Lightweight wall plate laser-inducing flexible forming system and method

A flexible forming and laser-induced technology, which is applied in the field of laser-induced flexible forming systems for lightweight panels, achieves the effects of no springback effect, low residual stress, and difficult forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

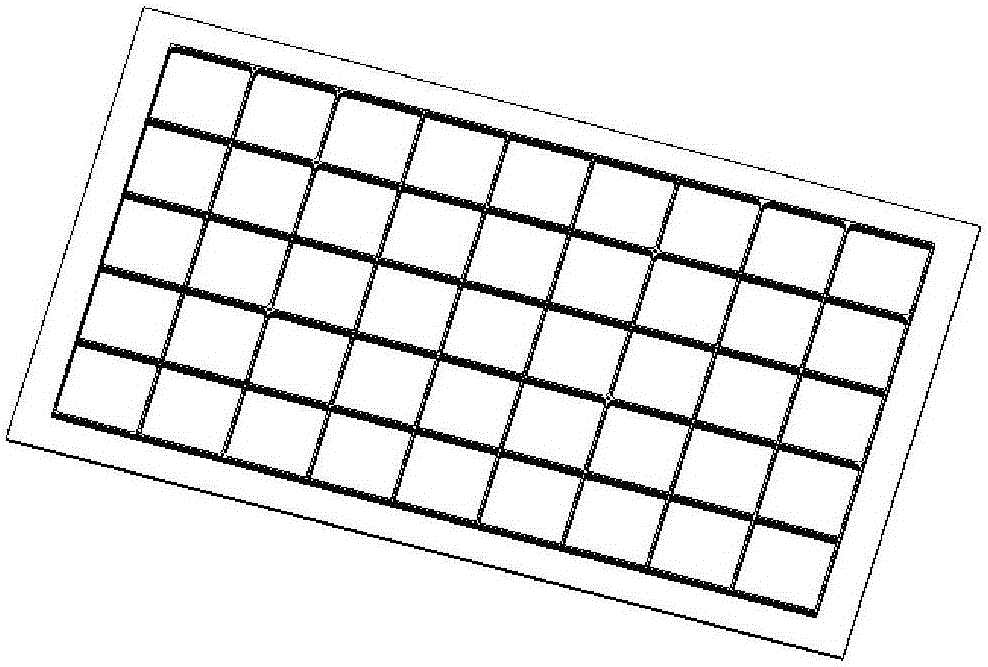

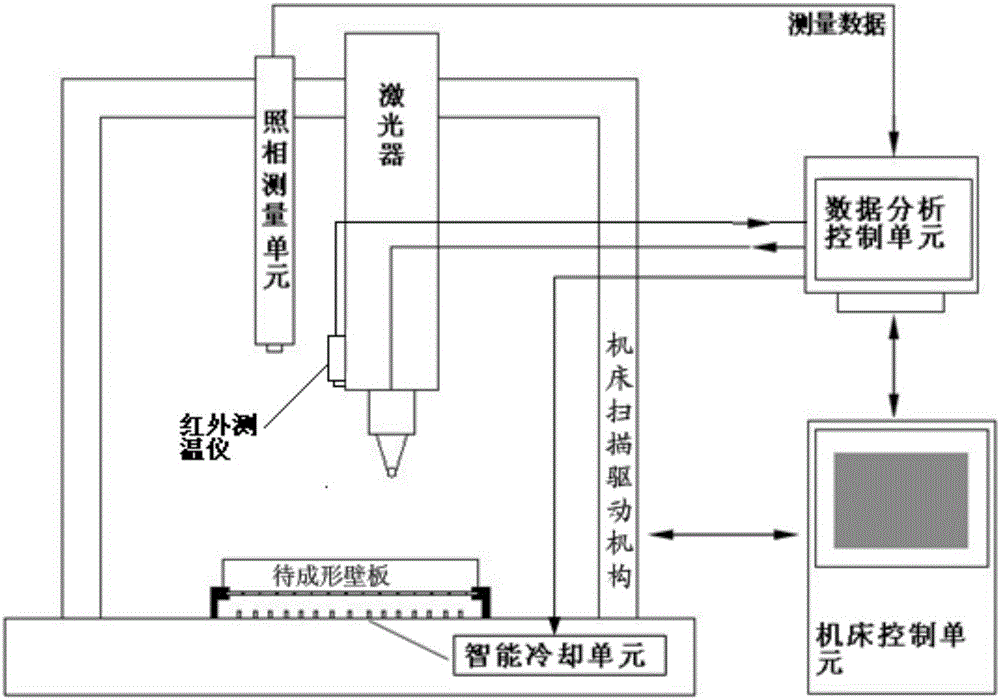

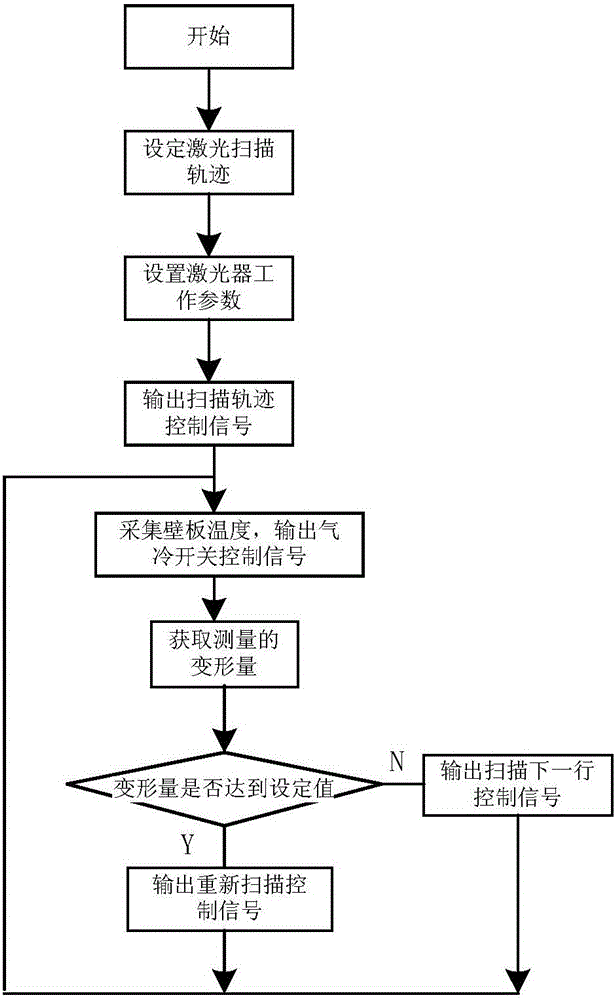

[0048] For the 700mm*400mm lightweight wall panel, the height of the reinforcing rib is 17.5mm, and the thickness of the groove is 2.5mm. Laser-induced forming is used to form a column wall panel structure, and an air hole is formed on the worktable of the machine tool every 5cm. The laser uses a circular light spot (10mm diameter) or a rectangular light spot (1.5mm*12mm), the scanning adopts the method of first acceleration and then deceleration, the speed is 20mm / s-40mm / s-20mm / s, and the energy input power at the reinforcing rib is 3000W, the energy of the part without reinforcement ribs is 1600W; the dislocation scanning interval D is 1-3mm, and the forward setting distance F is 30mm. Among them, when the laser scanning input energy, the infrared thermometer performs temperature measurement at the same time, and the system dynamically blows and cools the panel according to the feedback of the measured temperature field, which promotes the deformation of the panel and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com