Numerical control processing method and control system for die manufacture

A processing method and mold manufacturing technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of poor quality of parts and accessories, and the main structure cannot be well adapted to mold processing, so as to improve processing efficiency and processing accuracy , convenient processing and prolonging the life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

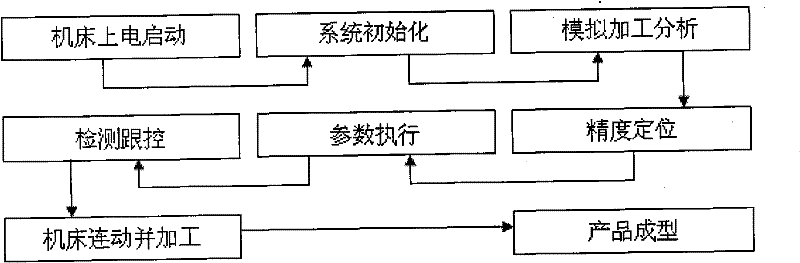

[0019] see image 3 , a kind of numerical control processing method based on mold manufacturing, it is characterized in that, its method comprises the following steps:

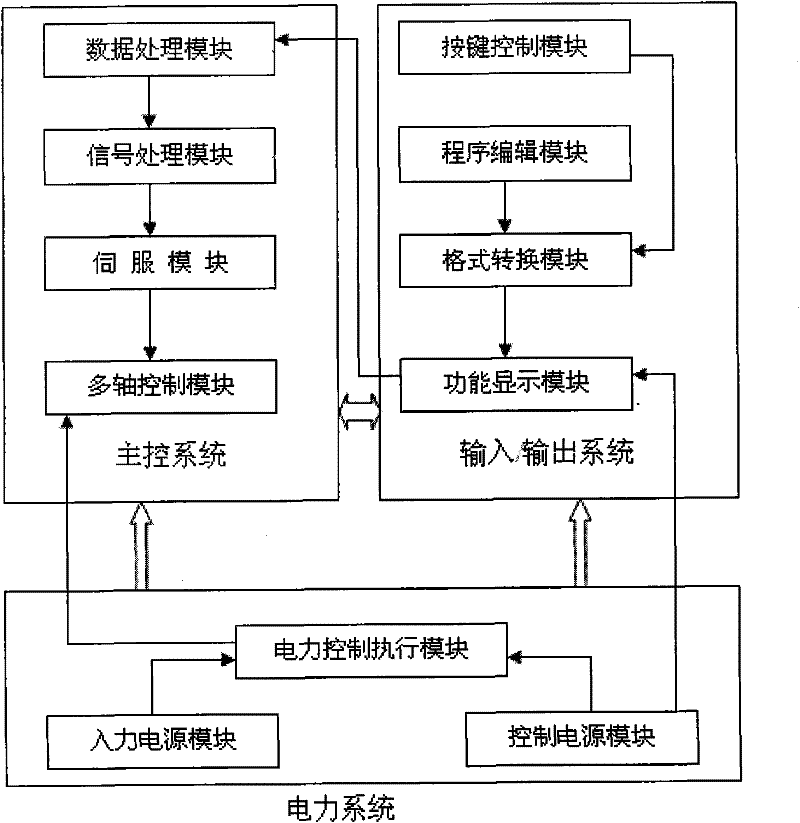

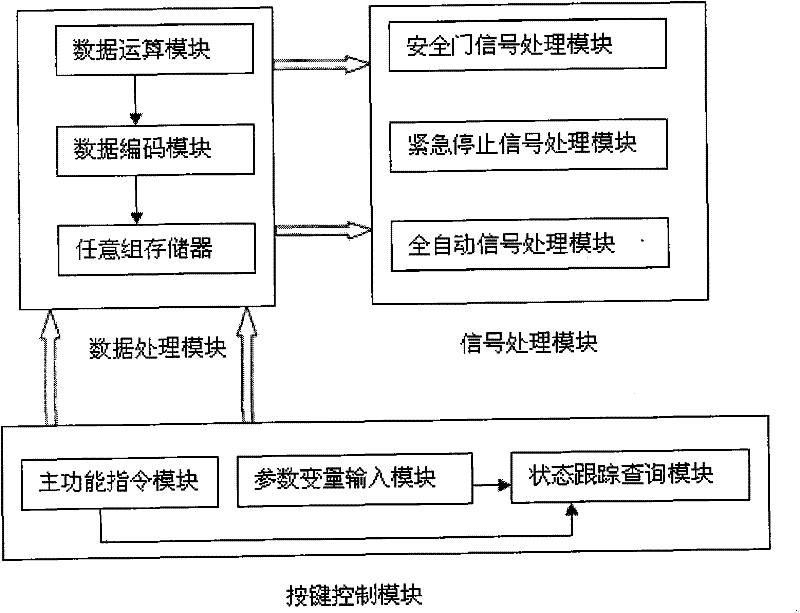

[0020] (1) Set up a CNC machine tool, which consists of a control system, a servo system, a detection system, a mechanical transmission system and an auxiliary system;

[0021] (2) A processing analysis system is set in the auxiliary system, and the simulation processing analysis is carried out by drawing software;

[0022] (3) The machine tool control system provides bearings to control the positioning accuracy, tracking accuracy and shock resistance of the CNC machine tool;

[0023] (4) The servo system is linked with the mechanical transmission system to control the key parameters of the numerical control machine tool, such as feed speed, spindle speed, spindle forward and reverse rotation, and automatic tool change, and the detection system follows up and corrects errors in a timely manner.

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com