Toner for developing electrostatic image

An electrostatic charge image and toner technology, which is applied in the direction of developer, electrography, instrument, etc., can solve the problems of toner scattering, background fog, inability to fully meet the heat resistance preservation and crush resistance, etc. Achieves sufficient low-temperature fixability, excellent heat-resistant storage, and crush resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0218] Hereinafter, specific examples of the present invention will be described, but the present invention is not limited to these examples.

Synthetic example 1

[0220] First, add p-toluenesulfonic acid monohydrate (8g) to a mixture of ethyl pyruvate (315g, 2.7mol) and acetic anhydride (554g, 5.4mol), and stir at 120°C for 24 hours under nitrogen flow to obtain a reaction solution . Next, after removing acetic acid produced by the reaction with excess acetic anhydride from the reaction solution under reduced pressure (40-50 mmHg), the residue is purified by distillation under reduced pressure (35-40 mmHg, 90-103°C) to obtain α - Ethyl acetoxyacrylate (250 g, 58% yield).

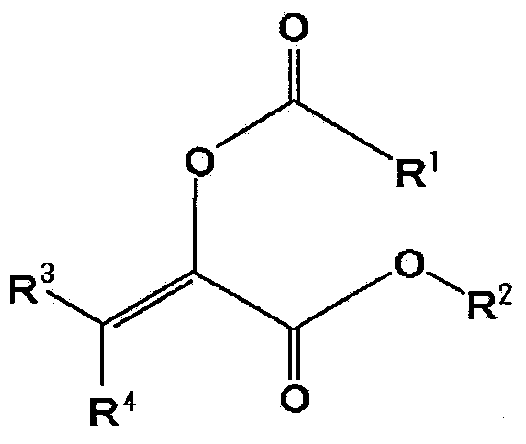

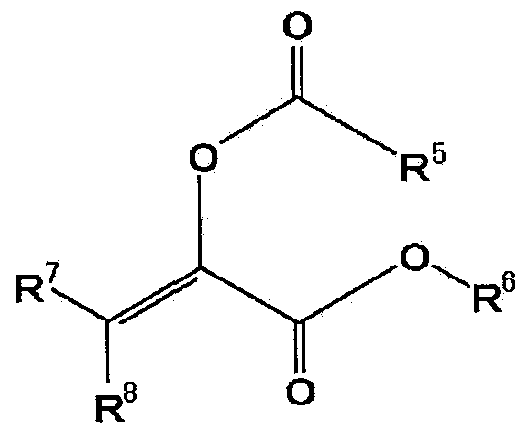

[0221] It should be noted that α-acetoxy ethyl acrylate can be used as a specific acrylic monomer represented by the above-mentioned general formula (1) (R in the general formula (1) 1 is methyl, R 2 is ethyl, R 3 and R 4 are all hydrogen atoms) or specific acrylic monomers represented by the above general formula (2) (R in general formula (2) 5 is methyl, R 6 is ethyl, R 7 and R 8 all hydrogen atoms) monomers. Hereinafter, this α-acetoxy ethyl acrylate is al...

Synthetic example 2

[0223]First, a solution of pyruvic acid (440 g, 5.0 mol), n-butanol (371 g, 5.0 mol) and p-toluenesulfonic acid monohydrate (2.5 g) in toluene (1 L) was heated to reflux for 16 hours while removing water under a nitrogen stream. , to obtain the first reaction solution. Next, after cooling the first reaction solution to room temperature (25°C), toluene was removed under reduced pressure (40mmHg) using an evaporator, and the residue was purified by vacuum distillation (40mmHg, 93-100°C) to obtain pyruvic acid Butyl ester (505g, yield 70%).

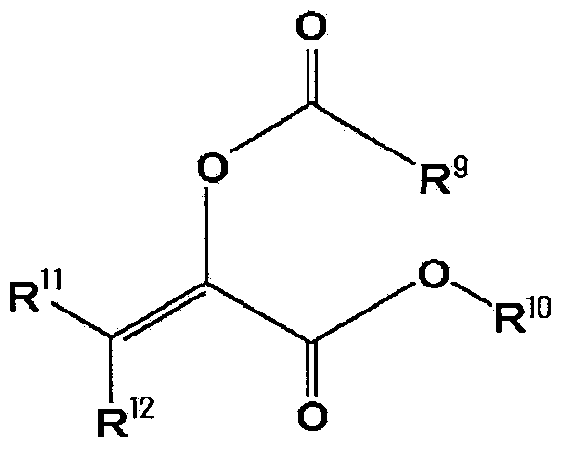

[0224] Next, p-toluenesulfonic acid monohydrate (5 g) was added to the mixture of butyl pyruvate (235 g, 1.6 mol) and acetic anhydride (333 g, 3.3 mol) obtained, and stirred at 120 ° C for 25 hours under nitrogen flow to obtain Second reaction solution. Next, after removing the acetic acid produced by the reaction with excess acetic anhydride from the second reaction solution under reduced pressure (5mmHg), the residue was purified by dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com