Rapid drying device for printed matter

A technology for rapid drying and printing, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problem of uneven heating of printed materials, achieve uniform heating and improve drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

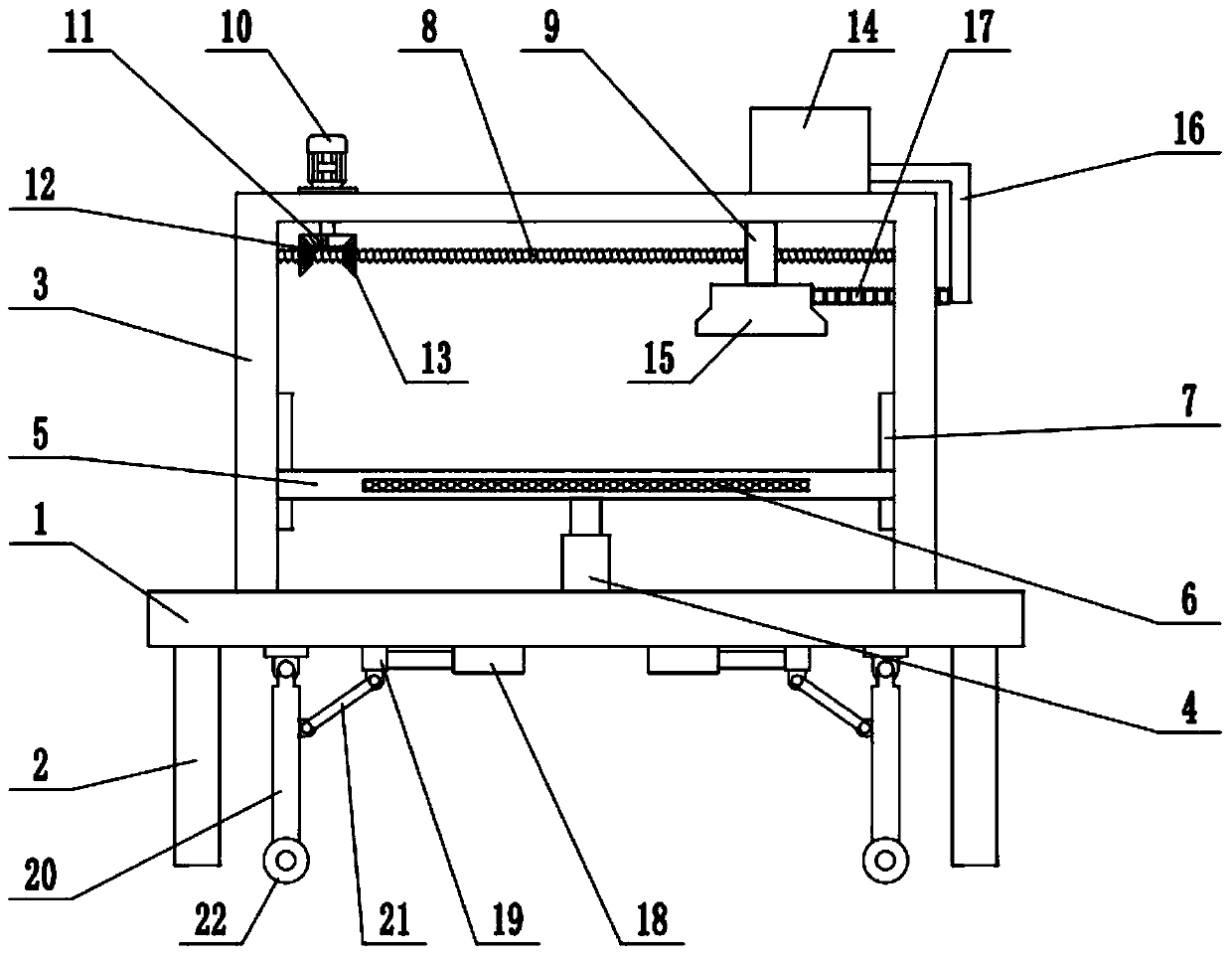

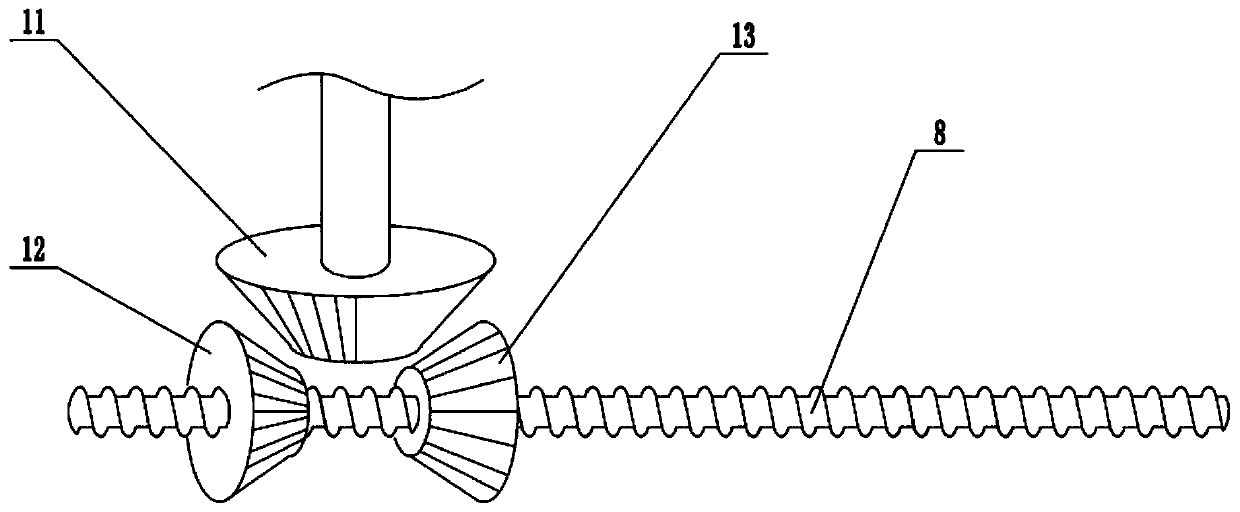

[0020] see Figure 1-3 , in an embodiment of the present invention, a printed matter rapid drying device includes a workbench 1, a drying plate 5, a hot air blower 14 and an air outlet 15, the lower surface of the workbench 1 is equipped with a foot 2, and the upper surface of the workbench 1 An oven body 3 is fixedly connected, and an oven door is installed on the side wall of the oven body 3. A telescopic mechanism 4 is fixedly connected to the upper surface of the workbench 1. The telescopic mechanism 4 is an electro-hydraulic telescopic cylinder. The top end of the telescopic mechanism 4 is fixedly connected with a The drying plate 5 is provided with a screw rod 8 above the drying plate 5, and the left and right ends of the screw rod 8 are respectively connected to the side wall of the oven body 3 in rotation. The screw rod 8 is covered with a slider 9, and the slider 9 It is threadedly connected with the screw mandrel 8, and the upper surface of the slider 9 is slidingly ...

Embodiment 2

[0022] On the basis of Embodiment 1, guide rails 7 are installed on the side walls of the oven box body 3, and the edges of the drying plate 5 are slidably connected with the guide rails 7 to control the expansion and contraction of the telescopic mechanism 4, which can drive the drying plate 5 to move up and down, and adjust the drying temperature. The height of the drying plate 5, the inside of the drying plate 5 is equipped with an electric heating plate 6, and the printed matter to be dried is placed on the drying plate 5, and the electric heating plate 6 can be used to heat the printed matter to improve the drying efficiency.

Embodiment 3

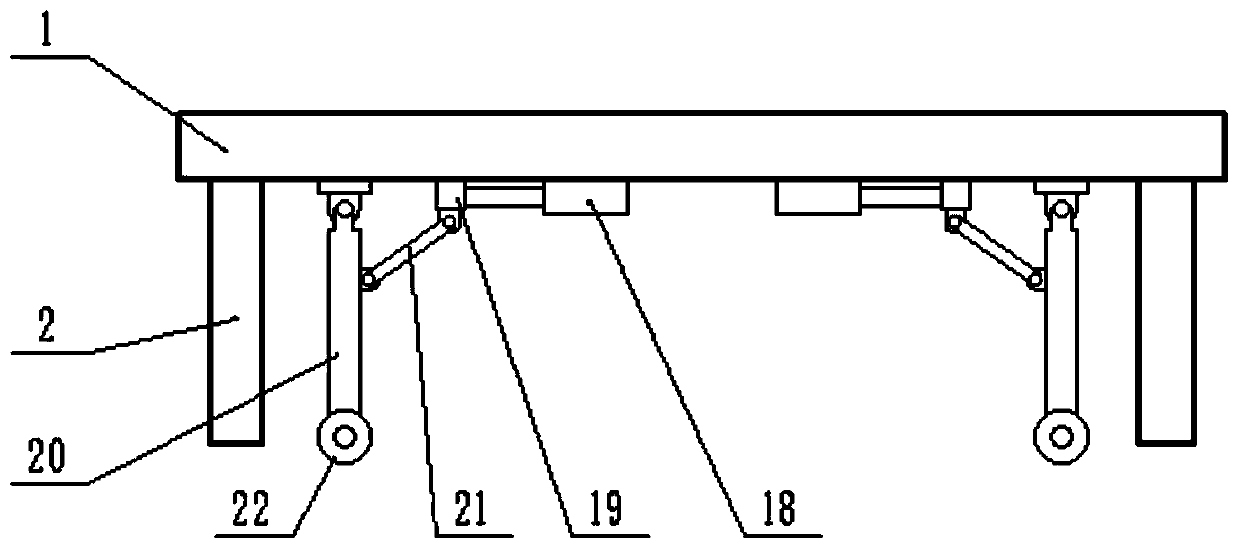

[0024] On the basis of Embodiment 1, a moving mechanism is installed on the bottom of the workbench 1, and the moving mechanism includes a cylinder 18, a moving block 19, a movable rod 20, a connecting rod 21 and a roller 22, and the lower surface of the workbench 1 is fixedly connected with a cylinder 18 , the protruding end of the cylinder 18 is fixedly connected with a moving block 19, the upper surface of the moving block 19 is slidingly connected with the lower surface of the workbench 1, the moving block 19 can slide left and right, and the lower surface of the workbench 1 is hinged with a movable rod 20, which is movable The lower end of bar 20 is equipped with roller 22, and the lower surface of moving block 19 is hinged with connecting rod 21, and the lower end of connecting rod 21 is hinged with the middle part of movable rod 20, and the extension of control cylinder 18 can drive moving block 19 to move laterally, thereby through The connecting rod 21 drives the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com