Dental repair material for temporary crowns and bridges and preparation method of dental repair material

A technology for repairing materials and dentistry, which can be used in dental preparations, dentistry, dental prostheses, etc., and can solve the problems of low production efficiency, long molding time, and high cost of preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

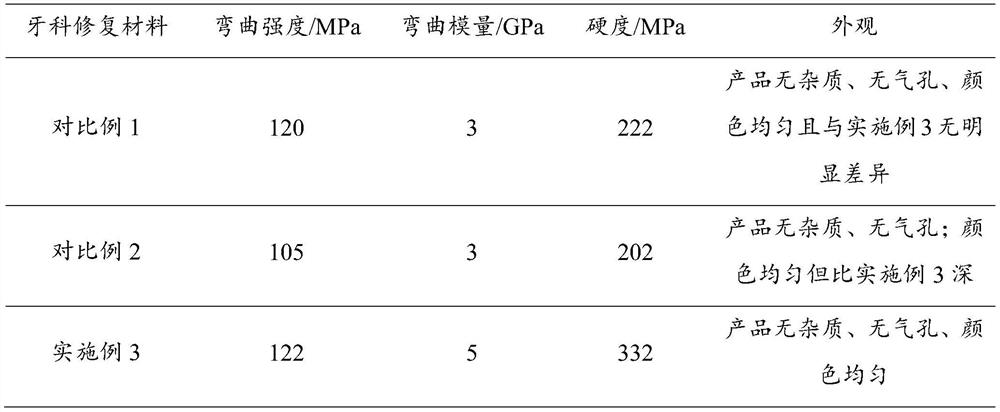

Embodiment 1

[0021] In this embodiment, a dental restoration material for a temporary crown and bridge is prepared, and the specific preparation steps include:

[0022] S1. According to the mass ratio of 10:6:2:3, take silica, alumina, fluorite, and cryolite, put them together in a ball mill, ball mill and mix them at a speed of 120rpm for 8 hours, and then pass through a 500-mesh sieve to obtain an inorganic filler powder;

[0023] S2. Weigh 200g methyl methacrylate, 0.2g azobisisobutyronitrile and 0.3g titanium nickel yellow and titanium dioxide mixed toner (the mass ratio of titanium nickel yellow and titanium dioxide is 1:20) and pour it into In the reactor, after ultrasonic mixing for 30 minutes, weigh 200 g of the inorganic filler powder prepared in step S1, pour it into the reactor while stirring, and after preliminary mixing for 5 minutes, transfer the materials in the reactor to a kneader and mix thoroughly for 30 minutes to prepare got the mixture;

[0024] S3. Fill the mixture...

Embodiment 2

[0026] In this embodiment, a dental restoration material for a temporary crown and bridge is prepared, and the specific preparation steps include:

[0027] S1. Take silicon dioxide, basalt powder, and alumina in a mass ratio of 10:1:6, put them together in a ball mill, and ball mill and mix them at a speed of 120 rpm for 2 hours, and then pass through a 500-mesh sieve to obtain an inorganic filler powder;

[0028] S2, take by weighing the mixed toner of 240g methyl methacrylate, 2.4g azobisisobutyronitrile and 0.4g titanium nickel yellow, iron oxide red and titanium dioxide (the quality of titanium nickel yellow, iron oxide red and titanium dioxide) ratio of 10:1:50) into the reactor, ultrasonically mixed for 30 minutes, weighed 160 g of the inorganic filler powder prepared in step S1, poured it into the reactor while stirring, and mixed the material in the reactor for 5 minutes Transfer to the kneader and fully mix for 45min to prepare the mixture;

[0029] S3. Fill the mixt...

Embodiment 3

[0031] In this embodiment, a dental restoration material for a temporary crown and bridge is prepared, and the specific preparation steps include:

[0032] S1. Take silicon dioxide, cryolite, and alumina according to the mass ratio of 20:7:20, put them together in a ball mill, ball mill and mix at a speed of 120 rpm for 12 hours, and then pass through a 500-mesh sieve to prepare inorganic filler powder;

[0033] S2. Weigh 200g methyl methacrylate, 200g inorganic filler powder, 0.5g initiator dibenzoyl peroxide and 0.2g mixed toner in sequence, wherein the mixed toner has a mass ratio of 1:0.1:0.0001:20 Iron oxide yellow, nickel titanium yellow, carbon nanotubes, titanium dioxide; then pour methyl methacrylate, dibenzoyl peroxide and mixed toner into the reactor, and after ultrasonic mixing for 30 minutes, the inorganic filler powder Pour into the reactor while stirring, and after preliminary mixing for 5 minutes, transfer the material in the reactor to a kneader and fully mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com