Toner for electrostatic image development

一种静电荷图像、调色剂的技术,应用在显影剂、电记录术、仪器等方向,能够解决得不到耐热保管性等问题,达到优异耐热保管性和耐破碎性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0167] Hereinafter, specific embodiments of the present invention will be described, but the present invention is not limited thereto.

Synthetic example 1

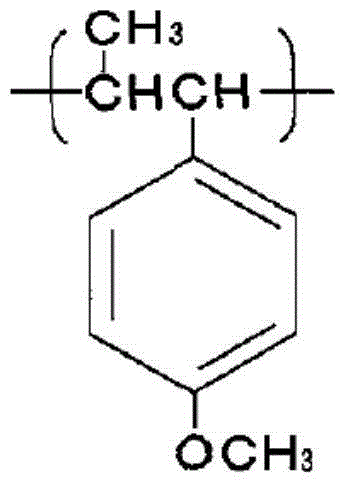

[0169] Put 148.0 mg (1.0 mmol) of potassium trifluoroallyl borate, 46.8 mg (0.25 mmol) of 4-bromoanisole, and K in a PYREX (registered trademark) tube substituted with argon. 2 CO 3 104.0mg (0.75mmol), 5.0mg (0.0075mmol) of PdCl2 (dtbpf), and then add 2.5ml of isopropanol / water (2 / 1) solution, and seal it with a rubber plug. The container was irradiated with ultrasonic waves at 120°C for 30 minutes.

[0170] Ammonium chloride and diethyl ether were added to the reaction mass, the ether phase was separated, the resulting reaction mixture was purified by thin layer chromatography using hexane as the eluent, and then washed with diethyl ether, filtered, and dried to obtain the formula ( 2-1) The specific monomer represented (hereinafter referred to as "specific monomer [1]").

Synthetic example 2

[0172] In Synthesis Example 1, except that 4-bromoanisole was changed to 3-bromoanisole, the specific monomer represented by the above formula (2-2) (hereinafter referred to as "specific Monomer [2]".).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com