cutter holder of a flexible base body through a bolt; the heads of piezoelectric stacks in the vertical direction are incontact with straight plate type flexible hinges, pre-tightening blocks are tightened through bolts to pre-tightening the lower ends of the piezoelectric stacks, and capacitive displacement sensors are clamped on sensor clamps; the heads of piezoelectric stacks in the horizontal direction are in contact with straight plate type flexible hinges, and capacitive displacement sensors are clamped on sensor clamps; and the lower portion of a base is connected with dovetail strips through bolts. The device has the advantages that the flexible base body can effectively reduce vibration conducted to amachine tool guide rail from a tool nose, the motion precision of the device is guaranteed, the self-lubricating effect of a mechanism is achieved, the service life is prolonged, and cutting machiningon various face types can be achieved; and meanwhile, the four piezoelectric stacks are provided with the capacitive displacement sensors for monitoring actual displacement in real time and feeding back the actual displacement to a controller for compensation, so that the machining precision is high.

Owner:JILIN UNIV

Novel cutting device for plastic machining

ActiveCN110125997ARealize pressure positioningReasonable structureMetal working apparatusElectric machineryEngineering

The invention discloses a novel cutting device for plastic machining. The novel cutting device comprises a base, wherein a material cutting panel is fixed to the top of a supporting frame, a bearing panel is further arranged on the top of the material cutting panel, two lifting concave cavities are formed in the top surface of the supporting frame, a lifting sliding block is arranged in each lifting concave cavity, supporting rib rods are fixed between the top ends of the lifting sliding blocks and the bearing panel, a control motor is fixed on the side part of the supporting frame, a drivinggear is fixed on a main shaft of the control motor, a supporting rod is fixed to the center of the bottom surface of the bearing panel, two pressing rods are further arranged on the bottom surface ofthe bearing panel, transmission rollers are arranged on the bottom surfaces of the pressing rods, a cutting groove is formed in the center of the bottom surface of the supporting rod, a cutting motoris arranged on the supporting frame, and a cutting cutter disc is fixed on a main shaft of the cutting motor. The novel cutting device has the advantages that the structure is reasonable, abutting-pressing and positioning of the materials can be effectively realized through the novel cutting device, removing operation of an adhered material can be carried out on the cutting cutter disc, the applicability is high, and the practicability is good.

Owner:营口鹏达塑料机械有限公司

Wide-adjustable-range saw blade device of four-side saw and four-side saw

InactiveCN113146281ARealize cutting processLarge adjustment rangeFeeding apparatusLarge fixed membersEngineeringStructural engineering

The invention discloses a wide-adjustable-range saw blade device of a four-side saw and the four-side saw. The wide-adjustable-range saw blade device of the four-side saw comprises a rack, wherein a cross beam is connected to the rack in a sliding mode, a first cutting part and a second cutting part are connected to the cross beam in a sliding mode, and each of the first cutting part and the second cutting part comprises a first base connected with the cross beam in a sliding mode. Second bases are connected to the first bases in a sliding mode, and saw blade mechanisms are installed on the second bases. A first driving mechanism is installed on the cross beam. Each first base is provided with a second driving mechanism and a third driving mechanism. The four-side saw comprises the wide-adjustable-range saw blade device. By the adoption of the four-side saw, the distance between the two cutting parts can be freely adjusted, plates with different width requirements can be machined, and the adjustable range is wide.

Owner:三倍机械科技(佛山)有限公司

A multifunctional cutting machine

ActiveCN109318278BRealize cutting processRetain removable installationMetal working apparatusStructural engineeringMechanical engineering

The invention provides a multifunctional cutting machine. A shaft seat plate of the multifunctional cutting machine is connected to the upper surface of a base. A speed adjuster is connected with theouter side of the shaft seat plate. Shaft bodies extend out from the two sides of the speed adjuster. The shaft bodies move and rotate. The shaft body on one side is an output shaft. The shaft body onthe other side is an input shaft. A rotating shaft is arranged at the midpoint of the side face of a cutter disk in a penetrating manner. An output shaft of the speed adjuster is in transmission connection with the rotating shaft of the cutter disk. A shaft seal assembly is arranged between the output shaft and the rotating shaft in a sleeving manner. A cutting cutter is embedded into the cutterdisk. When the multifunctional cutting machine is in use, vegetables and fruits are placed in a food groove, a push rod is pushed to push the vegetables and fruits to make contact with the cutter disk, and a handle of the speed adjuster is rotated, so that the output shaft of the speed adjuster is made to drive the rotating shaft to rotate, then the cutter disk is driven to rotate, and in this way, cutting machining of the vegetables and fruits is achieved. Therefore, time and effort are saved, and the work efficiency is high.

Owner:李聚稳

Cutting equipment for automobile aluminum alloy skylight frame

ActiveCN111185633ARapid positioningAvoid damageWork clamping meansLarge fixed membersMachiningPlunger

The invention provides cutting equipment for an automobile aluminum alloy skylight frame, and belongs to the technical field of automobile skylight machining. The cutting equipment comprises a positioning and clamping device and a cutting device, wherein the positioning and clamping device comprises a lower positioning and clamping mechanism and an upper clamping mechanism, the lower positioning and clamping mechanism comprises a positioning lifting platform, a positioning conical plunger, a clamping table and a lower clamping table lifting driving assembly, and the lower clamping table lifting driving assembly comprises an L-shaped swing rod set and a lifting driving set; the upper clamping mechanism comprises an upper fixing frame, an upper clamping lifting platform, an upper clamping air cylinder, an upper clamping guide assembly and an upper clamping table; and the cutting device comprises a left cutting mechanism, a right cutting mechanism and a cutting position adjusting drivingmechanism. According to the cutting equipment, the aluminum alloy skylight frame can be rapidly positioned and clamped, cutting machining of the aluminum alloy skylight frame is accurately and efficiently achieved, the cutting position is quite accurate, and the cutting effect is greatly improved.

Owner:ZHEJIANG ZHUOYI ALUMINUM

A kind of numerical control machine tool control method

ActiveCN109514347BVersatileIncrease flexibilityAutomatic control devicesFeeding apparatusNumerical controlControl engineering

The invention discloses a numerical control machine tool control method. The method comprises tool control and workpiece posture control. In tool posture control, X-direction horizontal movement of atool is controlled based on a sliding block and a guide rail mechanism; the tool is controlled to stretch and retract on the sliding block, and the tool feeding amount is controlled; and the angle ofa tool clamp is adjusted based on a rotating platform on the sliding block. In workpiece posture control, lifting and direction adjustment of a workpiece chuck are adjusted. The numerical control machine tool control method is easy to implement, good in flexibility and rich in function.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

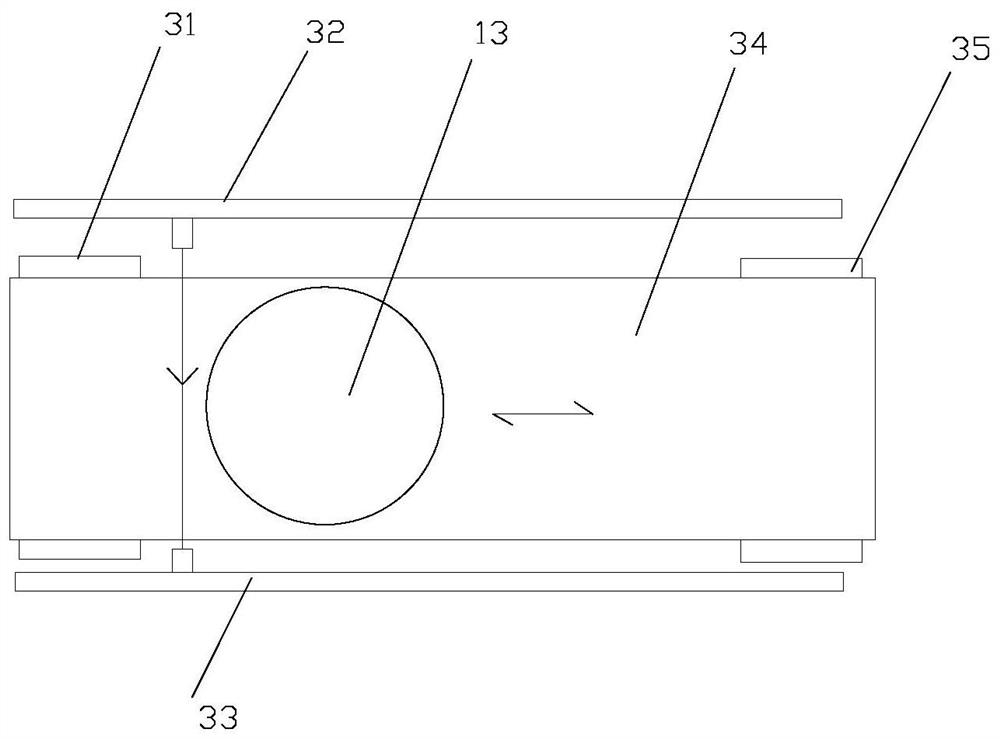

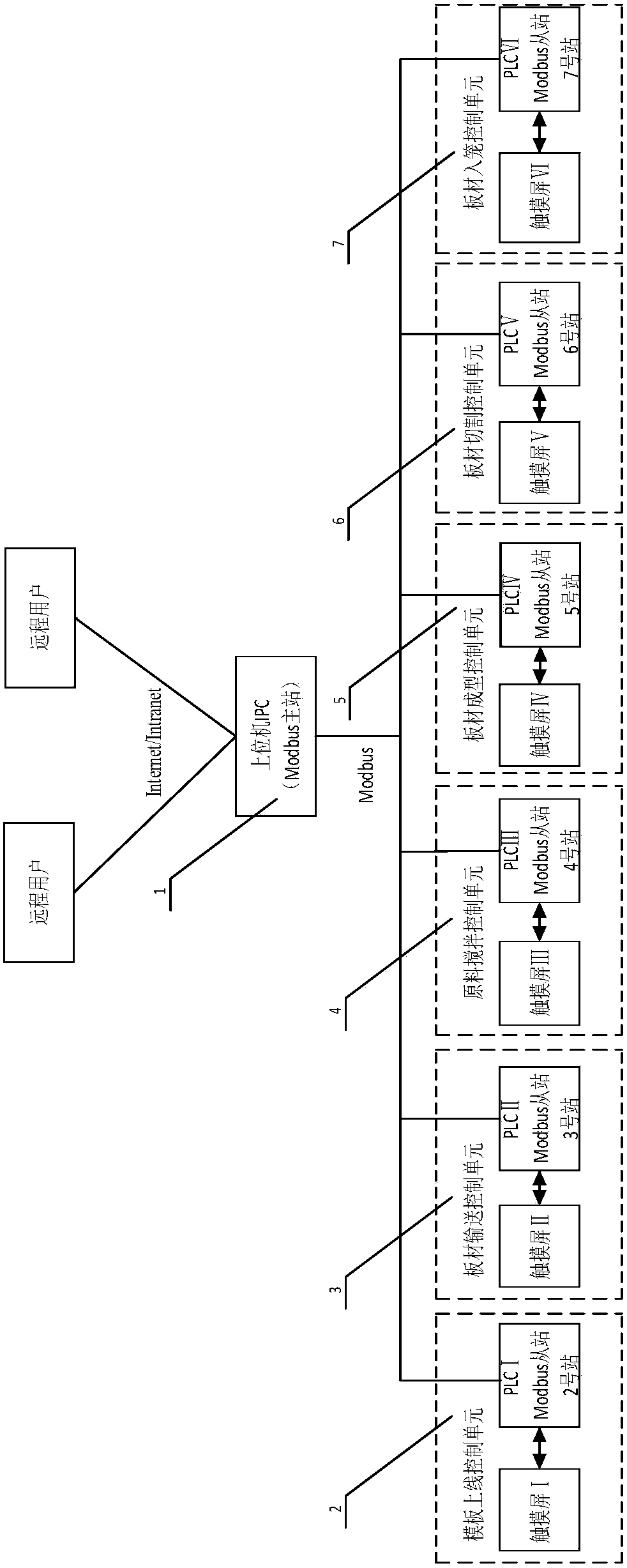

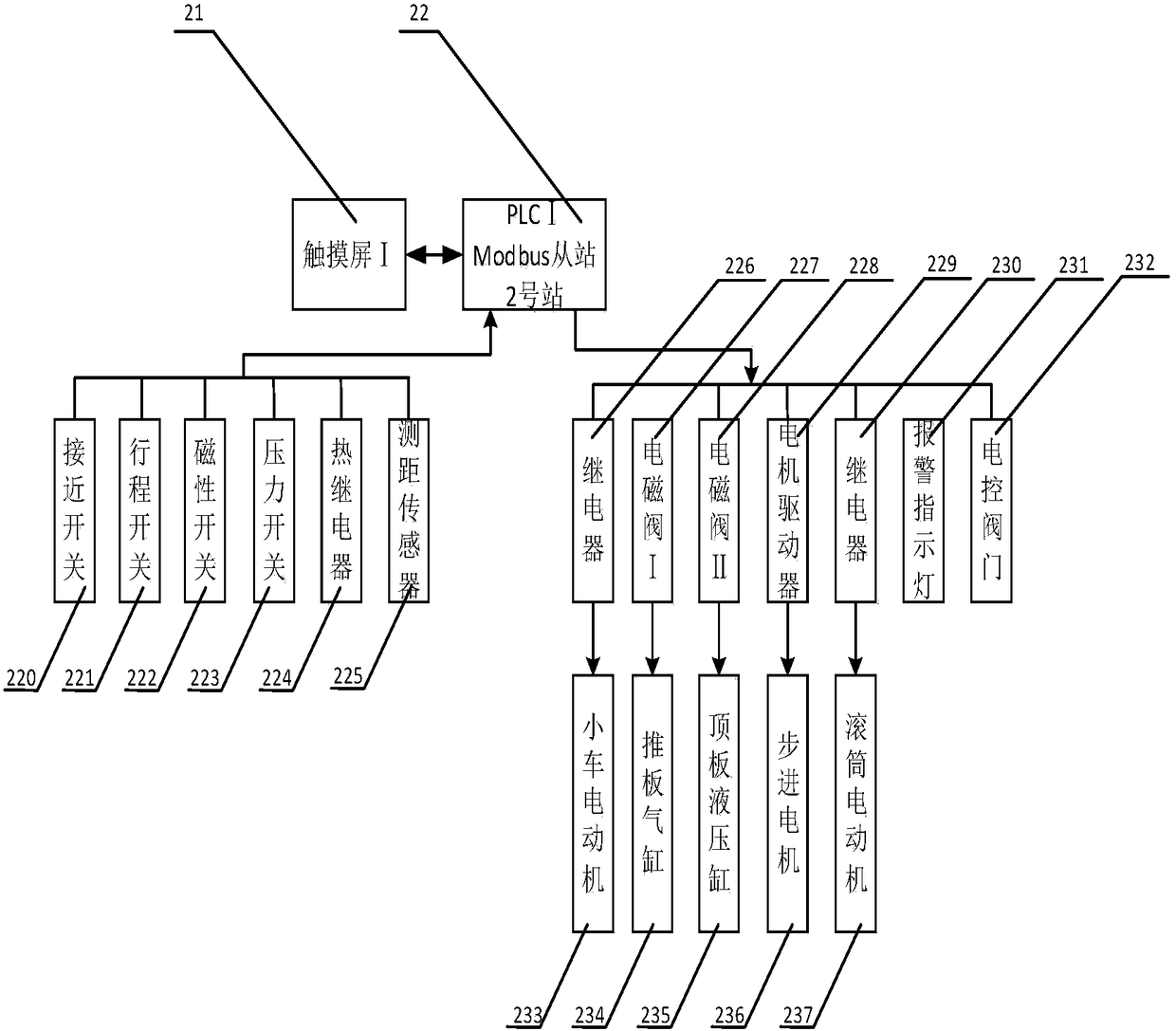

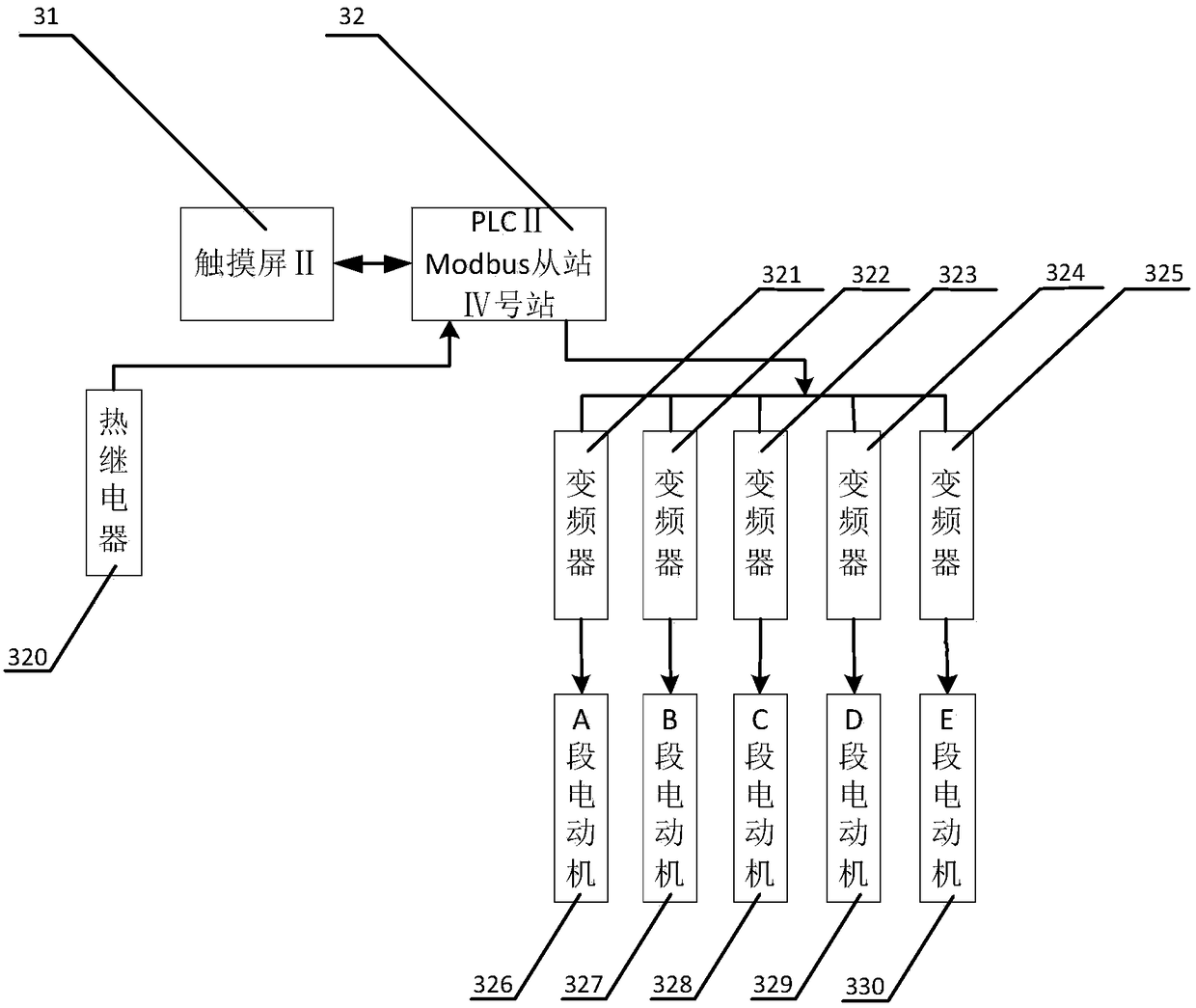

Distributed control system and control method of glass magnesium board production line

ActiveCN106020143BImprove reliabilityHigh degree of automationTotal factory controlProgramme total factory controlControl cellTouchscreen

Owner:JIANGSU UNIV OF SCI & TECH

Numerical control machine tool control method

ActiveCN109514347AVersatileIncrease flexibilityAutomatic control devicesFeeding apparatusNumerical controlMachine tool control

The invention discloses a numerical control machine tool control method. The method comprises tool control and workpiece posture control. In tool posture control, X-direction horizontal movement of atool is controlled based on a sliding block and a guide rail mechanism; the tool is controlled to stretch and retract on the sliding block, and the tool feeding amount is controlled; and the angle ofa tool clamp is adjusted based on a rotating platform on the sliding block. In workpiece posture control, lifting and direction adjustment of a workpiece chuck are adjusted. The numerical control machine tool control method is easy to implement, good in flexibility and rich in function.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

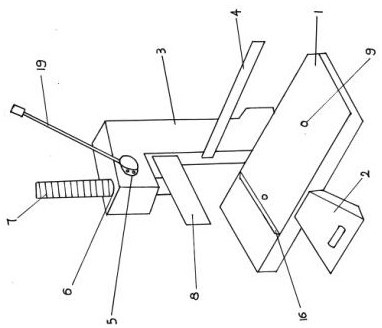

Field rapid and accurate cutting method for aerated concrete blocks

PendingCN112519009ARealize cutting processReduce volumeWorking accessoriesStone-like material working toolsGear wheelClassical mechanics

The invention discloses a field rapid and accurate cutting method for aerated concrete blocks. The problems that in existing field cutting of aerated concrete blocks, material waste is serious, and the cutting quality is poor are solved. A pedal tongue plate (2) and an inverted-L-shaped support (3) are connected to a rectangular base plate (1). A pair of supporting bearings (5) of a gear center shaft is arranged on a horizontal cantilever at the top end of the inverted-L-shaped support (3). A gear is arranged in the pair of supporting bearings (5) of the gear center shaft. A rack (7) movably penetrates through the horizontal cantilever at the top end of the inverted-L-shaped support (3) on the left side of the gear and is engaged with the gear. The lower end of the rack (7) is connected with an upper block cutting blade (8). The outer side end of a gear shaft is connected with a gear rotation manual rocker (19). A lower block cutting positioning blade (16) is movably arranged on the top end face of the rectangular base plate (1). Cutting machining of the blocks with the special shape requirement is achieved.

Owner:SHANXI NO 3 CONSTR ENG

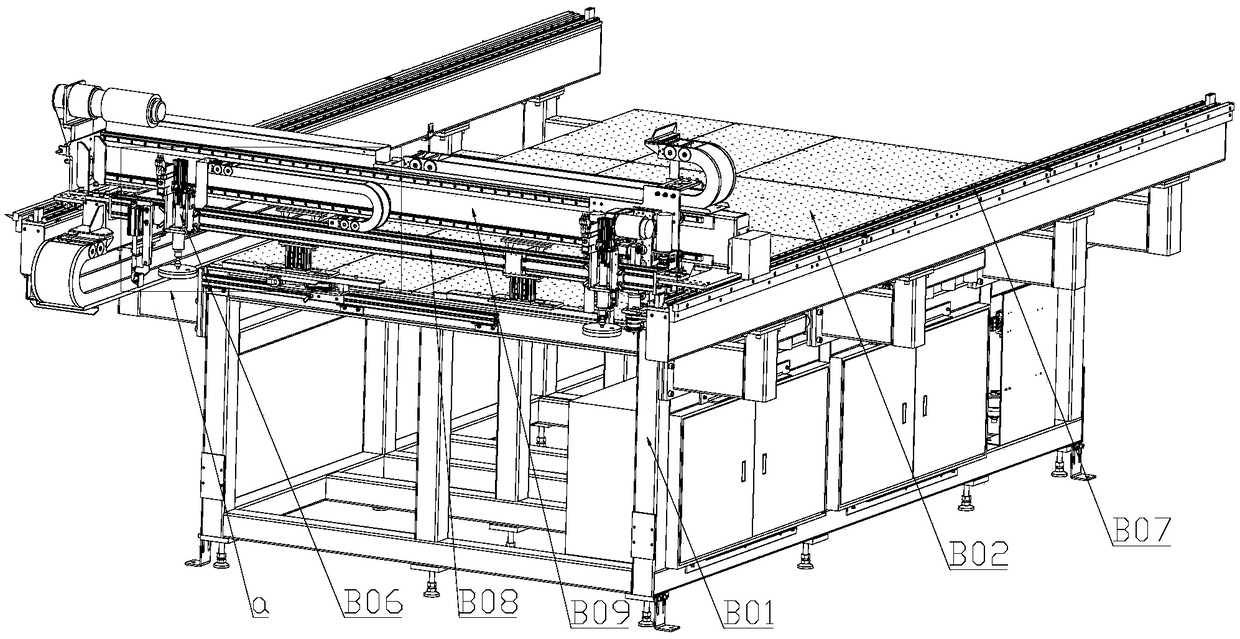

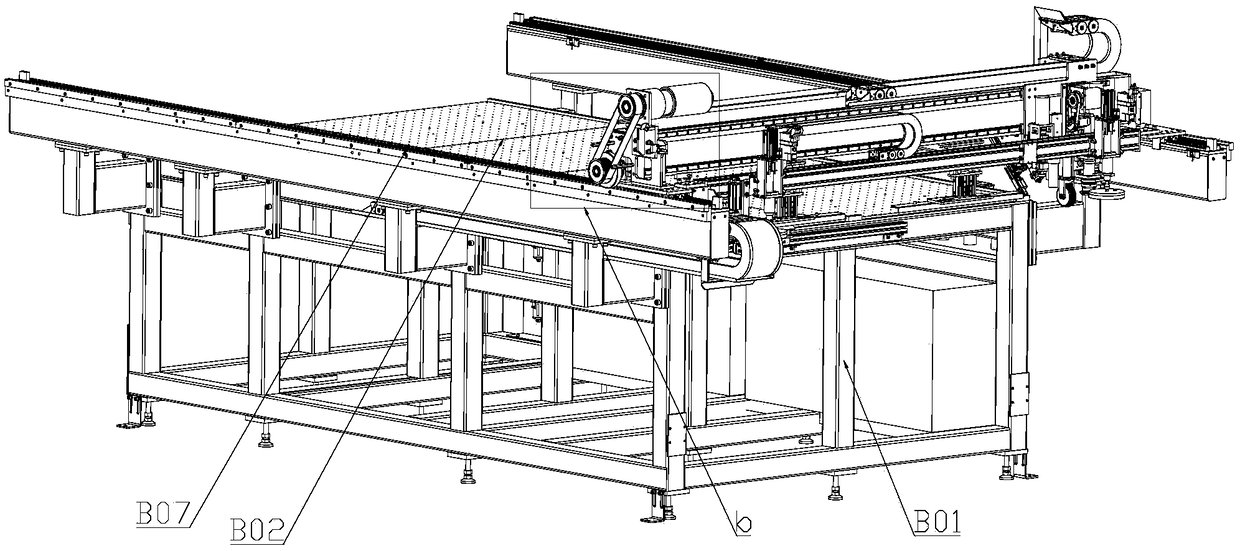

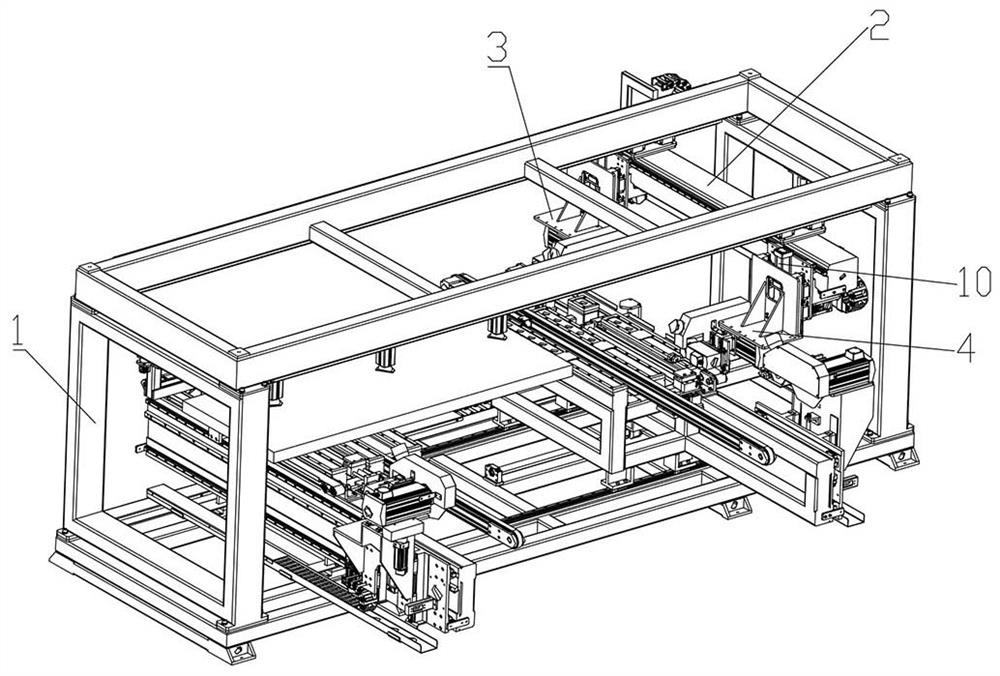

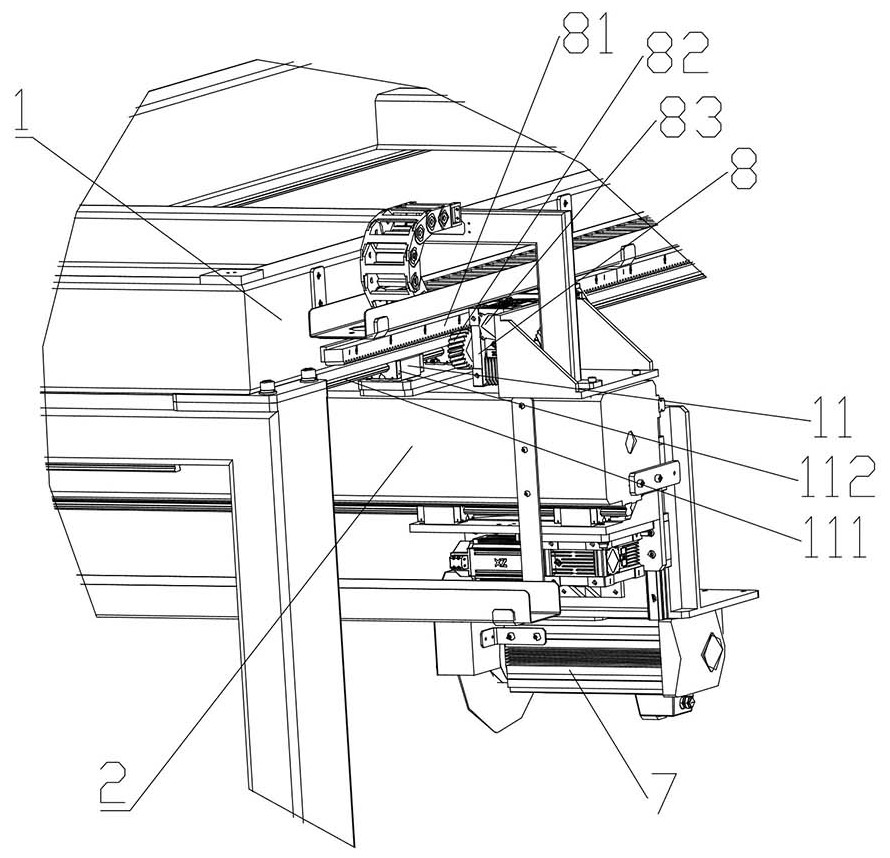

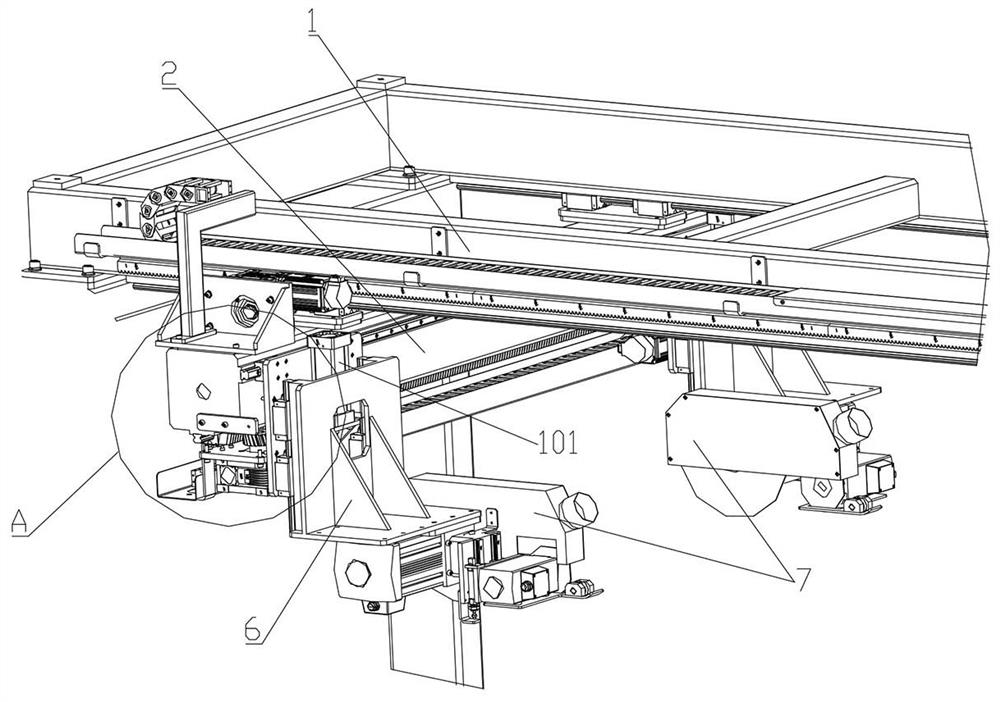

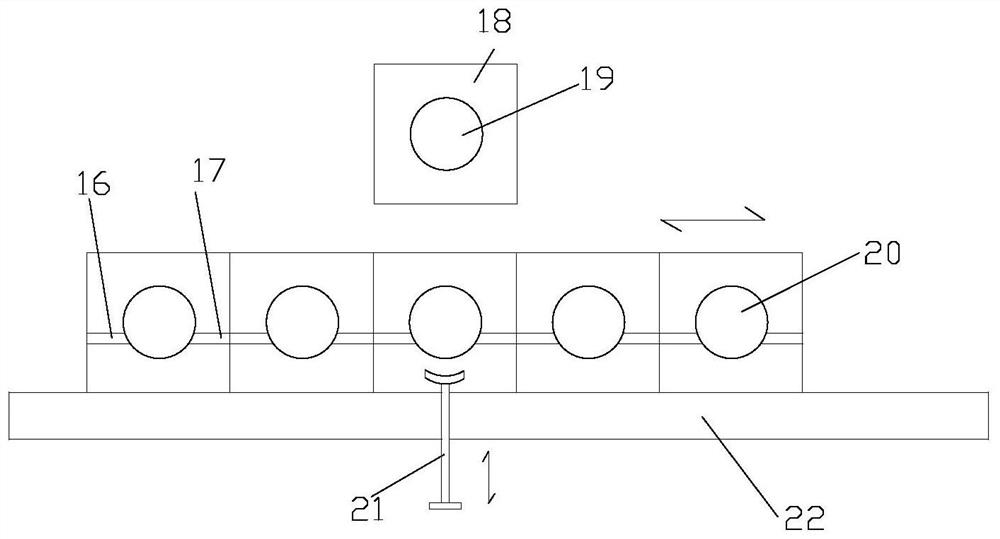

Laser cutting workbench and laser cutting system

ActiveCN112872627AHigh degree of automationImprove processing efficiencyLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a laser cutting workbench and a laser cutting system. The workbench comprises a platform assembly and a control assembly. The platform assembly comprises a platform base, a first cutting workbench, a second cutting workbench, a first workbench driving assembly and a second workbench driving assembly, wherein the first cutting workbench and the second cutting workbench are symmetrically arranged on the platform base, and the first workbench driving assembly and the second workbench driving assembly are arranged on the platform base and used for driving the first cutting workbench and the second cutting workbench to move in the long axis direction of the platform base. The control assembly comprises a control module. The control module is used for controlling the first workbench driving assembly and the second workbench driving assembly to act so as to drive the first cutting workbench and the second cutting workbench to move independently or alternately or drive the first cutting workbench and the second cutting workbench to be spliced into a large workbench and move. A single-station mode, a double-station mode and a large-size part cutting mode can be provided. The automation degree is high, the laser cutting machining efficiency can be improved, and meanwhile the requirement for cutting machining of large-size parts can be met.

Owner:浙江大捷智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com