Patents

Literature

613 results about "Machine tool control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

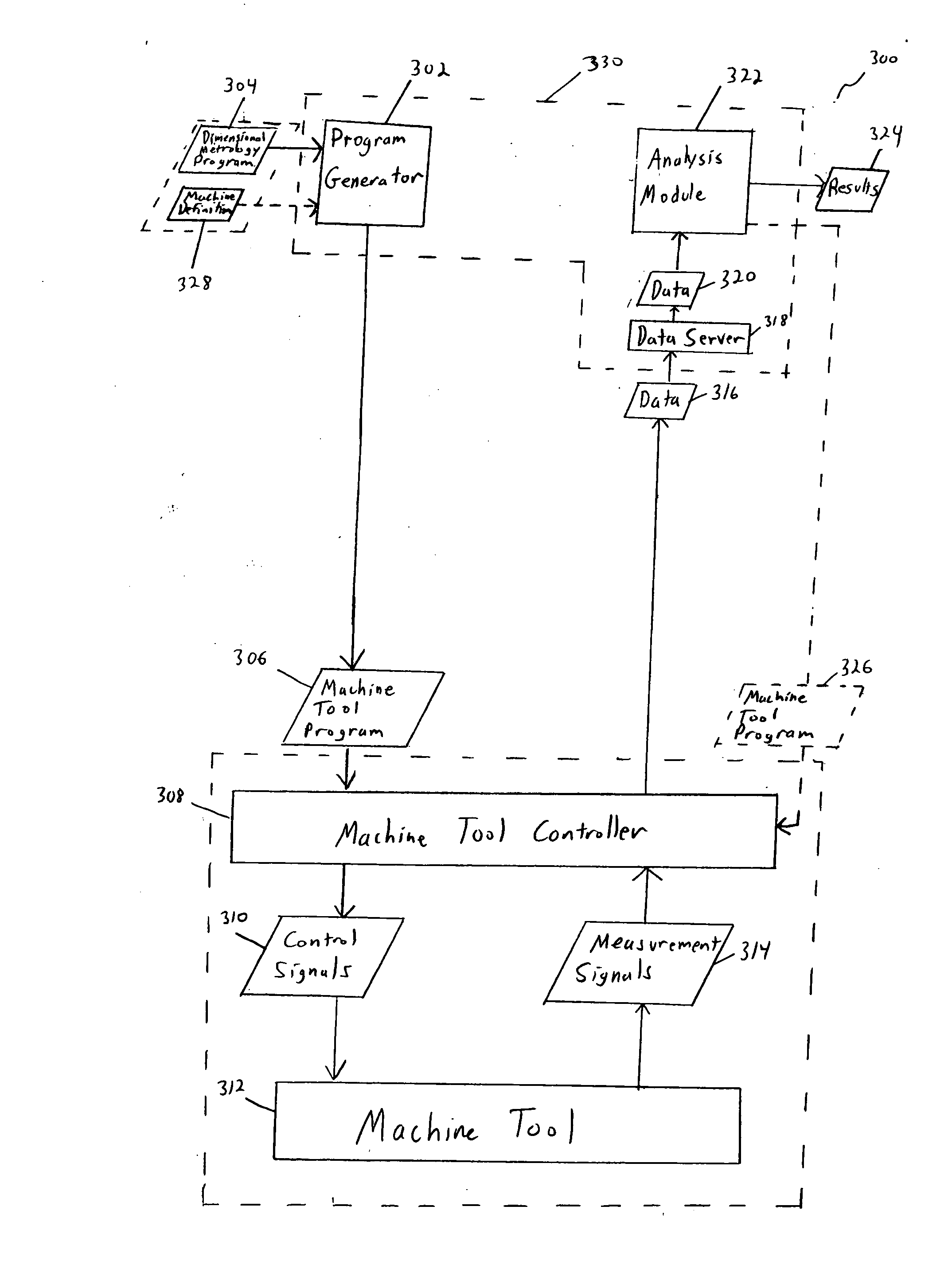

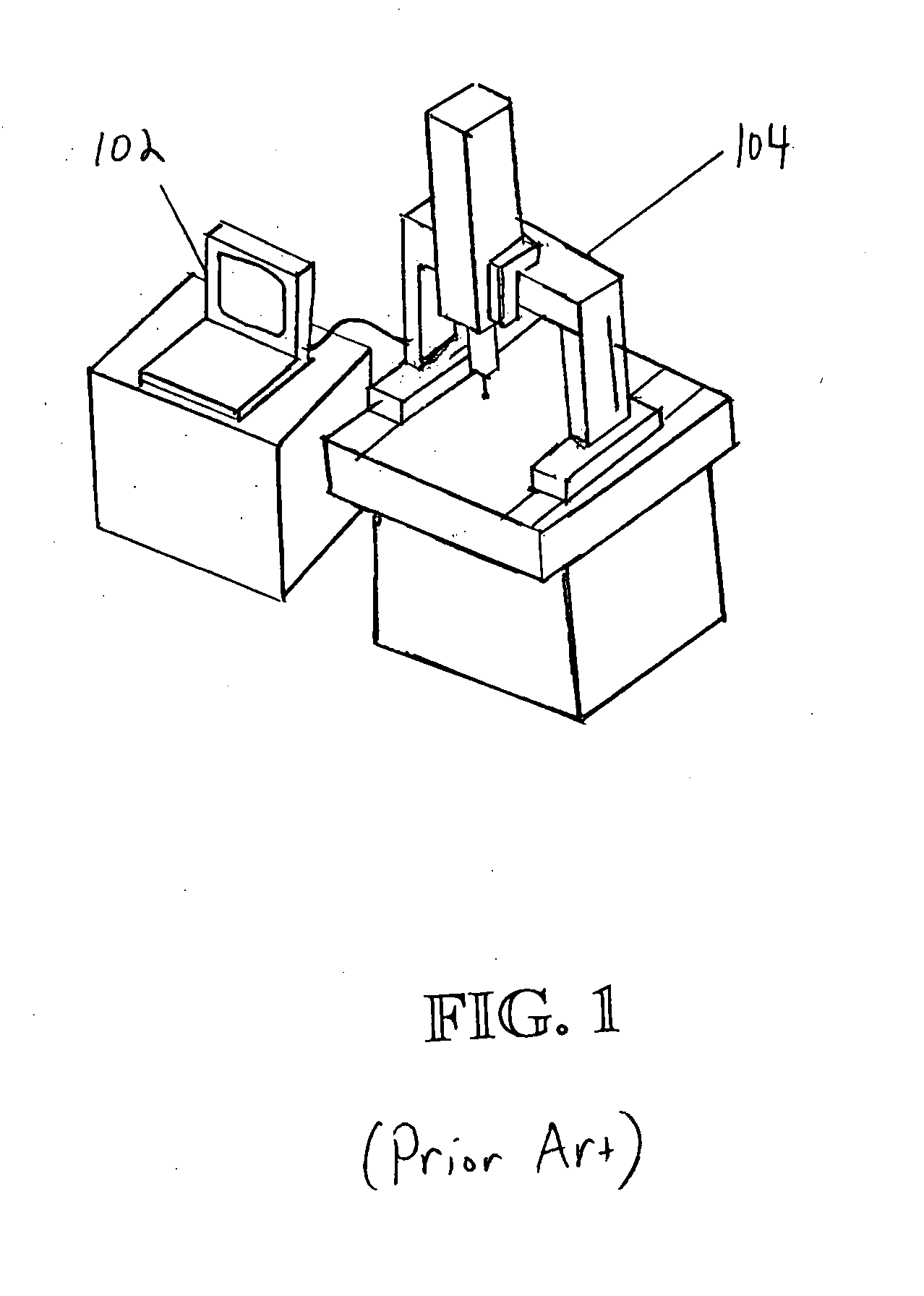

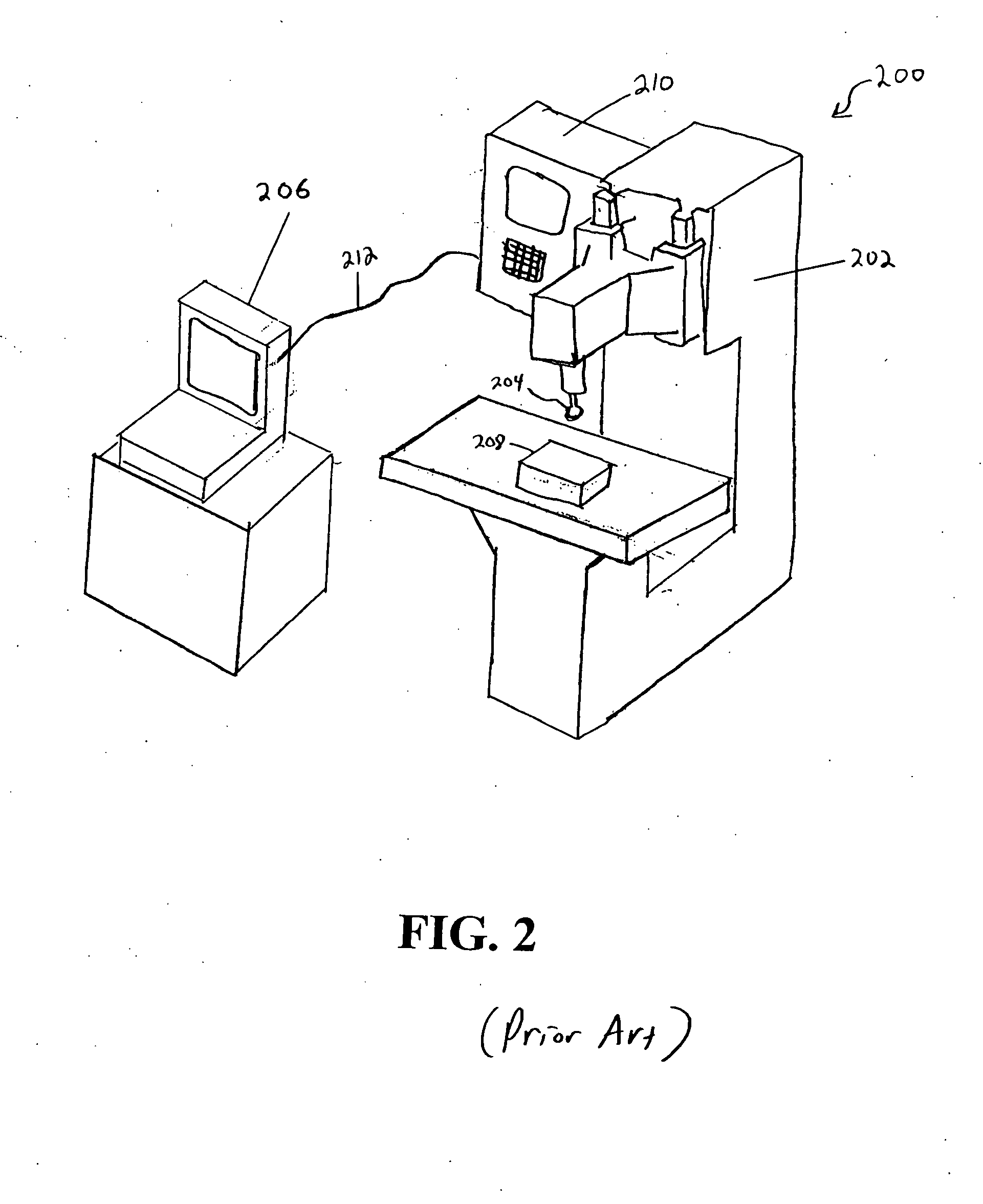

Apparatus and method for dimensional metrology

Generating a machine tool program for performing coordinate measurements. The machine tool program may be communicated to a machine tool controller such that the machine tool controller is operable to execute the machine tool program. The machine tool program may be generated from a dimensional metrology program. As part of generating the machine tool program, a path definition and a machine definition may be combined. Measurement data resulting from an execution of the machine tool program may be received by a data server and analyzed using dimensional metrology analysis. Indicators may be provided within the machine tool program to be used during dimensional metrology analysis.

Owner:HEXAGON TECH CENT GMBH

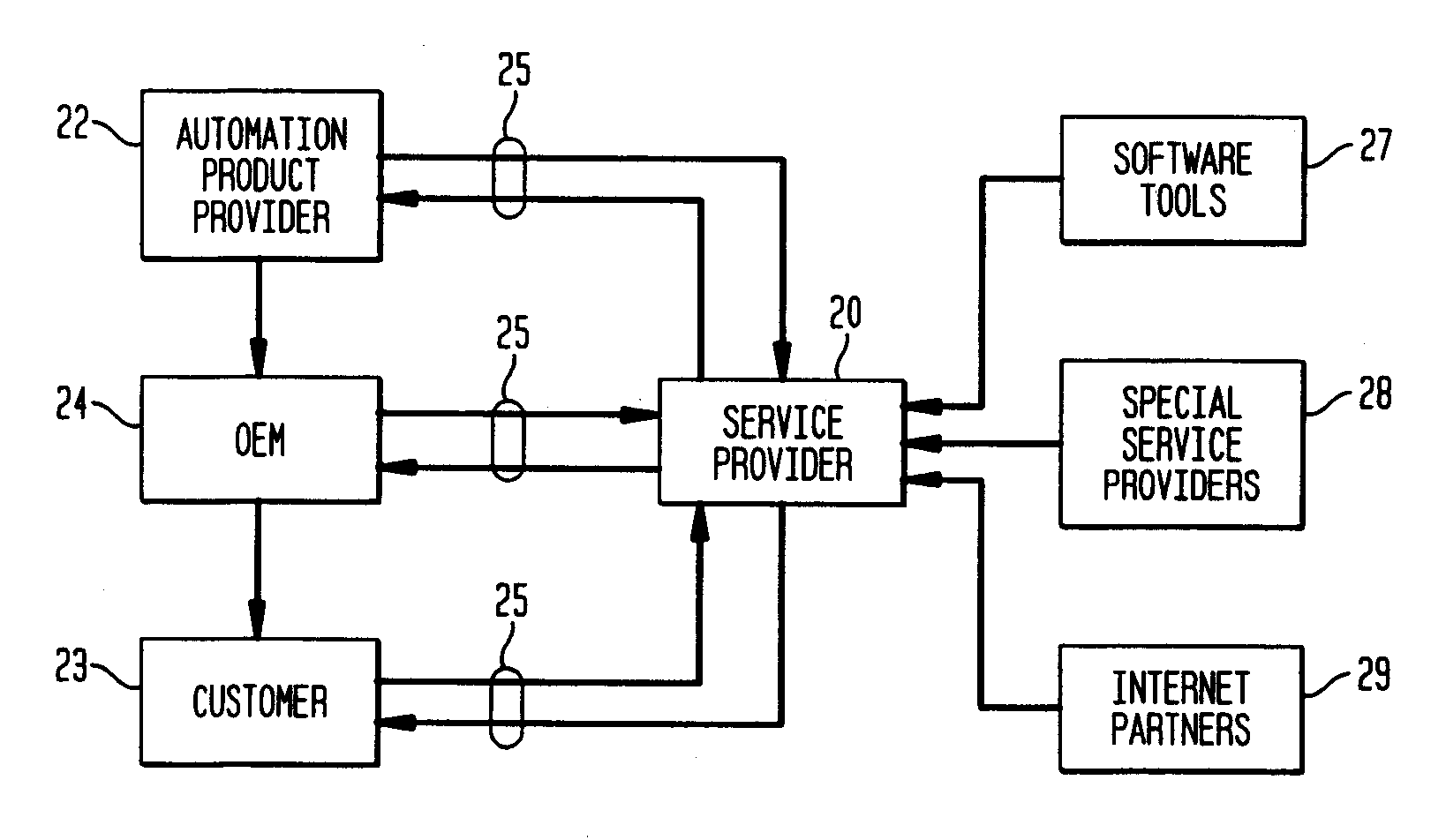

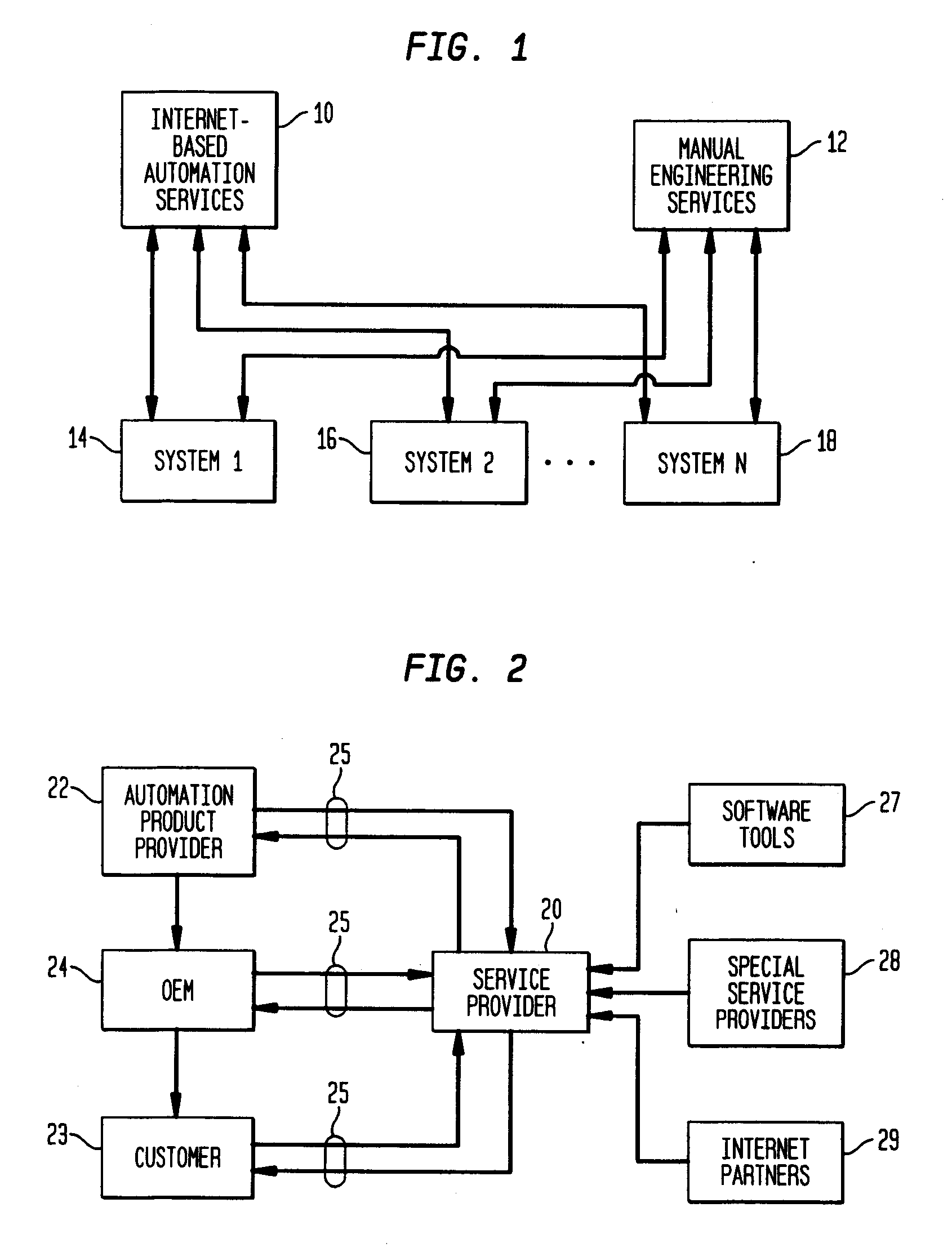

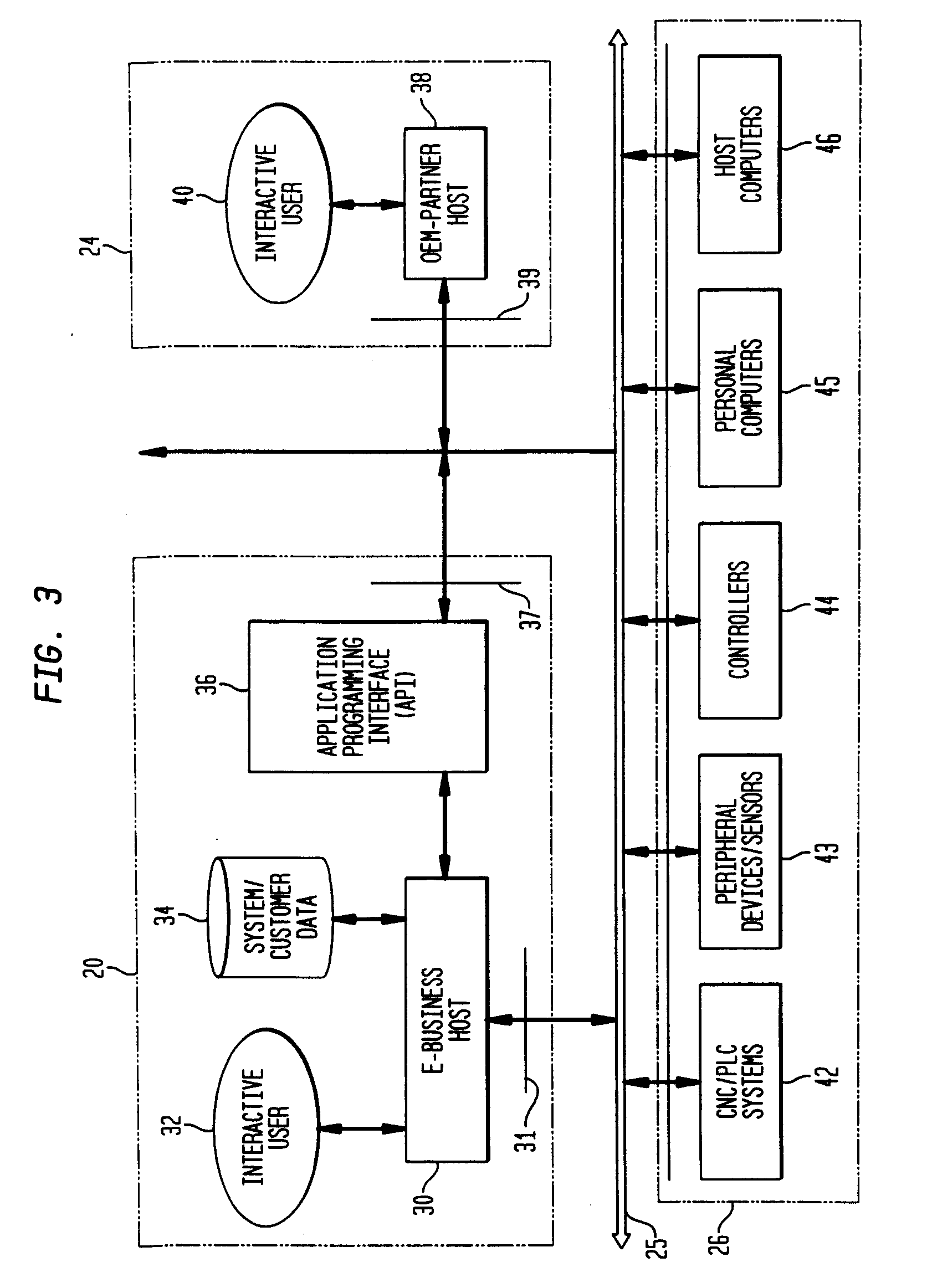

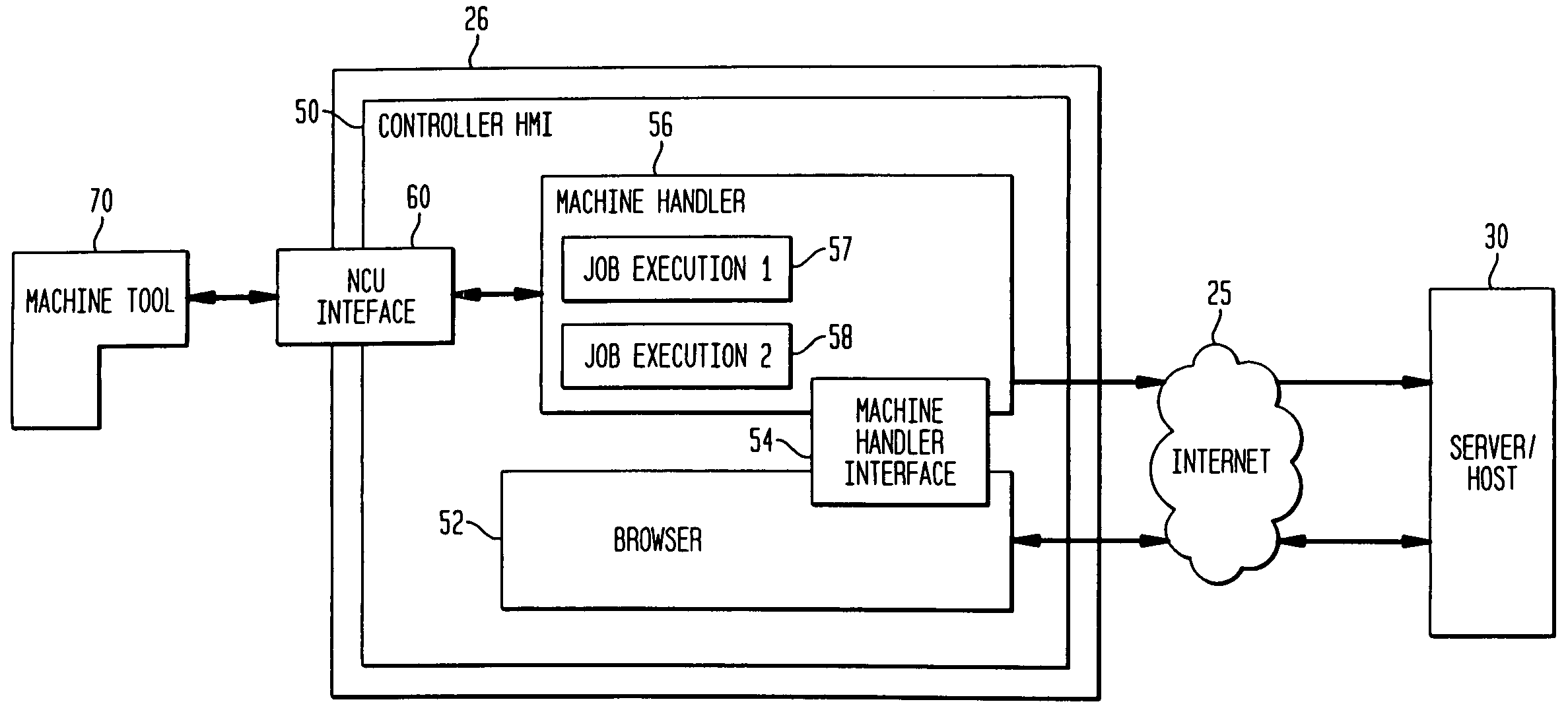

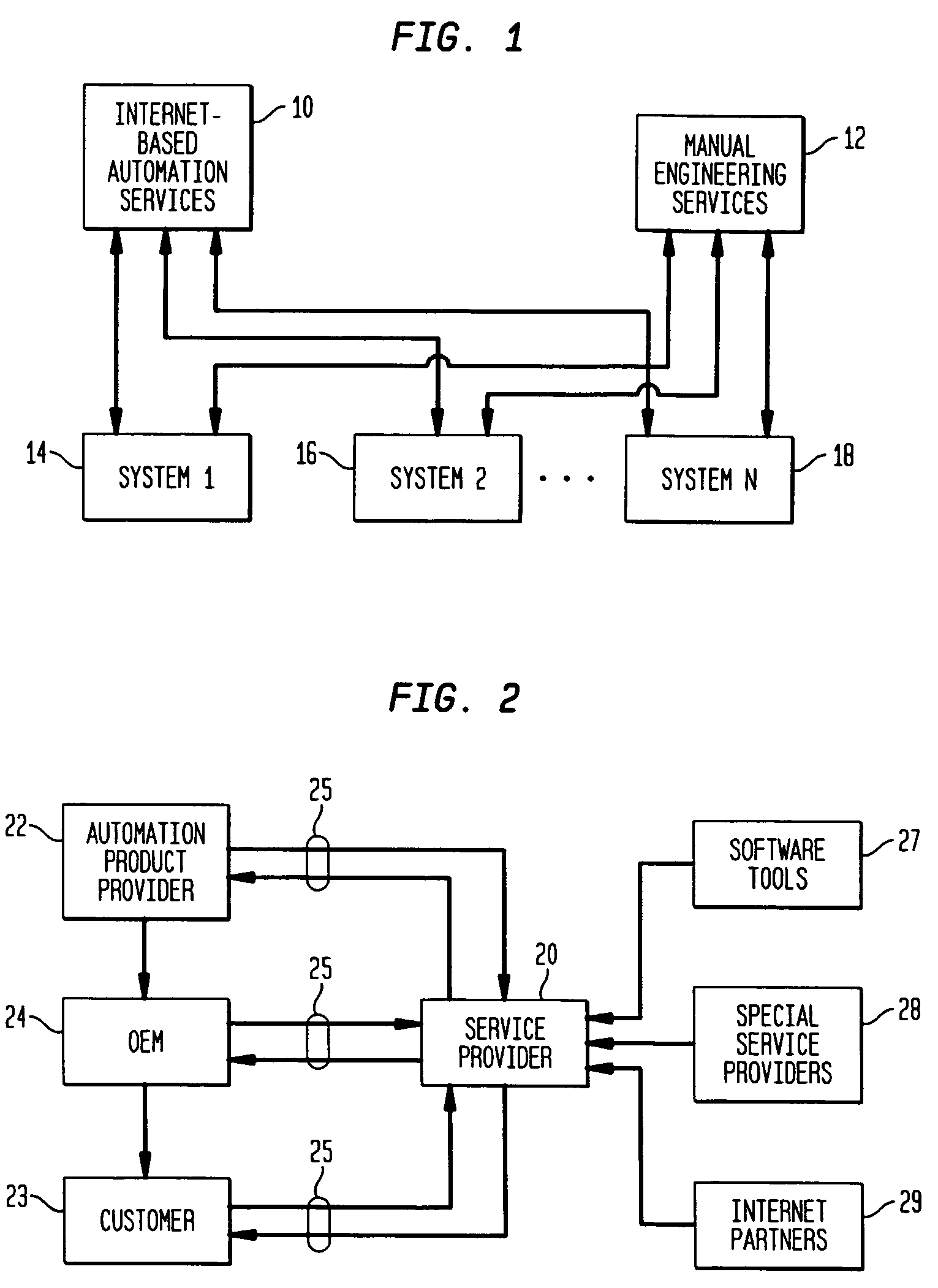

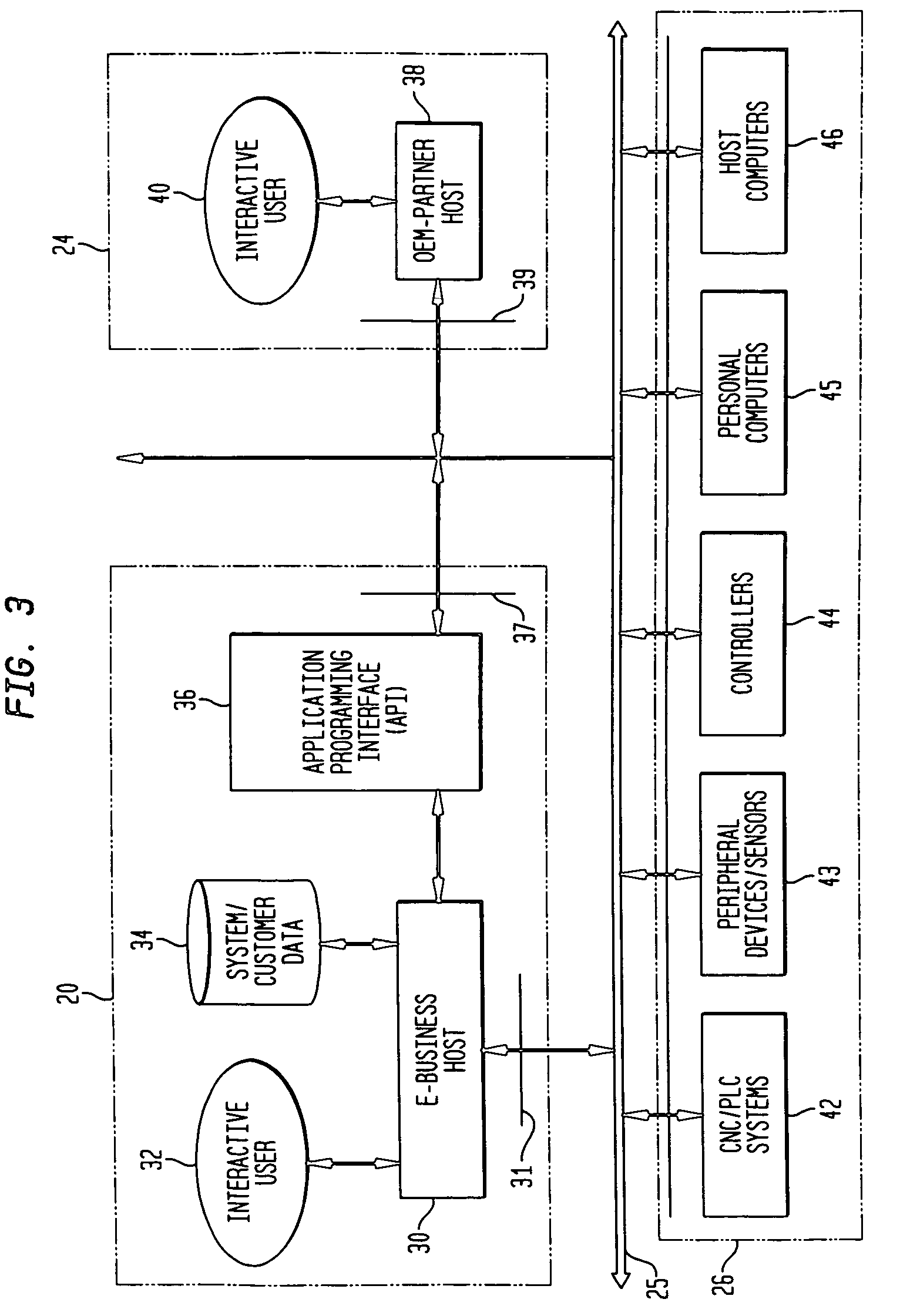

System architecture and method for network-delivered automation-related content

InactiveUS20070129826A1Improve securityProgramme controlComputer controlReal-time dataControl system

Content is generated on a host system based on real-time data from a controlled process collected over the internet from a customer's client automation system, such as a machine tool control system. The client system may request content from a host website. Instructions associated with the requested content, which may be in the form of software to be run on the client, is delivered to the client via download over the internet. The client, executing the software, captures real-time data associated with a controlled process and transmits it to the host, where content based on the data can be generated for the client and / or its owner. Data gathered by the host, and content generated on the basis of the data, may be made accessible to machine tool manufacturers. Also, data received by the host is associated with an identifier defined for each client system. A historical database for given client equipment can thereby be created.

Owner:KREIDLER VOLKER +2

Power distribution expert system

Content is generated on a host system based on real-time data from a controlled process collected over the internet from a customer's client automation system, such as a machine tool control system. The client system may request content from a host website. Instructions associated with the requested content, which may be in the form of software to be run on the client, is delivered to the client via download over the internet. The client, executing the software, captures real-time data associated with a controlled process and transmits it to the host, where content based on the data can be generated for the client and / or its owner. Data gathered by the host, and content generated on the basis of the data, may be made accessible to machine tool manufacturers. Also, data received by the host is associated with an identifier defined for each client system. A historical database for given client equipment can thereby be created.

Owner:SIEMENS AG

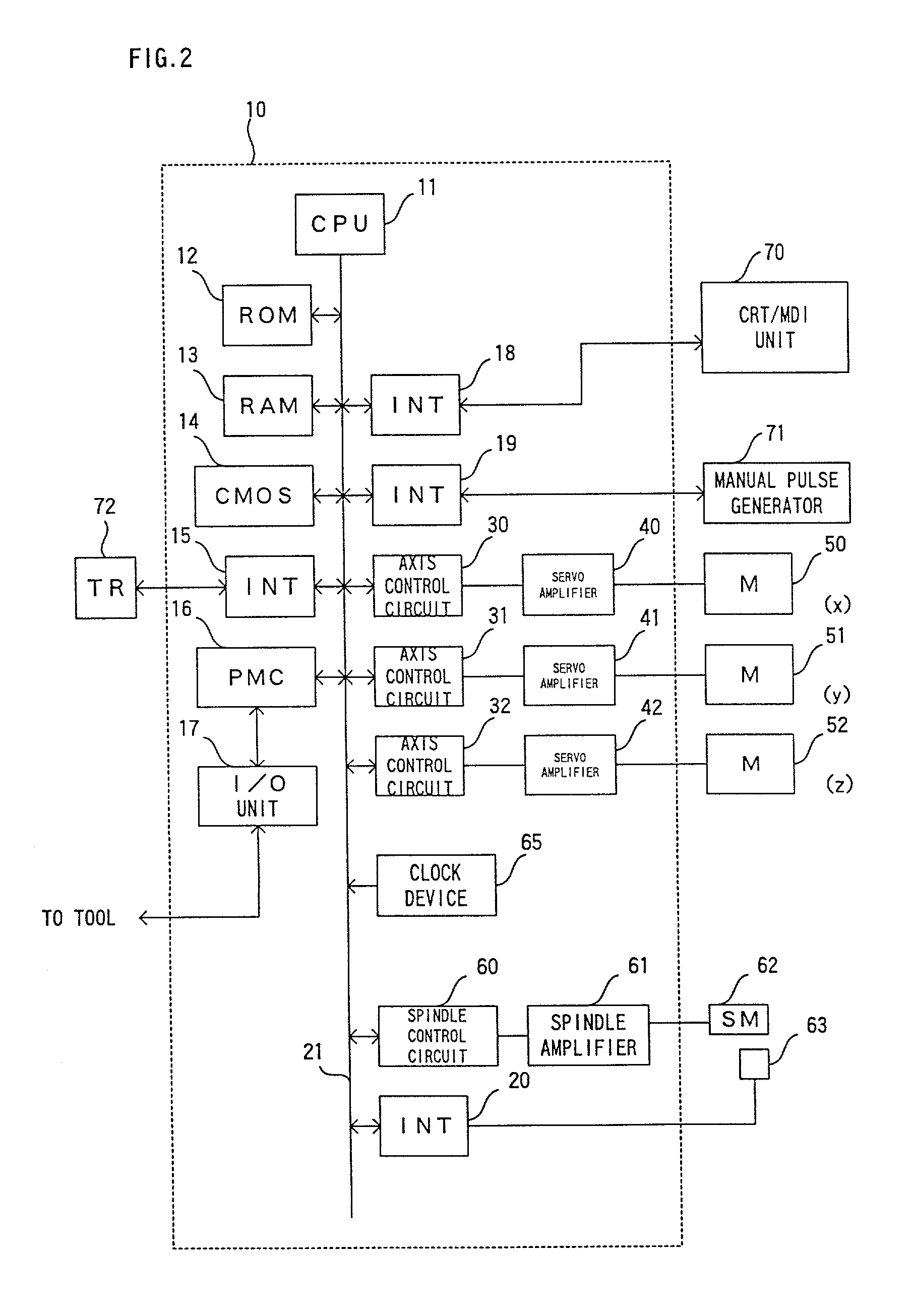

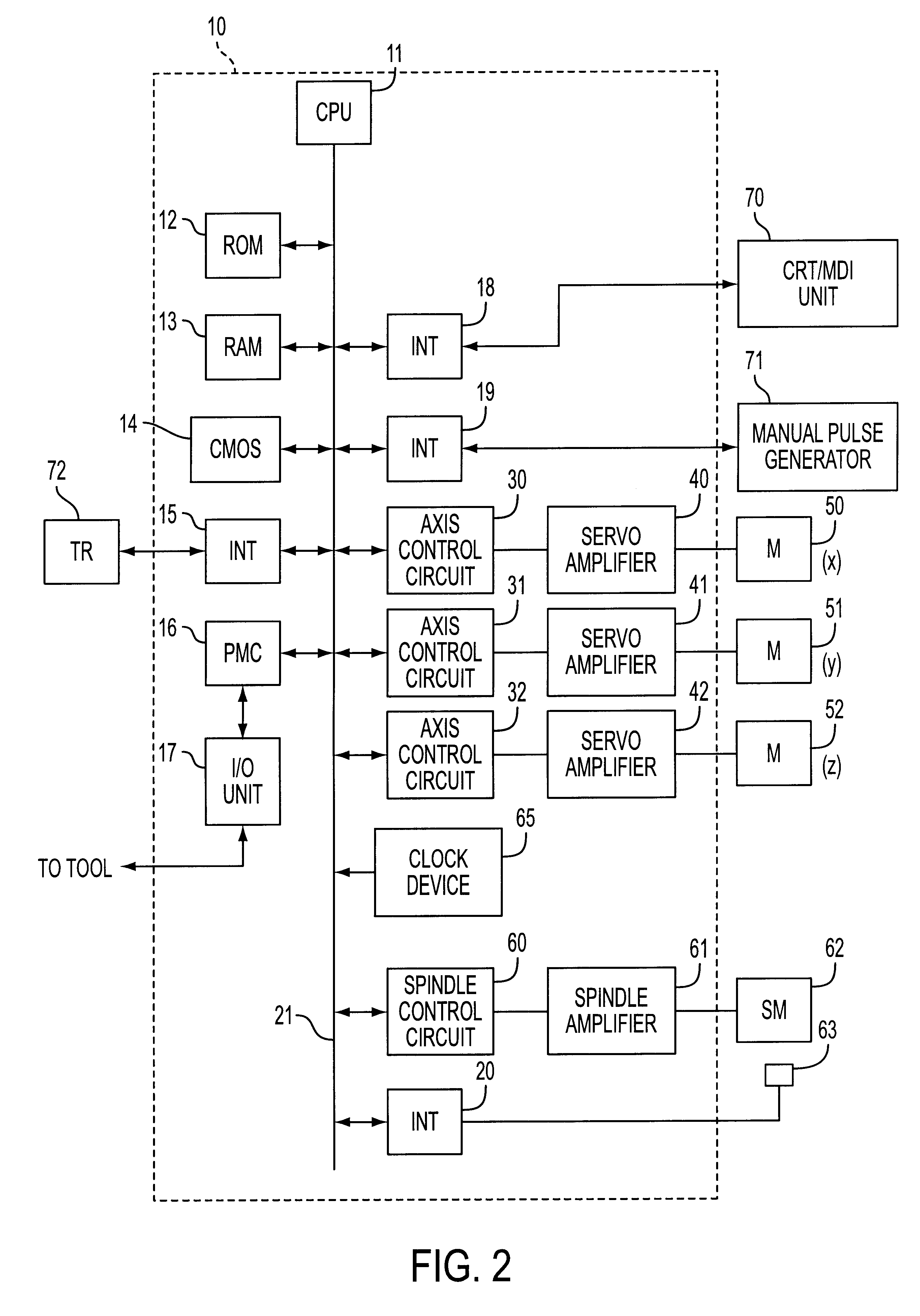

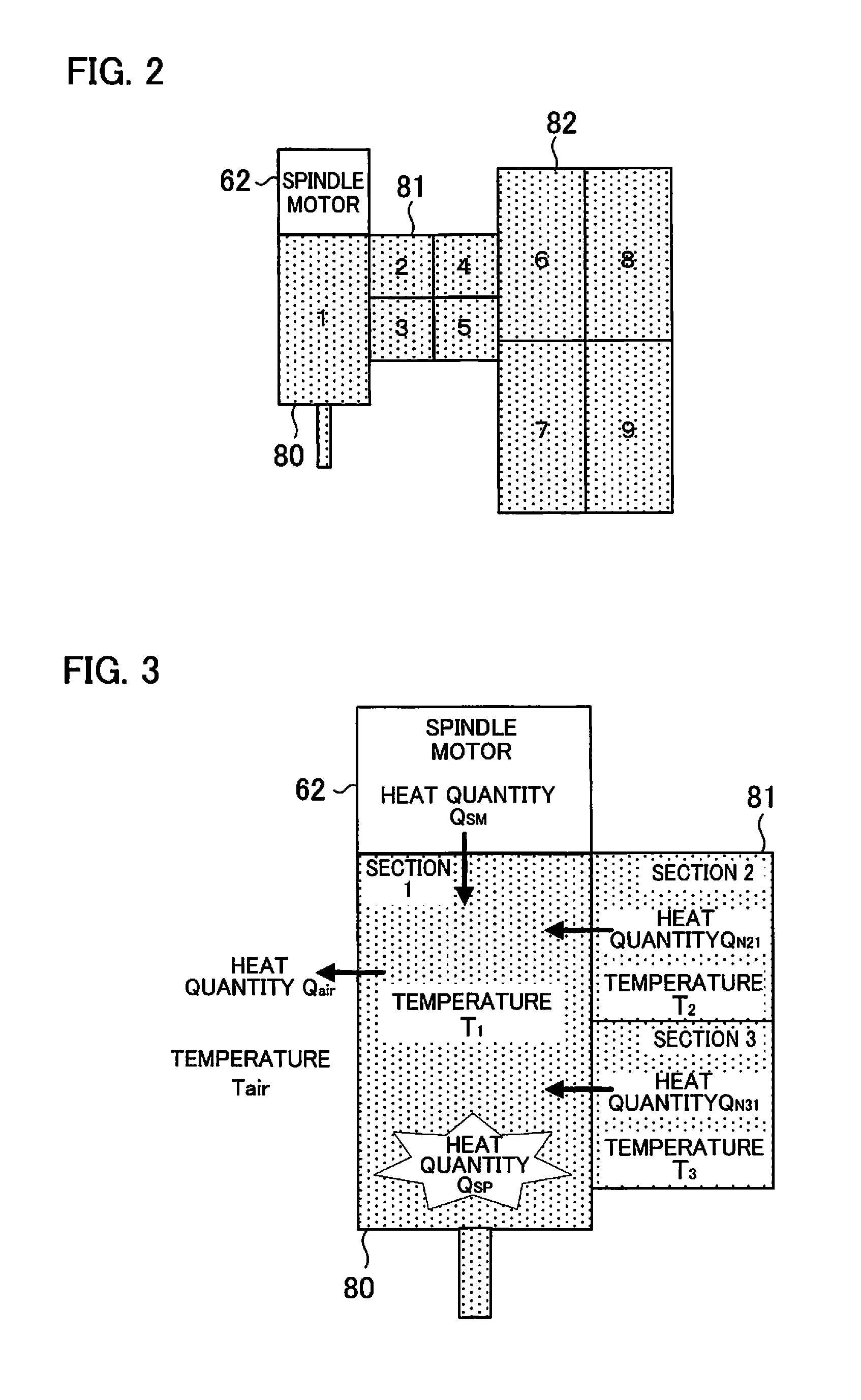

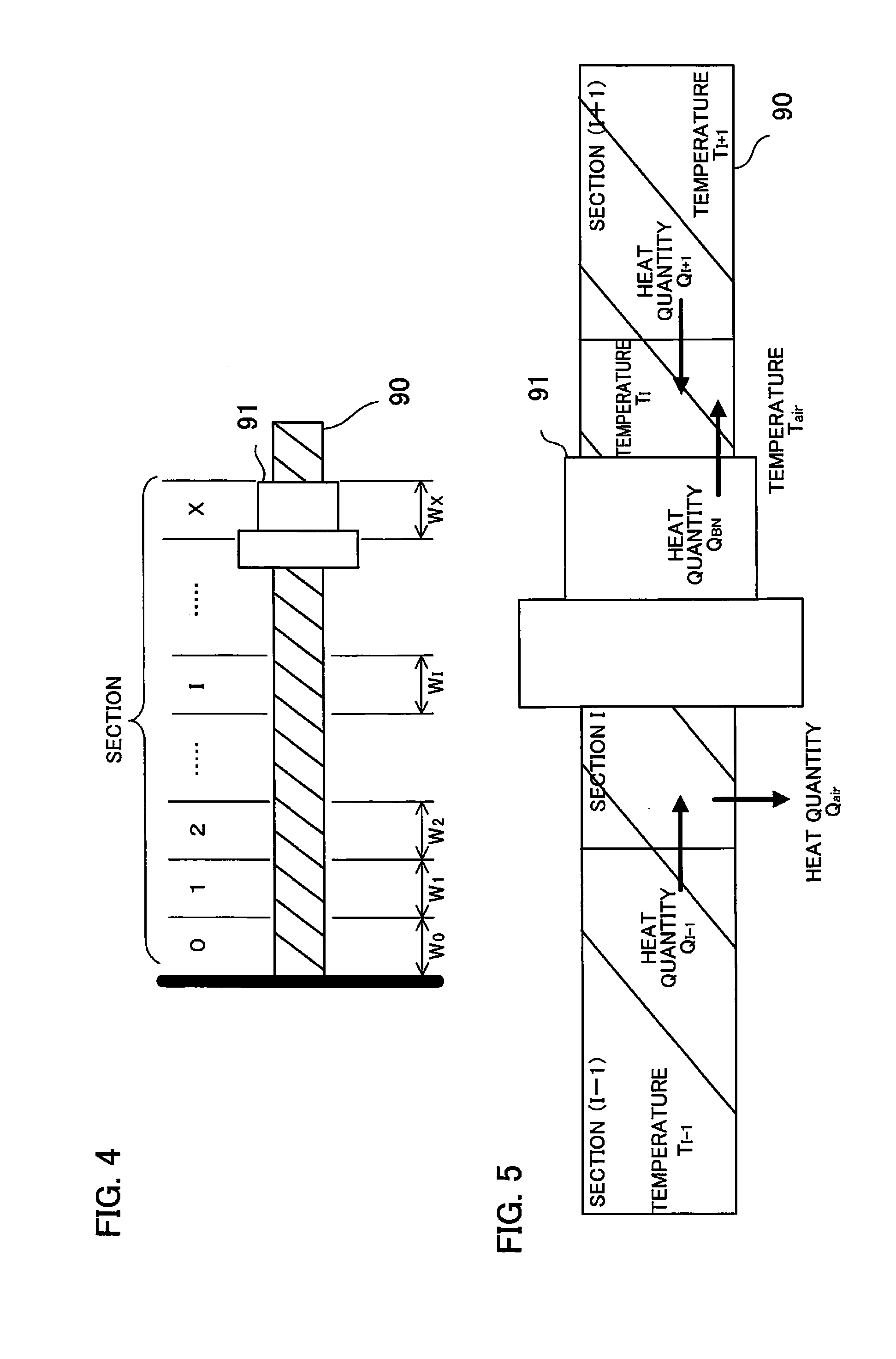

Method of correcting thermal displacement of machine tool

InactiveUS20020004688A1Thermal displacement can be easilyLow costDC motor speed/torque controlTemperatue controlNumerical controlMachine tool control

In a machine tool controlled by using a numerical control device, a correction amount is determined for thermal displacement due to heat generation and heat conduction in a spindle motor and a feed shaft motor, in addition to thermal displacement due to heat generated by rotation of a spindle and a feed shaft. A tool position is corrected based on the correction amount. An entire stroke of the feed shaft is divided into a finite number of sections, and for each section, a correction amount for thermal displacement due to axial movement of the feed shaft is determined. The tool position is corrected based on the determined correction amount.

Owner:FANUC LTD

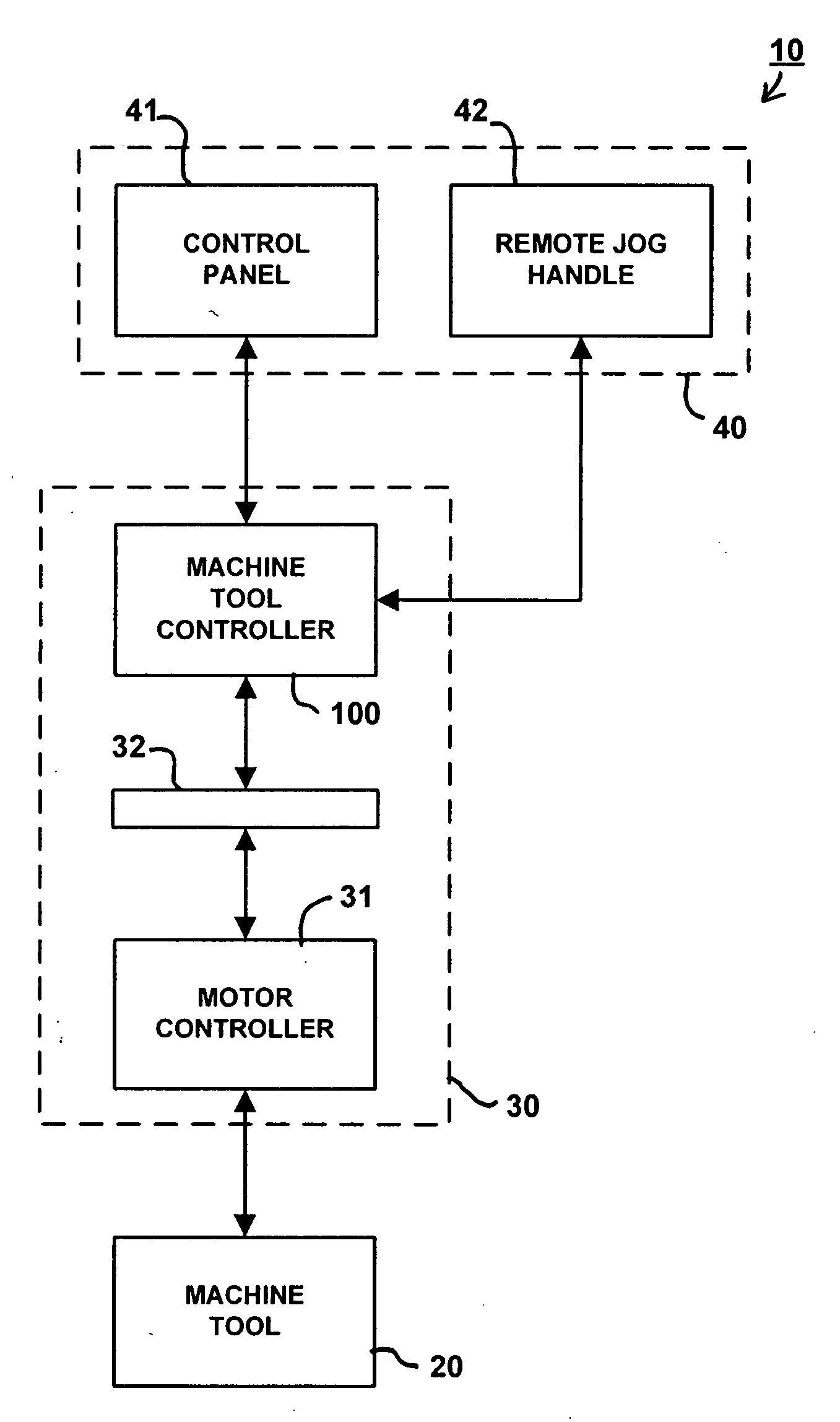

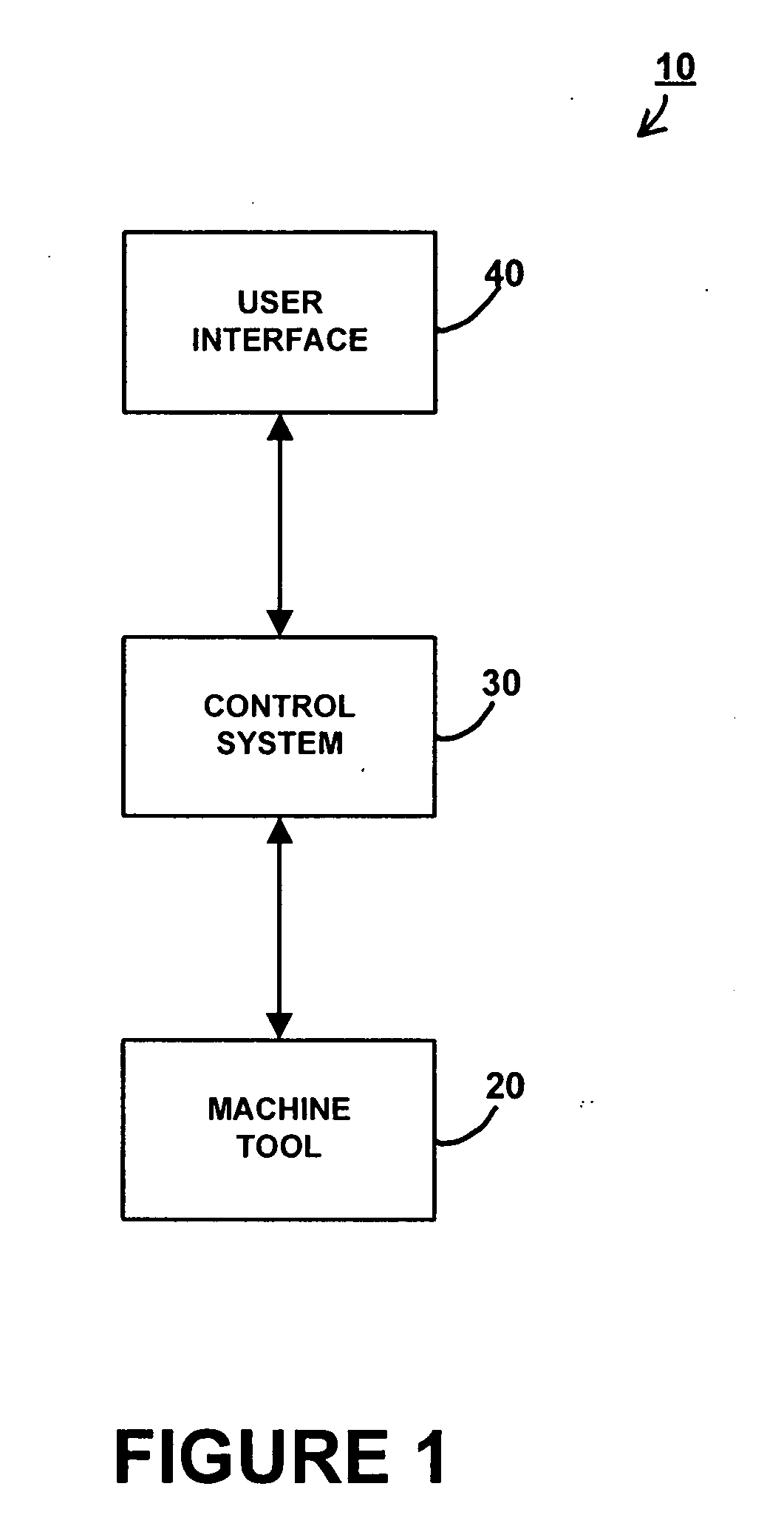

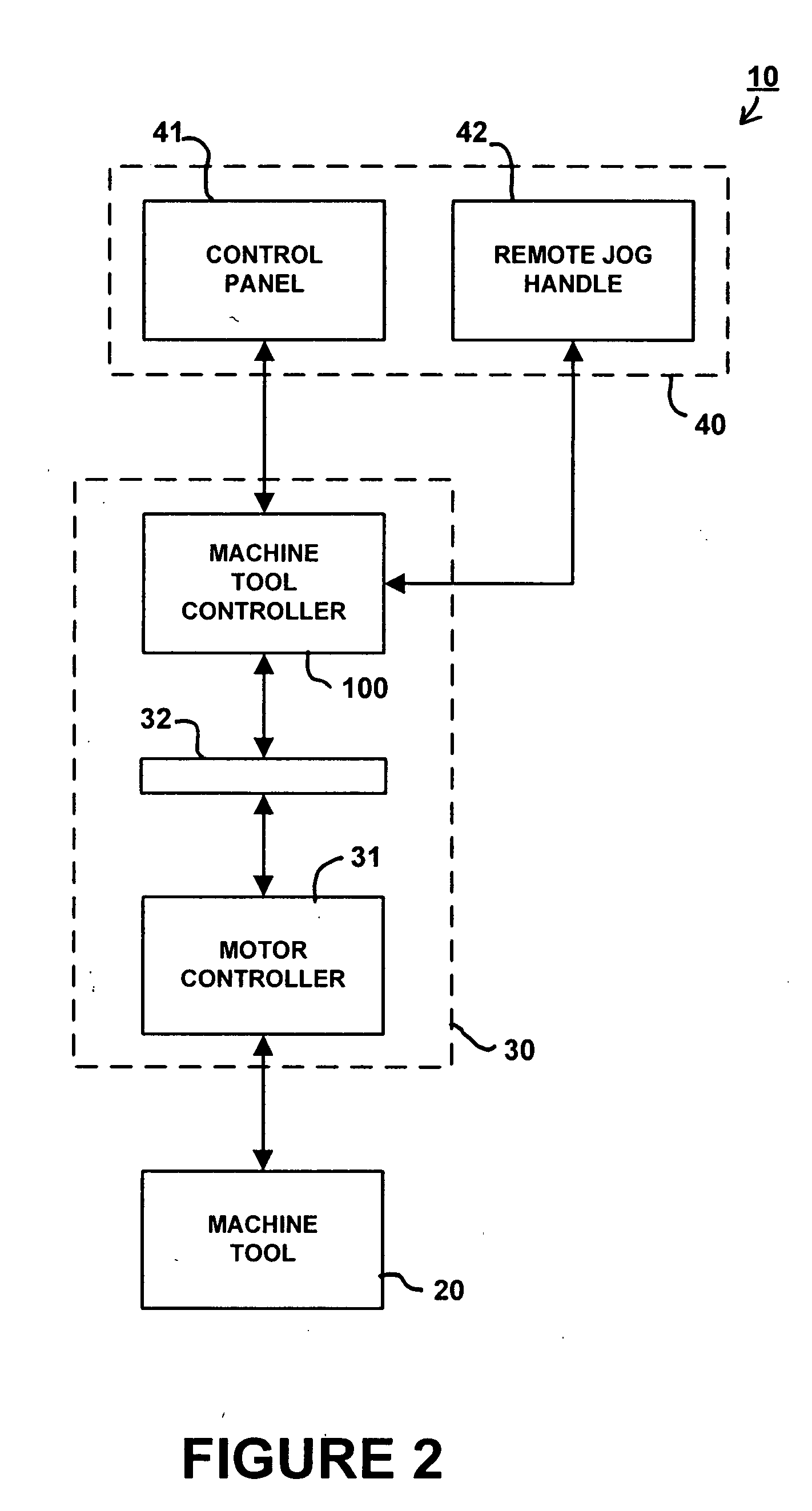

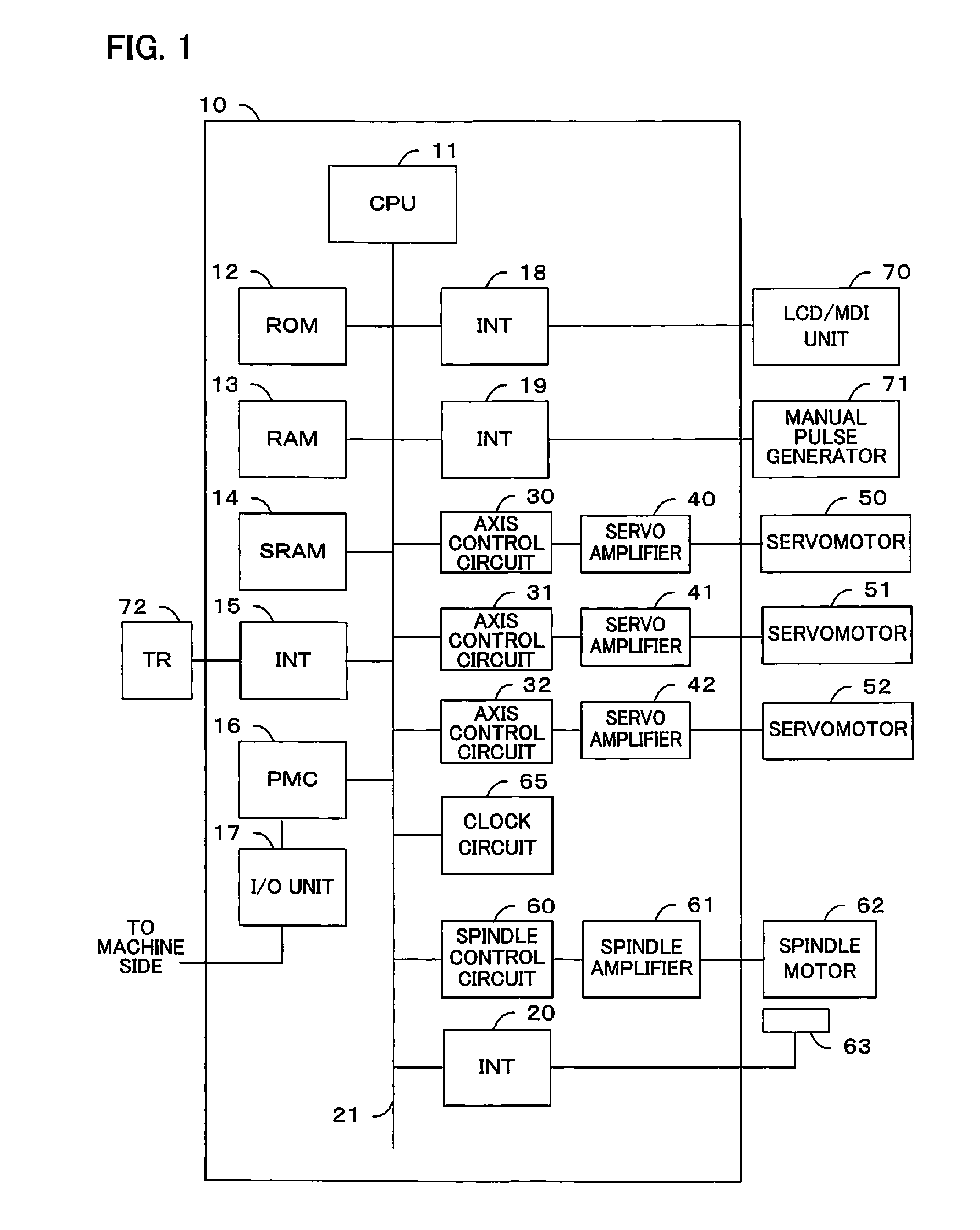

Machine tool control system

InactiveUS7949422B1Reduce complexityIncrease flexibilityProgramme controlComputer controlOperator interfaceControl system

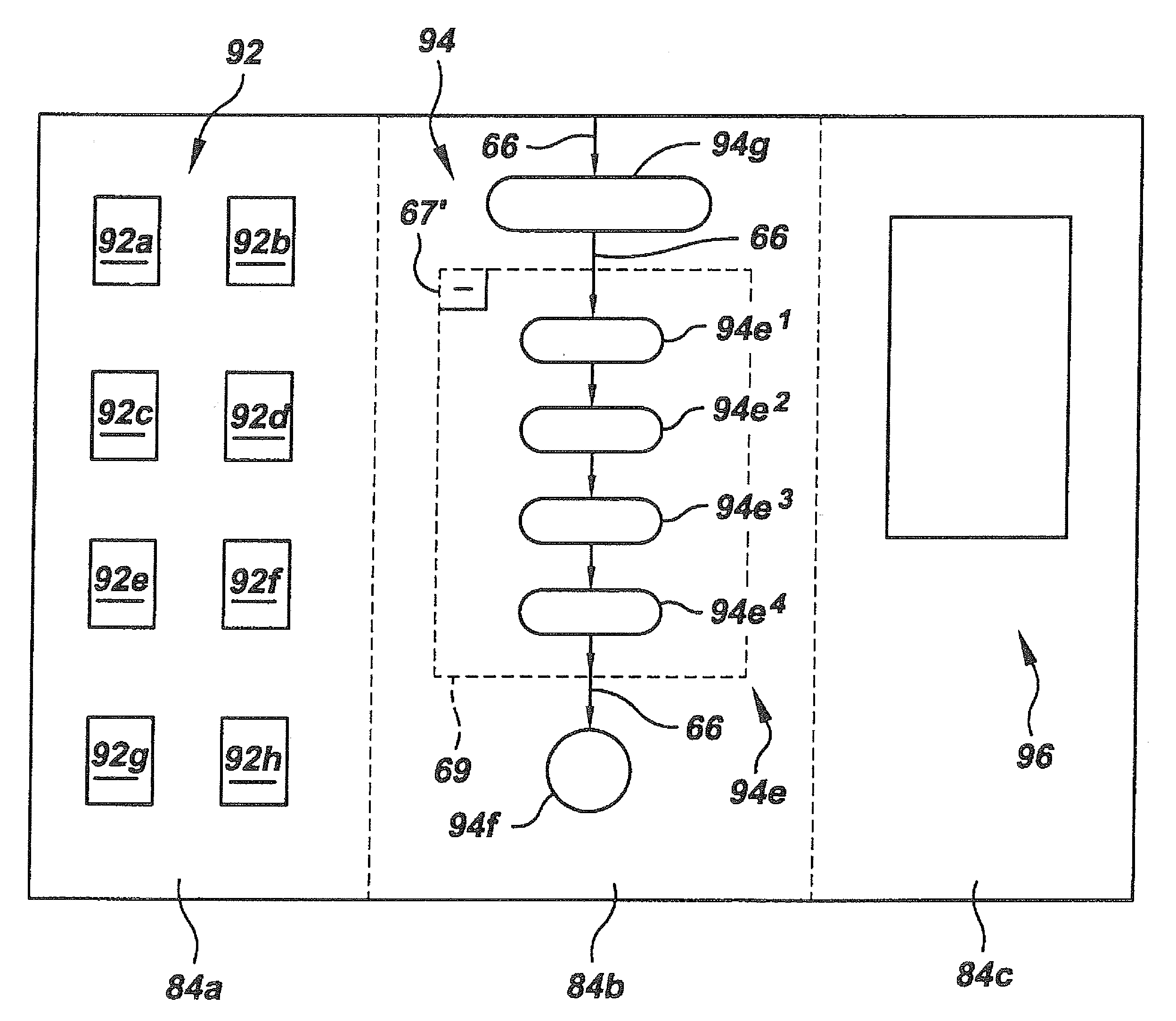

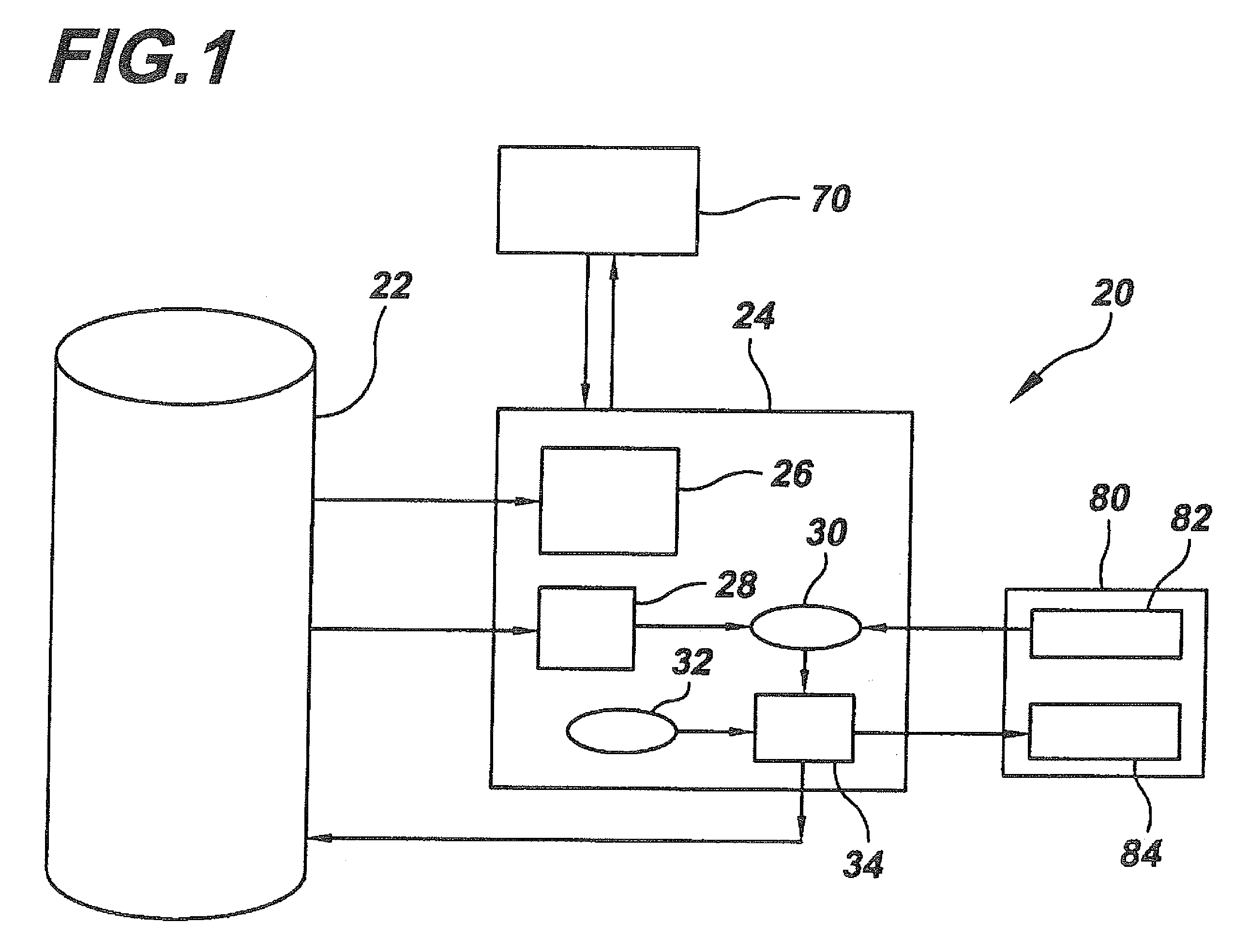

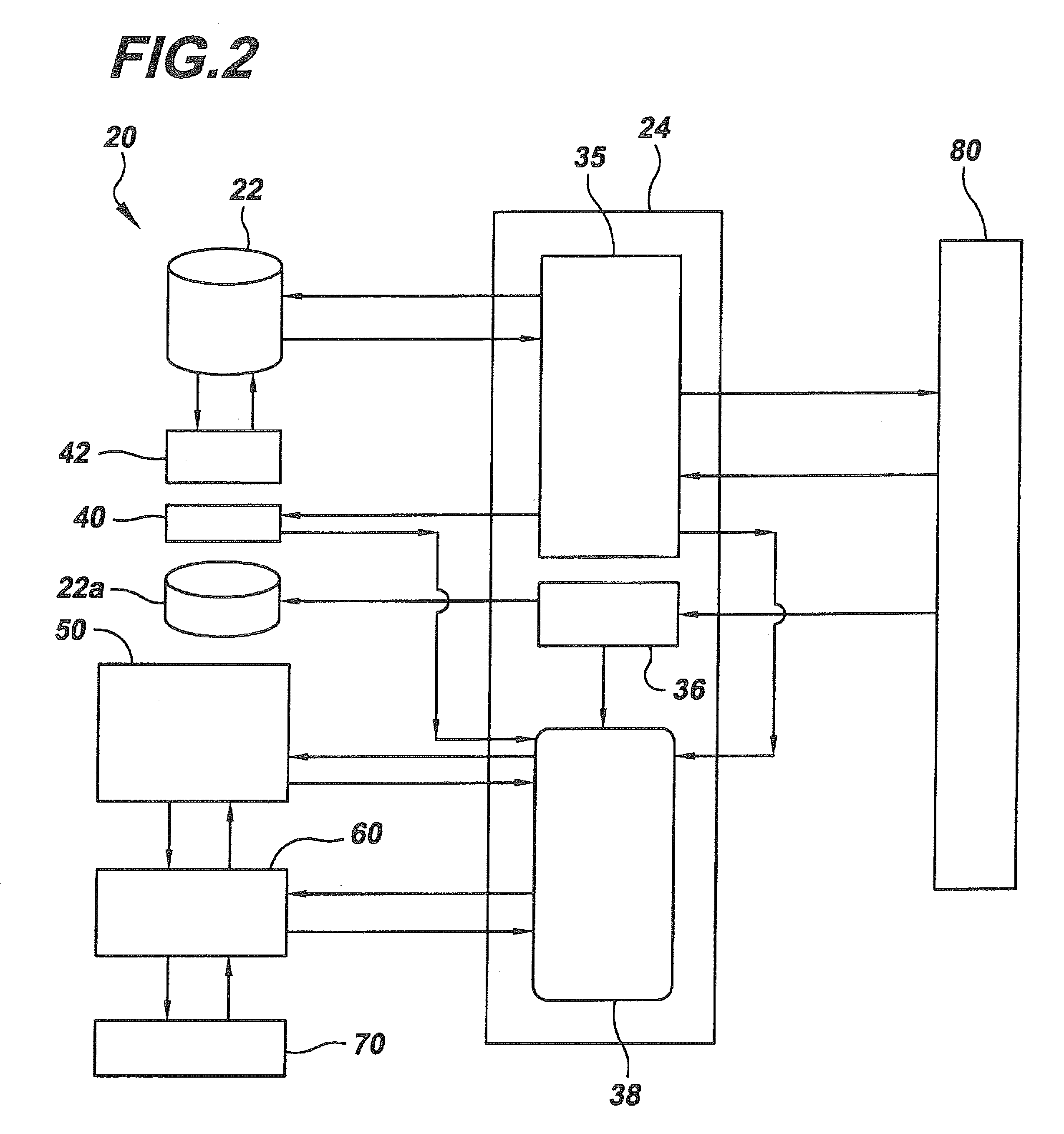

A machine tool control system. A machine tool controller is provided to receive commands from an input source and provide control instructions to a machine tool based at least in part on the commands. An operator interface is provided for inputting commands to the controller. The interface includes a display screen having images of individual command functions, the images being selectable on the screen to place into a sequence of command functions selected by an operator. A sequence generator indicates sequential ordering of the command functions represented by the sequence of images on the screen, such that a sequence of images on the screen selected by the operator is translated by the operator controller sequence generator into a sequence of commands to be inputted into the controller. The operator interface may include one or more images each representing a plurality of individual command functions in a defined sequence.

Owner:FIVES LANDIS

Method of correcting thermal displacement of machine tool

InactiveUS6471451B2Increase displacementLow costDC motor speed/torque controlTemperatue controlNumerical controlMachine tool control

Owner:FANUC LTD

Machine tool control system

InactiveUS20080243299A1Improve performanceEasy to useSpecial data processing applicationsNumerical controlControl communicationsControl system

A machine tool controller is provided that includes a processor configured to execute a sequence of instructions in accordance with an operating program and a user program. A volatile memory temporarily stores instructions and data during execution of the sequence of instructions by the processor, and is coupled to the processor via a first interface. A first non-volatile memory stores the operating program and is coupled to the processor via a second interface. A second non-volatile memory stores the user program and is coupled to the processor via a third interface. A video controller is configured to control a user display in accordance with display data generated by the processor and is coupled to the processor via a fourth interface. A dual-port memory is coupled to the processor via a fifth interface and couples a serial bus controller configured to control communications with an external device via a serial bus to the processor. An external bus interface is configured to communicate control commands for controlling a machine tool generated by the processor via an external bus and is coupled to said processor via a sixth interface.

Owner:HAAS AUTOMATION

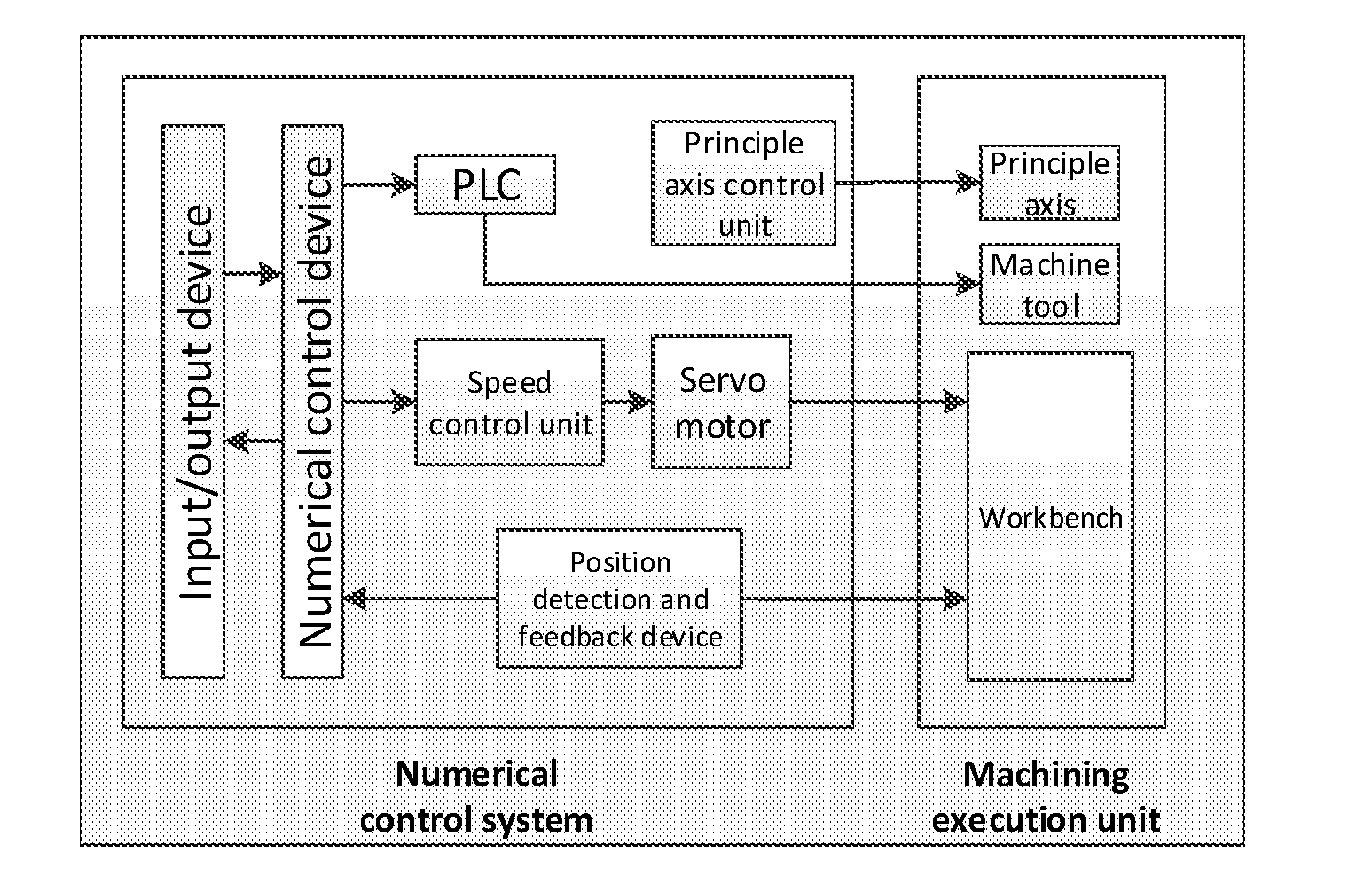

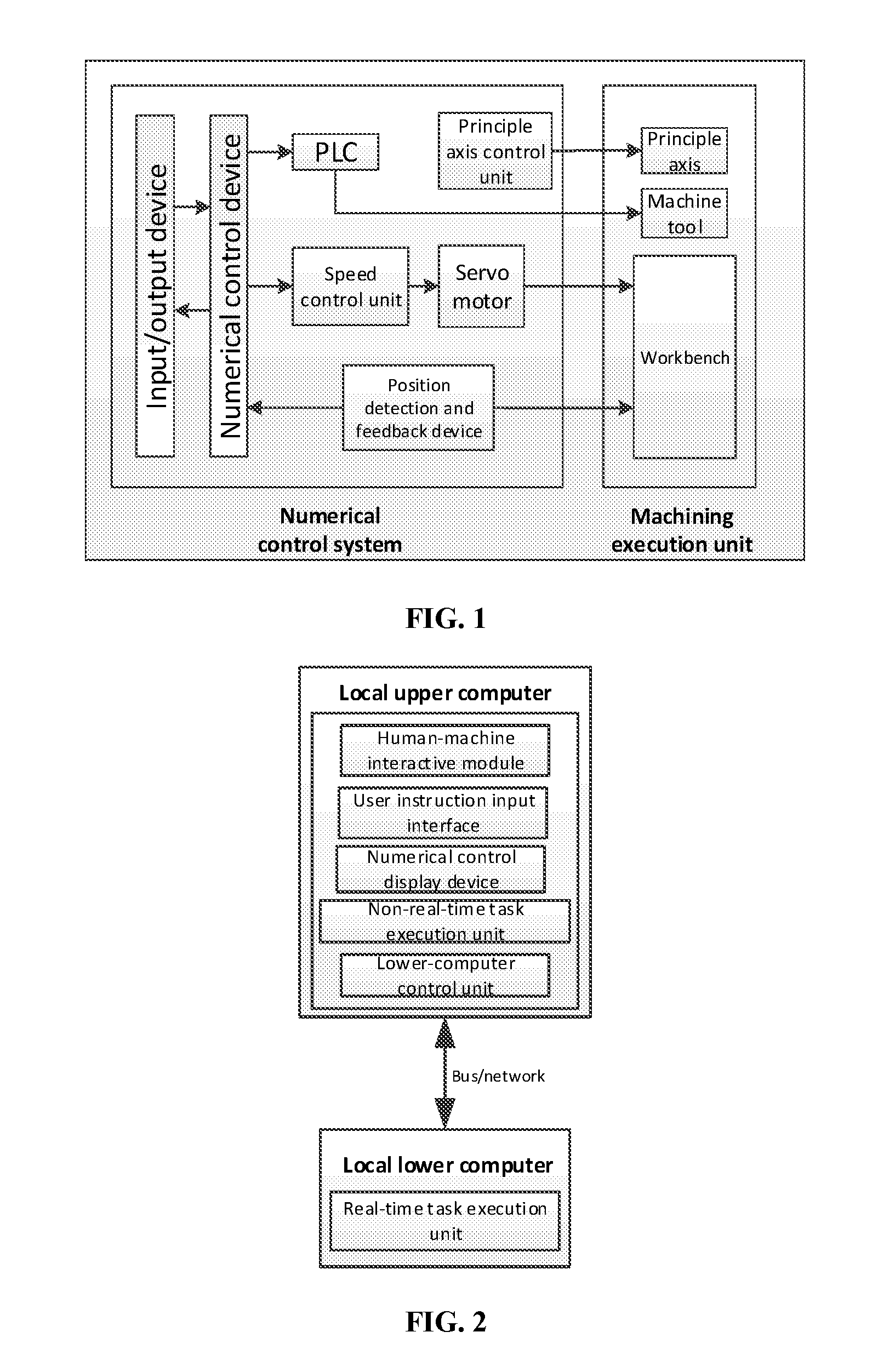

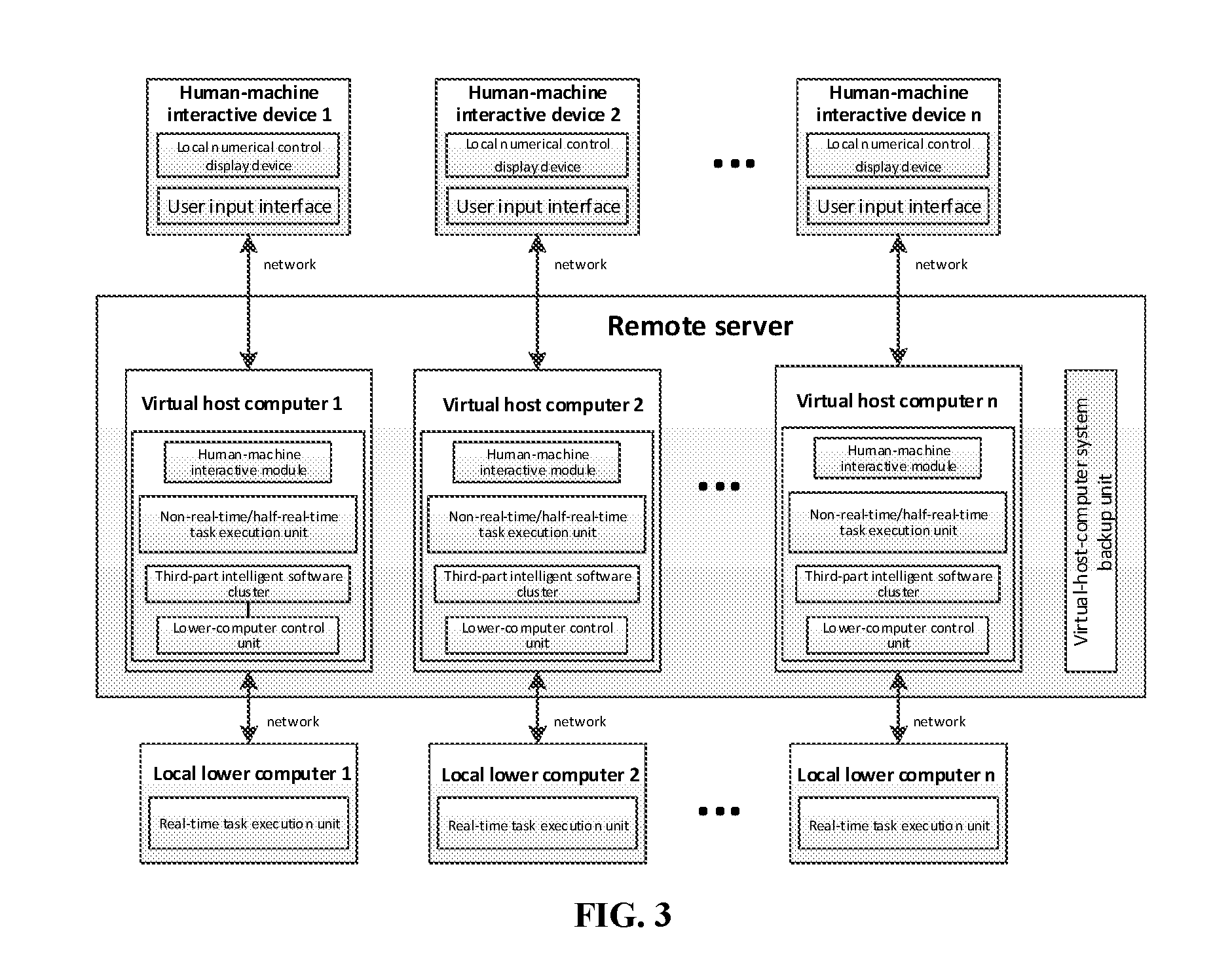

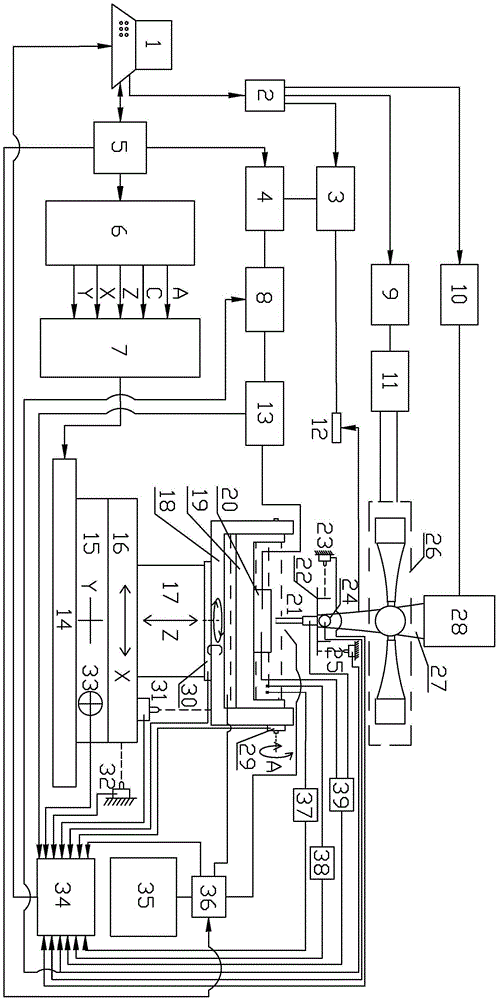

Numerical control system based on virtual host computer

ActiveUS20170045879A1Optimize data processingImprove performanceComputer controlSimulator controlProcessing InstructionMachine tool control

The invention discloses a numerical control (NC) system based on a virtual host computer, the NC system comprising the virtual host computer arranged on a remote server, a local lower computer and a human-machine interactive device for human-machine interaction. The human-machine interactive device is used for providing a human-machine interactive input / output interface. The virtual host computer integrates a human-machine interactive module, a non-real-time / half-real-time task execution unit and a lower-computer control unit, and is used for receiving a NC machining instruction, processing the instruction to form a machine-tool control instruction through the non-real-time / half-real-time task execution unit, and transmitting the control data to the local lower computer through the lower-computer control unit by utilizing a network. The local lower computer controls a machine tool to execute real-time motion control and logic control. The NC system employs a new architecture formed by the upper computer and the lower computer by utilizing virtualization technology, and solves the restriction problems of data processing capability, HMI function expansion and remote machining of a conventional NC system.

Owner:HUAZHONG UNIV OF SCI & TECH

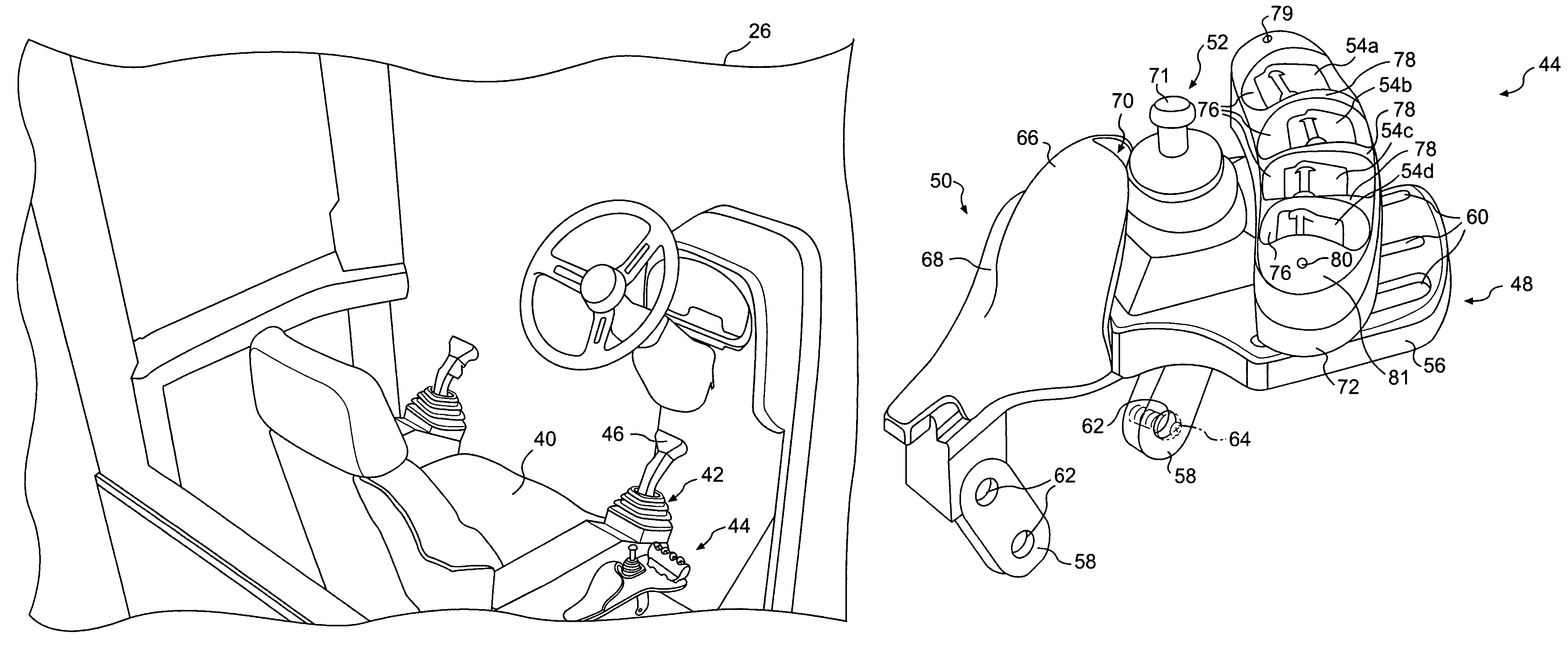

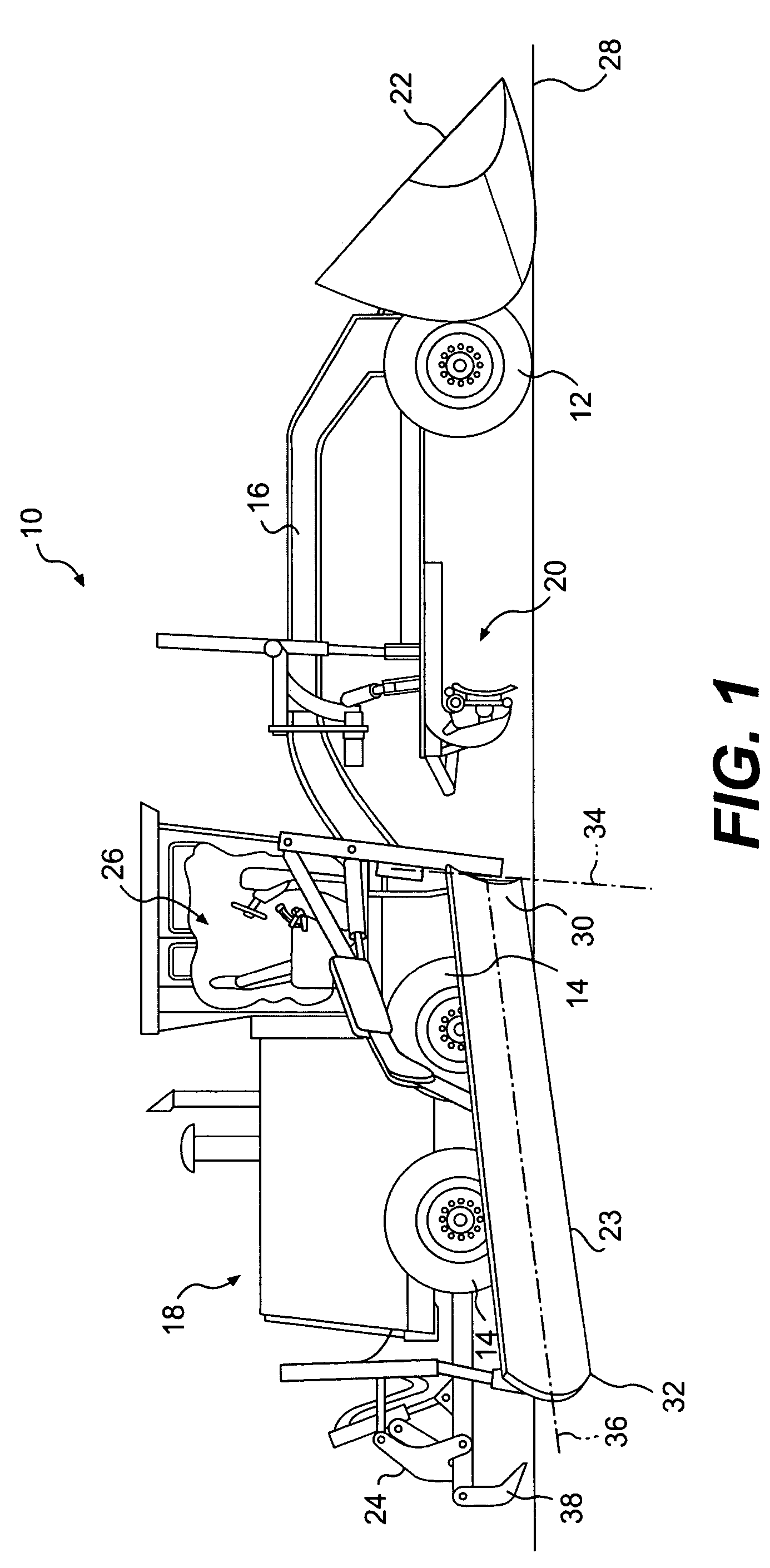

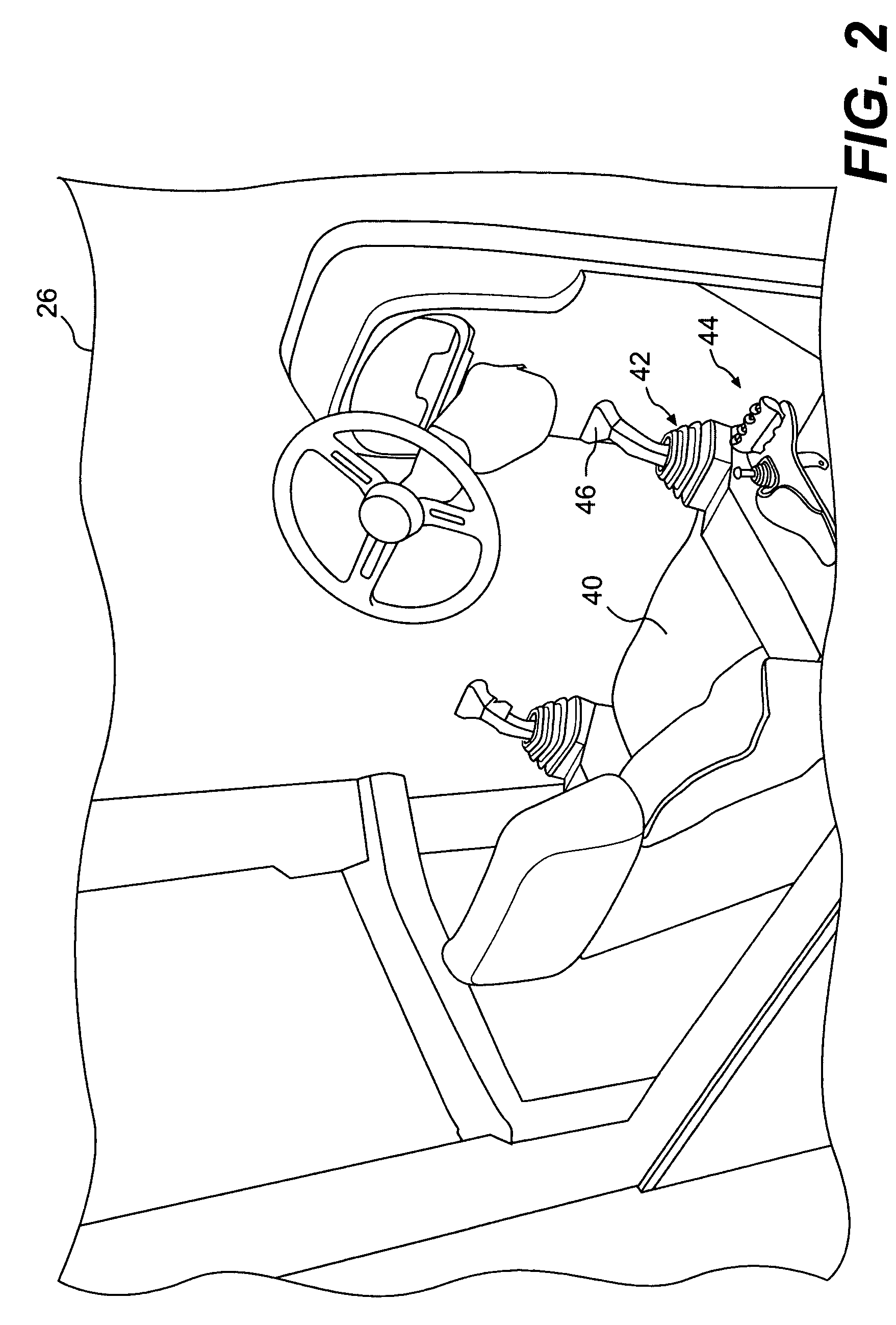

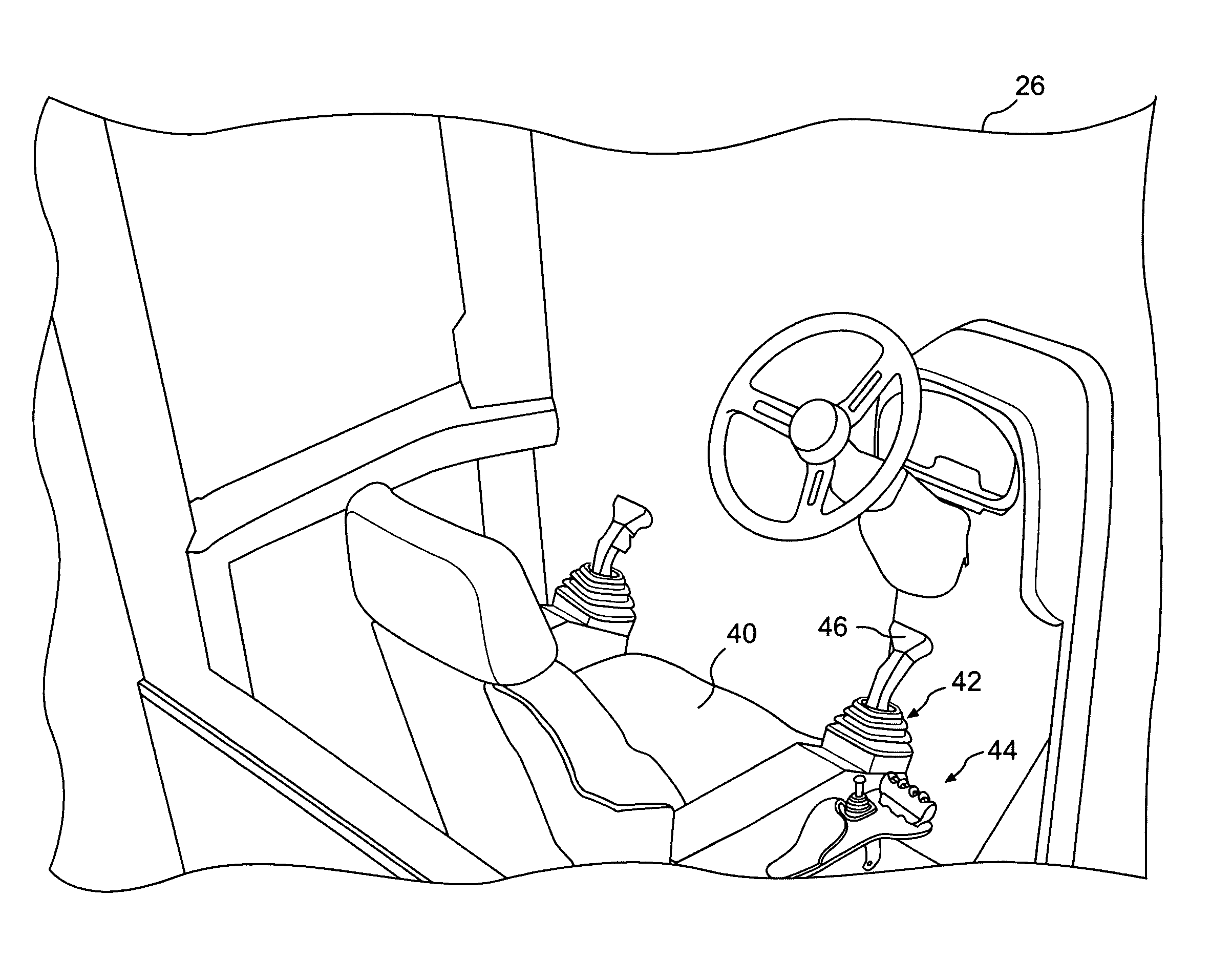

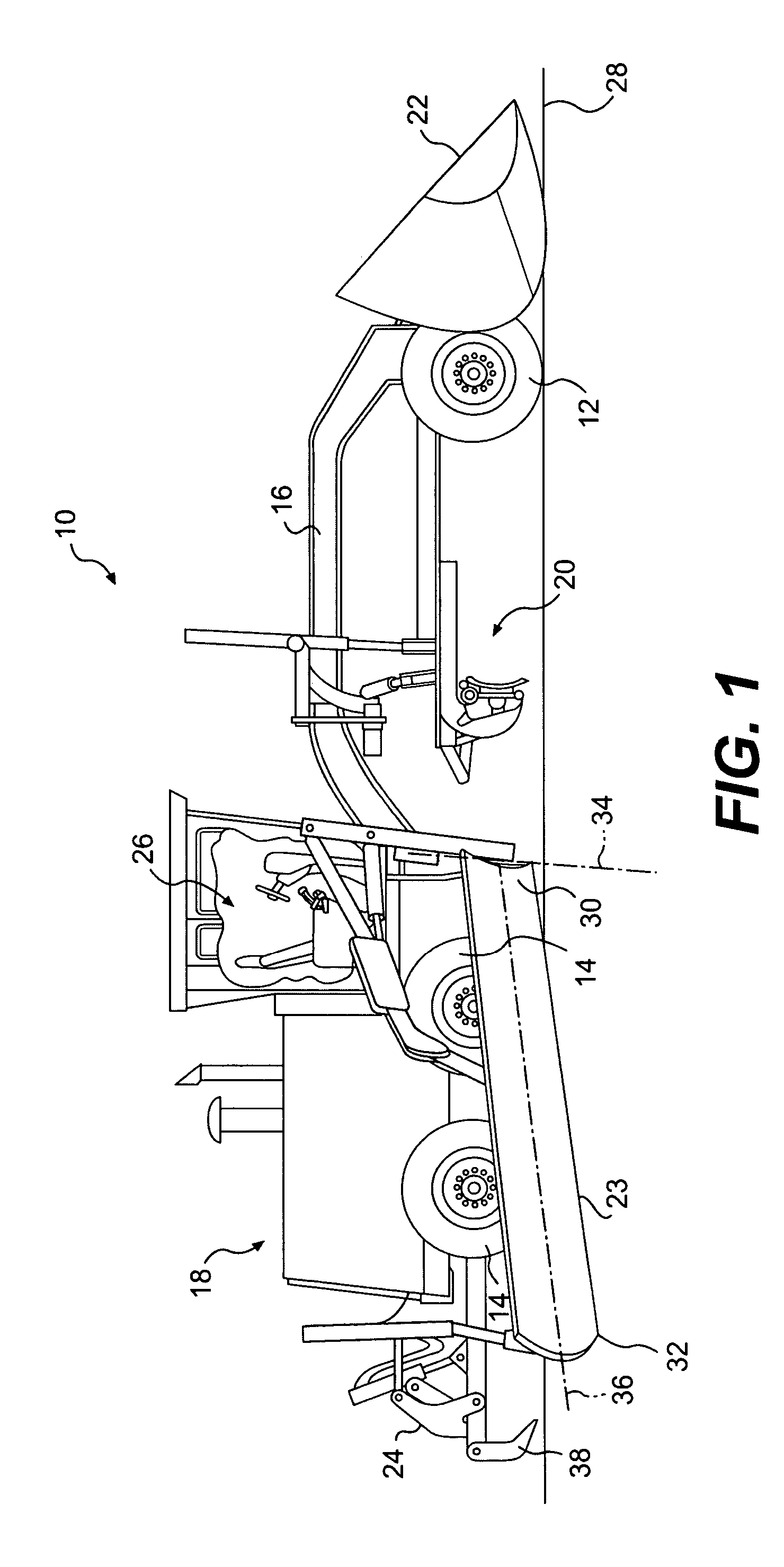

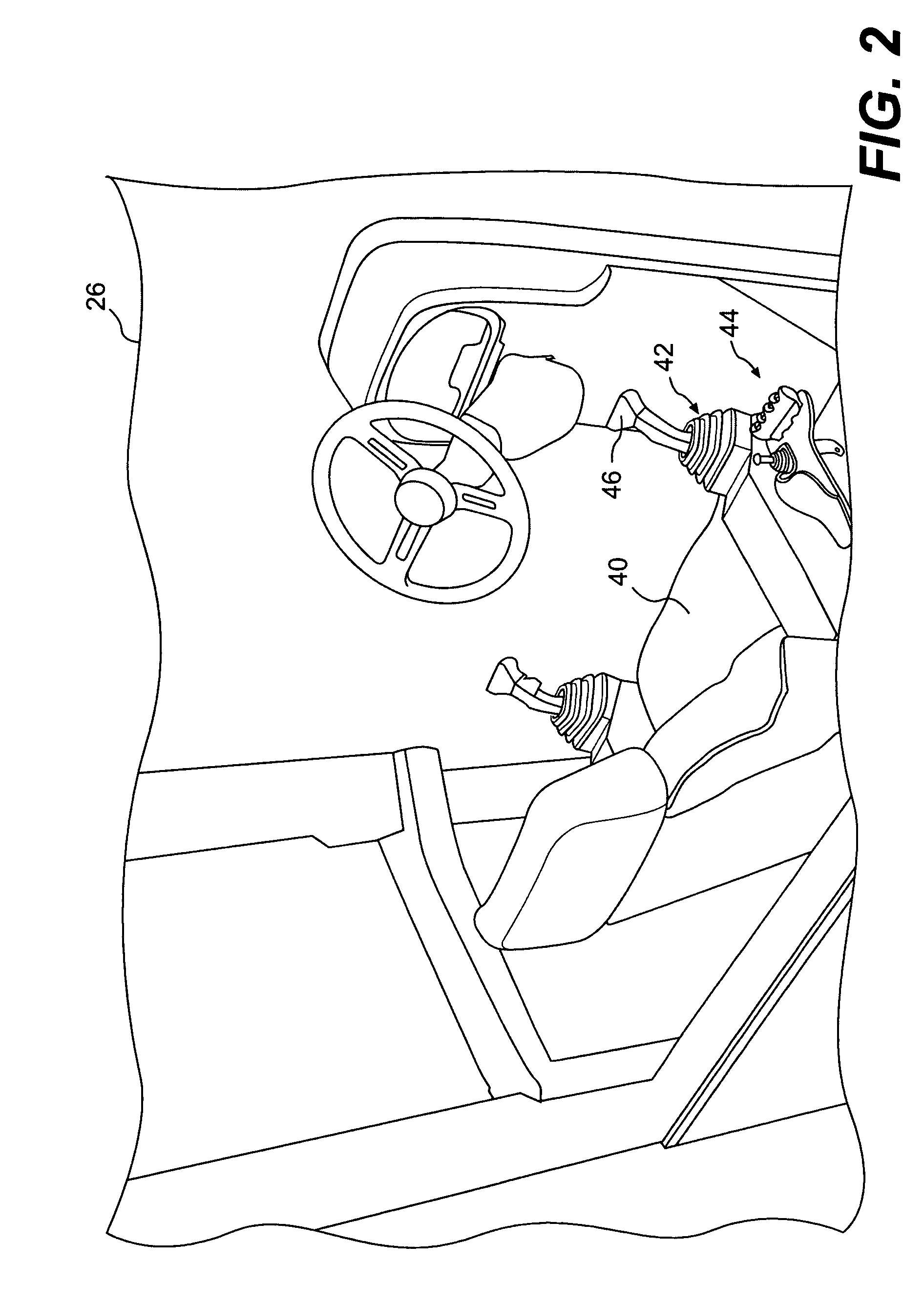

Machine tool control console

InactiveUS7635045B2Manual control with multiple controlled membersSoil-shifting machines/dredgersMachine tool controlEngineering

A control console for a work machine having at least one work tool has a rest and a plurality of operator control devices. The plurality of operator control devices are adjustable relative to the rest and configured to control at least one function of the at least one work tool.

Owner:CATERPILLAR INC

Work machine tool control console

InactiveUS20060021819A1Control functionManual control with multiple controlled membersSoil-shifting machines/dredgersMachine tool controlEngineering

A control console for a work machine having at least one work tool has a rest and a plurality of operator control devices. The plurality of operator control devices are adjustable relative to the rest and configured to control at least one function of the at least one work tool.

Owner:CATERPILLAR INC

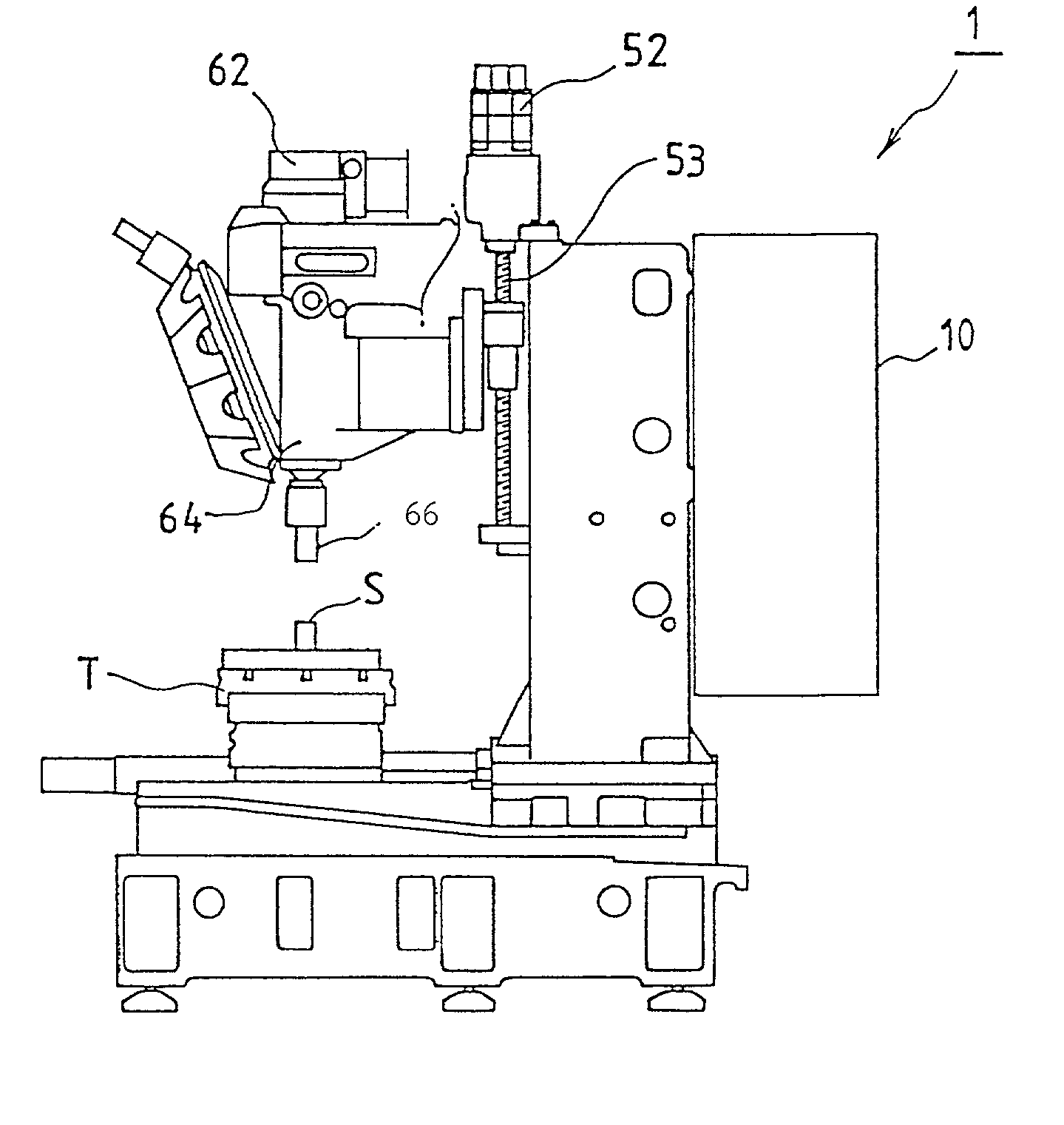

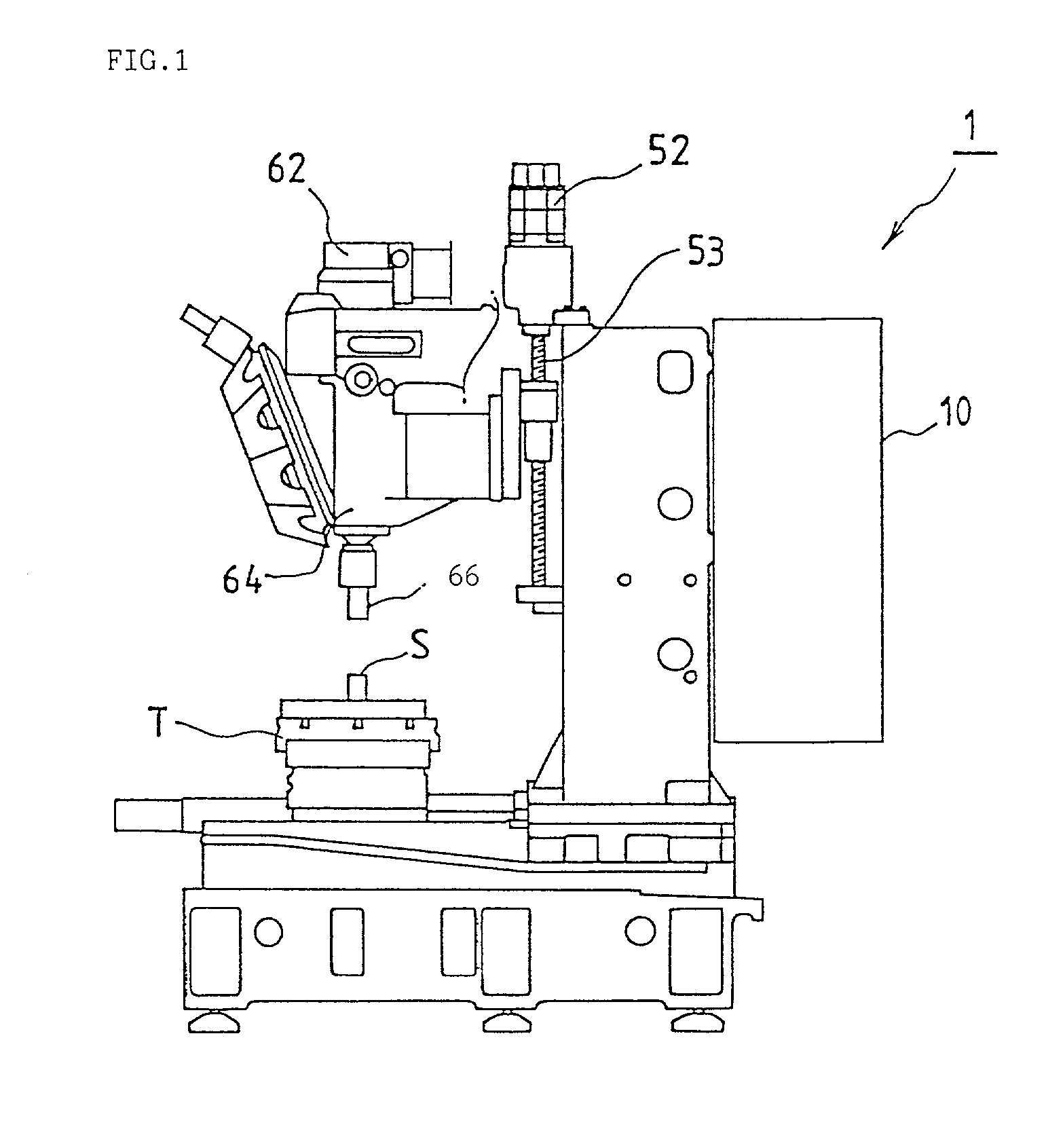

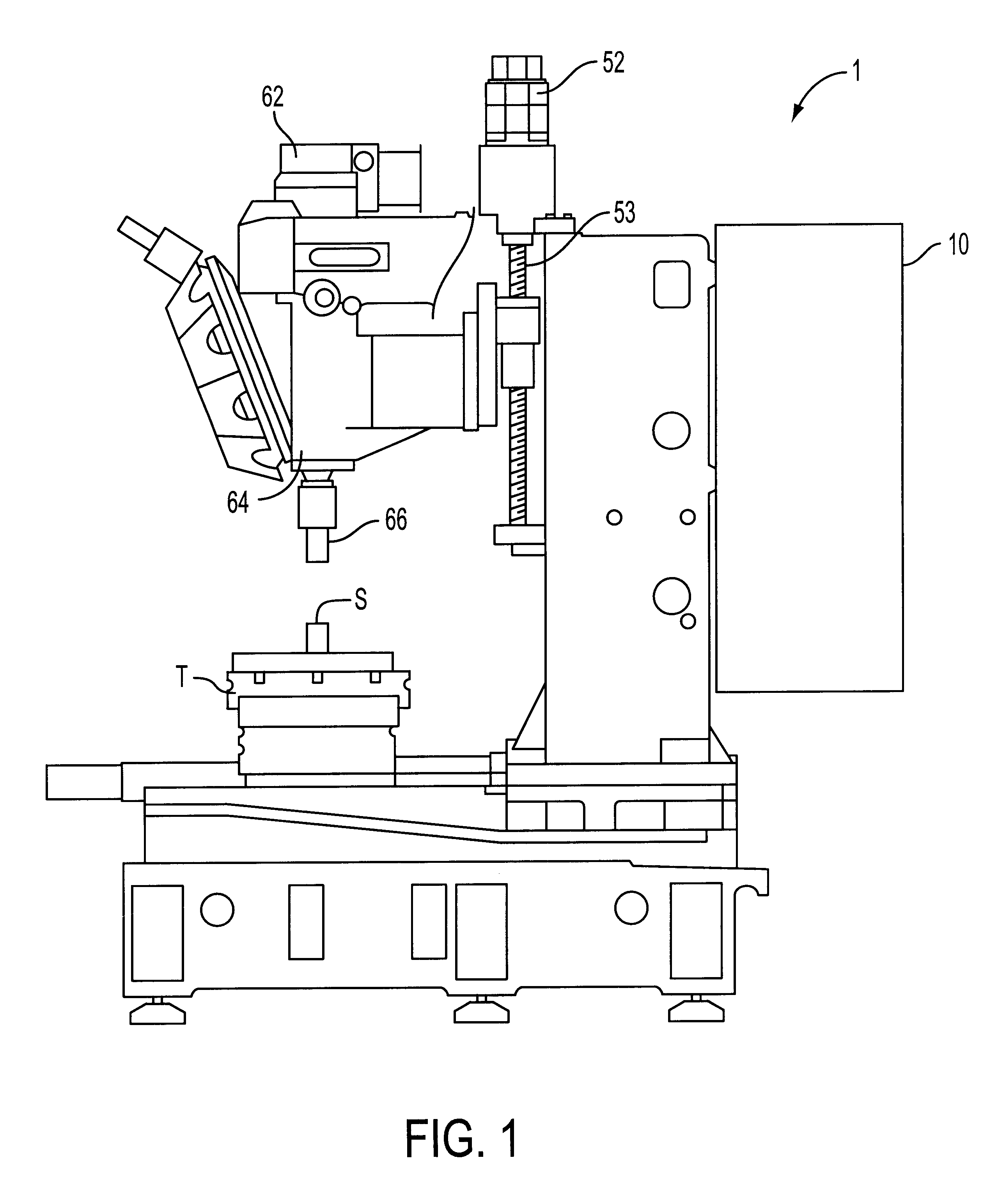

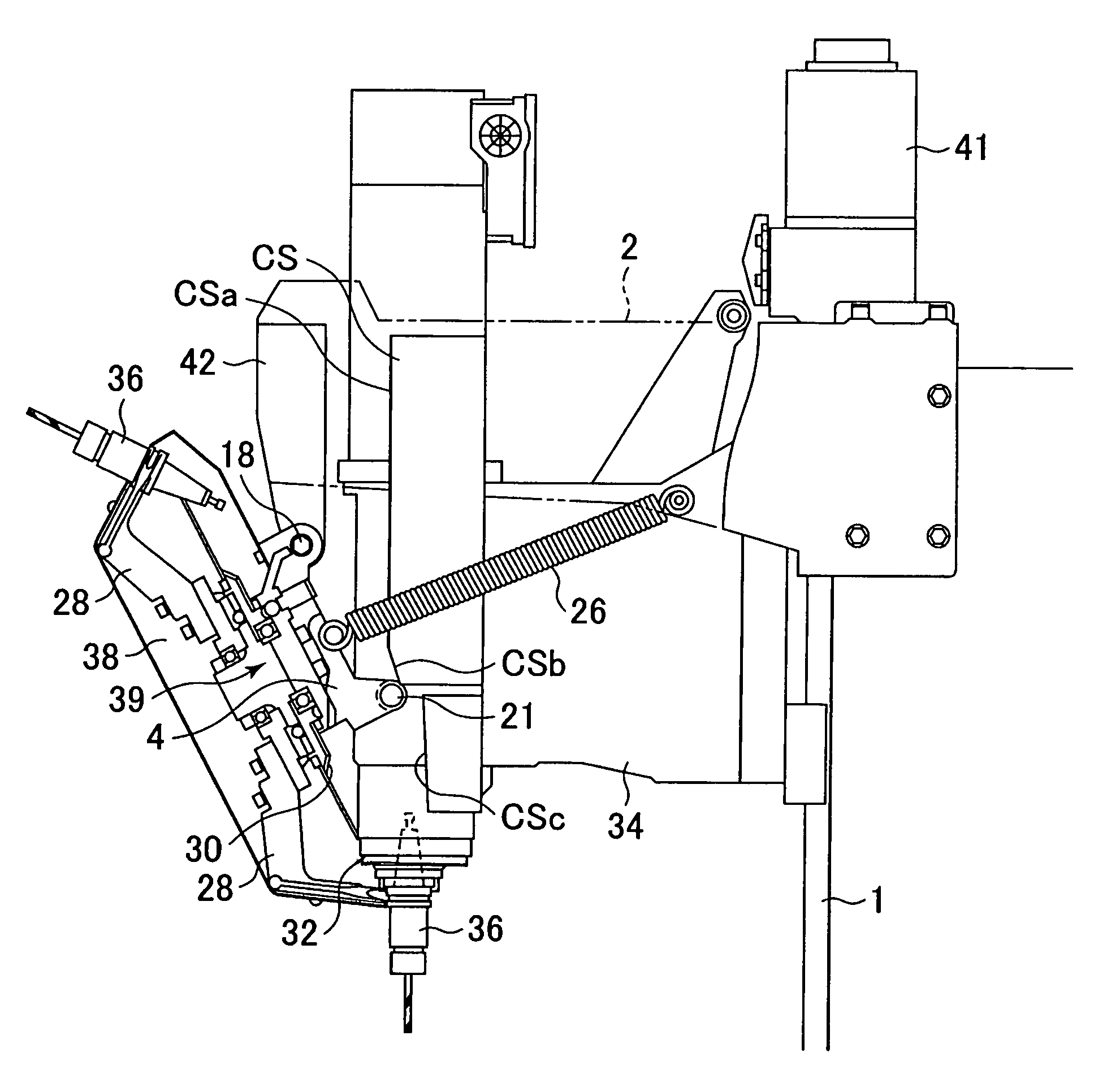

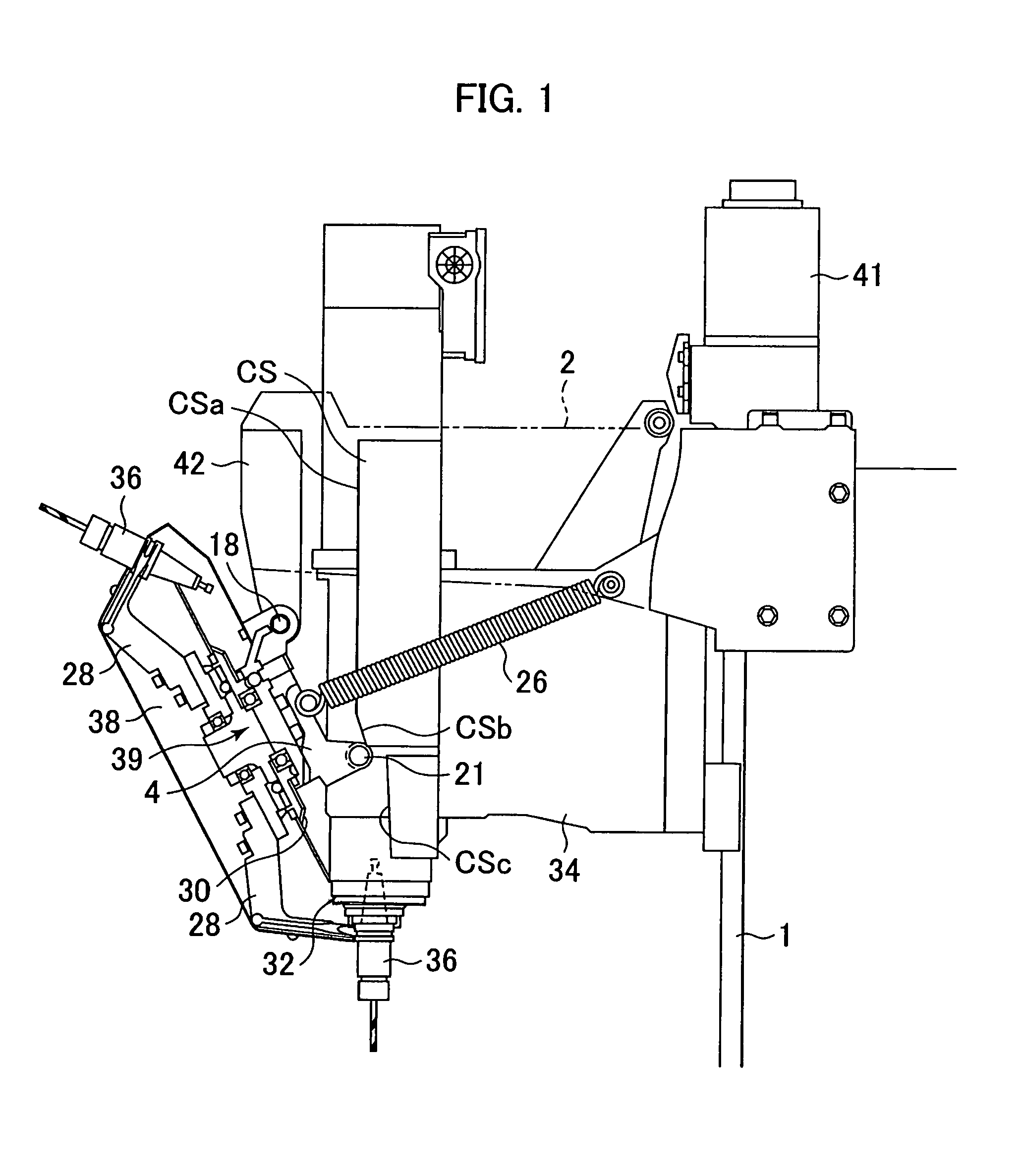

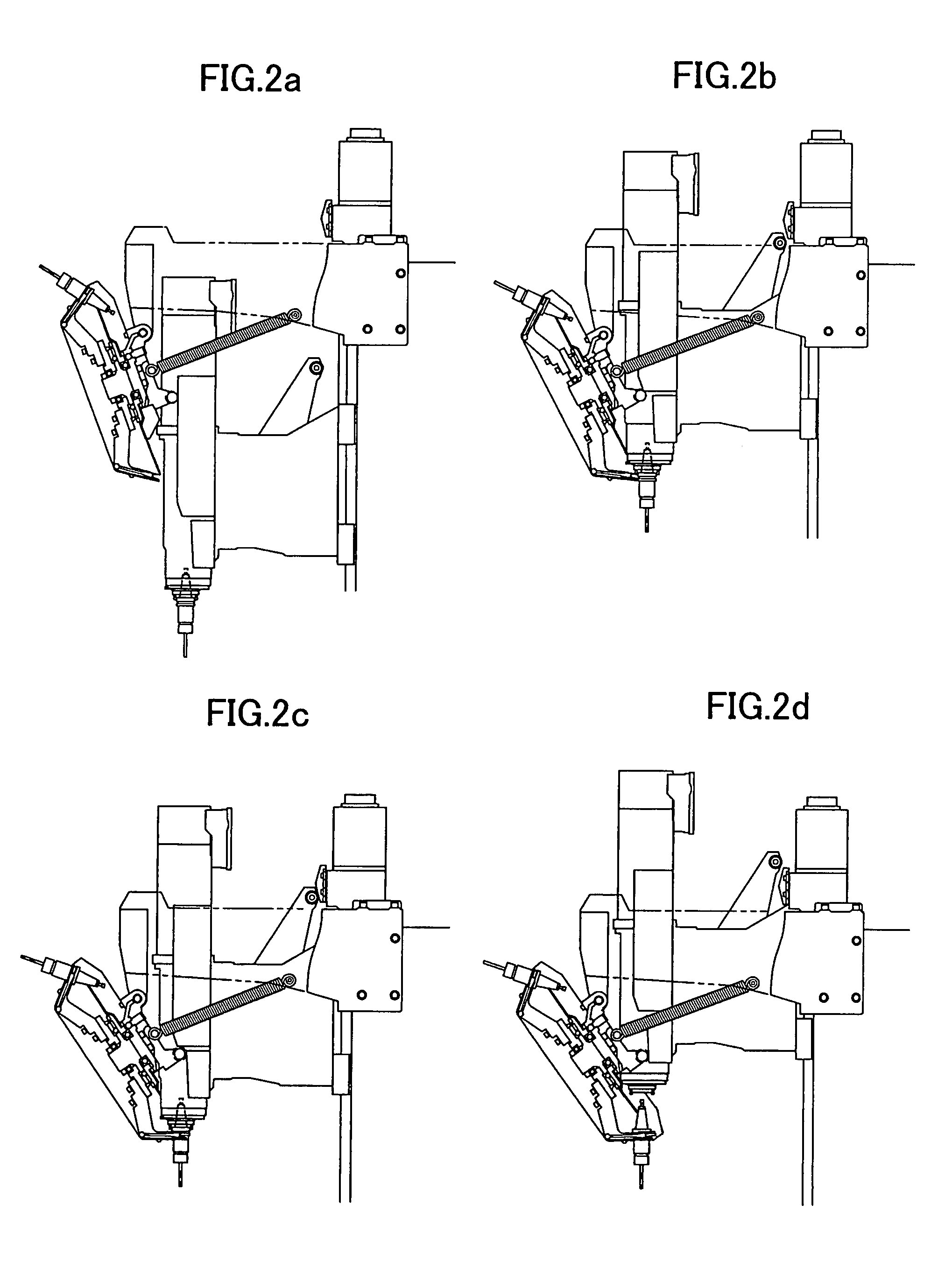

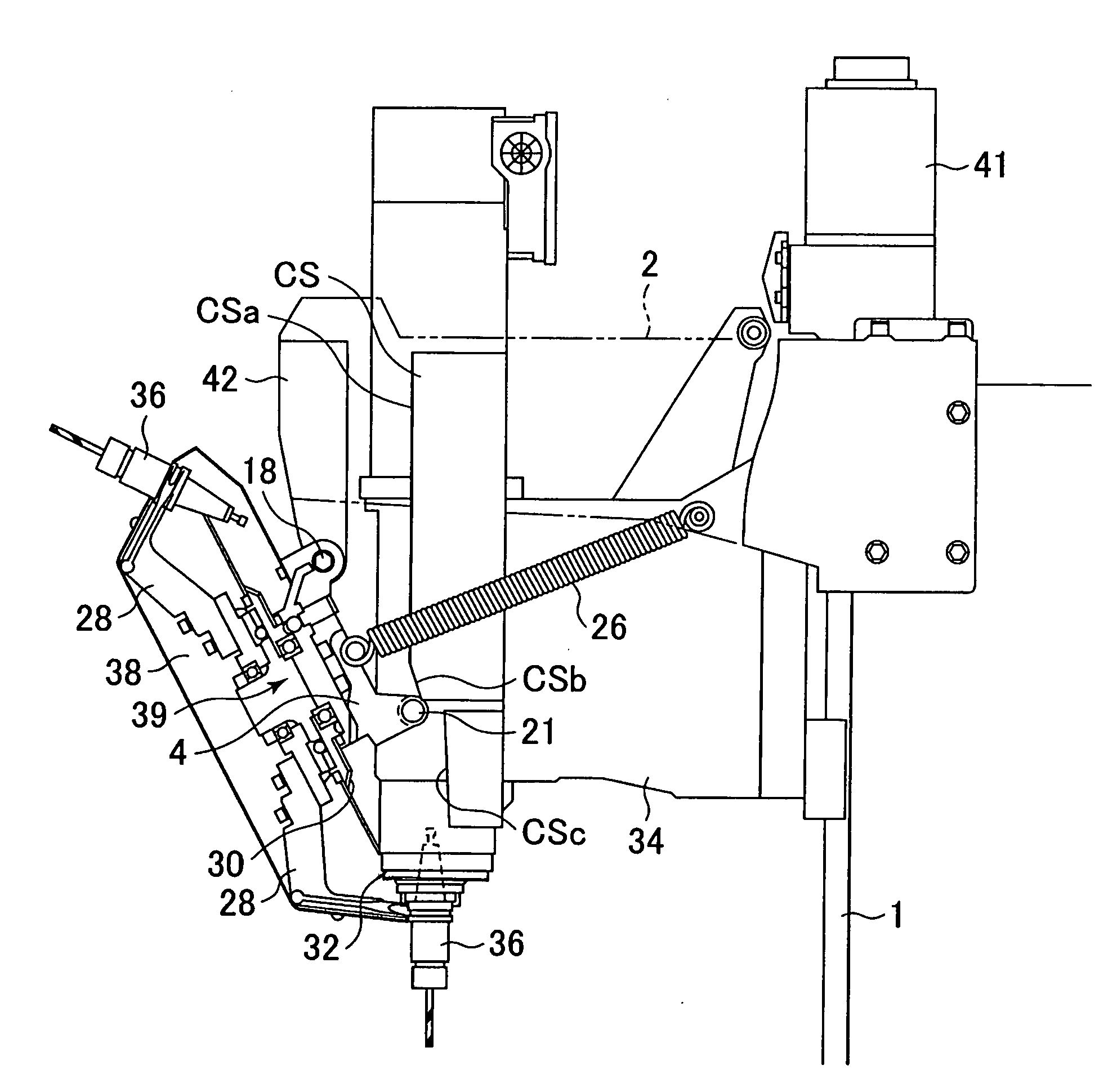

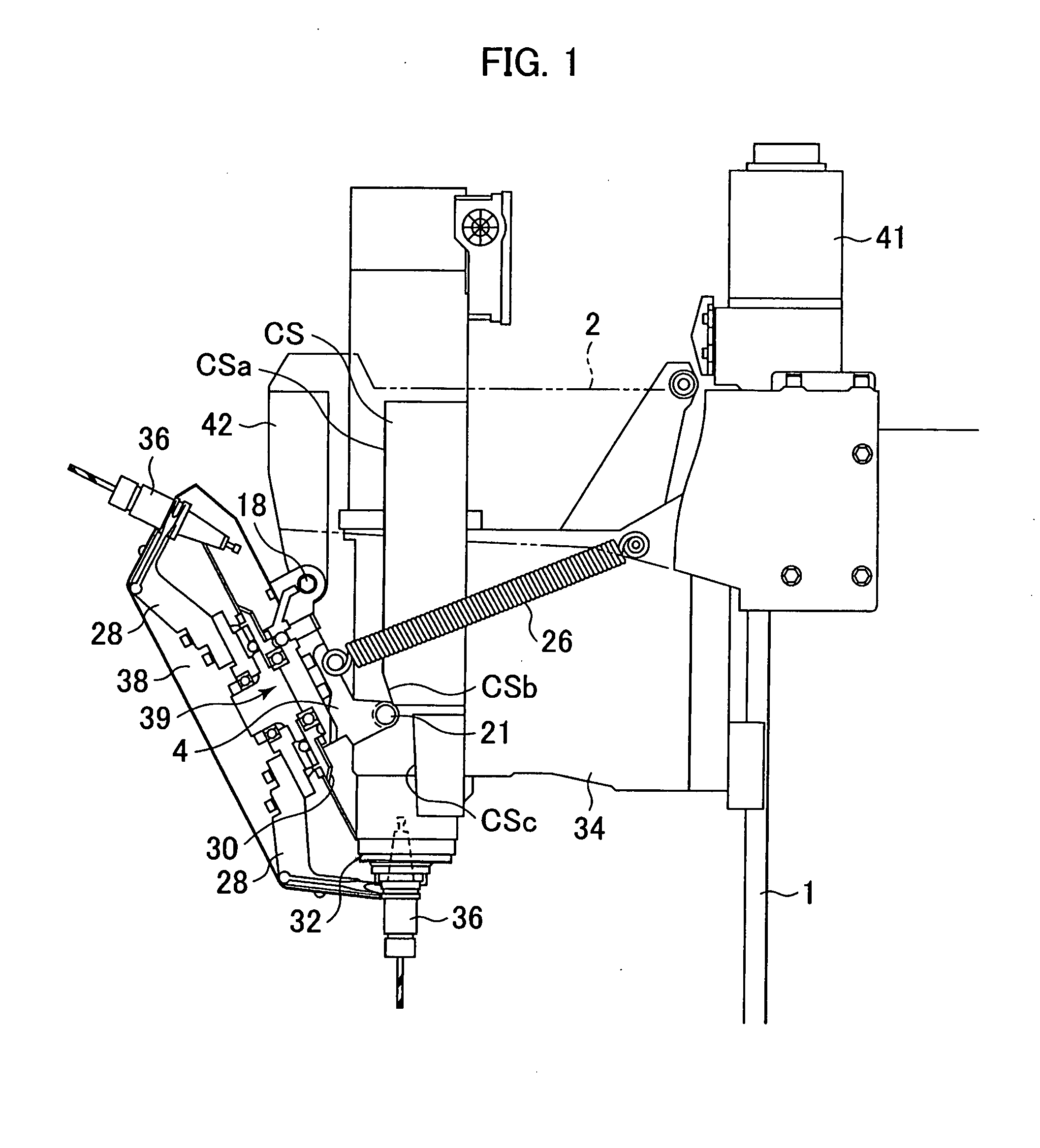

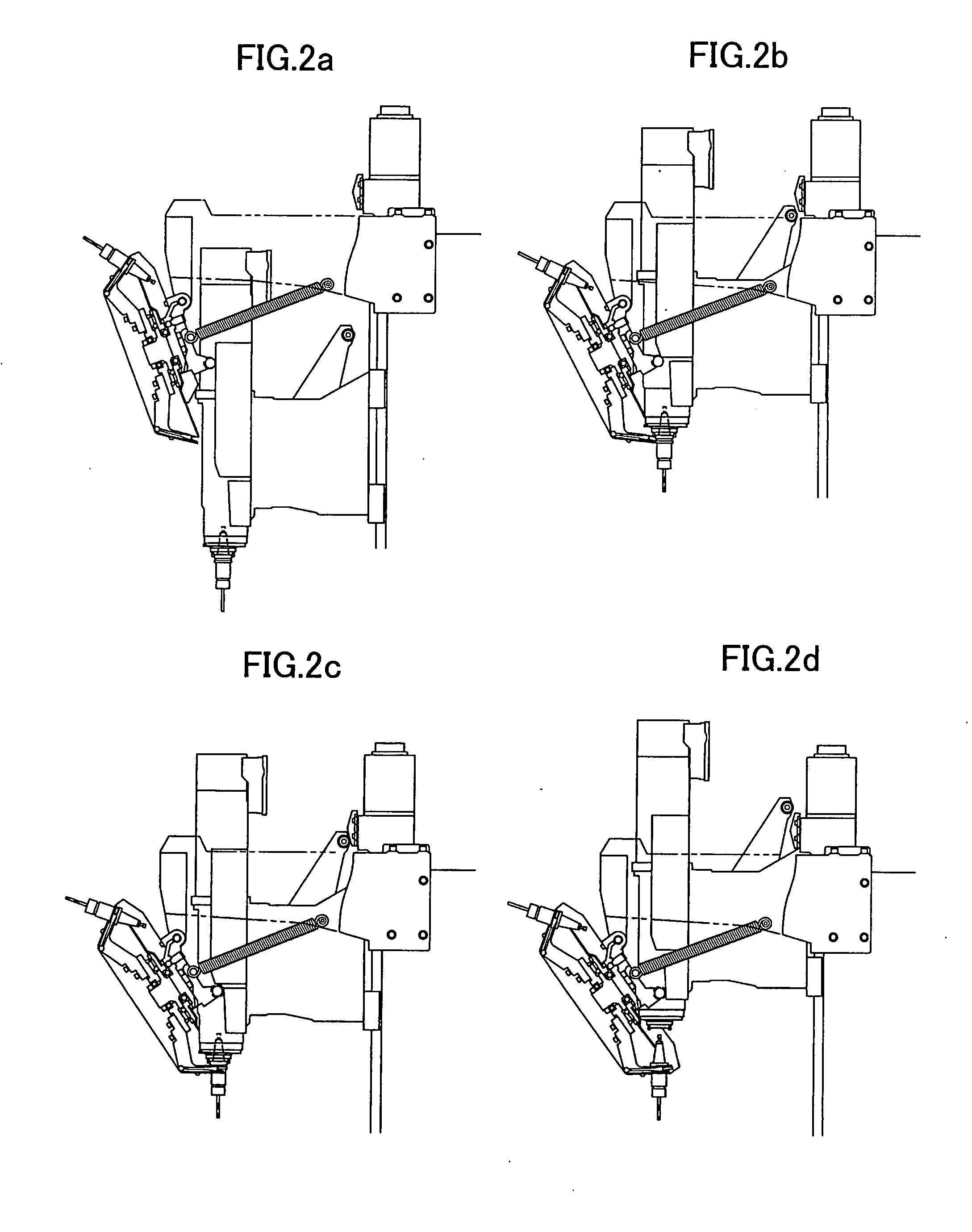

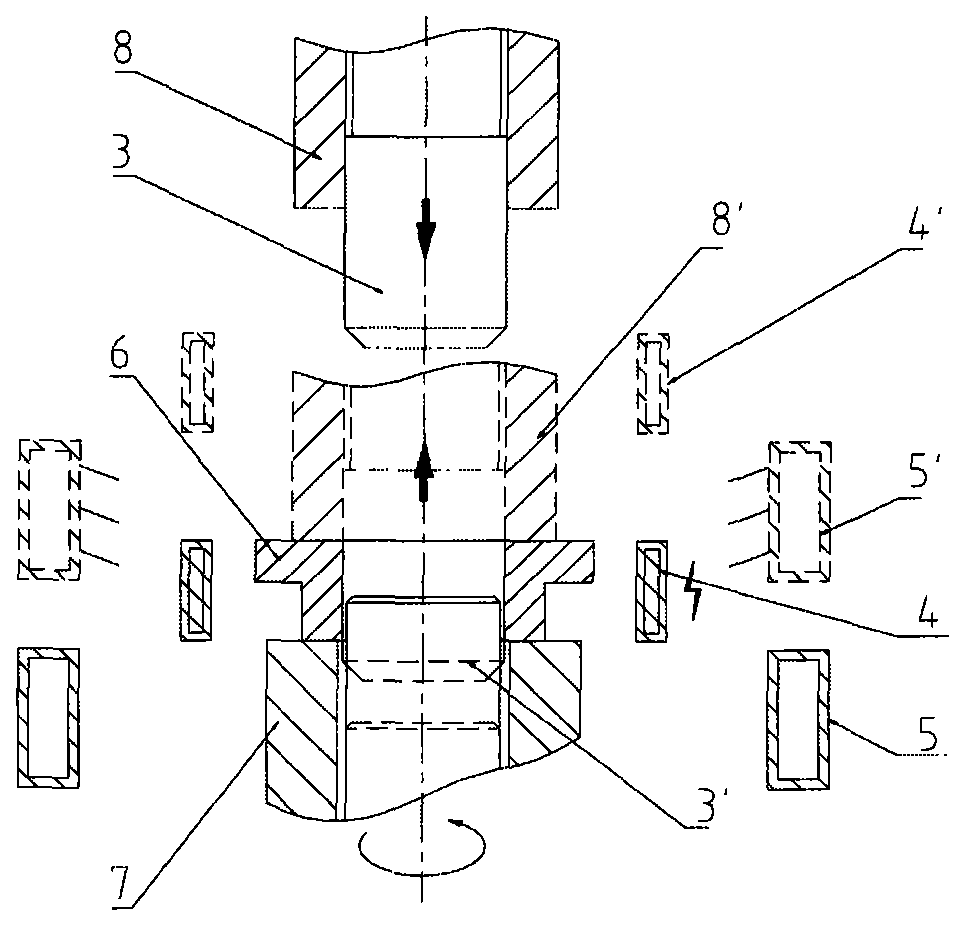

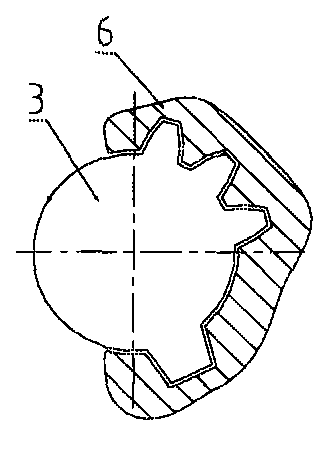

Automatic tool changing method and device for machine tool controlled by numerical controller

ActiveUS7445587B2Reduce impactSimple structurePrecision positioning equipmentMachine tool componentsMachine tool controlCam

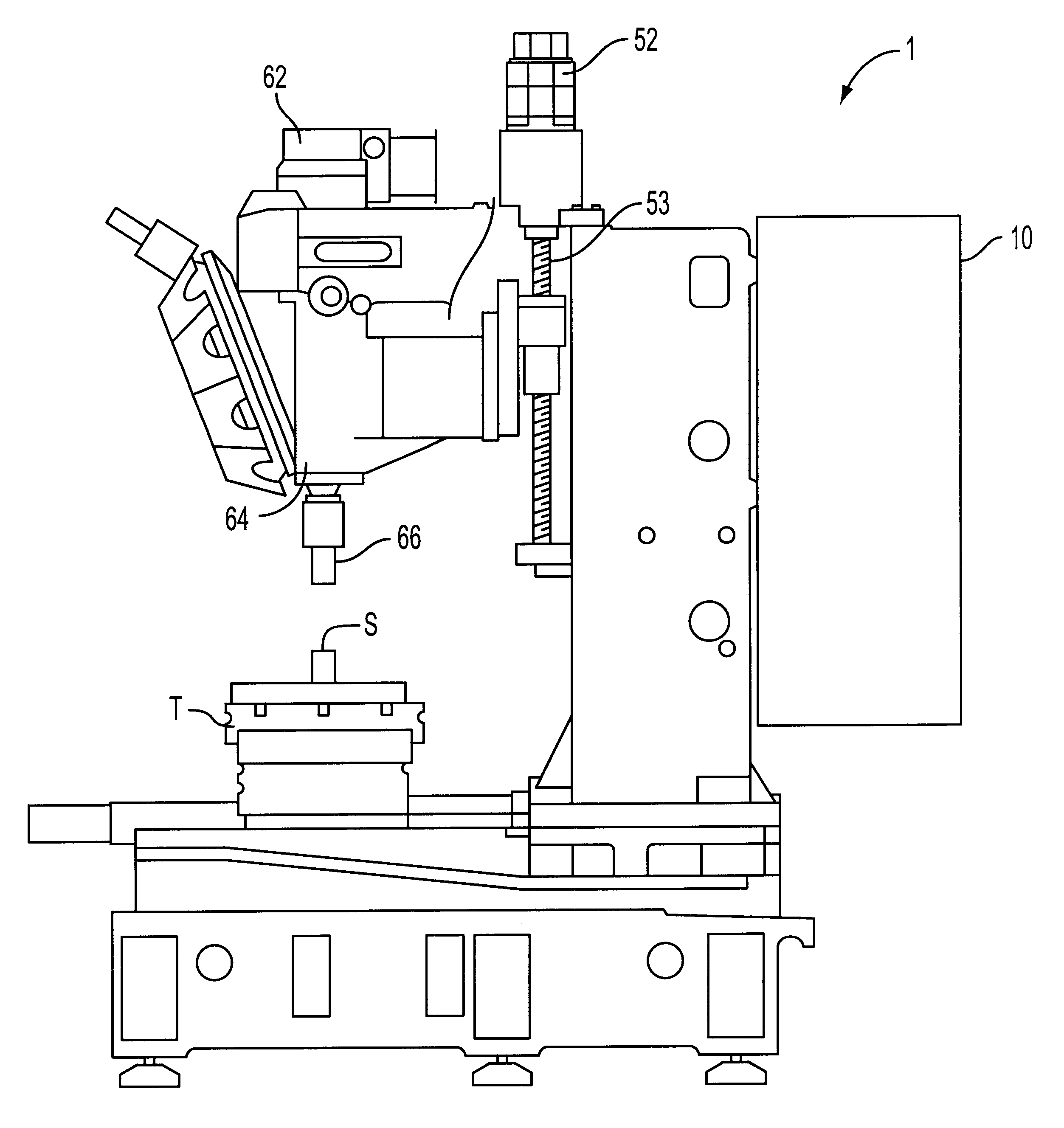

An automatic tool changing method and an automatic tool changing device for a machine tool with a numerical controller capable of reducing the occurrence of impact due to tool exchange with a simple structure. A turret that rotates about a pivot shaft is provided on an arm and holds multiple tools. A swing cam CS that cooperates with a swing roller provided on the turret is provided on a spindle head. As the spindle head descends the turret rotates due to the action of the swing roller and the cam CS and exchanges tools. In order to lessen the impact that occurs at this time, the velocity of the spindle head is controlled. The ideal swing velocity pattern for the turret is obtained, and from this swing velocity pattern the swing position of the turret at each moment is obtained. From the swing roller and cam CS positions at this position the position of the spindle head 34 is obtained. From the acquired spindle head position the spindle head velocity pattern is obtained, and the spindle head is controlled using this velocity pattern. As a result, an ideal swing pattern can be achieved, and therefore no impact arises.

Owner:FANUC LTD

Automatic tool changing method and device for machine tool controlled by numerical controller

ActiveUS20070225139A1Nimble and fast tool exchangeEliminating problem relating to durabilityTool changing apparatusStorage devicesMachine tool controlCam

An automatic tool changing method and an automatic tool changing device for a machine tool with a numerical controller capable of reducing the occurrence of impact due to tool exchange with a simple structure. A turret that rotates about a pivot shaft is provided on an arm and holds multiple tools. A swing cam CS that cooperates with a swing roller provided on the turret is provided on a spindle head. As the spindle head descends the turret rotates due to the action of the swing roller and the cam CS and exchanges tools. In order to lessen the impact that occurs at this time, the velocity of the spindle head is controlled. The ideal swing velocity pattern for the turret is obtained, and from this swing velocity pattern the swing position of the turret at each moment is obtained. From the swing roller and cam CS positions at this position the position of the spindle head 34 is obtained. From the acquired spindle head position the spindle head velocity pattern is obtained, and the spindle head is controlled using this velocity pattern. As a result, an ideal swing pattern can be achieved, and therefore no impact arises.

Owner:FANUC LTD

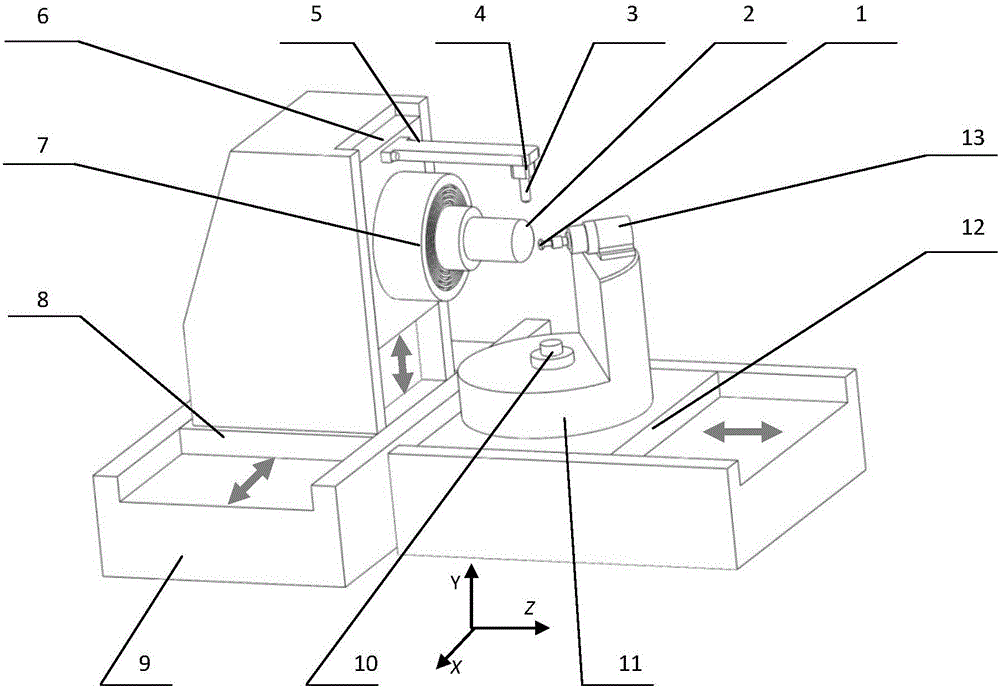

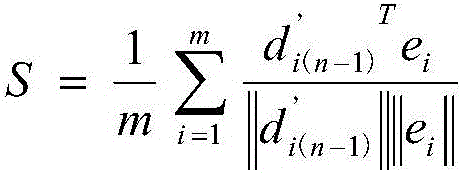

Online testing method for ultra-view-field cutter

ActiveCN105773309AImprove machining accuracyImprove processing efficiencyMeasurement/indication equipmentsControl systemMachine tool control

The invention discloses an online testing method for an ultra-view-field cutter. The online testing method includes the steps that a machine-tool control system is used for driving a transverse movement working table of a machine tool to drive a CCD camera to move to the position above the cutter which needs to be detected and is installed on a rotary working table, and controlling the transverse movement working table to drive the CCD camera to move so as to achieve focusing of the cutter needing to be detected; the transverse movement working table drives the cutter to move to enable a cutter cutting blade to be located in the center of a view field of the CCD camera, the center of the cutting blade and the center of a rotary table are coincided, and the position is set to be the initial position of the cutter; indexing rotation is carried out with the initial position as the symmetric point; coordinates of all sample points of a sub pixel peripheral point group at the edge of the cutting blade and direction vectors of all sample points are obtained; and every two adjacent images are matched and jointed. By means of the method, the machining accuracy and efficiency of complicated surfaces are greatly improved.

Owner:TIANJIN UNIV

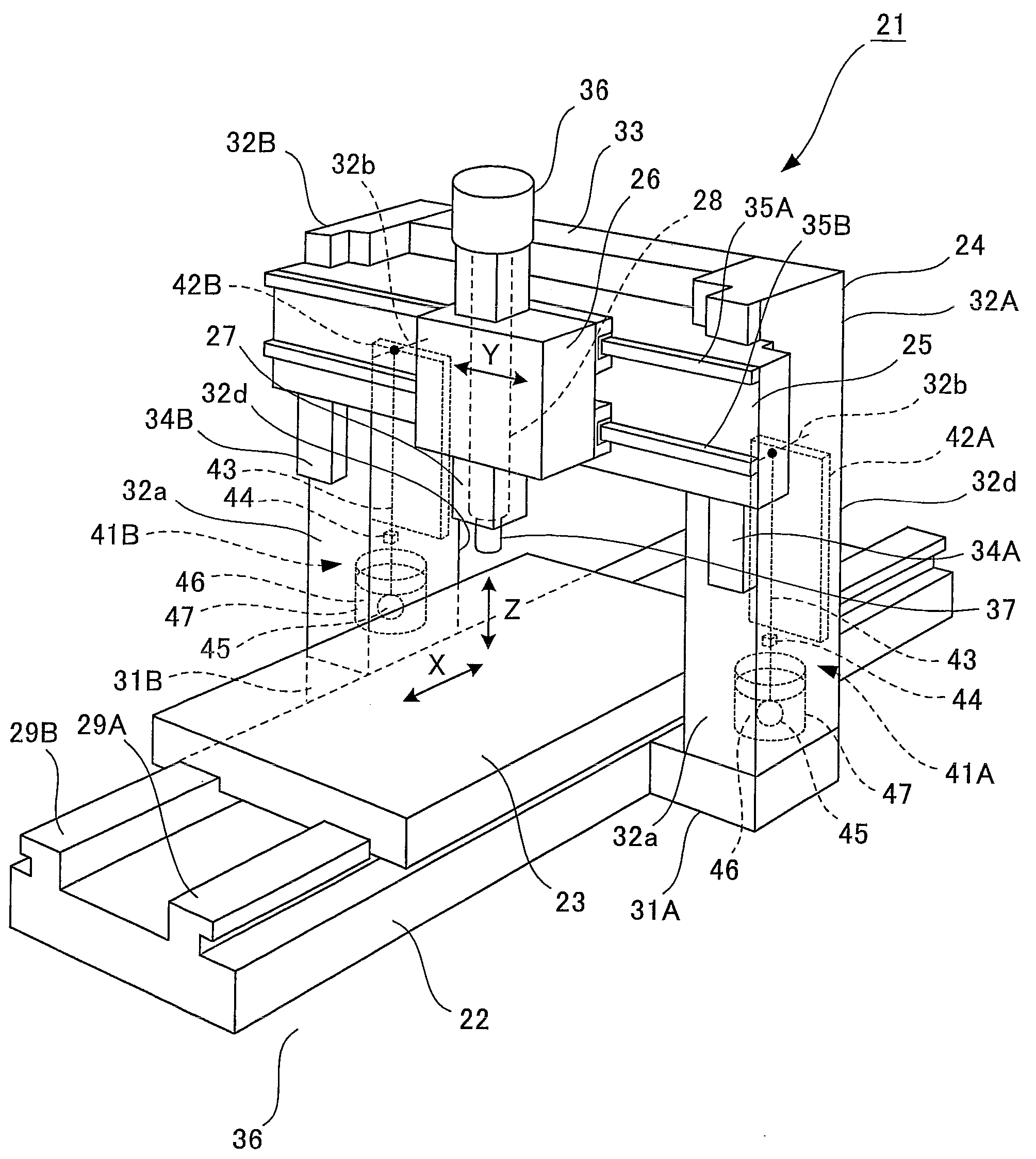

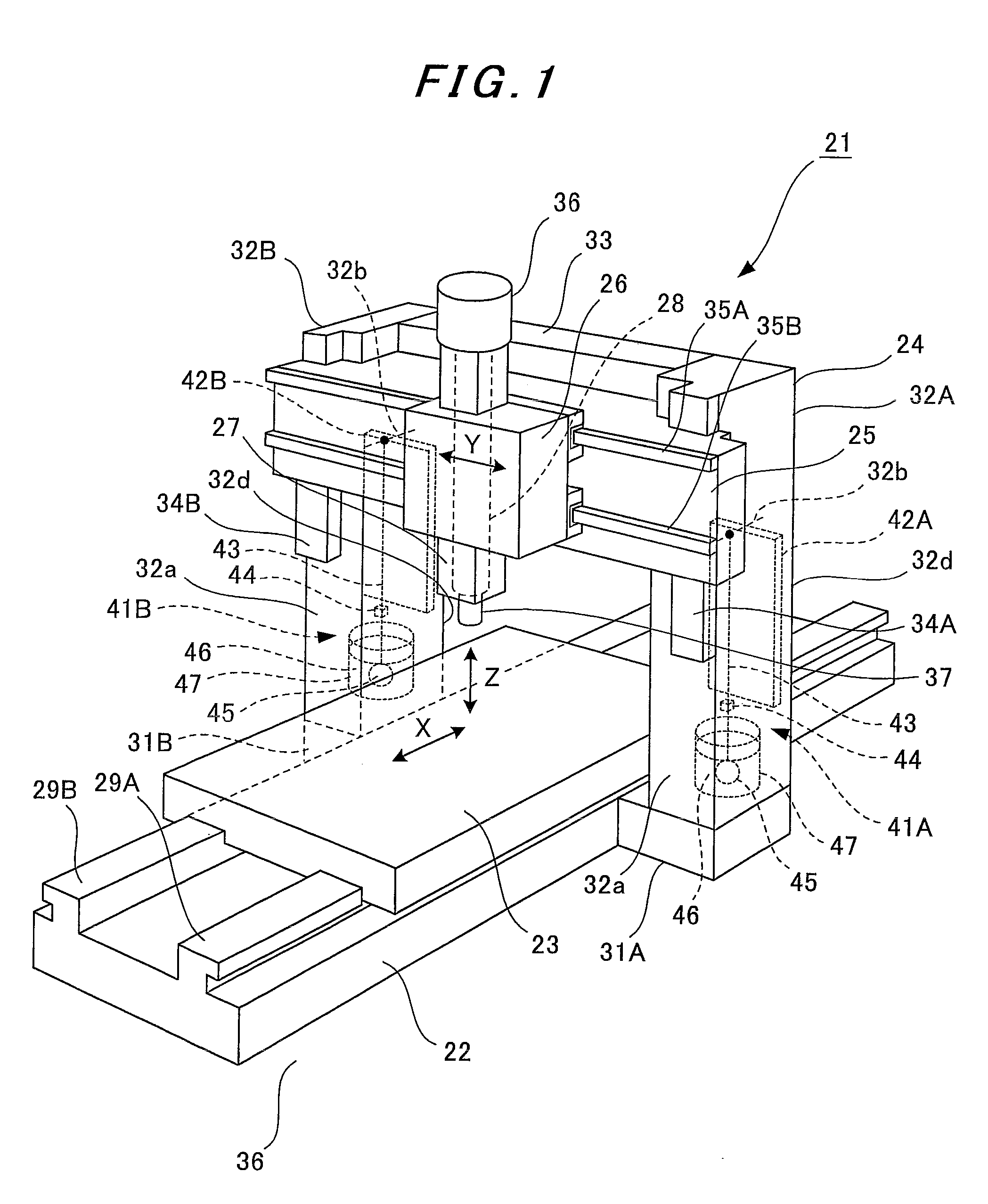

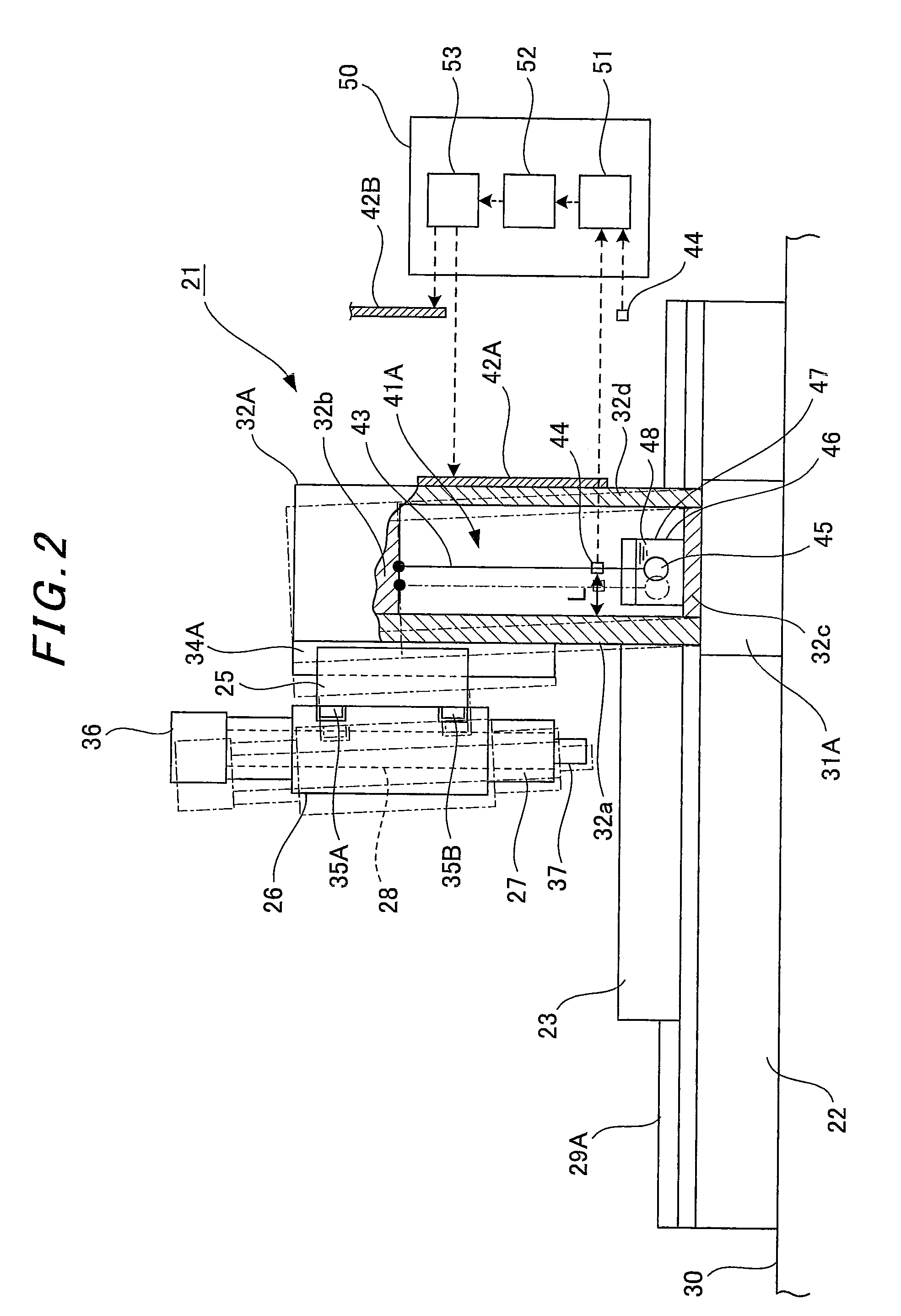

Spindle inclination detector and machine tool including the same

InactiveUS20100024206A1Low costSimple structureThread cutting machinesMeasurement/indication equipmentsThermal deformationMachine tool control

An object of the present invention is to provide: a spindle inclination detector capable of surely detecting spindle inclination with a simple configuration; and a machine tool including the spindle inclination detector. Spindle inclination detectors (41A, 41B) are equipped in columns (32A, 32B) of a portal bridge (24) of a machine tool (21). Each spindle inclination detector includes: a string (43) which hangs vertically with an upper end fixed to the column (reinforcement (32b)) and a lower end attached to a weight (45); a gap sensor (44) which is attached to the string to measure a distance to a front face plate (32a) of the column; and an oil damper (46). Moreover, a spindle inclination correction controller provided to the machine tool controls a Peltier device (42A,42B) attached to a rear face plate (32d) of the column, on a basis of an average distance measured by the gap sensor, and thus corrects an inclination of a spindle (28) due to the thermal deformation of the column by correcting thermal deformation of the column.

Owner:MITSUBISHI HEAVY IND LTD

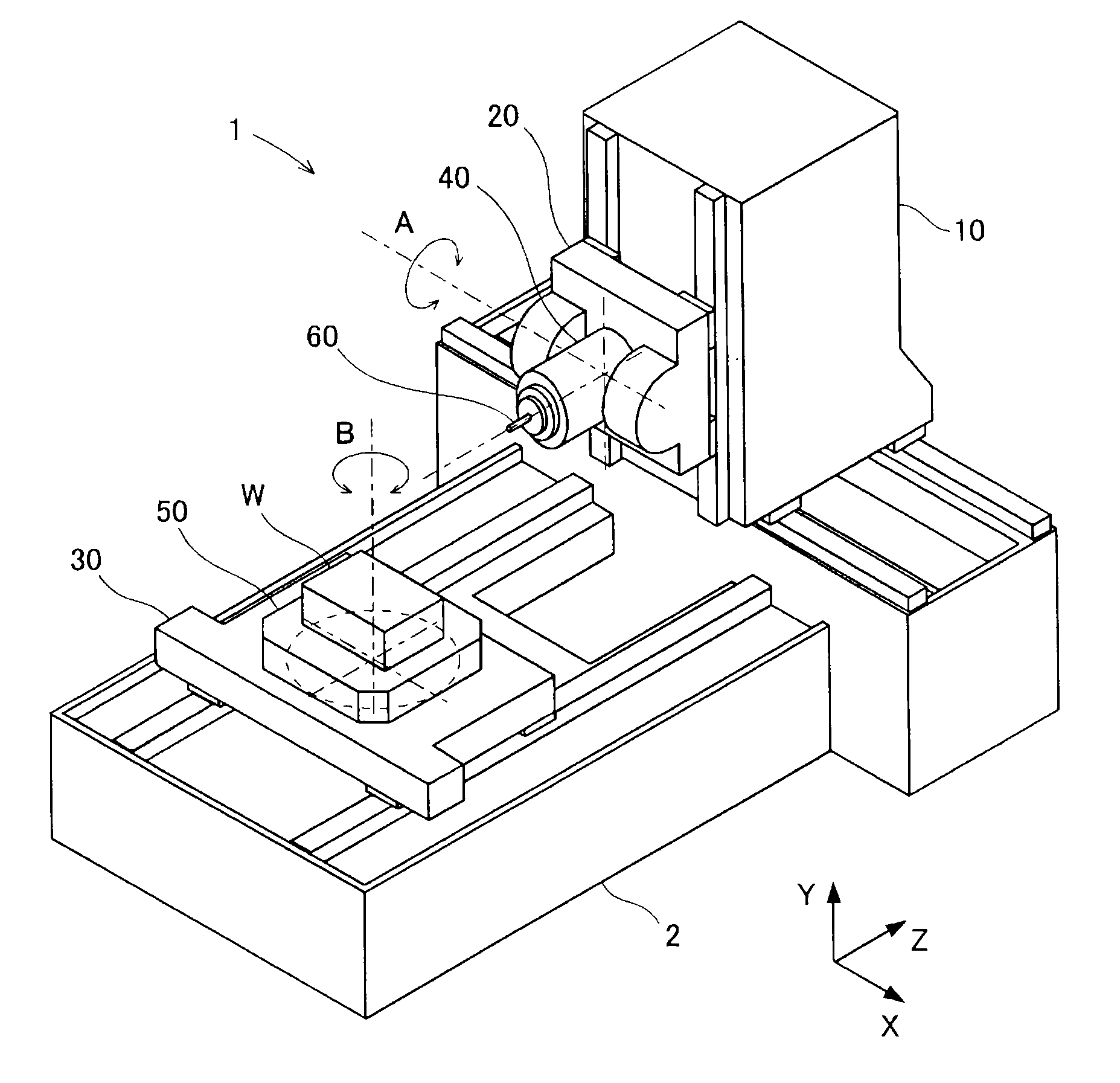

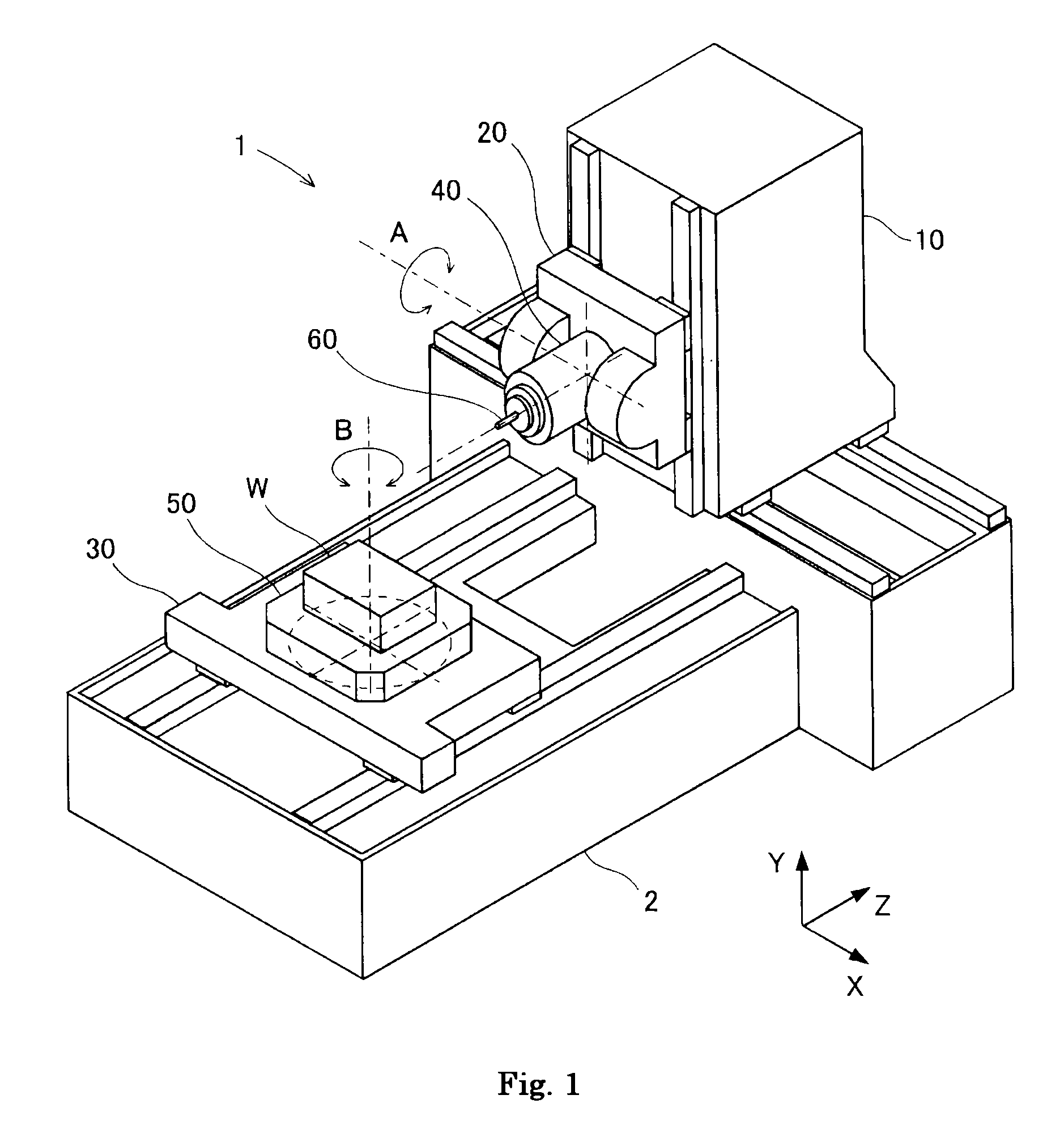

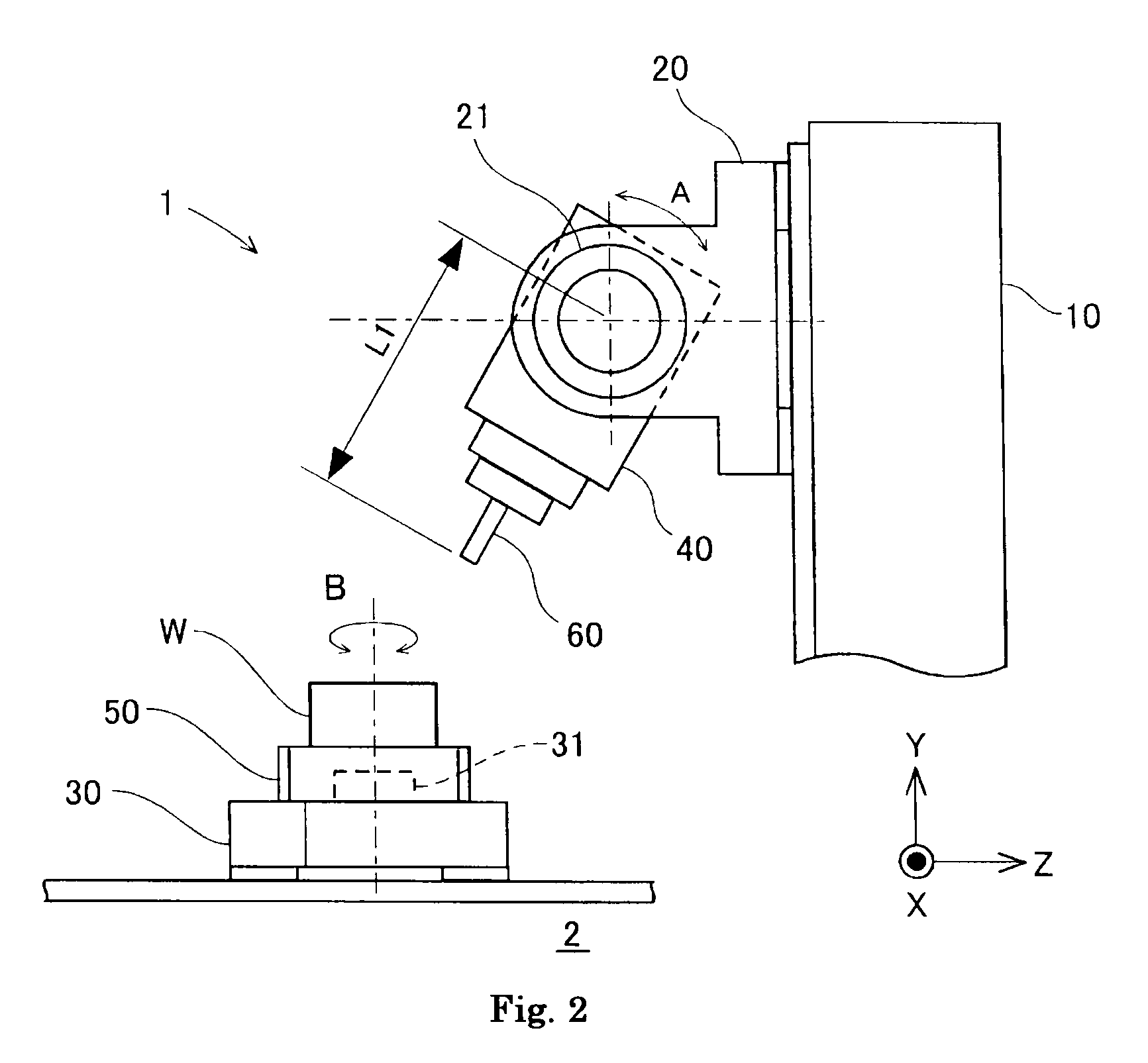

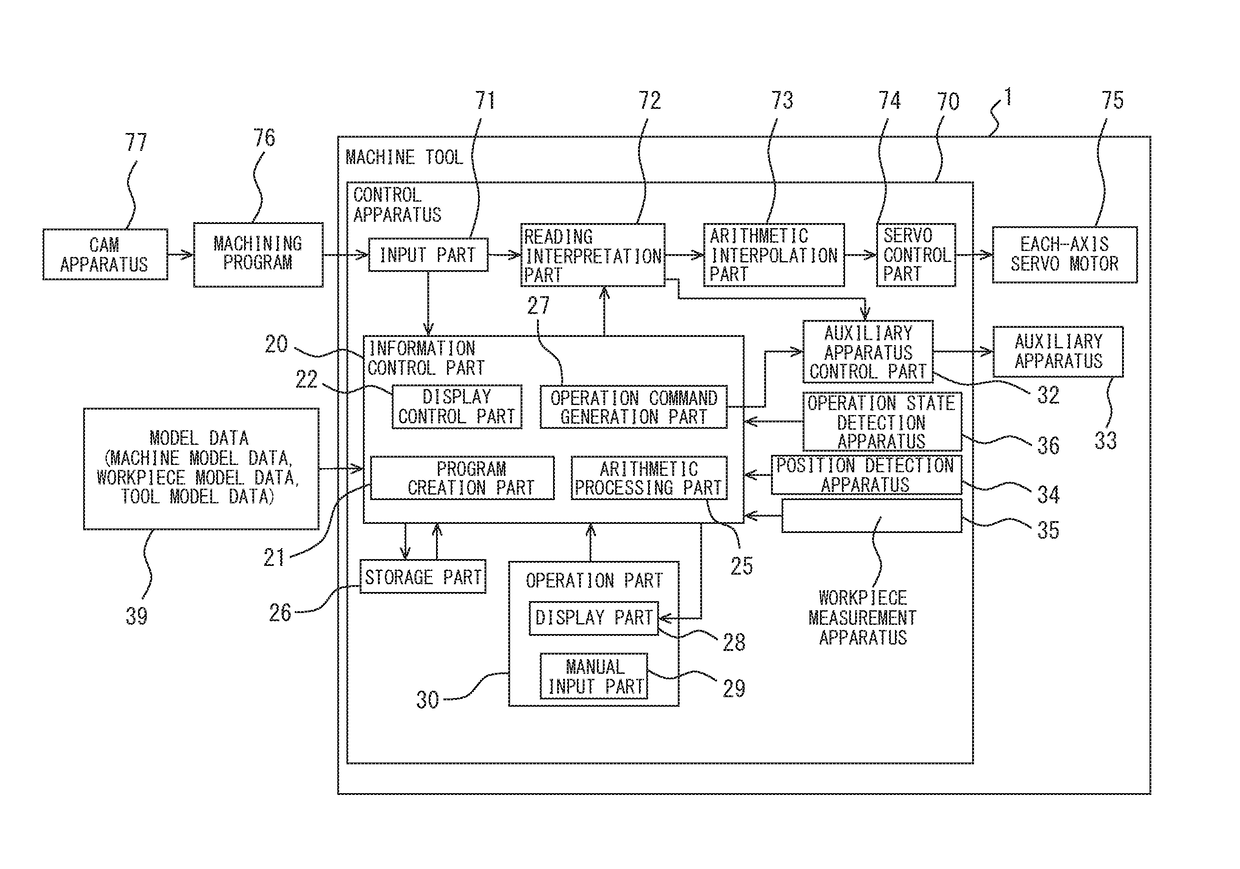

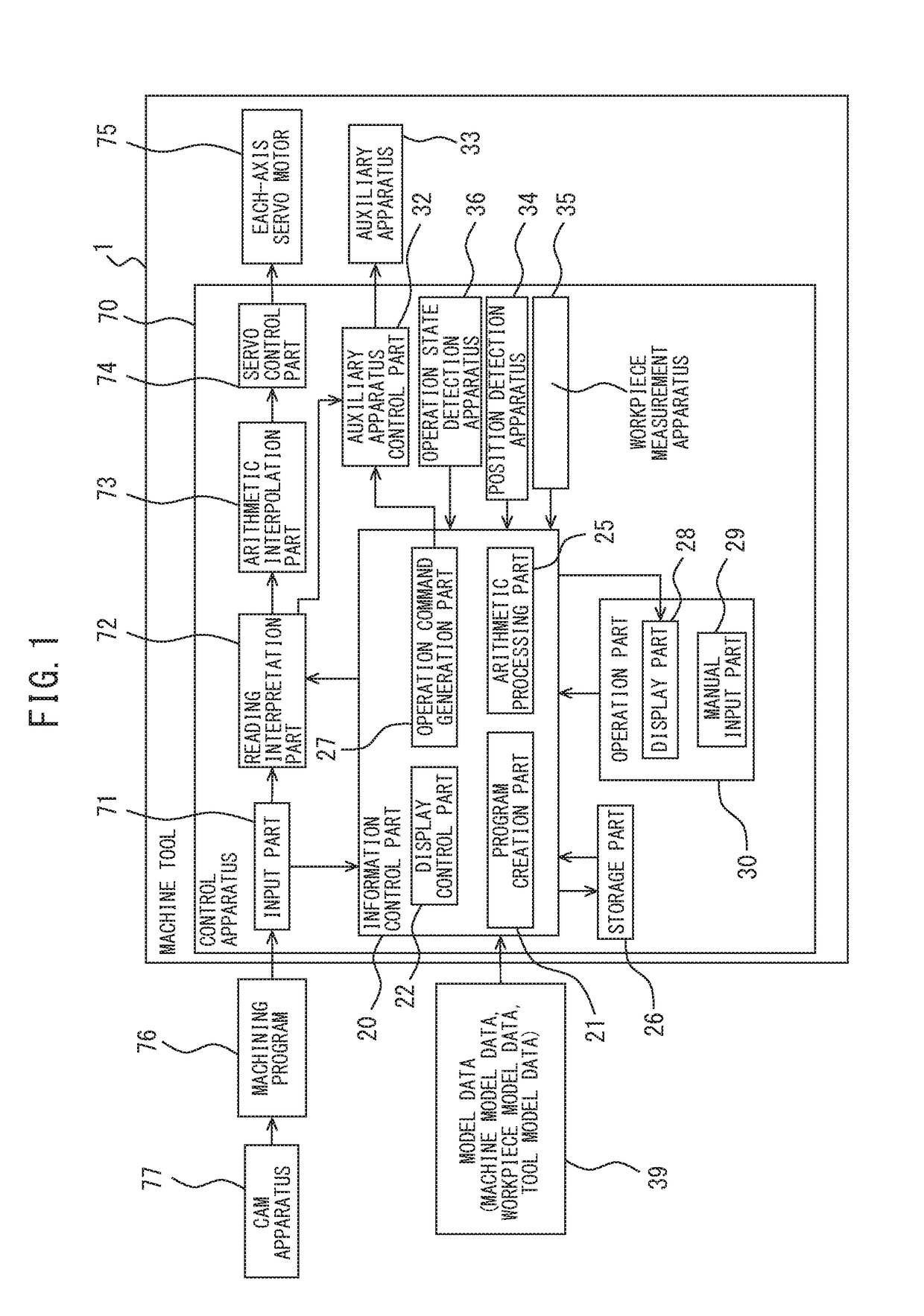

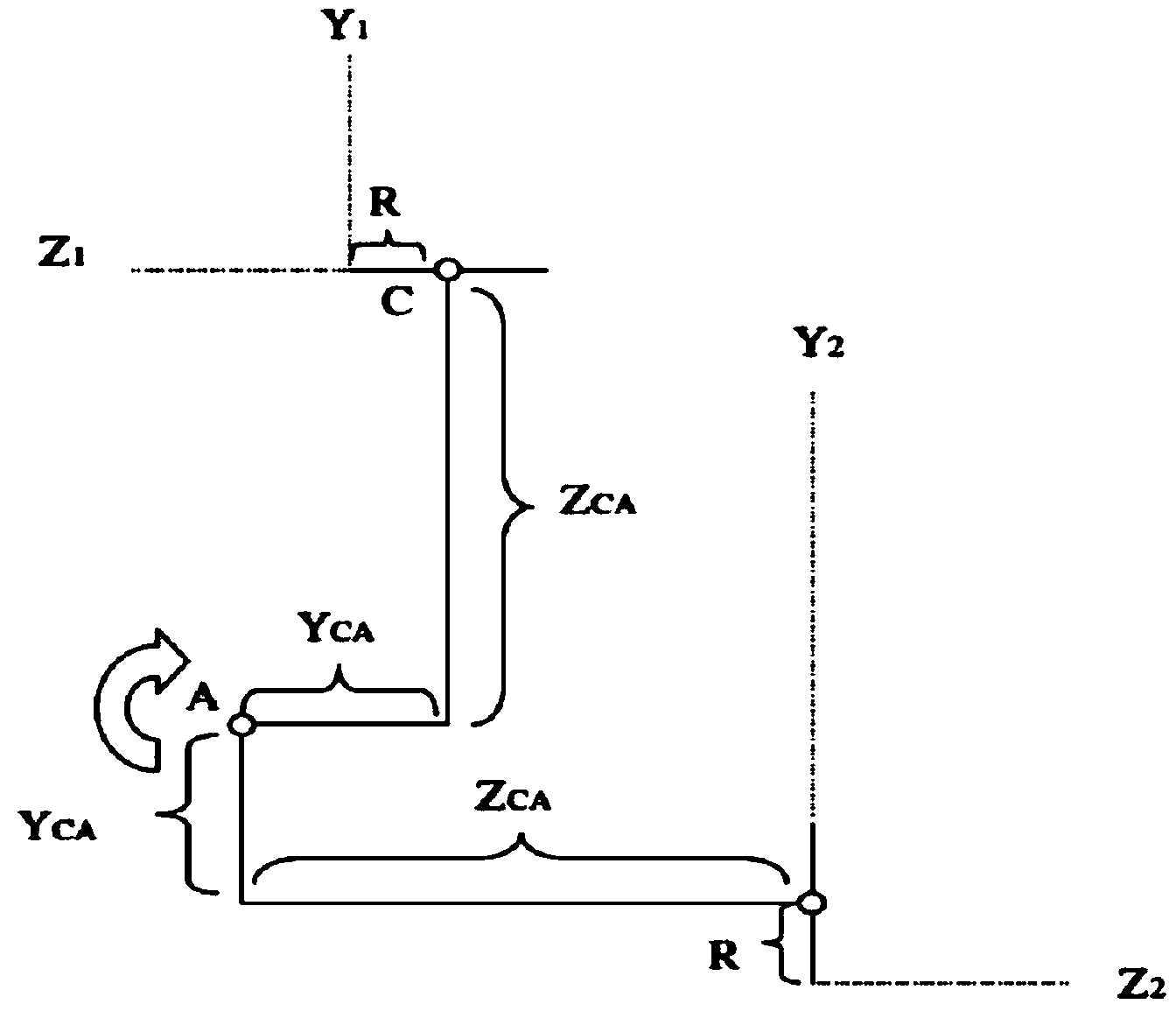

Controller for machine tool and five-axis simultaneous control machine tool controlled thereby

InactiveUS20110044778A1Improve machining accuracyAutomatic control devicesPlaning/slotting machinesSynchronous controlControl data

It is an object of the present invention to provide a controller for a machine tool and a five axis simultaneous control machine tool controlled thereby which can improve the machining accuracy in machining by controlling a driving axis including a linear axis and a pivoting axis.The controller comprises a detecting member 102 detecting a machining position where a pivoting axis is reversed in machining by the machine tool 1 based on the control data, an allowable position error setting member 103 setting an allowable position error Δ between a commanded machining position P1 and an actual machining position P2, an allowable acceleration deciding member 107 deciding the allowable acceleration about the pivoting axis based on a distance L1, L2 from the machining position of the reversed axis to a center of the pivoting axis and based on the allowable position error Δ being set, and a controlling member 108 controlling a velocity about the driving axis based on the allowable acceleration.

Owner:JTEKT CORP

Machine tool control method and machine tool control device

InactiveUS20170308055A1Easy to operateErroneous operation can be suppressedProgramme controlComputer controlMachine tool controlComputer science

This method of controlling machine tool for machining a workpiece by moving a tool and the workpiece relatively to each other comprises: displaying an image of the machine tool on a display unit, pre-storing a motion of the machine tool corresponding to an operation by an operator with respect to the image of the machine tool; obtaining a content of the operation by the operator with respect to the image of the machine tool; generating an operation command for causing the machine tool to operate according to the operation content; and activating the machine tool on the basis of the operation command.

Owner:MAKINO MILLING MASCH CO LTD

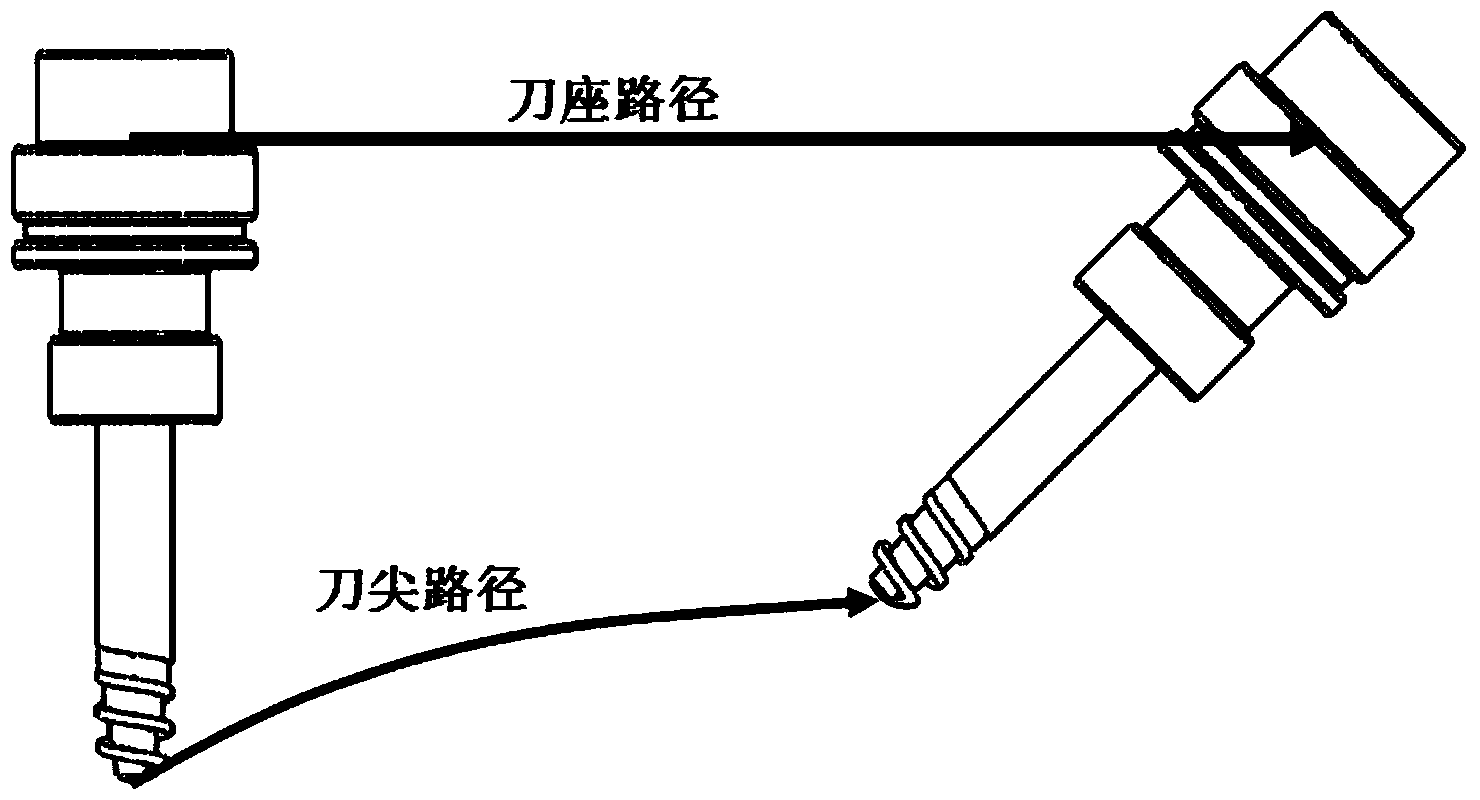

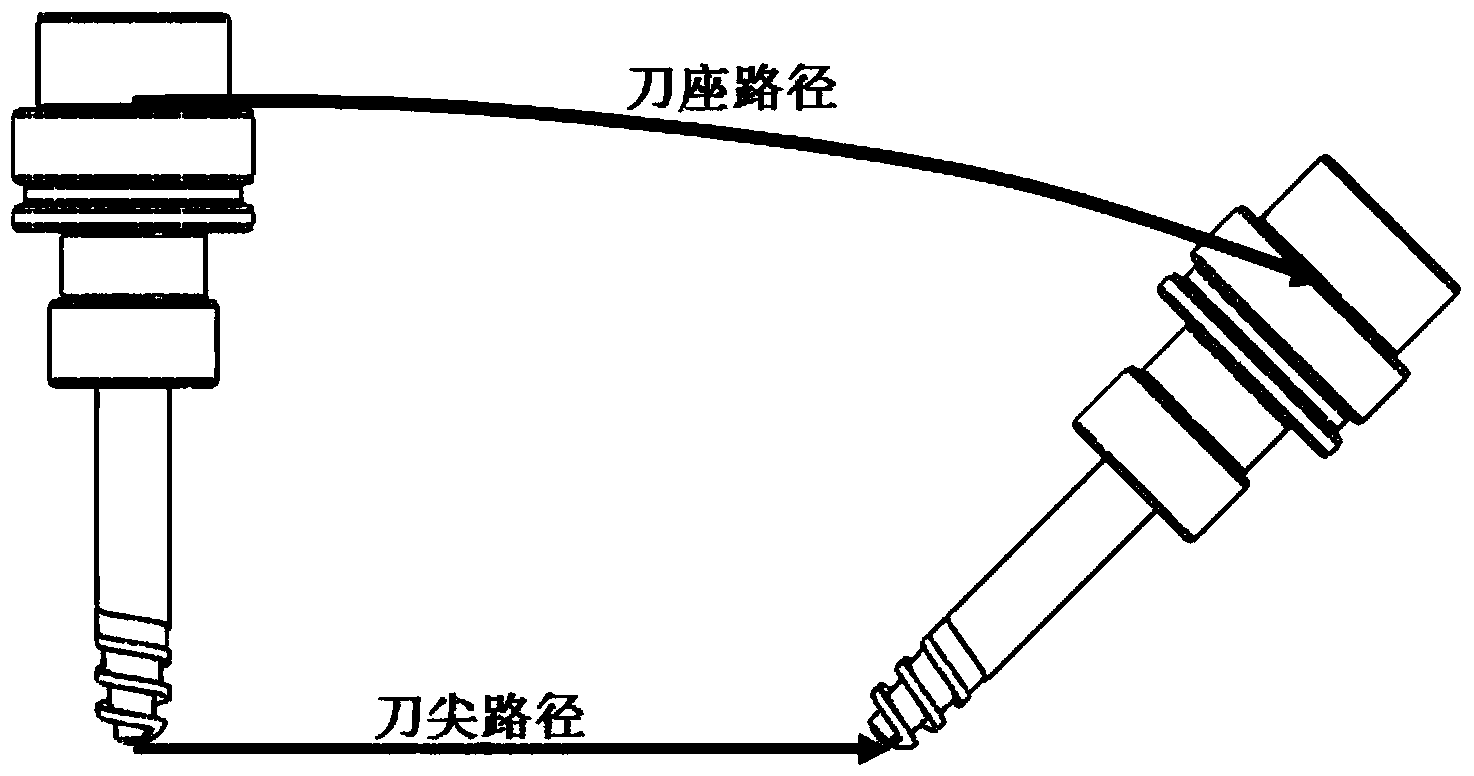

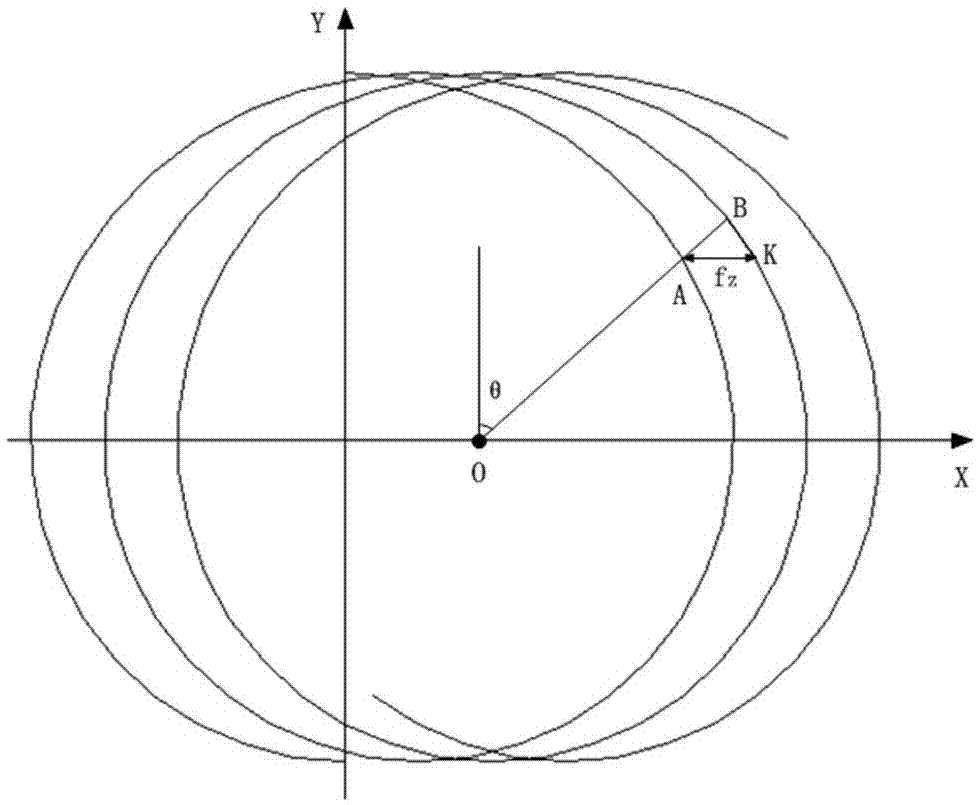

Cutter point control method for rotating tool of double-rotating-work-table five-shaft machine tool

ActiveCN103862326AImprove rigidityImprove processing efficiencyAutomatic control devicesFeeding apparatusControl systemMachine tool control

The invention discloses a cutter point control method for a rotating tool of a double-rotating-work-table five-shaft machine tool. On the basis of a standard numerical control system with an RTCP (rotating tool center point) function, compiling post treatment is carried out according to the structural form of a five-shaft numerical control machine tool. The post treatment refers to a process for converting cutter position source files into a numerical control program identified by a machine tool control system. An RTCP option function is realized on a control system, the coordinate transformation is calculated through a controller, the processing procedures can maintain unchanged, and for the same batch of parts, the frequent program change due to installing and clamping position change is not needed. Only corresponding coordinate positions need to be written into parameters. Meanwhile, the method also brings following advantages that machined workpieces are diverse, the machining efficiency is improved, and the machining precision is high.

Owner:盐城永鑫塑料制品有限公司

Multi-axis linkage ultrasonic modulation micro-electrochemical machining system

ActiveCN105290548AAchieve protectionEasy to controlElectrical-based machining electrodesElectric circuitsElectrolysisMachine tool control

A multi-axis linkage ultrasonic modulation micro-electrochemical machining system comprises an ultrasonic vibration system, an ultrasonic synchronization system, an electrochemical machining power supply system, a multi-axis machine tool control system, a working liquid circulating system, a machining positioning and gap detection system and an online parameter observation and control system. A transverse and longitudinal excitation device is additionally arranged on the joint of an amplitude-change pole, and a machine tool can machine a complex three-dimensional curve or special-shaped hole groove; a machine tool working table is a multi-axis linkage control feeding mechanism, the micro feeding movement of the multi-dimensional space of the working table is achieved, and it is ensured that the machining process is stable; an encoder and a micro displacement sensor are additionally arranged on a machine tool feeding mechanism, and therefore machining gap control and workpiece precise positioning feeding movement can be facilitated; in the machining process, parameter changes can be online observed in real time, preparing and conveying of needed work liquid can be completed by controlling a working liquid delivery device; and workpiece and tool electrode protection can be achieved during machining area collision or short circuit by controlling a switch of an electromagnetic valve and the multi-axis machine tool control system.

Owner:YANGZHOU UNIV

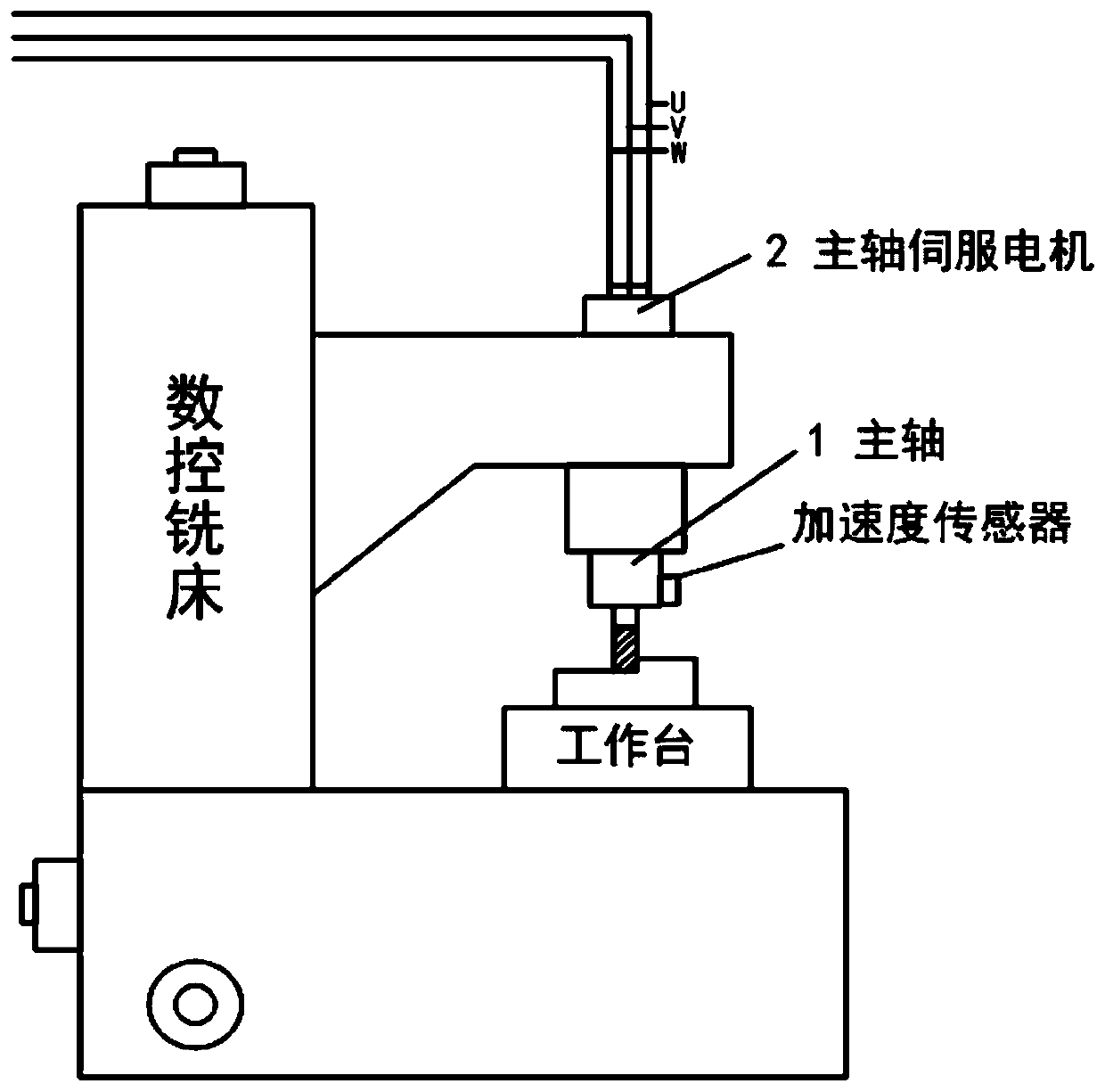

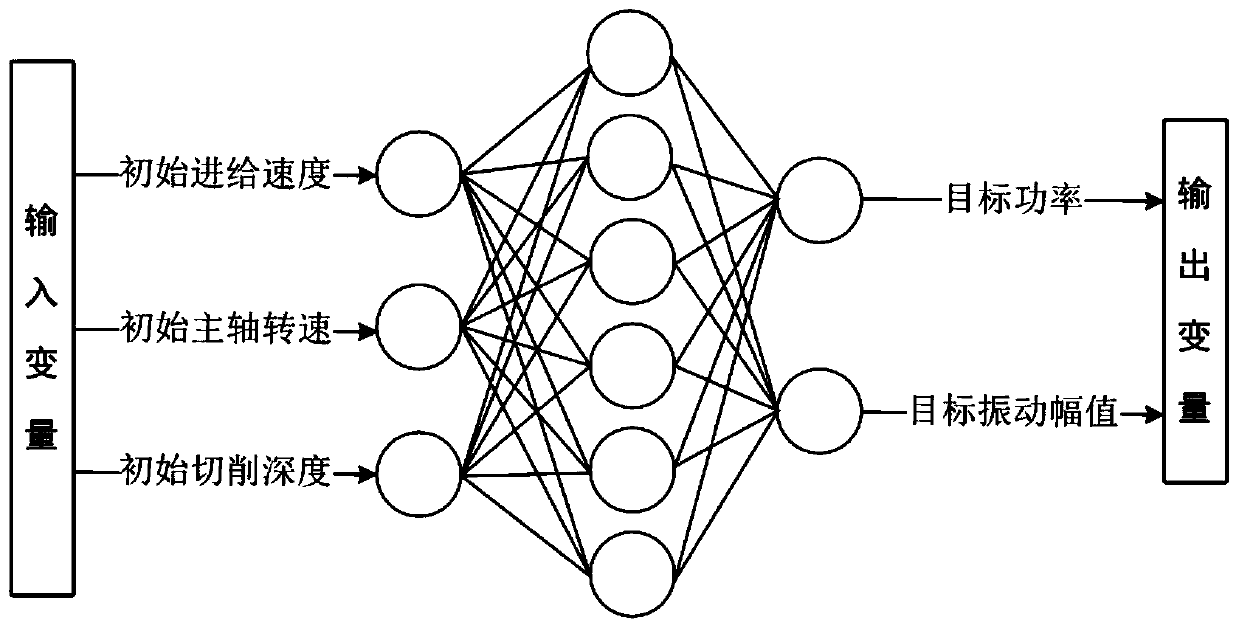

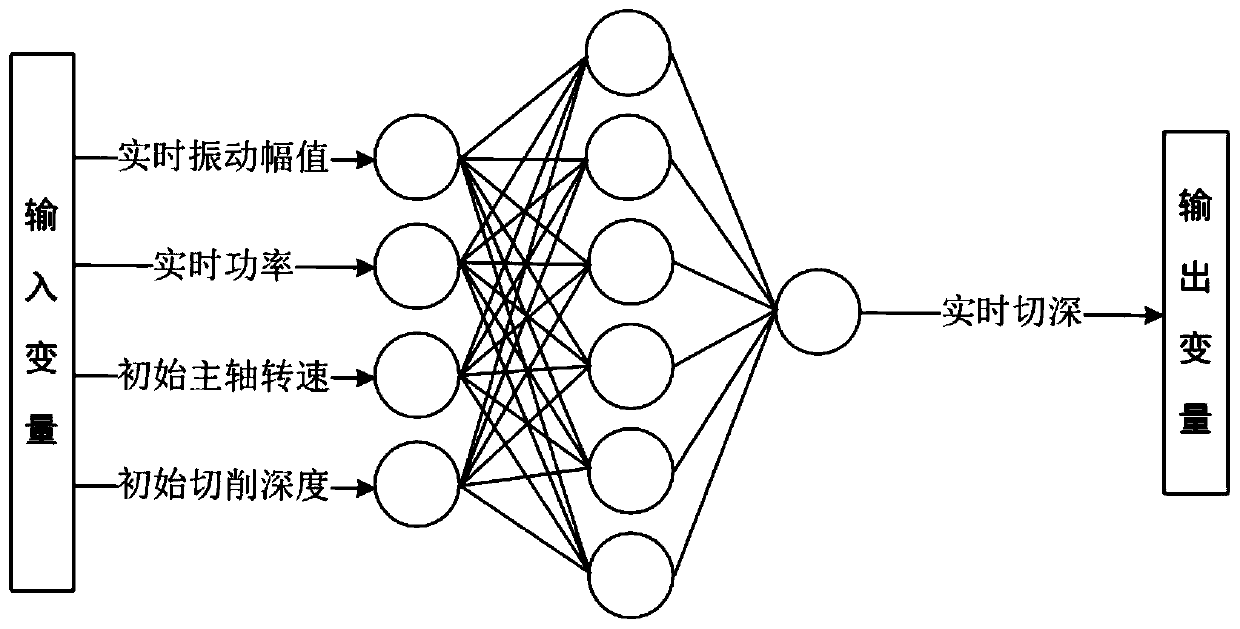

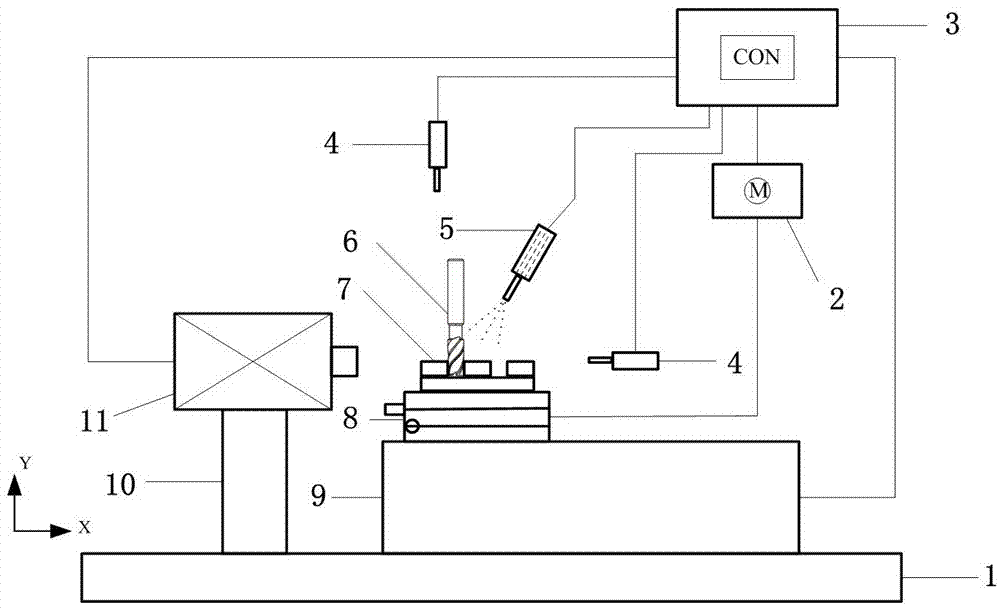

Adaptive machine tool control method based on GA-BP neural network algorithm

ActiveCN110488754AImprove processing efficiencySave production time and costProgramme controlComputer controlNumerical controlMachine tool control

The invention discloses a machine tool self-adaptive control method based on a GA-BP neural network algorithm, and belongs to the technical field of numerical control machining. The method comprises the steps that a spindle motor power signal and a spindle vibration signal in the workpiece numerical control machining process are monitored in real time, and the feeding speed and the spindle rotating speed are optimized in real time and adjusted adaptively based on the spindle power signal and the spindle vibration signal; and the whole signal acquisition process does not influence normal processing. The machine tool self-adaptive control method based on the neural network algorithm can be used to effectively improve the machining efficiency and the machining quality, prolong the service life of a cutter and a machine tool and reduce the cost.

Owner:DALIAN UNIV OF TECH

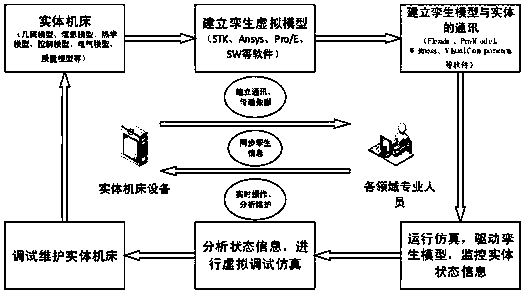

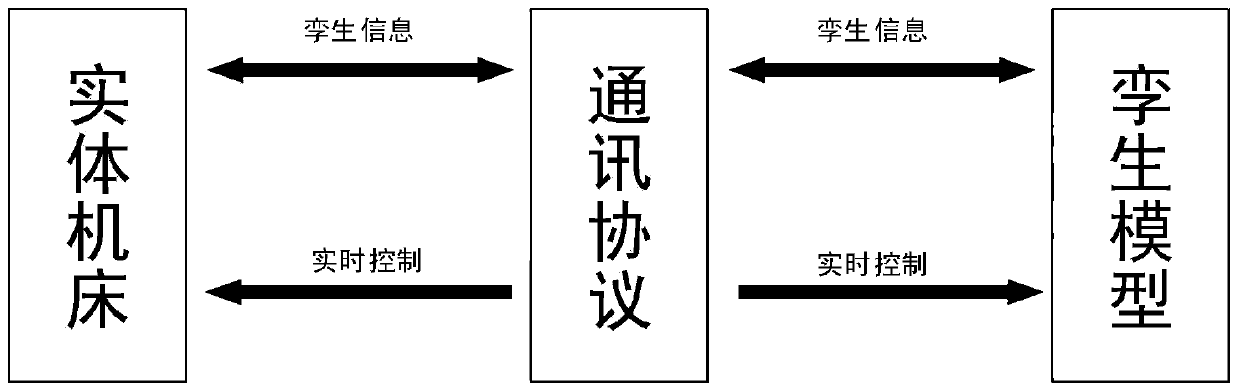

Five-axis numerically-controlled machine tool control method based on digital twins

InactiveCN110865607APredict processing effectGuide actual engineering operationsProgramme controlComputer controlNumerical controlControl engineering

The invention relates to a five-axis numerically-controlled machine tool control method based on digital twins. The five-axis numerically-controlled machine tool control method based on the digital twins is characterized by comprising the steps of: 1, establishing a twin virtual model similar with a physical entity; 2, establishing a digital twin model of a five-axis numerically-controlled machinetool; 3, establishing a communication between the twin virtual model and the entity five-axis numerically-controlled machine tool in virtual simulation software; 4, establishing a processing and analysis system for twin data; and 5, enabling the five-axis numerically-controlled machine tool and the twin virtual model to keep twin information synchronization in real time. The five-axis numerically-controlled machine tool control method based on the digital twins is scientific and reasonable; data real-time synchronization can be carried out between the twin virtual model and the entity five-axis numerically-controlled machine tool; not only can simulation be carried out before machining, a scheme for solving problems can be timely found, a product machining effect can be predicted and theactual engineering operation is guided, but also a machining state can be monitored in real time and visually displayed in the machining process so as to timely find and correct problems of the machining link and improve machining efficiency.

Owner:TIANJIN UNIV

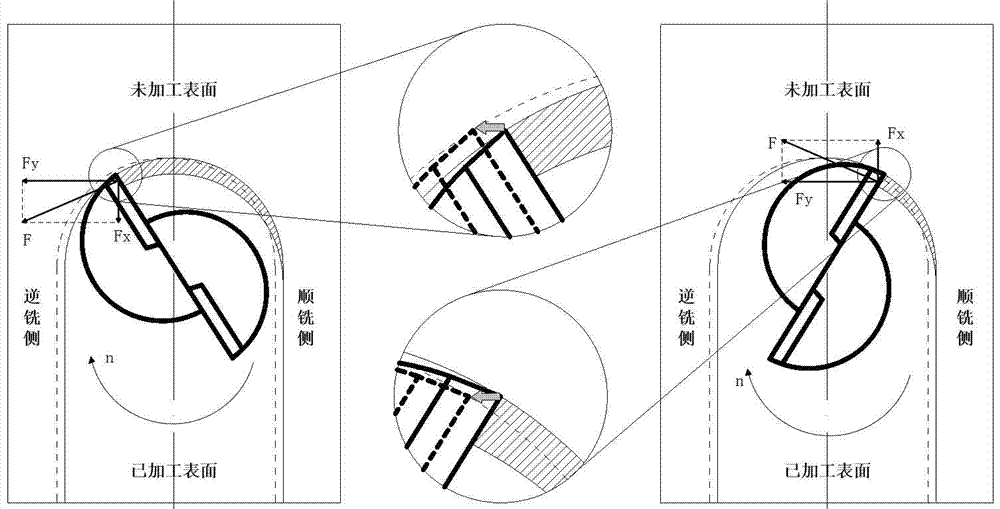

Method for predicting and compensating machining deformation error of miniature trough

ActiveCN107511516AEliminate uncertaintyImprove machining accuracyMeasurement/indication equipmentsMilling equipment detailsMilling cutterDevice form

The invention relates to the field of machining, in particular to a method for predicting and compensating a machining deformation error of a miniature trough. A device form predicting and compensating the machining deformation error of the miniature trough comprises a machine tool working table, a micro milling cutter, a miniature groove piece, a dynamometer and a support, and the dynamometer and the support are arranged on the machine tool working table in parallel. According to the method, a displacement sensor is utilized to online monitor machining deformation of the miniature groove piece in real time, a sensing working table is utilized to transmit the adjusting information so as to conduct real-time adjustment on the miniature groove piece, uncertain factors caused by manual adjusting and radial undercut caused by workpiece deformation are eliminated, and accordingly the machining accuracy and the workpiece quality are improved. An adjuster is independent of a machine tool control system, a tool path planed by an existing program cannot be affected, the programming time is saved greatly, and accordingly the production efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

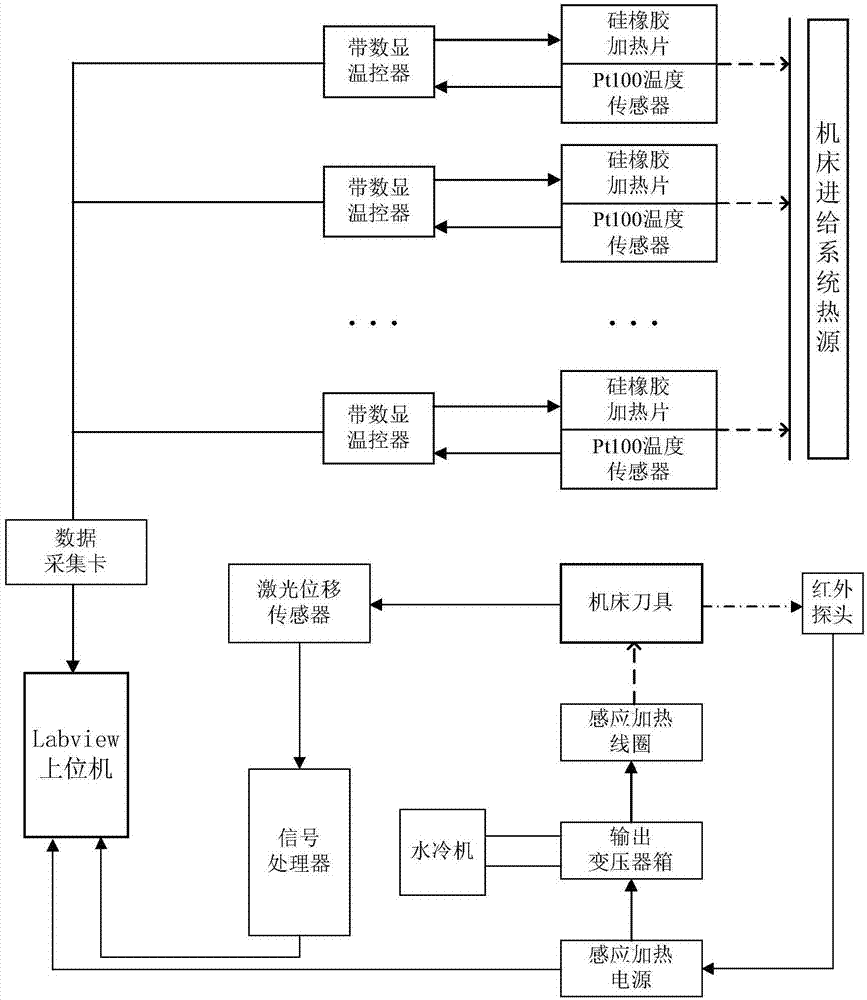

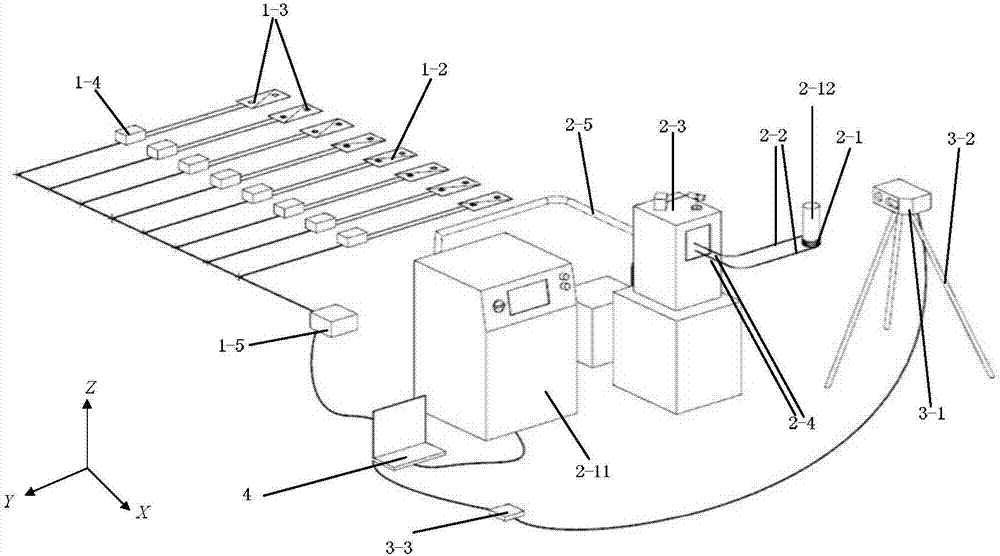

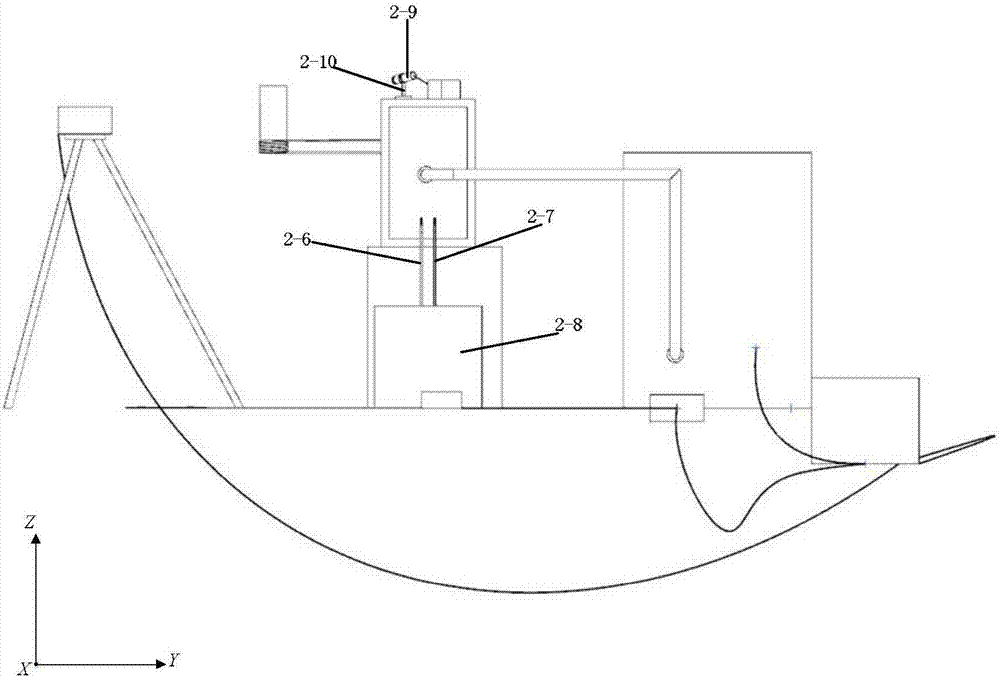

Thermo-mechanical load simulation and error detection system and method for machine tool cutting machining process

ActiveCN107498391AThe actual working conditions meetExperimental conditions meetMeasurement/indication equipmentsControl systemMachine tool control

The invention discloses a thermo-mechanical load simulation and error detection system and method for a machine tool cutting machining process. The machine tool thermo-mechanical load simulation and error detection system comprises a machine tool working table, a spindle core rod, a controller, a control system, a cutting thermal simulation device, a one-way cutting force simulation device and a machine tool feeding system heat source simulation device, wherein the cutting thermal simulation device and the one-way cutting force simulation device are arranged on the machine tool working table. According to the thermo-mechanical load simulation and error detection system and method for the machine tool cutting machining process, a mechanism of a machine tool does not need to be dismounted from the machine tool, so that an experimental situation more accords with the actual working condition; and meanwhile, an error value can be fed back to a compensation module in a machine tool control system, the machining error can be decreased, and the machining precision can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

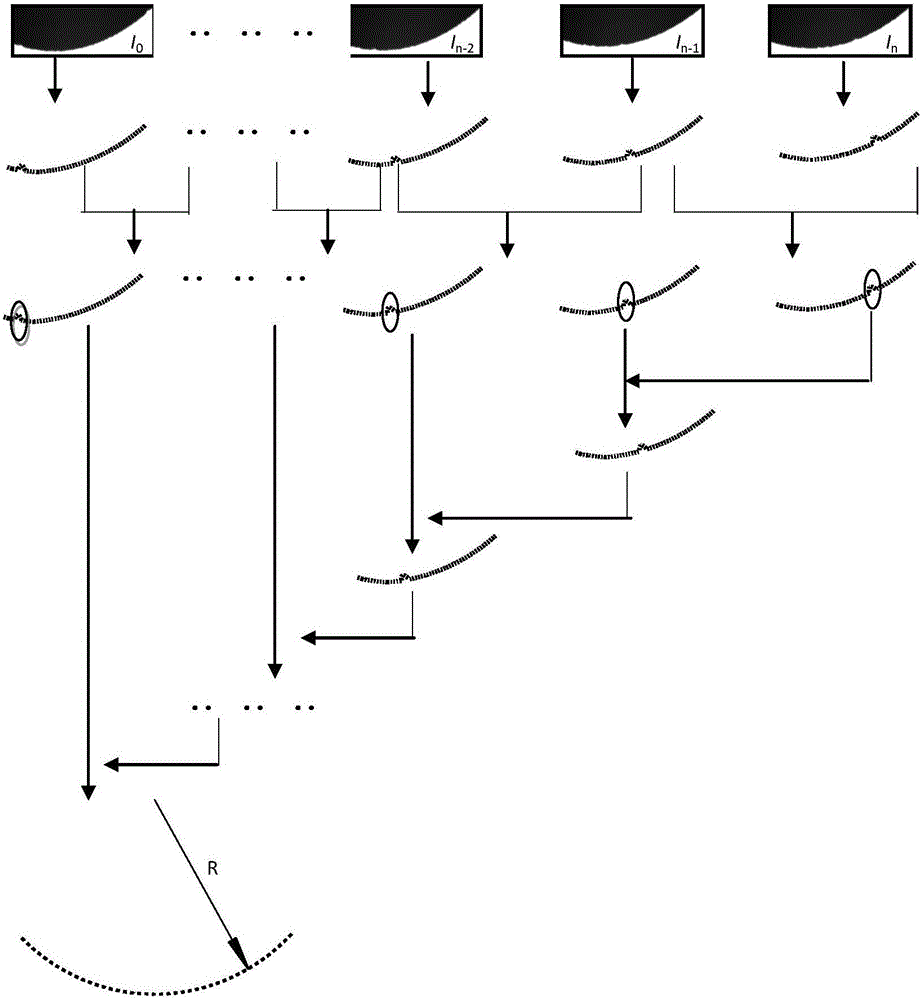

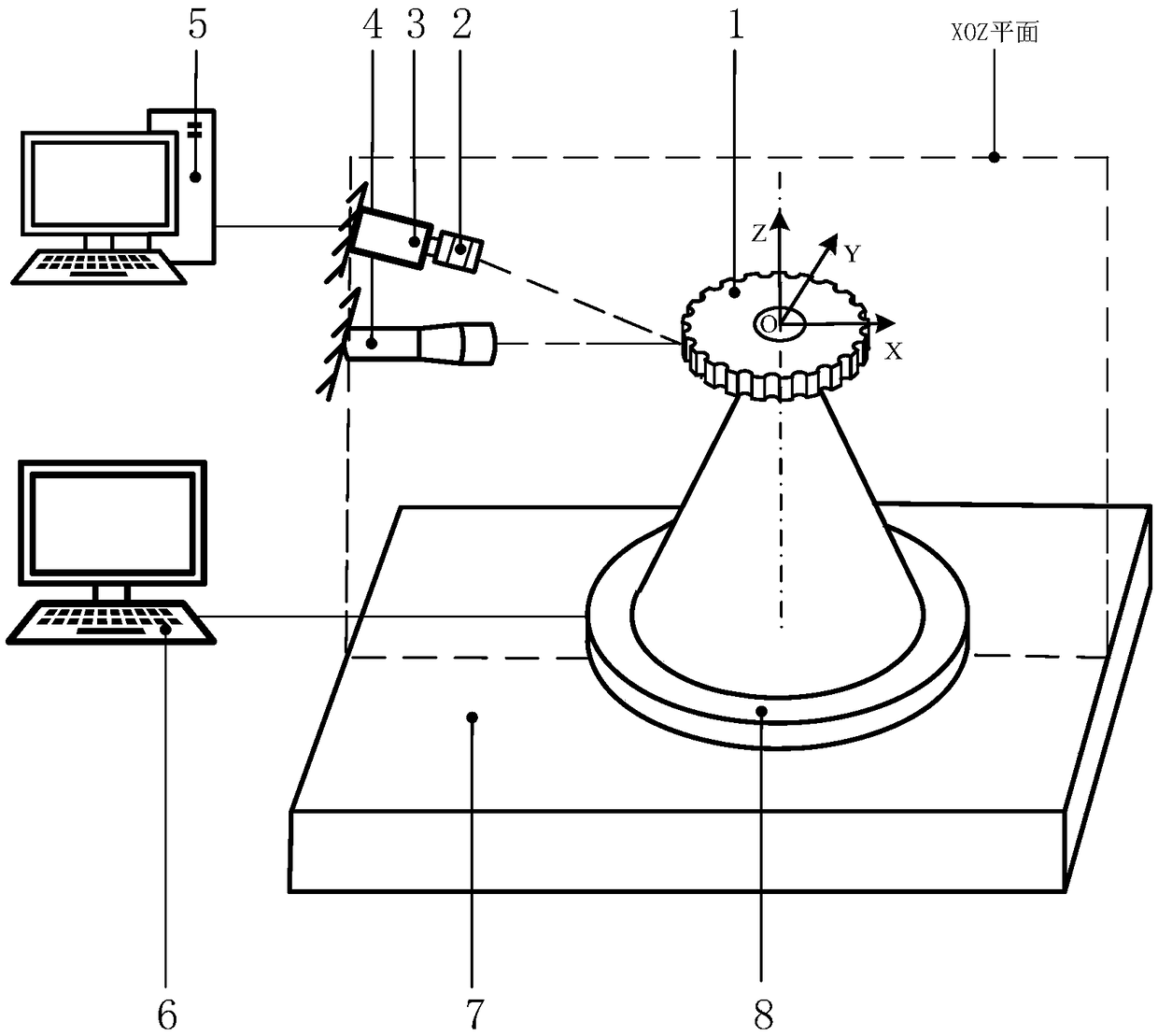

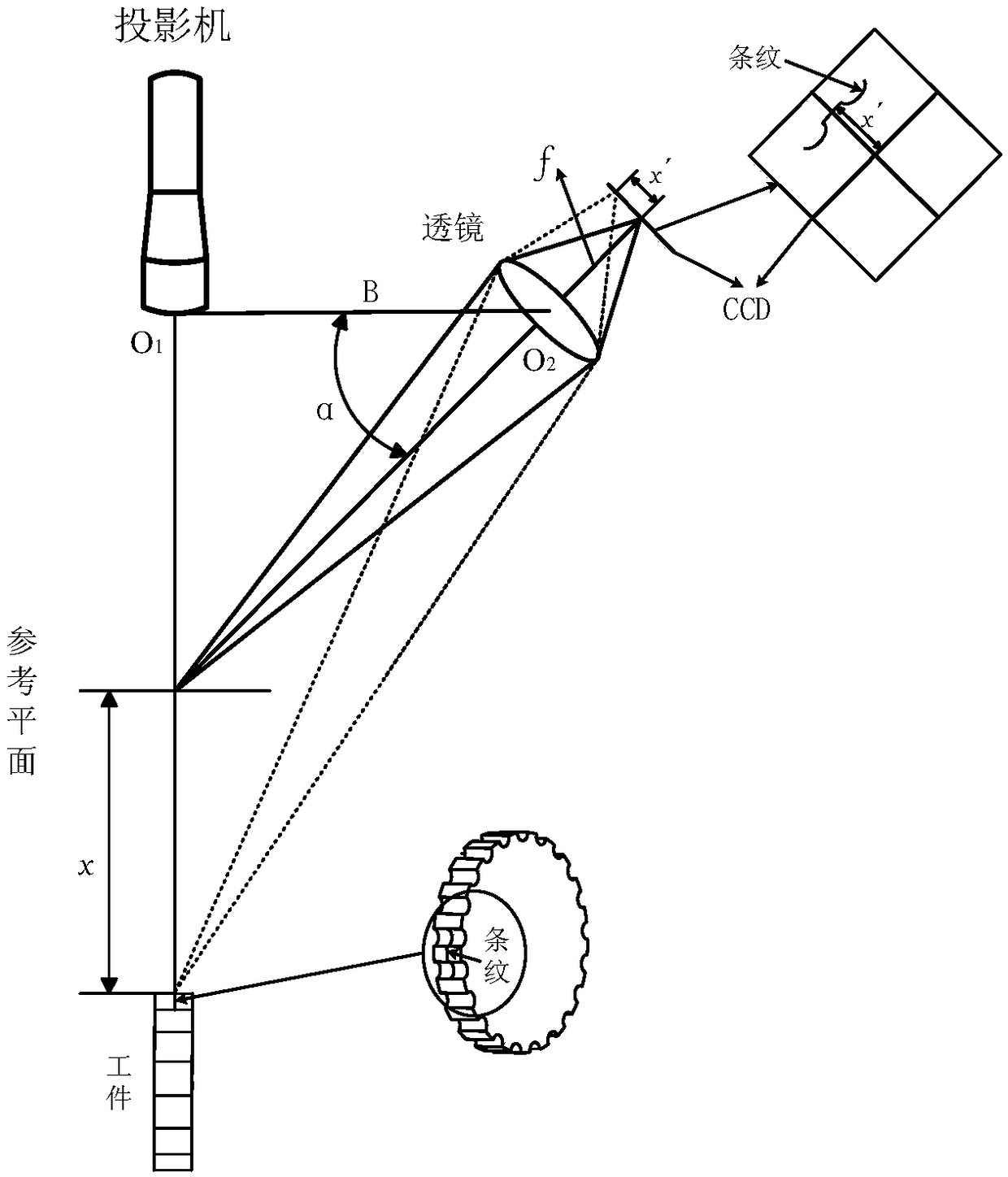

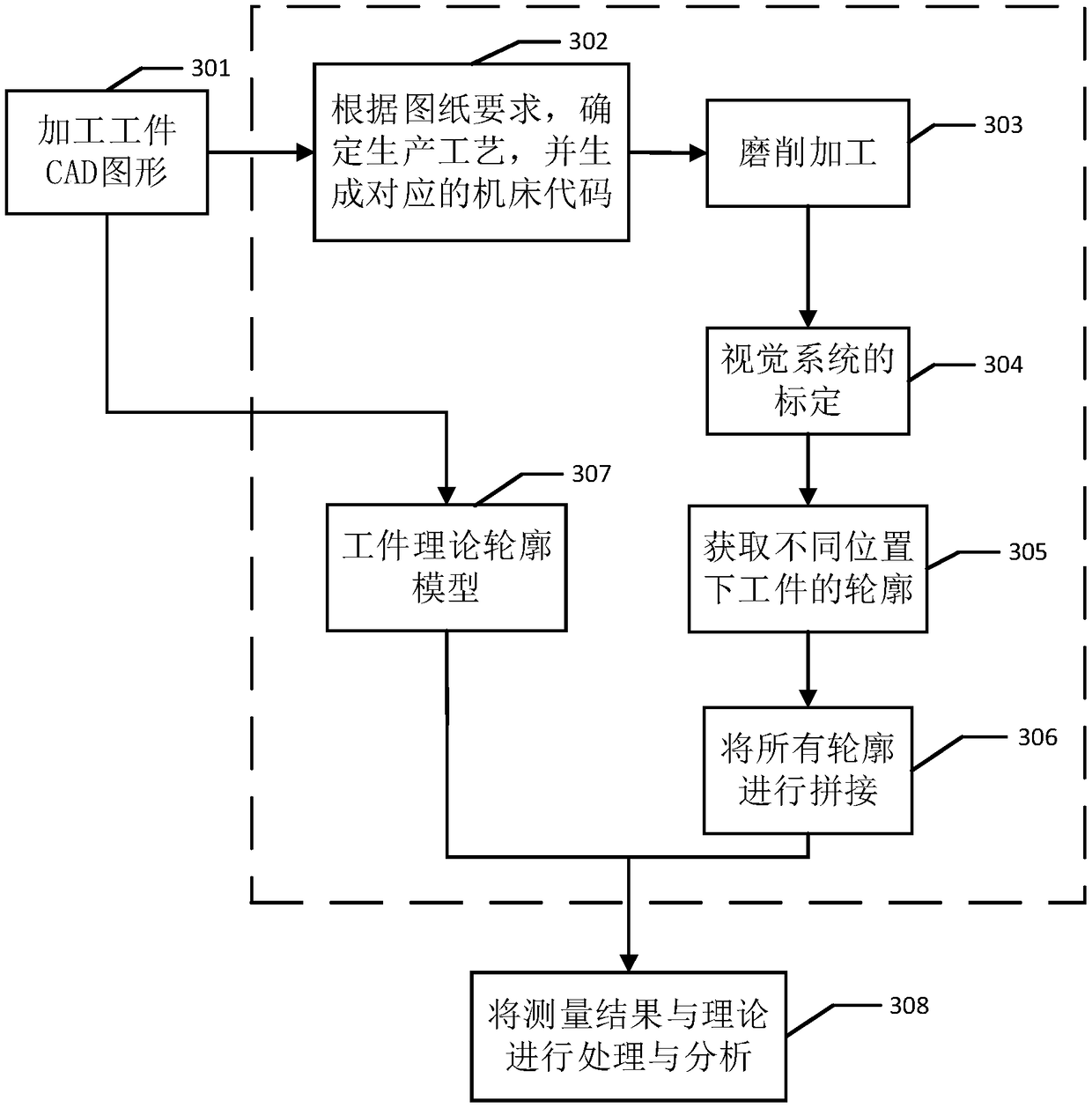

On-machine non-contact workpiece contour detection system and method of cycloid gear grinder

InactiveCN108789155ALow costHigh precisionGrinding feed controlUsing optical meansControl systemMachine tool control

The invention discloses an on-machine non-contact workpiece contour detection system of a cycloid gear grinder. The on-machine non-contact workpiece contour detection system of the cycloid gear grinder comprises a machine tool rotary table, a machine tool bed, a CCD camera, a telecentric lens, a projector, a machine tool control system and an upper computer. The machine tool rotary table is installed on the machine tool bed at the bottom, and workpieces are clamped on the machine tool rotary table through central positioning holes. The CCD camera and the projector are fixed to the machine toolbed on the left side. The machine tool control system is connected with the machine tool rotary table in a circuit mode to be used for controlling the rotary table to rotate so as to measure workpiece contours at different positions. The CCD camera is connected with the upper computer in a circuit mode to be used for transmitting the photographed image to the upper computer for processing. The invention further discloses an on-machine non-contact workpiece contour detection method of the cycloid gear grinder. The on-machine non-contact workpiece contour detection system and method of the cycloid gear grinder have the characteristics of low cost, high efficiency and high precision, can be widely applied to various occasions of on-machine non-contact detection and processing, and have greatpotential.

Owner:SOUTH CHINA UNIV OF TECH +1

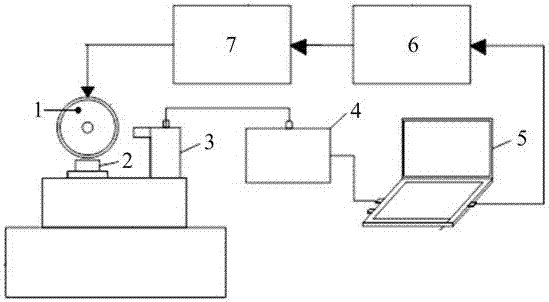

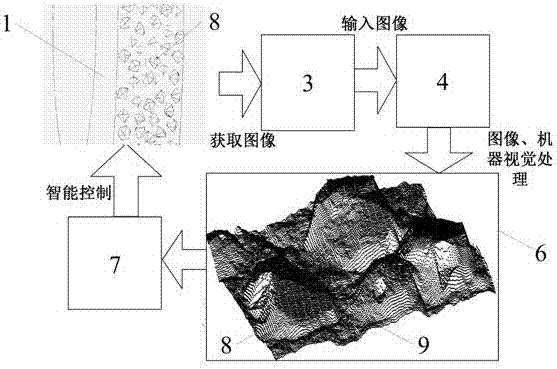

Grinding wheel sharpening finishing image visual monitoring device and method

PendingCN106941605AImprove sharpening efficiencyImprove trimming accuracyTelevision system detailsColor television detailsReconstruction methodEngineering

The invention discloses a grinding wheel sharpening finishing image visual monitoring device, and the device comprises an image collection apparatus which is used for taking a picture of three-dimensional shape of a surface micro-abrasive-particle edge of a grinding wheel; an image and machine vision processing system which enables an abrasive particle three-dimensional point cloud shape to be displayed through a three-dimensional reconstruction method; and a CNC integrated control system which is used for observing the condition of the micro-abrasive-particle edge according to the abrasive particle three-dimensional point cloud shape and adaptively adjusting the sharpening finishing technological parameters of the grinding wheel, thereby achieving the online monitoring and intelligent control of the sharpening finishing of the grinding wheel. The invention also provides a grinding wheel sharpening finishing image visual monitoring method. The device employs a high-definition CCD camera and the image and machine vision processing system, extracts the features of the abrasive particle three-dimensional point cloud shape of the surface of the grinding wheel, reconstructs the three-dimensional point cloud shape, restores the condition of the micro-abrasive-particle edge, feeds back the condition to a machine tool CNC control system, adaptively adjusts the sharpening finishing technological parameters, and achieves the online monitoring and intelligent control of the sharpening finishing of the grinding wheel.

Owner:SOUTH CHINA UNIV OF TECH

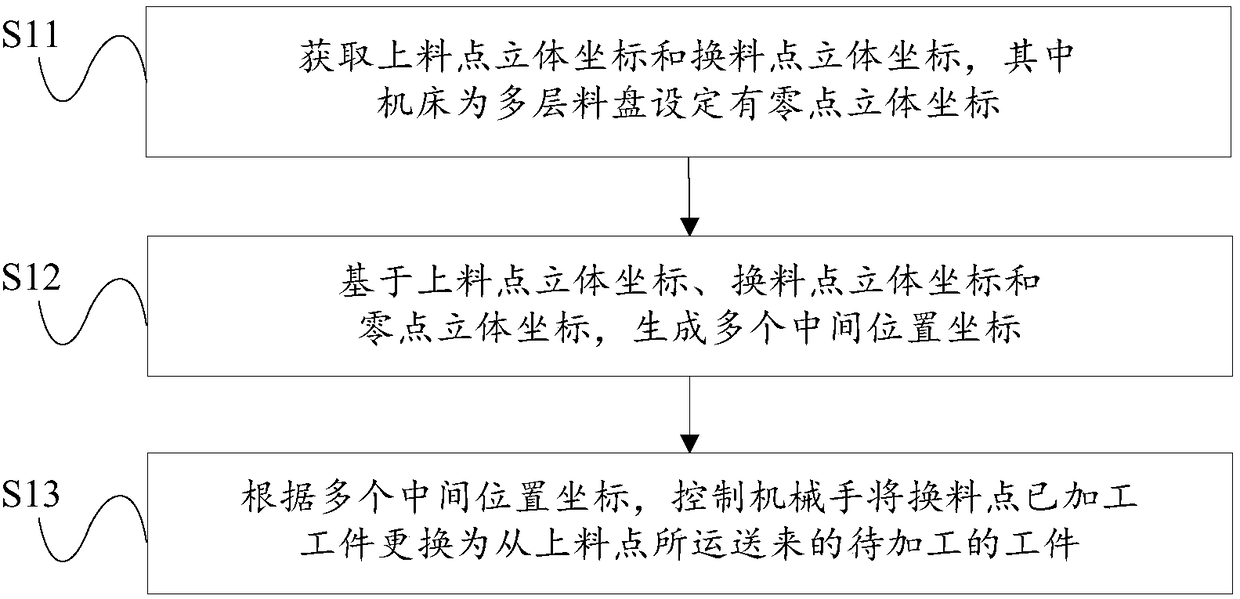

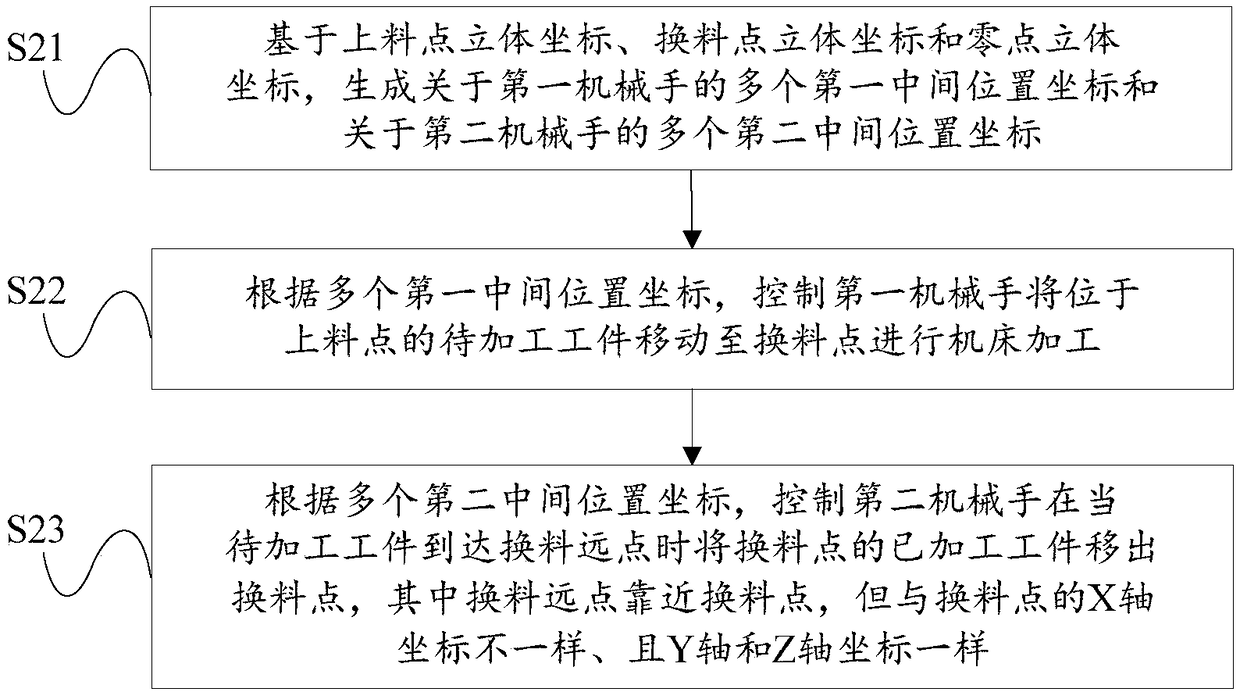

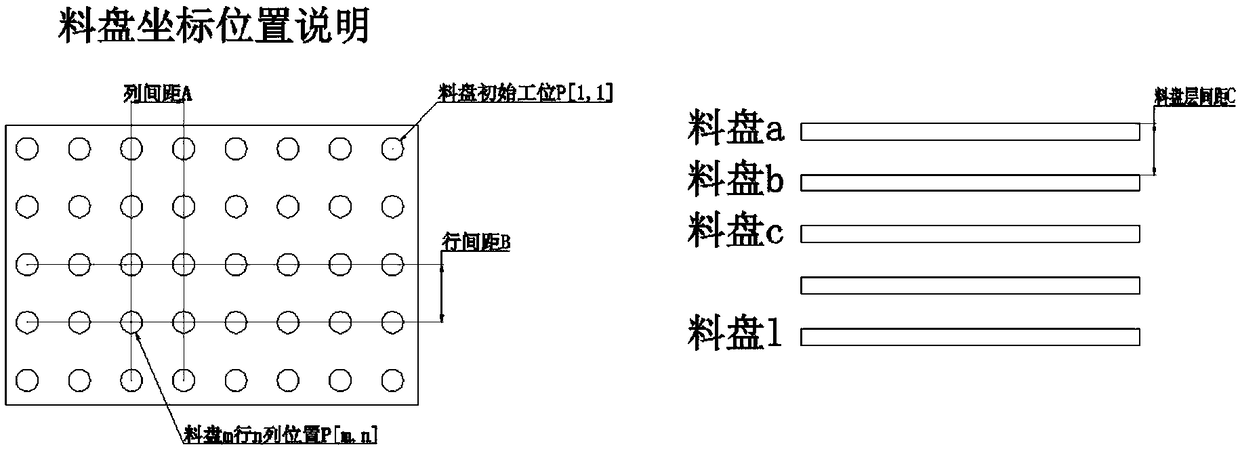

Truss type mechanical arm control method and system for automatic feeding and discharging of machine tool

ActiveCN108581590AEasy to operateRealize automatic controlProgramme-controlled manipulatorMetal working apparatusAutomatic controlThree-dimensional space

The invention relates to the technical field of automatic machine tool control. The embodiment of the invention provides a truss type mechanical arm control method and system for automatic feeding anddischarging of a machine tool. The method comprises the steps that three-dimensional coordinates of a feeding point and three-dimensional coordinates of a reloading point are obtained, and the machine tool sets zero-point three-dimensional coordinates for multiple layers of material discs; on the basis of the three-dimensional coordinates of the feeding point, the three-dimensional coordinates ofthe reloading point and the zero-point three-dimensional coordinates, a plurality of middle position coordinates are generated; and according to the multiple middle position coordinates, a mechanicalarm is controlled to replace machined workpieces at the reloading point with to-be-machined workpieces conveyed from the feeding point. Accordingly, automatic control over feeding and discharging ofthe machine tool in the multi-axis three-dimensional space is achieved; meanwhile, since only two points need to be given, the programming testing process is simple, and testing personnel can easily conduct operation; and furthermore, in the embodiment, the models and the types of machine tools are not limited, so that the technical scheme has high universality.

Owner:上海西码智能科技股份有限公司

Controller for machine tool

ActiveUS20160001410A1Shorten warm-up timeOperation can be efficientlyProgramme controlAutomatic control devicesWarming upMachine tool control

A thermal displacement state (target thermal displacement state) in which thermal displacement of a machine tool is saturated when the machine tool is operated based on a machining program is previously stored, and a warm-up operation pattern of a motor is determined so as to approach the target thermal displacement state. The motor is driven based on the warm-up operation pattern and the warm-up operation of the motor is stopped if the thermal displacement state of the machine tool is within a predetermined range.

Owner:FANUC CORP

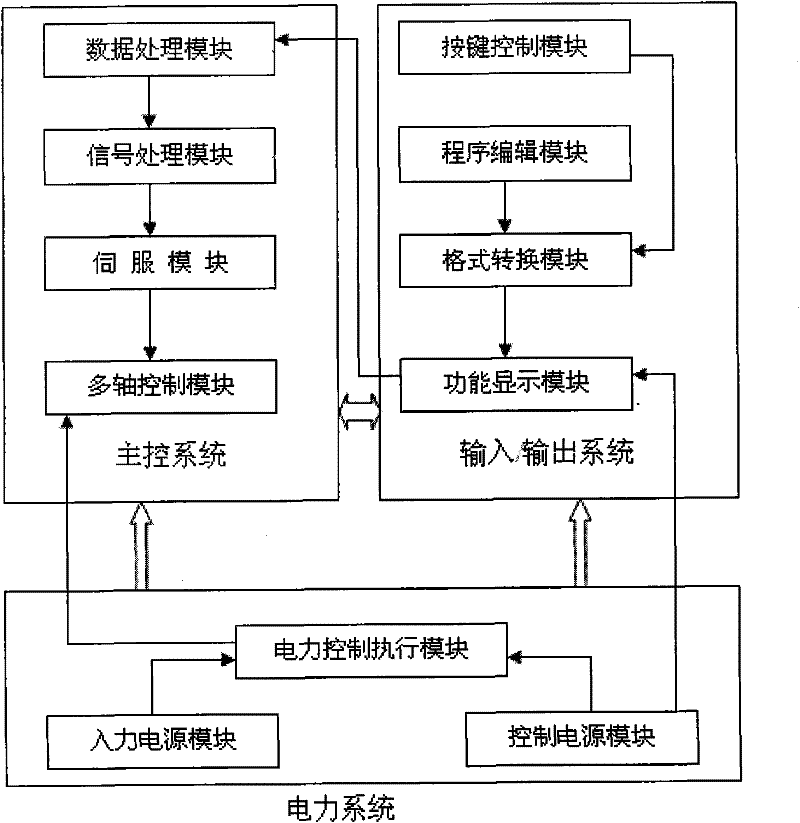

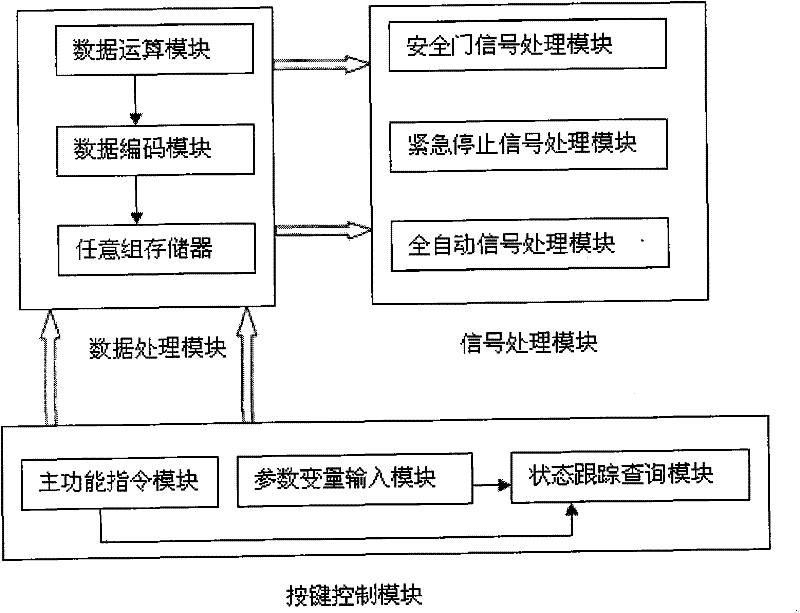

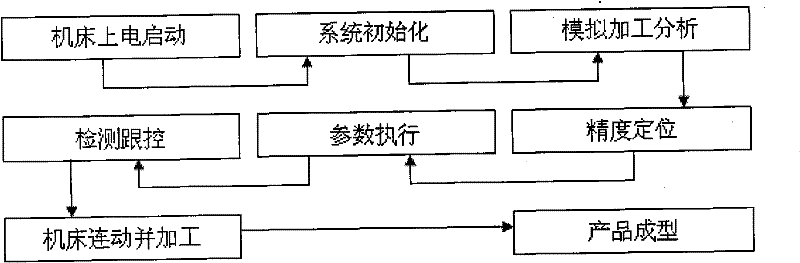

Numerical control processing method and control system for die manufacture

The invention discloses a numerical control processing method based on die manufacture, which comprises the steps as follows: firstly, a numerical control machine is arranged and consists of a machine control system, a servo system, a detection system, a mechanical transmission system and an auxiliary system; secondly, a processing analysis system is arranged in the auxiliary system and implements analog processing analysis by using mapping software; thirdly, the machine control system provides a cushion cap for controlling the locating precision, tracing precision and anti-seismic intensity of the numerical control machine; and fourthly, the servo system is interlocked with the mechanical transmission system to control the feed speed, spindle rotation speed, the positive and negative rotation of the spindle and key parameters for automatic cutter replacing of the numerical control machine, and the detection system follows up to control and corrects errors properly. The invention alsoprovides a control system for realizing the method.

Owner:DONGGUAN GUANHUI HARDWARE

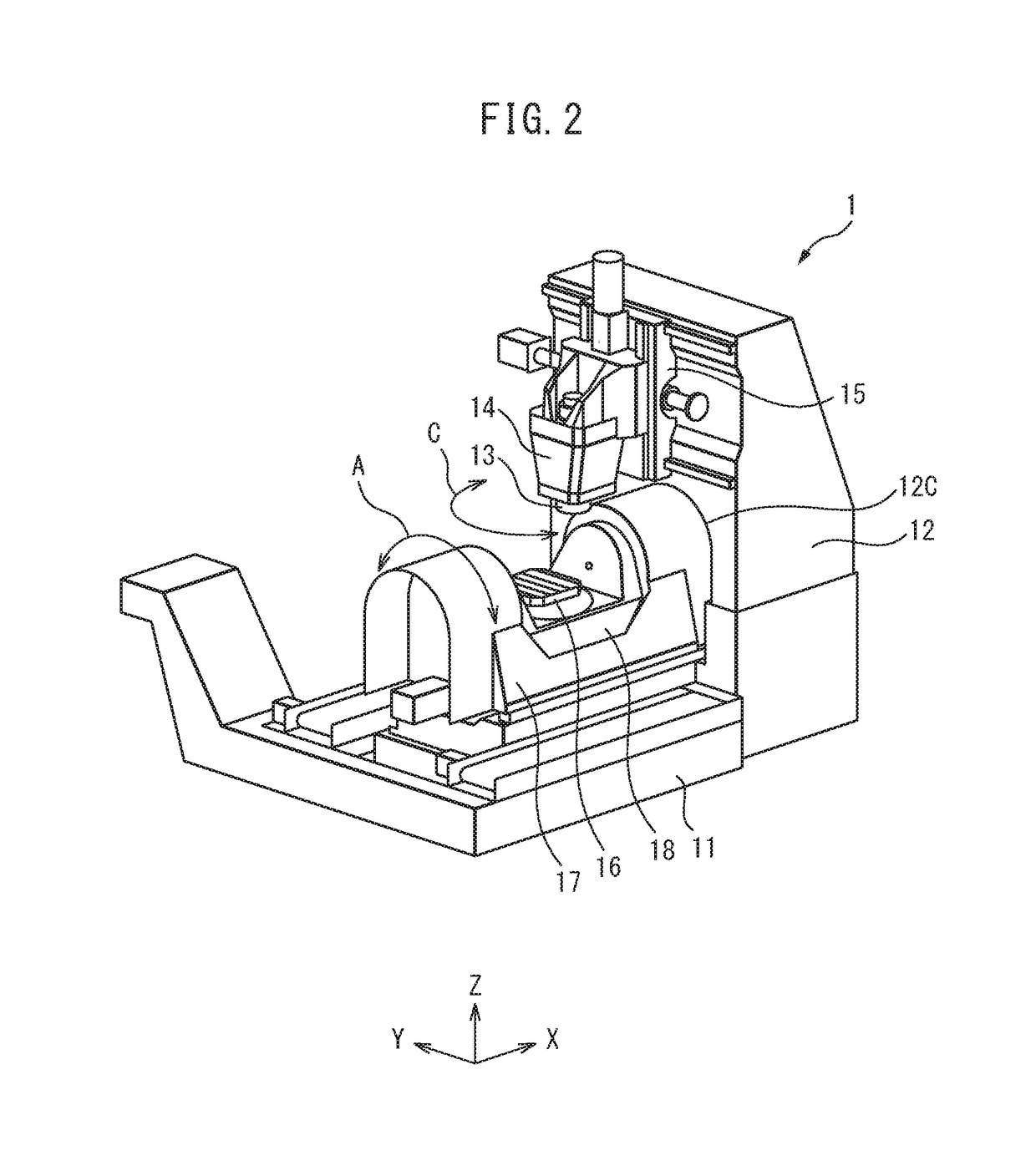

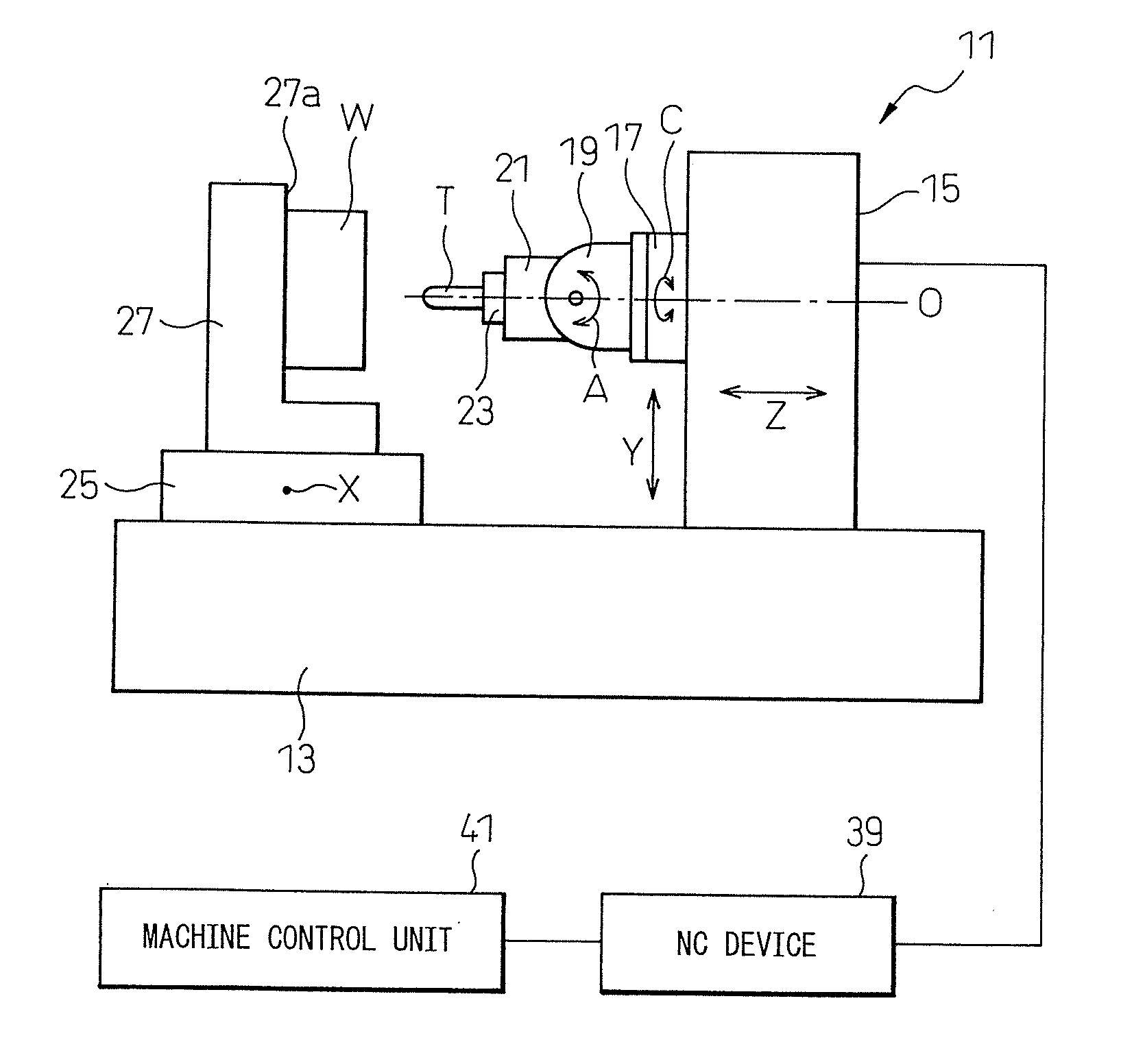

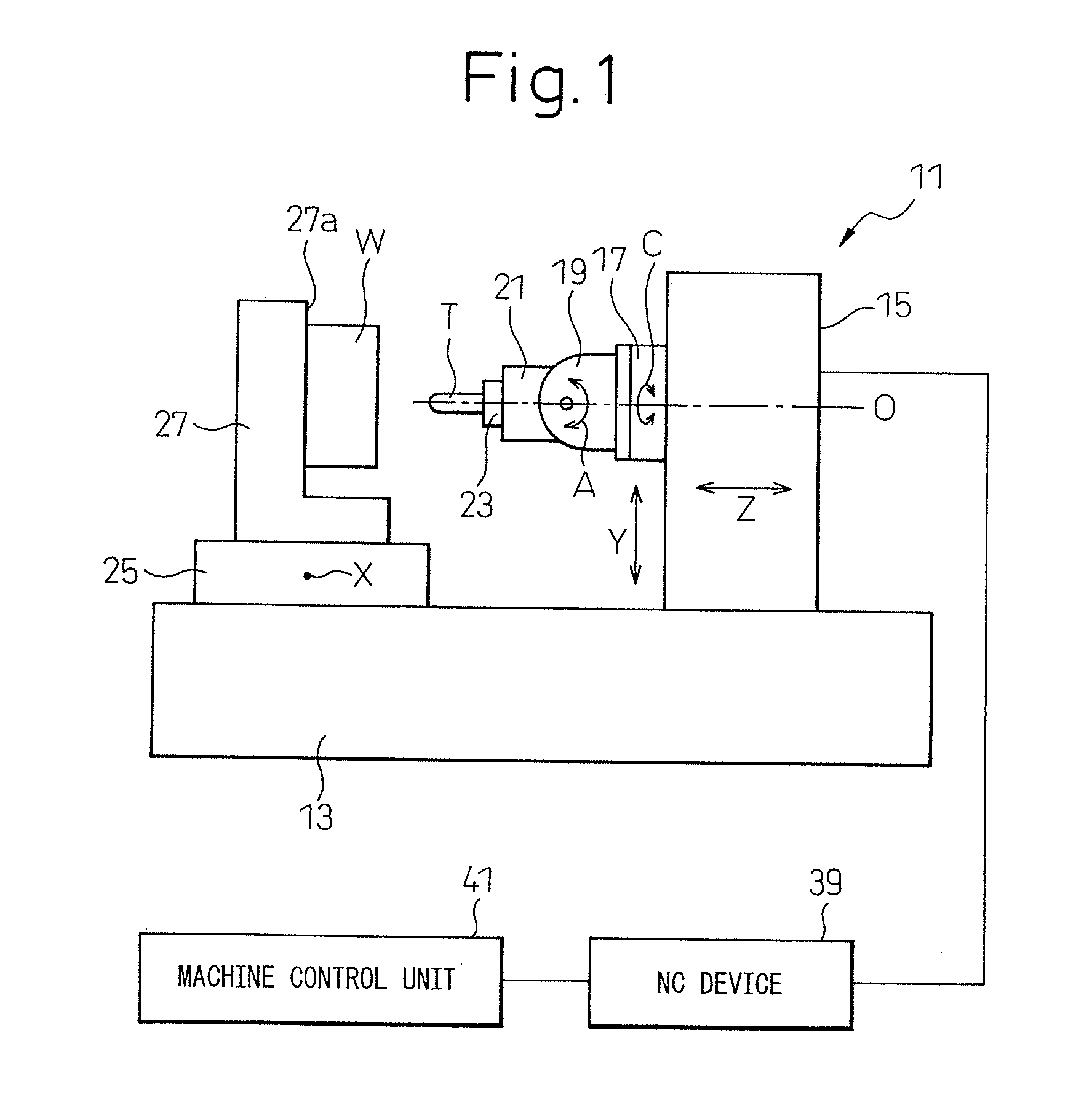

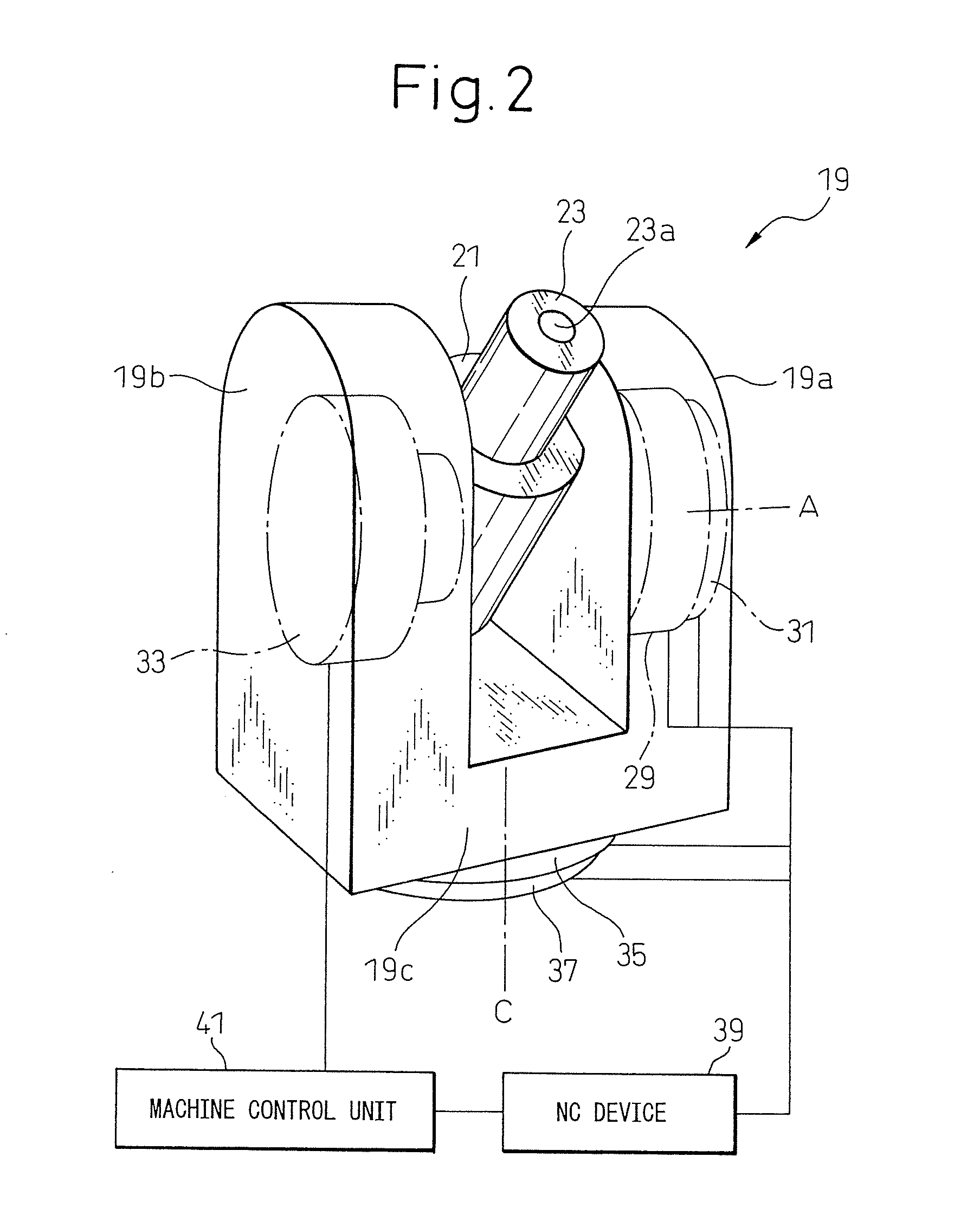

Machining Method and Machine Tool

ActiveUS20110014001A1Avoid breakingProgramme controlAutomatic control devicesRotational axisMachine tool control

A minimum five-axis machine tool (11) has first to third linear feed axes orthogonal to each other as well as first and second rotational feed axes orthogonal to each other, wherein a rotational axis line of the first rotational feed axis C is parallel to the first linear feed axis Z. While a tool T and a work W are moved relatively through the second and third linear feed axes X, Y to perform machining of the work W by means of the tool T, the machine tool controls the first rotational feed axis C such that a rotational axis line of the second rotational feed axis A is perpendicular to the direction of relative movement of the perpendicular to the direction of relative movement of the tool T to the work W, and controls a power supplied to a motor for the second rotational feed axis A when a torque around the second rotational feed axis A exceeds a specified threshold.

Owner:MAKINO MILLING MASCH CO LTD

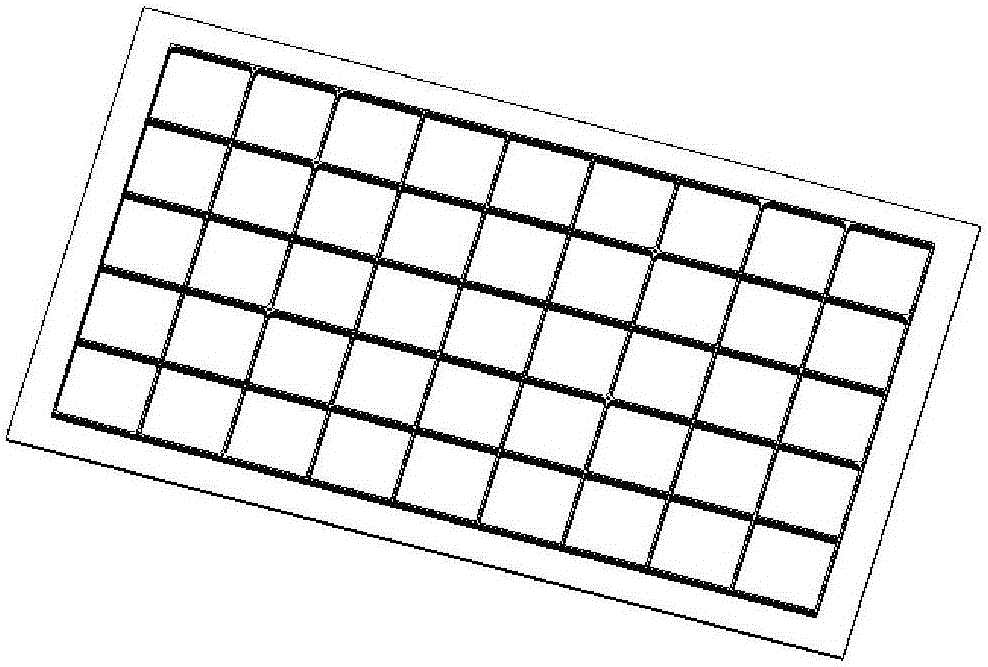

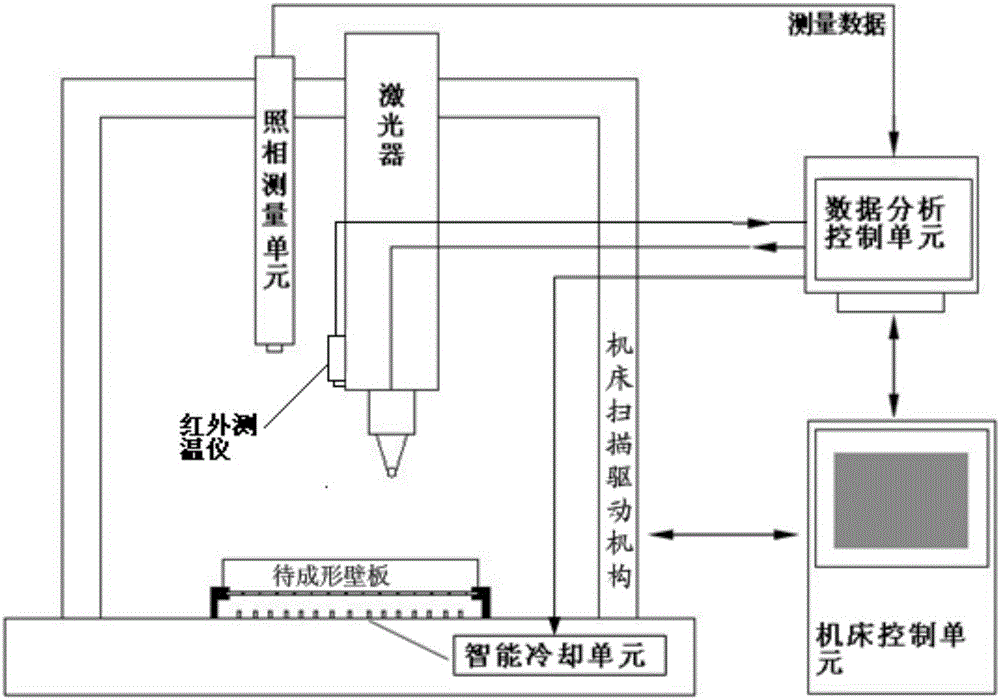

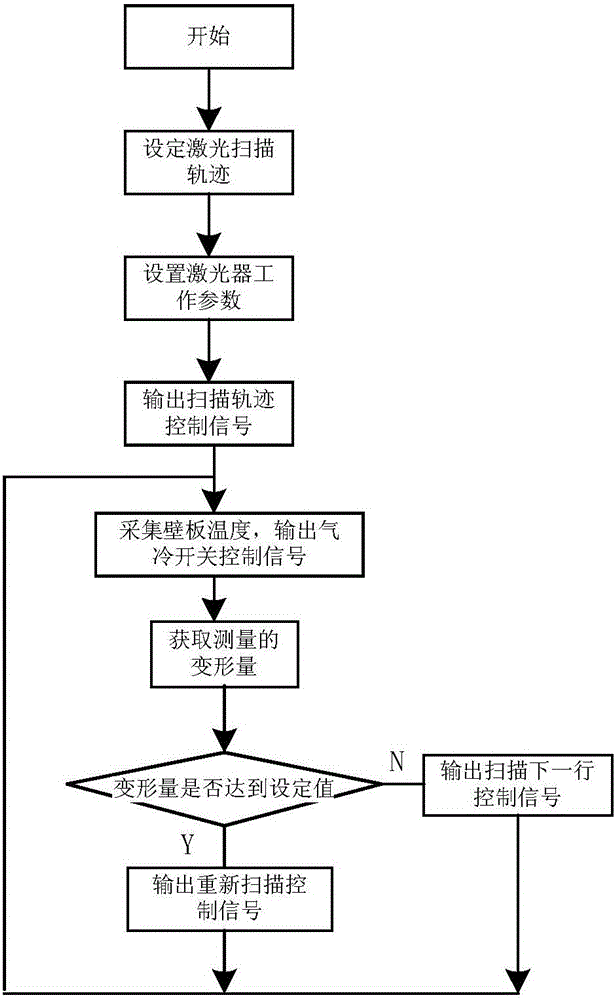

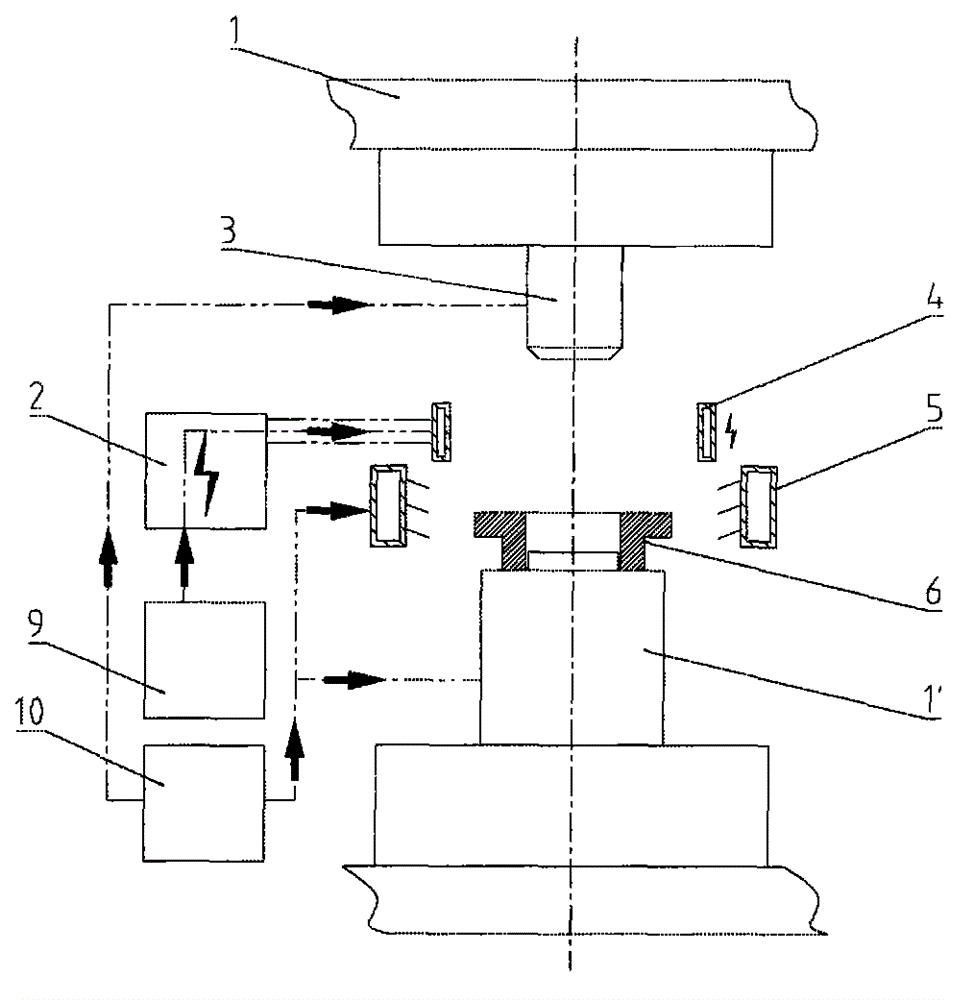

Lightweight wall plate laser-inducing flexible forming system and method

The invention discloses a lightweight wall plate laser-inducing flexible forming system and method. The system comprises a photograph measurement unit, a laser device, an infrared thermometer, an intelligent cooling unit, a machine tool workbench, a machine tool scanning drive mechanism, a data analysis control unit and a machine tool control unit. In each scanning line, a laser beam irradiates a lightweight wall plate plane piece to be formed, the temperature of a lightweight wall plate is measured, and cooling control is carried out according to the measured temperature so that the lightweight wall plate plane piece to be formed can bend and deform in the direction of the laser beam. The deformation of the lightweight wall plate plane piece is measured, whether the deformation of the lightweight wall plate plane piece reaches the set value or not is judged, and if the set value is reached, the laser irradiation of the next scanning line is carried out; and if the set value is not reached, the laser irradiation of the scanning line is carried out again. Online measurement and real-time automatic control can be achieved, accurate forming of the lightweight wall plate is achieved, and the problems that the lightweight wall plate is large in forming difficulty, low in efficiency and the like are solved.

Owner:BEIJING SATELLITE MFG FACTORY

Induction shape correcting and die quenching and tempering technological method and equipment for annular parts

InactiveCN105886746ACompact structureSmall footprintFurnace typesIncreasing energy efficiencyControl systemInductor

The invention relates to an induction shape correcting and die quenching and tempering technological method and equipment for annular parts. The method includes the steps that a workpiece is fed; an inductor is used for heating; a core die is corrected; an upper die and a lower die are used for pressure quenching; a core die is driven to conduct induction tempering; the core die is separated; and the workpiece is discharged. The equipment includes an induction heating power source, a quenching machine tool conducting actions of the whole process, a cooling water circulation device and a quenching liquid circulation device. The heating inductor, a quenching liquid injecting box, an upper pressing die, a lower pressing die, the core die and other parts, an executing mechanism for movement of the parts and a workpiece clamping mechanism are located on a framework of the quenching machine tool. The induction heating power source, the cooling water circulation device and the quenching liquid circulation device are connected with the heating inductor, the upper pressing die, the lower pressing die, the core die, the quenching liquid jetting box and a drive mechanism of the quenching liquid jetting box of the machine tool through pipelines, and program actions are completed through a control system of the machine tool. By means of the induction shape correcting and die quenching and tempering technological method and equipment for the annular parts, heat treatment deformation of the annular parts can be effectively corrected and limited, and the qualification rate of the products is increased.

Owner:BEIJING JINHE CHANGLI SCI & TRADE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com