Process for nano colloid gold for immune detection and reaction apparatus therefor

A reaction device and nano-colloid technology, which is applied in the field of preparation of nano-colloidal gold for immunoassay and its reaction device, can solve the problems of water volatilization, uneven stirring, affecting the size difference of colloidal gold particles, sphericity particle size distribution, etc. , to achieve the effect of good sphericity, narrow particle size distribution and small particle size difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, adopt the reaction apparatus shown in the present invention to prepare, and reaction conditions are: reaction temperature is 60 ℃, stirring rate is 300rpm, mass percentage content 1% trisodium citrate add-on 4mL, 0.025mol / L K 2 C0 3 The addition amount is 0.6mL, and the addition amount of 1% tannic acid is 0.6mL, and the mass percentage composition 1% HAuCl 4 The amount added was 1 mL, and the reaction time was 10 min.

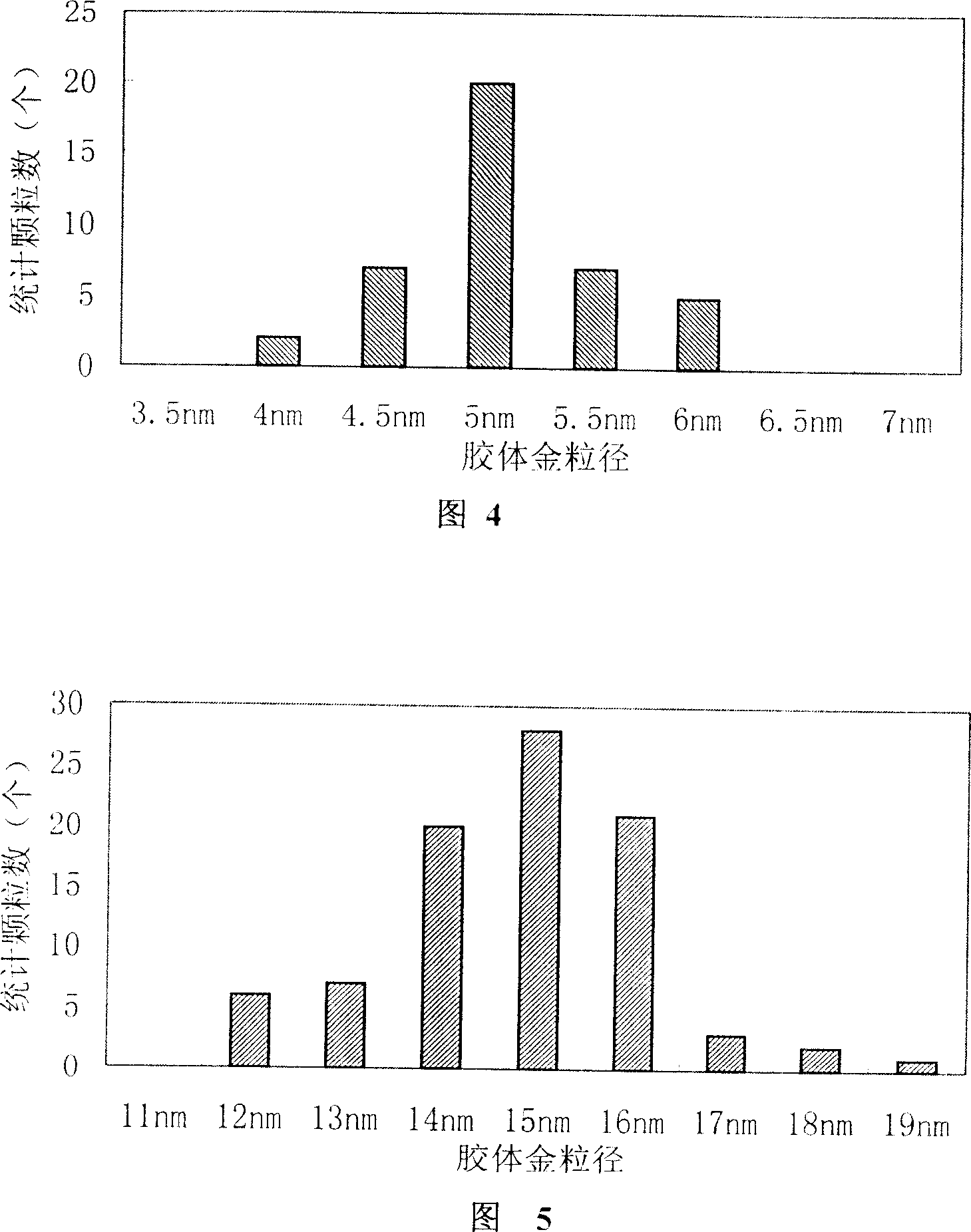

[0028] Test results: The TEM photo of colloidal gold is shown in Figure 2. Colloidal gold particles have very good sphericity, narrow particle size distribution, and small particle size differences. There is no floating matter (no dry point) on the surface of the colloidal gold solution, and no coagulation phenomenon is found; the average particle size of the colloidal gold is 5.07nm, and Fig. 4 is a particle size distribution diagram; the colloidal gold is placed in a sealed place at 4°C for 30 days and no coagulation phenomenon occurs ...

Embodiment 2

[0029] Embodiment 2, prepare with reaction apparatus shown in the present invention, reaction conditions are: reaction temperature is 100 ℃, reaction time is 10min, stirring rate is 300rpm, mass percent content 1% trisodium citrate add-on 12.2mL, mass Percent content 1% HAuCl 4 The amount added is 3 mL.

[0030] Test results: The TEM photo of colloidal gold is shown in Figure 3. Colloidal gold particles have very good sphericity, narrow particle size distribution, and small particle size differences. There is no floating matter (no dry point) on the surface of the colloidal gold solution, and no coagulation phenomenon is found. The average particle size of the colloidal gold was measured to be 14.88nm, and Figure 5 is a particle size distribution diagram; the colloidal gold was sealed at 4°C for 30 days without coagulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com