Multi-axis linkage ultrasonic modulation micro-electrochemical machining system

A processing system and micro-electrolysis technology, applied in the direction of electric processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the service life of tool electrodes, unfavorable development of micro-processing automation, and burning of workpieces and tool electrodes, so as to improve processing Quality and processing efficiency, strong market application value, and the effect of promoting horizontal and vertical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

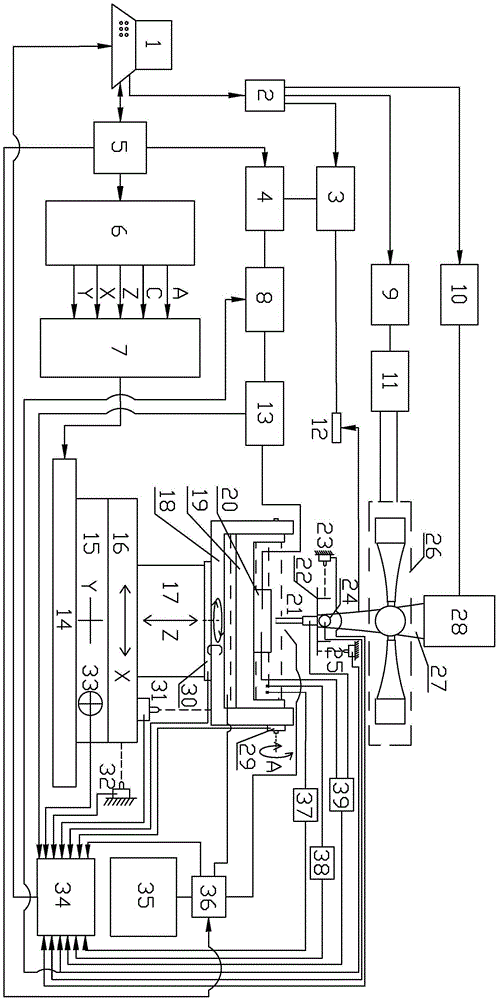

[0035] Such as figure 1 As shown, the multi-axis linkage ultrasonic modulation micro electrolytic machining system of the present invention includes:

[0036] Ultrasonic vibration system, including an ultrasonic power supply 10, an ultrasonic generator 9, an ultrasonic adjustment circuit 11, a horizontal and vertical excitation device 26, a transducer 28, a horn 27, and a tool electrode 21;

[0037] The ultrasonic synchronization system is provided with a vibration measuring piece 22;

[0038] Power supply system for electrolytic processing, including current limiting resistor 12, pulse power supply 3, solenoid valve switch 4, synchronous chopper 8, and current sensor 13;

[0039] Multi-axis machine tool control system, including servo drive unit 6, servo motor unit 7, Y-axis feed mechanism 15, X-axis feed mechanism 16, Z-axis feed mechanism 17, C-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com