Cleaning apparatus and method for ultrahigh vacuum chamber

An ultra-high vacuum, cleaning device technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage to electronic components, potential safety hazards, and large temperature gradients, and achieve the effect of long degassing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

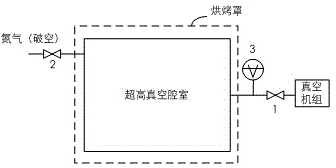

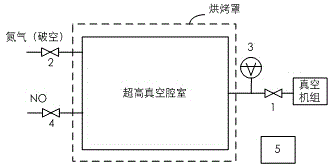

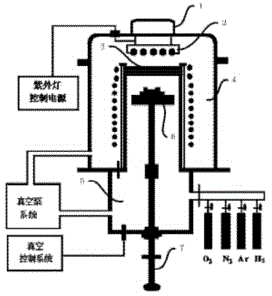

[0046] Such as Figure 5 as shown, Figure 5 It is a structural schematic diagram of the cleaning device used in the ultra-high vacuum chamber of the present invention. The cleaning device of the present invention mainly includes the following components: an ultra-high vacuum chamber, and an ultra-high vacuum chamber with pollutants attached to its inner wall, that is, the object to be cleaned. The vacuum unit is used to evacuate the ultra-high vacuum chamber to make the chamber reach an ultra-high vacuum state. Vacuum valves 1, 2, and 4 are valves for on-off gas and UV light. Vacuum gauge 7, tests the degree of vacuum in the chamber. Quadrupole mass spectrometer 6, to test the partial pressure of pollutants in the chamber (the atomic mass unit AMU range is 0-300). Inert gas, ionized under ultraviolet light, bombards the inner surface of the cavity to remove pollutants. The ultraviolet UV light source 5 is used to irradiate the inert gas to make it ionized (wavelength 100...

Embodiment 2

[0073] In another embodiment of the present invention, 10% oxygen is added to the gas source.

[0074] During cleaning, a small amount of inert gas (one or more of He / Ne / Ar / Kr / Xe) is injected in an ultra-high vacuum state, and the partial pressure of the inert gas can be tested by a vacuum gauge and then transmitted to the automatic pressure controller. The controller compares this value with the previously set threshold, and if it is lower than the threshold, the opening of the fine-tuning valve will be increased, otherwise, the opening will be decreased. After a certain wavelength of UV light irradiates the inert gas atoms, the atoms are ionized and bombard the inner wall of the cavity, see reaction formula (1), and the hydrocarbons adhering to the cavity wall are dissociated and become gaseous hydrocarbons, see Reaction formula (2). Gaseous hydrocarbons are pumped out of the chamber by the vacuum unit. Adding 10% oxygen can dissociate strong oxidizing ozone molecules and ...

Embodiment 3

[0080] In a third embodiment of the present invention, 10% of water vapor is used instead of 10% of oxygen.

[0081] During cleaning, a small amount of inert gas (one or more of He / Ne / Ar / Kr / Xe) is injected in an ultra-high vacuum state, and the partial pressure of the inert gas can be tested by a vacuum gauge and then transmitted to the automatic pressure controller. The controller compares this value with the previously set threshold, and if it is lower than the threshold, the opening of the fine-tuning valve will be increased, otherwise, the opening will be decreased. After a certain wavelength of UV light irradiates the inert gas atoms, the atoms are ionized and bombard the inner wall of the cavity, see reaction formula (1), and the hydrocarbons adhering to the cavity wall are dissociated and become gaseous hydrocarbons, see Reaction formula (2). Gaseous hydrocarbons are pumped out of the chamber by the vacuum unit.

[0082] After water vapor enters the vacuum chamber, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com