Multi-purpose lignin-carbohydrate binding system

a lignin-carbohydrate and binding system technology, applied in the field of multi-purpose lignin-carbohydrate binding system, can solve the problems of insufficient hardness or sphericity of granular fertilizers, insufficient cost-effective components, and inconvenient use of conventional binders in fertilizer formulations, etc., to achieve increased roundness or sphericity, increased durability and uniformity, and increased hardness or crush resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

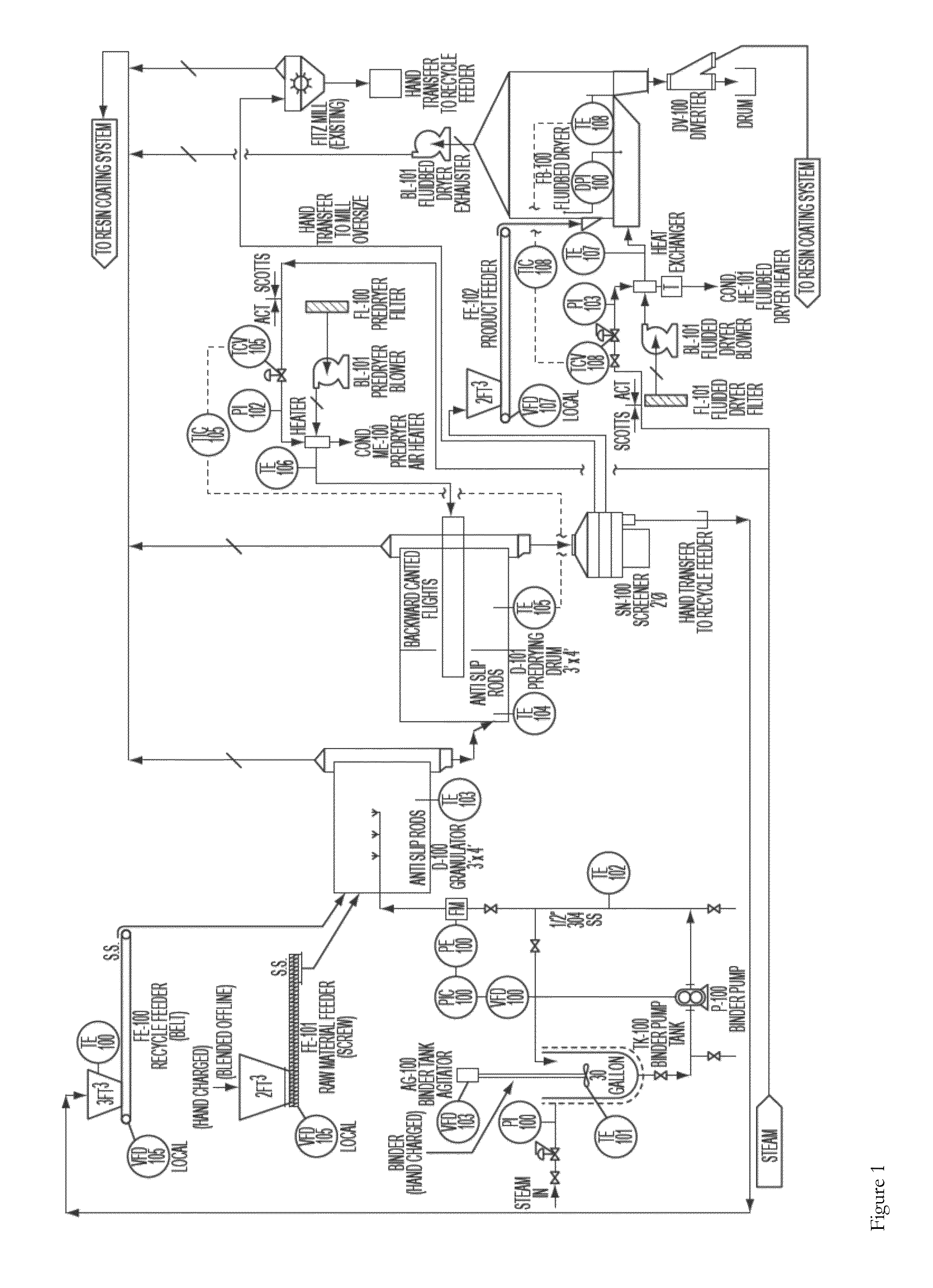

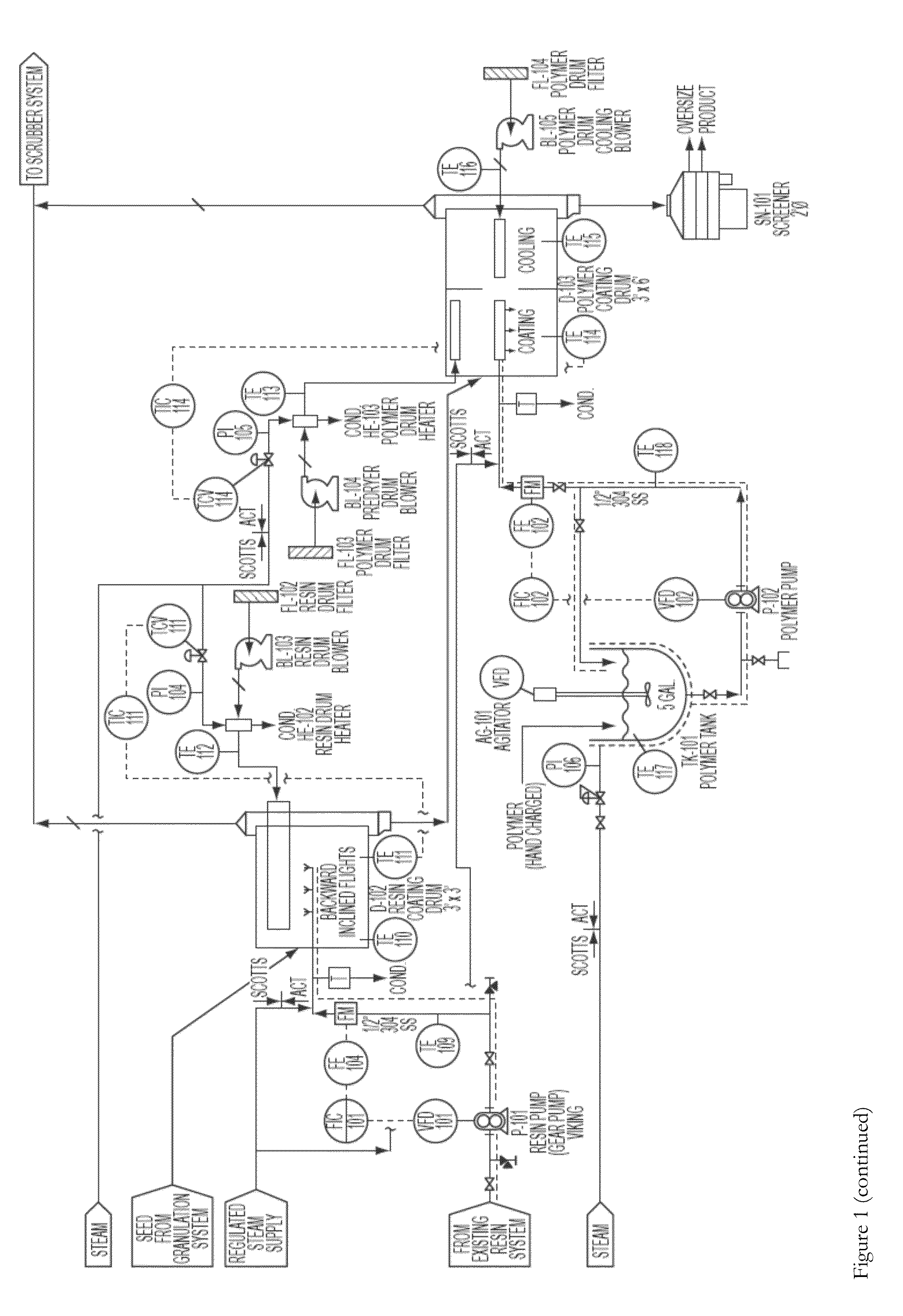

[0048](A) General Process for Preparing the Agglomerated Particles.

[0049]The granulation process is conducted at ambient temperatures and therefore can be used for fertilizer and pesticide combinations, as well as biological materials such as seed.

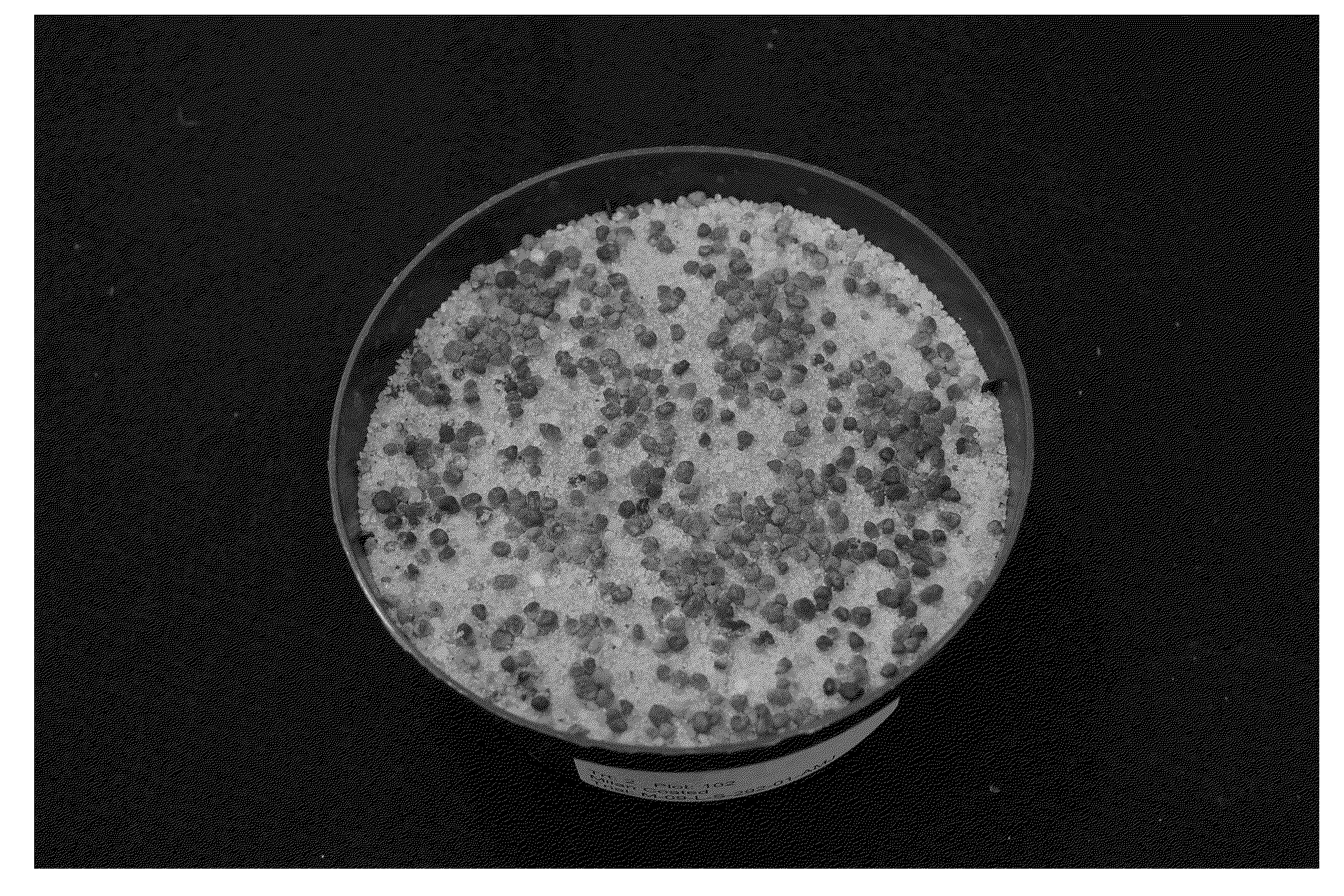

[0050]Granules of the invention initially require all materials in the formulation to be sized in powder form with an approximate size of 20-40 SGN. All particle components, such as fertilizers, micronutrients, seeds, and perlite are mixed together to form a relatively uniform particle blend. This blending process ensures that the mixture is thoroughly mixed. The particle blend is then feed into a granulator apparatus at ambient temperature and normal humidity.

[0051]As the mixed powder blend enters the granulator, typically a horizontal rotating drum, the binder solution (i.e., lignosulfonate and polyols) is applied at a temperature range of 110-130° F. and solution viscosity of 10-20 cps. The viscosity of the binder solution allows for at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com