Method of producing hollow silicon dioxide microsphere with mercapto on internal and external surfaces

A technology of silica, inner and outer surfaces, applied in the directions of silica, fibrous fillers, etc., can solve the problems of complex method, uneven size, broken hollow balls, etc., and achieves low preparation cost, uniform size and good sphericity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

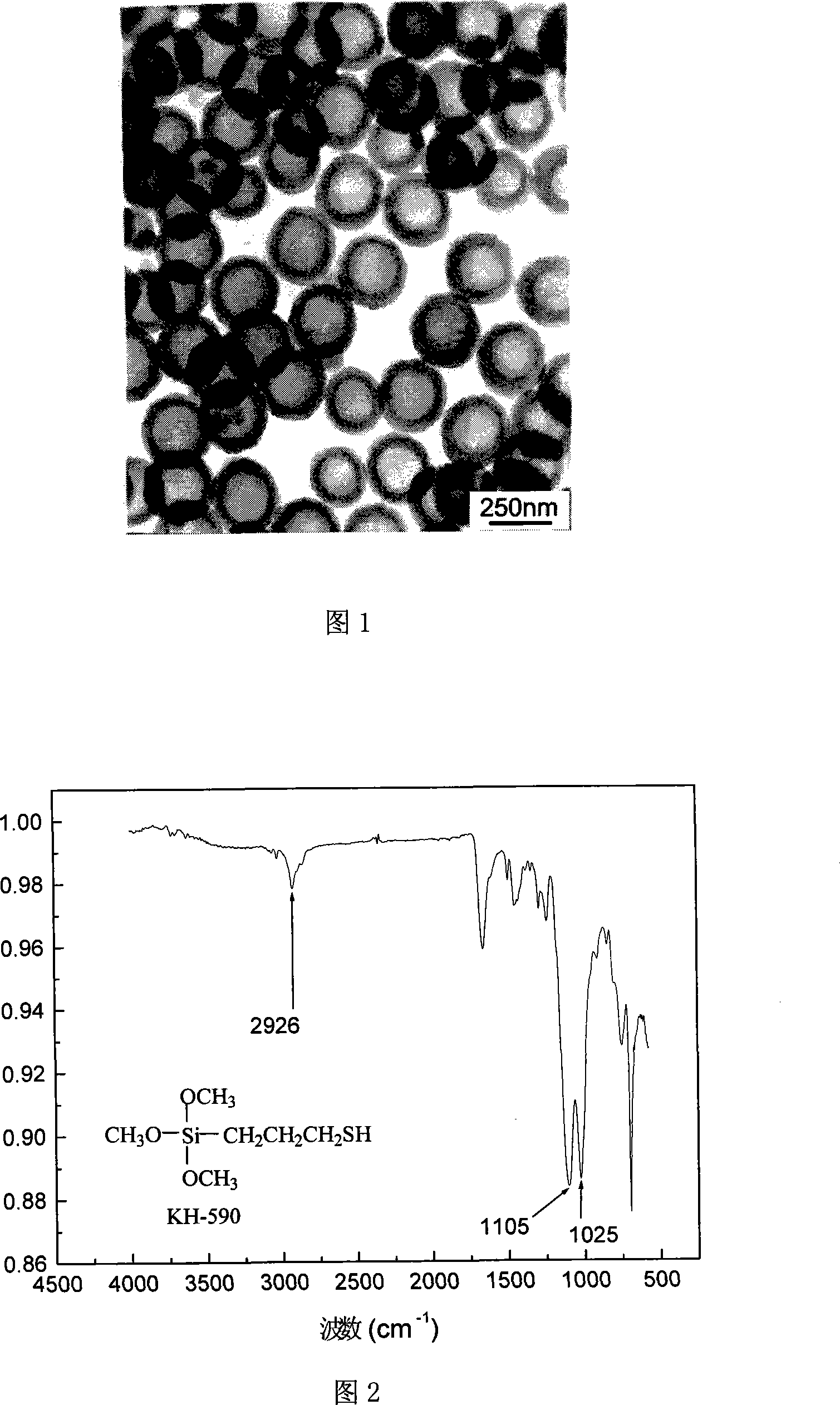

[0023] In a 250mL four-necked flask equipped with a thermometer, a condenser, a stirrer, and nitrogen, add 100g of PS (polystyrene) emulsion (wherein the PS content is 3wt%) and 40mL of ethanol, stir for 30min under nitrogen protection, and heat up to 50°C. Add 15mL of ammonia water into the flask, stir for 5-10min, then quickly add 1g of 3-mercaptopropyltrimethoxysilane, react for 7-8h, centrifuge the prepared emulsion, wash with ethanol and deionized water for 3-4 times, that is The hollow silica microspheres with mercapto groups on the inner and outer surfaces were obtained. Its infrared spectrum is shown in Figure 1.

Embodiment 2

[0025] In a 250mL four-necked flask equipped with a thermometer, a condenser, a stirrer, and nitrogen, add 100g of PS emulsion (PS content is 5wt%) and 55mL of ethanol, stir for 60min under nitrogen protection, and heat up to 60°C. Add 20mL ammonia water into the flask, stir for 10-15min, then quickly add 293-mercaptopropyltriethoxysilane, react for 7-8h, centrifuge the prepared emulsion, wash with ethanol and deionized water for 3-4 times, That is, hollow silica microspheres with mercapto groups on the inner and outer surfaces are obtained.

Embodiment 3

[0027] In a 250mL four-neck flask equipped with a thermometer, a condenser, a stirrer, and nitrogen, add 100g of PS emulsion (PS content is 4wt%) and 40mL of ethanol, stir for 45min under nitrogen protection, and heat up to 30°C. Add 30mL of ammonia water into the flask, stir for 5-10min, then quickly add 1.5g of 3-mercaptopropyltrimethoxysilane, react for 7-8h, centrifuge the prepared emulsion, wash with ethanol and deionized water for 3-4 times , that is, hollow silica microspheres with mercapto groups on the inner and outer surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com