On-machine non-contact workpiece contour detection system and method of cycloid gear grinder

A workpiece contour, non-contact technology, applied in the direction of grinding machine parts, workpiece feed movement control, measuring devices, etc., can solve the problems of slow measurement speed and low precision, and achieve cost saving, high precision and efficiency fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings.

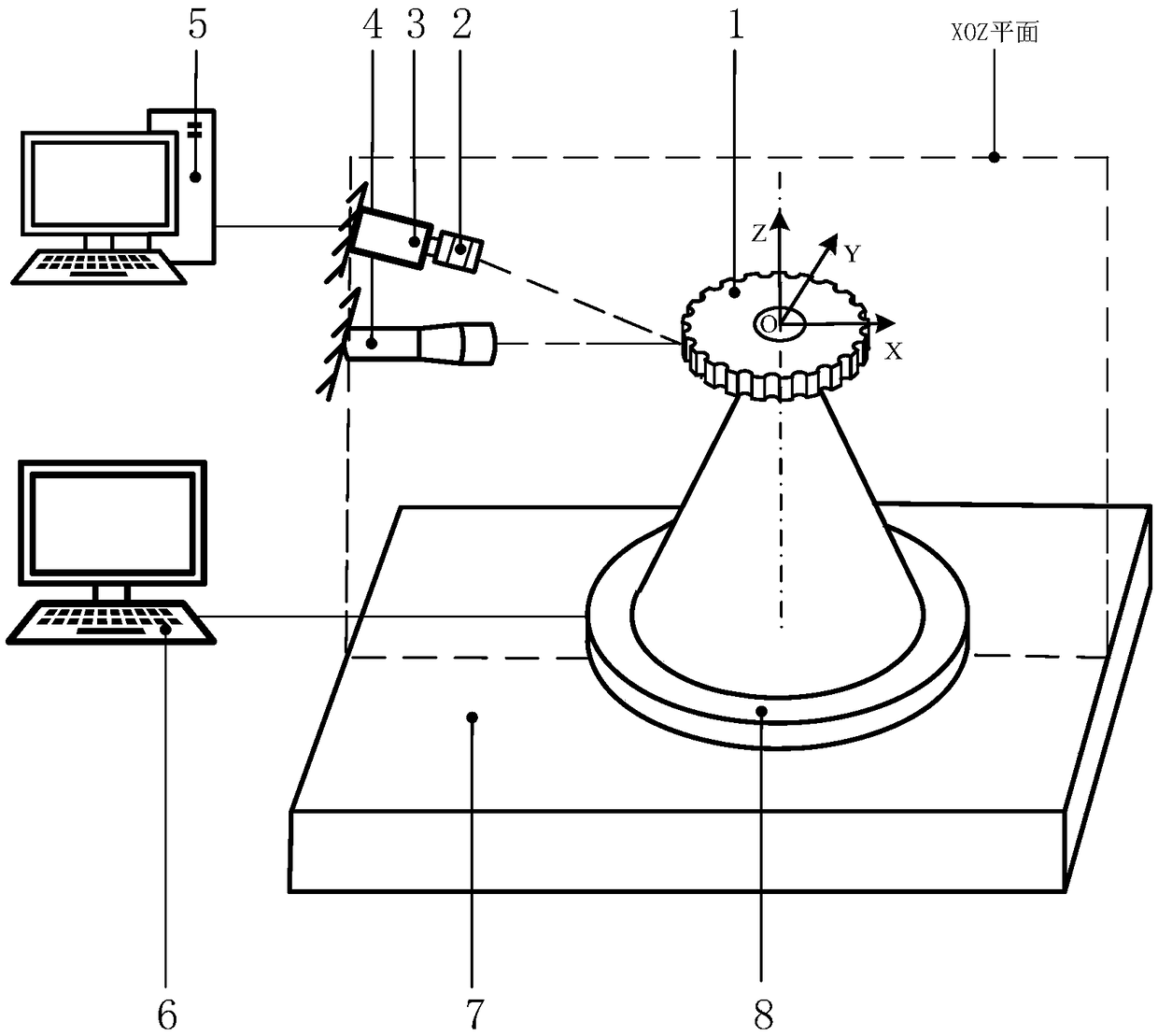

[0038] Such as figure 1 As shown, an on-machine non-contact workpiece contour detection system for a cycloidal gear grinder includes: machine tool turntable 8, machine bed 7, CCD camera 3, telecentric lens 2, projector 4, machine tool control system 6, upper computer 5. The machine tool turntable 8 is installed on the bottom machine tool bed 7, and the workpiece 1 is clamped on the machine tool turntable 8 through the center positioning hole; the CCD camera 3 and projector 4 are fixed on the left machine tool bed 7; The control system 6 of the machine tool is connected with the turntable 8 of the machine tool, and is used to control the rotation of the turntable to measure the contour of the workpiece at different positions; the CCD camera 3 is connected with the upper computer 5, and is used to transmit the capture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com