Transmission Error Detection Test Bench and Comprehensive Test Method of Front Drive Automotive Mechanical Gearbox

A mechanical gearbox and transmission error technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of large footprint, low measurement accuracy, low transmission efficiency, etc., to reduce the footprint, reduce interference factors, The effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

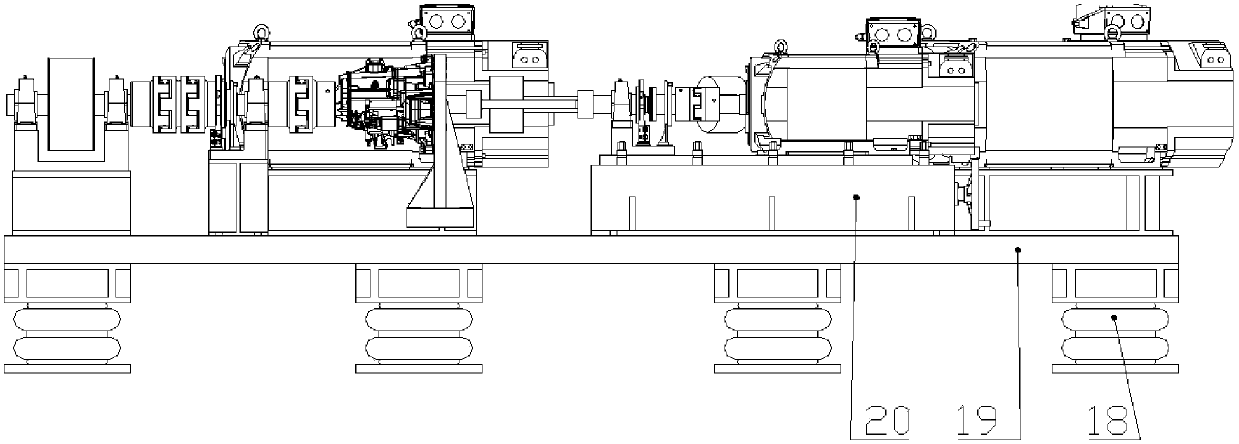

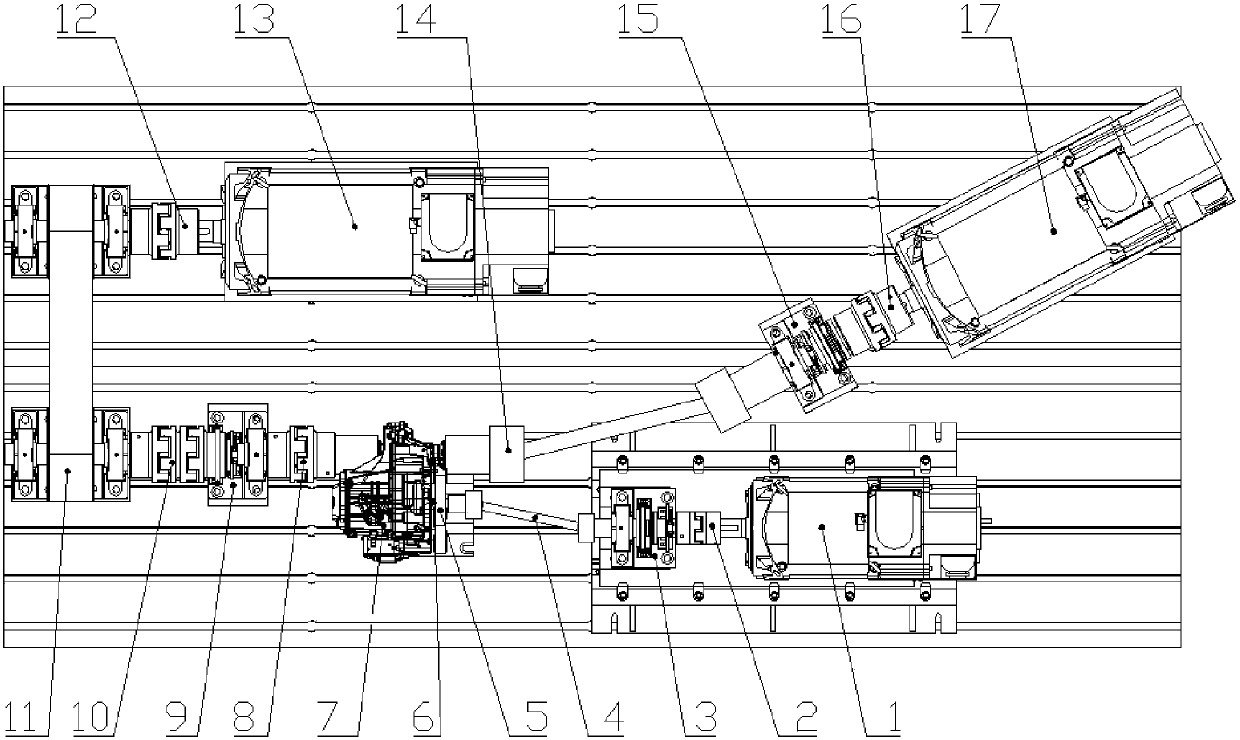

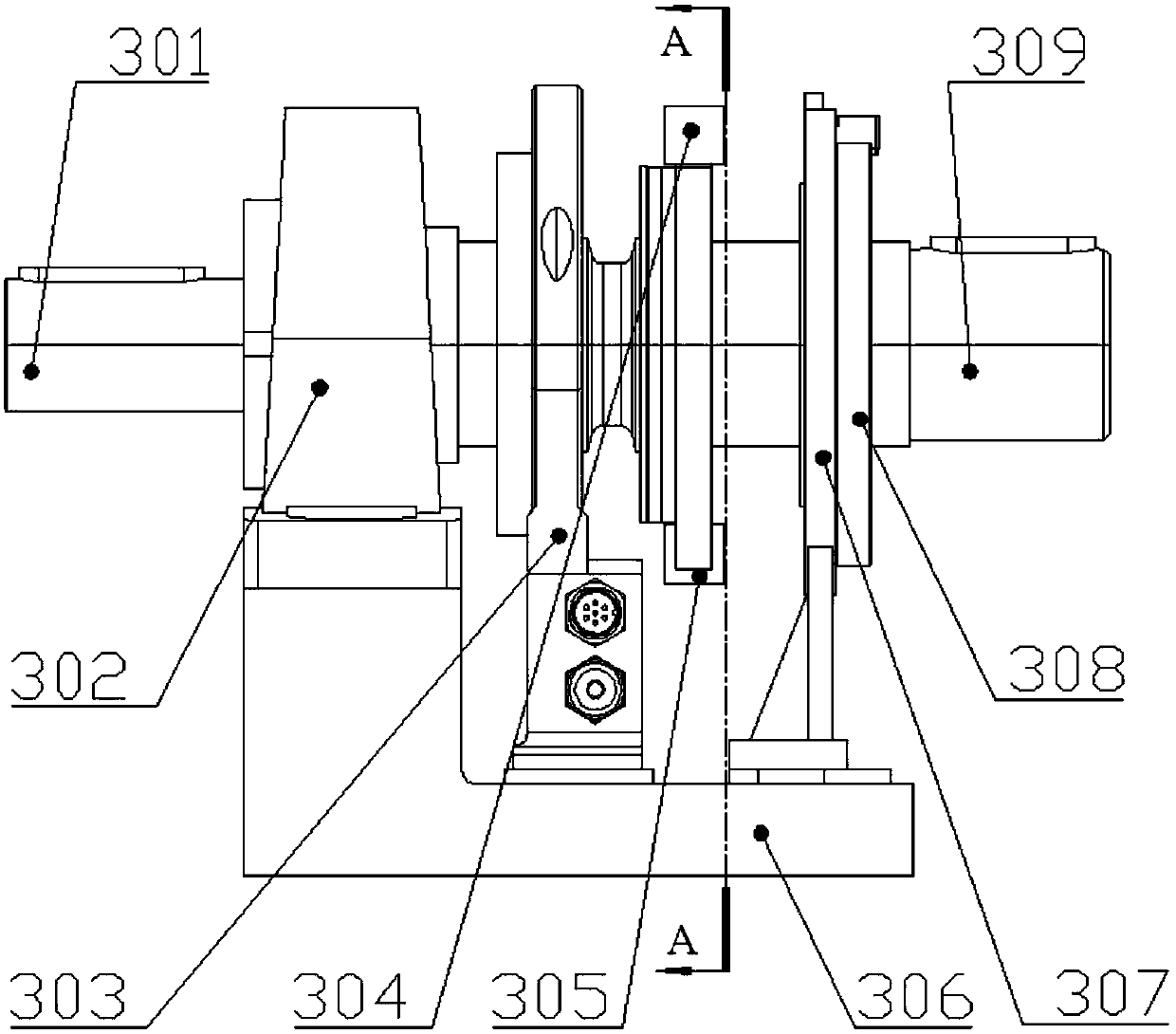

[0057] An air spring support device 18 is installed under the T-slot installation platform 19, and the air spring support device 18 is connected and fixed to the ground through anchor bolts; the AC drive motor sliding table base 20 and the gearbox special clamp 5 are respectively installed on the T-slot installation platform Above 19, the AC drive motor 1 is installed on the base 20 of the AC drive motor slide table, the output shaft of the drive motor 1 is connected to the input shaft transmission error comprehensive detection device 3 through the elastic coupling 2, and the input shaft transmission error comprehensive detection The device 3 is connected with the input spline shaft 6 of the gearbox through a spherical cage type synchronous universal joint 4, and the gearbox 7 of the front-wheel drive vehicle under test is positioned and clamped by the special clamp 5 for the gearbox. The gearbox of the front-drive car has two output The half shaft, wherein the output shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com