Patents

Literature

50results about How to "Save production time and cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear power pipeline defect detection system based on deep learning attention mechanism

InactiveCN111899224AAccurate detectionImprove detection efficiencyImage analysisCharacter and pattern recognitionAlgorithmEngineering

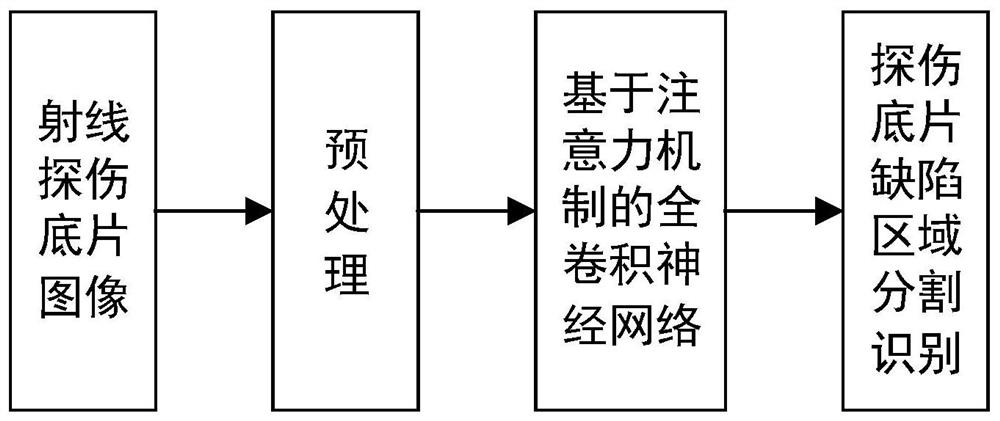

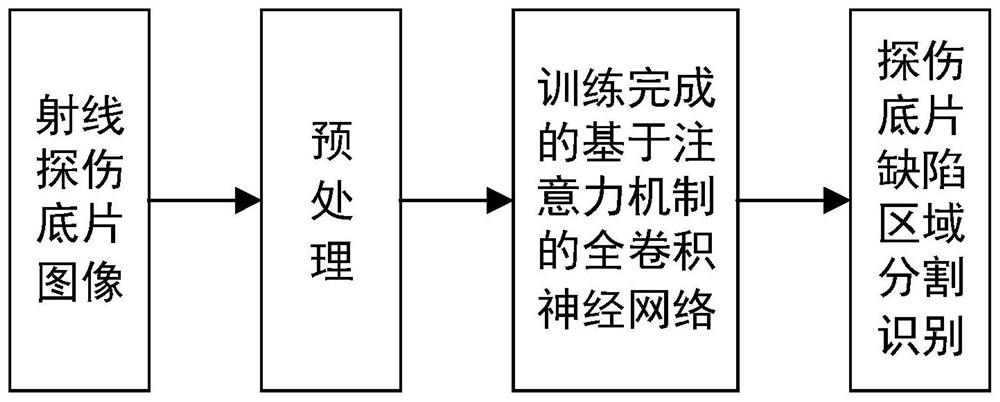

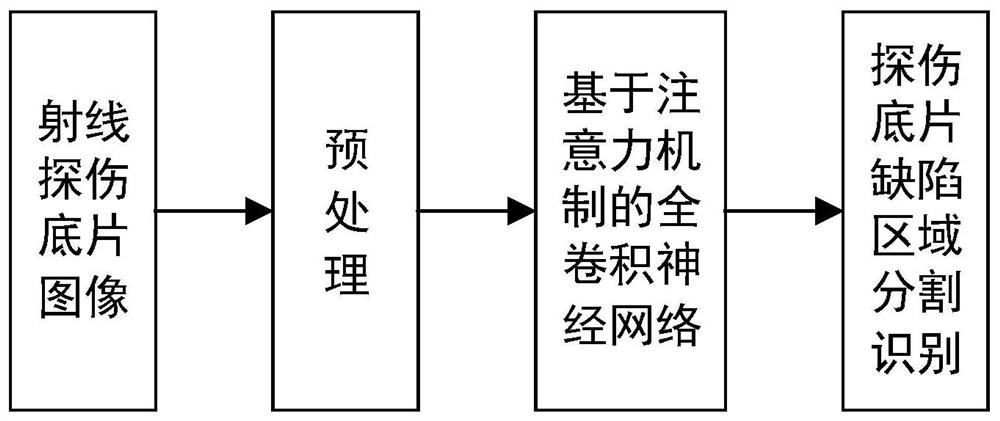

The invention discloses a nuclear power pipeline defect detection system based on a deep learning attention mechanism. The method comprises the following steps: preprocessing a radiographic inspectionnegative image; constructing a full convolutional neural network which comprises an encoder module, an attention mechanism module and a decoder module which are connected in sequence, selecting an Adam optimizer to perform gradient updating on the constructed full convolutional neural network, and training the full convolutional neural network after gradient updating by using a Focal Loss loss function; and testing the trained full convolutional neural network to obtain a probability graph, and performing threshold binarization processing on the probability graph to obtain a binarized image of the defect area as a nuclear power pipeline defect detection result. The invention can be applied to assisting film judging personnel in industrial production to quickly detect defect areas for classification and evaluation, and the defect areas are quickly judged by analyzing digitally scanned flaw detection negative film images, so that the detection efficiency is improved, and the productiontime cost is saved.

Owner:烟台市计量所 +1

Compound deodorant of plant extracts and biological enzymes and preparation method thereof

InactiveCN109865423AWill not cause secondary pollutionReduce typesDispersed particle separationAir quality improvementSide effectPollution

The invention relates to a compound deodorant of plant extracts and biological enzymes. The compound deodorant comprises the following components in parts by weight: 5 parts of a plant extract composition, 20 parts of a biological enzyme composition, 2-4 parts of zinc diricinoleate, 0.01-0.05 part of potassium sorbate, 3-6 parts of ethanol, 5-8 parts of fatty acid glyceride, and 56.95-64.99 partsof deionized water. The specially selected biological enzymes contained in the product can carry out neutralization and condensation reactions with groups in the odorous substances such as milk thiolgroups, amino groups, aldehyde groups, amine groups and the like, and the pollutants in the odorous gases are transformed into harmless carbohydrates. The plant extracts carry out reactions with odorous molecules mainly by adsorbing odorous gases, and the odorous gases are transformed into odorless and harmless carbohydrates, so that the rapid deodorization effect is achieved. The effective components of the plant extracts in the product are all extracted from natural plants, do not have any toxic and side effects on human body, do not stimulate skins, have extremely low inhaling toxicity, anddo not cause secondary pollution.

Owner:惠州市铭铠防霉抗菌科技有限公司

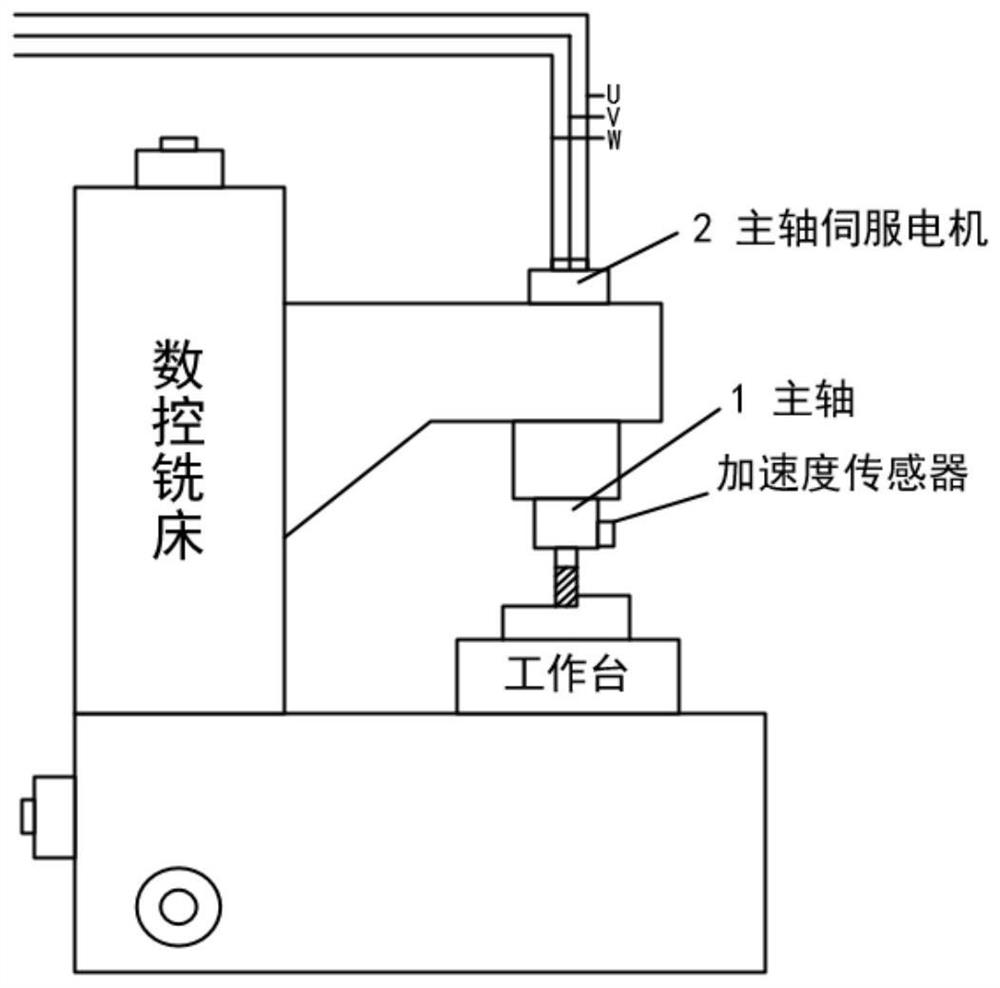

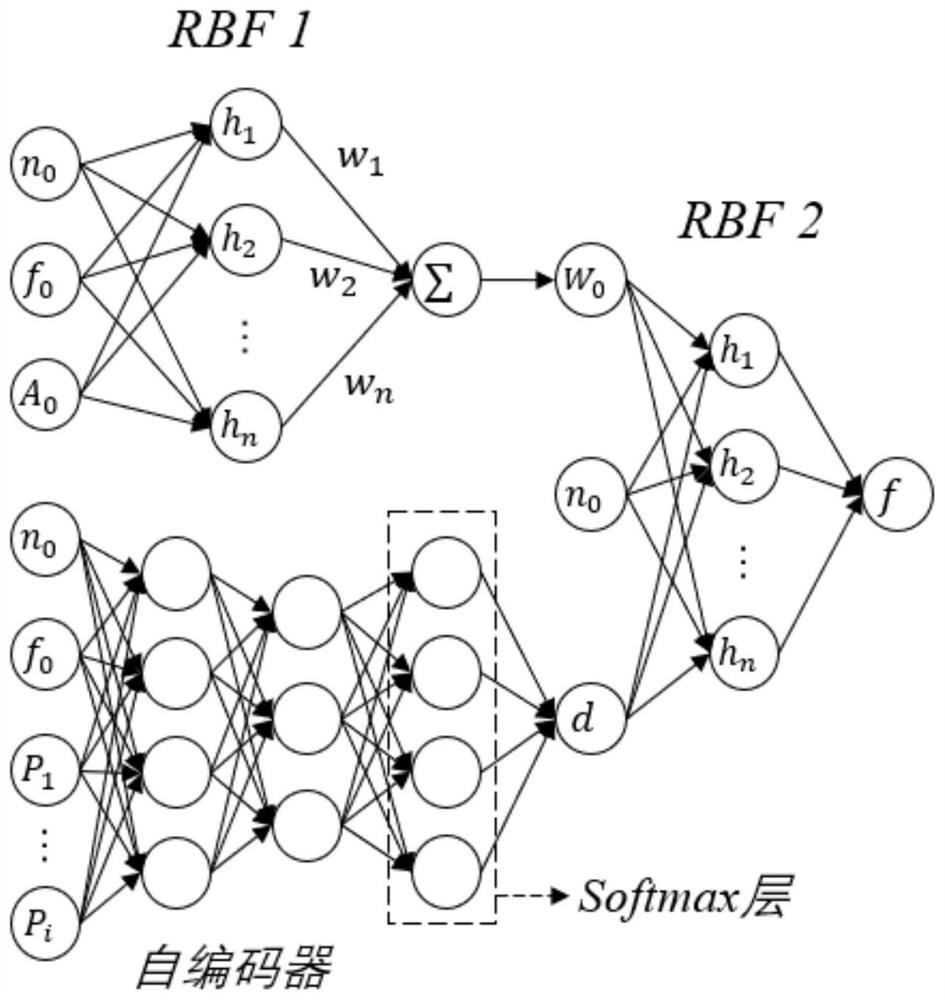

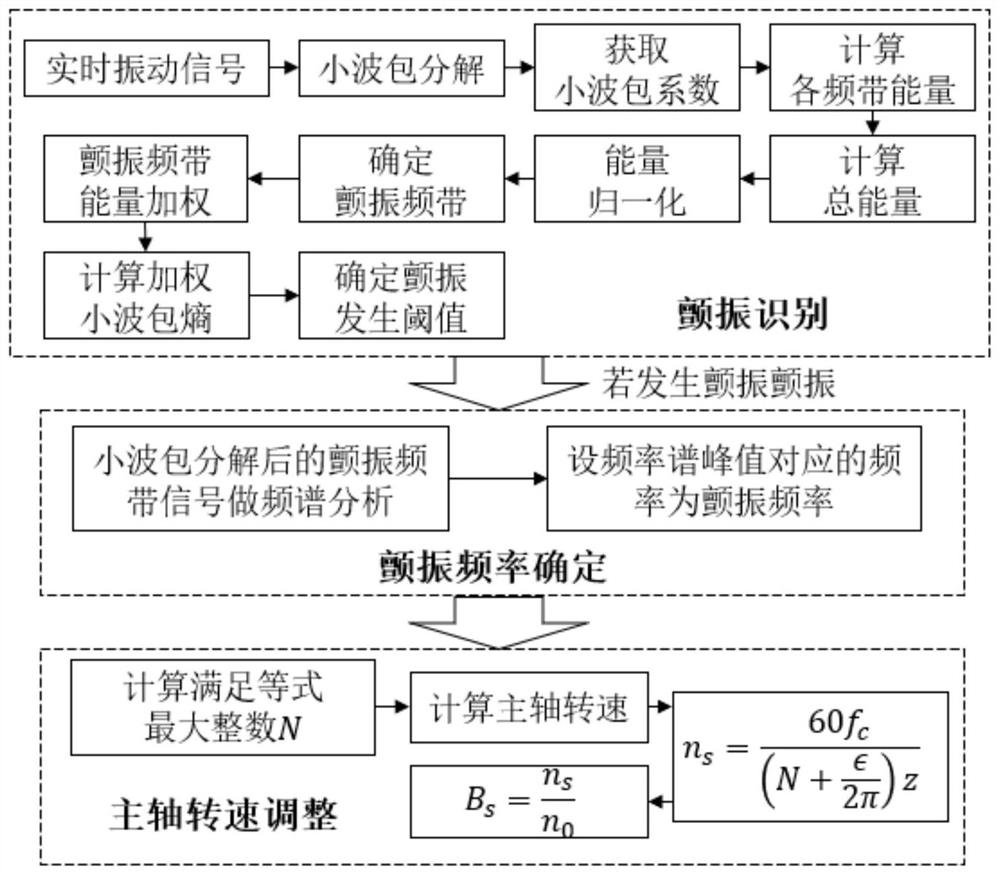

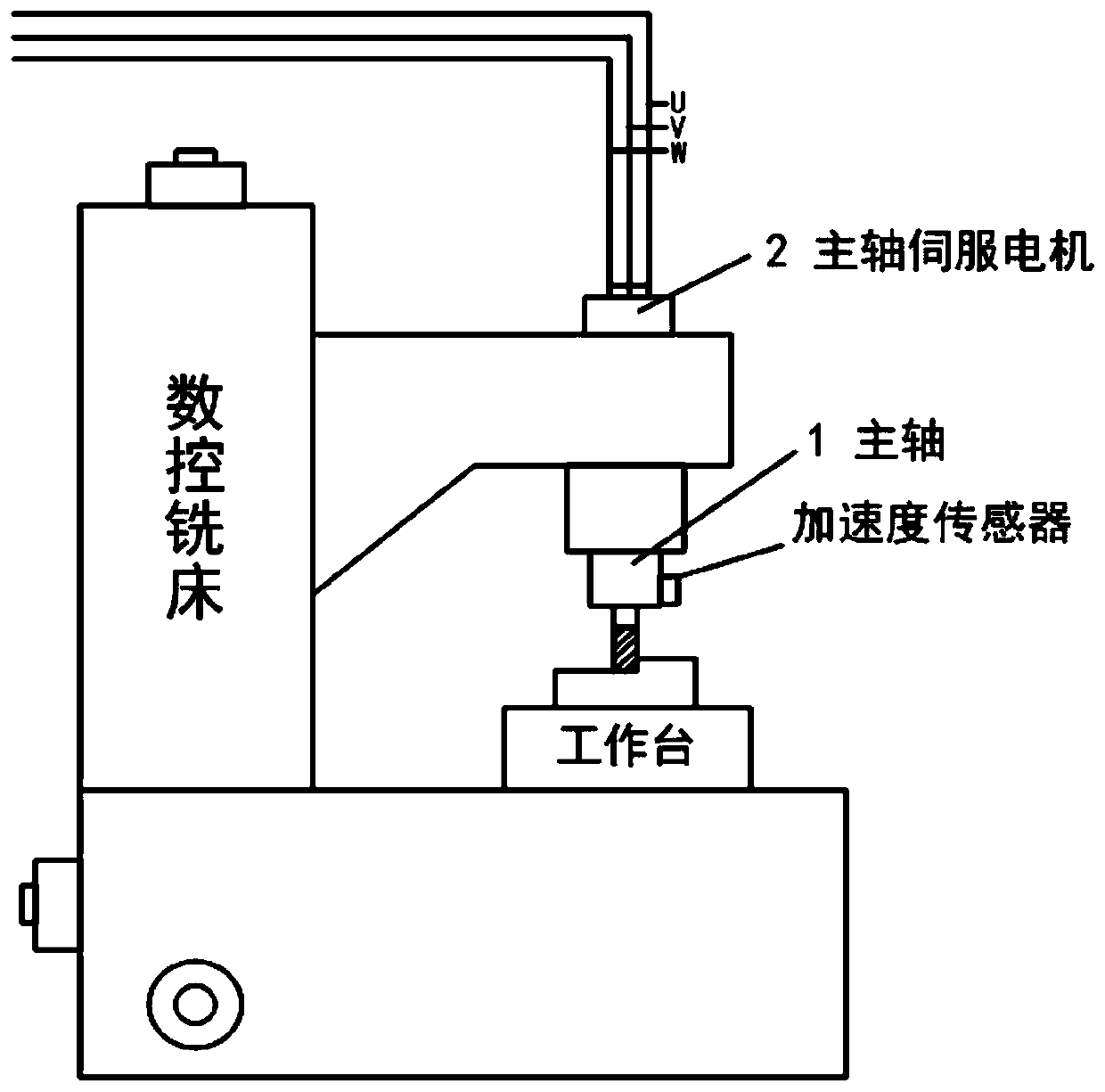

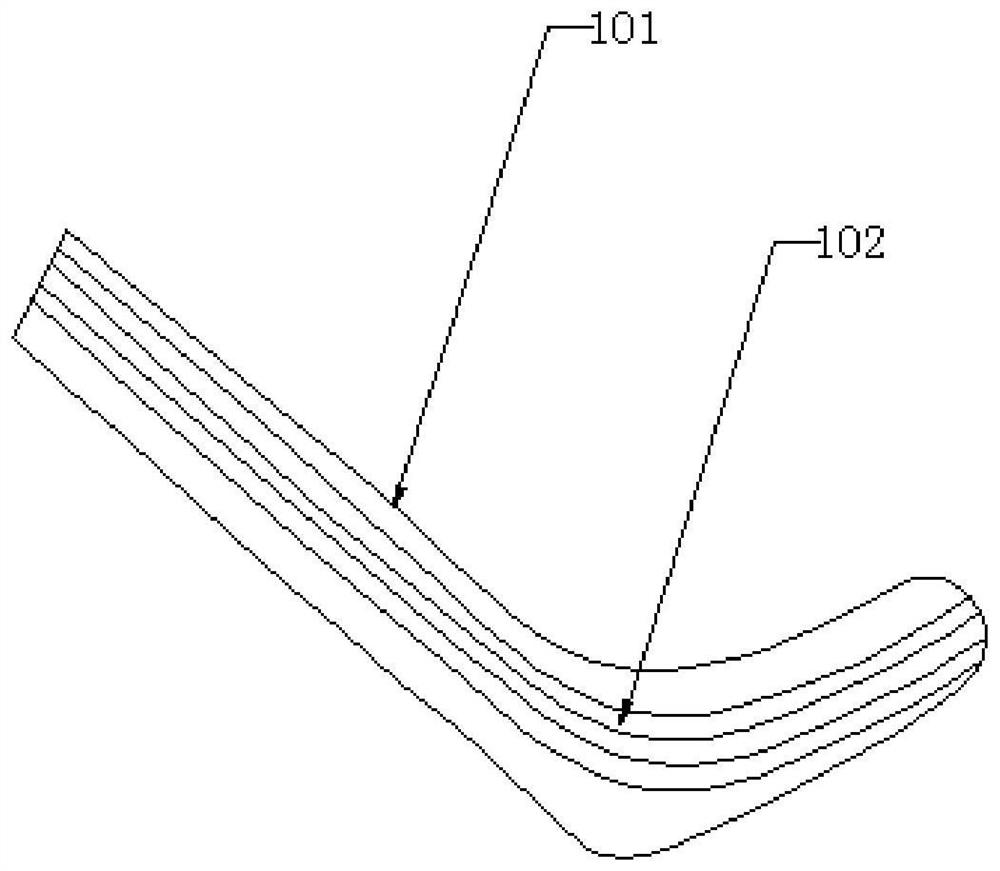

Machine tool self-adaptive control method considering flutter suppression

ActiveCN111694320AImprove processing efficiencySave production time and costProgramme controlComputer controlNumerical controlControl engineering

The invention discloses a machine tool self-adaptive control method considering flutter suppression. A spindle motor power signal and a spindle vibration signal in the numerical control machining process are monitored in real time, real-time self-adaptive regulation and control are conducted on the feeding speed and the spindle rotating speed based on the spindle power signal and the spindle vibration signal, and normal machining is not affected in the whole signal collecting process. According to the machine tool self-adaptive control method considering chatter suppression, the machining efficiency can be effectively improved, flutter generated in the machining process can be monitored and suppressed, the machining quality is improved to the maximum extent on the basis that the machiningefficiency is improved, the service life of a cutter and a machine tool can be prolonged, and the production cost is reduced.

Owner:DALIAN UNIV OF TECH

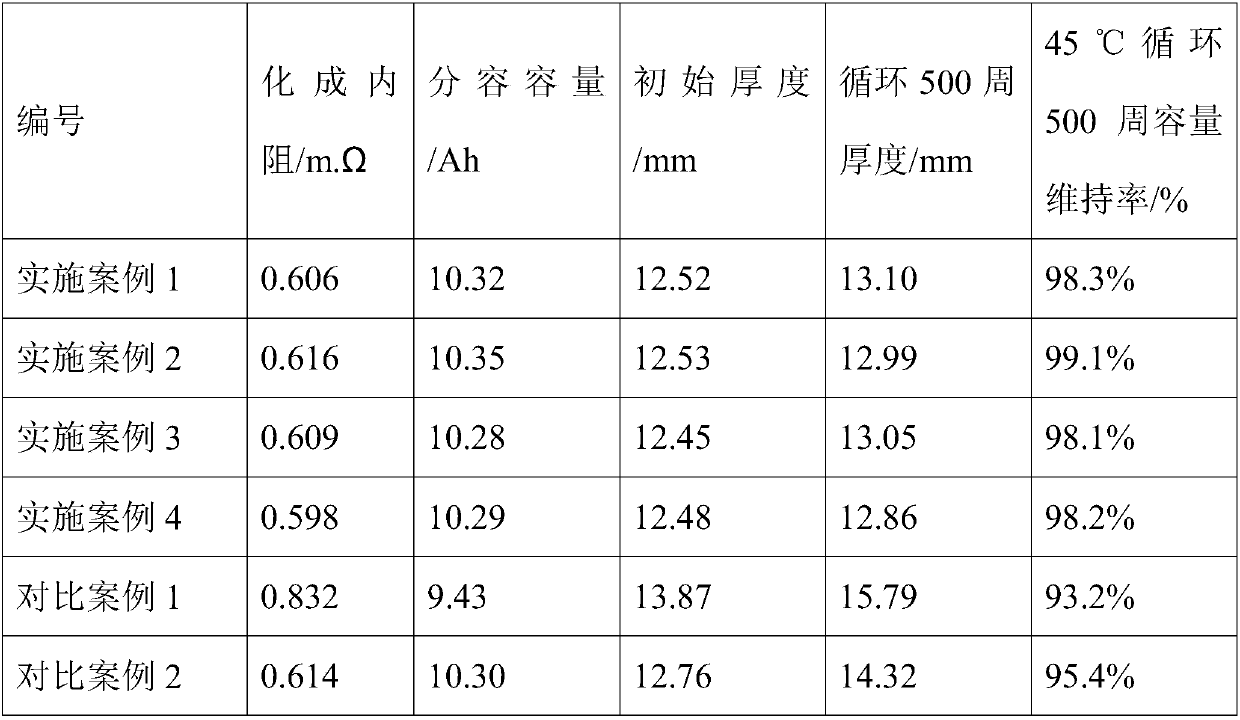

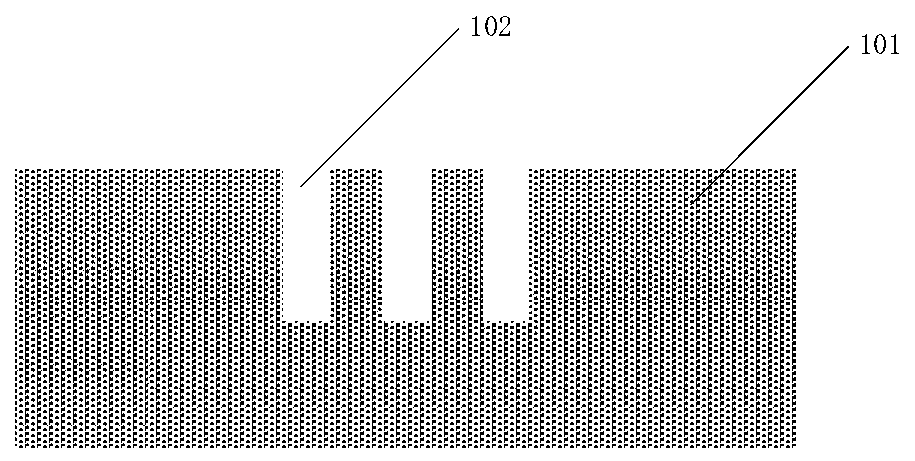

Formation aging method for inhibiting gas expansion of lithium titanate battery

ActiveCN107658504AReduce moistureSolve flatulenceFinal product manufactureElectrolyte accumulators manufactureChemical reactionAge method

The invention discloses a formation aging method for inhibiting the gas expansion of a lithium titanate battery. The formation aging method is used for solving the gas expansion problem of the lithiumtitanate battery generated in the using process. The method comprises three steps of previous standing, formation and aging. In the formation step, the lithium titanate battery after previous standing adopts a constant-current charging manner of first high current and then low current, the battery is charged to a cut-off voltage higher than a working voltage platform and is discharged to a half-charge state after standing. The formation aging method is based on a lithium titanate battery gas production mechanism; the charging manner of first high current and then small current is adopted in the formation process, the lithium titanate material is promoted to form an SEI film in a forced manner under high potential; the battery is discharged in the half-charge state after formation standing, and the battery is placed in a low temperature environment to promote further growth and densification of the SEI film formed in the formation process. The dense SEI film is formed on the surface ofthe anode lithium titanate material, so that the chemical reaction of an electrolyte is prevented at the position of the anode; and the purposes of inhibiting gas production and reducing expansion are reached.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

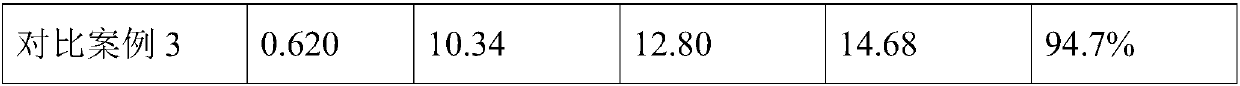

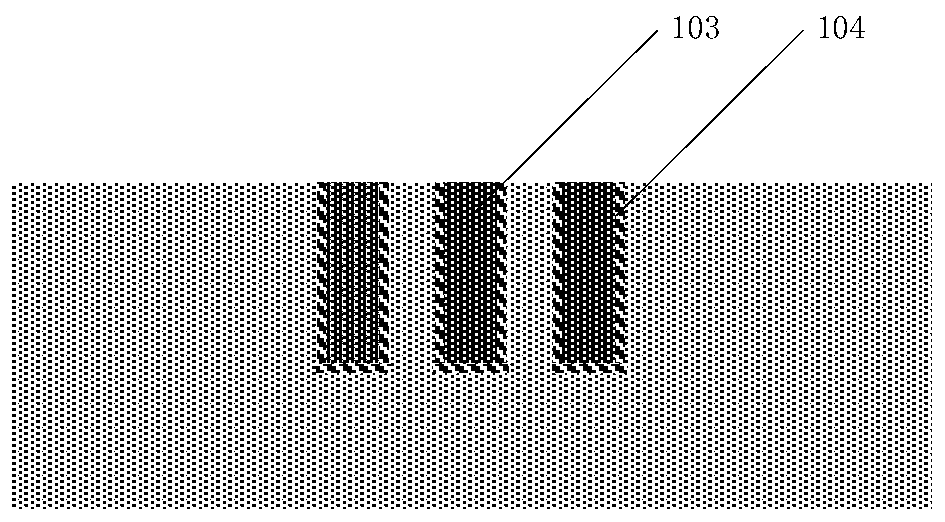

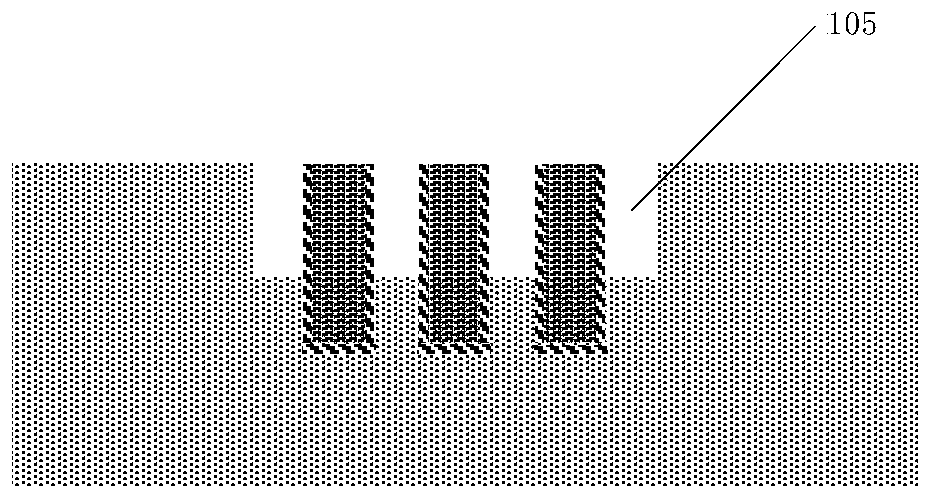

Method for manufacturing silicon cavity structure with TSV structure at bottom

ActiveCN110010547ASimplify the manufacturing processSave production time and costSemiconductor/solid-state device manufacturingMaterials scienceSilicon

The invention discloses a method for manufacturing a silicon cavity structure with a TSV structure at the bottom. The specific processing comprises the following steps of (101) metal pillar fabrication, (102) cavity fabrication, and (103) cavity processing. The method for manufacturing the silicon cavity structure with the TSV structure at the bottom has the advantages that the bonding and grounding of a subsequent chip are facilitated, the manufacturing process of the process is simple, and the cost and production time can be greatly saved.

Owner:浙江集迈科微电子有限公司

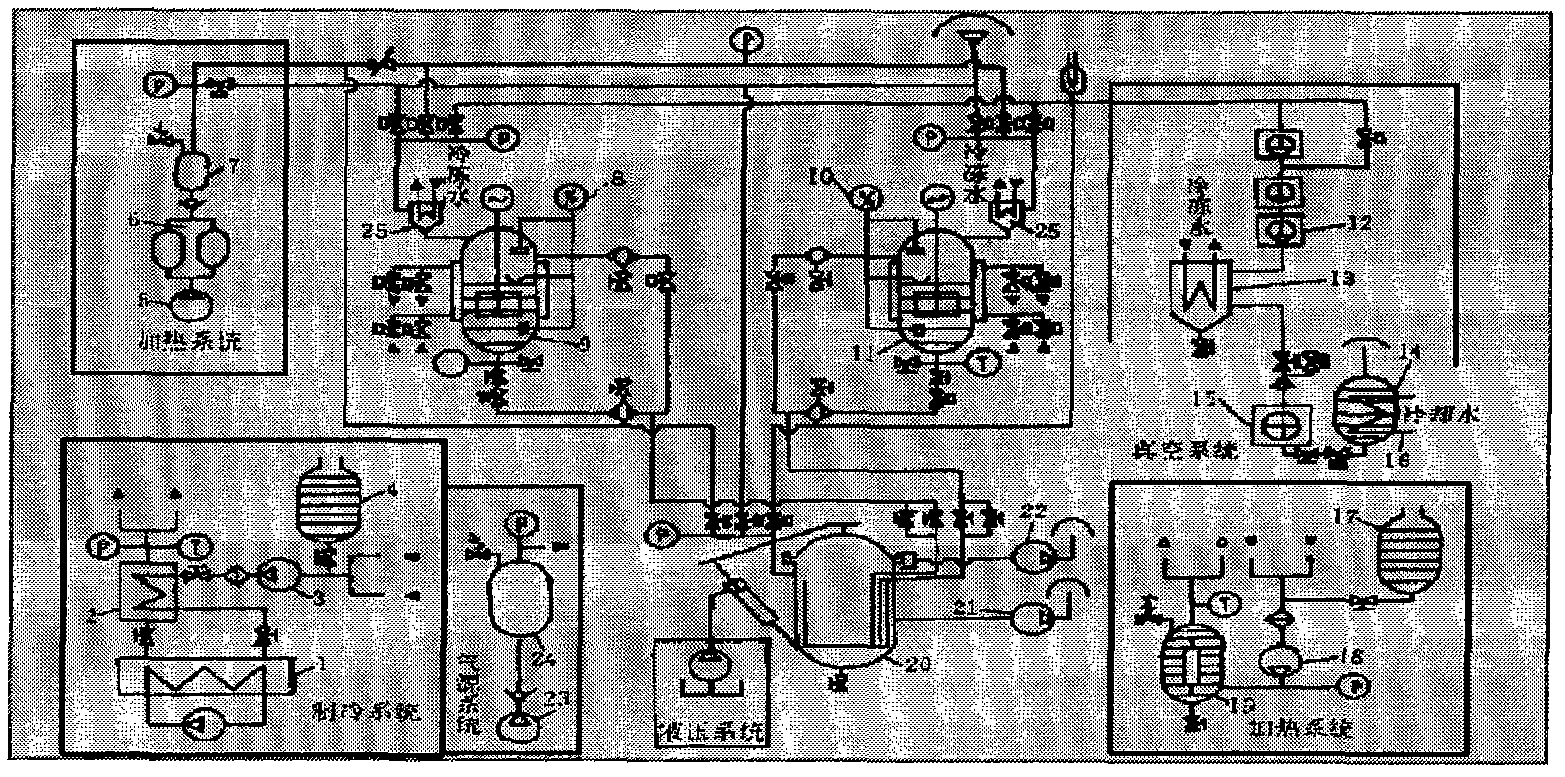

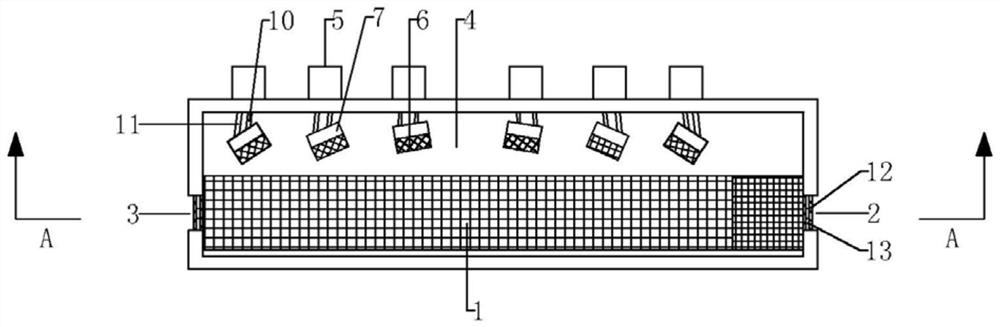

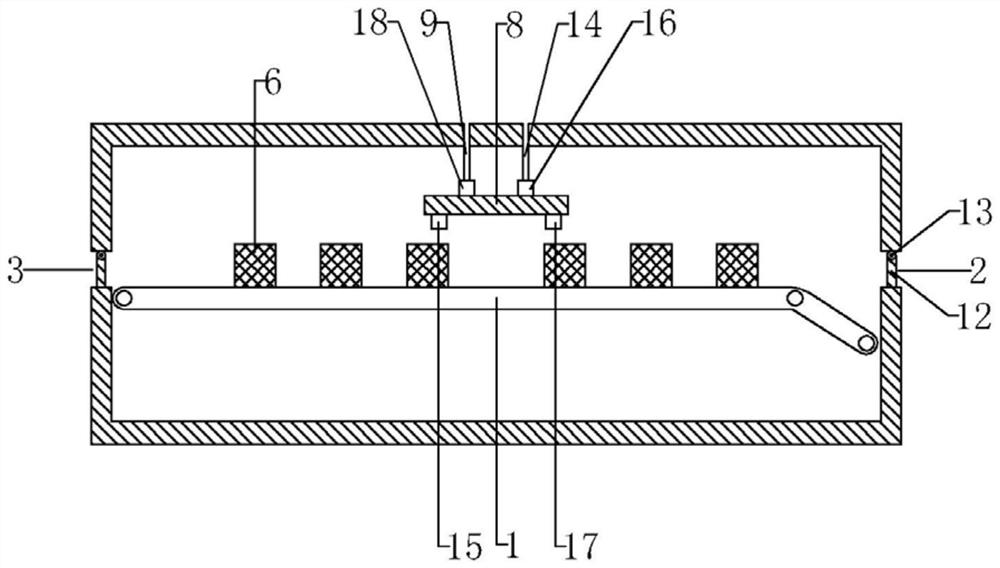

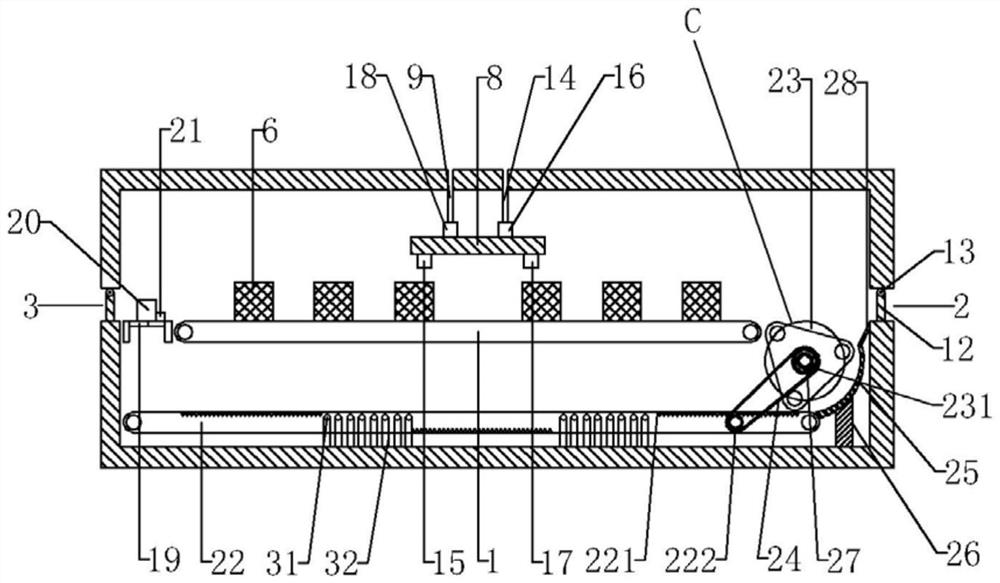

Vacuum pressure paint dipping cluster equipment with improved drying device

InactiveCN102179340ADoes not take up spaceSolve storage problemsPretreated surfacesCoatingsThermal energyInfrared

The invention provides vacuum pressure paint dipping cluster equipment, which comprises an input and output chamber, a preheating working chamber, a paint dipping working chamber, a leveling working chamber, a curing working chamber, a shared vacuum control chamber used for controlling vacuum degrees of the preheating chamber, a paint storage chamber, the paint dipping chamber, the leveling chamber, a drying chamber and the curing chamber, a conveyor positioned in the shared vacuum control chamber and provided with a bearing surface, and a carrier loader positioned on the bearing surface of the conveyer, wherein the drying working chamber is provided with a high infrared radiator for radiating near infrared and far infrared outside. The high infrared radiator is adopted for heating, the radiated mid infrared is absorbed by a coating and converted into heat energy to heat a film; and most high energy density near infrared passes through the film to heat a substrate, heats the film internally and accelerates the evaporation of a solvent in the coating.

Owner:张家港市佳龙真空浸漆设备制造厂

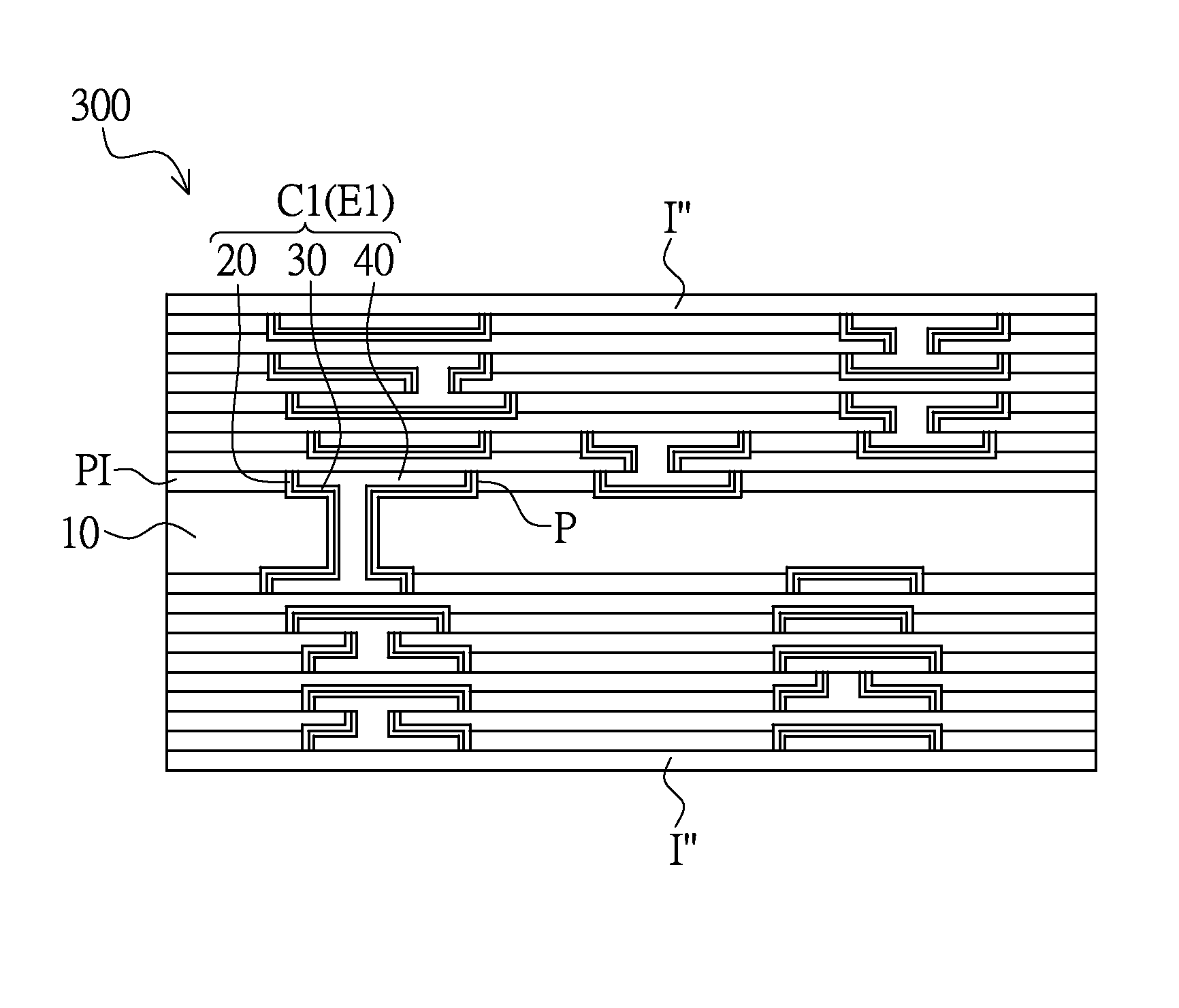

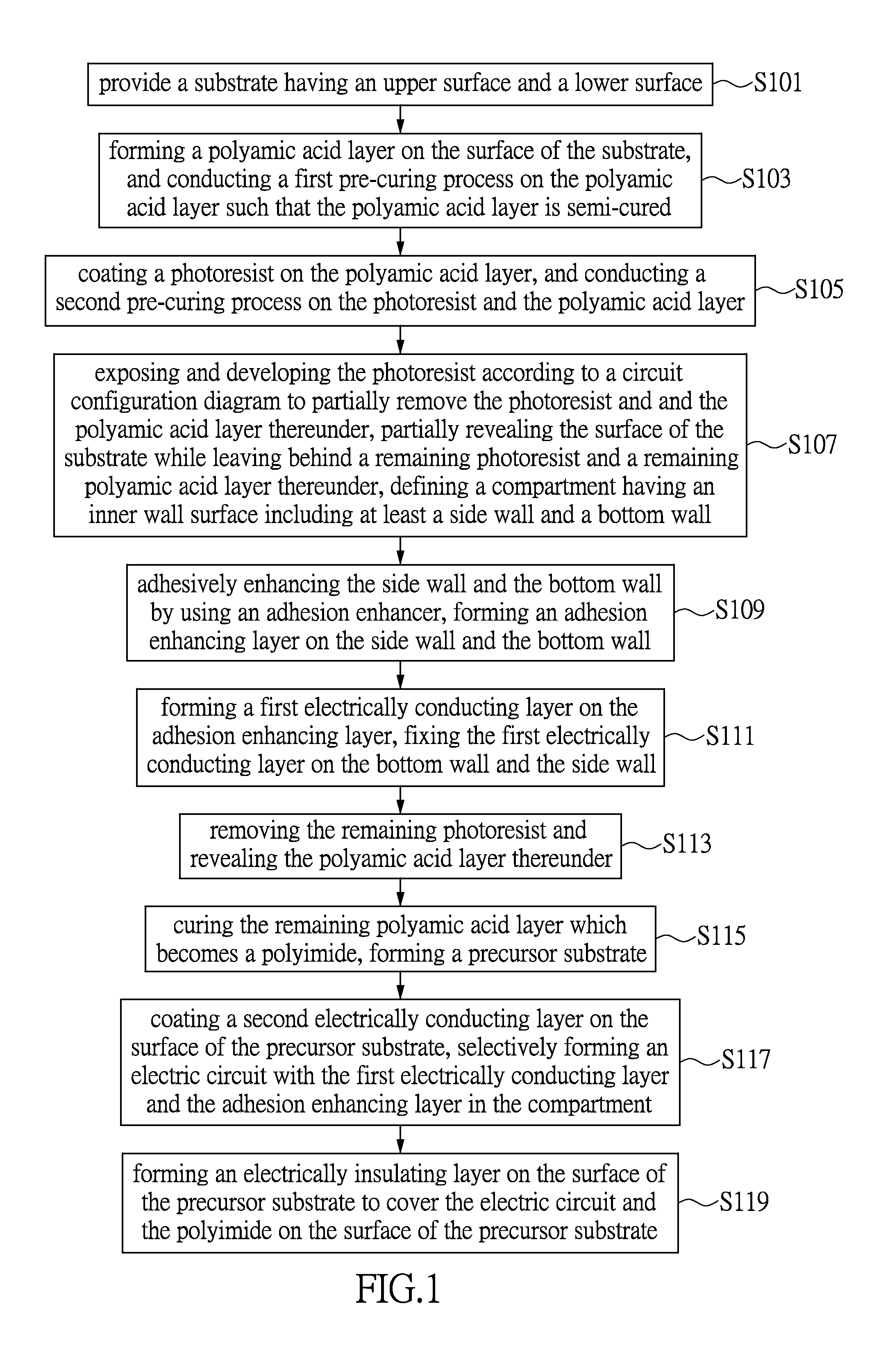

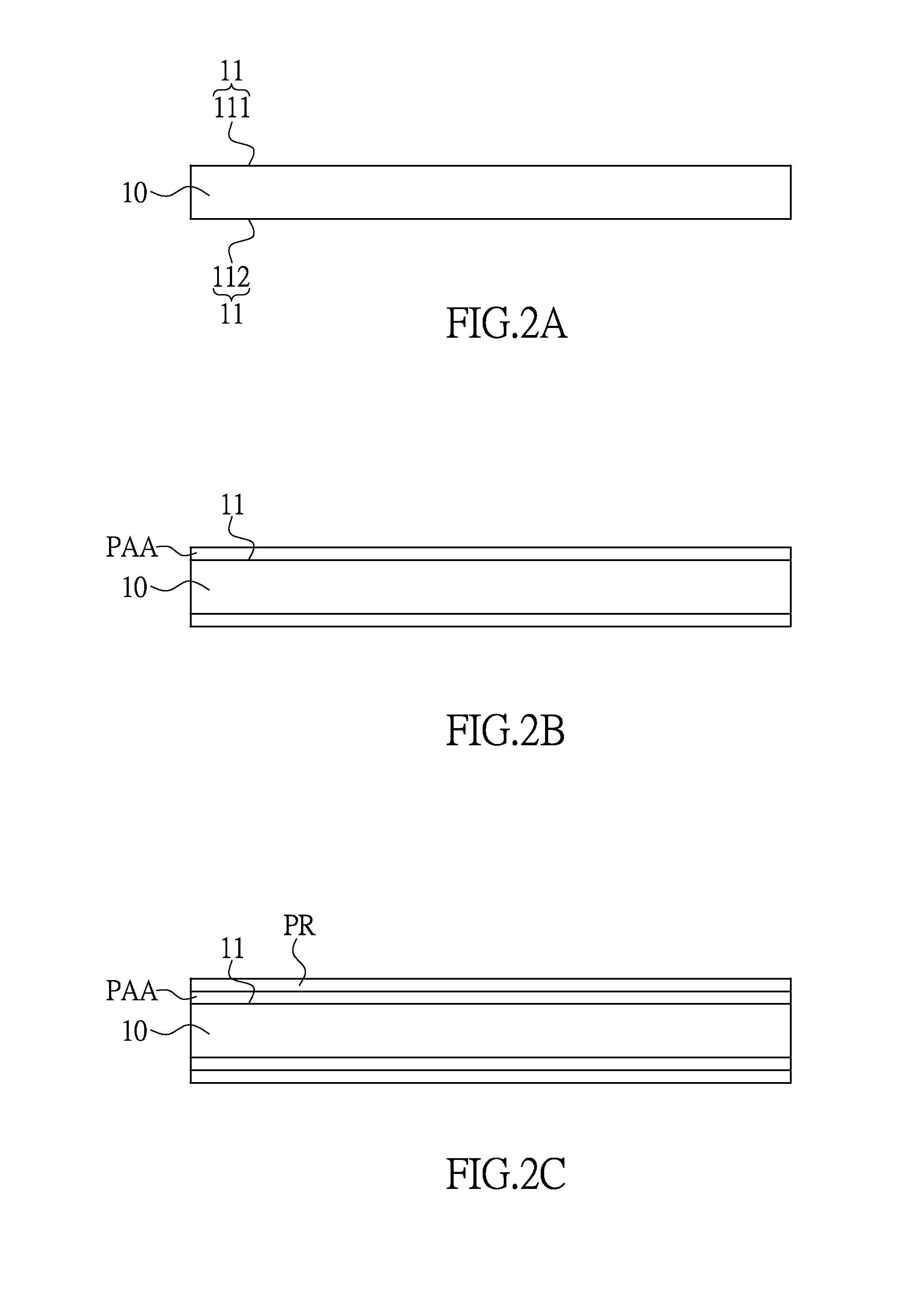

Flexible circuit board and process for producing the same

ActiveUS20140224527A1Reduce thicknessSave production time and costLayered productsPrinted circuit aspectsPolyimideNickel

A flexible circuit board comprises a substrate which has a polyimide layer recessed to define at least a compartment. The compartment includes an inner wall surface having a side wall and a bottom wall. The compartment is for containing a multilayer unit, wherein the multilayer unit includes an adhesion enhancing layer formed on the wall of the compartment, a first electrically conducting layer disposed on the adhesion enhancing layer, and a second electrically conducting layer formed on the first electrically conducting layer. The adhesion enhancing layer is palladium. The first electrically conducting layer is nickel. The substrate is composed of polyimide (PI).

Owner:ICHIA TECH

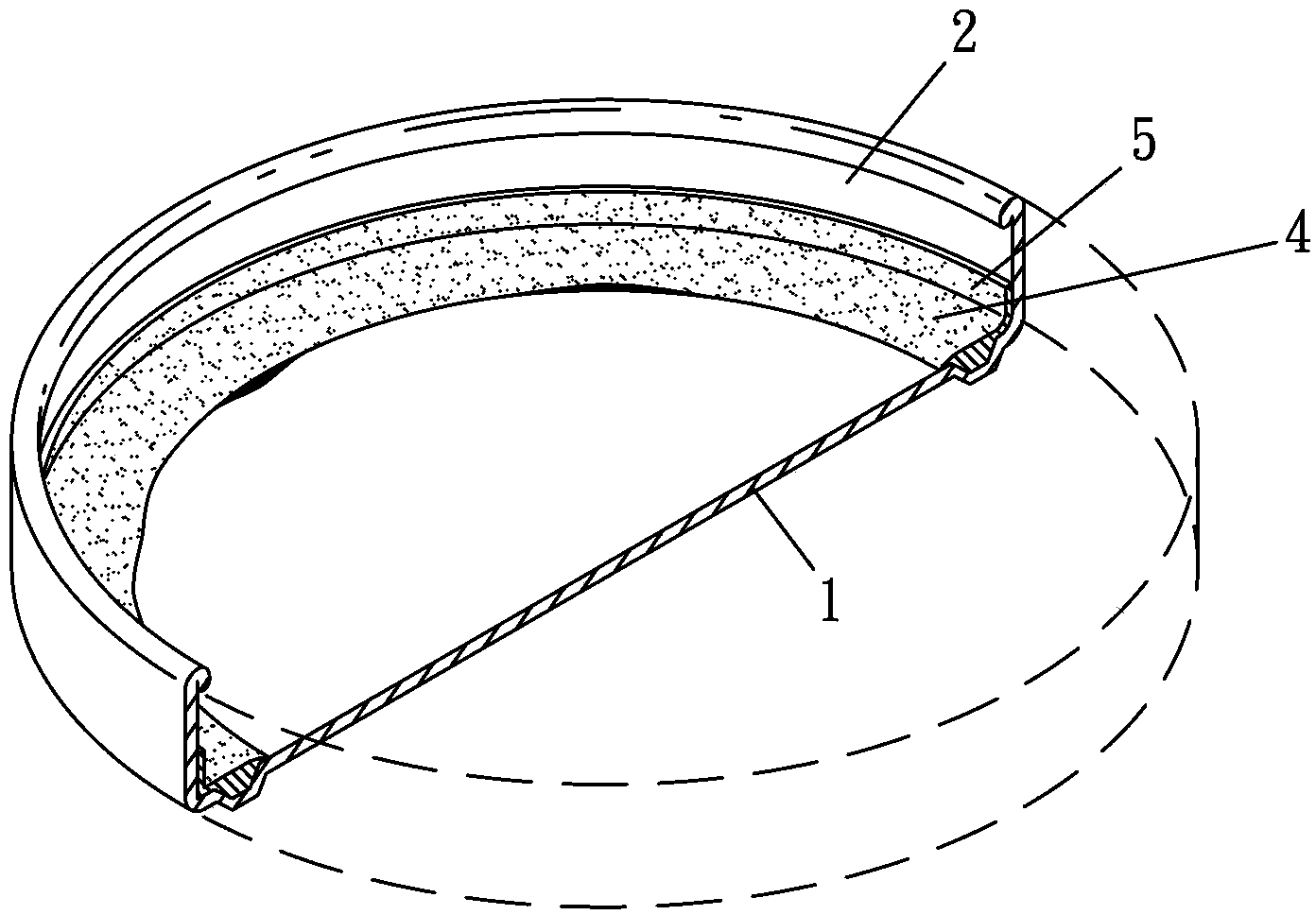

Preparation method of cover sealing glue layer

The invention relates to a preparation method of a cover sealing glue layer. The preparation method is capable of realizing rapid preparation and excellent sealing effect of the cover sealing glue layer. According to the preparation method, a glue-injection machine, which is capable of realizing injection of a plurality of points of glue at the same time, is used for injection of a plurality of points of the cover sealing glue on the inner surface of a pre-heated cover in one time; and the cover sealing glue points are subjected to compression moulding using a molding press, so that an annular cover sealing glue layer is formed on the periphery of the inner surface of the cover. Rapid coating of the cover sealing glue can be realized by using the multipoint glue-injection machine, and rapid formation of the cover sealing glue layer is realized by compression moulding, so that processing is quick, and production cost is reduced. In addition, the cover sealing glue layer is uniformized because of compression moulding, and excellent sealing effect is achieved when an opening is covered by the cover.

Owner:蔡鸿森

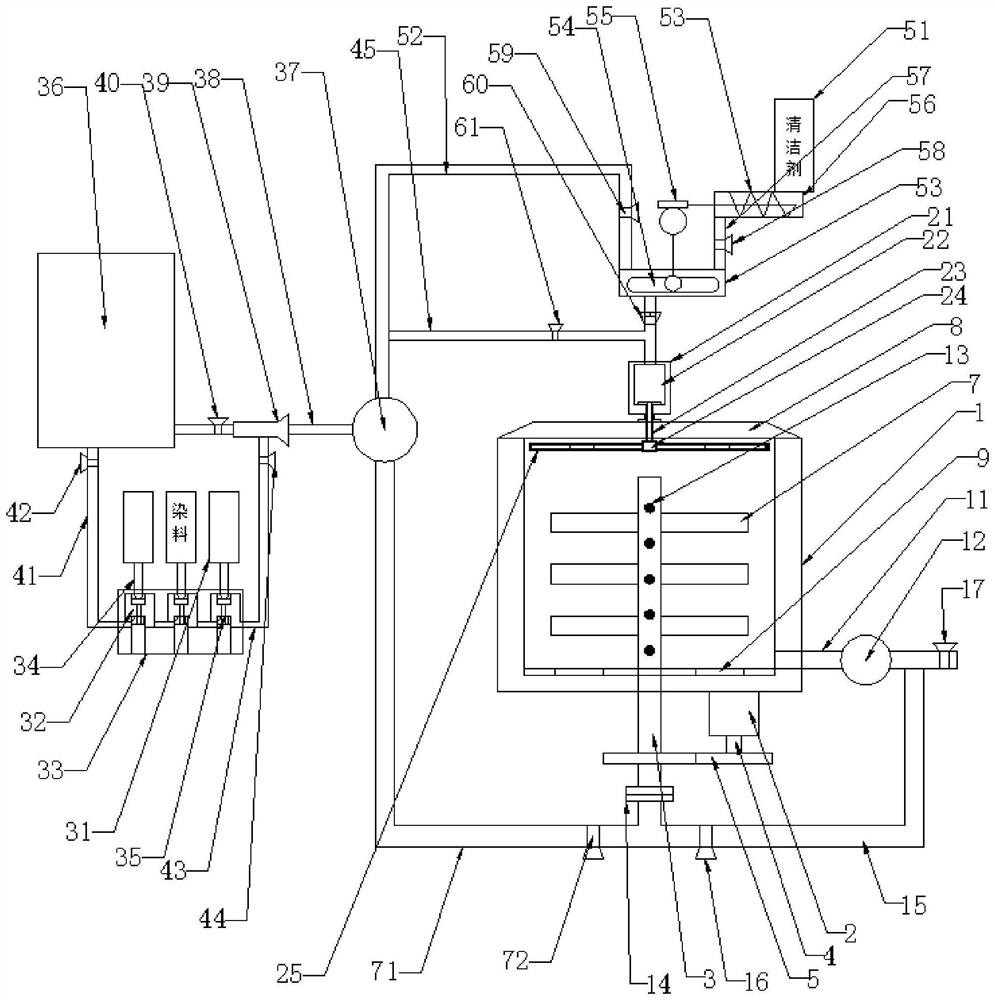

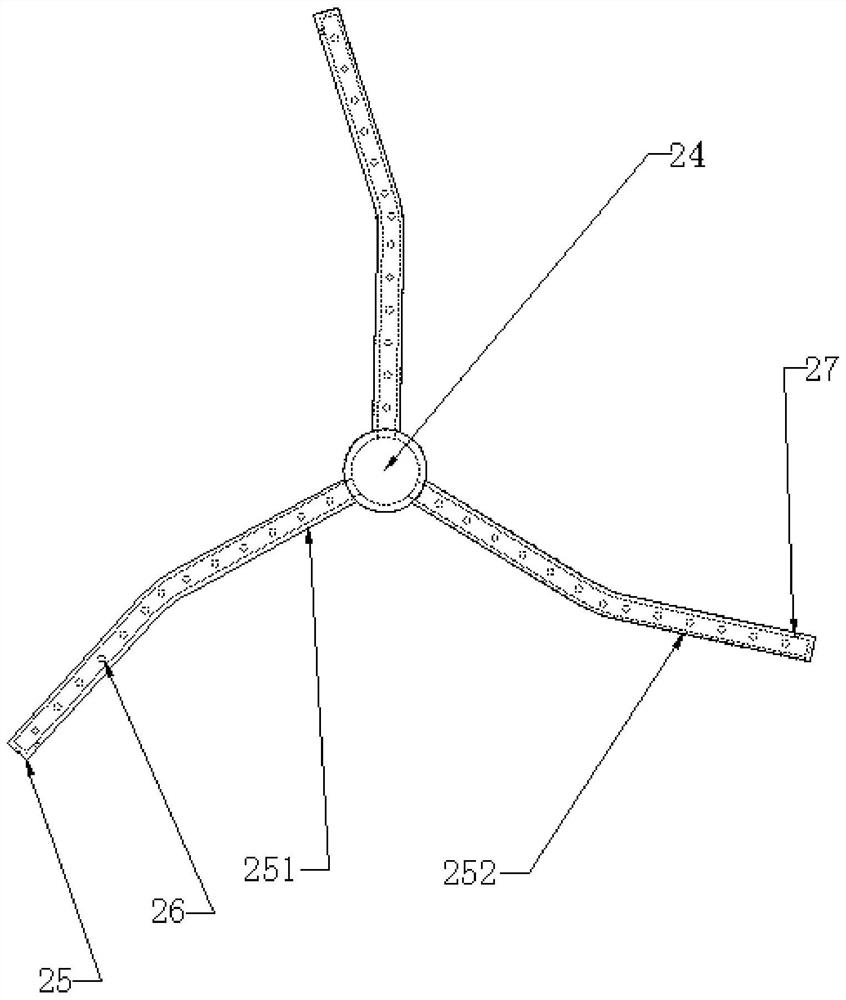

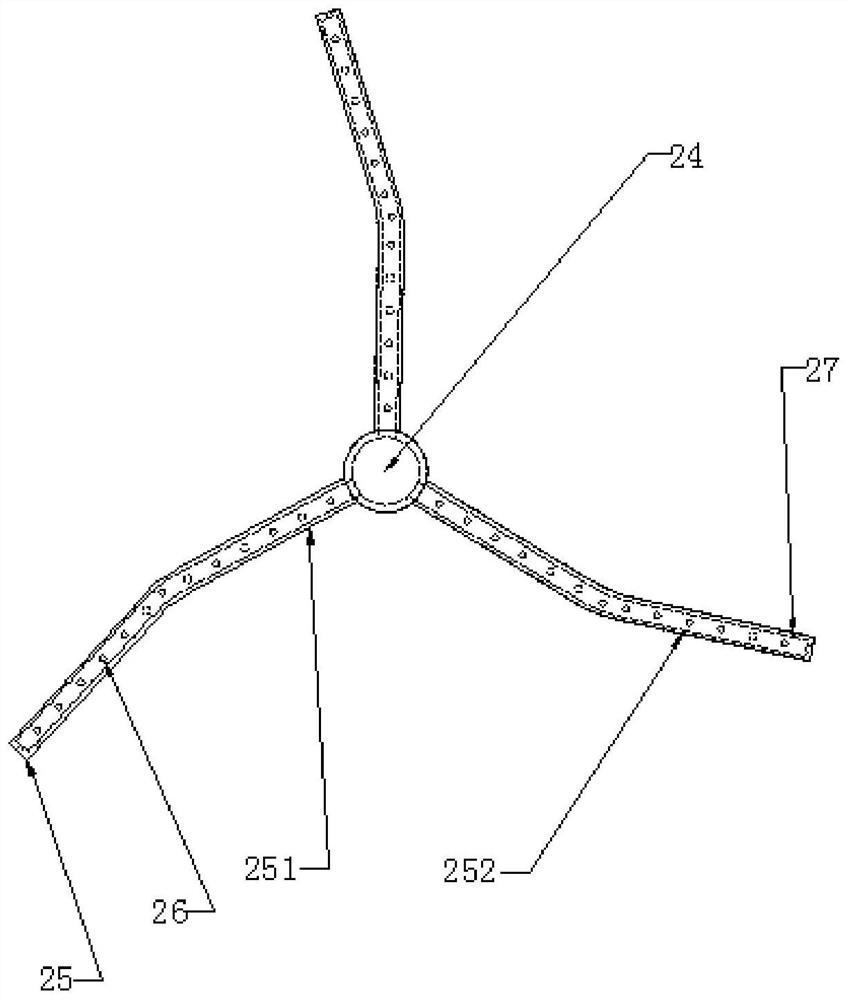

Anti-varicosity sock production equipment

InactiveCN112411068AEmission reductionLow costTextile treatment containersTextile treatment machine arrangementsCirculating pumpMechanical engineering

The invention relates to anti-varicosity sock production equipment. The equipment comprises a dyeing cylinder, wherein a stirring assembly is arranged in the dyeing cylinder and comprises a stirring motor and a stirring rotating shaft, the stirring motor is arranged at the bottom of the dyeing cylinder, an output end of the stirring motor is connected with a vertical rotating shaft, a driving fluted disc is arranged at the lower end of the vertical rotating shaft, a driven fluted disc matched with the driving fluted disc is arranged on the side wall of the stirring rotating shaft, the upper end of the stirring rotating shaft penetrates through the bottom in the dyeing cylinder and then extends into the dyeing cylinder, a plurality of stirring blades are arranged on the side wall of the stirring rotating shaft in the height direction, a cylinder cover is arranged at the top of the dyeing cylinder, a heating device and a temperature sensor are arranged in the dyeing cylinder, a dye discharging pipe is arranged at the bottom of the side wall of the dyeing cylinder, a circulating pump is arranged on the dye discharging pipe, the dyeing cylinder comprises a dyeing cylinder shell and a dyeing cylinder inner container, and a heat preservation layer is arranged between the inner wall of the dyeing cylinder shell and the outer wall of the dyeing cylinder inner container. The dyeing uniformity and the dyeing efficiency are improved.

Owner:胡数丽

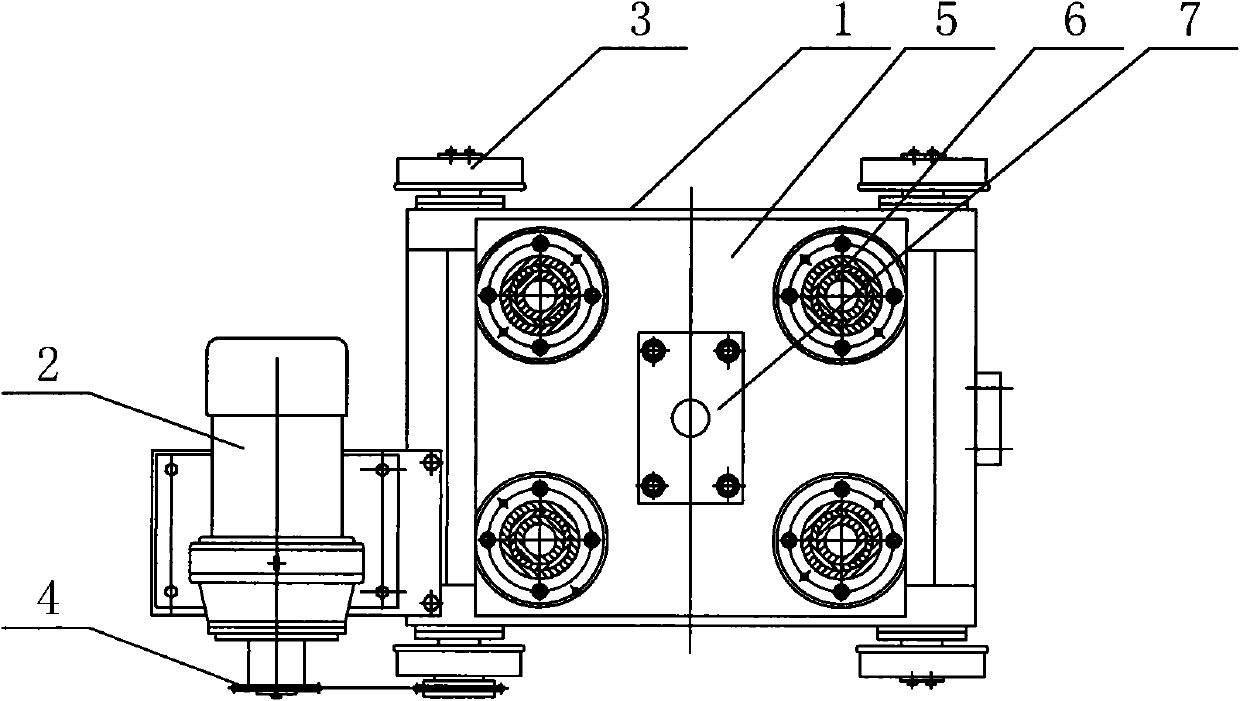

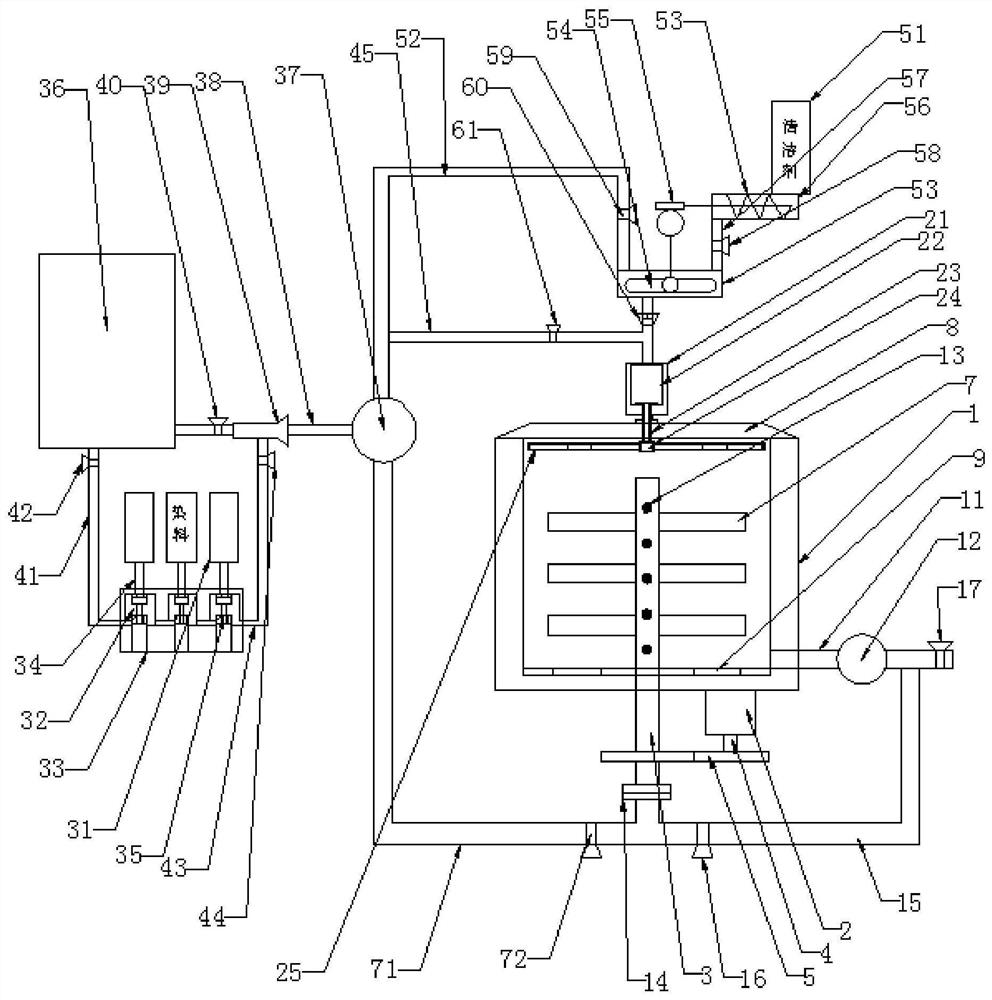

Air blowing system of motor stator-winding paint dipping system

InactiveCN101908801AReduce usageSave production time and costManufacturing dynamo-electric machinesSpare timeWork in process

The invention relates to an air blowing system of a motor stator-winding paint dipping system, which comprises a casing rack, wherein the casing rack is arranged at both sides of a motor stator; a station wiring terminal is correspondingly arranged on the upper part in the central position of the casing rack; a hoisting hook is arranged on the centre of the wiring terminal; and air-drafting boards are respectively installed on the inner sides of the casing rack. The air blowing system of a motor stator-winding paint dipping system is designed to be a structure which can draft and intake air from two sides, and speed up the drying and cooling of the motor stator by utilizing the flowing of air. The motor stator-winding paint dipping system can solve the problems of unfinished products are stored and packed for occupying a large production room because the spare time exists between two technology procedures of the traditional single product, can ensure that a plurality of technology procedures of paint dipping can be successively circulated on equipment, and does not have the room occupation phenomenon of unfinished products, thereby saving the production time and cost, improving the operation efficiency, and lowering the labor cost because the fewer workers are employed.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

Vacuum pressure lacquer-dipping cluster device

InactiveCN102806176ADoes not take up spaceSave production time and costPretreated surfacesCoatingsVacuum pressureLacquer

The invention provides a vacuum pressure lacquer-dipping device which comprises a vacuum unit, a lacquer-dipping tank and a lacquer-storing tank connected with the lacquer-dipping tank, wherein the bottom of the lacquer-dipping tank is communicated with the bottom of the lacquer-storing tank through a lacquer-conveying pipeline; a lacquer-conveying valve is arranged on the lacquer-conveying pipeline; the lacquer-dipping tank is respectively communicated with the vacuum unit, an air compressor and a nitrogen tank through a communicating valve; an infrared heating device is mounted in the lacquer-dipping tank; the vacuum pressure lacquer-dipping device is characterized in that: the vacuum unit is provided with a roots pump, a first mechanical pump and a second mechanical pump; the first mechanical pump and the second mechanical pump are serially connected with the roots pump; and a low-temperature catcher is mounted on a vacuumizing pipeline between the lacquer-dipping tank and the vacuum unit. A vacuum system provided by the invention is used for quickly vacuumizing till the pressure is below 0.1Pa. The low-temperature catcher is arranged in the pipeline, so that the risk in styrene explosion during the preheating or vacuumizing process of the system is effectively prevented.

Owner:张家港市佳龙真空浸漆设备制造厂

Method for jointly preparing ginger tea and ginger starch

InactiveCN108902407AIncrease productivitySave production time and costTea substituesBulk chemical productionFiltrationSpray dried

The invention relates to a method for jointly preparing ginger tea and ginger starch, the method comprises washing, smashing and sieving, supercritical extraction, sedimentation, filtration, spray drying, and the like, and the method simultaneously prepares ginger extract and the ginger starch. The ginger extract can be prepared into the ginger tea, the extraction rate of the ginger starch can reach 40.5%, the production efficiency is improved, the production time cost is shortened, and the production cost is reduced; ginger residue can be reused in the preparation of the ginger tea for preparation of the ginger starch, the bioavailability of the ginger residue is increased, environment pollution due to ginger residue discharge can be reduced, the problems of the environment pollution dueto the ginger residue discharge and waste residue bioavailability can be solved, the problems of post-treatment of ginger tea production waste and environmental pollution due to incomplete treatment can be solved.

Owner:广西西林县农本生物科技有限公司

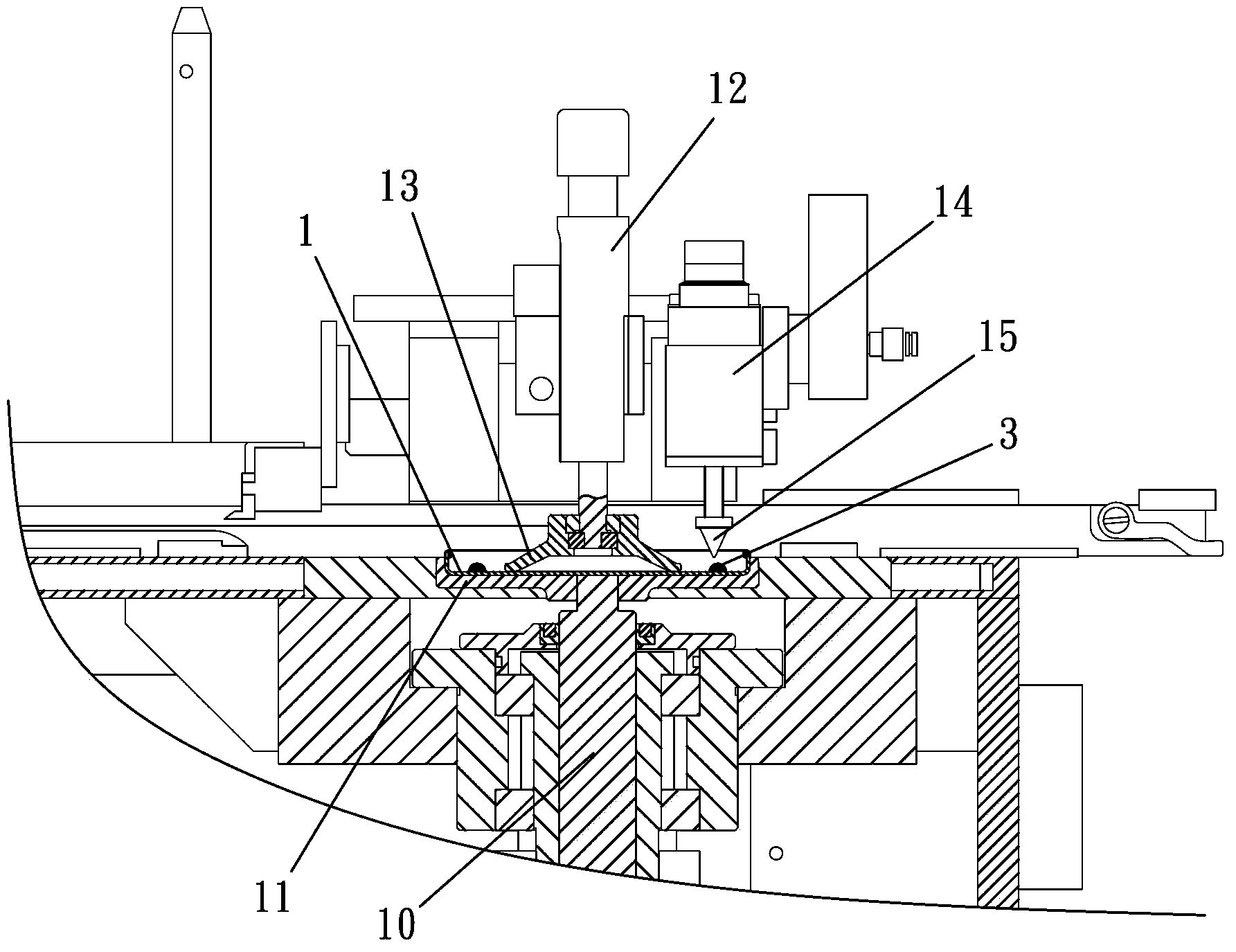

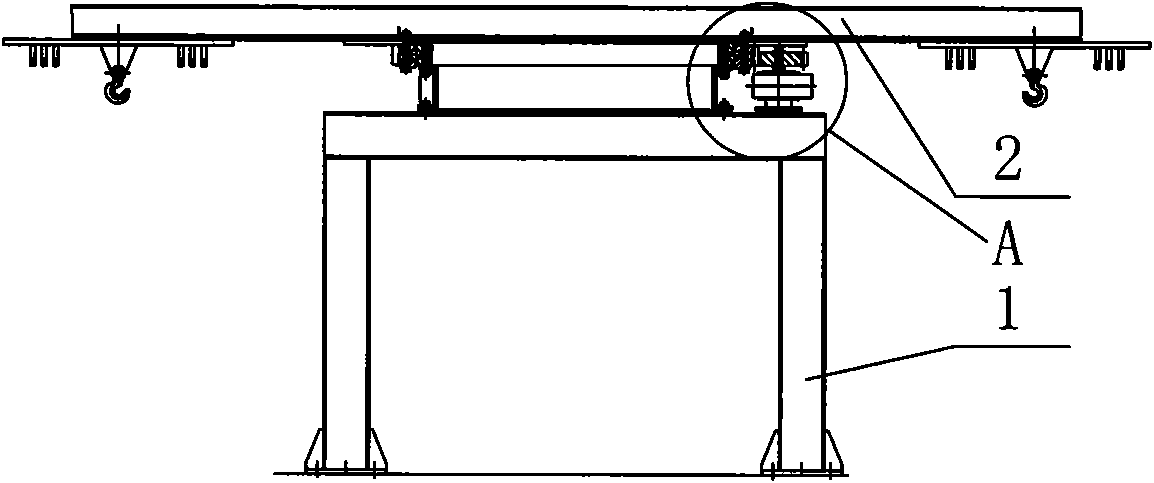

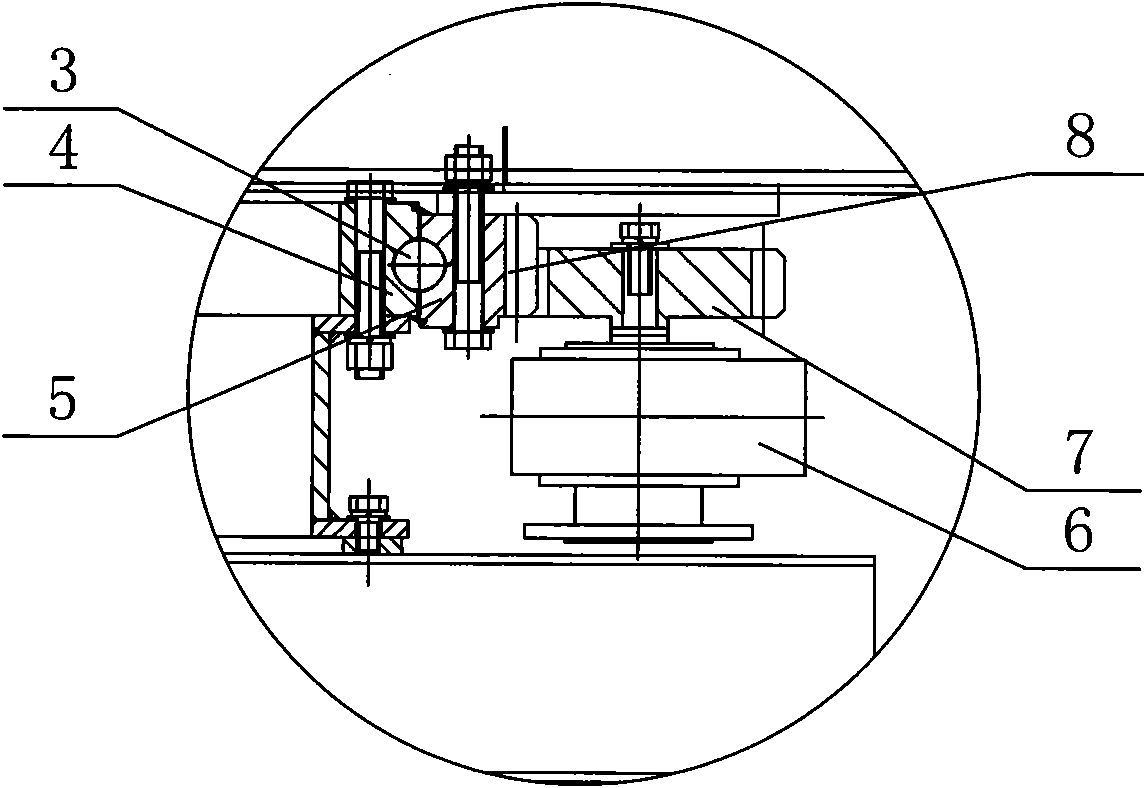

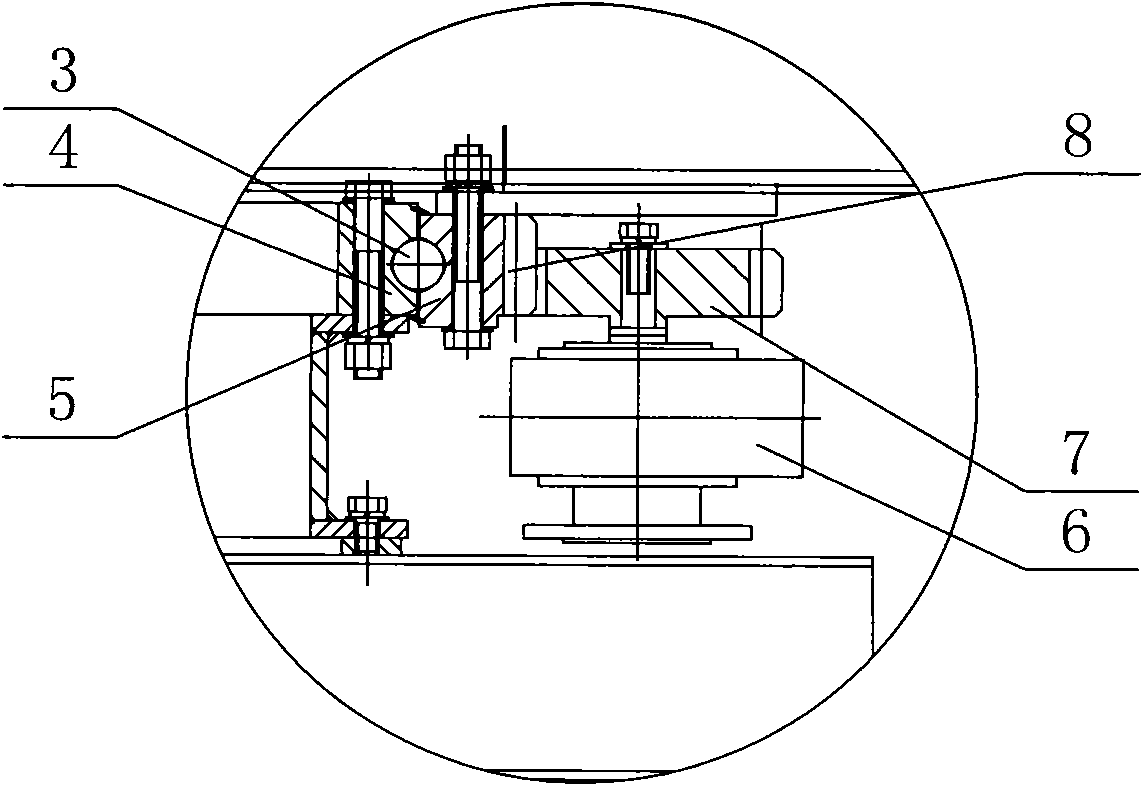

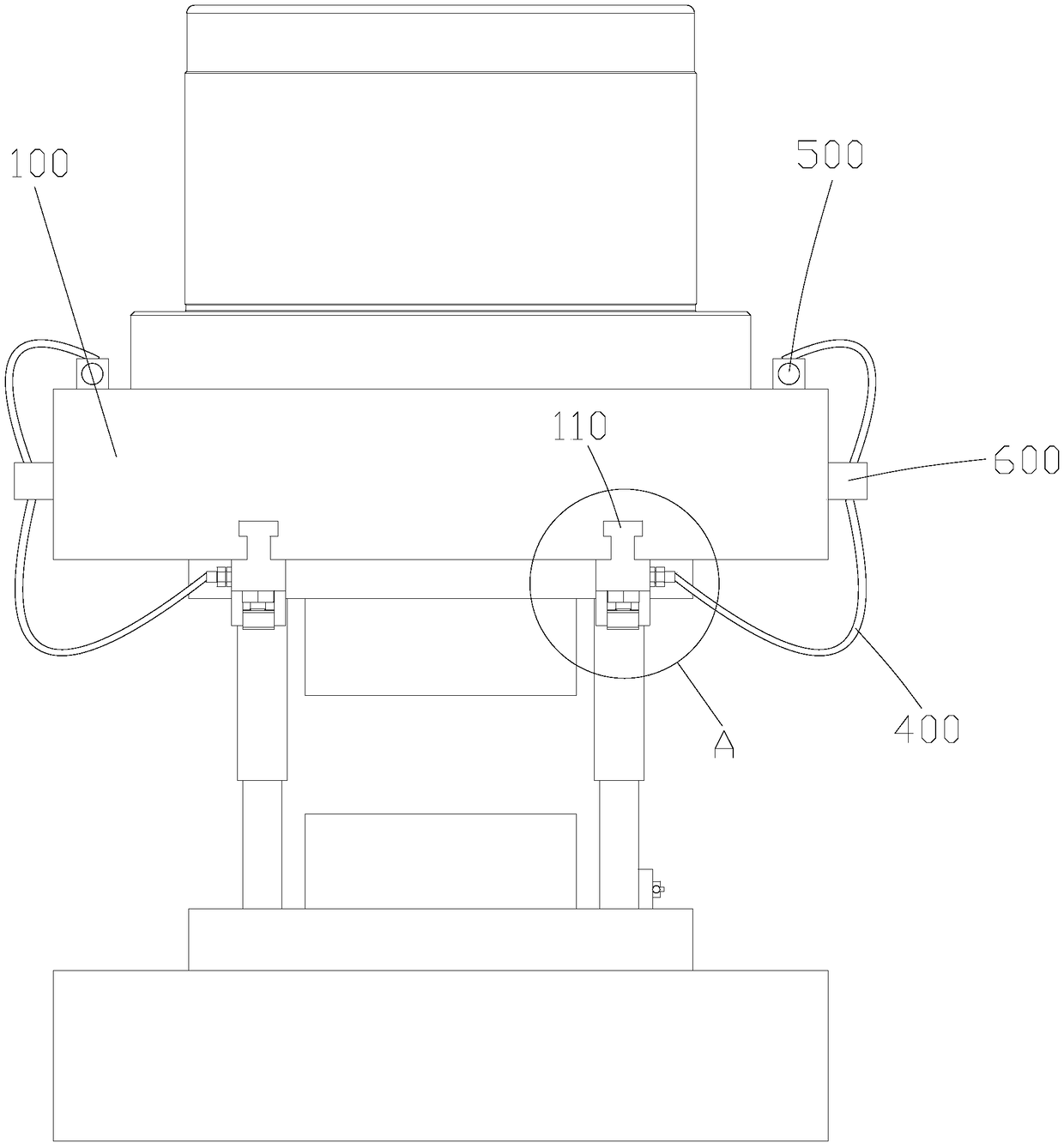

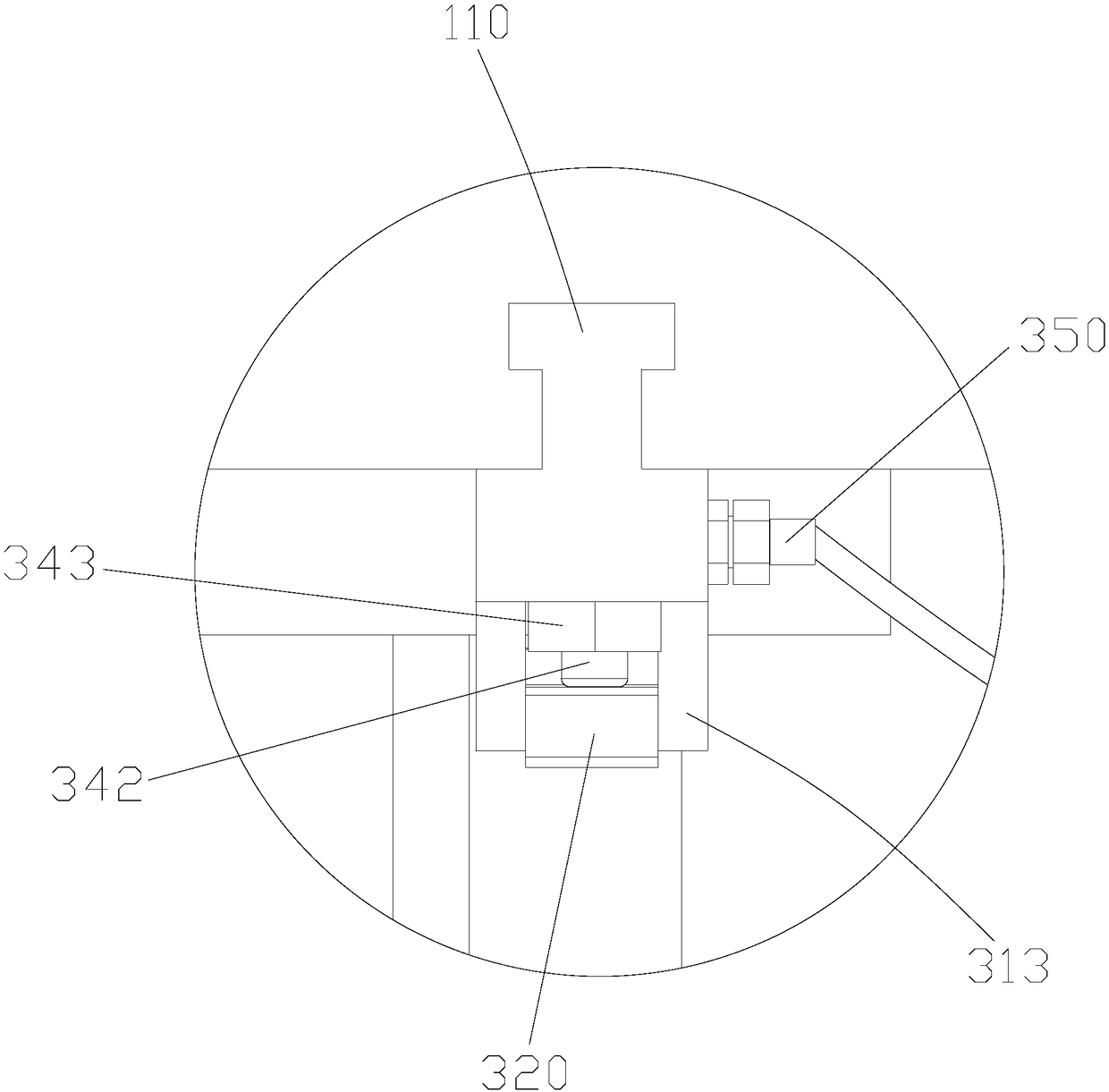

Rotary support driving mechanism in motor stator winding dipping lacquer system

InactiveCN101908805ASave production time and costImprove work efficiencyManufacturing dynamo-electric machinesLacquerCircular section

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

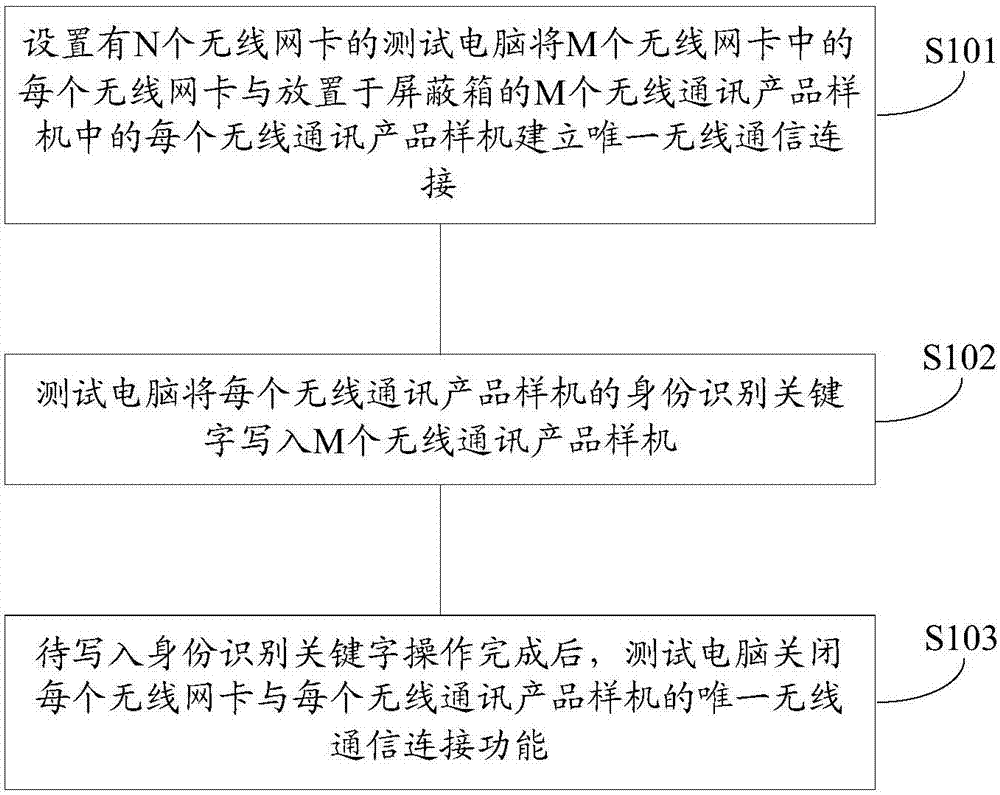

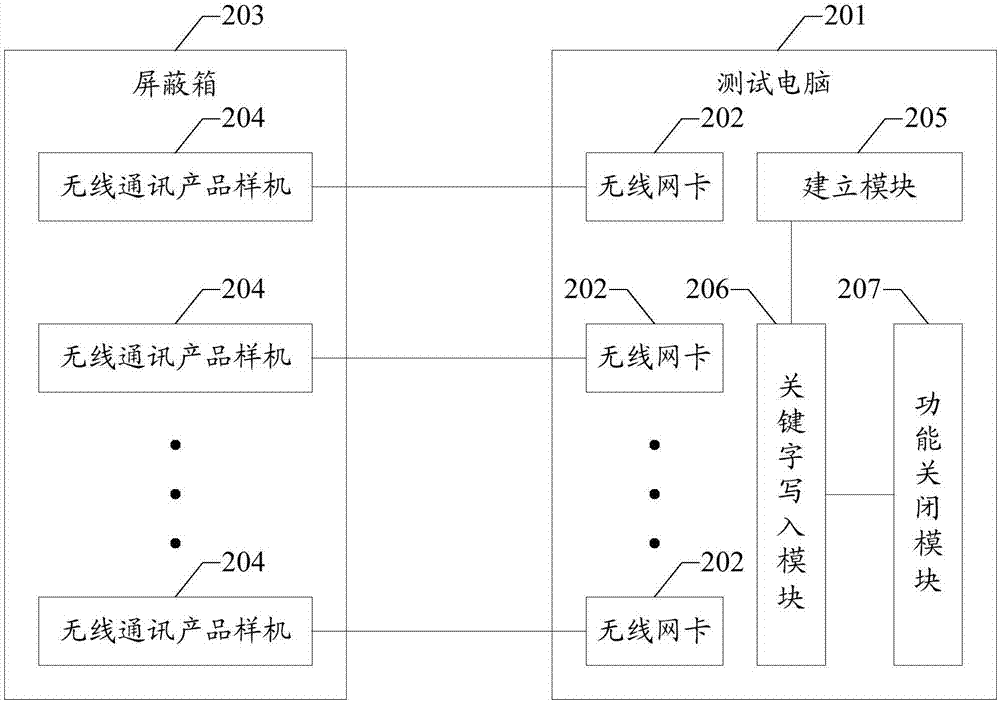

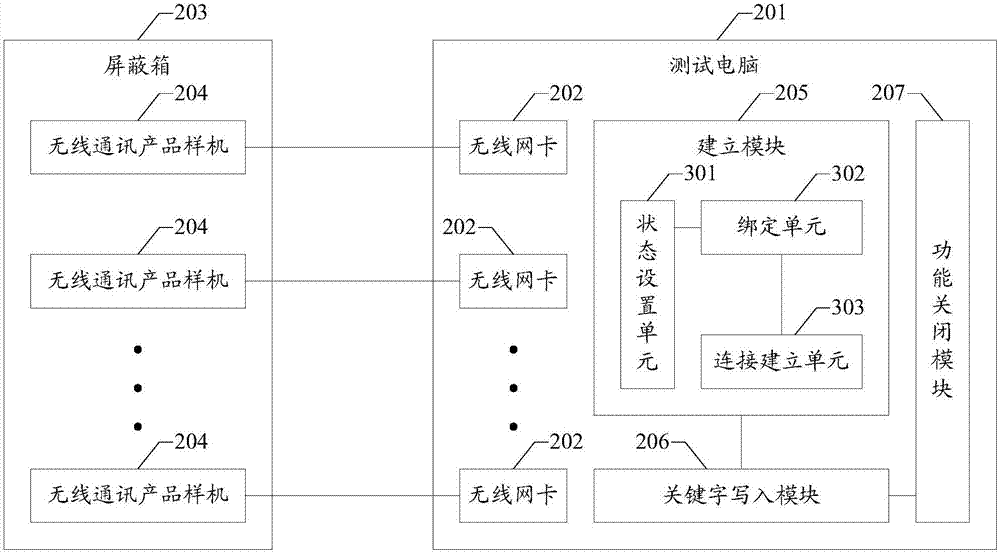

Method and system for writing values to wireless communication computer product sample

ActiveCN107426719ASave production time and costImprove test efficiencyConnection managementNetwork data managementTest efficiencyRadio frequency

The invention belongs to the field of production automation, and provides a method and system for writing values to a wireless communication computer product sample. The method includes the following steps: arranging a test computer having N wireless network cards, establishing the only wireless communication connection between each of M wireless network cards with each of M wireless communication product machine samples which are disposed in a shielding box; a test computer writing identity identifying key words of each wireless communication computer product sample to M wireless communication computer product samples; and after writing the identity identifying key words, the test computer turning off the only wireless communication connection between each wireless network card and each wireless communication computer product sample. According to the invention, the technical solution has the following characteristics: 1. increases test efficiency; 2. avoids radio frequency interference caused by poor shielding of the shielding box; and 3. is applicable to all wireless communication products which are unable to be joined through communication wire material interfaces, and also protects consistency of product appearance and production.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

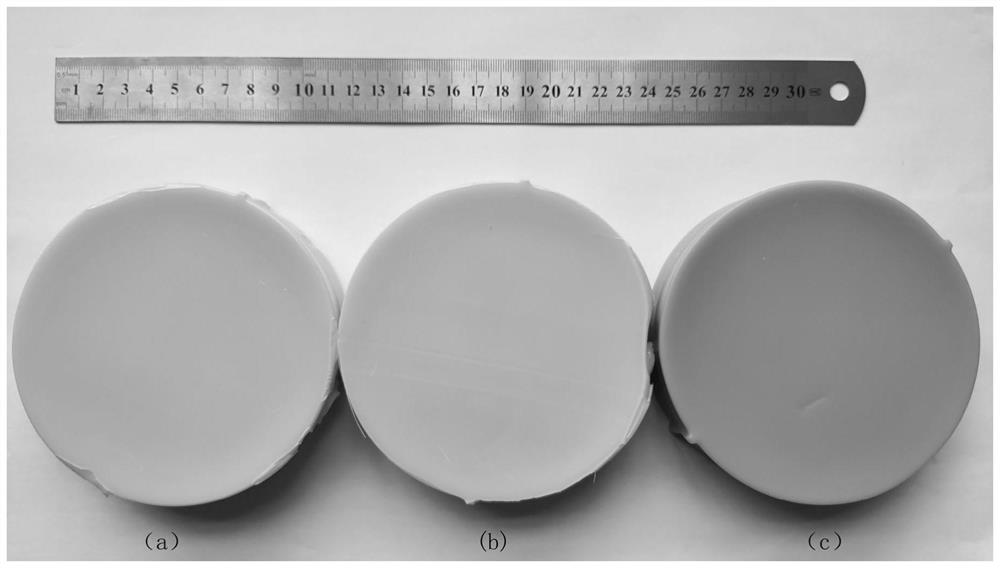

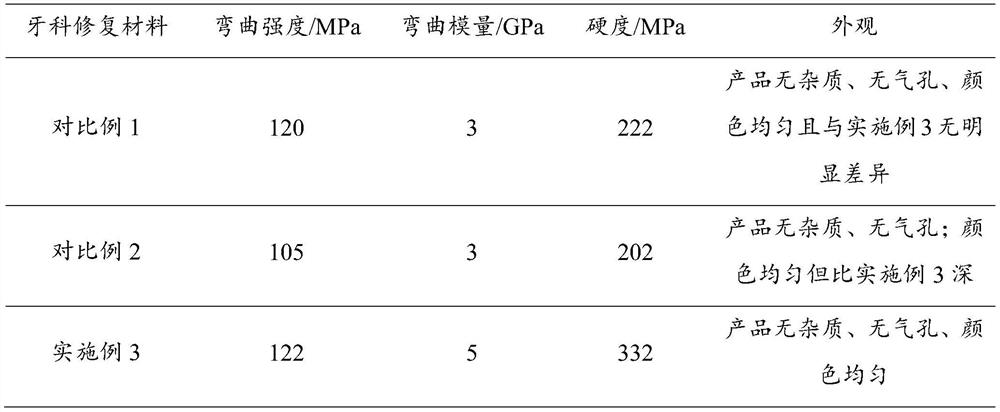

Dental repair material for temporary crowns and bridges and preparation method of dental repair material

PendingCN114652616AHigh strengthHigh modulusImpression capsDentistry preparationsRepair materialMethacrylate methyl

The invention discloses a dental restoration material for temporary crowns and bridges and a preparation method thereof, and the preparation method comprises the following steps: mixing preparation raw materials comprising methyl methacrylate, an inorganic filler, an initiator and a toner to prepare a mixture, injecting the mixture into a mold, and carrying out warm isostatic pressing curing molding to prepare the dental restoration material for temporary crowns and bridges. By adding the inorganic filler, the mechanical property of the dental restoration material can be enhanced, and by adopting a warm isostatic pressing curing molding mode, the curing molding time can be remarkably shortened, the production time cost can be reduced, the production efficiency can be improved, and the mechanical property of the product material can be further improved; further, the prepared dental restoration material has high strength, high modulus and high surface hardness.

Owner:佛山(华南)新材料研究院

Air energy high-temperature heat pump tunnel type multifunctional drying production equipment

PendingCN112696910ASolve uneven heatingImprove drying effectDrying gas arrangementsDrying chambers/containersThermodynamicsProcess engineering

The invention relates to the field of drying devices, in particular to air energy high-temperature heat pump tunnel type multifunctional drying production equipment. The production equipment is provided with a rectangular hollow drying box, wherein a feeding port and a discharging port are formed in the two ends of a pipeline respectively; a conveying belt is arranged in the pipeline; a heat pump heating main machine is arranged along the conveying belt; the heat pump heating main machine is connected with a hot air exchanger through a heat supply pipeline; a cooling pipeline is connected between the heat pump heating main machine and the hot air exchanger; a fan is arranged and fixedly connected with the hot air exchanger; a moisture exhaust and air return fan is arranged above the conveying belt and connected with an air return duct; an opening of the air return duct penetrates through the outer wall of the drying box; and the outer wall of the air return duct is connected with the through position of the drying box in a closed mode. Materials are in a sealed state in the equipment, and can be continuously fed through the feeding port in the operation process of the equipment, so that the equipment can continuously work, and the problem that existing equipment can only conduct drying in batches in the working process is solved.

Owner:贵州九鼎新能源科技开发集团有限公司

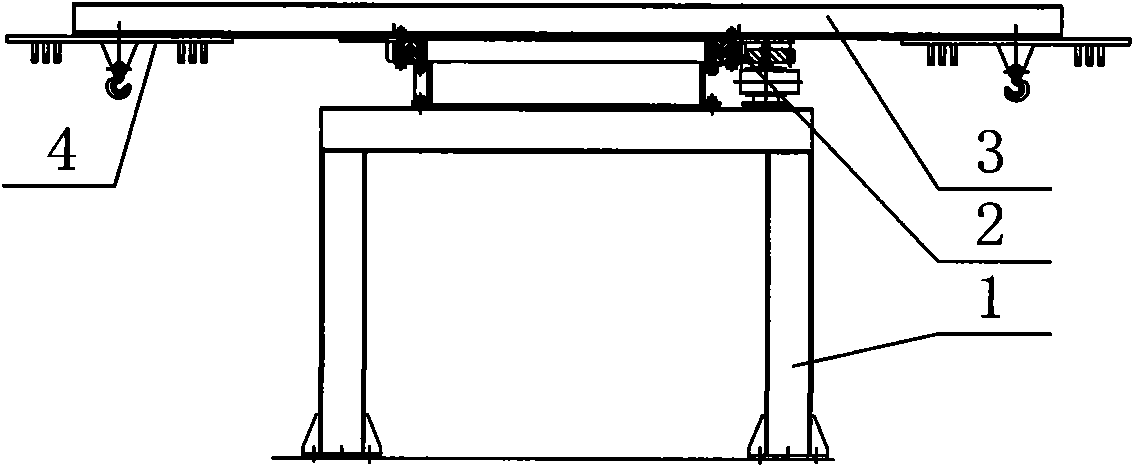

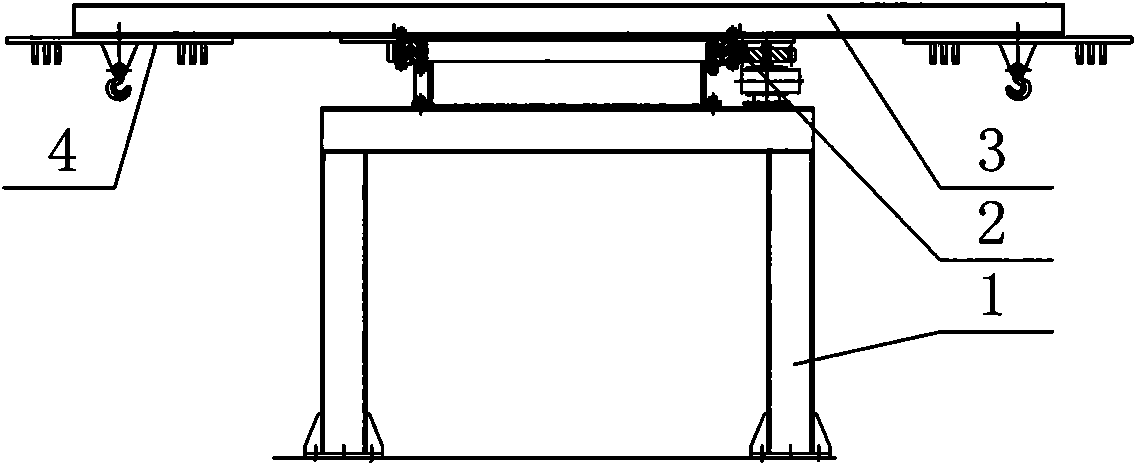

Feeding trolley of electric machine stator winding paint-dipping system

InactiveCN101908804ADoes not take up spaceReduce usageManufacturing dynamo-electric machinesElectric machineEngineering

The invention relates to a feeding trolley of an electric machine stator winding paint-dipping system, comprising a feeding trolley body, wherein an electric machine is fixed on the trolley body; two pairs of track wheels are arranged below the trolley body; the electric machine drives the track wheels to run through a pulley; a lifting plate is arranged on the trolley body; the lifting plate is connected with the trolley body through four sliding poles; the sliding poles are arranged on the lower surface of the lifting plate, and are inserted into sliding pole holes arranged on the trolley body; the lower surface of the centre of the lifting plate is supported on a supporting rod of a hydraulic oil cylinder; and the hydraulic oil cylinder is fixed on the trolley body, and moves with the trolley body. The feeding trolley of the electric machine stator winding paint-dipping system can enable the electric machine stator winding to feed and discharge stably in the process of feeding or discharging.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

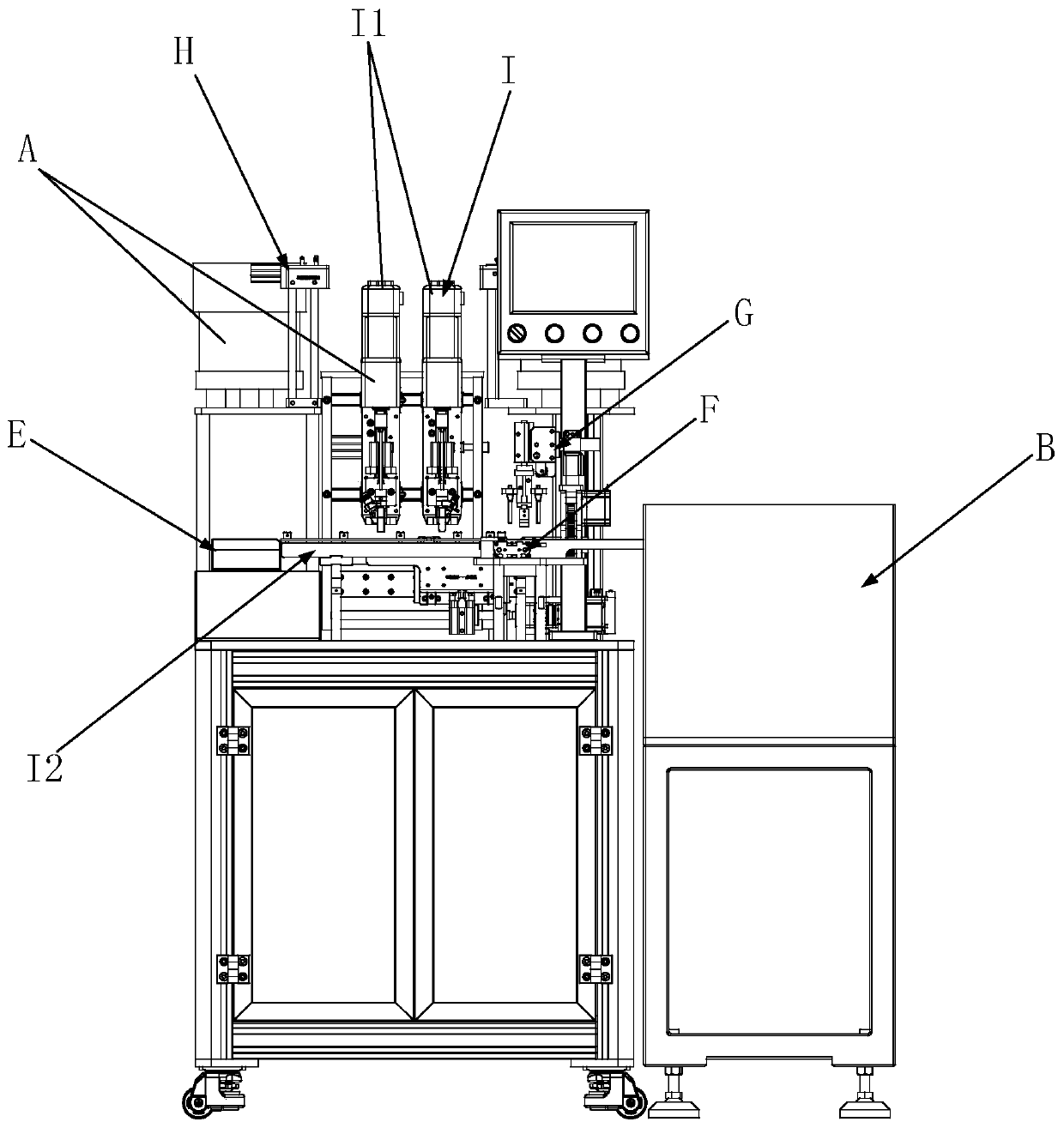

Automatic screw assembling equipment for copper bar production

PendingCN110405460AGuaranteed Position AlignmentAvoid the problem of damaging the copper bar itselfMetal working apparatusEngineeringCopper

The invention relates to automatic screw assembling equipment for copper bar production. The automatic screw assembling equipment for copper bar production comprises a plurality of screw assembling devices, a copper bar conveying disc, a copper bar feeding device cooperating with the copper bar conveying disc and a copper bar discharging device; the copper bar feeding device comprises a copper barposition adjusting device and a feeding grabbing device; and each screw assembling device comprises an automatic screw feeding device and a screw installing mechanism, copper bars not assembled withscrews enter the copper bar position adjusting device through the copper bar conveying disc to be aligned and then are fed to the screw installing mechanisms through the feeding grabbing device for screw assembling, and lastly discharging is achieved through the copper bar discharging device. The automatic screw assembling equipment for copper bar production has the beneficial effects that automatic screw assembling in copper bar production can be achieved, and the production efficiency is greatly improved; and in addition, position correction of the copper bars can be effectively guaranteed in the production process, and the problem that the copper bars are damaged in the screw installing process is avoided.

Owner:YUEQING HENGTONG ELECTRIC

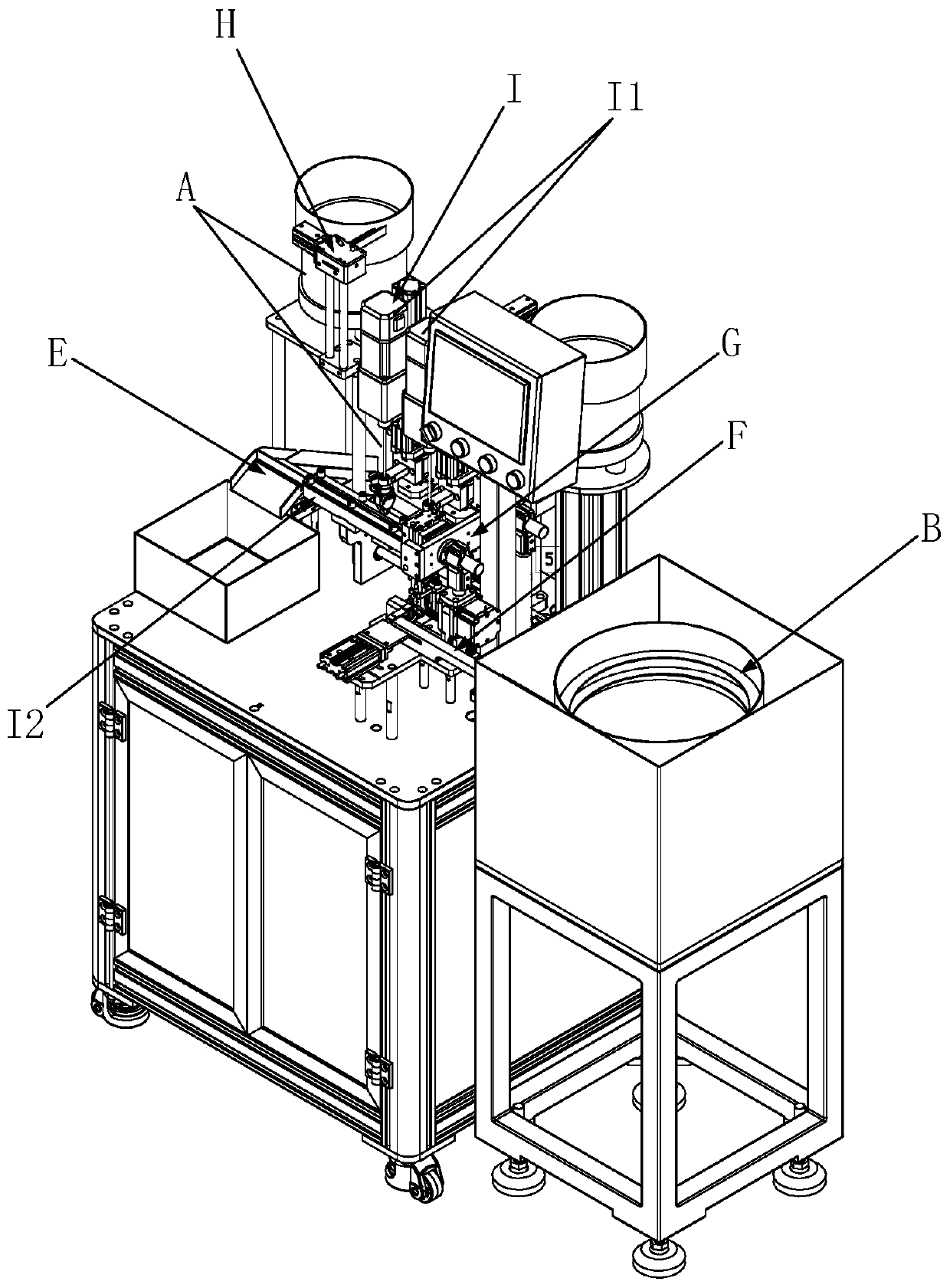

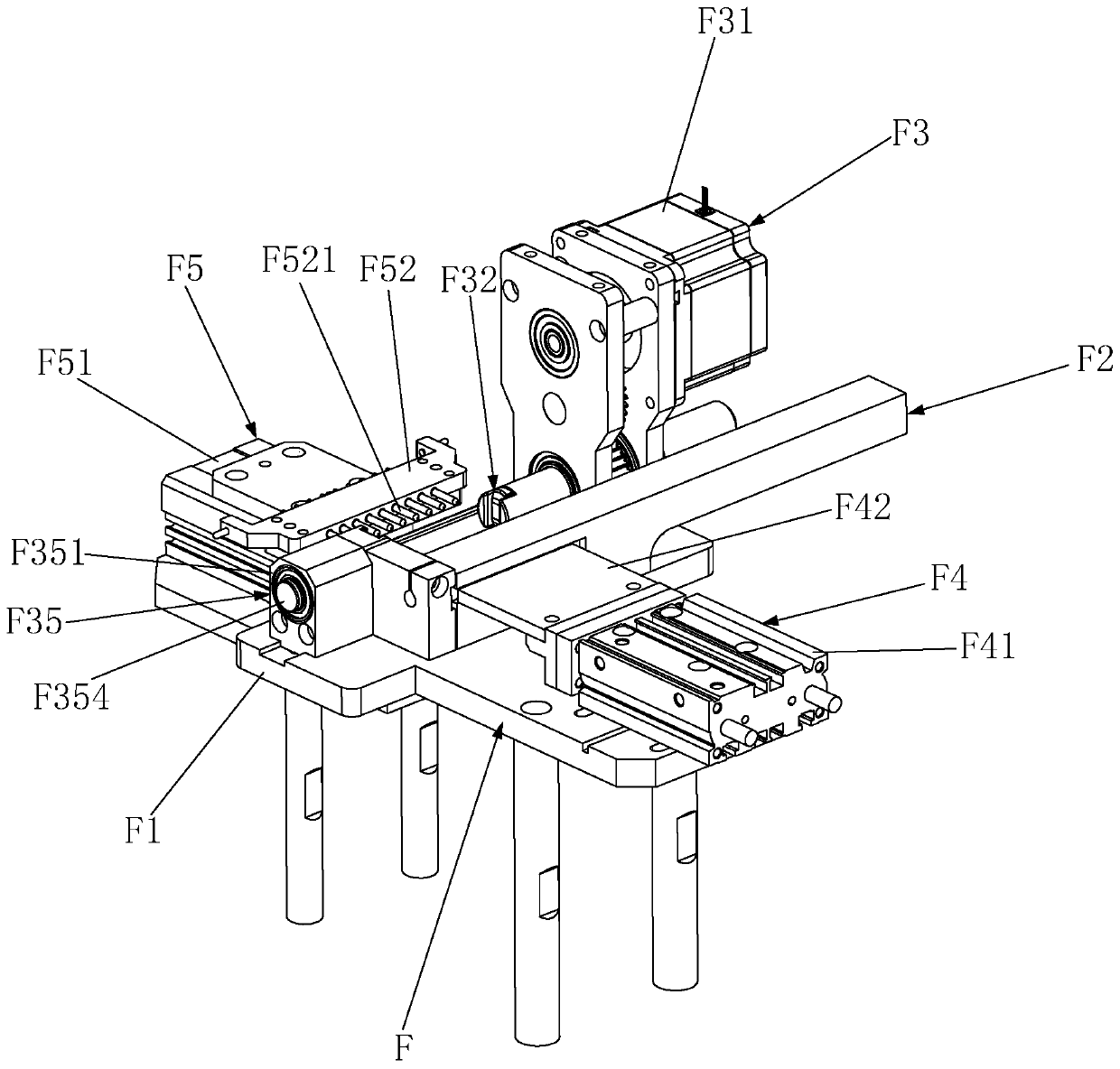

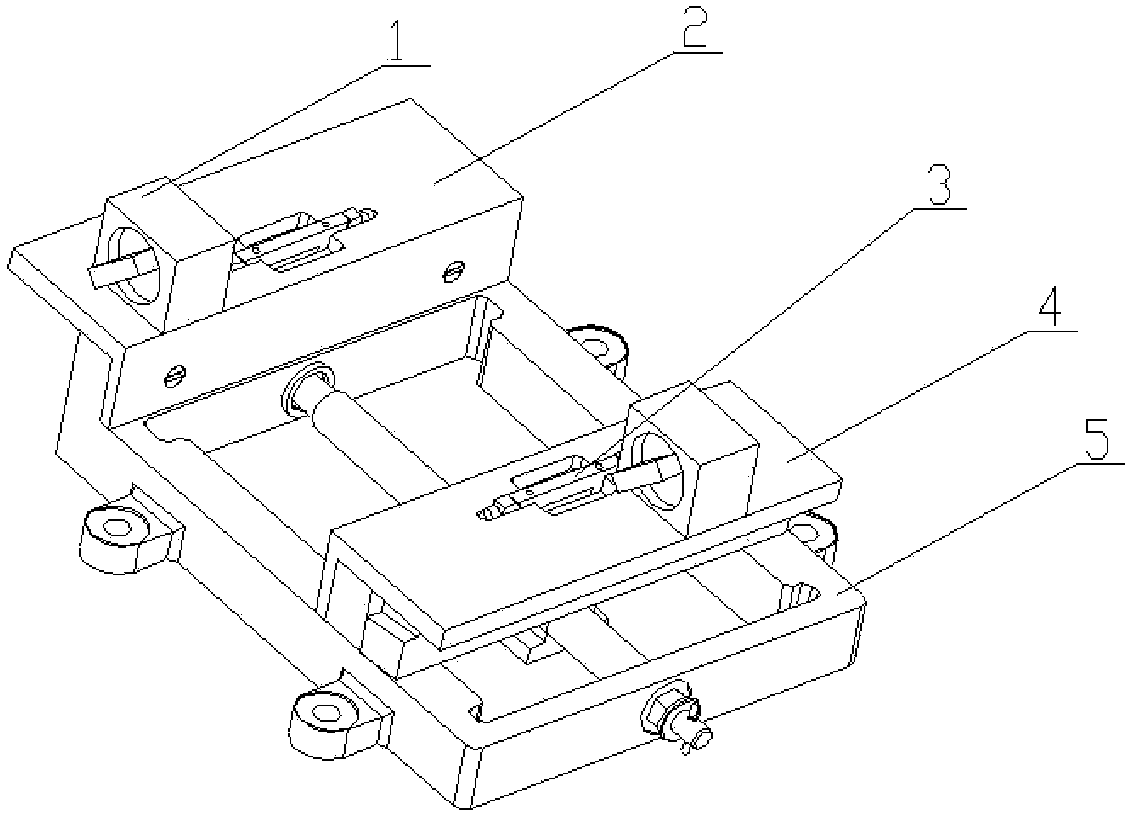

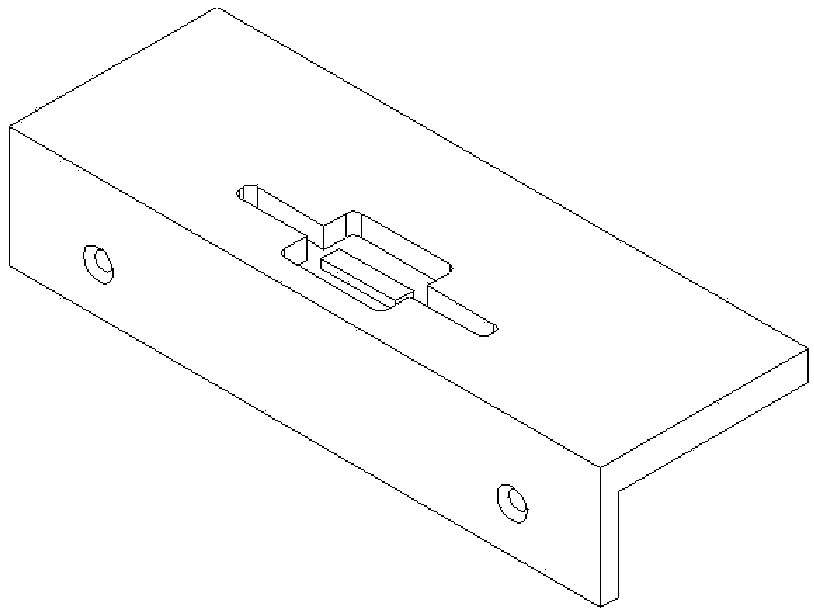

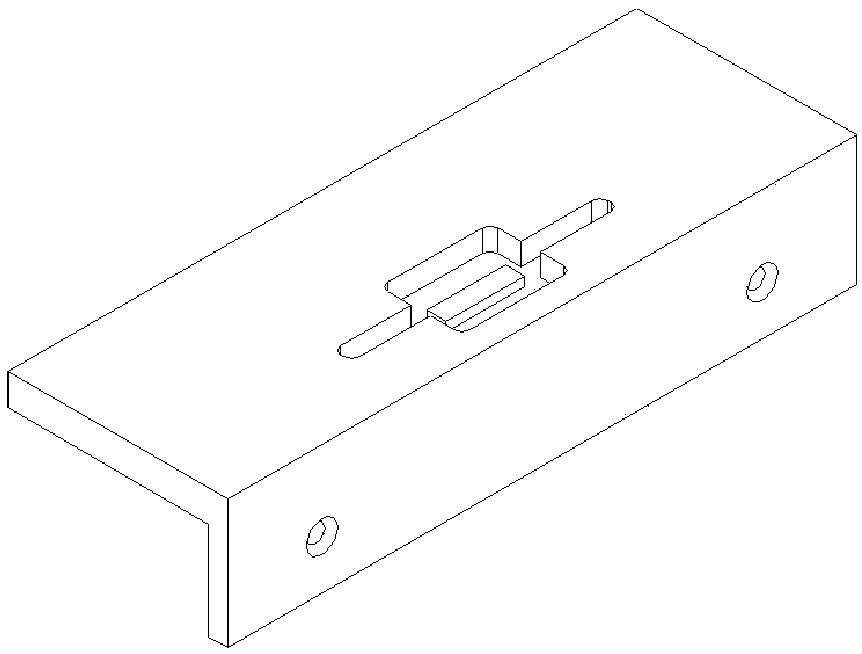

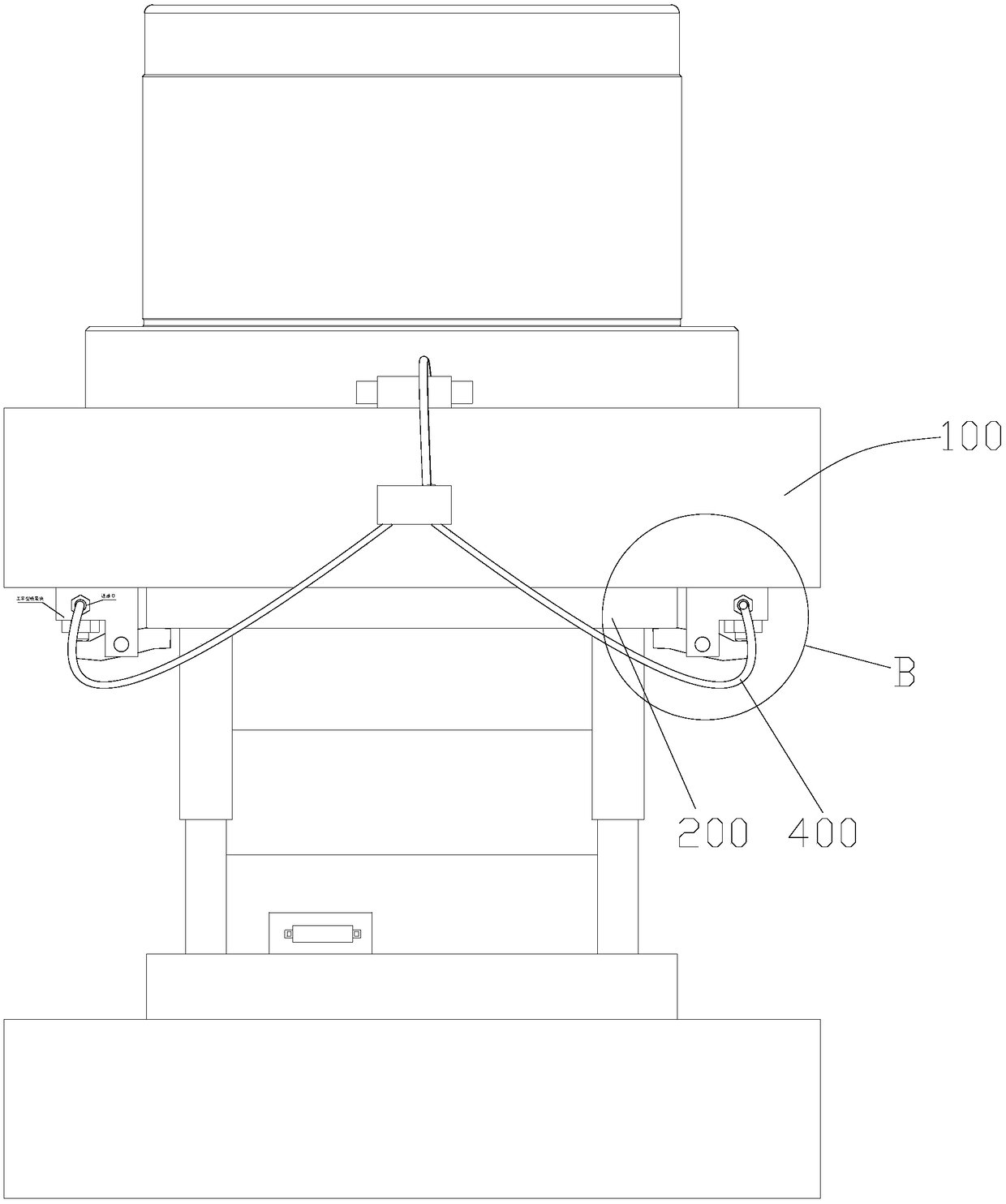

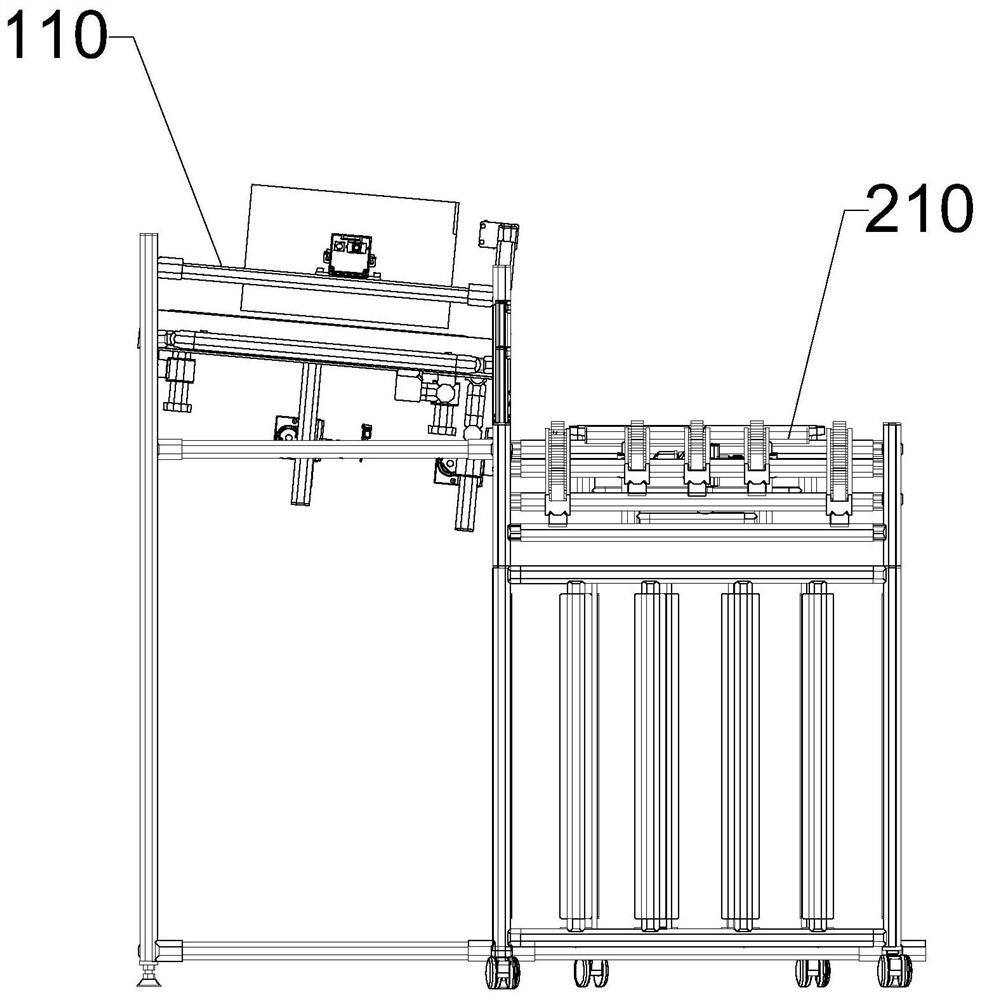

Assembly device for circuit board and lock body

ActiveCN107700958AImprove installation efficiencySave production time and costNon-mechanical controlsElectrical and Electronics engineering

The invention relates to an assembly device for a circuit board and a lock body and relates to the technical field of circuit board assembly. The assembly device comprises a left side lock body installation support, a right side lock body installation support, a flat-mouth clamp and switch type magnetic seats. Different circuit boards can be installed by means of the coordination of opening-closing sizes of the flat-mouth clamp and the switch type magnetic seats, lock body components are fixed to corresponding grooves on the left side lock body installation support and the right side lock bodyinstallation support, then the fact that a fast card can be used to be the same as the loading card is realized. By means of the assembly device for the circuit board and the lock body, the problemsthat the manual one-by-one locating is needed in the installation of the lock body to the circuit board and the installation efficiency is low are well solved, the installation efficiency is improved,the production efficiency is drastically improved, and the production time and cost are saved.

Owner:BEIJING NORTH VEHICLE INTELLIGENT EQUIP TECH CO LTD

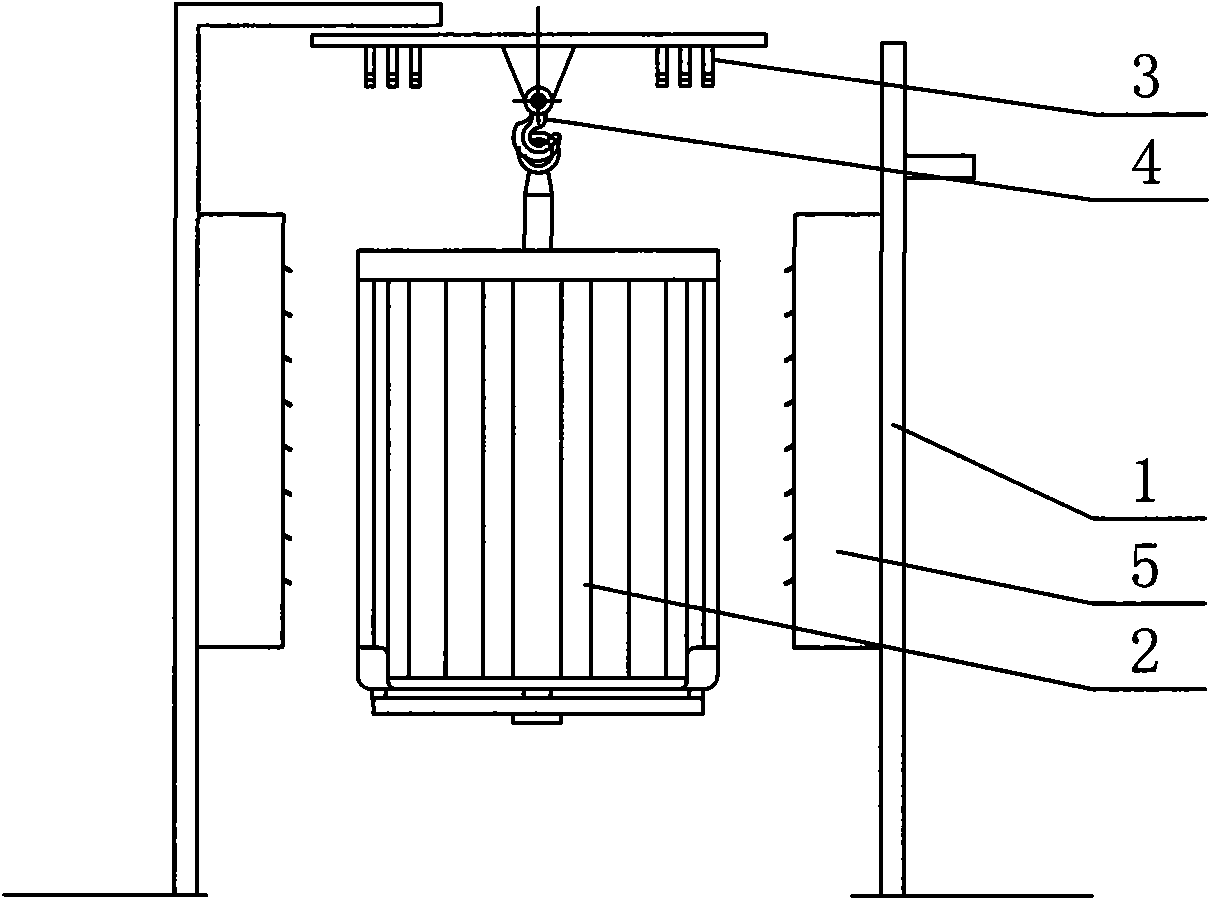

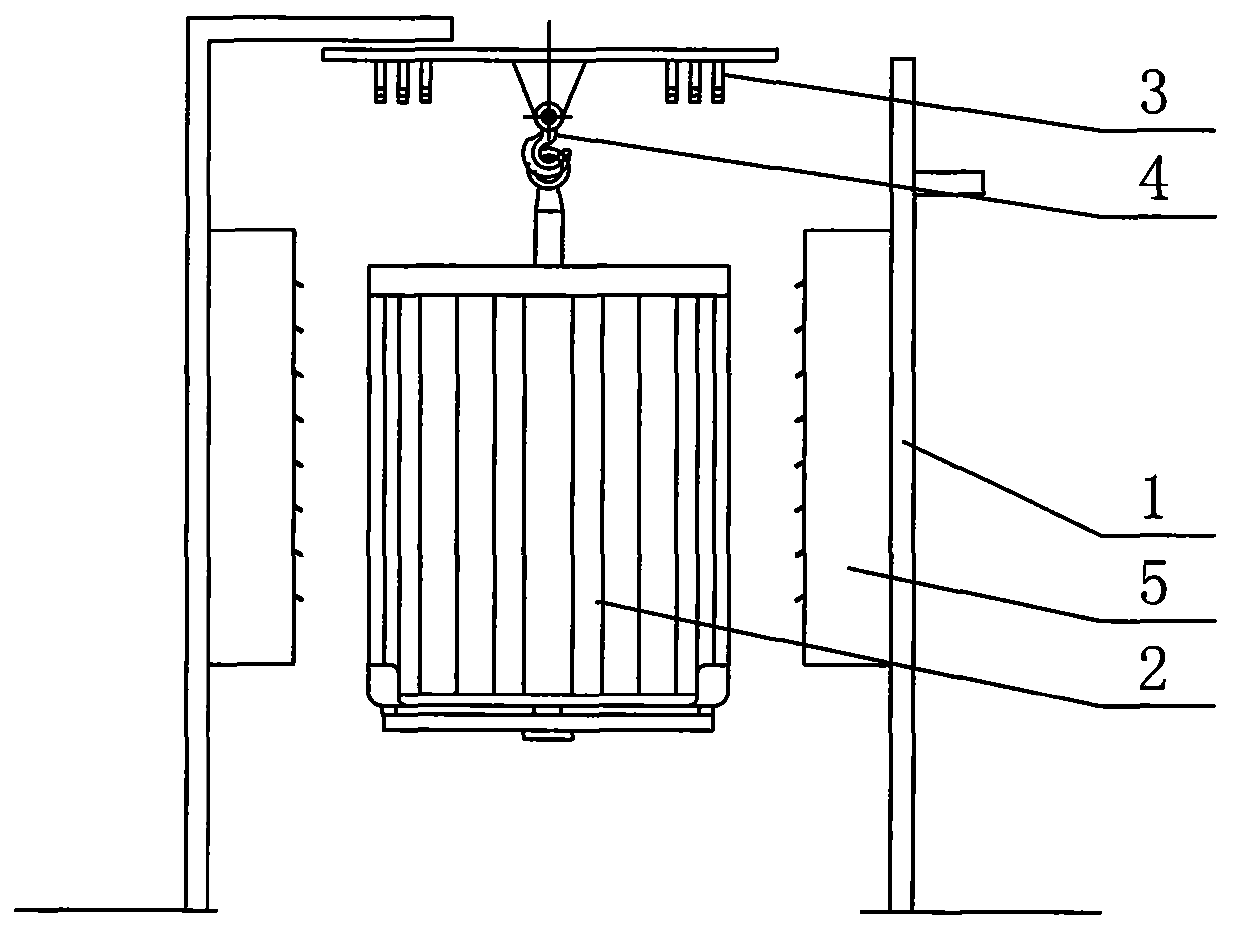

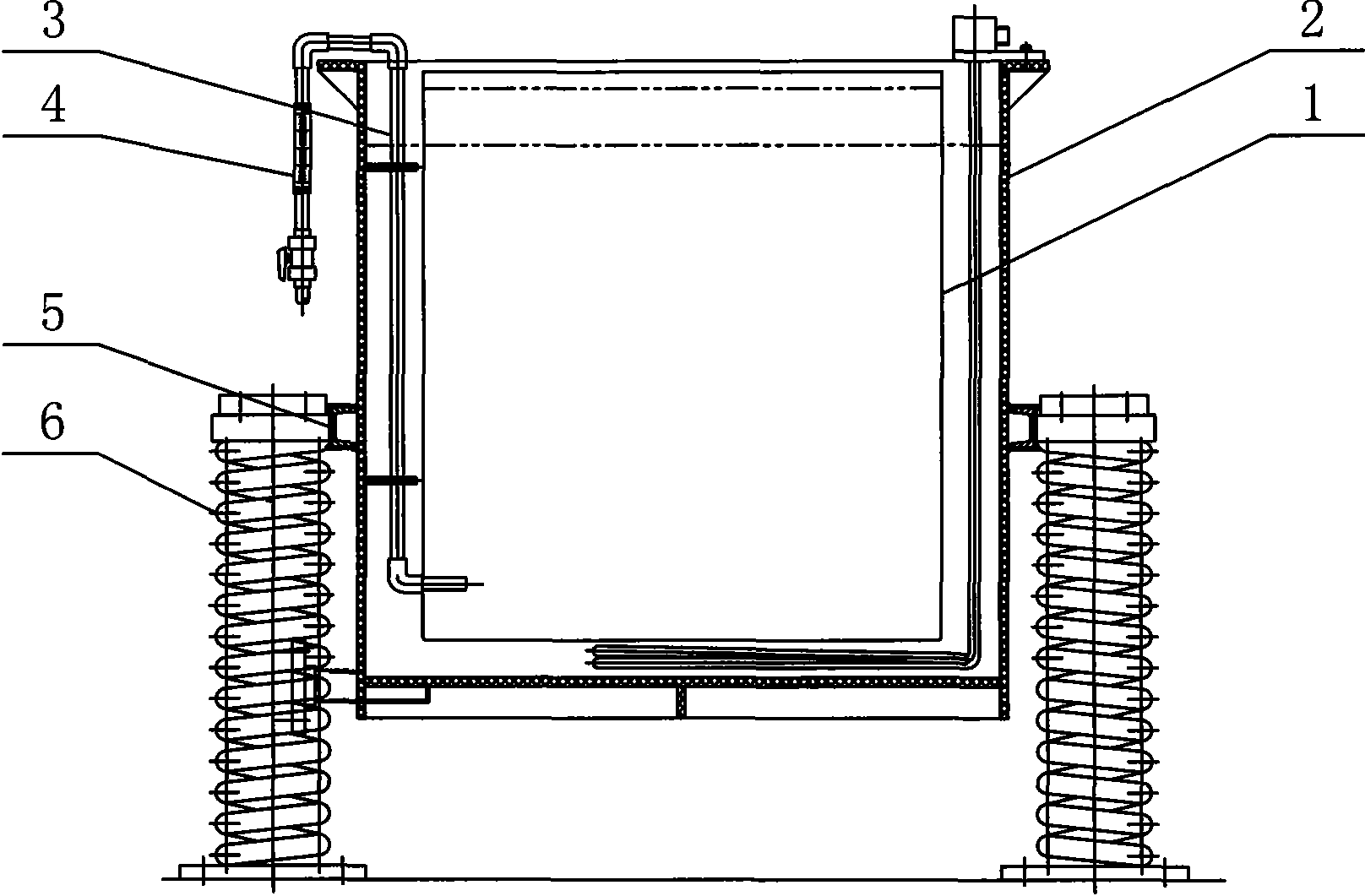

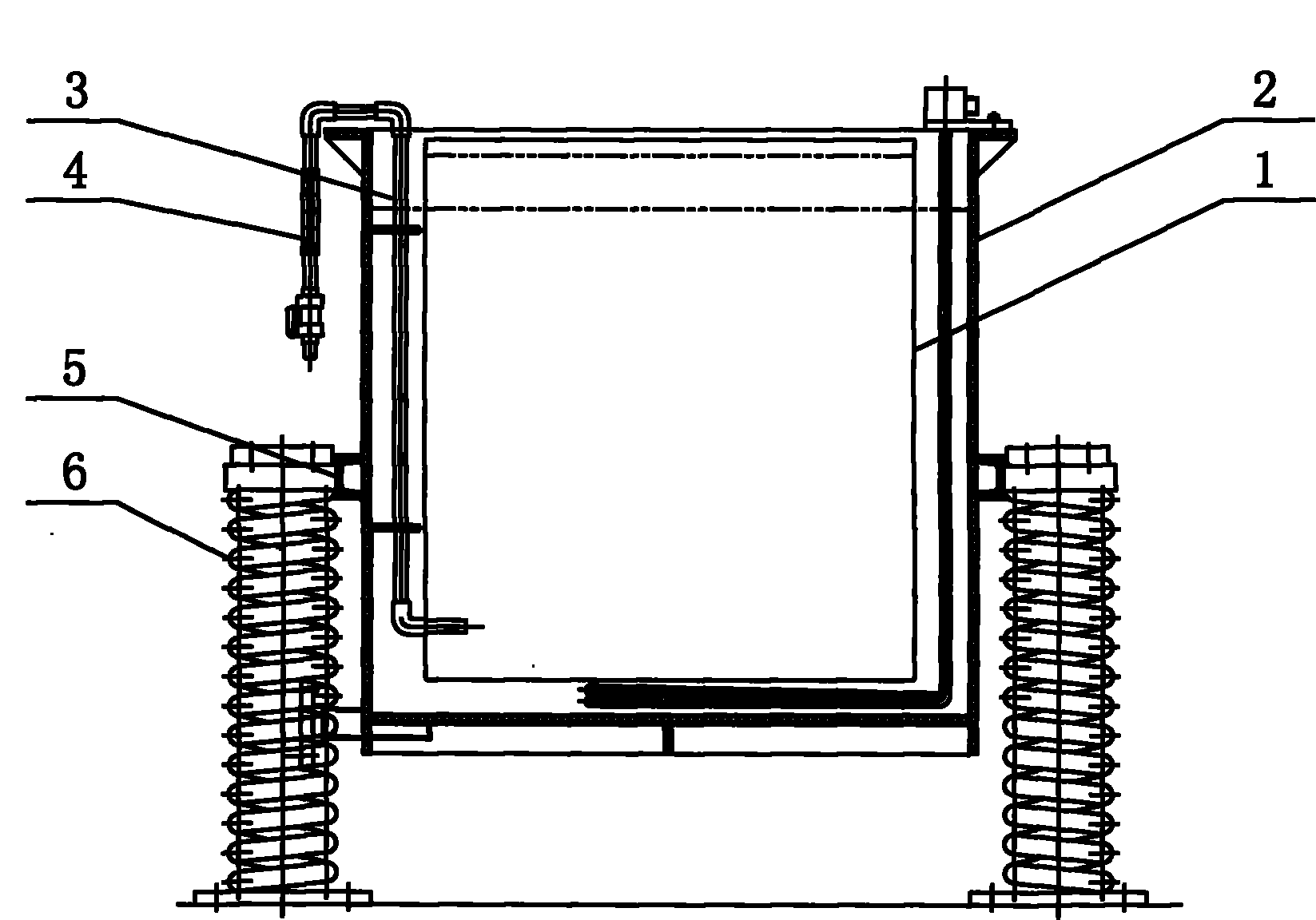

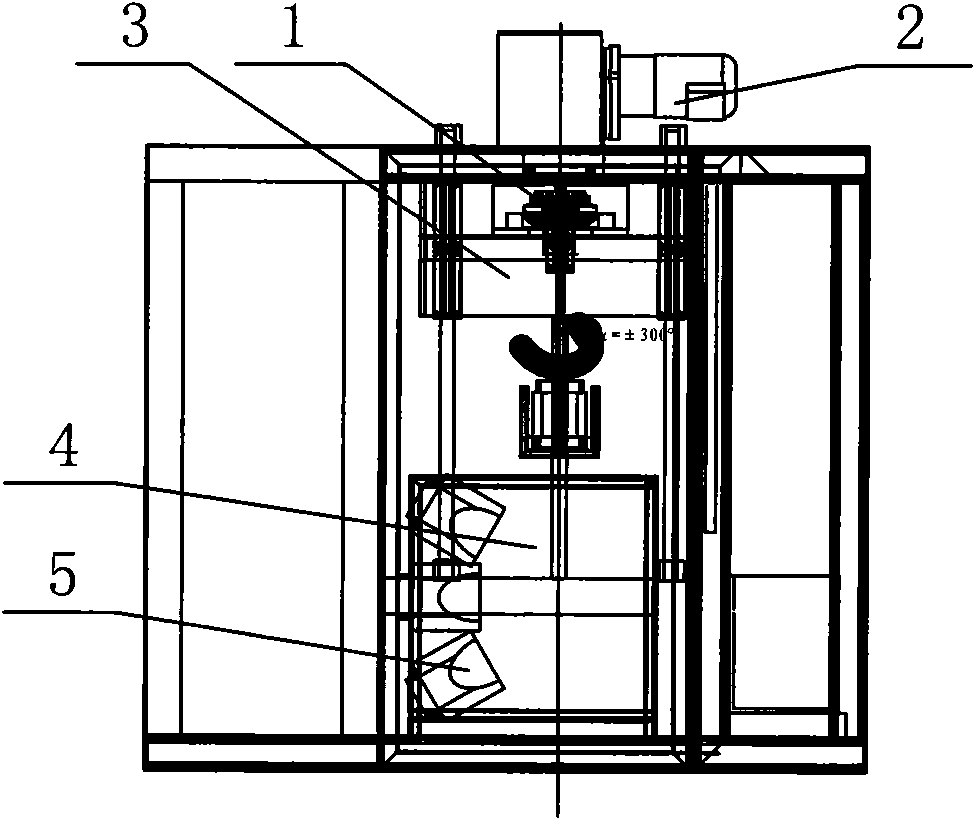

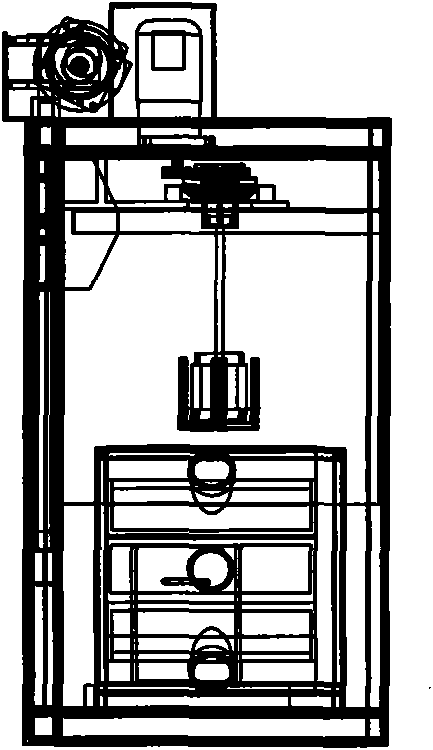

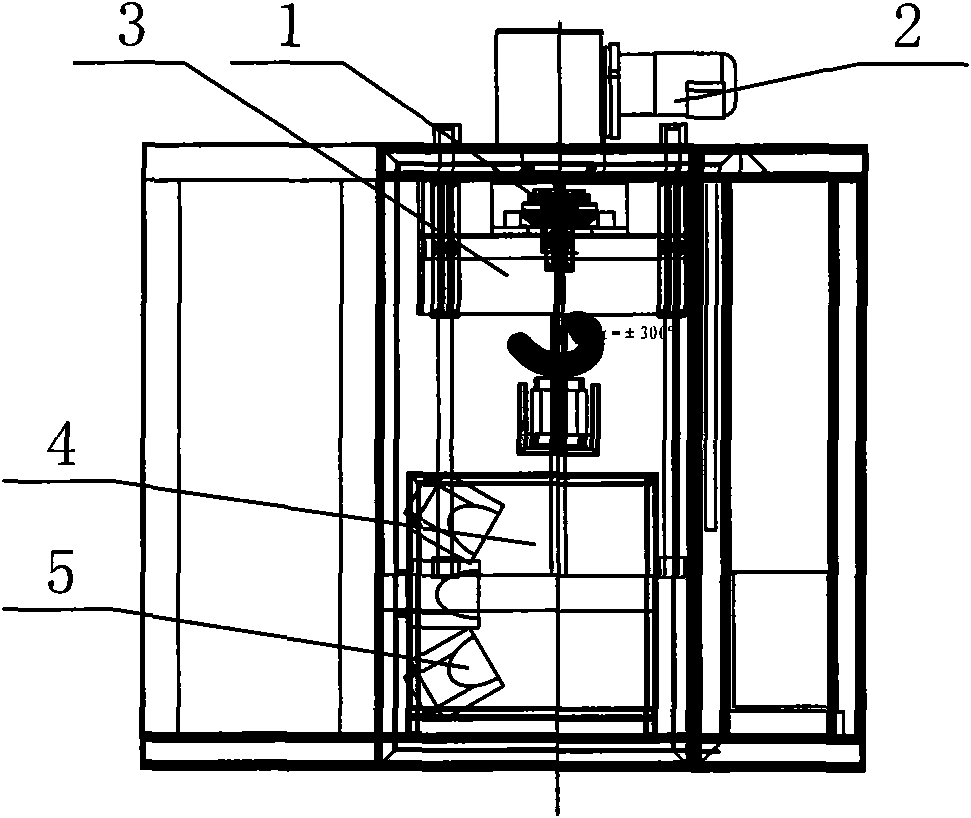

Automatic hoisting furnace of motor stator winding lacquer dipping system

InactiveCN101902106ASave production time and costImprove work efficiencyManufacturing dynamo-electric machinesWork in processLacquer

The invention discloses an automatic hoisting furnace of a motor stator winding lacquer dipping system, comprising a lacquer dipping groove and a hoisting furnace, wherein the lacquer dipping groove is positioned in the hoisting furnace and is provided with an n-shaped lacquer feeding pipe; the lacquer feeding pipe is erected on the casing wall of the hoisting furnace; the inner side of the lacquer feeding pipe is connected into the lacquer dipping groove; a liquid level pipe is arranged on an outside pipeline of the lacquer feeding pipe; a supporting block is fixed on the outer side wall of the hoisting furnace; and the lower part of the supporting block is connected with a hoisting spring. The automatic hoisting furnace of the motor stator winding lacquer dipping system can be used for automatically hoisting the lacquer dipping groove when reaching the lacquer dipping workstation and keeping the liquid level height of the groove. The motor stator winding lacquer dipping system can solve the problems that that current single product occupies larger production space for storing and stacking unfinished products due to being idle between two process links, ensure that a plurality of process links for dipping lacquer are sequentially circulated on one set of equipment, avoid the phenomenon that the unfinished products occupy the space, save the production time and cost, improve the work efficiency and require fewer workers so as to reduce the labor cost.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

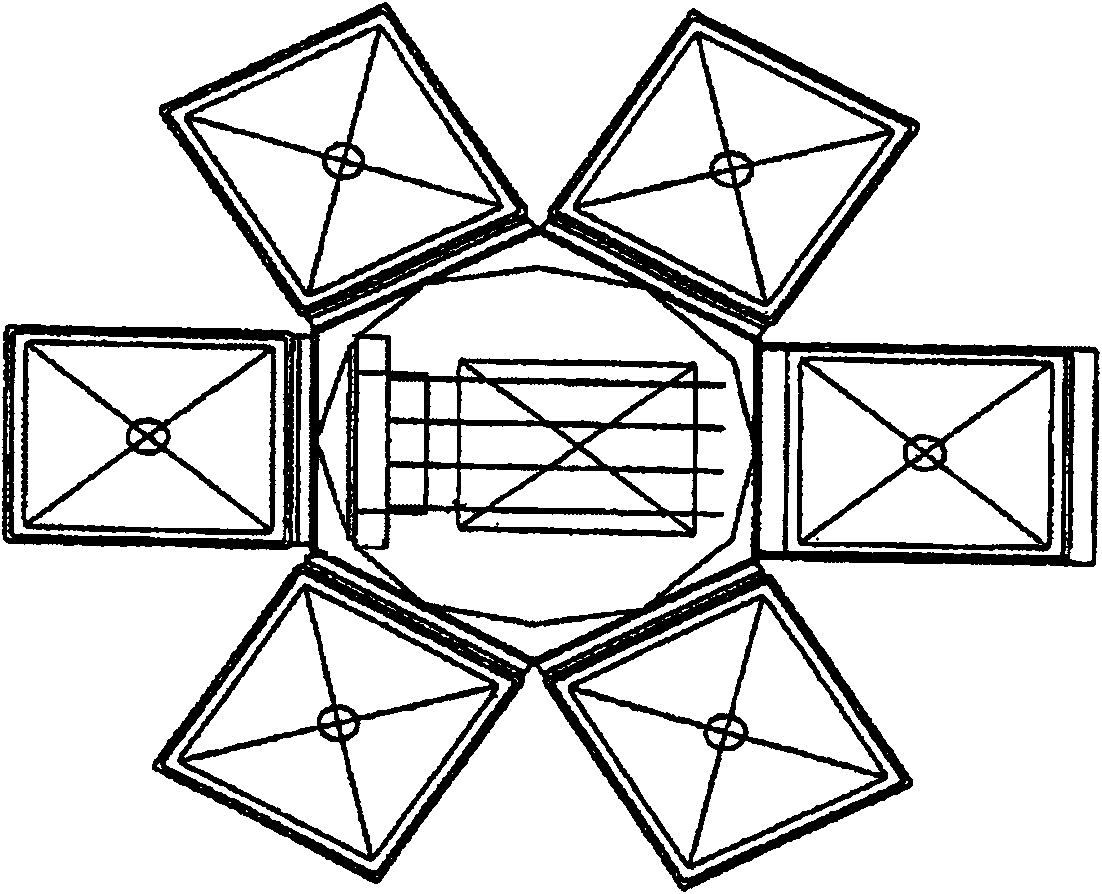

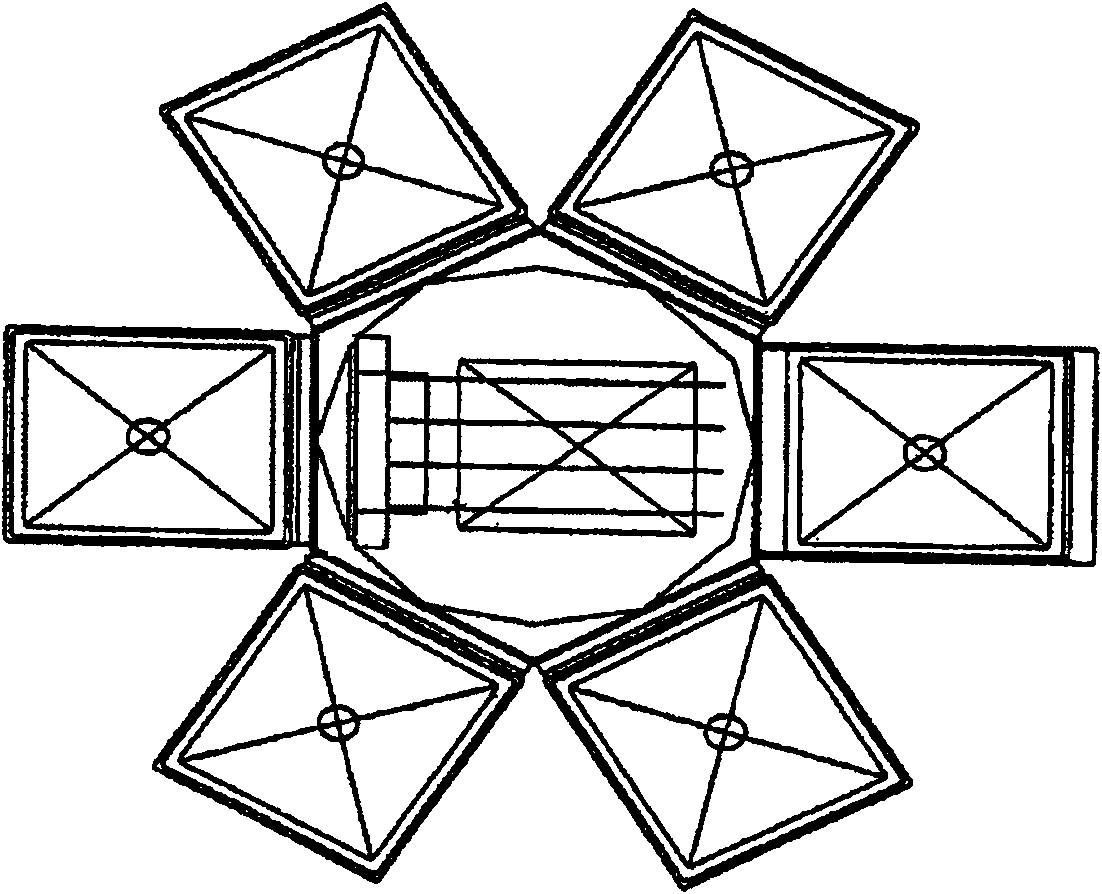

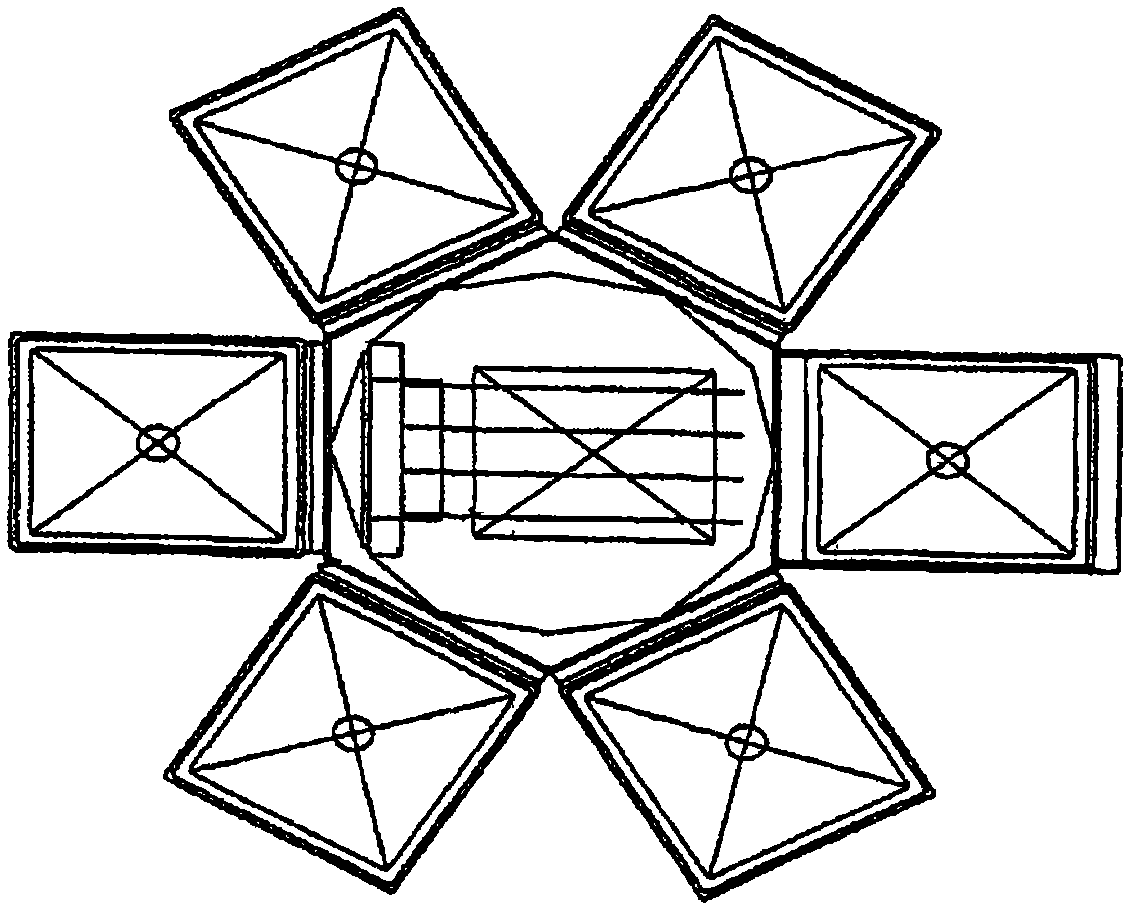

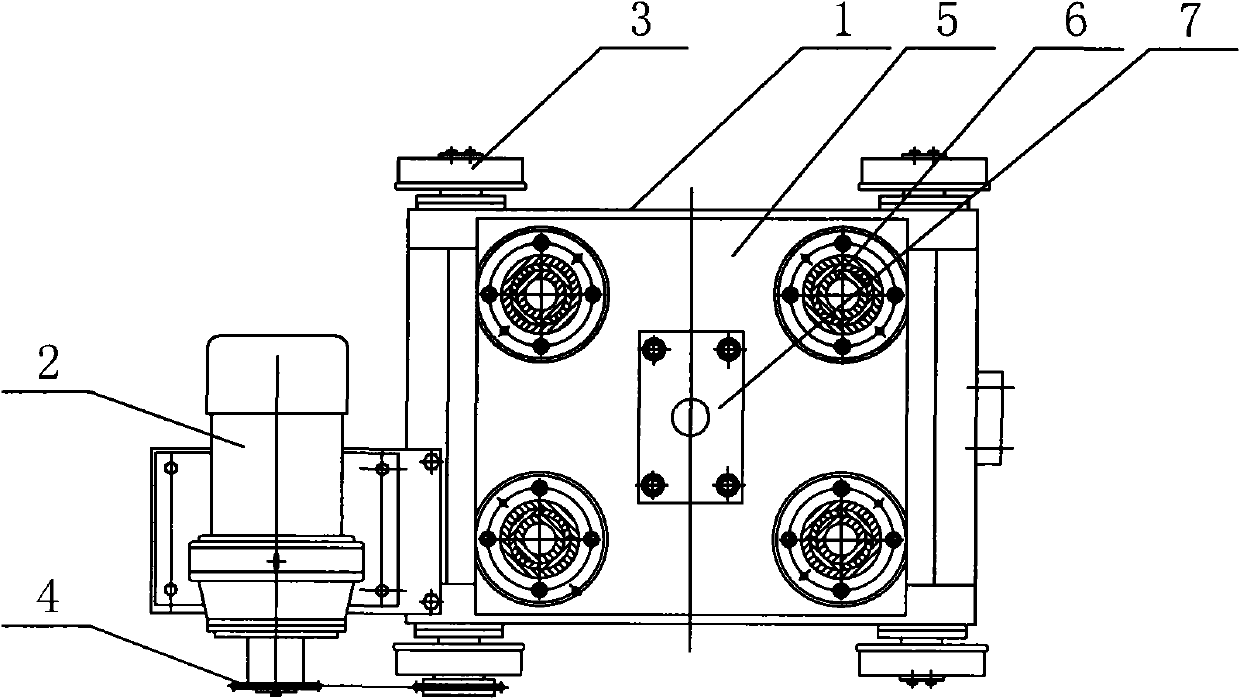

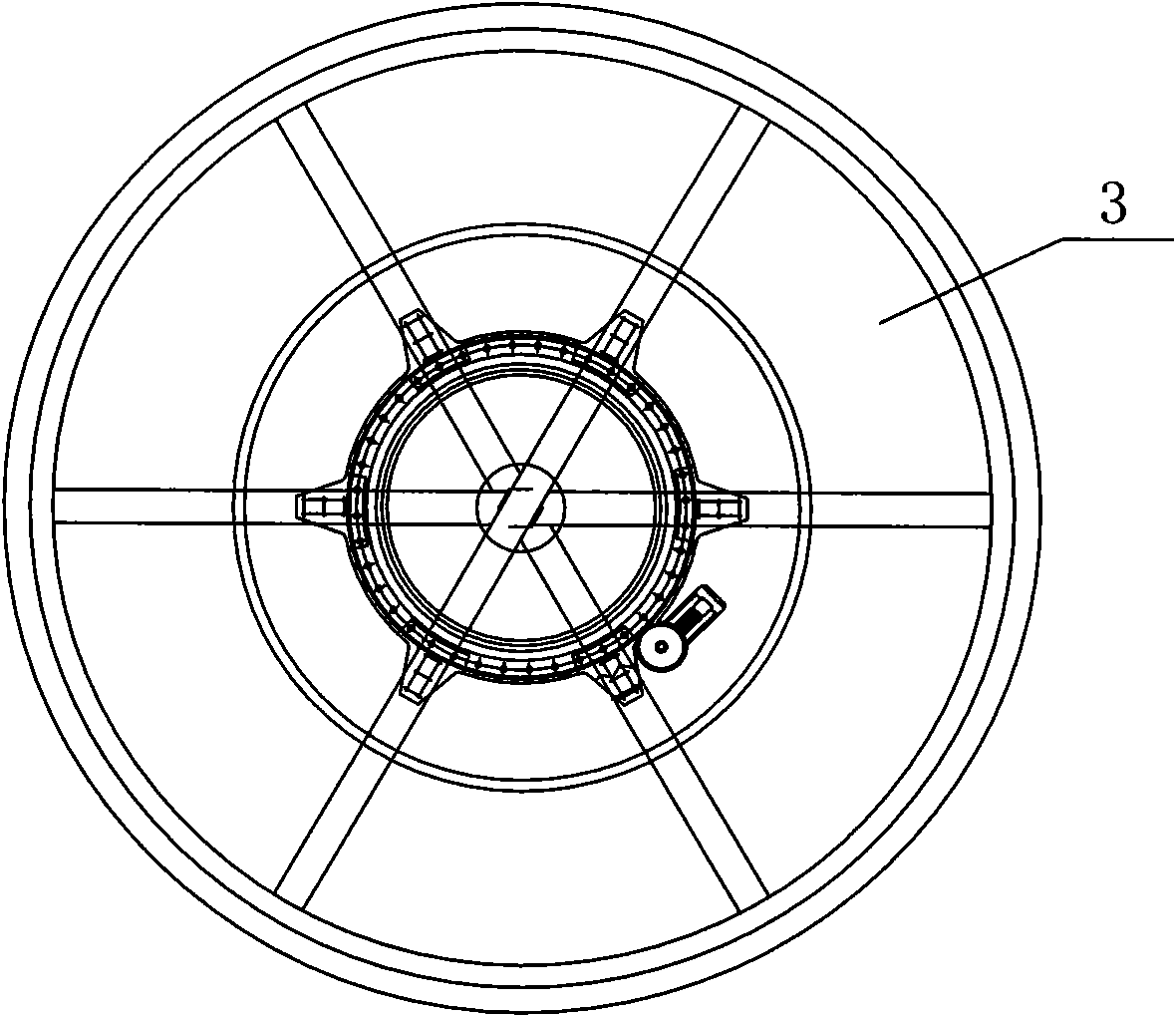

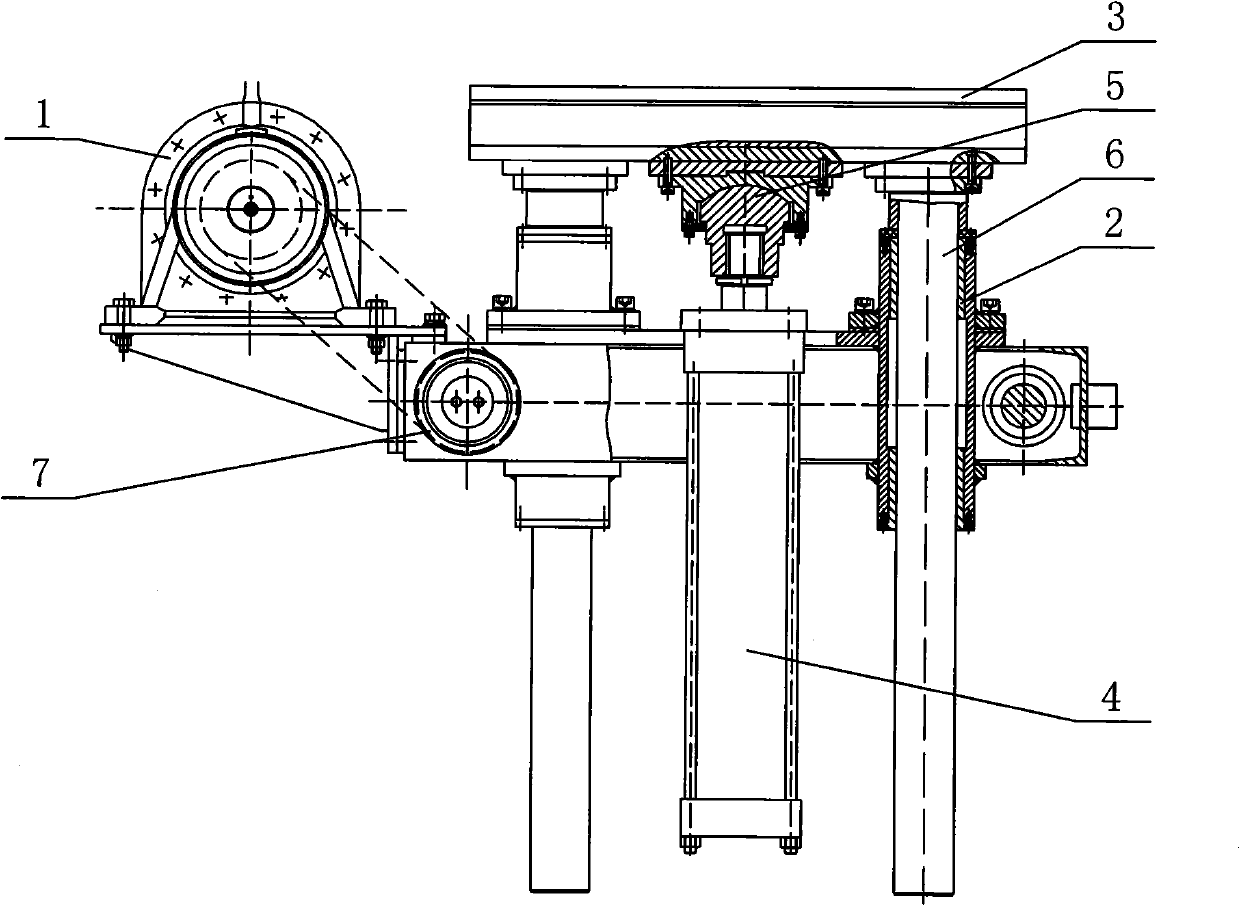

Rotation supporting structure of electric machine stator winding paint-dipping system

InactiveCN101908803AReduce usageSave production time and costManufacturing dynamo-electric machinesElectric machineEngineering

The invention relates to a rotation supporting structure of an electric machine stator winding paint-dipping system, comprising a central bottom frame arranged in the centre and used for supporting, wherein the central bottom frame supports a rotation platform through rotation support, and the rotation platform is circular; and a plurality of work stations are uniformly arranged on the rotation platform. The rotation supporting structure of the electric machine stator winding paint-dipping system is designed into the supporting structure with central rotation, so that various technologies are sequentially carried out according to the circular rotation structure. The electric machine stator winding paint-dipping system can solve the problem of large production space occupation of the storage and the piling of unfinished products due to the space between two technology links. A plurality of technology links for paint dipping can be circulated sequentially on the same equipment. The phenomenon of space occupation of unfinished products does not exist. The invention saves production time and cost, and increases the work efficiency. Fewer workers can be employed, and the labour cost is reduced as well.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

Motor drying station of motor stator winding paint dipping system

InactiveCN101908806AReduce usageSave production time and costManufacturing dynamo-electric machinesUltravioletEngineering

The invention relates to a motor drying station of a motor stator winding paint dipping system, comprising a rotating mechanism, wherein the rotating mechanism is driven by a motor, and the lower part of the rotating mechanism is connected with a lifting mechanism; the rotating mechanism runs to drive the lifting mechanism to move up and down; a UV (Ultraviolet) lamp box is arranged corresponding to the lower part of the lifting part; and a plurality of UV lamps are arranged in the UV lamp box. The invention relates to the motor drying station of the motor stator winding paint dipping system, and the rotating mechanism and the lifting mechanism are driven by the motor to run so as to convey a motor stator winding into the UV lamp box for drying.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

Mode locking system for fine-blanking machine

The invention relates to a mode locking system for a fine-blanking machine. The mode locking system comprises a mode locking device, wherein the mode locking device comprises a locking block, a lock tongue, a rotating shaft, an embedded oil cylinder and a hydraulic hose coupler; the locking block comprises a body, a slider and supporting plates; the slider is arranged at the upper part of the body; a chute is formed in a worktable on the fine-blanking machine; the slider can slide in the chute; the supporting plates are arranged at the lower part of the body; the lock tongue is rotationally connected between the two supporting plates; the inner end of the lock tongue is located below the body, and the outer end of the lock tongue extends to be below a fine-blanking die; the embedded oil cylinder comprises a piston rod, an elastic piece and an oil cylinder flange; the oil cylinder flange is fixedly mounted on the lower surface of the body; the lower end of the piston rod is in contact with the upper surface of the inner end of the lock tongue; the elastic piece sleeves the piston rod; the hydraulic hose coupler is mounted on a side surface of the body; and a hydraulic hose is inserted into the hydraulic hose coupler and communicated with the embedded oil cylinder. The mode locking system can realize quick locking of the die, is simple to operate, does not need accurate alignment, can be suitable for fine-blanking dies with different sizes and thicknesses, and has a wide application range.

Owner:武汉华夏精冲技术有限公司

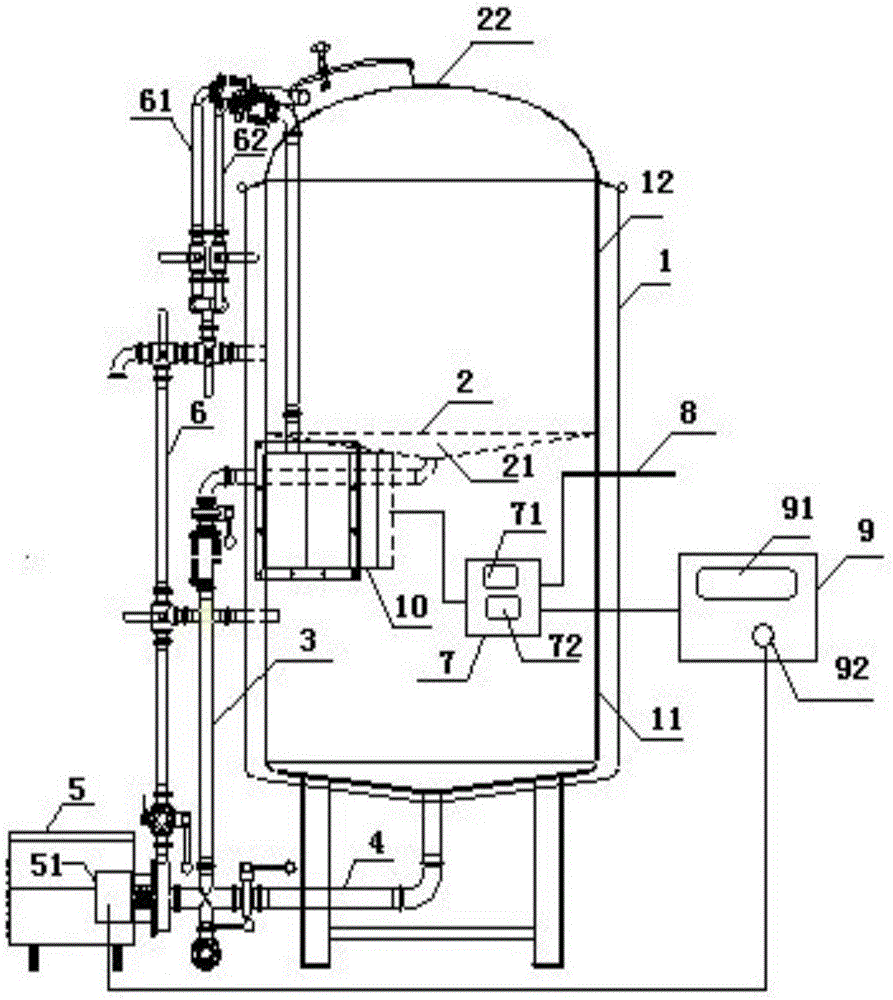

Intelligent beer saccharifying tank and production method thereof

The invention discloses an intelligent beer saccharifying tank and a production method thereof. The intelligent beer saccharifying tank comprises a tank body, wherein the tank body consists of a saccharifying cavity and a filtering cavity; a filtering plate is arranged at the bottom of the filtering cavity and connected with one end of a wort-out pipeline through a bottom groove, and the other end of the wort-out pipeline is connected with a water-in pipeline; one end of the water-in pipeline is connected with a water pump, and the other end is connected with the saccharifying cavity; the water pump is connected with a wort filtering main pipeline through a frequency converter inside the water pump; one line of the exit end of the wort filtering main pipeline is connected with the filtering cavity through a turbid wort backflow pipe, and the other line is connected with the saccharifying cavity through a clean wort backflow pipe; a temperature acquisition control module is arranged in the saccharifying cavity; an input end of the temperature acquisition control module is connected with a temperature sensor, one line of an output end is connected with a control panel with a temperature display, and the other line of the output end is connected with a heating pipe; and the control panel is connected with the frequency converter through an adjusting button. The equipment can realize real-time control on temperature and time in a beer saccharifying process and effectively control the beer filtering time, thereby improving the beer quality and saving labor.

Owner:贾欣

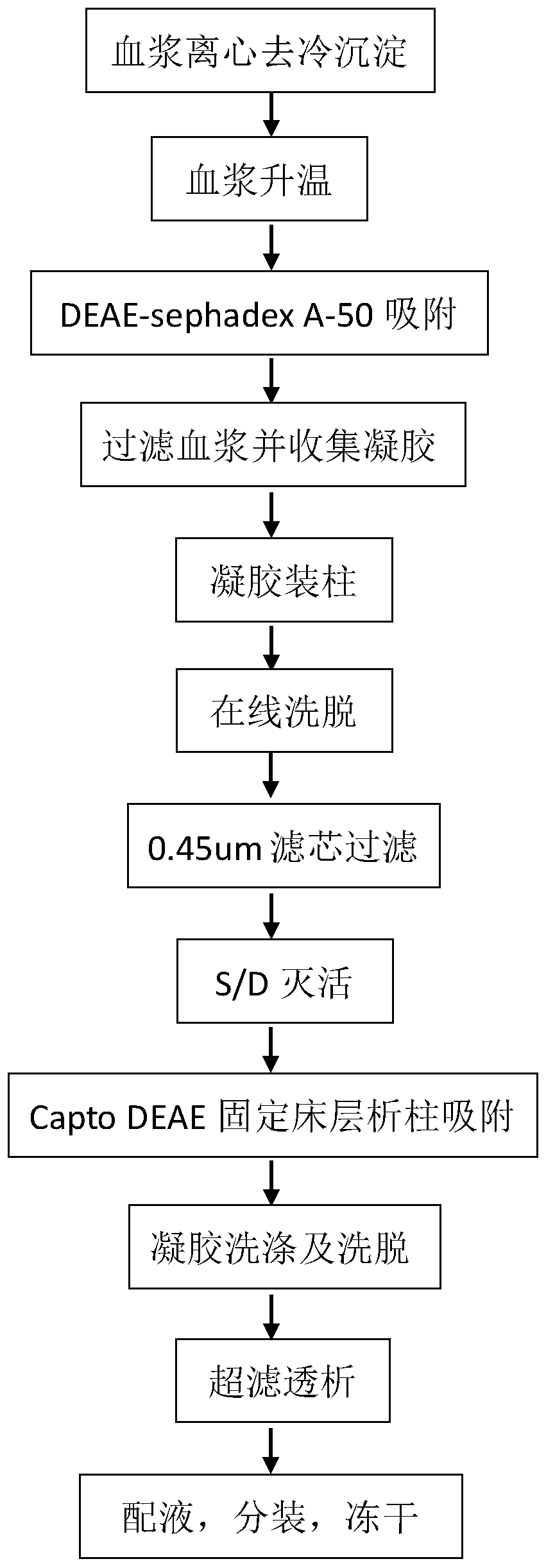

A method for preparing human prothrombin complex from plasma

The invention discloses a method for preparing a human prothrombin complex from plasma. The method comprises: directly adsorbing the human prothrombin complex from the plasma by using DEAE A-50 gel, filling the adsorbed A-50 gel into a chromatographic column of a fixed bed, pumping eluant into the filled chromatographic column by using a peristaltic pump for online washing and elution, performing S / D inactivation on the eluant, and performing secondary chromatographic purification by using the chromatographic column of the fixed bed to obtain a high-purity human prothrombin complex product. According to the method, elution flow and speed can be accurately controlled by online elution after filling the gel into the column, the problems of contamination, cross contamination, gel leakage and the like caused by an open operation are reduced, an obtained product is high in purity, an IX factor titer can exceed 27IU / ml, and the IX factor specific activity exceeds 0.8IU / mg protein. Meanwhile, a self-flushing type filter with a pressure difference controller and an automatic solid matter stripping system is adopted, so the pressure difference in the whole filtering process is stable and controllable, gel particles can be well protected, broken colloidal particles flowing into a plasma tank in the filtering process are remarkably reduced, and gel losses in a production process can be reduced by above 20%.

Owner:广东双林生物制药有限公司

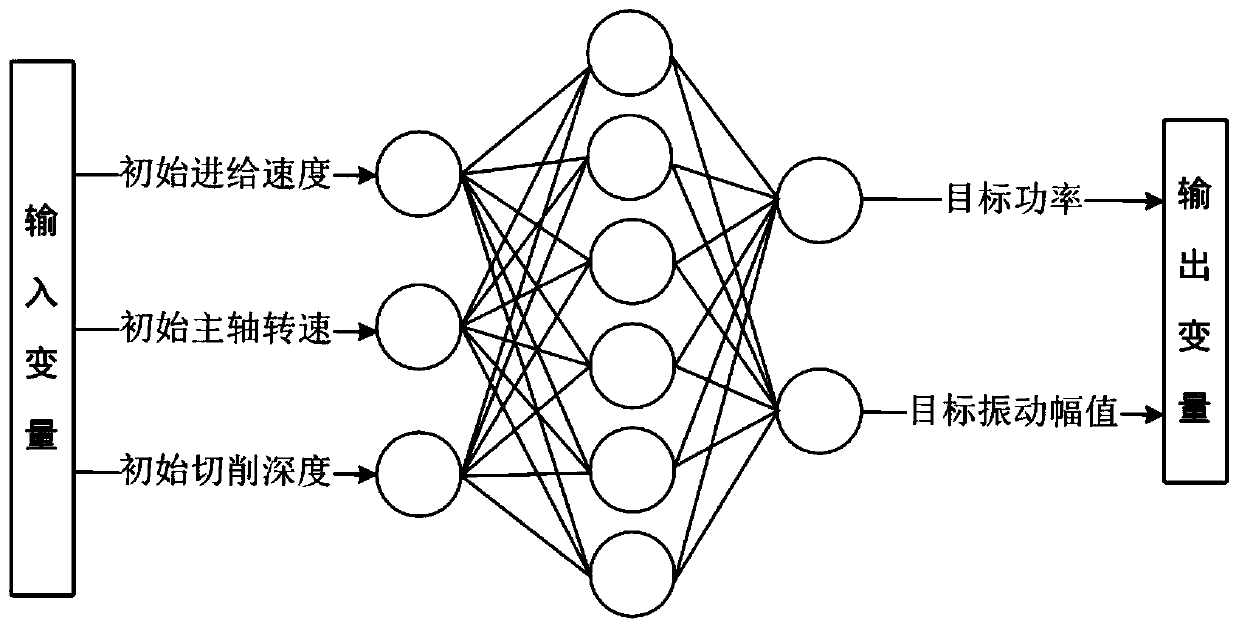

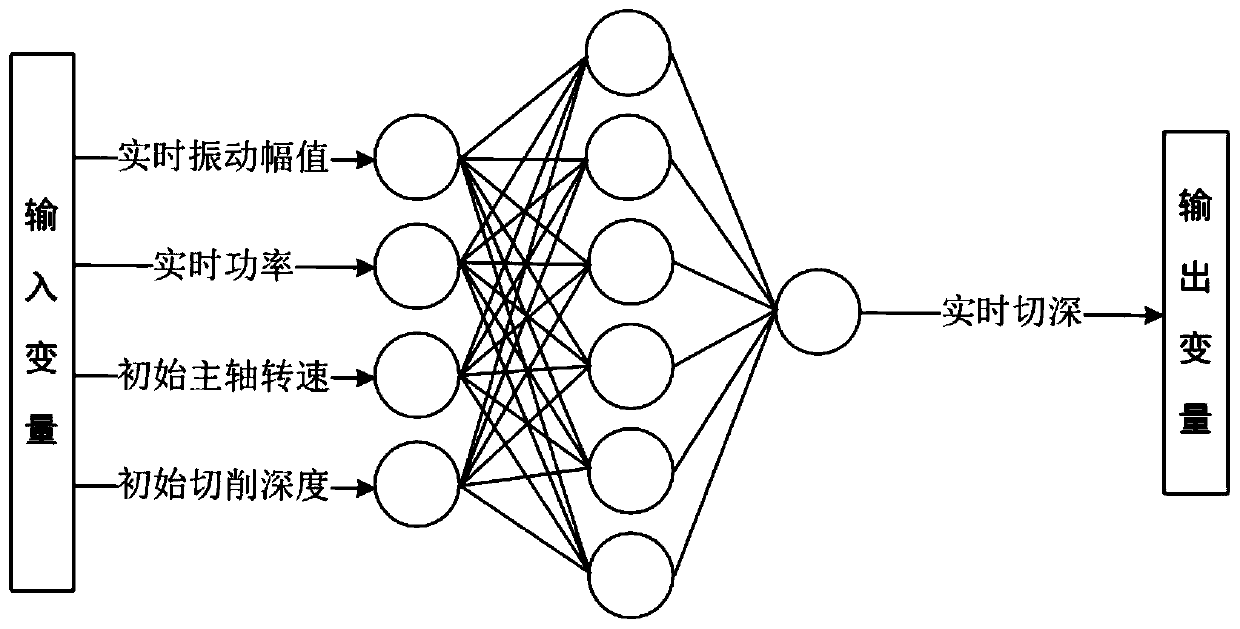

A Machine Tool Adaptive Control Method Based on ga-bp Neural Network Algorithm

ActiveCN110488754BImprove processing qualityEasy to processProgramme controlComputer controlNumerical controlAlgorithm

The invention discloses a machine tool self-adaptive control method based on a GA-BP neural network algorithm, and belongs to the technical field of numerical control machining. The method comprises the steps that a spindle motor power signal and a spindle vibration signal in the workpiece numerical control machining process are monitored in real time, and the feeding speed and the spindle rotating speed are optimized in real time and adjusted adaptively based on the spindle power signal and the spindle vibration signal; and the whole signal acquisition process does not influence normal processing. The machine tool self-adaptive control method based on the neural network algorithm can be used to effectively improve the machining efficiency and the machining quality, prolong the service life of a cutter and a machine tool and reduce the cost.

Owner:DALIAN UNIV OF TECH

Ultra-high molecular weight polyethylene fiber varicose veins sock and production equipment thereof

InactiveCN112472420AEmission reductionLow costTextile treatment machine arrangementsFeet bandagesYarnKapok fiber

The invention relates to an ultra-high molecular weight polyethylene fiber varicosity sock and production equipment thereof. The sock comprises a sock body, which is composed of, by weight, 45-55% ofan outer-layer fabric and 45-55% of an inner-layer fabric, wherein the outer-layer fabric is woven from yarn, the yarn is prepared from, by weight, 45 parts of kapok fiber, 45 parts of cotton fiber, 2parts of a softener, 4 parts of a dispersant and 90 parts of water, the inner-layer fabric is woven by 75-80% by weight of inner-layer yarns and 25-30% by weight of nano-silver plated fibers, the inner-layer yarn is prepared from the following raw materials in parts by weight: 15 parts of spandex, 25 parts of kapok fiber, 25 parts of cotton fiber, 15 parts of zinc oxide / gelatin / polyvinyl alcoholcomposite antibacterial fiber, 2 parts of a softener, 4 parts of a dispersing agent, 0.15 part of an antibacterial agent and 90 parts of water, and at least two parallel soft magnetic strips are arranged on the outer side of the sock body. According to the invention, the ultra-high molecular weight polyethylene fiber varicose veins sock is not prone to breeding bacteria.

Owner:胡数丽

Preparation method of detection reagent for porcine circovirus type 2

InactiveCN109627291AShort production processShorten the timeVirus peptidesMicroorganism based processesEscherichia coliKanamycin

The invention relates to the technical field of animal disease detection, and discloses a preparation method of a detection reagent for porcine circovirus type 2. The preparation method specifically comprises the following steps of S1, expression of recombinant ORF2 protein, wherein pET-28a-ORF2 is converted into escherichia coli BL21 competent cells, the positive escherichia coli BL21 competent cells are selected for clone and inoculated into an LB culture medium containing kanamycin, overnight culture is performed, 50 microliters of a bacteria solution is taken the next day to be inoculatedinto 5 milliliters of the LB culture medium containing the kanamycin, culture is performed for 2 h until the OD600 value is 0.6-0.8, IPTG with the final concentration of 1 millimeter is added, sampling is carried out after induction is performed for 8 h, and a strain pET-28a-BL21 is induced as a negative control, and the protein expression situation is identified by SDS-PAGE gel electrophoresis; S2, soluble analysis of the recombinant ORF2 protein, wherein 2 microliters of a recombined strain pET-28a-ORF2-BL21 is added into 2 milliliters of the LB culture medium containing the kanamycin. The preparation method of the detection reagent for the porcine circovirus type 2 can more effectively improve the production efficiency, and can also improve the accuracy of the detection reagent for detecting the circovirus type 2.

Owner:广州昭越生物科技有限公司

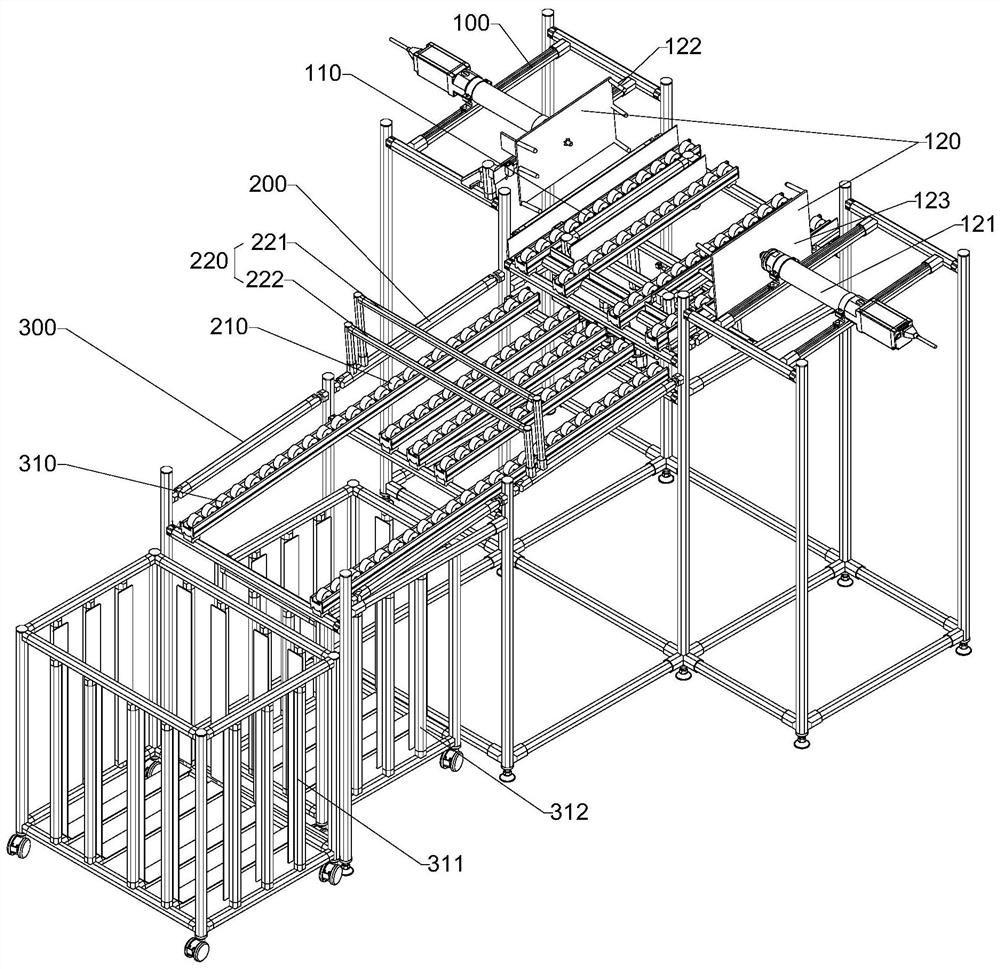

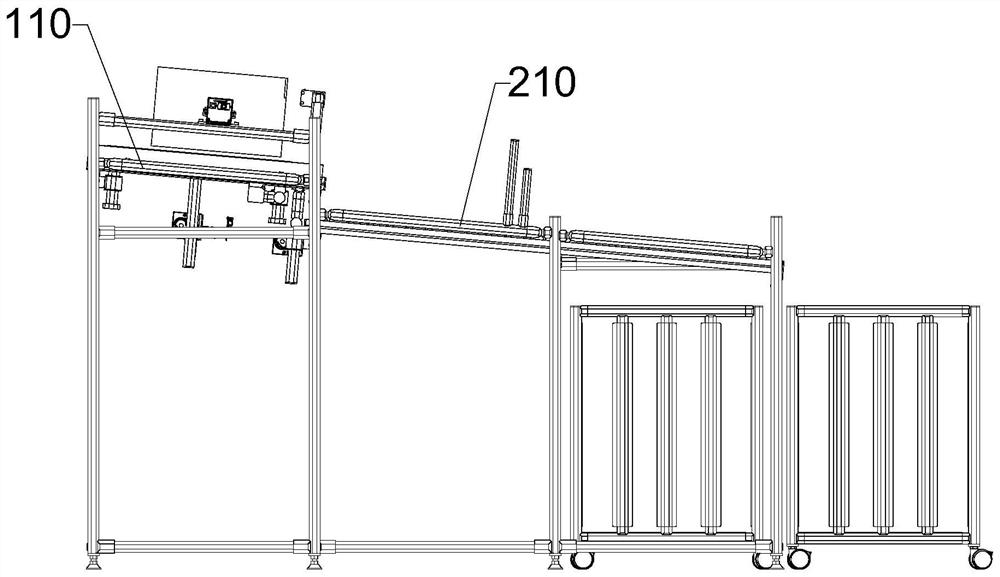

Automatic folding device and folding method for transport box

ActiveCN113184305ASimple structureImprove folding efficiencyRigid containersConveyor partsEngineeringMechanical engineering

The invention relates to the technical field of packaging boxes, and discloses an automatic folding device and a folding method for a transport box. The device comprises a first folding mechanism and a second folding mechanism, wherein the first folding mechanism comprises a first conveying roller bed used for transporting the transport box to be folded and a first push rod assembly used for achieving folding of the two opposite side faces of the transport box to be folded, the first push rod assembly is arranged on the two sides of the first conveying roller bed in the conveying direction of the transport box to be folded, the second folding mechanism is arranged on the downstream of the first folding mechanism, the second folding mechanism comprises a second conveying roller bed used for receiving the transport box folded by the first folding mechanism, and a second folding piece, the second conveying roller bed and the first conveying roller bed are arranged in a spaced mode in the vertical direction, and the second folding piece is used for folding a side plate, relative to the downstream of the conveying direction of the first conveying roller bed, of the transport box. The purposes of improving the folding efficiency and reducing the folding cost can be achieved through improvement of the structure of the folding device and the folding method.

Owner:一汽丰田汽车(成都)有限公司

Feeding mechanism of motor stator winding dipping paint system

InactiveCN101908802AReduce usageSave production time and costManufacturing dynamo-electric machinesEngineeringWork in process

The invention discloses a feeding mechanism of a motor stator winding dipping paint system, comprising a motor, a movable vehicle body, a platform and a hydraulic oil cylinder. The hydraulic oil cylinder is fixed on the movable vehicle body; the end part of the hydraulic oil cylinder is supported in the centre of the platform through a supporting block; sliding poles are respectively arranged at the four corners of the platform and pass through sliding holes of the movable vehicle body; the movable vehicle body is provided with a belt wheel which drives the hydraulic oil cylinder to stretch; and the belt wheel is driven by the motor to run. In the invention, the platform on the feeding mechanism of the motor stator winding dipping paint system is used for supporting a motor stator winding and is pushed by the hydraulic oil cylinder to rise or lower. The motor stator winding dipping paint system can solve the problems of storage of unfinished products and larger production space occupied by piling up caused by vacancy between two process rounds of a single product, so that a plurality of process rounds of the dipping paint are sequentially circulated on one apparatus without the phenomenon of space occupation of the semi-finished product, thereby the cost of production time is saved, the work efficiency is improved, fewer workers are employed and the labor cost is also reduced.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com