Fire barrel type gas burner

A gas burner and fire tube type technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of overheating and burning of the heating surface of the furnace, uneven heating of the furnace, and achieve reasonable matching, ensuring uniformity, avoiding The effect of uneven heating of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

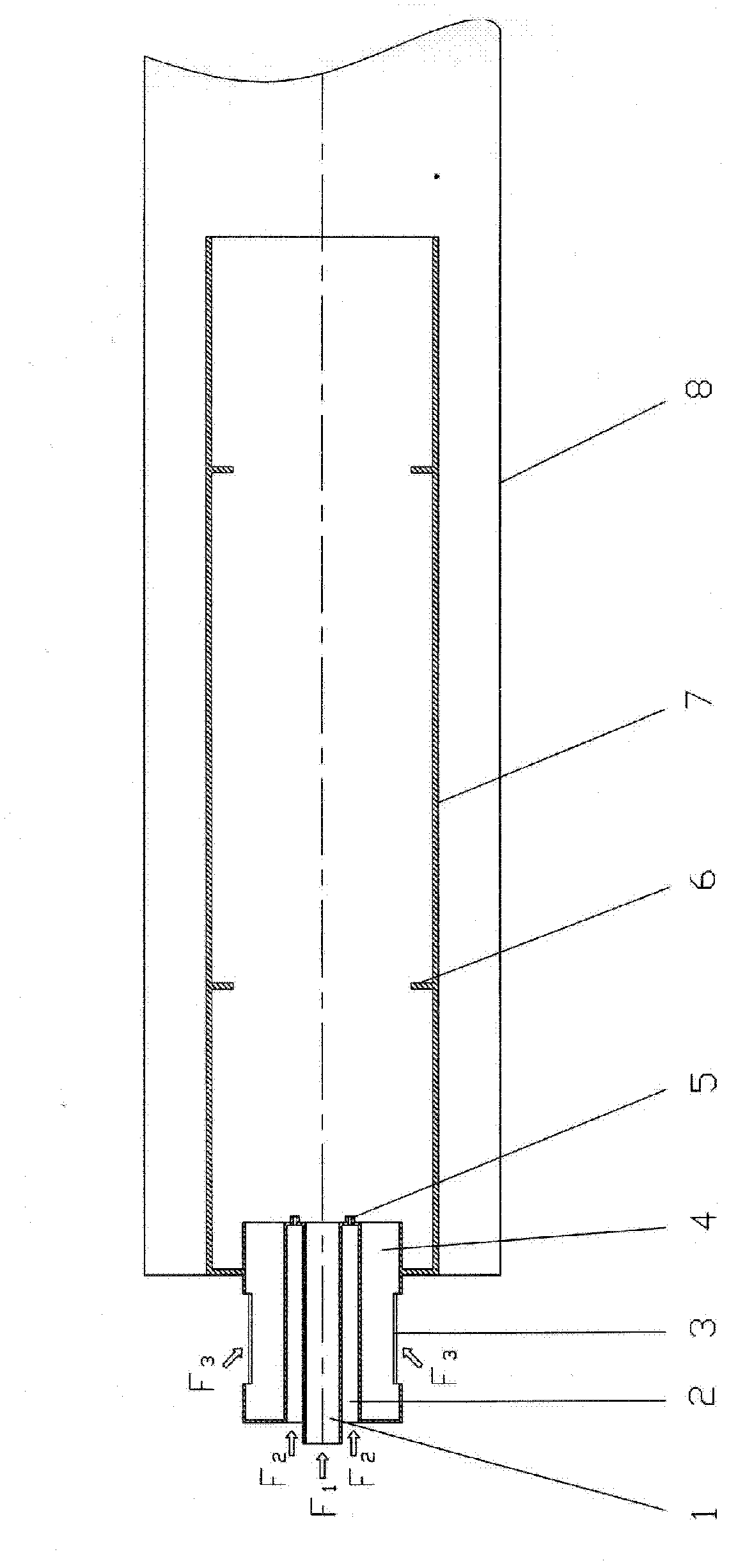

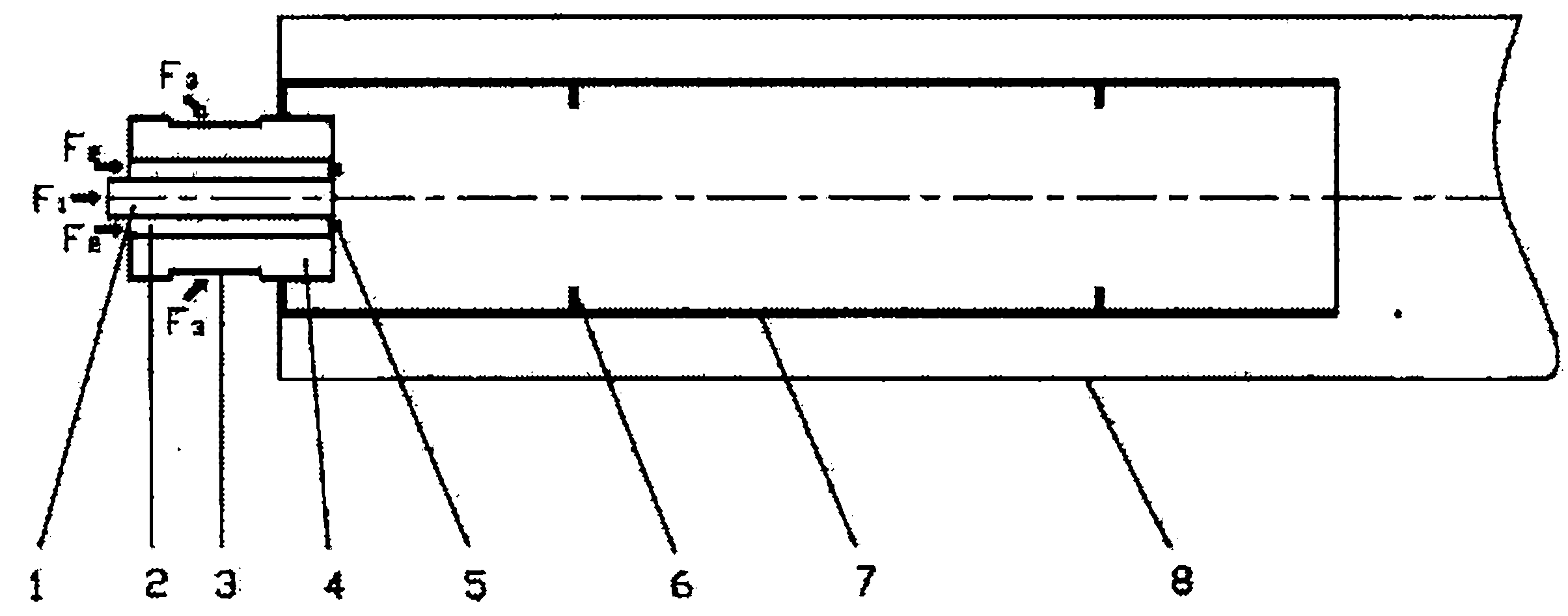

[0012] refer to figure 1 , The torch type gas burner of the present invention can be generally divided into two parts, the intake air distribution device at the front and the tubular combustion chamber at the rear. As shown in the drawings, it can be divided into 1. Central combustion-supporting air channel; 2. Gas channel; 3. Injection air inlet; 4. Injection air channel; 5. Gas inlet nozzle; 6. Annular rib; 7. Tubular combustion chamber; 8. Hearth. Among them, the size of the tubular combustion chamber is selected according to the shape of the furnace: the diameter is 2 / 3 to 3 / 4 of the furnace diameter, and the length is 1 / 2 to 2 / 3 of the furnace length; the annular rib is located 1 / 4 from the inlet and outlet of the combustion chamber ~1 / 3 of the pipe length, the height of the rib plate is 1 / 10~1 / 5 of the diameter of the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com