Flexible clamp for pipe fitting welding and adjusting method thereof

A flexible fixture, pipe fitting welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of long fixture production cycle, increased difficulty in tooling management, and welding slag falling between grooves or holes. Medium problem, to shorten the production preparation cycle and production cost, improve the scope of use and flexibility, and solve the difficulty of tooling management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

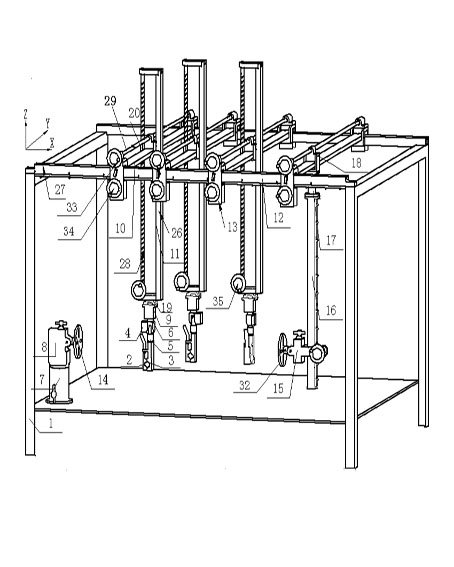

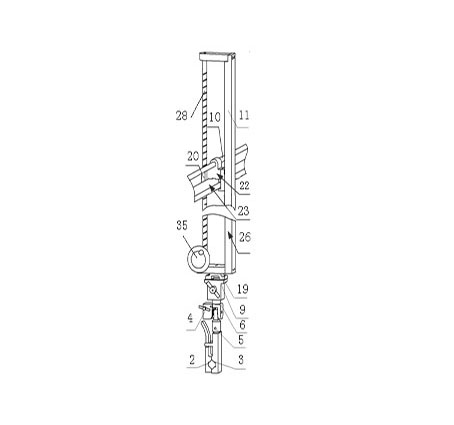

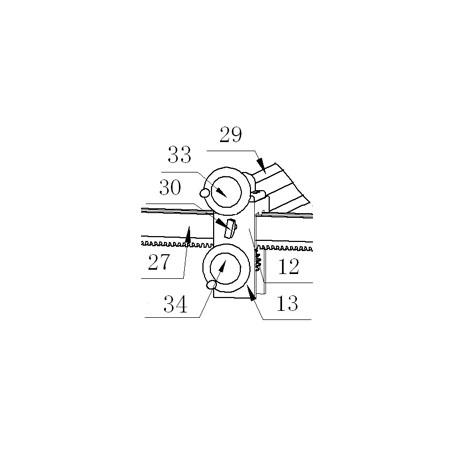

[0018] Such as Figure 1-3 As shown, the pipe welding flexible fixture includes a base support 1, the bottom of which is a fixed-end flange around the Z-axis angle adjustment mechanism 7 and a fixed-end flange around the Y-axis angle adjustment mechanism 8, and the fixed-end flange around the Y-axis angle adjustment mechanism 8. The Y-axis angle adjustment mechanism 8 is connected with a flange rotation mechanism 14 for equally dividing chute. The upper part of the base bracket 1 is provided with a top Y-direction displacement adjustment mechanism 10 for adjusting pipe fittings, a vertical Z-direction displacement adjustment mechanism 11, a top X-direction displacement adjustment mechanism 12, and a flange Y-direction displacement adjustment mechanism 18 for adjusting flanges; The direction displacement adjustment mechanism 10 is perpendicular to the vertical Z direction displacement adjustment mechanism 11 . Wherein, the top Y-direction displacement adjustment mechanism 10 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com