Thermo-mechanical load simulation and error detection system and method for machine tool cutting machining process

A cutting and load simulation technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of increased cutting force, large cutting force, machining error, etc., to reduce machining error, improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]In order to clarify the functions and effects that can be realized by the device of the present invention, the specific implementation of the device will be described in detail below in conjunction with the accompanying drawings.

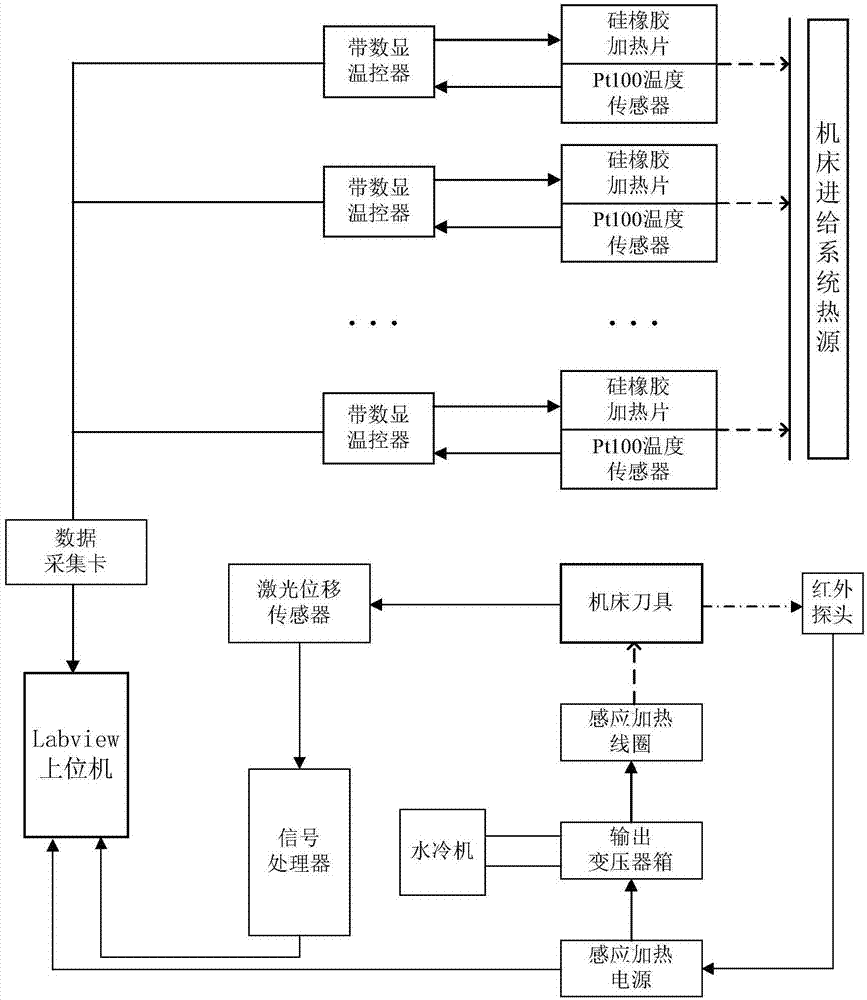

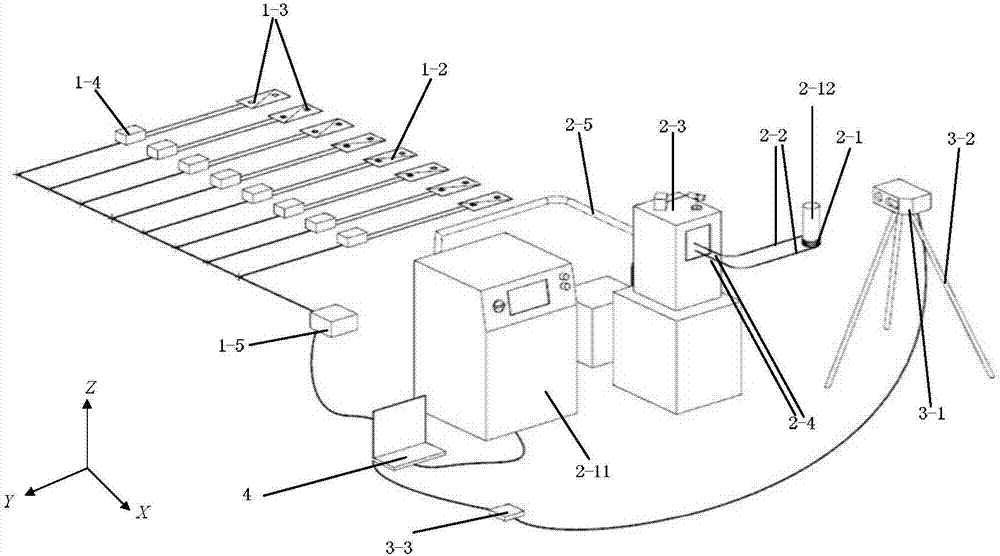

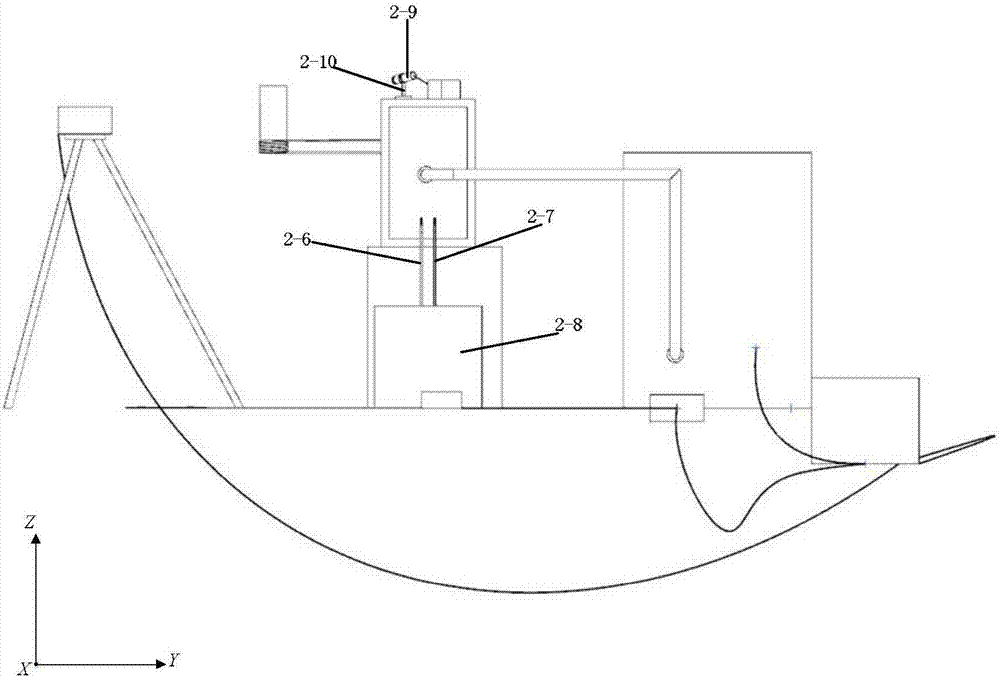

[0052] In order to solve the above-mentioned technical problems existing in the prior art, a thermal load simulation method and system for the cutting process are provided, including a heat source simulation device 1 of the machine tool feed system, a cutting heat simulation device 2 at the cutting edge of a tool, a one-way cutting A force simulation device 3, a host computer control system 4, a spindle mandrel 5 for simulating a tool, a controller 6 and a machine tool table 7.

[0053] Among them, in the heat source simulation device 1 of the feed system of the machine tool, the nickel-chromium alloy resistance wire 1-1 is wrapped between two silicon rubber insulating sheets 1-2, and the sheet platinum resistance temperature sensor 1-3 is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com