Adaptive machine tool control method based on GA-BP neural network algorithm

A neural network algorithm, GA-BP technology, applied in the field of machine tool self-adaptive control based on GA-BP neural network algorithm, can solve the problems of difficulty in establishing fuzzy control theory, ineffective control of complex systems, and lack of systematicness, achieving the realization of The effect of self-adaptive real-time control, improving the level of intelligence and reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

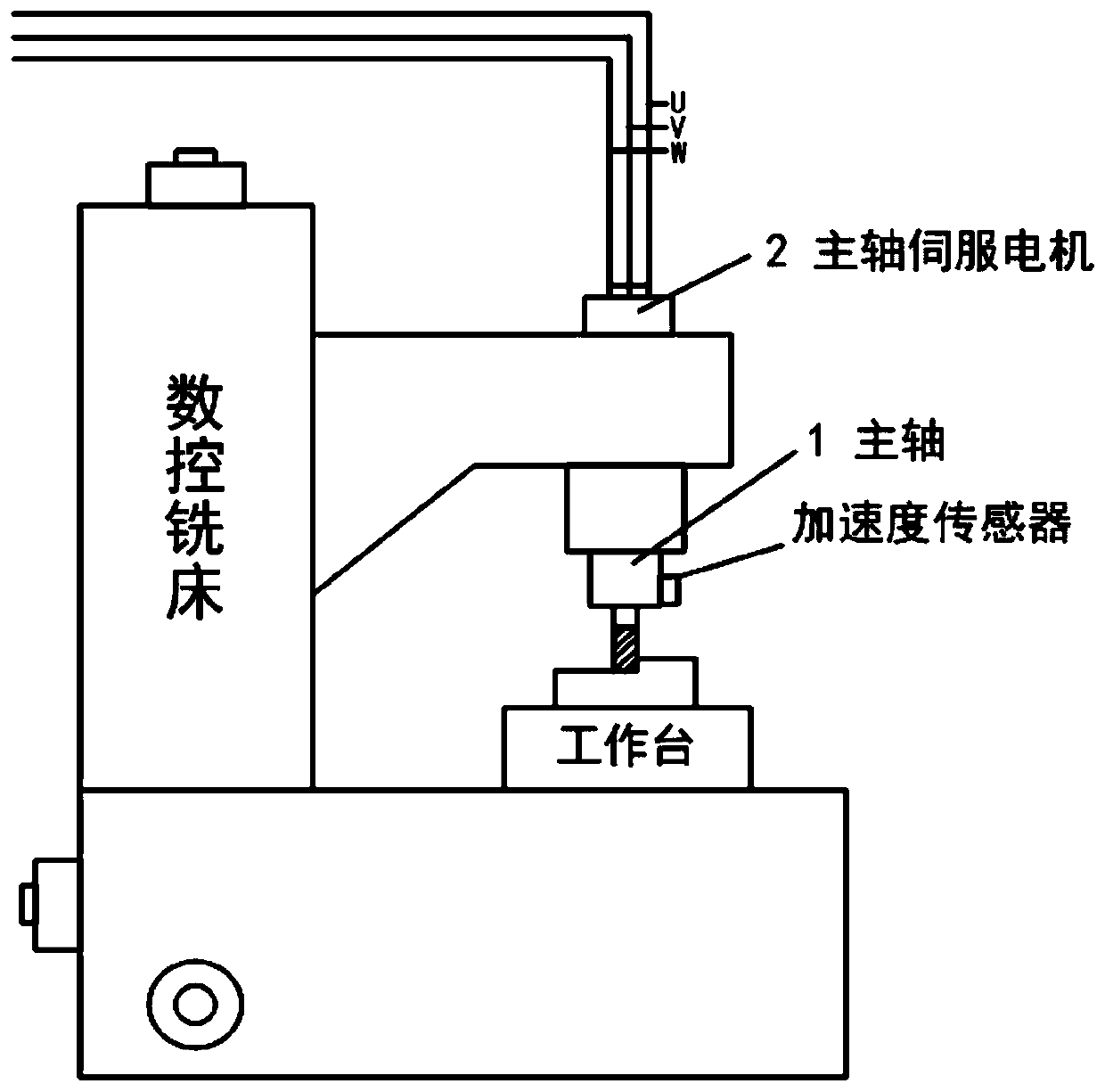

[0050] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings, taking a certain type of vertical milling machine as an example to describe the implementation of the present invention in detail.

[0051] The first step is to collect the machining state data with variable cutting parameters

[0052] Such as figure 1 As shown, the power sensor is arranged on the spindle motor (2), and its three coils are respectively set on the three power lines of the spindle motor UVW; the acceleration sensor is arranged at the lower end of the outer edge of the spindle (1), close to the tool side.

[0053] The variable parameter processing process is:

[0054] First choose a domestic milling cutter with a diameter of 10mm and a 45 steel workpiece with a length and width of 200mm and 100mm respectively, and then combine and match a total of 600 sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com