Patents

Literature

176results about How to "Solve uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

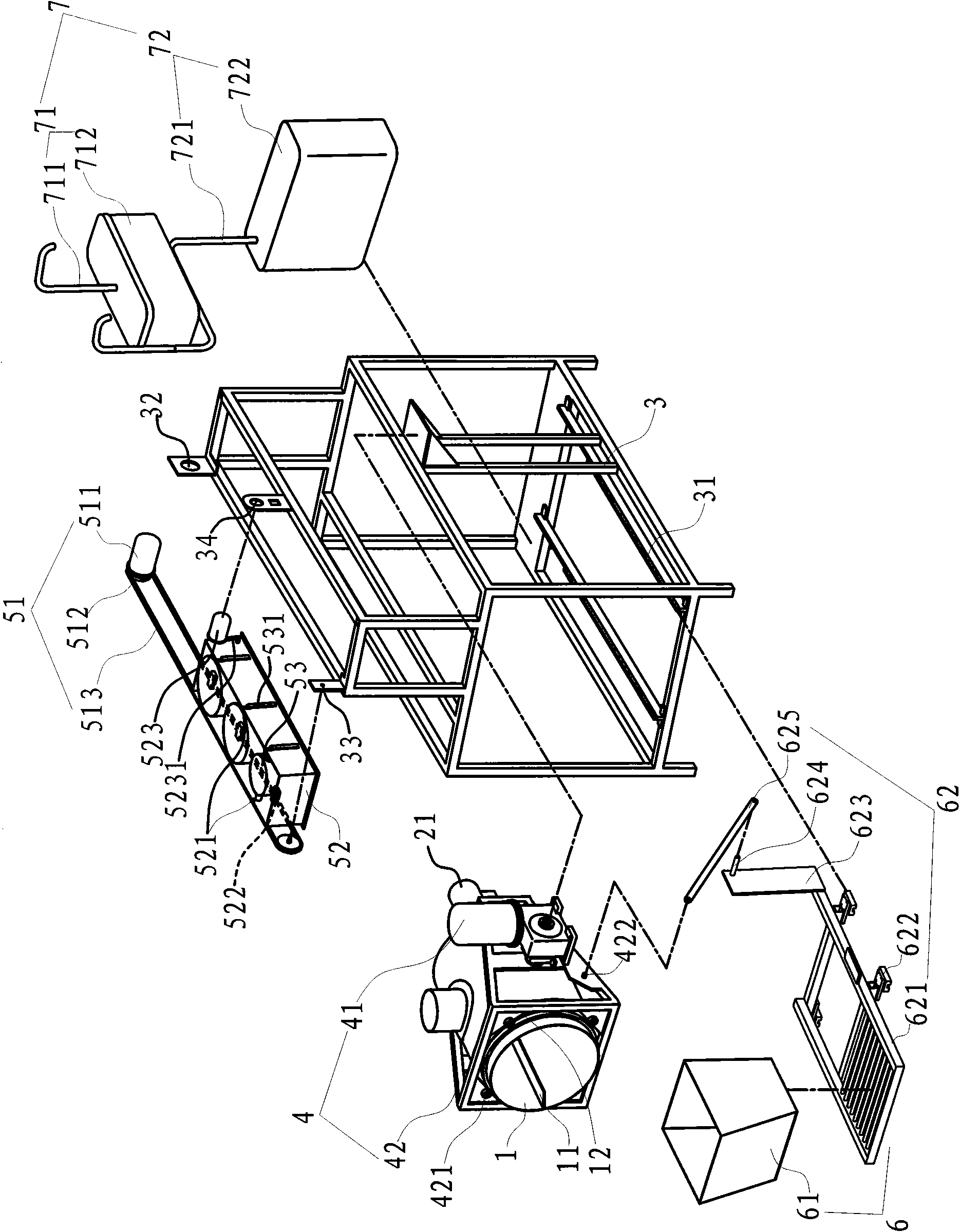

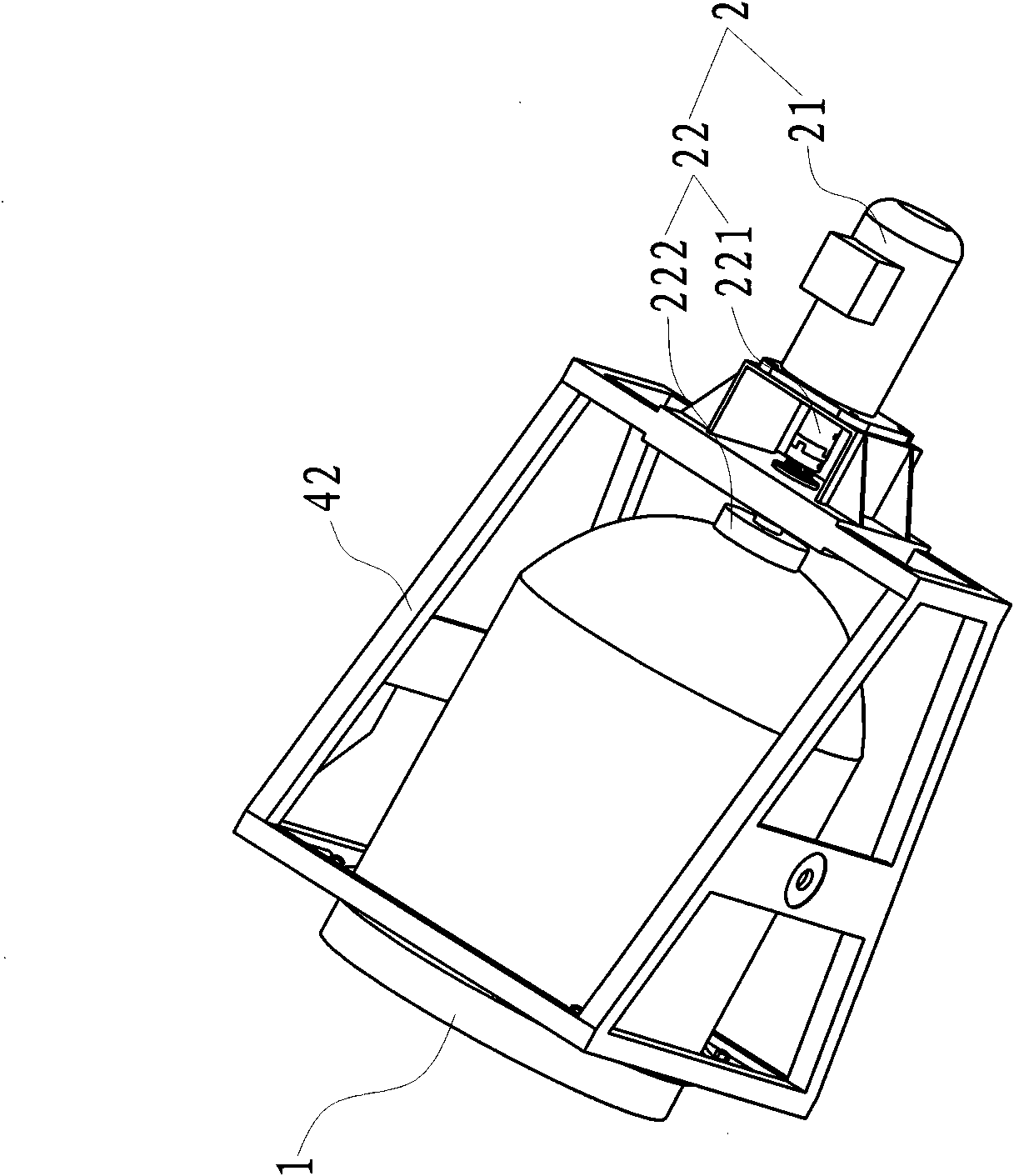

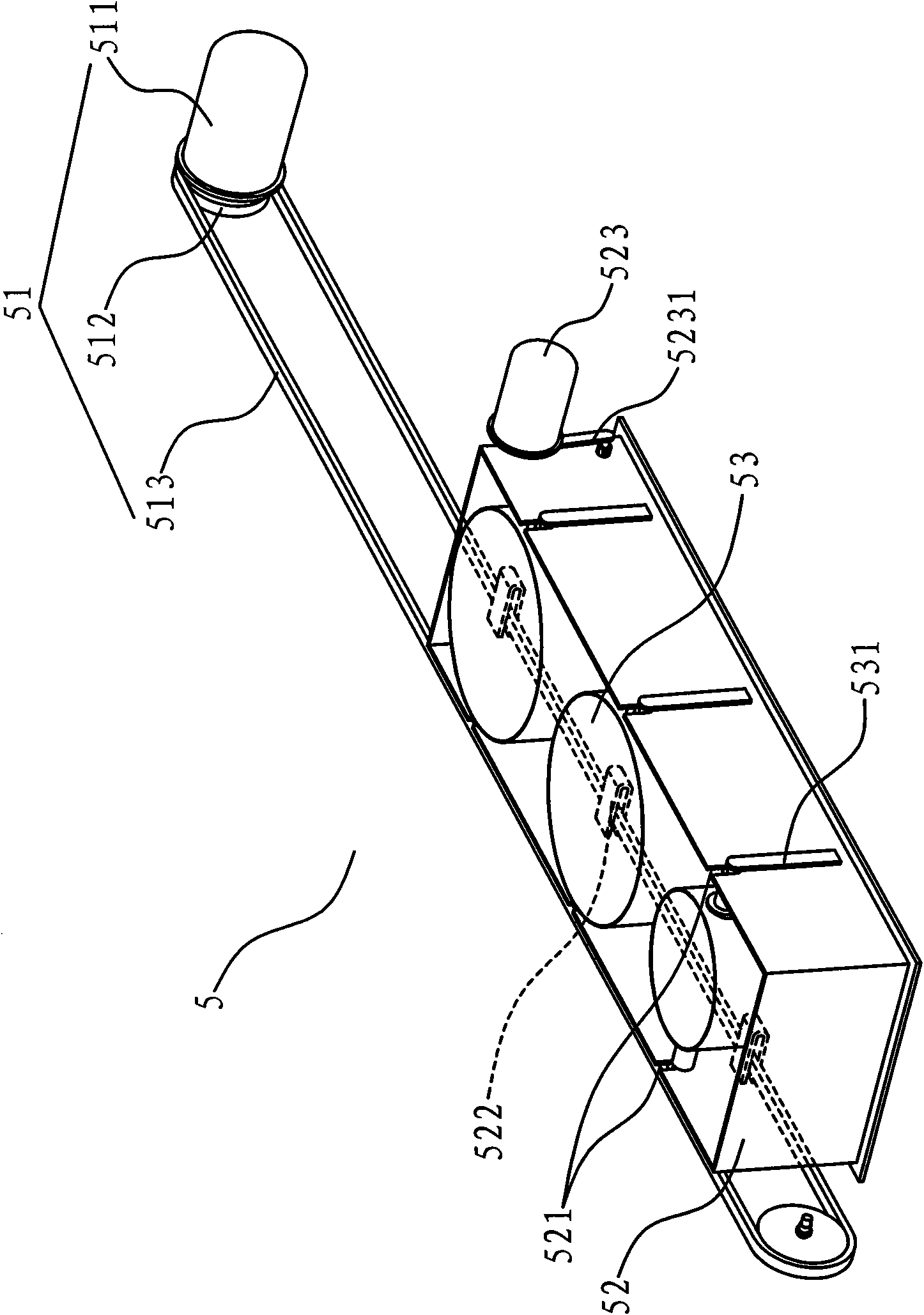

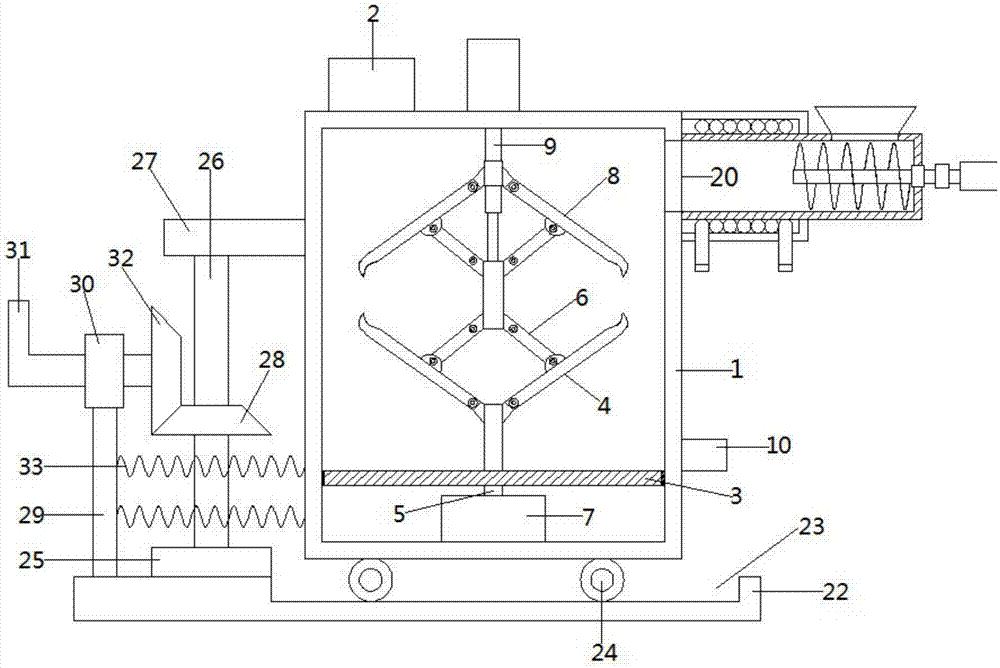

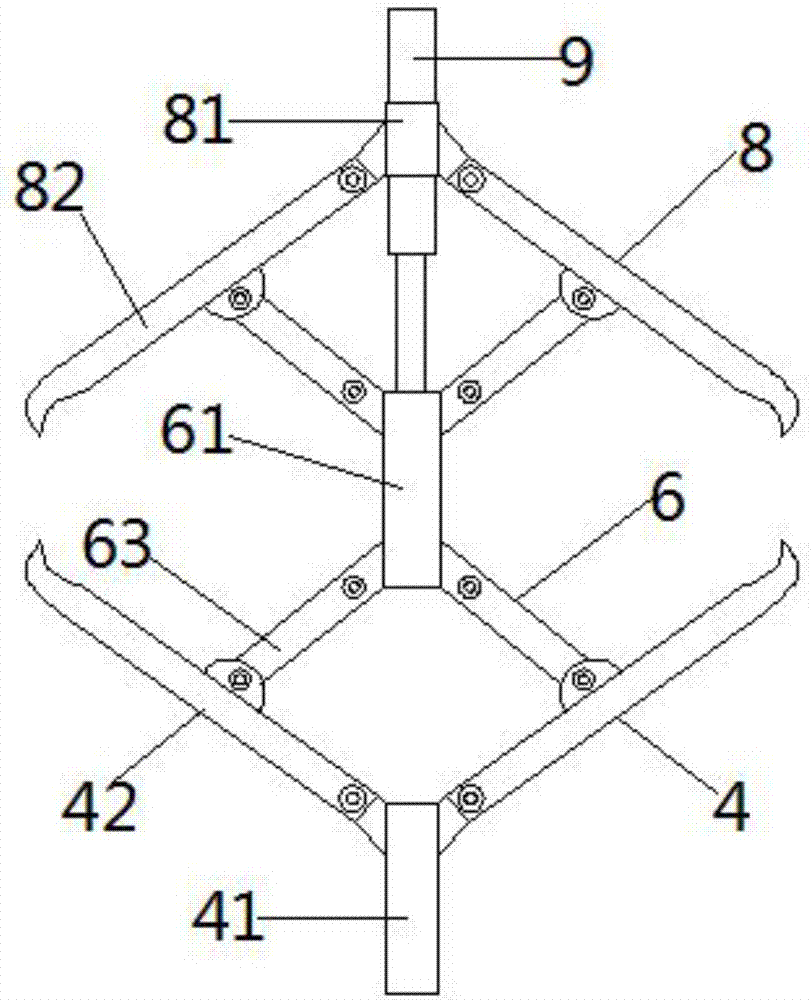

Cooking device

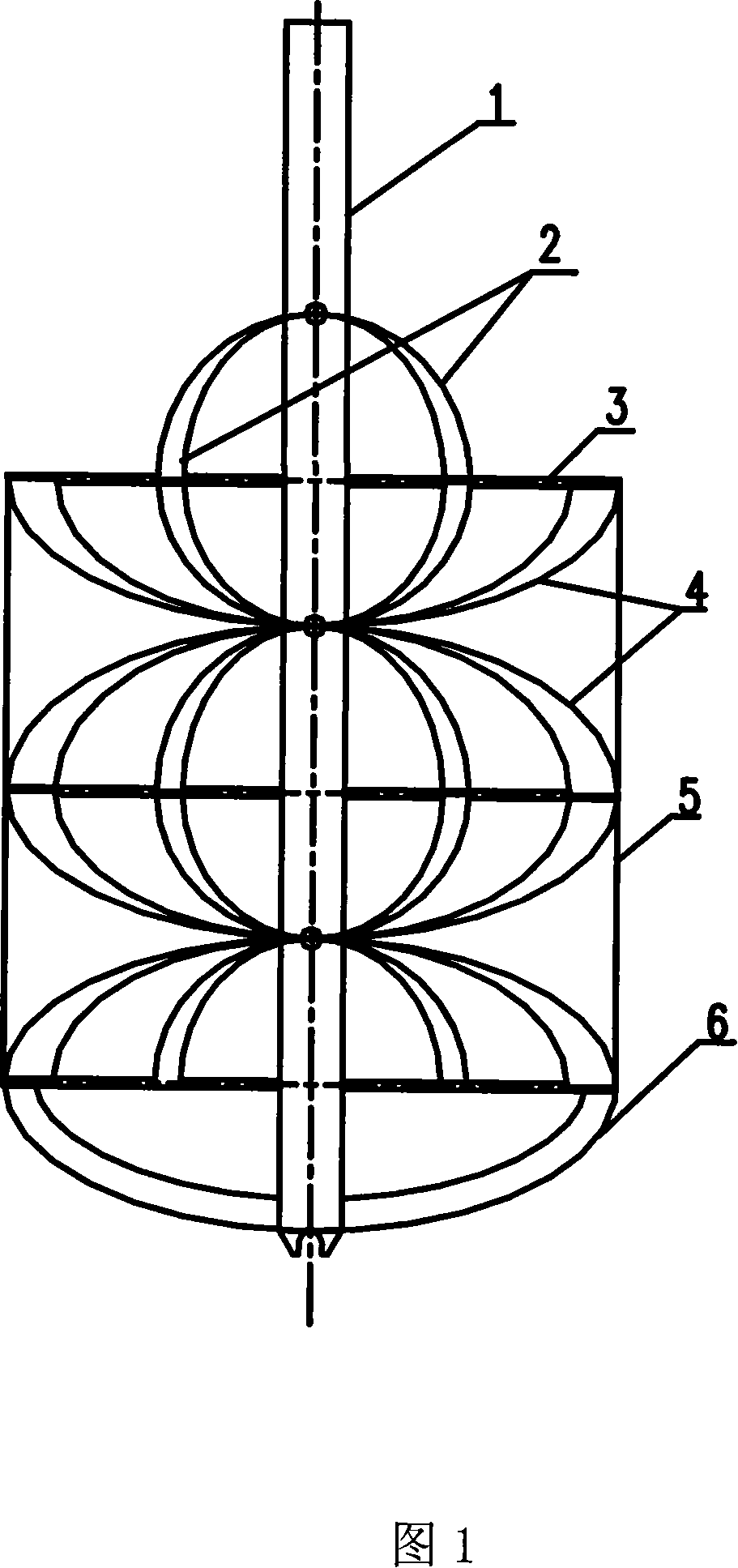

InactiveCN101637353ASolve uneven heatingAvoid fire control difficultiesCooking vessel constructionsBarrel ShapedSpherical shaped

The invention discloses a cooking device, which comprises a bracket, a pot body arranged on the bracket, a rotary mechanism arranged on the bracket and a turning mechanism arranged on the bracket, wherein the pot body is in a barrel shape or a spherical shape; the end part of the pot body is provided with an opening; the rotary mechanism is connected with the pot body, and drives the pot body to rotate along a rotary axis of the pot body; and the turning mechanism is connected with the pot body, and drives the pot body to rotate on the bracket along a turning axis. When the cooking device is in a working state, an angle of the rotary axis of the pot body and a horizontal plane is between 0 to 60 degrees. The cooking device achieves automation in feeding materials, stir-frying and putting dishes out, saves labor, reduces manual operations of a worker, and can stir the materials in the pot body sufficiently and evenly.

Owner:PANSUM TECH

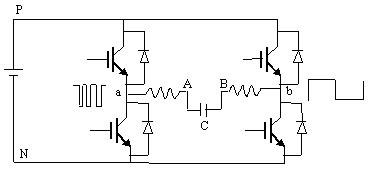

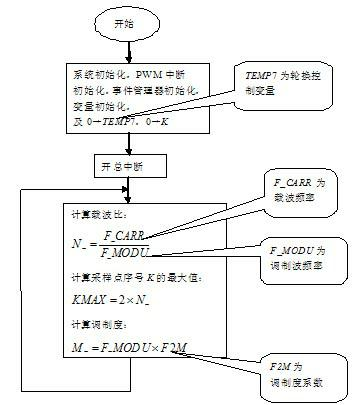

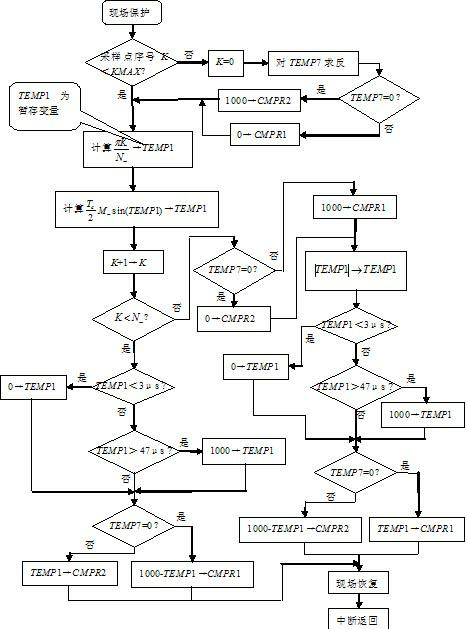

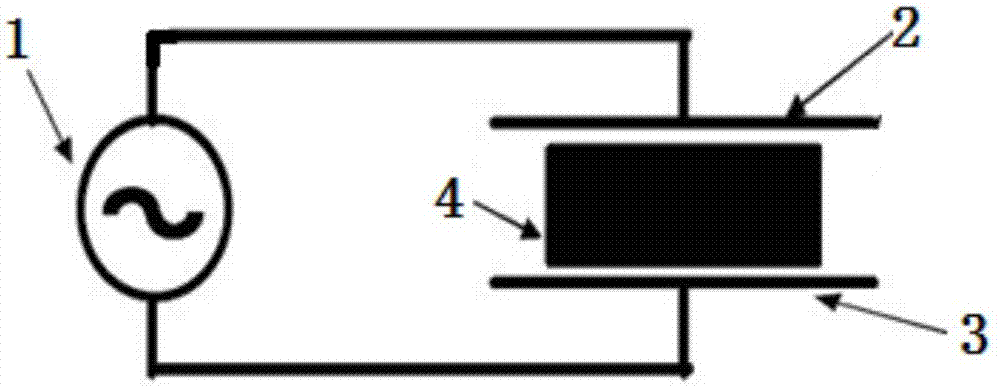

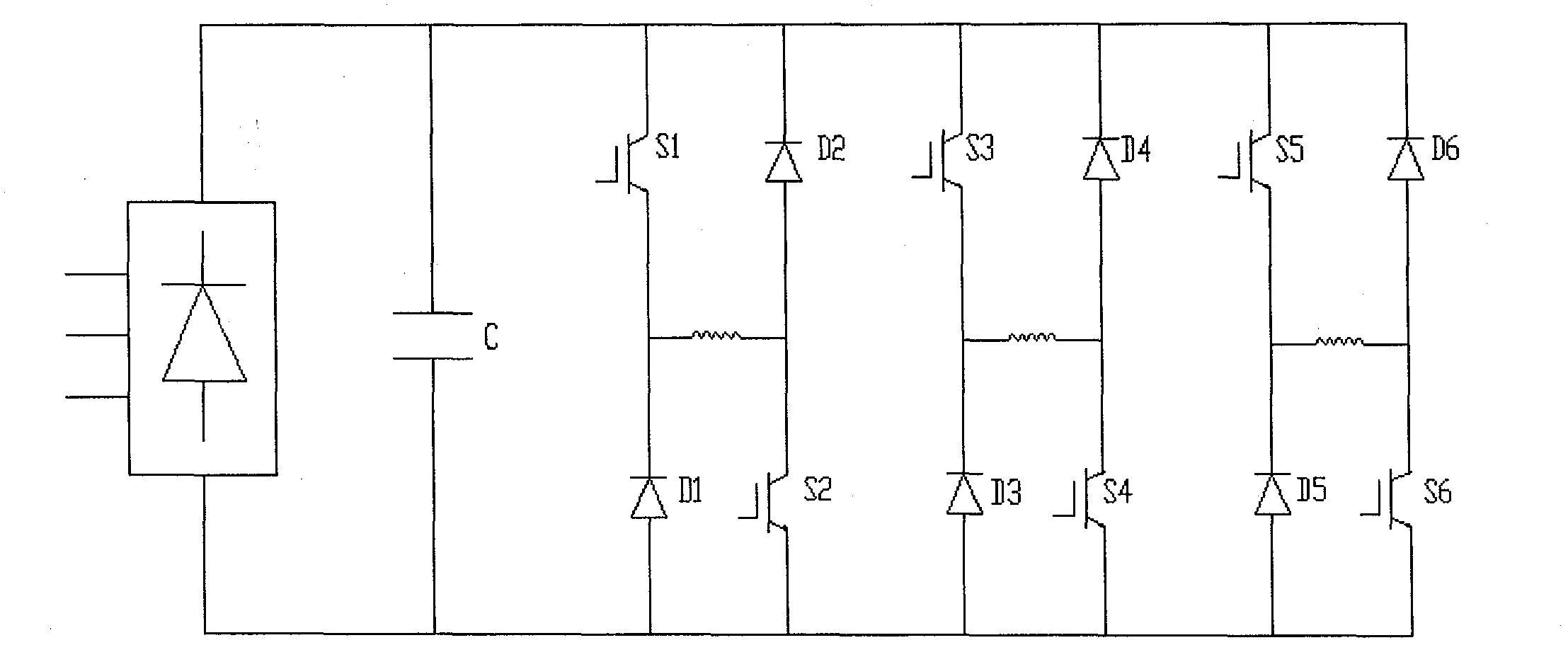

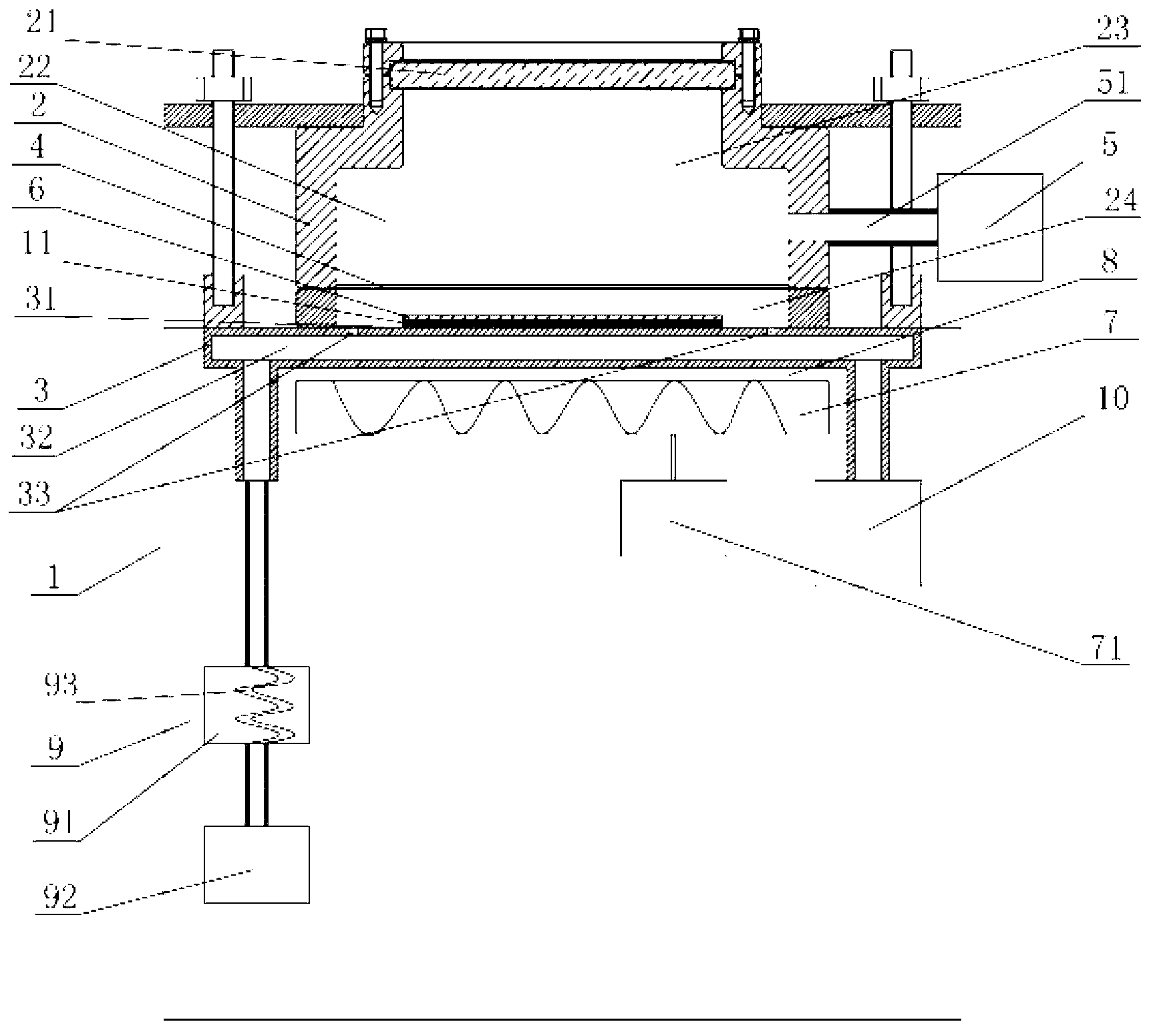

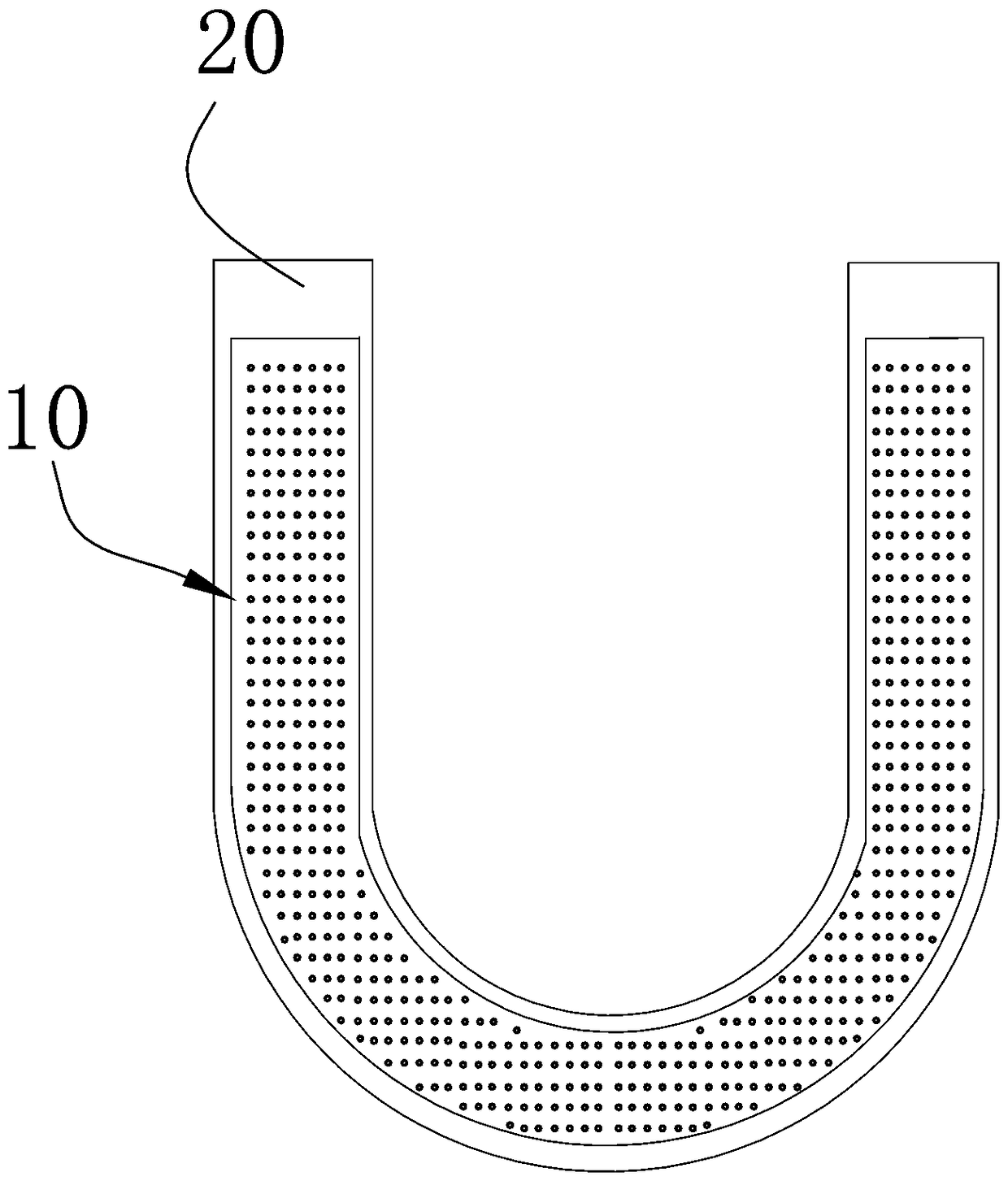

Pulse-width modulation (PWM) output method for solving problem of nonuniform heating of bridge arm switch of single-phase full-bridge inverter circuit

InactiveCN102611348ASolve uneven heatingAvoid failureAc-dc conversionSquare waveformFull bridge inverter

The invention relates to a pulse-width modulation (PWM) output method for solving the problem of nonuniform heating of a bridge arm switch of a single-phase full-bridge inverter circuit. The PWM output method is characterized in that two bridge arms use the modulation wave period T as an interval for alternately outputting PWM waves and square wave voltage. The problem of nonuniform heating caused by great work frequency differences of two bridge arm switches is solved, the temperature of an overheat switch is obviously reduced, insulated gate bipolar translator (IGBT) power switch device faults caused by overheat is effectively overcome, the reliability of a switch device is favorably improved, and the service life is prolonged.

Owner:FUZHOU UNIV

Liquid mixing device capable of rapidly mixing materials

InactiveCN107349852AExtended range of mixingChange fixed mixShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringDrive motor

Owner:林红英

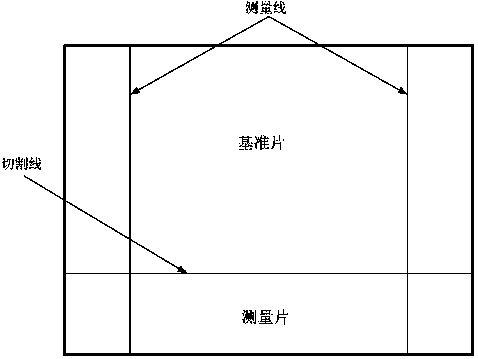

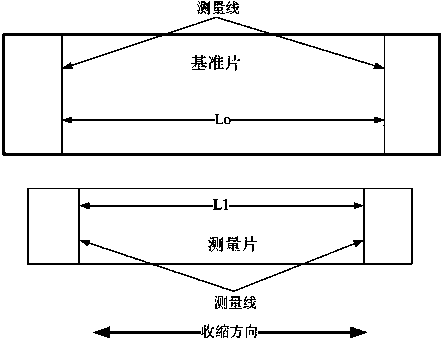

Method for measuring shrinkage factor of PDP (Plasma Display Panel) glass

ActiveCN103454302AReduce measurement errorEasy to measureMaterial thermal coefficient of expansionEngineeringPlasma display

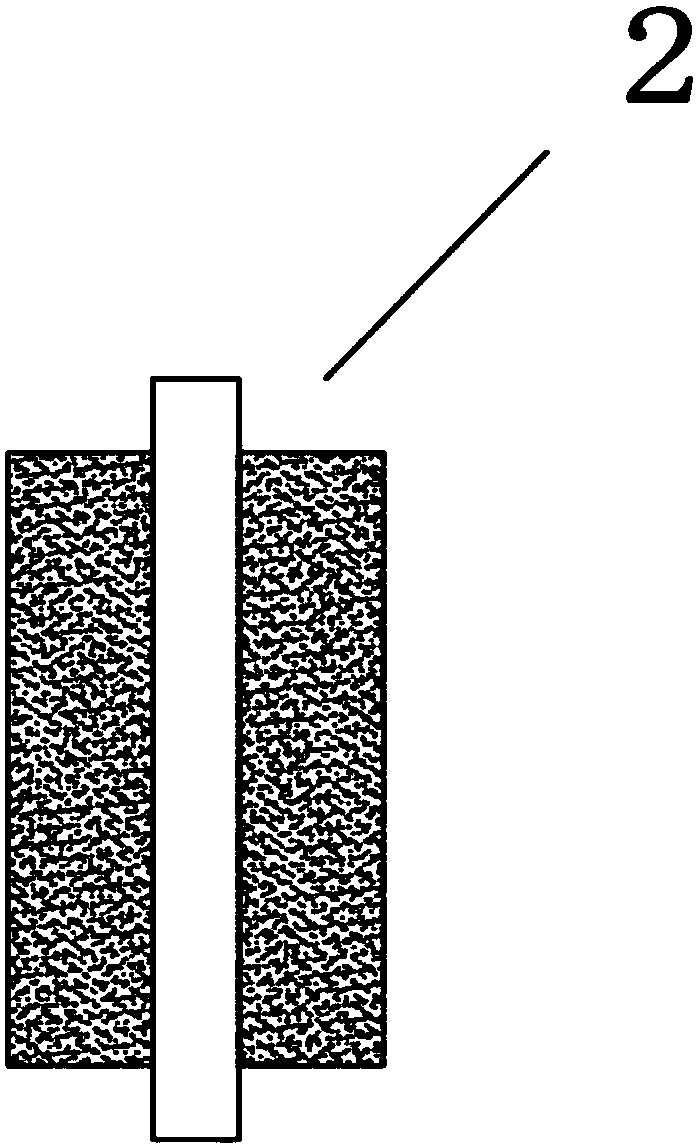

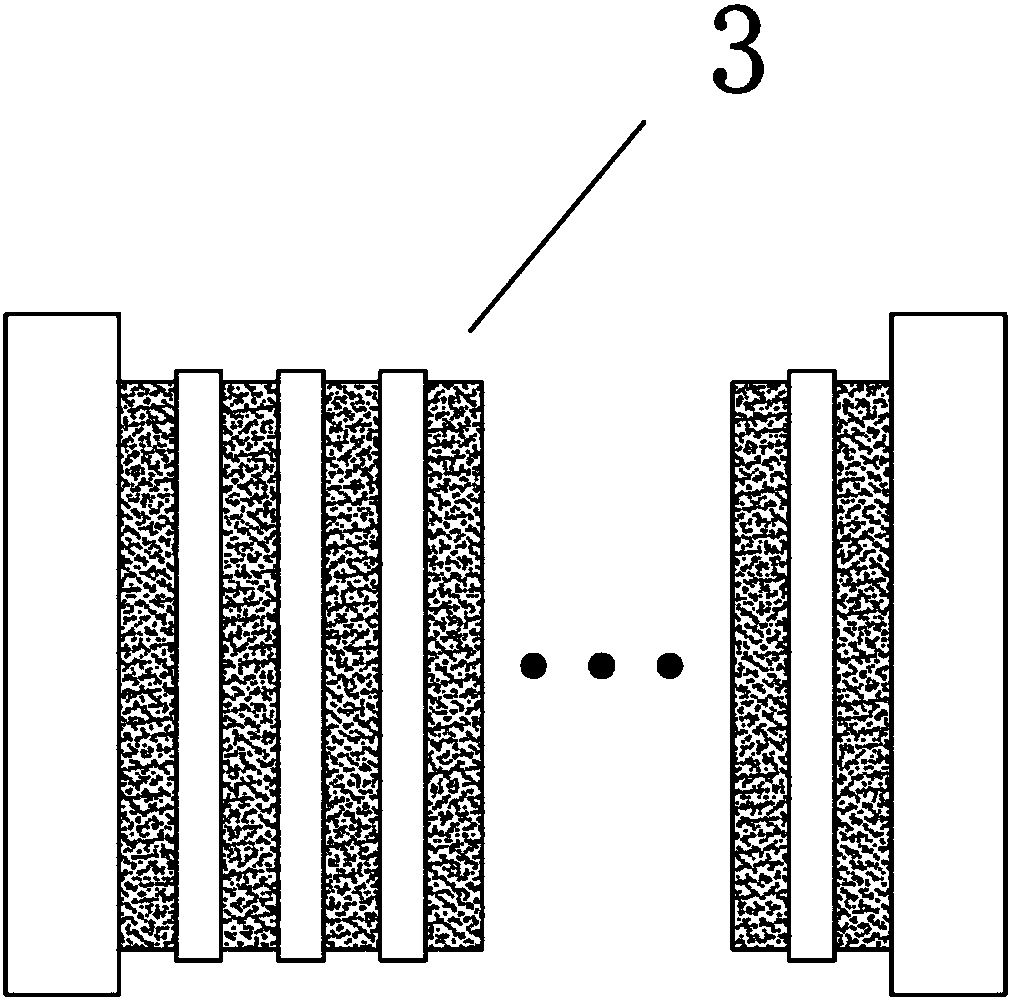

The invention discloses a method for measuring shrinkage factor of PDP (Plasma Display Panel) glass. The method comprises the following steps: step 1, marking out a measuring line on a PDP glass sampler sheet, and cutting the PDP glass sampler wafer into a reference sheet and a measuring sheet, wherein the cutting line cuts the measuring line; step 2, vertically placing the measuring sheet, arranging porcelain boats on the top and the bottom of the measuring sheet respectively, sealing and surrounding the measuring sheet, and filling flexible high-temperature resistant materials between the upper and the lower ends of the measuring sheet and the inner walls of the porcelain boats and between the side edge of the measuring sheet and the inner walls of the porcelain boats; step 3, heating the porcelain boats and the measuring sheet according to a preset heating curve in an integrated manner; step 4, carrying out annealing cooling to the measuring sheet after heating, comparing the displacement of the measuring line of the measuring reference sheet and the measuring sheet and calculating the shrinkage factor. The method for measuring the shrinkage factor of PDP glass can solve the problem of non-uniform heating and enables the whole piece of glass to be in a stable temperature environment during glass heat treatment to achieve uniform heat shrinkage effect, and furthermore, the measured shrinkage factor data is accurate and reliable.

Owner:SICHUAN XUHONG OPTOELECTRONICS TECH

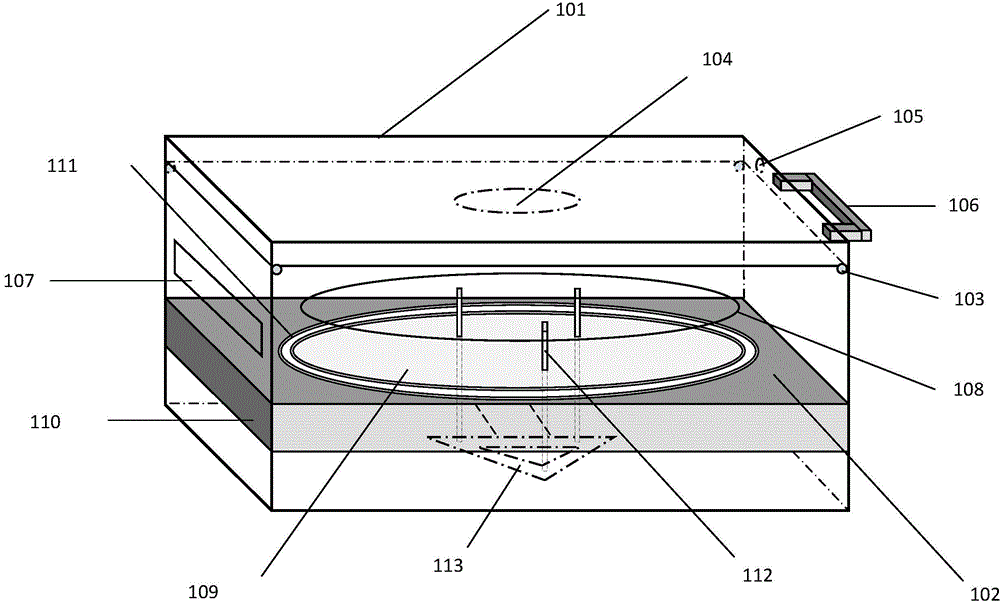

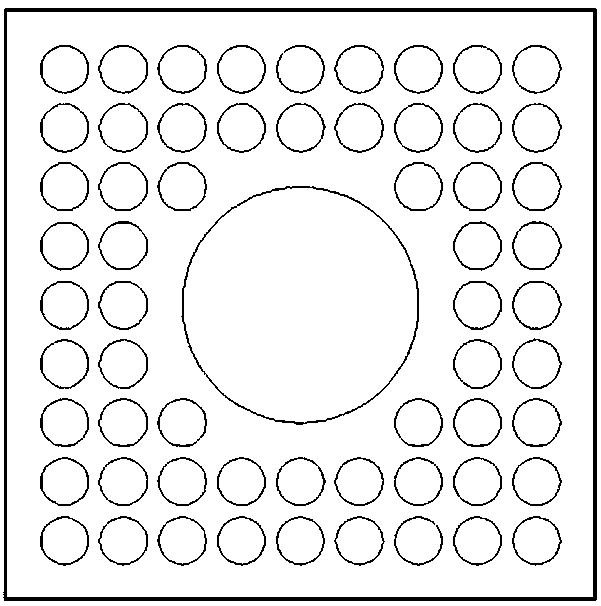

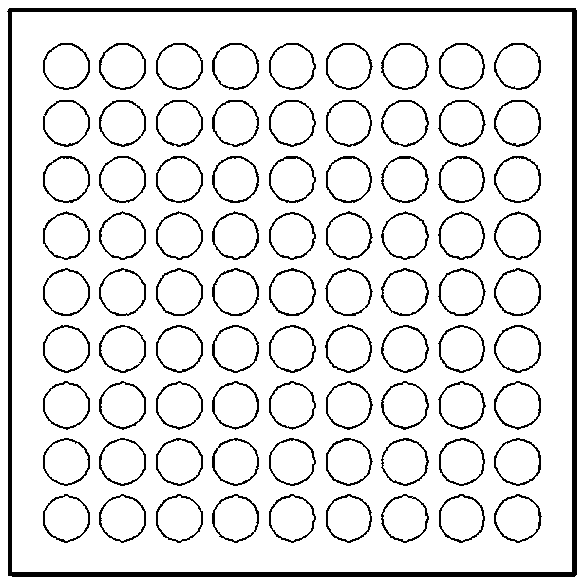

Semiconductor substrate heat treatment device

ActiveCN105280518ASolve uneven heatingEliminate the effects of turbulenceSemiconductor/solid-state device manufacturingNitrogenSmart city

The concept of "smart city, smart life" is deeply rooted among people. People also have increasingly high technological requirement for semiconductor products. Acting as an important step of the semiconductor processing procedure, a substrate heat treatment device constantly wins public attention, and ensuring of even heating of a wafer in the heating procedure is always a difficult problem to practitioners. The invention provides a semiconductor substrate heat treatment device comprising an exhaust device and a heating cavity. Nitrogen is filled in the heating cavity in the heating procedure, and heat is indirectly transmitted to the surface of the wafer by nitrogen so that the problem uneven heating caused by warping of the wafer can be eliminated.

Owner:ACM RES SHANGHAI

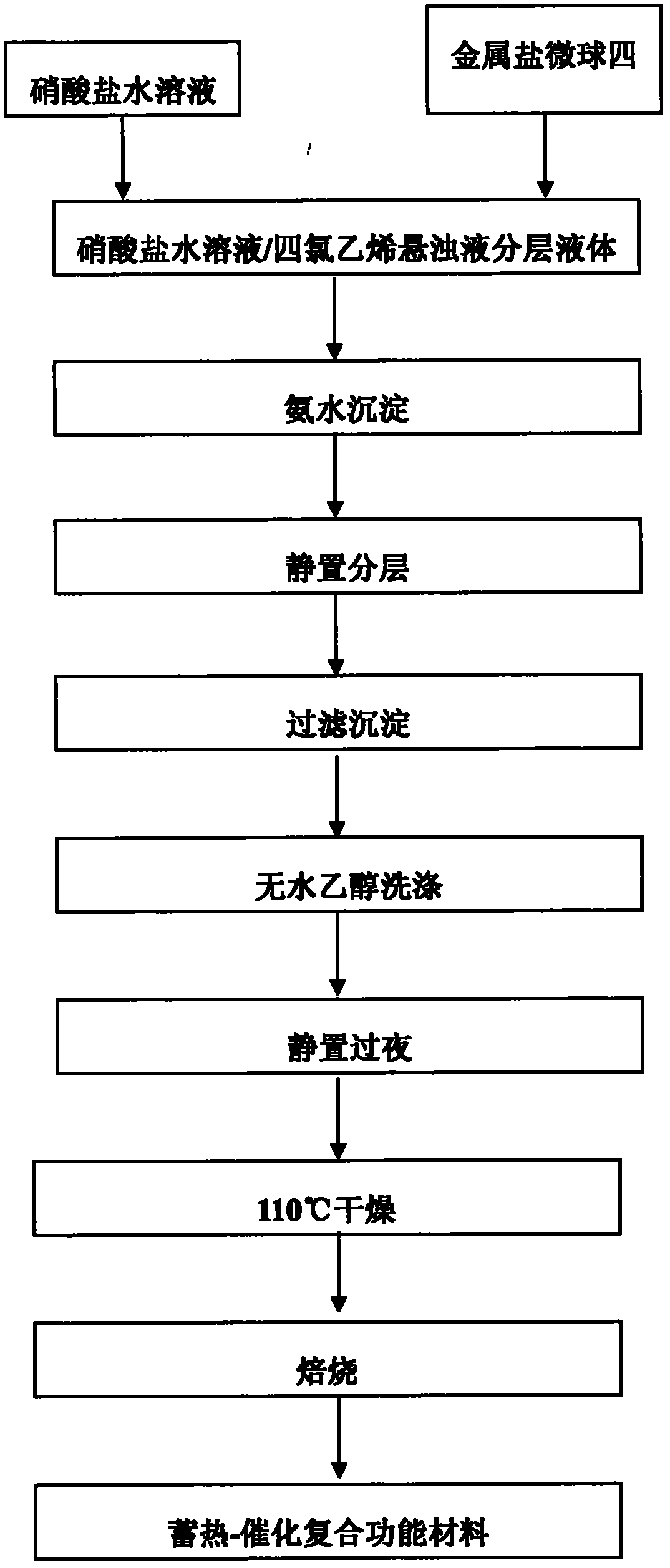

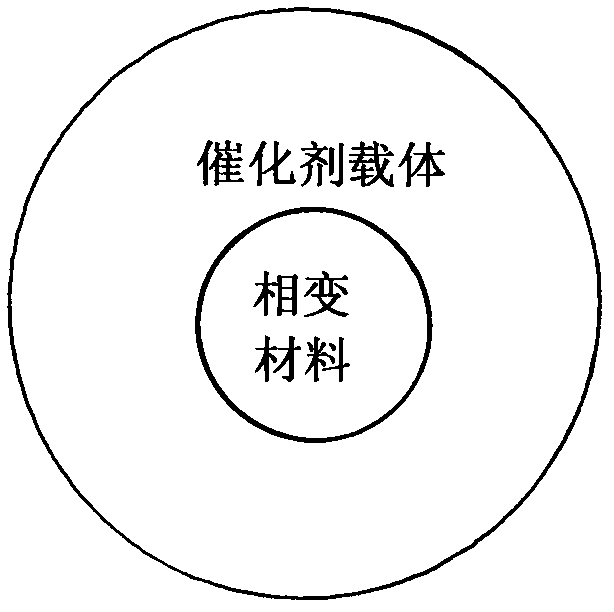

Heat-storing catalytic composite functional material and preparation method thereof

InactiveCN102166532ATo avoidStable temperatureCatalyst carriersHeat-exchange elementsInorganic materialsPhase-change material

The invention relates to a catalyst carrier with a heat-storing function and a preparation method thereof, belonging to the field of application catalysis. The heat-storing catalytic composite functional material is of a nuclear shell structure, wherein an inorganic material such as aluminum oxide, titanium oxide, magnesium oxide or zirconium oxide is used as a shell layer for tightly coating a metal salt used as a phase-change material, such as Na2CO3, K2CO3, Li2CO3, NaCl, KCl or LiCl or mixture thereof as a nuclear layer. The heat-storing catalytic composite material has the textural characteristics of a traditional catalyst carrier on pattern, specific area, crystallographic form and the like, and the phase-change material metal salt of the nuclear layer and the catalyst inorganic material of the shell layer are combined to form an enhanced body.

Owner:KUNMING UNIV OF SCI & TECH

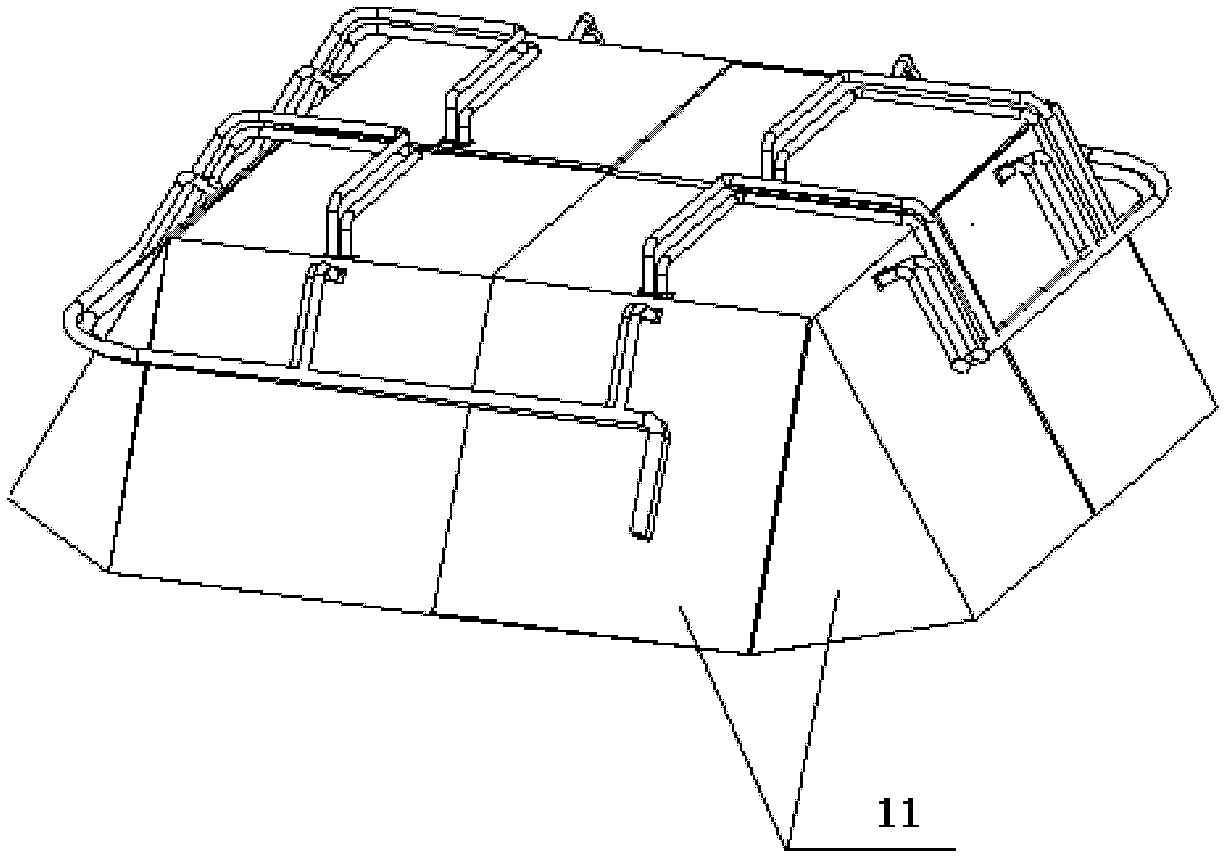

Solar heat collecting device

InactiveCN102425865ASolve uneven heatingOvercoming control signal hysteresisSolar heating energySolar heat collector controllersControl systemControl signal

The invention discloses a solar heat collecting device, comprising at least one heat collecting module, wherein each heat collecting module comprises a hollow container with an inlet and an outlet, a flow controller is arranged between the hollow container and an inlet main pipe and / or an outlet main pipe; each heat collecting module also comprises at least one temperature sensor and / or a light intensity sensor which is in communication connection with a control system and is used for measuring the temperature and / or illuminated light intensity value of the hollow container; and the control system comprises a feed-forward control unit which generates feed-forward regulating signals for regulating each flow controller after analyzing and calculating according to the temperature and / or light intensity value of each hollow container, thereby changing the quantity and / or rate of flow of a heat-absorbing working medium flowing into the corresponding hollow container, and enabling the heat-absorbing working medium at the outlet of each heat collecting module to reach the preset pressure value and temperature value. The solar heat collecting device disclosed by the invention ensures thatthe pressure and temperature of the heat-absorbing working medium at the outlet of each heat collecting module are uniform, control signal lag is eliminated, and the generating efficiency is improved.

Owner:深圳市联讯创新工场科技开发有限公司

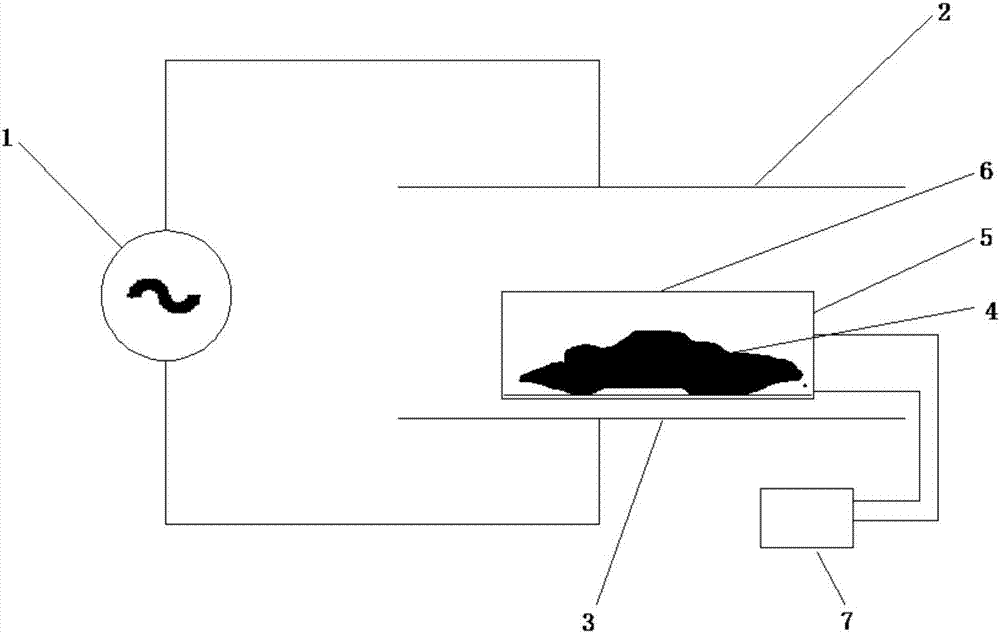

Uniform-unfreezing type radio frequency heating device

InactiveCN107373296AWide applicabilityImprove the quality of thawed foodDielectric heatingFood preservationRadio frequencyMedium vessel

Owner:SHANGHAI OCEAN UNIV

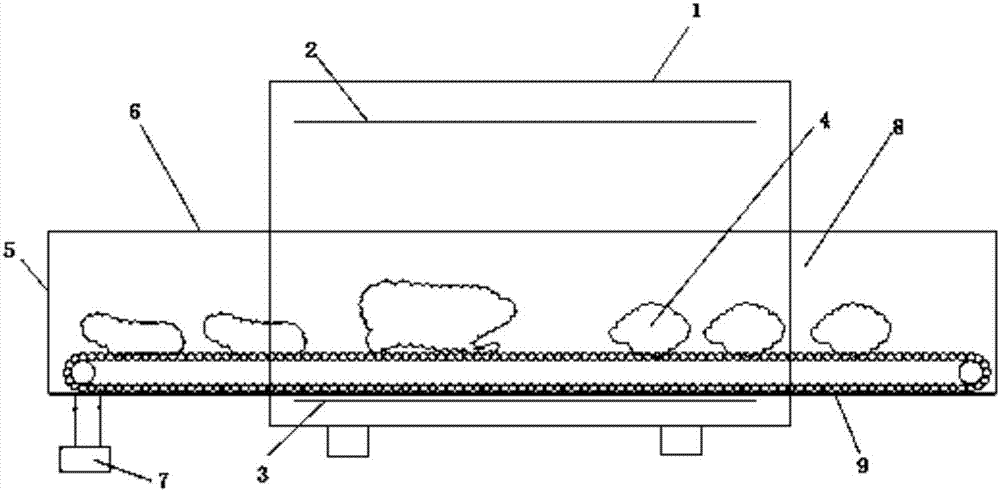

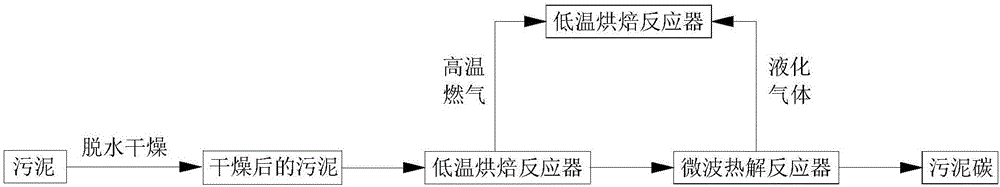

Directional staged pyrolysis and carbonization method for sludge

InactiveCN106753462ASolve uneven heatingHigh specific surface areaSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMicrowaveCarbonization

The invention discloses a directional staged pyrolysis and carbonization method for sludge. The method comprises following steps: (1), dewatering and drying: the sludge is dewatered until water content is 40%-60%; (2), low-temperature baking: the sludge dewatered and dried in the step (1) is subjected to low-temperature baking treatment at the temperature of 200-350 DEG C; (3), medium-temperature carbonization: solid products obtained through low-temperature baking treatment in the step (2) are subjected to microwave heating to reach 500-800 DEG C for medium-temperature carbonization, and sludge carbon is obtained. The sludge is wholly heated with microwaves, so that the problem of uneven heating of materials in an amplification process due to the fact that a heating source drives heat exchange by temperature difference between materials in traditional heating mode is solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

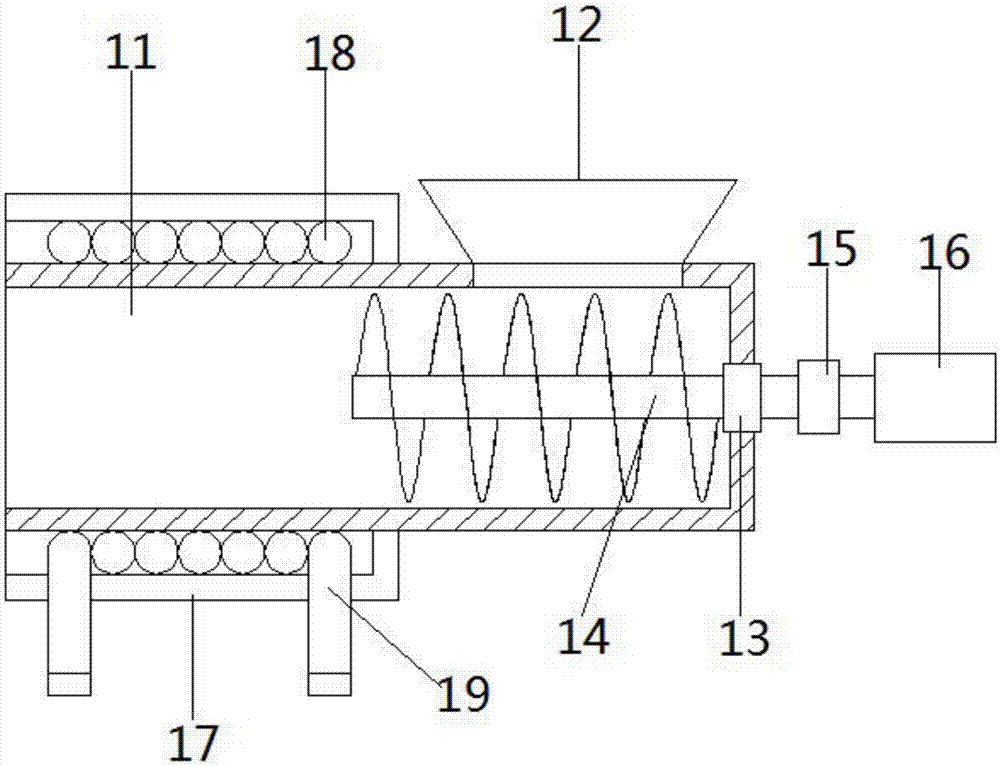

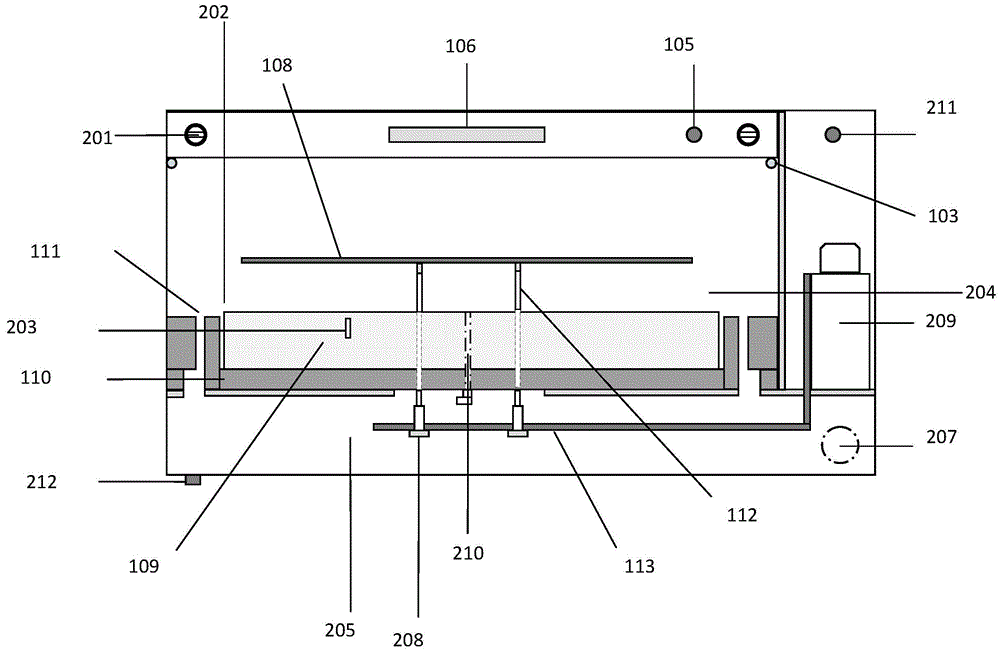

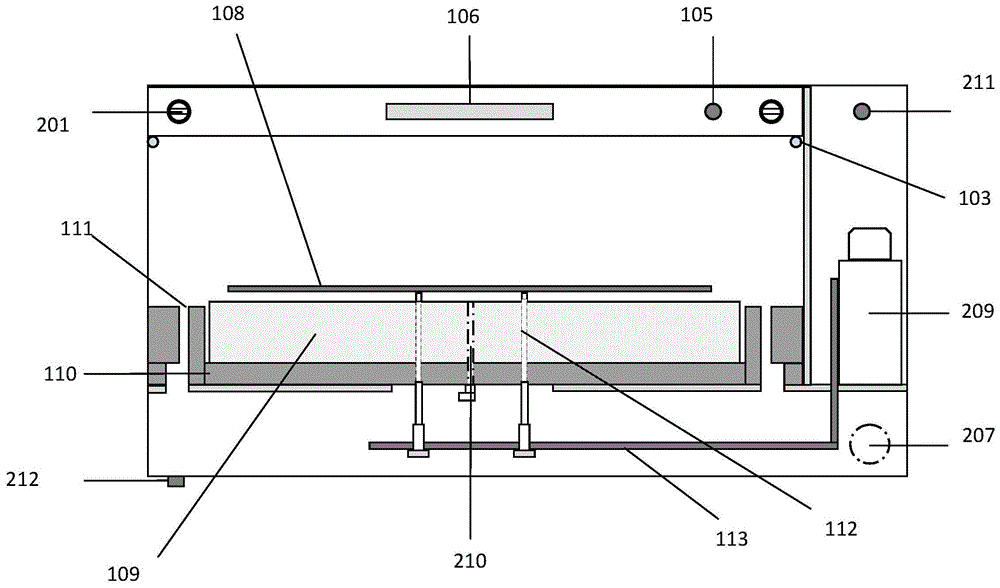

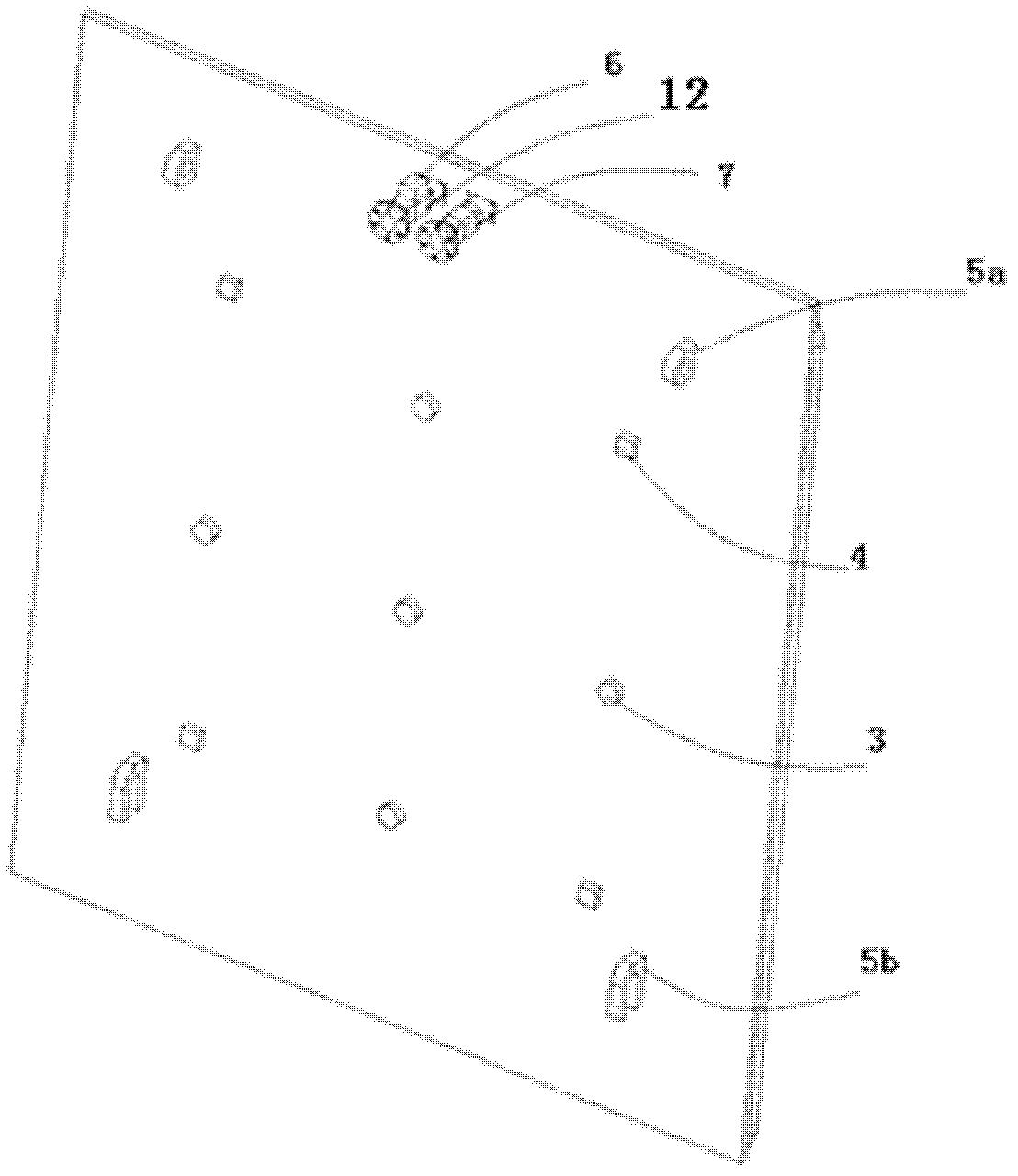

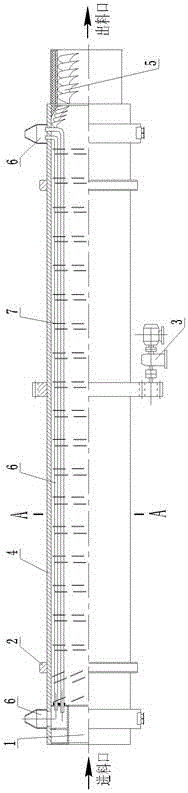

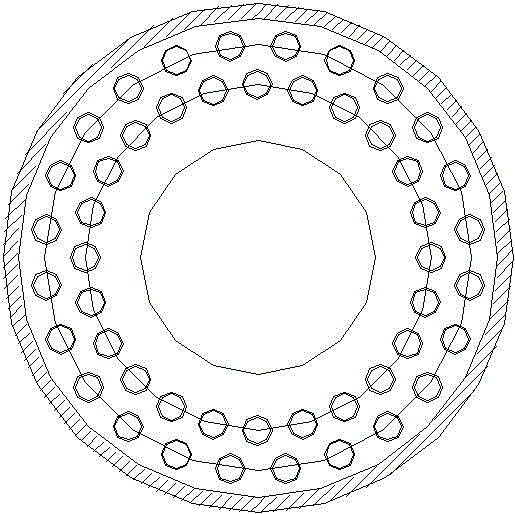

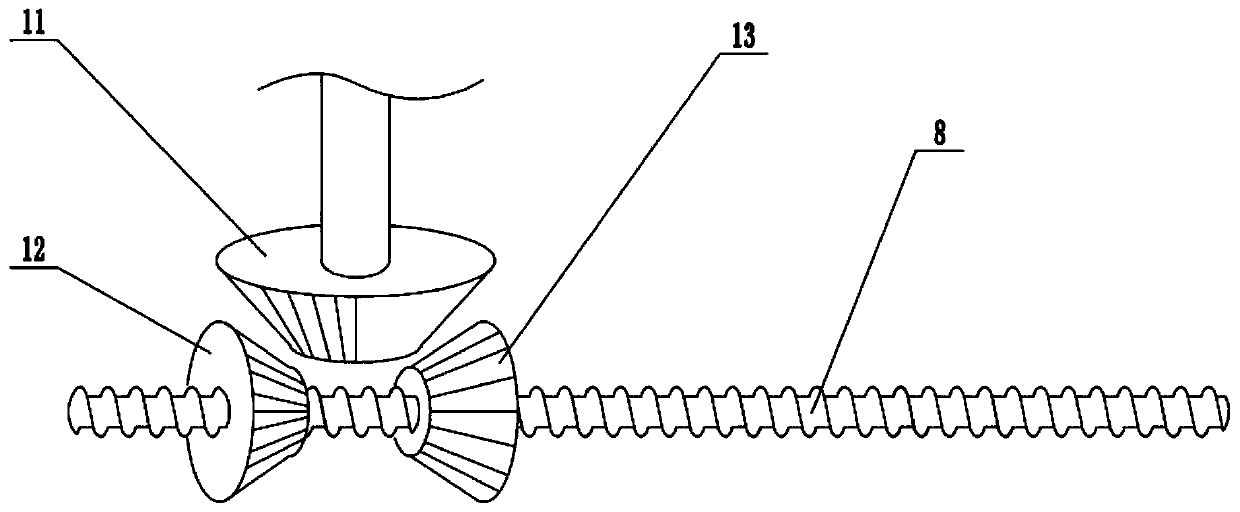

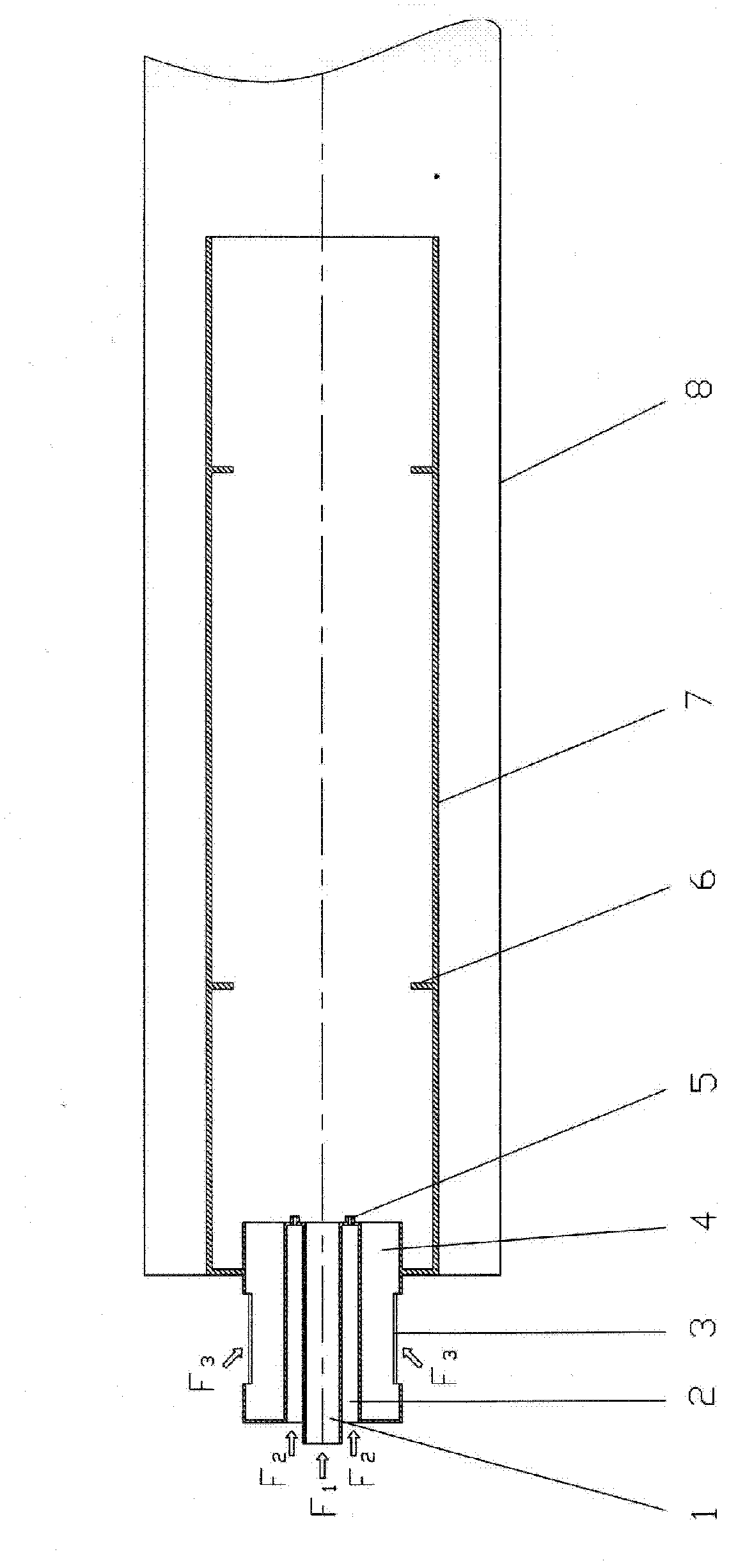

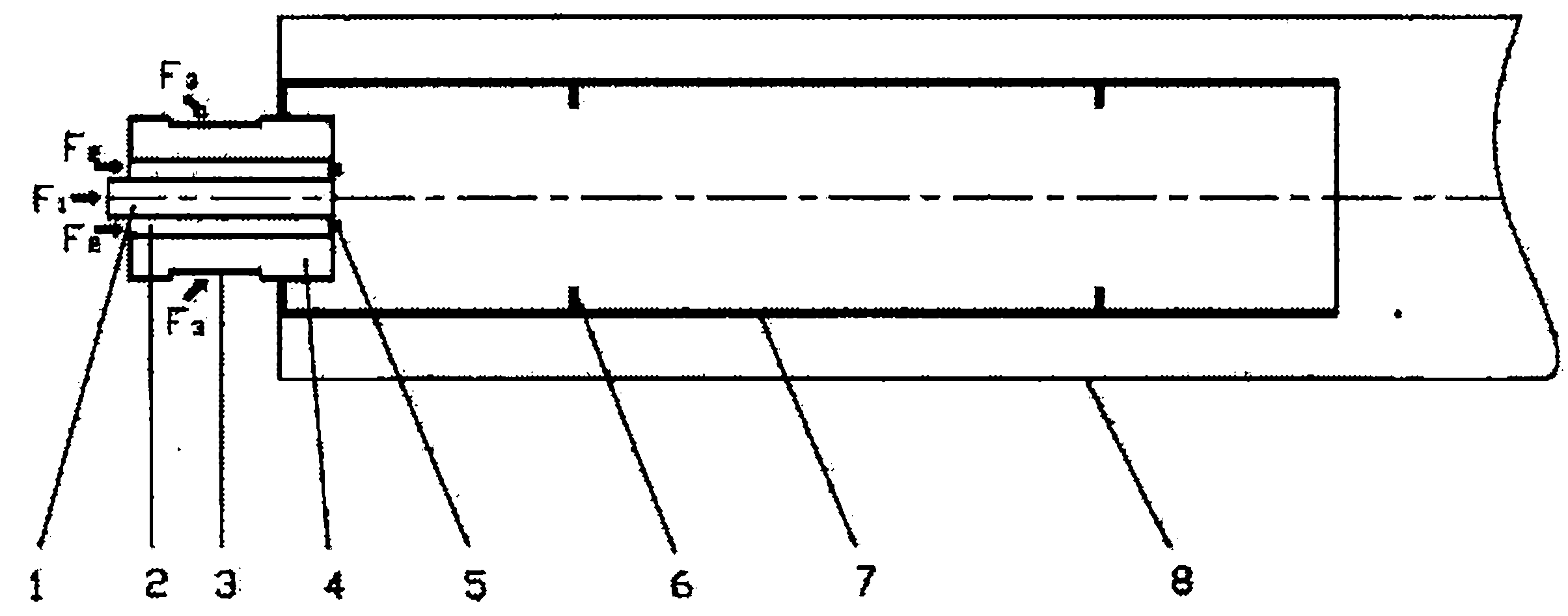

Internal heat rotary kiln coal dry distillation device

InactiveCN104910939AAvoid pollutionSolve pollutionIndirect heating destructive distillationSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heat rotary kiln coal dry distillation device comprising a kiln body (4) with a feeding device (1) and a discharge device (5) respectively arranged on the two ends. The kiln body (4) has a sealed structure. A heating device (6), a rotation stabilization device (2) and a transmission device (3) are respectively arranged on the kiln body (4). The kiln body (4) is cylindrical. A pipe rack spiral plate (7) and a heating device (6) are arranged in the kiln body (4). The kiln body (4) is inclined towards the end provided with the discharge device (5), such that the kiln body end with the feeding device (1) is higher than the end with the discharge device (5). The internal heat rotary kiln coal dry distillation device provided by the invention has a simple and fully sealed structure. With the device, continuous production can be realized, and no dust, coal gas or pollutant is discharged to the surrounding environment during a dry distillation process. With the device, the production efficiency is greatly higher than that of prior arts.

Owner:SANMENXIA CHEM MACHINERY

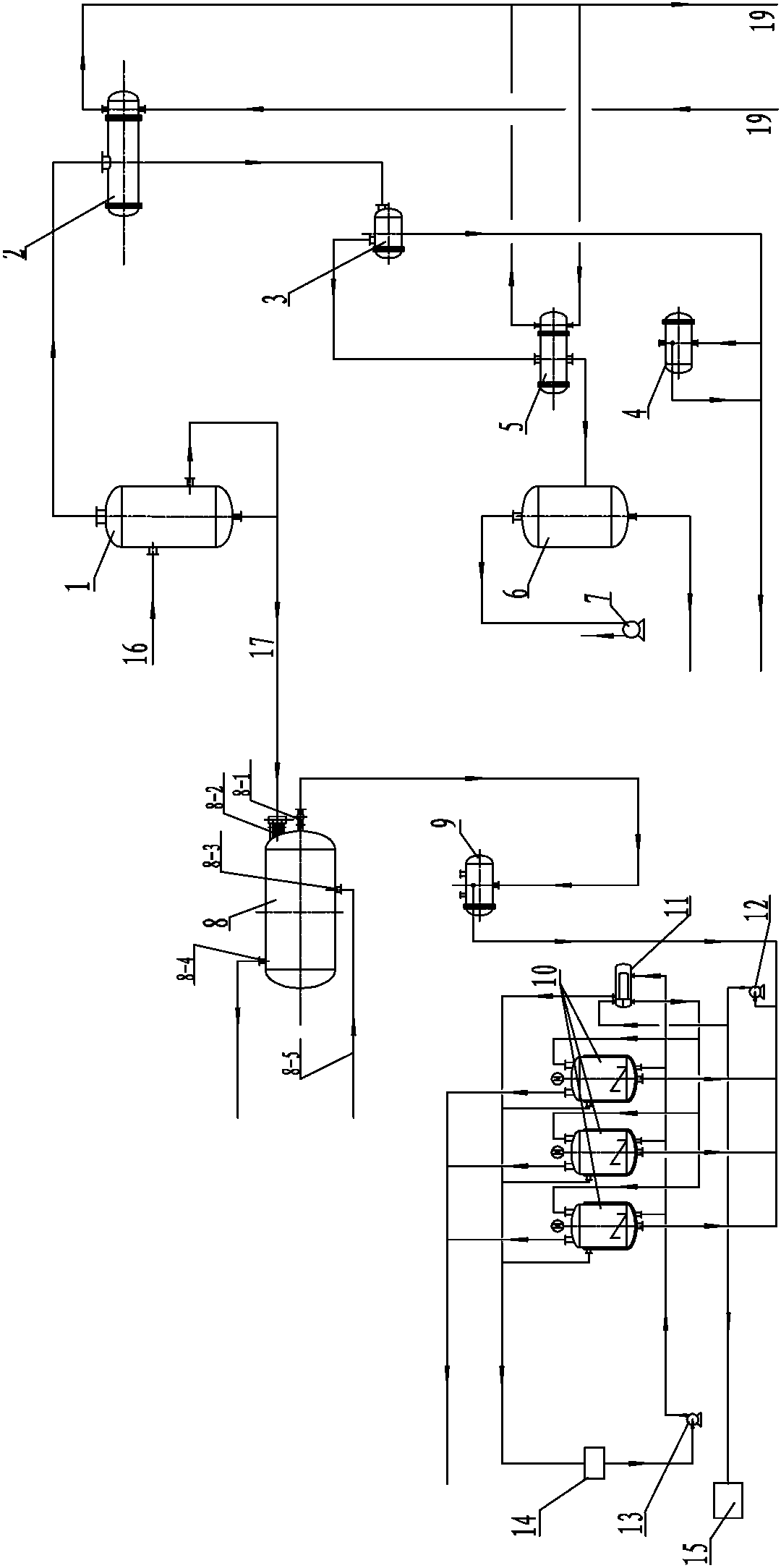

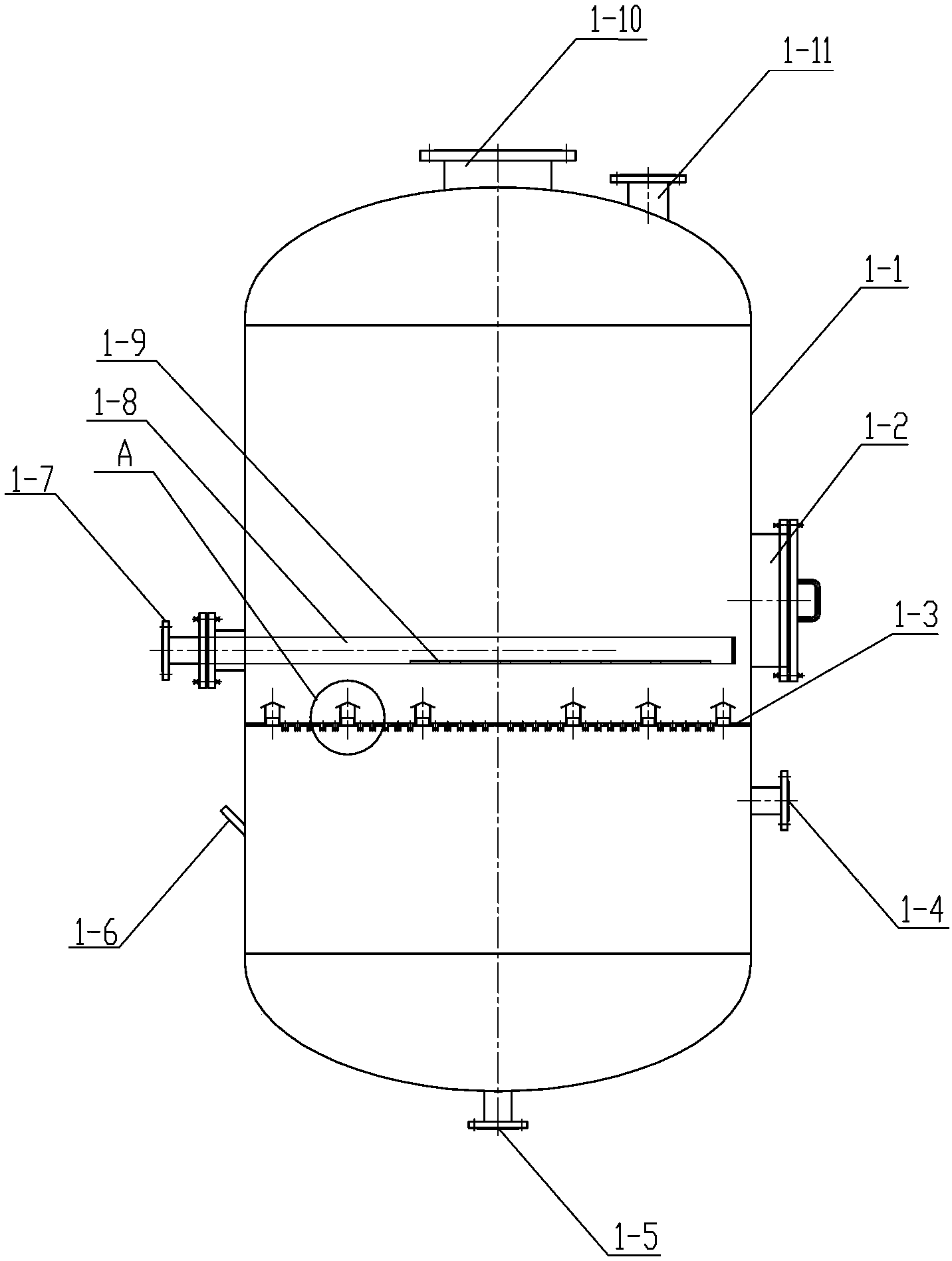

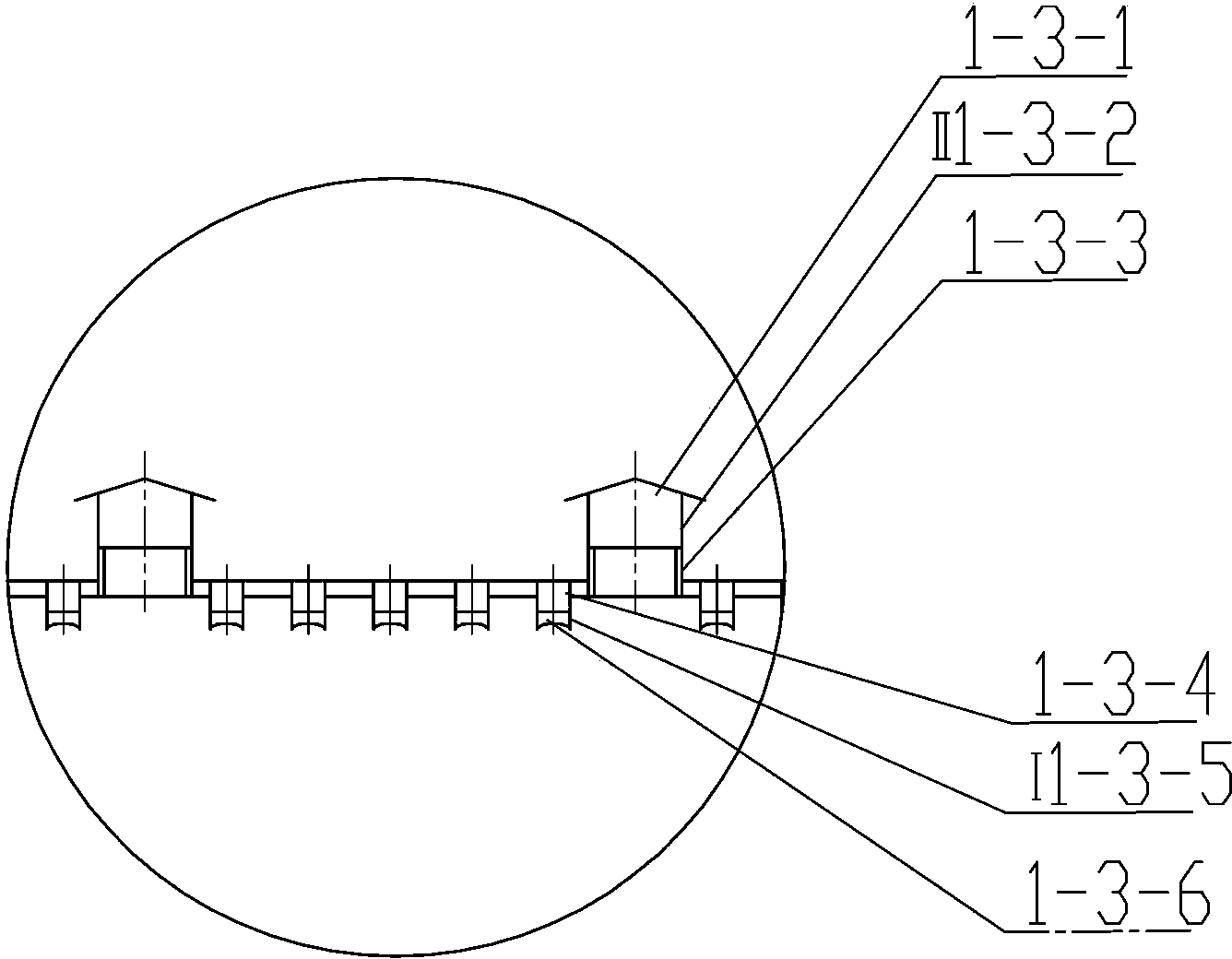

System for producing modified coal tar pitch and preparation method thereof

ActiveCN103756704AReduce consumptionReduce the power requiredWorking-up pitch/asphalt/bitumenTarProcess engineering

The invention relates to a system for producing modified coal tar pitch and a preparation method of the modified coal tar pitch. The method comprises the following steps: feeding mid-temperature pitch from a revaporizer of a tar processing device into modified intermediate pitch processing equipment with a flash oil-gas treatment device through a pipeline, allowing the flash oil and gas generated by flashing through a vacuum flasher to enter heavy oil treatment equipment for performing separation and condensation recycling on heavy wash oil fraction, and feeding the modified intermediate pitch generated by flashing into pitch modification reaction equipment for producing modified coal tar pitch. According to the system and the method, various indexes of the modified coal tar pitch are obviously improved, the energy and power consumption is greatly reduced, and pollutant escape in the whole reaction process is avoided.

Owner:ANSHAN XINGDE ENG TECH

Method for producing low-hydroxyl value high-temperature sulfuration silicon rubber raw rubber

InactiveCN101173045ASolve the problem of poor uniformitySolve uneven heatingDecompositionWeight distribution

The invention relates to the field for producing silicon rubber, in particular to a preparation method of sulfuration silicon rubber crude rubber with low hydroxyl value high temperature. The invention adopts the method that: firstly, all materials are dehydrated before preparation and then the polyreaction is conducted; after the catalyzer loses activity caused by decomposition, the material which can react with a SiOH group is added. The silicon rubber crude rubber prepared by the invention has narrow molecular weight distribution and extremely micro-hydroxy-terminated. The invention also discloses a double-pair screw belt scraping wall type stirrer.

Owner:JIANGSU HONGDA NEW MATERIAL

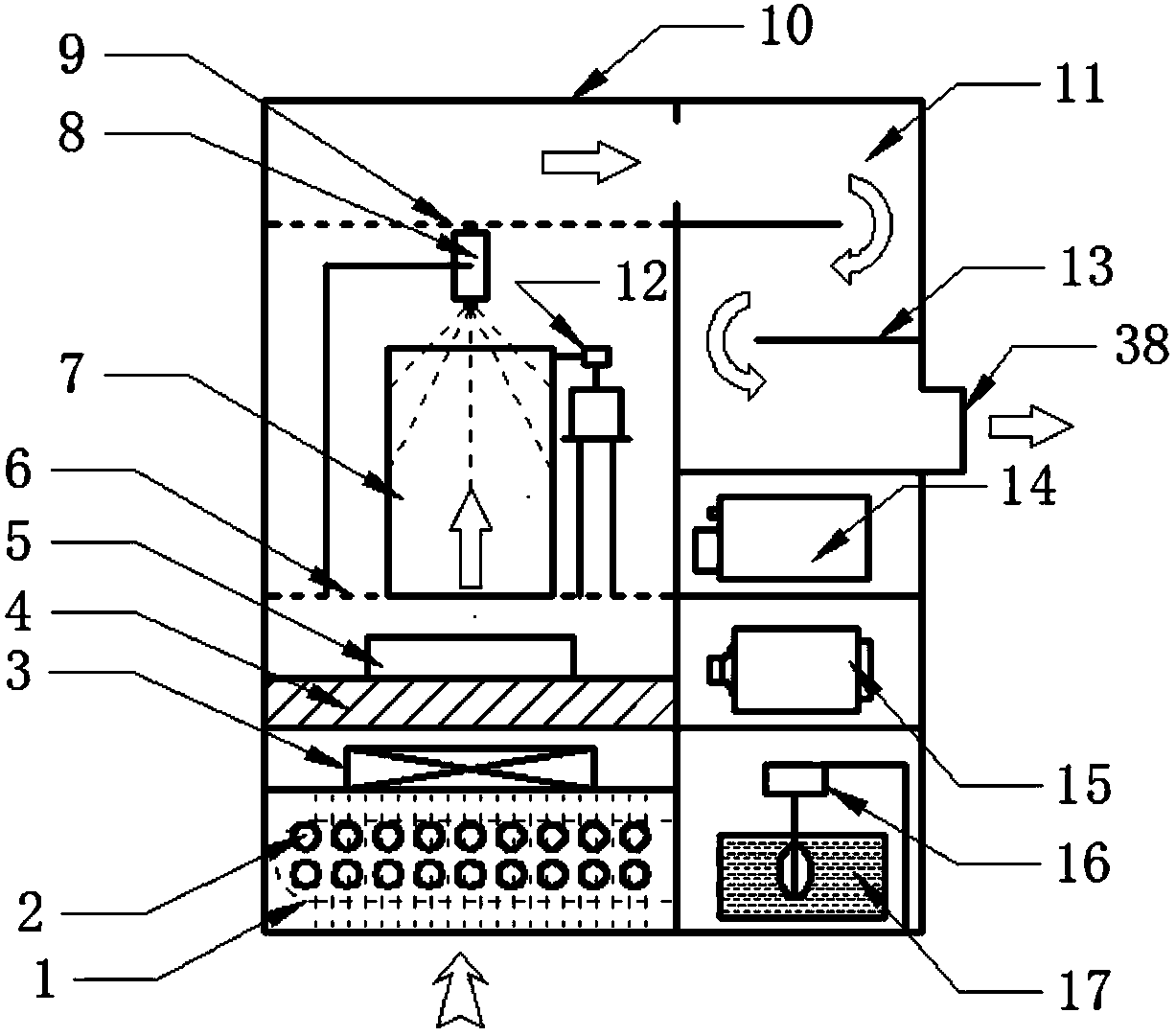

Oil smoke generating device

PendingCN108303358AImprove stabilityOvercome the splash phenomenonStructural/machines measurementParticle suspension analysisExperimental researchControl system

The invention discloses an oil smoke generating device. The device comprises an air temperature and humidity control system, an air purification system, an oil smoke generating system, an automatic cleaning system, a waste liquid recovery system and a cabinet with rectification and mixed flow functions. An oil-water mixing mode, a conveying mode and a heating mode of the oil smoke generating system fundamentally change an oil smoke generating mode. The oil smoke generated by the device has the characteristics of stable smoke generation and high accuracy, can represent real oil smoke and can simulate oil smoke produced in different cooking manners. The generated oil smoke can be used for oil smoke purification product detection and oil smoke detection instrument parameter calibration and asan oil smoke generating source for experimental researches.

Owner:TIANJIN UNIV

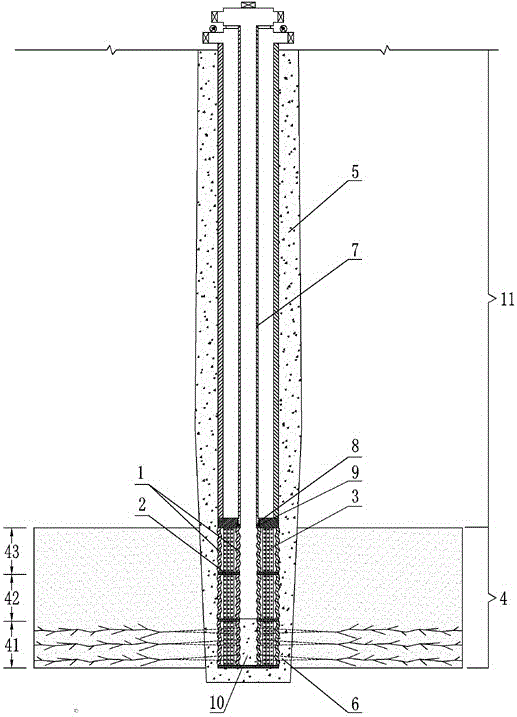

Oil gas slice mining method through in-situ heat injection in oil shale thick ore bed

The invention provides an oil gas slice mining method through in-situ heat injection in an oil shale thick ore bed, relates to an oil shale in-situ heat injection mining technology, and solves the problems of steam supply quantity insufficiency and ore bed heating non-uniformity occurring when a conventional full-thick-section in-situ heat injection mining is used in the oil shale thick ore bed. The method comprises the following steps of 1, connecting a plurality of vacuum corrugated casing pipes by an annular blind plate; winding a heat insulation material in an annular gap formed between two sleeved metal corrugated pipes, and then performing vacuum pumping; putting the component into an oil shale ore bed section in an open hole well; and injecting cement for forming a cement ring; 2, performing lower section perforation; 3, performing lower section hydraulic fracturing; 4, performing lower section steam injection and oil gas mining; 5, performing grouting sealing in the lower section vacuum corrugated casing pipes; and 6, sequentially circulating the step 1 to the step 5, and performing steam injection on other sectional oil shale ore bodies of the ore bed from bottom to top for mining the oil gas. The oil gas slice mining method is used for oil gas mining through in-situ heat injection in the thick and ultra-thick oil shale ore bed, and has the advantages that the steam supply quantity is sufficient; the heating of the thick ore bed is uniform; the heat loss is small; and the oil gas mining rate is high.

Owner:TAIYUAN UNIV OF TECH

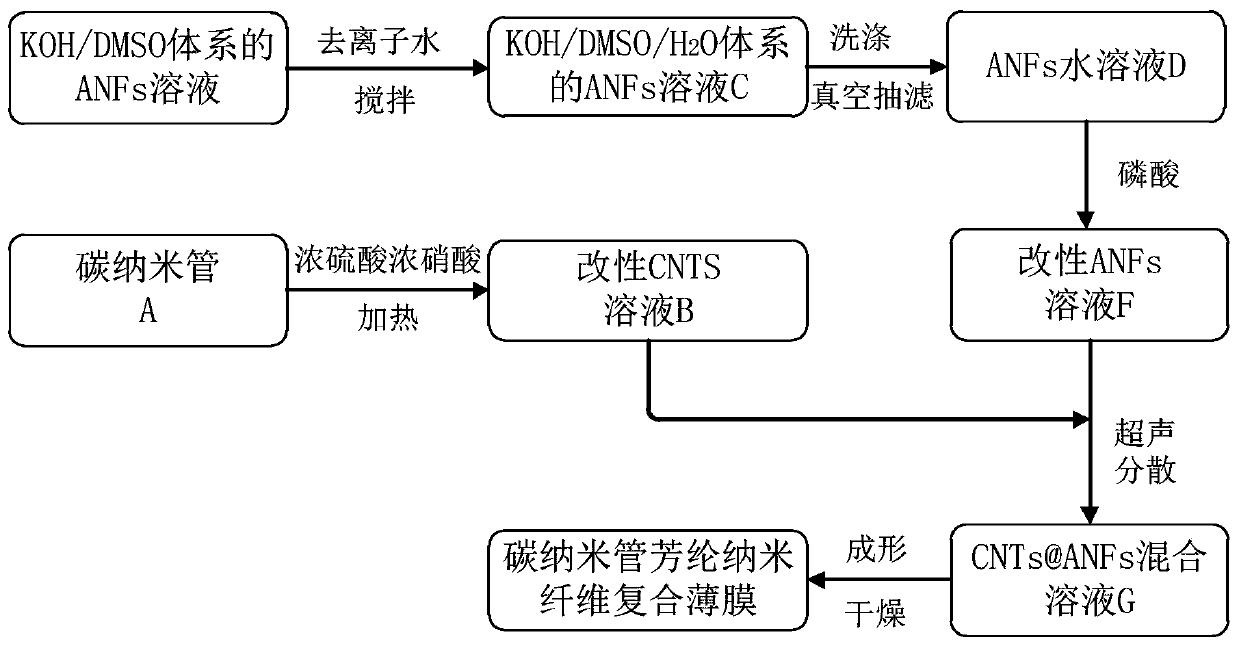

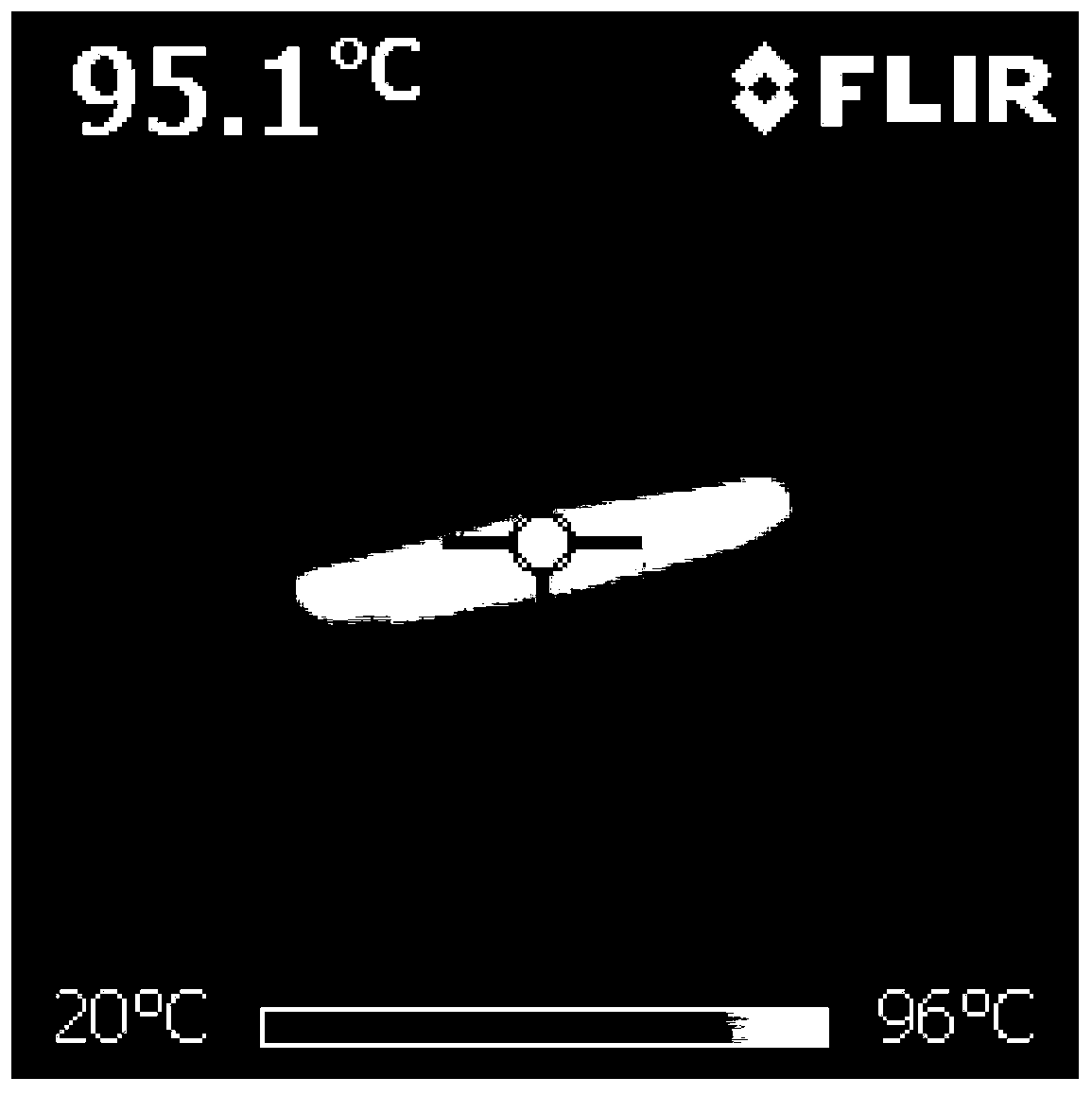

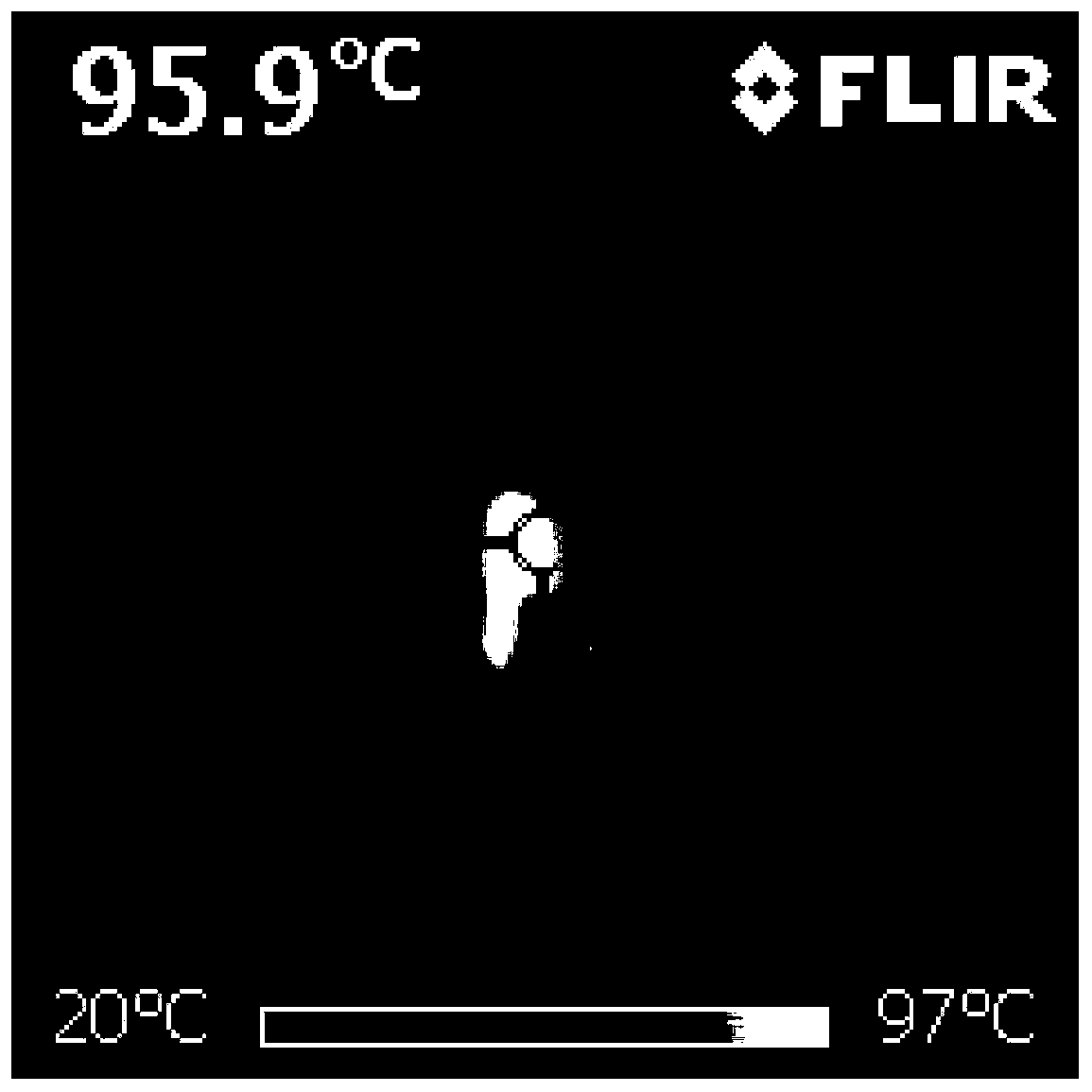

Flexible far infrared heating aramid nano-fiber thin film and preparation method

ActiveCN109763374AEvenly heatedNo hair lossCellulosic pulp after-treatmentNon-fibrous pulp additionScale structureCarbon nanotube

The invention discloses a flexible far infrared heating aramid nano-fiber thin film and a preparation method. The flexible far infrared heating aramid nano-fiber thin film is prepared by uniformly dispersing carbon nanotubes with a nano-scale structure and excellent mechanical properties and electric properties and aramid nano-fibers with excellent mechanical properties, and the film forming performance of the aramid nano-fibers and the advantages that a strong network crosslinking structure is easily generated by abundant functional groups on the surfaces of the aramid nano-fibers are sufficiently expressed; the dispersion performance and film forming performance of the carbon nanotubes are cooperatively improved and an aramid nanocellulose based novel material with flexibility, conductivity and low-temperature far infrared heating performance is developed; the problems of a current flexible heating material that the surface is not uniformly heated, the temperature different is too great, the heating performance is not stable and the service life is relatively low are improved, and the product grade is improved; and the flexible far infrared heating aramid nano-fiber thin film canmeet the requirements of application to electric heating physiotherapy functional clothing, intelligent physiotherapy safety clothing, medical far infrared therapy chambers and the like.

Owner:SHAANXI UNIV OF SCI & TECH

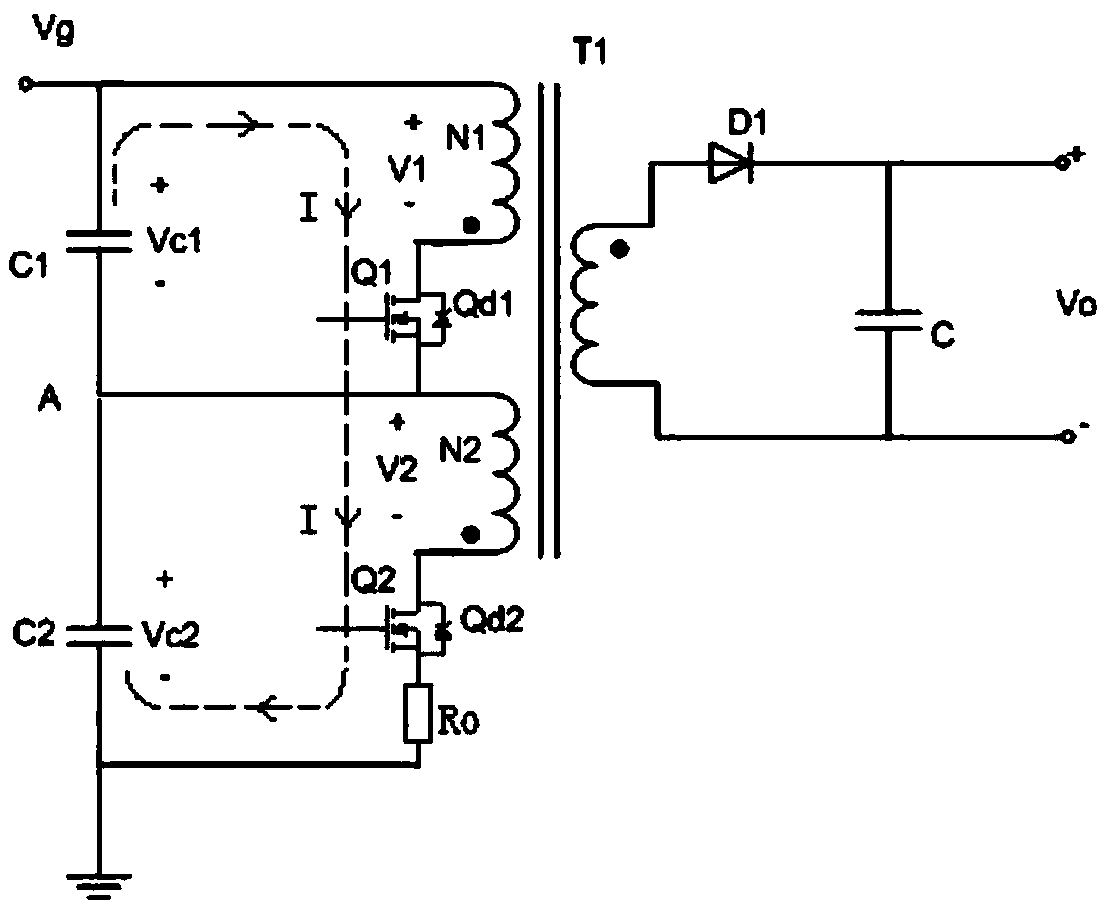

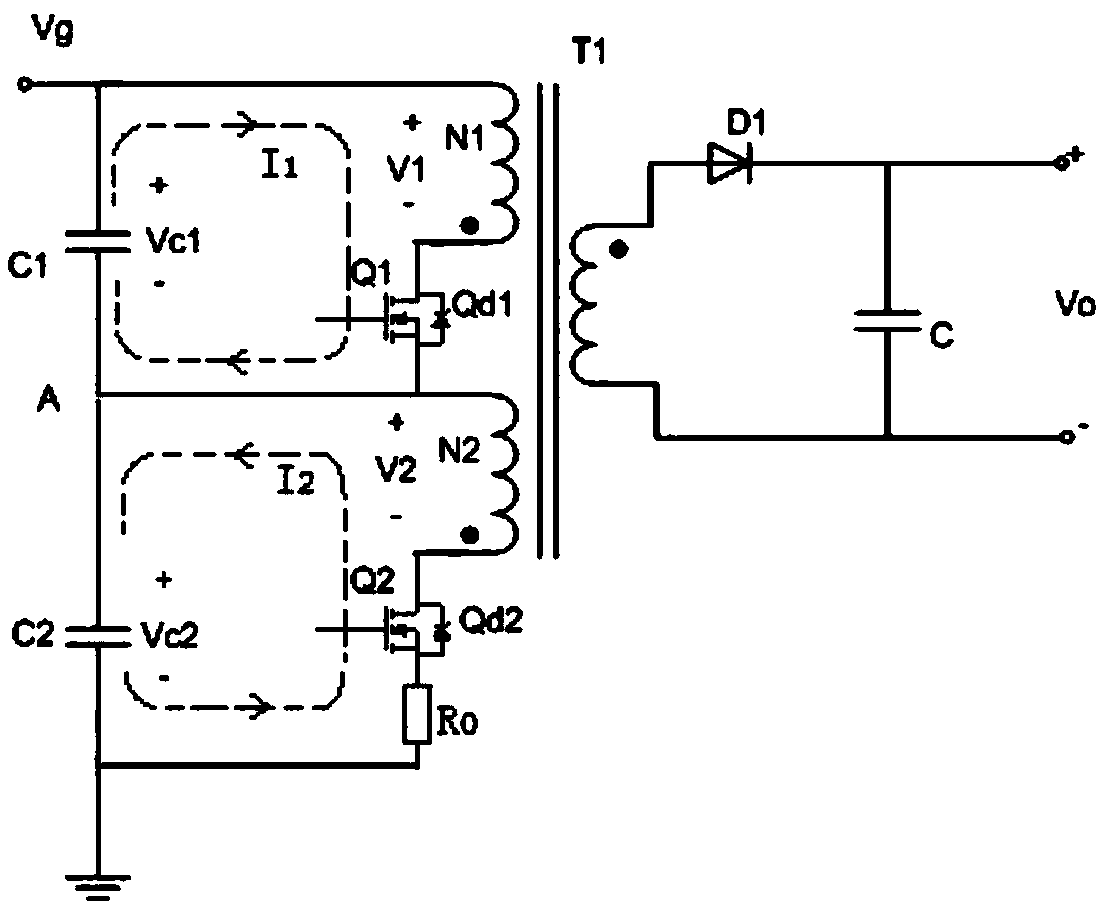

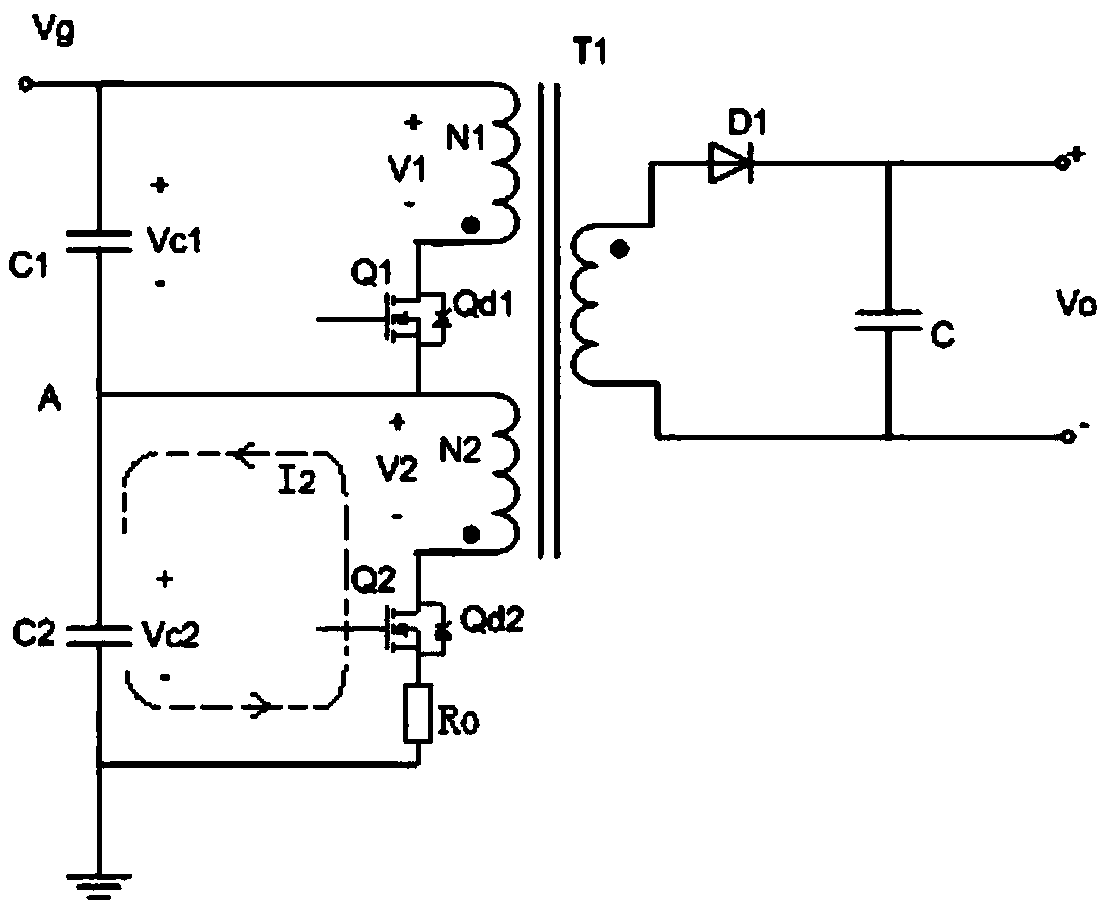

High withstand voltage flyback convert

PendingCN109004838ASolve the problem of large differences in product batch flow pointsSolve the problem of large differences in batch flow pointsDc-dc conversionElectric variable regulationCapacitanceEngineering

A high withstand voltage flyback converter circuit provided by the invention includes at least two identical power converter primary winding units and voltage sharing capacitors, each stage of the primary winding unit is composed of the same primary winding, A switch transistor for controlling that on / off of the primary win and the same compensation circuit are formed, one end of the primary winding is used as the input end of the primary winding unit, the other end of the primary winding is used as the output end of the primary winding unit through the conductive inflow end of the switch tubeto the conductive outflow end of the switch tube, and the other end of the compensation circuit is used as the output end of the primary winding unit through the compensation circuit; The control terminal of each switch is provided with a synchronous driving signal, and the other end of each synchronous driving signal is connected to the output terminal of the primary winding unit, and all the primary windings are controlled in the same phase and share a magnetic core. Each primary winding unit is connected in series with each other, and each voltage equalizing capacitor is connected in series with each other. The series point of each primary winding unit is connected with the voltage-sharing series point of each voltage-sharing capacitor to form a corresponding loop.

Owner:MORNSUN GUANGZHOU SCI & TECH

High-temperature fuel cell system and operating method thereof

ActiveCN108232247AImprove consistencyAvoid uneven heatingFuel cell heat exchangeFuel cell controlFuel cellsHeat conducting

The invention provides a high-temperature fuel cell system and an operating method thereof. The high-temperature fuel cell system comprises a high-temperature fuel cell pile and a heat conducting oilpre-heater; a first heat conducting oil flowing channel with an inlet and an outlet is formed in the heat conducting oil pre-heater; a second heat conducting oil flowing channel is formed in a single-cell bipolar plate; a closed heat conducting oil loop is formed after the first heat conducting oil flowing channel communicates with the second heat conducting oil flowing channel; a fluid flowing driving part and a flow adjusting part are arranged on the closed heat conducting oil loop. The operating method comprises the following steps: heating the heat conducting oil pre-heater through a firstheating device; heating the high-temperature fuel cell pile through heated heat conducting oil; detecting the temperature of the high-temperature fuel cell pile in real time through a pile temperature detecting part; when the temperature of the pile reaches a preset value T1, starting the high-temperature fuel cell pile. According to the high-temperature fuel cell system and the operating methodthereof, the problem of non-uniform heating caused by electric heating during a starting process of a fuel cell can be solved effectively.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

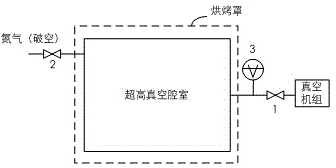

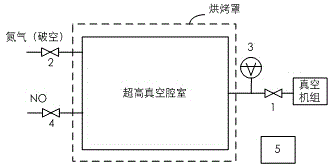

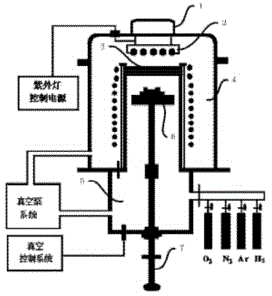

Cleaning apparatus and method for ultrahigh vacuum chamber

ActiveCN105575767ASolve uneven heatingSolve the problem of long degassing timeSemiconductor/solid-state device manufacturingUltra-high vacuumUltraviolet lights

The invention relates to a cleaning apparatus and method for an ultrahigh vacuum chamber. The cleaning apparatus comprises an ultraviolet light source, a control device, a vacuum pump system and a cleaning gas source. The cleaning apparatus is characterized in that the cleaning apparatus further comprises a quadrupole mass spectrograph used for testing the partial pressure of pollutants in the chamber, a vacuum gauge used for performing real-time monitoring on vacuum degree in the chamber, a pressure intensity control instrument, a fine adjustment valve, a cold plate and a temperature control unit; the pressure intensity control instrument controls the opening degree of the fine adjustment valve and accurately controls the partial pressure of a cleaning gas in the vacuum cleaning chamber; circulating water is led into the cold plate, so that the temperature of the outer wall of the chamber can be controlled through water temperature; and the temperature control unit provides circulating water with stable temperature. The invention also discloses a cleaning method for an ultrahigh vacuum chamber.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

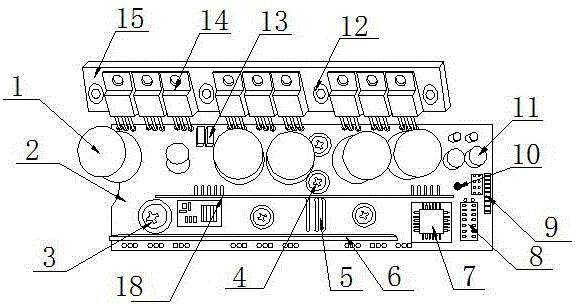

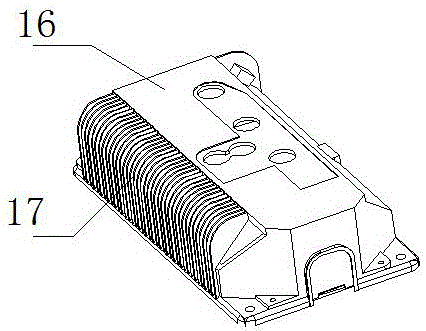

Power controller based on die-casting mould structure

InactiveCN106659038AImprove cooling effectImprove performanceCircuit arrangements on support structuresHermetically-sealed casingsPower controllerBridge type

The invention discloses a power controller based on a die-casting mould structure. The power controller comprises a large-current filtering element, a main PCB, a three-phase motor output terminal, a power input terminal, a current detection element, a bus bar, a master control MCU, a signal input filtering module, a wiring terminal, an indicating lamp, an auxiliary power supply discrete element, an elliptical positioning hole, an upper and lower bridge separation driver, a power switch tube, an aluminum substrate, an aluminum housing, heat dissipation teeth and a bridging type crossover auxiliary PCB. According to the technical scheme of the power controller in the invention, a double-row aluminum substrate and an aluminum shell are connected to improve heat dissipation effect, so that the thermal damage to the switch tube is reduced. Based on the bridging manner of PCBs, the current uniformity of power switch tubes connected in parallel is guaranteed to the greatest extent. Meanwhile, the large-current impact resistance of the entire circuit is improved. The power input terminal and three output terminals (U, V and W) are led out in the casting mode by using a copper column and the aluminum shell of a die-casting mould. Therefore, the problem that water flows into the incoming and outgoing lines and the structure of a common controller in the prior art can be solved.

Owner:刘军

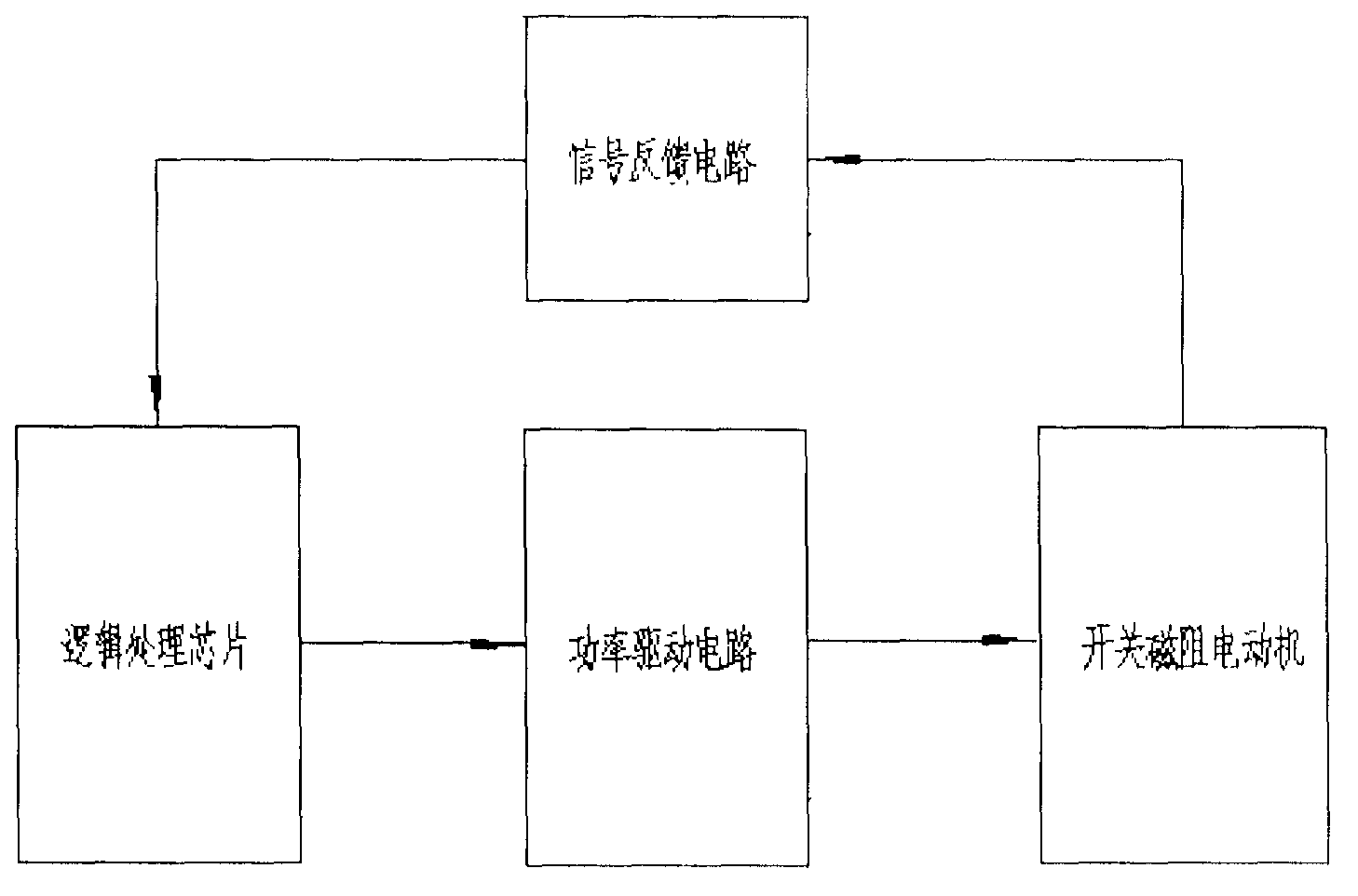

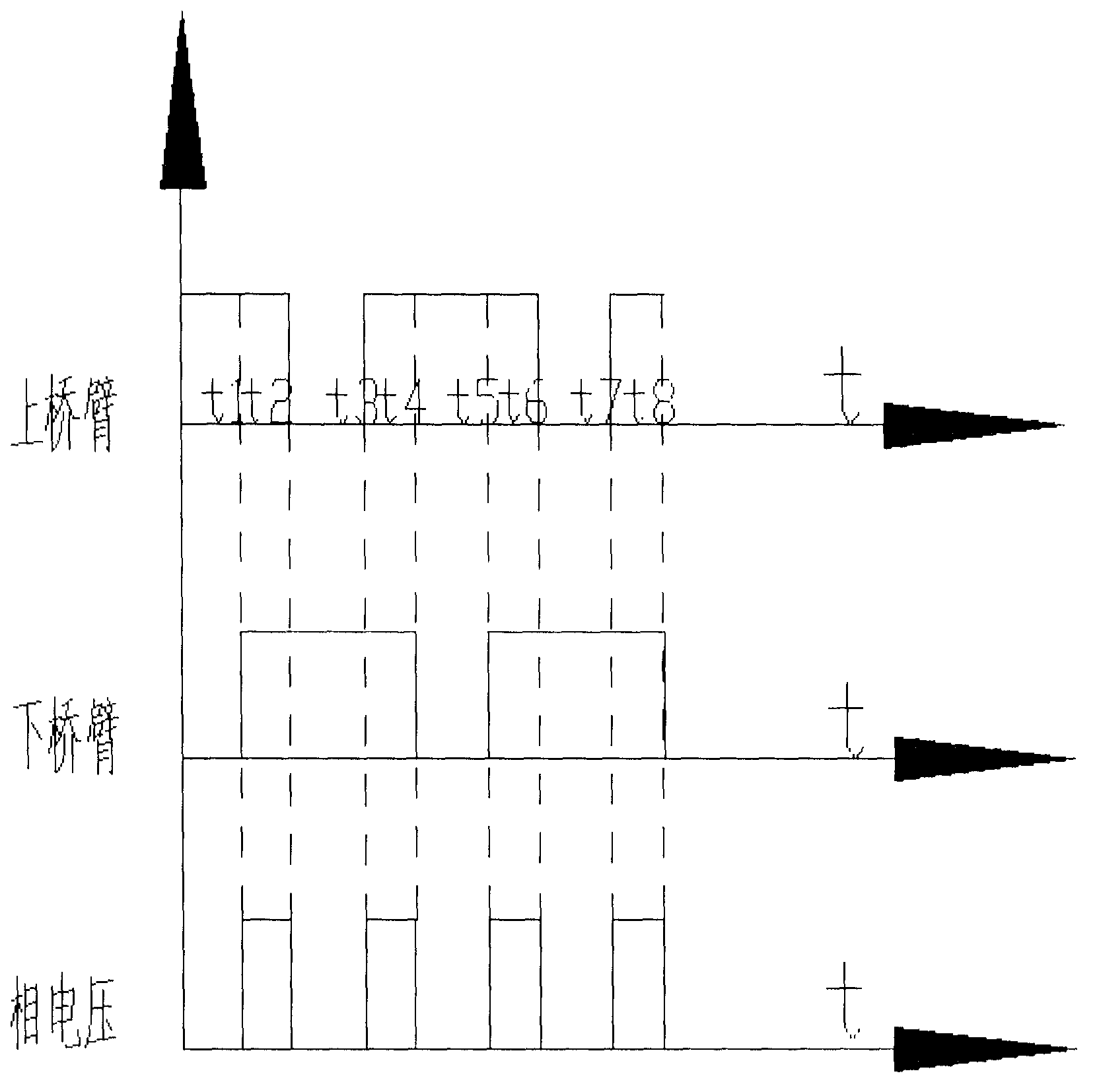

Method for logically controlling combined chopped waves of power switch devices of switched reluctance motor

InactiveCN103840719ASolve uneven heatingBalance the frequency of useElectronic commutation motor controlBridge typeElectric machine

The invention discloses a method for logically controlling combined chopped waves of power switch devices of a switched reluctance motor. A combined chopped wave logical control circuit adopted in the method comprises a signal feedback circuit, a logical processing chip and a power drive circuit, wherein the logical processing chip and the power drive circuit are connected in sequence. A power switch tube set in the power drive circuit is of an asymmetric bridge type topological circuit structure. Each phase is of a structure of an upper bridge arm and a lower bridge arm, wherein the structure is composed of two power switch tubes, two diodes and a motor winding in series connection. When the current of the switched reluctance motor is increased, the power switch tubes of the upper bridge arm and the lower bridge arm are switched on simultaneously; when the current is reduced, one power switch tube is switched off and the other power switch tube is switched on. According to the method for logically controlling the combined chopped waves of the power switch devices of the switched reluctance motor, consumption of a switch is evenly distributed to the two switch devices on one phase, the use frequency of the switch devices is balanced, so that the problem that the power switch devices emit heat unevenly is solved, the switching stress of the power switch devices is reduced, and the service life of the power switch tubes is prolonged.

Owner:浙江仕迈电机有限公司

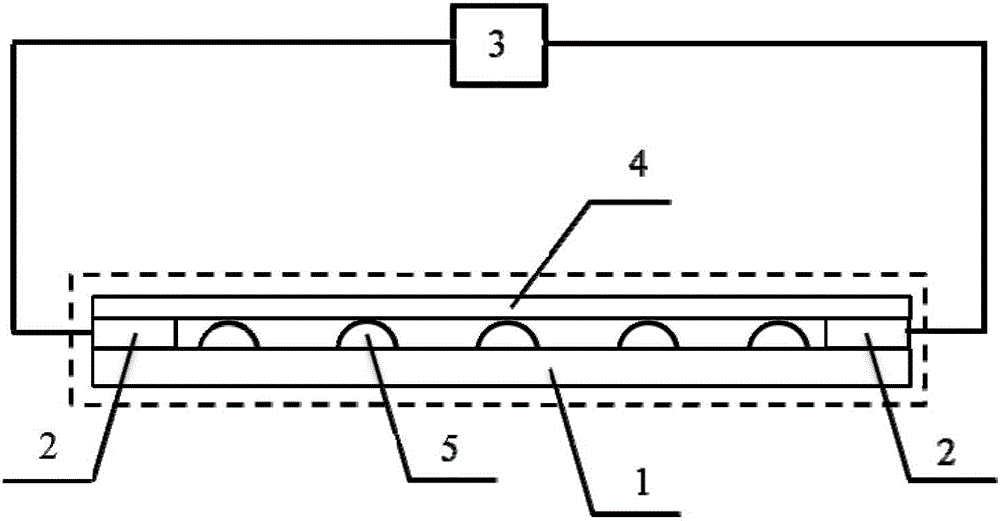

Hot-stamping device of optical waveguide

ActiveCN103158252ASmooth demouldingImprove Hot Embossing QualityOptical articlesTemperature controlHot stamping

The invention discloses a hot-stamping device of optical waveguide. The hot-stamping device is characterized in that a cover plate is arranged at the top of a hot-stamping cavity body; the hot-stamping cavity body is fixedly arranged above a sample platform and is internally provided with a working cavity which is internally provided with a high-temperature-resistant film layer; the film layer divides the working cavity into a pressure cavity and a vacuum cavity; the pressure cavity is positioned above the vacuum cavity and is connected with a pneumatic boosting device by a gas pipeline; a mold is placed on a platform surface of the sample platform and is positioned in the vacuum cavity; a heating device with a temperature control system is arranged below the sample platform; a gap is reserved between the sample platform and the heating device; the sample platform is internally provided with a heat buffering cavity; the vacuum cavity is communicated with the heat buffering cavity; and one side of the heat buffering cavity is connected with a cooling device, and the other side of the heat buffering cavity is connected with a vacuumizing device. The hot-stamping device disclosed by the invention has the advantages that the temperature, cooling and pressure of hot stamping can be controlled, the hot-stamping sample is heated uniformly, the demolding is smooth after hot stamping, and the hot-stamping quality of the optical waveguide can be greatly improved.

Owner:NINGBO UNIV

Toilet seat and preparation method

InactiveCN108354502AImprove sealingImprove thermal conductivityBathroom coversHeat conductingCasting mold

The invention discloses a toilet seat and a preparation method. The toilet seat includes a heating unit and a wrapping body; the wrapping body wraps the heating unit through a casting molding process.The toilet seat has the advantages that by means of the toilet seat, the heating unit of the toilet seat is sealed in a toilet seat body to form the integrated toilet seat, not only is the sealing effect great, the safety is high, but also the process is simple, the heat conducting performance is better, and more energy is saved. The invention also provides the preparation method for preparing the toilet seat.

Owner:JOMOO KITCHEN & BATHROOM

Graphene electric heating fabric provided with magnet

PendingCN106714344AImprove conductivityFast conductivityElectrotherapyOhmic-resistance waterproof/air-tight sealsElectricityFiber

The invention provides a graphene electric heating fabric provided with a magnet. The graphene electric heating fabric comprises at least a graphene fabric body, two electrodes, at least a power supply connecting member, a plurality of permanent magnets, and at least an insulation waterproof layer. The graphene fabric body is formed by graphene fibers. The two electrodes are fixedly disposed on the graphene fabric body, and are connected with the power supply connecting member. The surface of the graphene fabric body is fixedly provided with the plurality of permanent magnets, and the insulation waterproof layer is disposed on the outer surface of the graphene fabric body and the outer surfaces of the electrodes in a covered manner. Compared with the prior art, the graphene electric heating fabric provided with the magnet has advantages of antibiotic and bacteriostatic effect, far-infrared health care warm-keeping effect, magnetotherapy, light weight, good flexibility, uniform heating, high heating efficiency, small energy consumption, recyclability, comfortable touch feeling, and good service performance.

Owner:靖江墨烯服饰科技有限公司

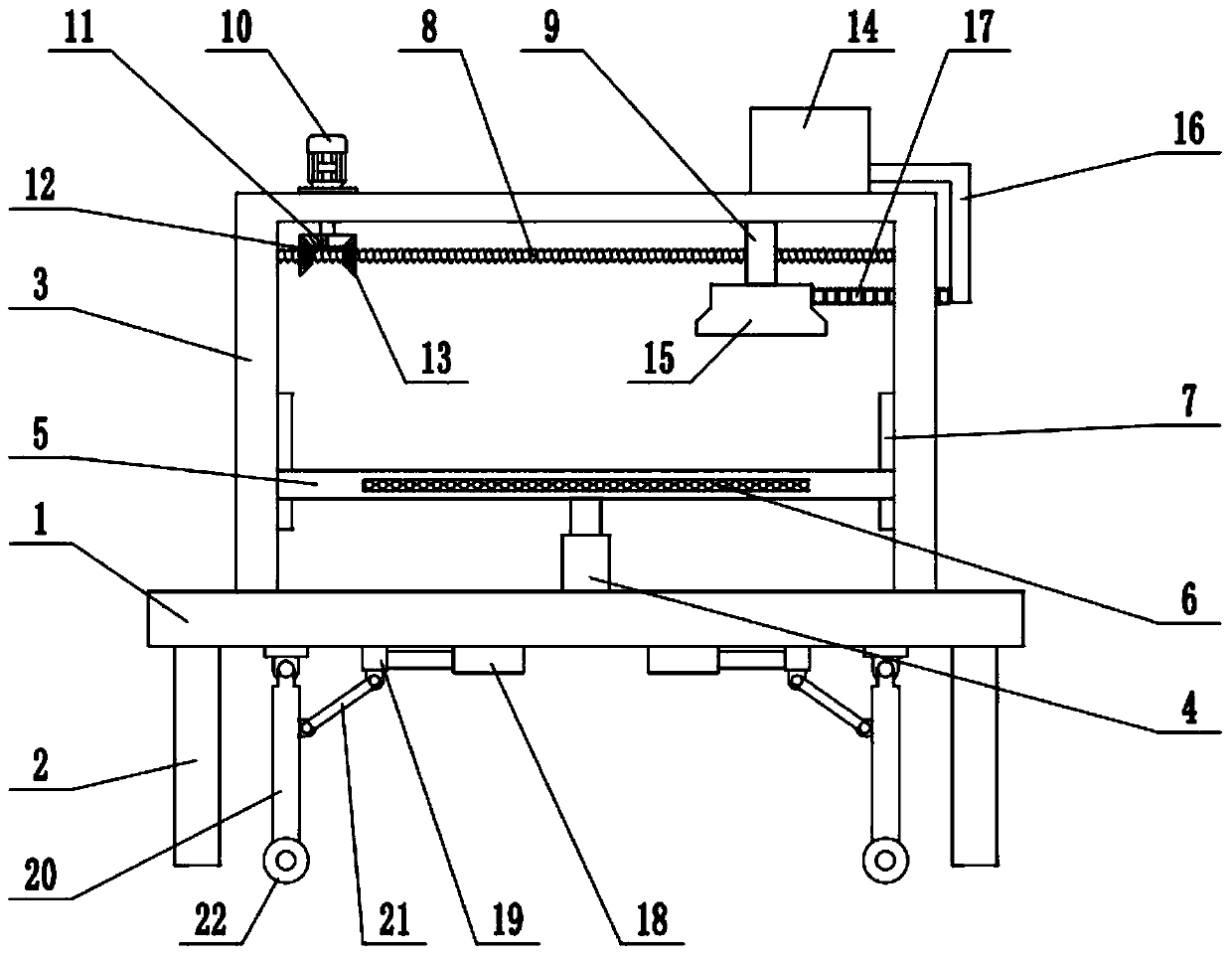

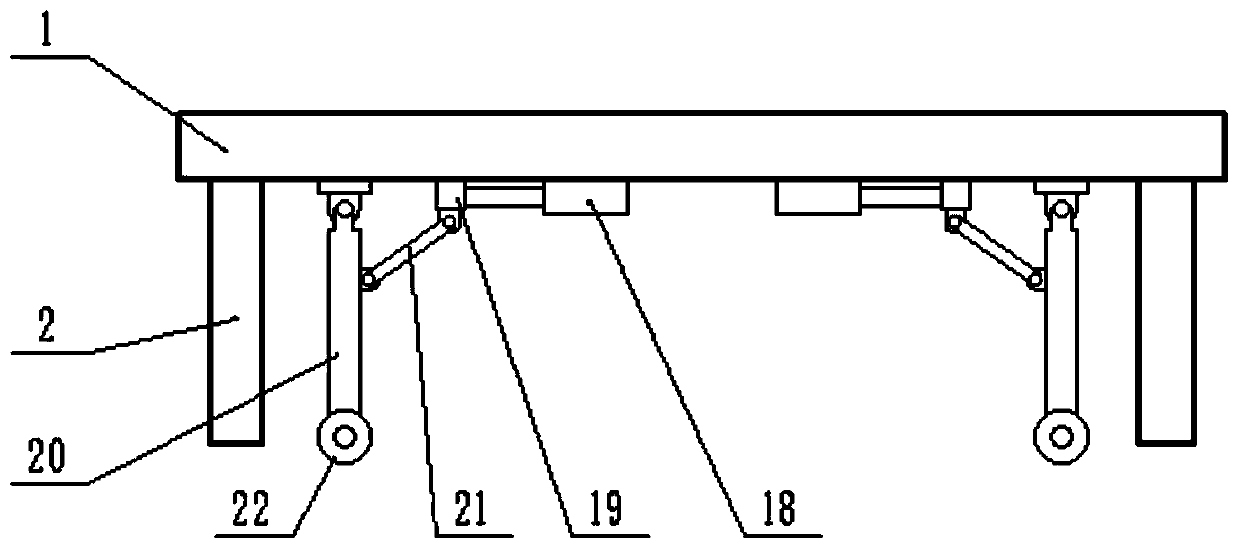

Rapid drying device for printed matter

InactiveCN111391501AEvenly heatedImprove drying efficiencyPrinting press partsPhysicsElectric heating

The invention relates to the field of drying equipment, in particular to a rapid drying device for printed matter. The rapid drying device comprises a workbench, a drying plate, an air heater and an air outlet, wherein supporting legs are arranged on the lower surface of the workbench, a drying oven body is fixedly connected to the upper surface of the workbench, and a telescopic mechanism is fixedly connected to the upper surface of the workbench; the drying plate is fixedly connected to the top end of the telescopic mechanism, a lead screw is arranged above the drying plate, and the left endand the right end of the lead screw are rotationally connected with the side wall of the drying oven body; and the lead screw is provided with a sliding block in a sleeved mode, and the air outlet isfixedly connected to the lower surface of the sliding block. The lower surface of the printed matter is heated through an electric heating plate, the printed matter on the drying plate is dried through the air heater, and in the drying process, the air outlet moves left and right, so that the printed matter is heated more evenly; and the device can dry the upper surface and the lower surface of the printed matter at the same time, and solves the problem that the printed matter is not heated evenly enough in the drying process through existing printed matter drying equipment.

Owner:李明辉

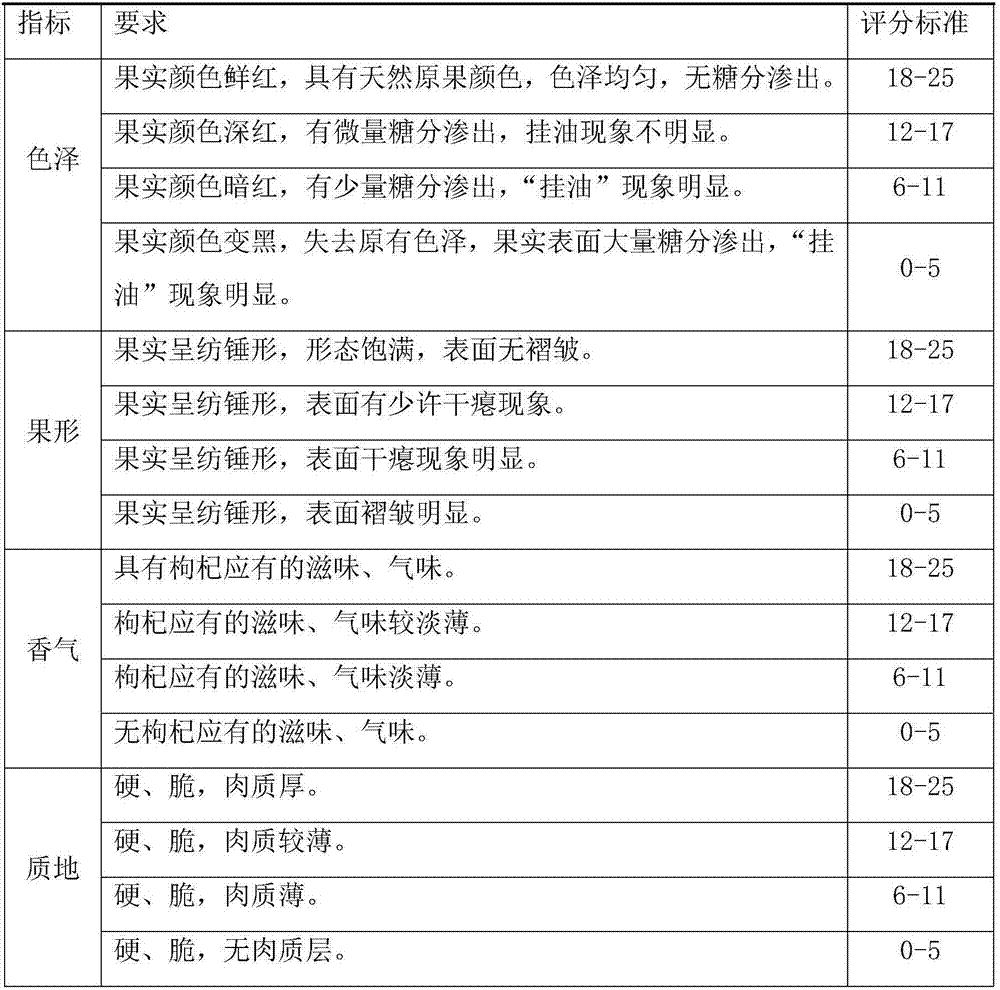

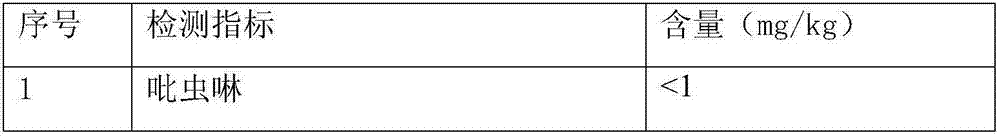

Microwave vacuum drying method of Chinese wolfberry fruits

InactiveCN107361125ASolve uneven heatingInhibitory activityFruits/vegetable preservation by irradiation/electric treatmentFood dryingBiotechnologyProcess engineering

The invention relates to the technical field of food processing, in particular to a microwave vacuum drying method of Chinese wolfberry fruits. The microwave vacuum drying method of the Chinese wolfberry fruits comprises the following steps of performing sorting, performing automatic sorting, removing peach stems, performing sterilization and enzyme deactivation treatment on fresh Chinese wolfberry fruits with high-pressure water mist under a high pressure pulse electric field, performing microwave vacuum predrying, performing microwave vacuum drying and performing nitrogen-filled packaging. Segmented-type microwave vacuum drying is particularly adopted and combined with timely disk inversion, so that the drying time of the Chinese wolfberry fruits is effectively shortened, the dried Chinese wolfberry fruits are bright red in color, plump in shape, crisp in mouth feel, easy to chew, safe and hygienic.

Owner:NINGXIA UNIVERSITY

Fire barrel type gas burner

InactiveCN102494341AGuaranteed uniformitySolve the uneven heating of the furnaceGaseous fuel burnerRam-air intakeCombustion chamber

Aiming to solve the problems that a hearth of gas-fired heat power equipment is not uniformly heated, the local heating surface of the hearth is overheated and subjected to burning loss, and the like, the invention provides a fire barrel type gas burner, which can be structurally divided into two parts, including an air intake and distribution device at the front part and a tubular combustion chamber at the rear part, wherein the air intake and distribution device at the front part includes a center combustion air passage, an annular fuel gas passage and an injection air passage which are coaxial and arranged sequentially from inside to outside; and the tubular combustion chamber at the rear part is a steel barrel provided with an opened tail part on the whole. The fire barrel type gas burner has the advantages that the center combustion air introduced in a forced manner improves the ability of the gas-fired equipment in jetting the outside air, and the overall excess air factor of the gas-fired equipment can be controlled through adjusting the combustion air introduced from the center in a forced manner; and the shape of the gas flame can be effectively controlled through the length and the pipe diameter of the tubular combustion chamber, so that the tubular combustion chamber is reasonably matched with the hearth space, and the problems that the hearth is not uniformly heated, the local part of the hearth is overheated and subjected to burning loss and the like are solved.

Owner:HARBIN INST OF TECH

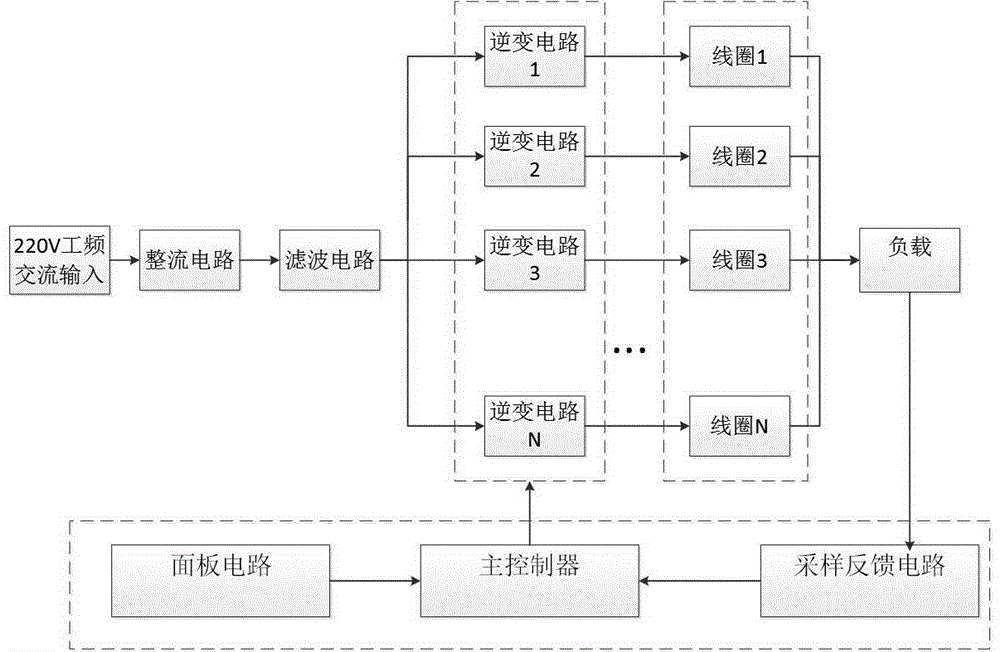

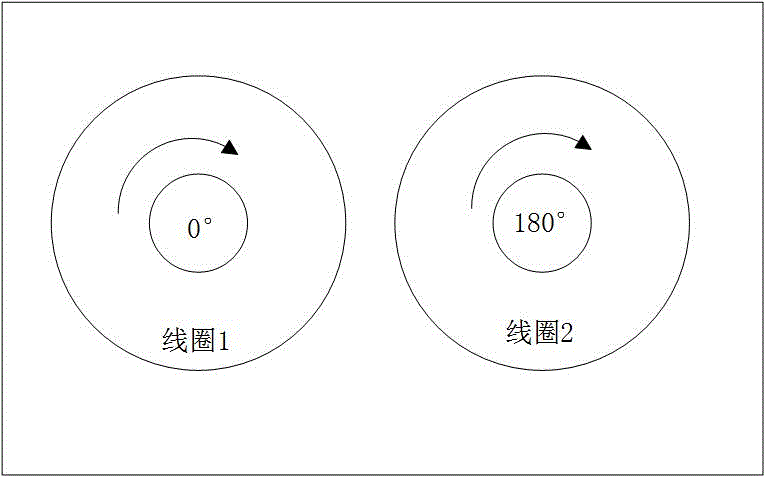

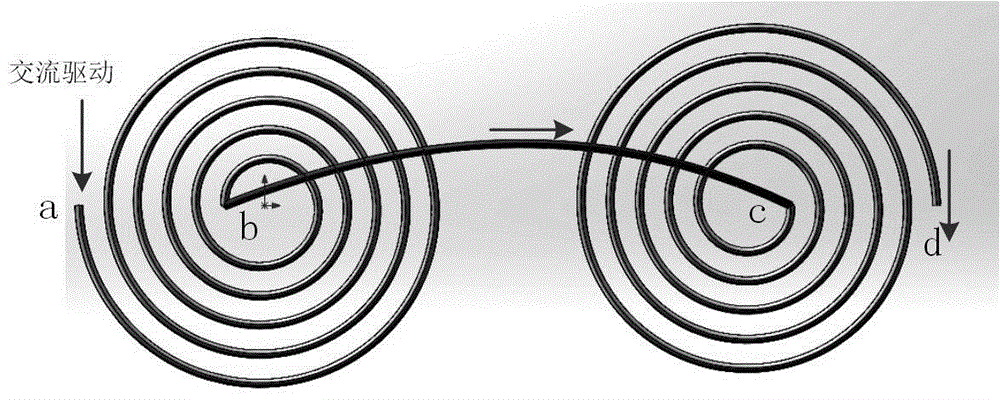

Induction heating equipment with multi-phase multiple coils, and method for induction heating equipment

ActiveCN106102199AImprove machine efficiencyExtend your lifeInduction heating controlMagnetic coreIntegrated circuit

The invention relates to induction heating equipment with multi-phase multiple coils and a method for the induction heating equipment. The induction heating equipment comprises a main circuit, a control circuit, N coils, and magnetic cores, wherein N is a positive integer which is greater than or equal to 2; the main circuit comprises a rectifier circuit, a filter circuit and N inverter circuits; the control circuit comprises a main controller and a panel circuit which is connected with the main controller; the input end of the rectifier circuit is connected to a 200V power-frequency alternating current power supply; the output end of the rectifier circuit is connected to the N inverter circuits through the filter circuit; the N inverter circuits are correspondingly connected with the N coils; and the magnetic cores are arranged below the corresponding coils. By adoption of the induction heating equipment, the efficiency of electromagnetic heating equipment can be increased; and the temperature balance can be improved.

Owner:FUZHOU UNIVERSITY

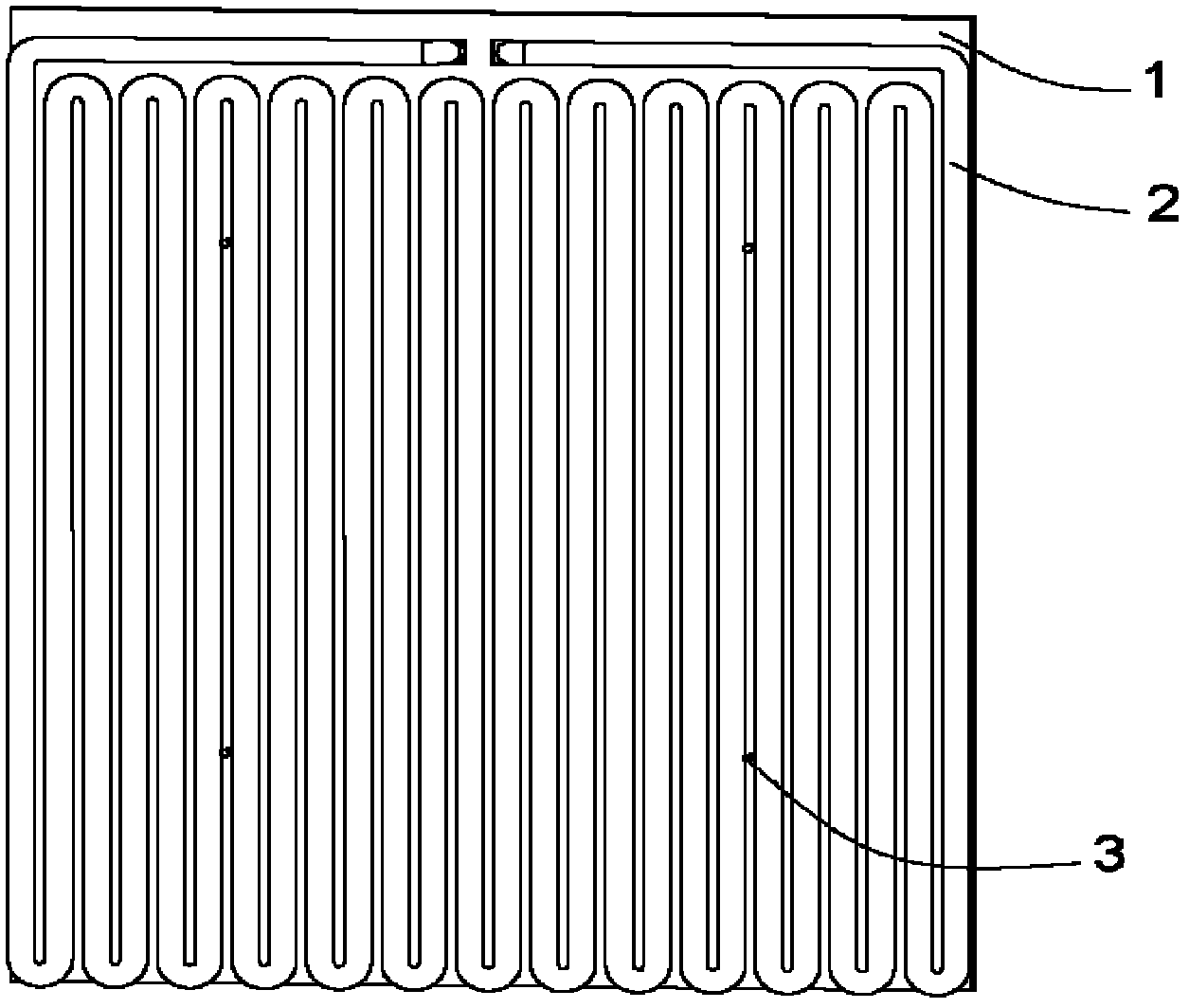

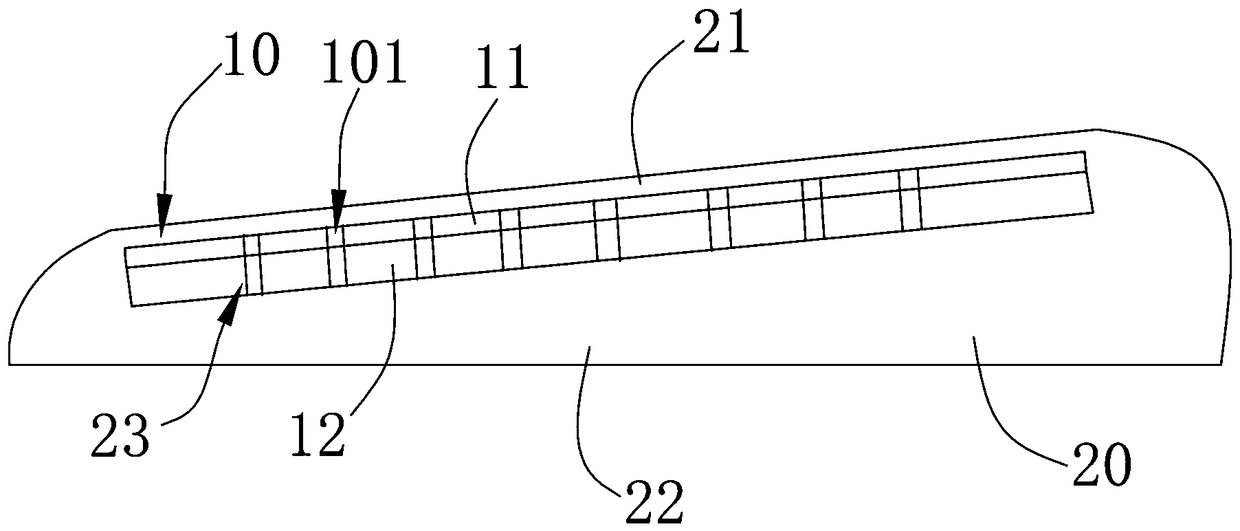

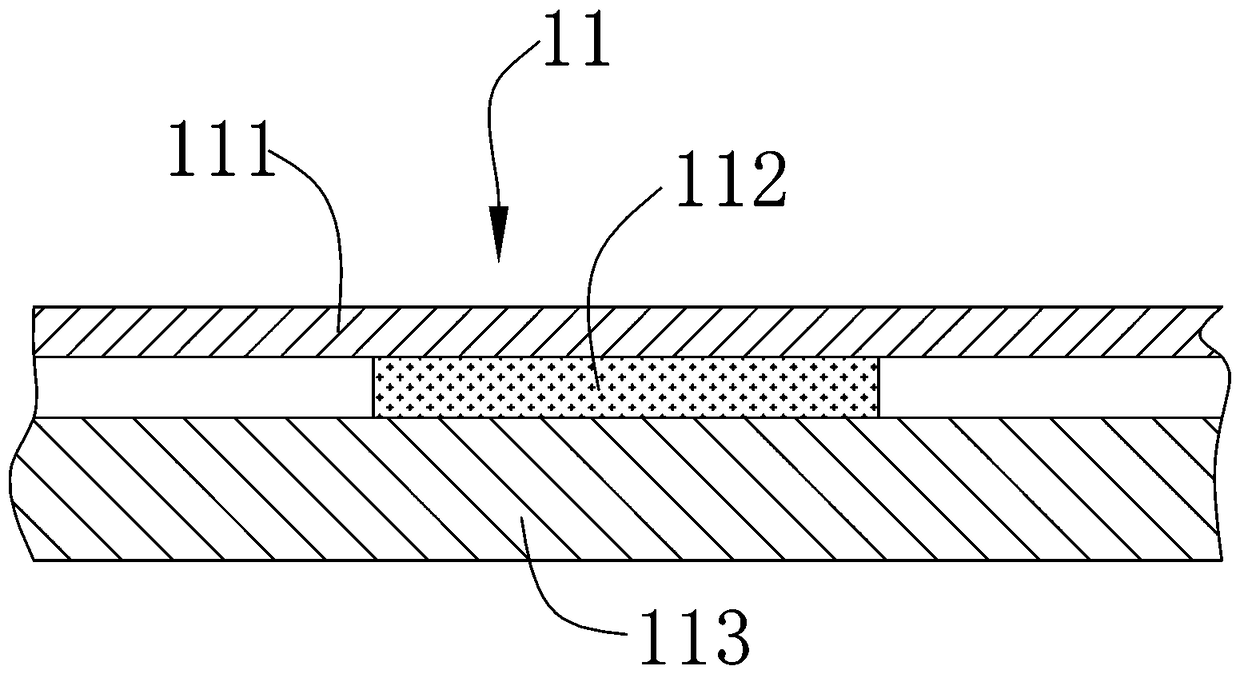

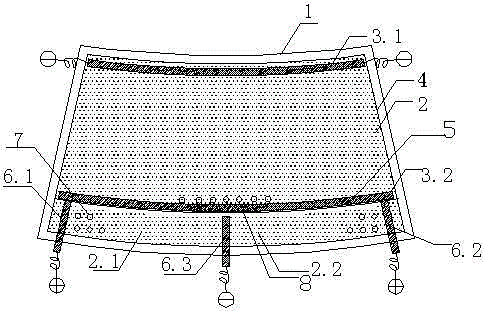

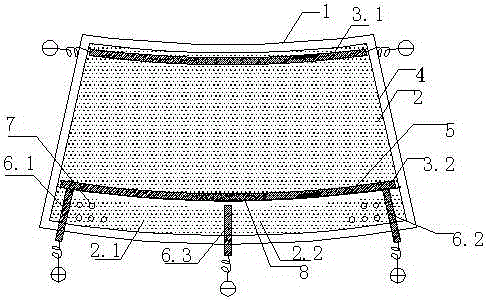

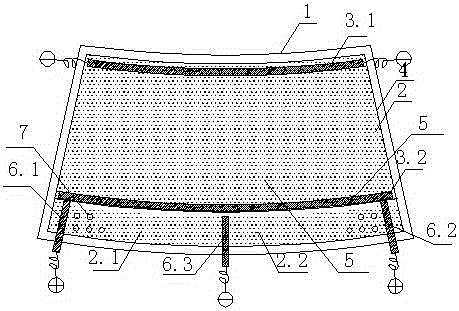

Vehicle laminated glass with low-resistance region in heating region

InactiveCN105329213ASolve uneven heatingReduced risk of burnoutVehicle cleaningWindscreen wiperElectrically conductive

Provided is a vehicle laminated glass with low-resistance regions in a heating region. The peripheral edges of an electrothermal film (2) on a glass substrate (1) are provided with edge non-conductive regions. The electrothermal film (2) is provided with an upper bus (3.1) and a lower bus (3.2). The lower bus (3.2) divides the electrothermal film (2) into a primary vision heating region and a windscreen wiper rest position heating region (2.1). The windscreen wiper rest position heating region (2.1) is provided with a plurality of low-resistance regions. Each low-resistance region is formed by a plurality of low-resistance assemblies (7). The resistance of the low-resistance assemblies is smaller than the resistance of the electrothermal film. Technical effects of the glass are that through arranging the low-resistance regions, a problem of nonuniform heating of arc glass is solved, and risks that a windscreen wiper motor is burnt down are reduced. A segment of mesh bus is arranged on the lower bus, heating power distribution positions can be optimized and defrosting and deicing performance is improved.

Owner:FUJIAN WANDA AUTOMOBILE GLASS IND

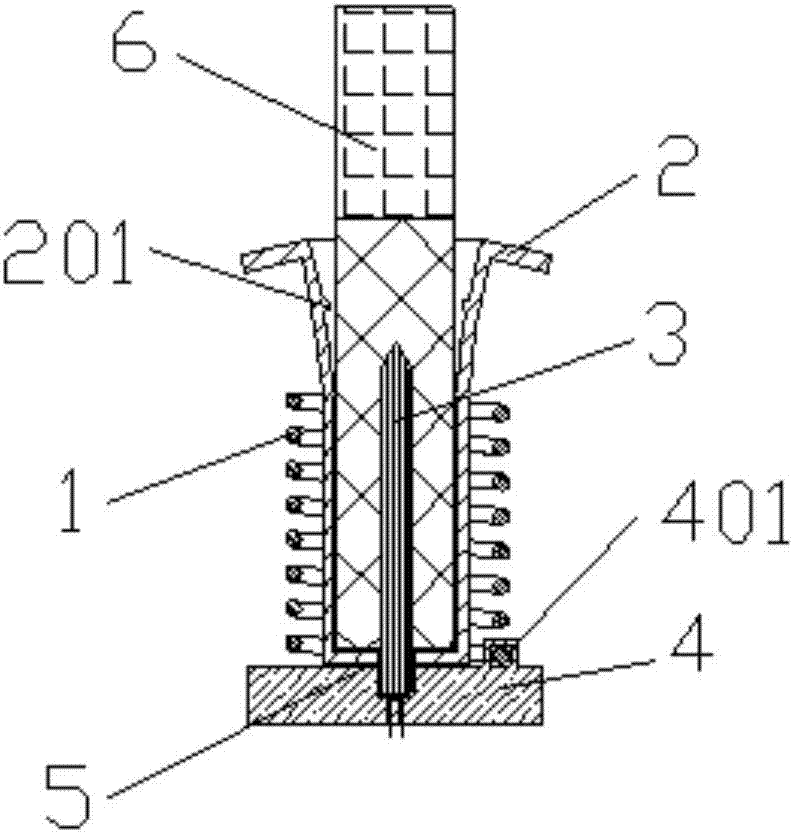

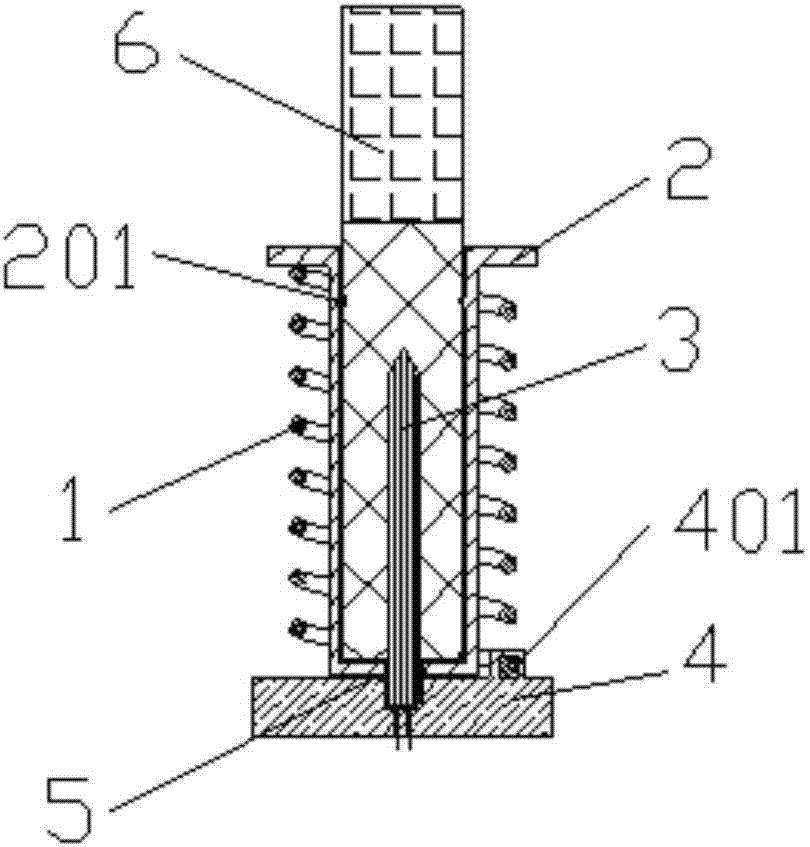

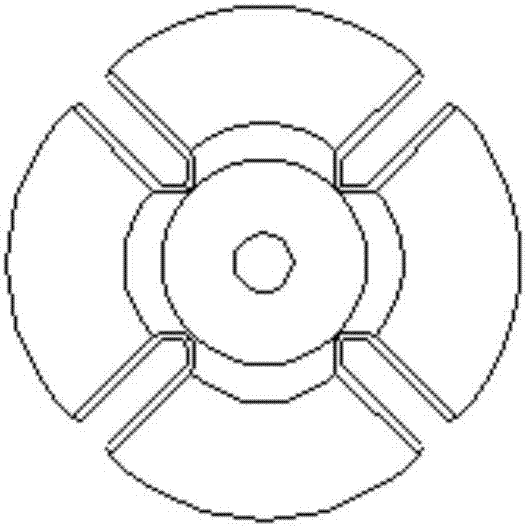

Intelligent cigarette heating cavity part device

The invention discloses an intelligent cigarette heating cavity part device. The device comprises a heating cavity part and an intelligent spring, and the heating cavity part is placed in an internal space of the intelligent spring; the heating cavity part comprises a heating piece which is flat and is located in the geometric center of the inner space of the heating cavity part and a heating cavity part base which is provided with an air vent facilitating circulation of an airway in the cigarette suction process and a buckle used for fixing the bottom of the intelligent spring, and a circuit port is reserved in a small hole to be used for connecting the heating piece with the intelligent spring; the heating cavity part is integrally shaped like a cylinder, the inner wall of the upper half of the heating cavity part is provided with small domes in four directions, and the portion from the upper port of the heating cavity part to a certain place of the upper half of the heating cavity part is divided into four parts equally and slightly expands outwards by a certain angle. The intelligent spring can deform and tie the heating cavity, so that a cigarette is fixed, a consumer smokes conveniently by using the device, and the pleasant sensation in the smoking process is improved.

Owner:CHINA TOBACCO YUNNAN IND

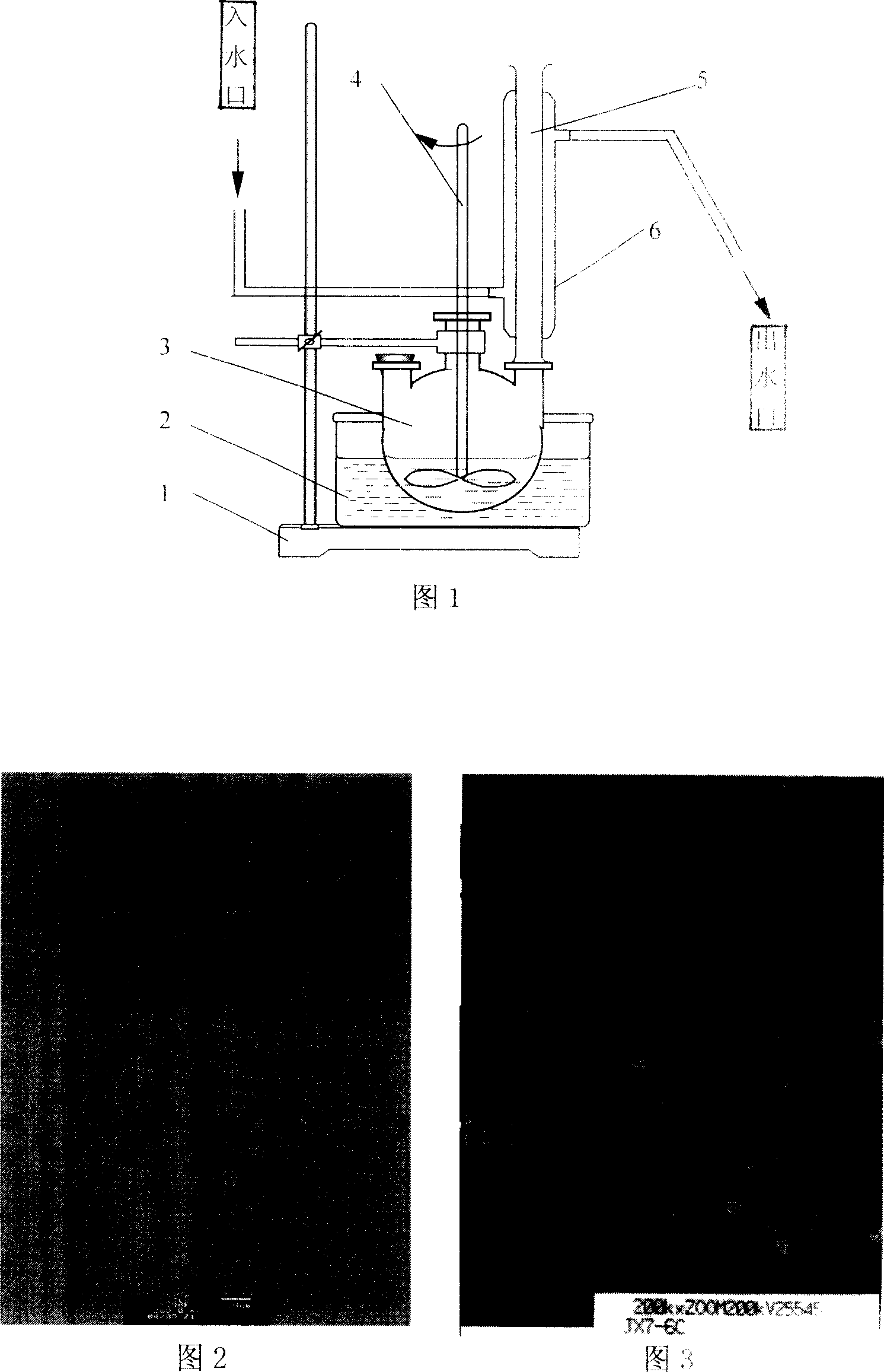

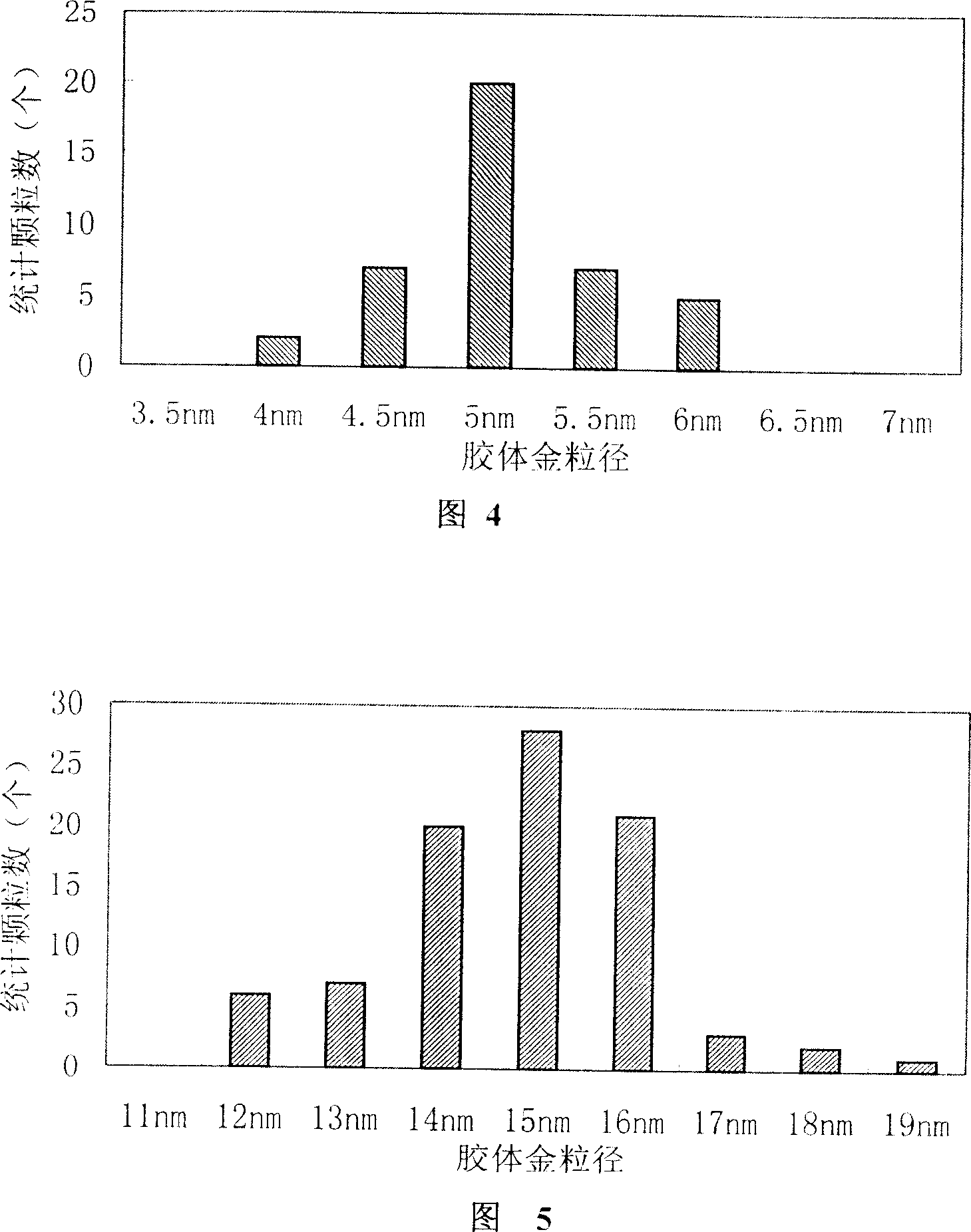

Process for nano colloid gold for immune detection and reaction apparatus therefor

The invention relates to a technology method and reacting device for making detection using nanometer colloidal gold that includes the following steps: setting material intake on reacting device, and having sealing cover, whisking device is set in the reacting device, and condensate reflux unit is set on top, heater is set on the bottom of the reactor and the four sides of bottom to form heating area to take equal heating to reaction liquid; adding auric chloride acid solution into reacting device to take heating, starting whisking device and taking cooling by using condensate reflux unit; after solution boiling, adding citric acid-3-natrium solution, after boiling for 10 minutes, stop heating; cooling and filtering to gain colloidal gold. The invention could gain the colloidal gold that has good sphericity and size distribution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com