Patents

Literature

717results about How to "Avoid uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

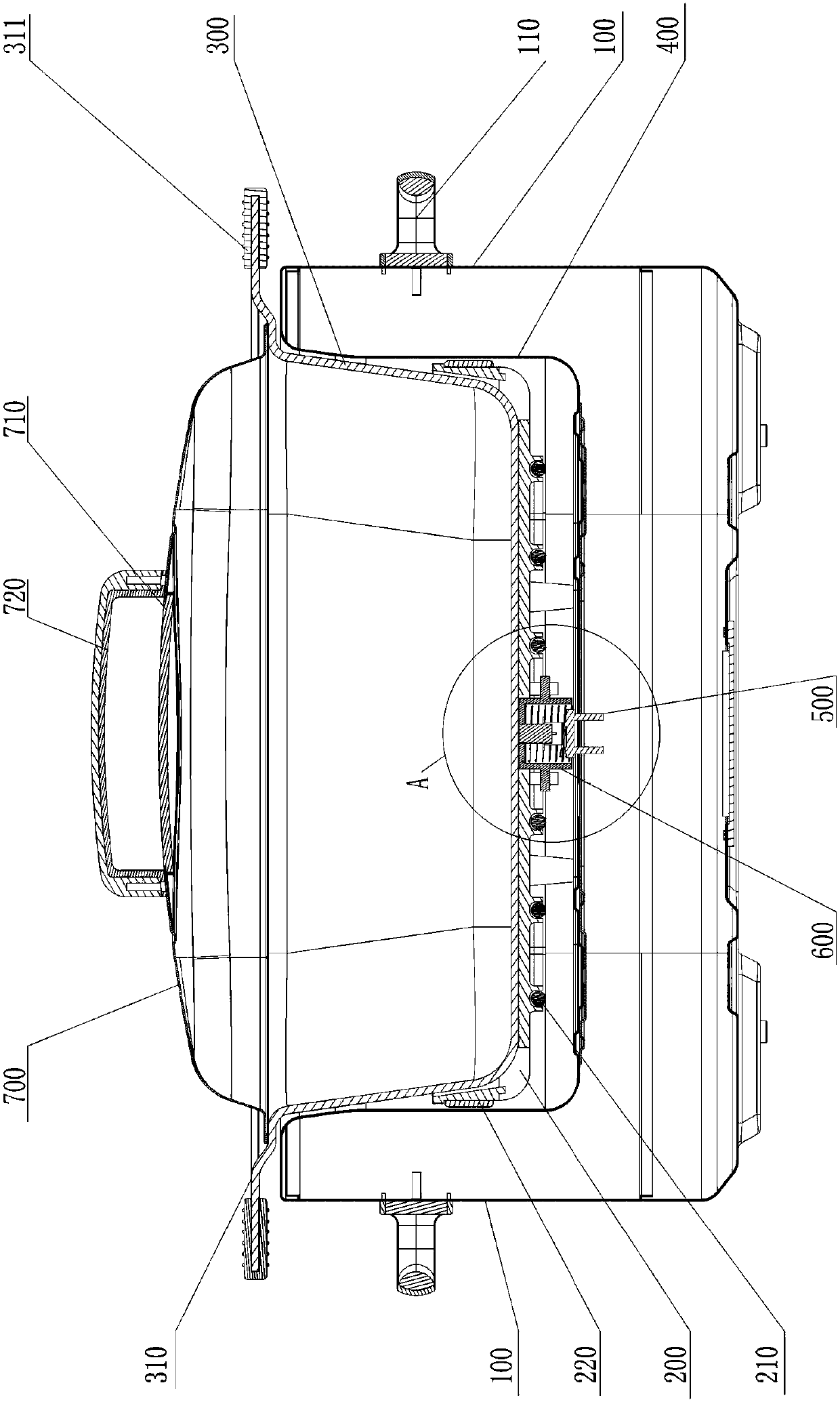

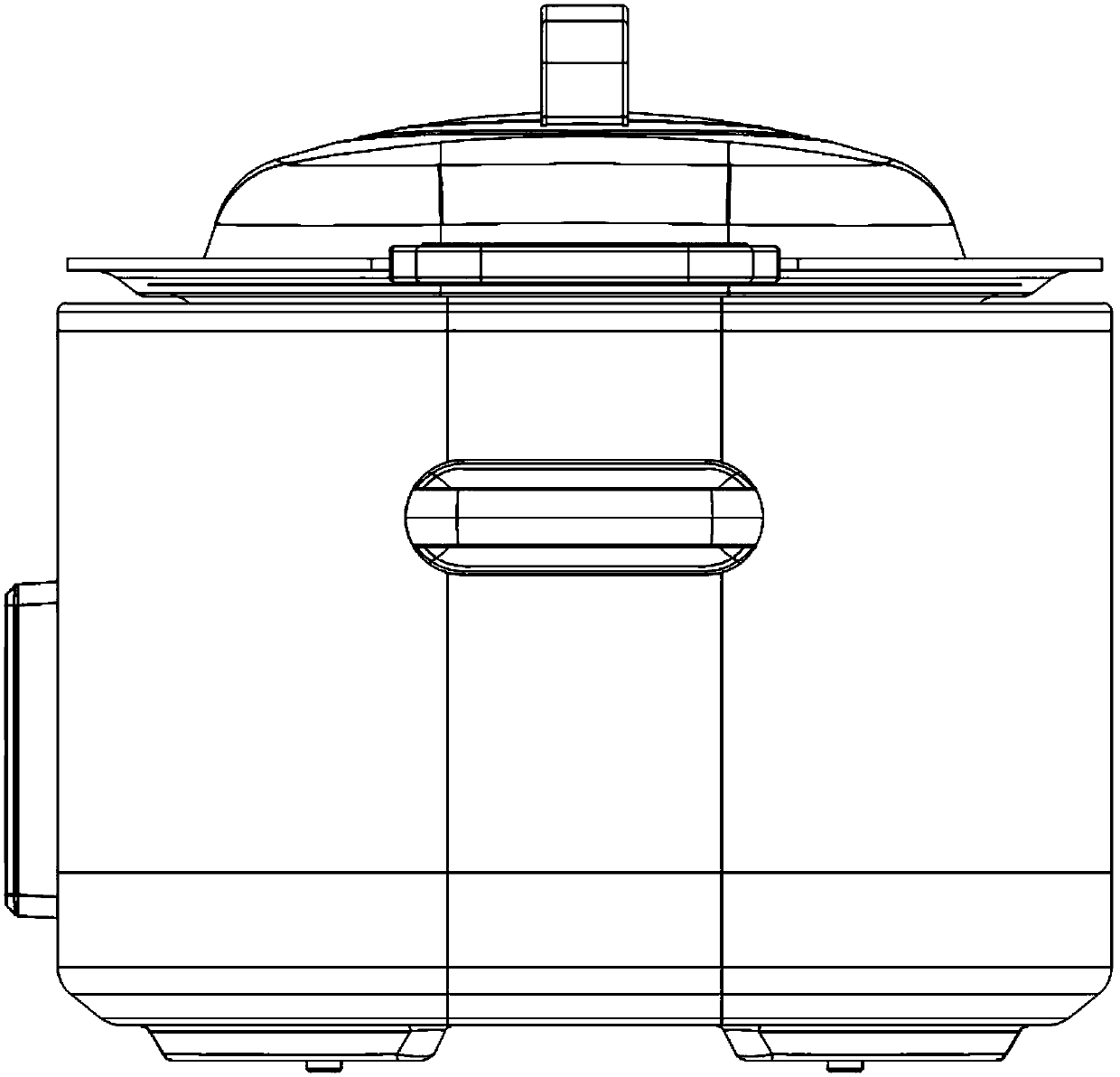

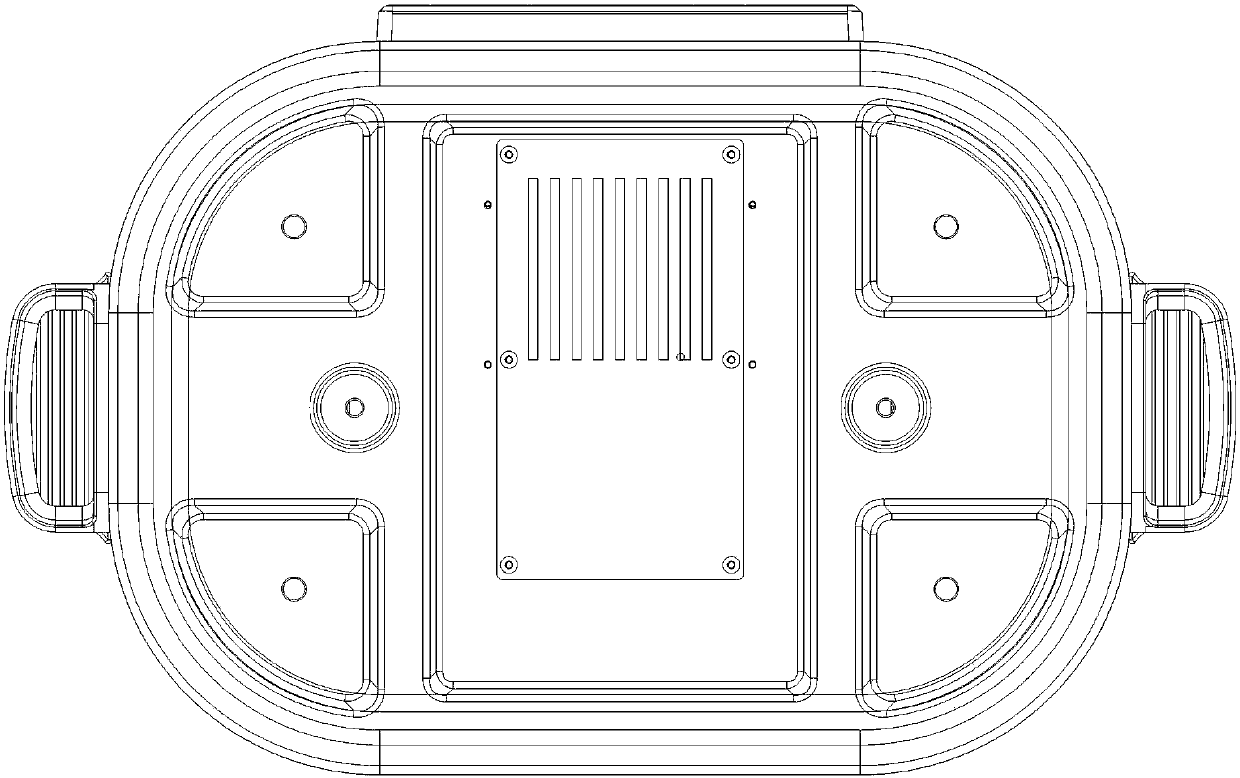

Multifunctional pot

PendingCN107836981AEvenly heatedAvoid uneven heatingHot plates heating arrangementsWarming devicesEngineeringHeat losses

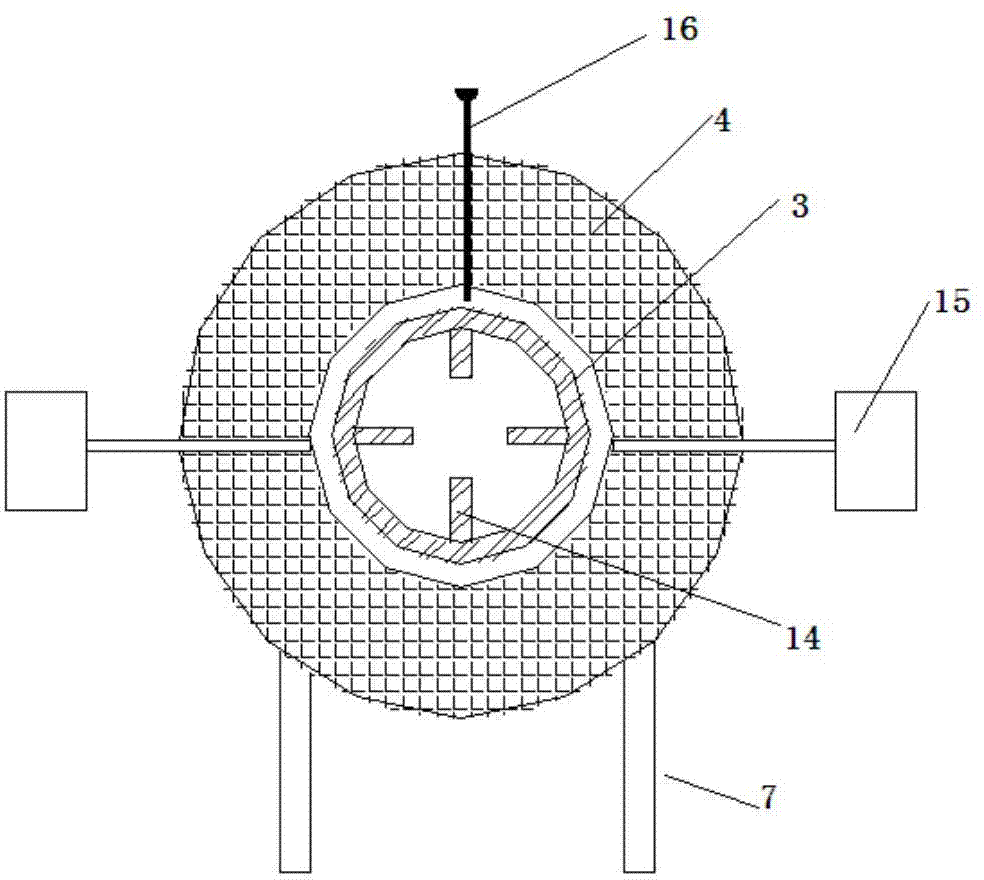

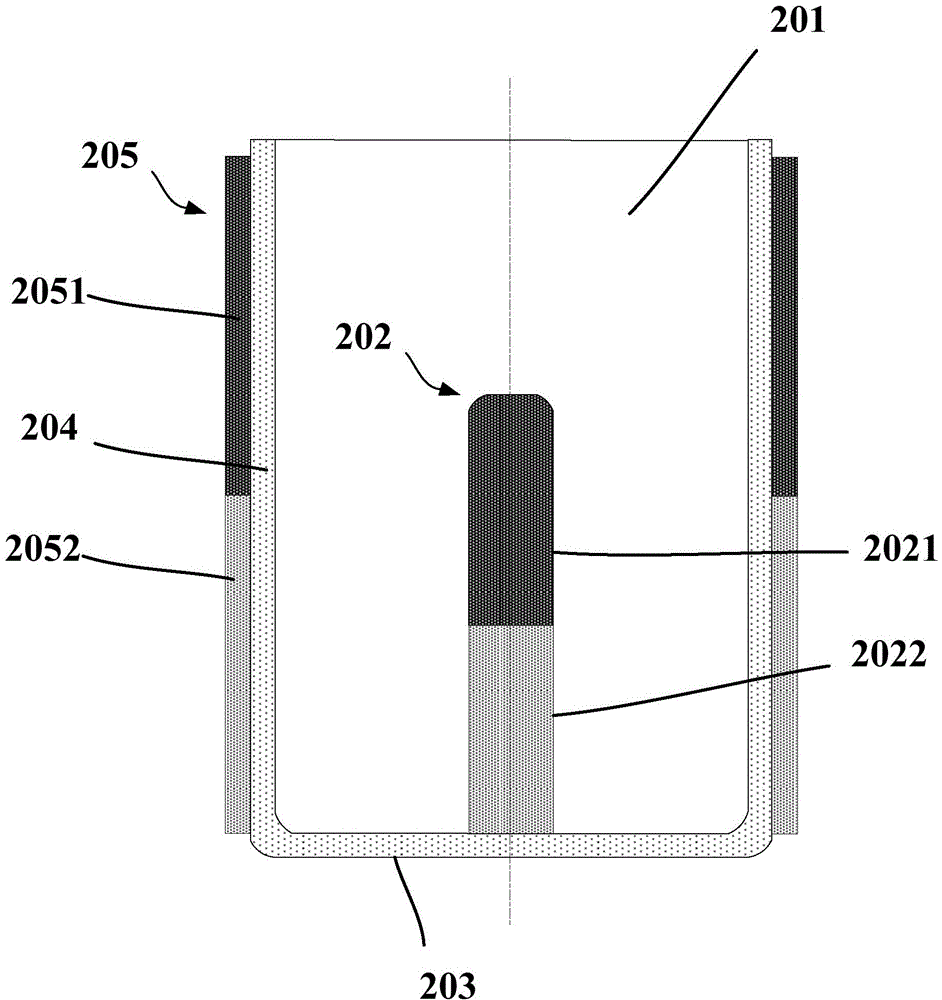

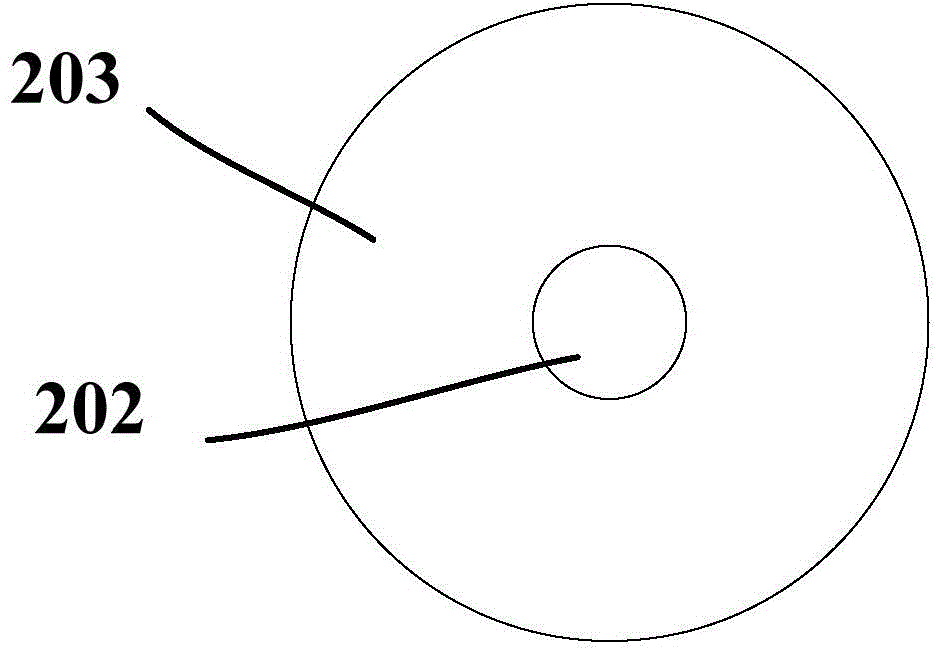

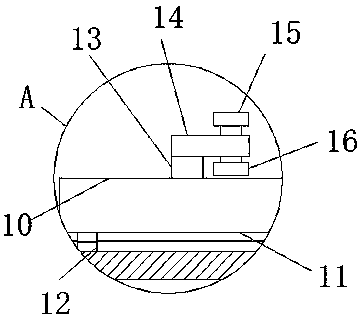

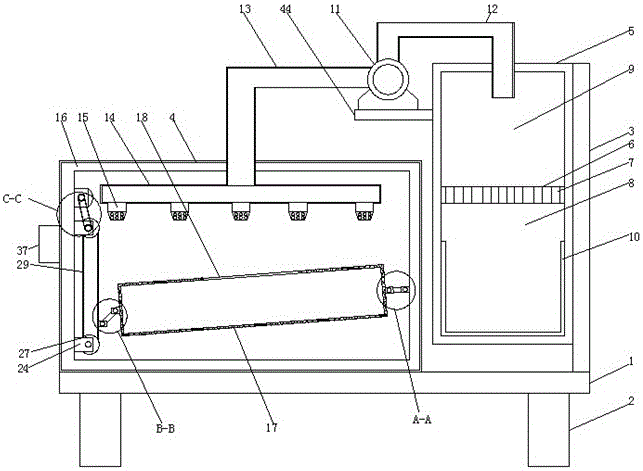

The invention discloses a multifunctional pot. The pot includes a housing, a heating element heat conduction disk and a pot body, a liner is arranged in the housing, and the upper end of the housing is connected with the upper end of the liner; the heating element heat conduction disk is arranged in the liner, the height of the heating element heat conduction disk is lower than the depth of the liner, a bottom heating element is arranged at the outer bottom of the heating element heat conduction disk, an annular heating element is arranged on the outer side wall of the heating element heat conduction disk, and the bottom heating element and the annular heating element are in series connection and are electrically connected to a working circuit of the multifunctional pot; the pot body is arranged on the heating element heat conduction disk, the inner wall of the heating element heat conduction disk is in contact with the outer wall of the pot body, and the height of the pot body is larger than the depth of the heating element heat conduction disk. The heating element heat conduction disk of the multifunctional pot directly heats the pot body evenly, the inner wall of the heating element heat conduction disk can be in close contact with the outer wall of the pot body, hence, most of heat can be transmitted to the pot body, the liner can effectively keep the heating element from transmitting heat to the outside world, the heat loss is small, and the energy utilization rate is high.

Owner:NINGBO JINYU ELECTRIC APPLIANCE

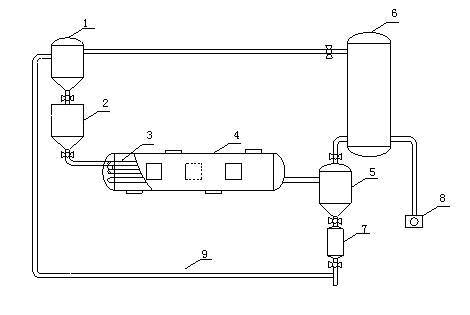

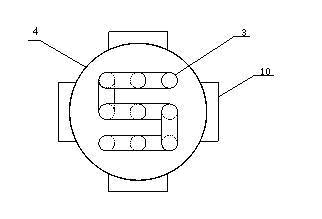

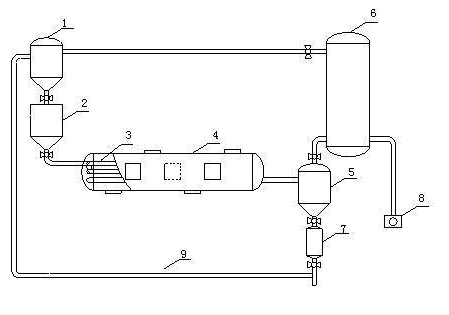

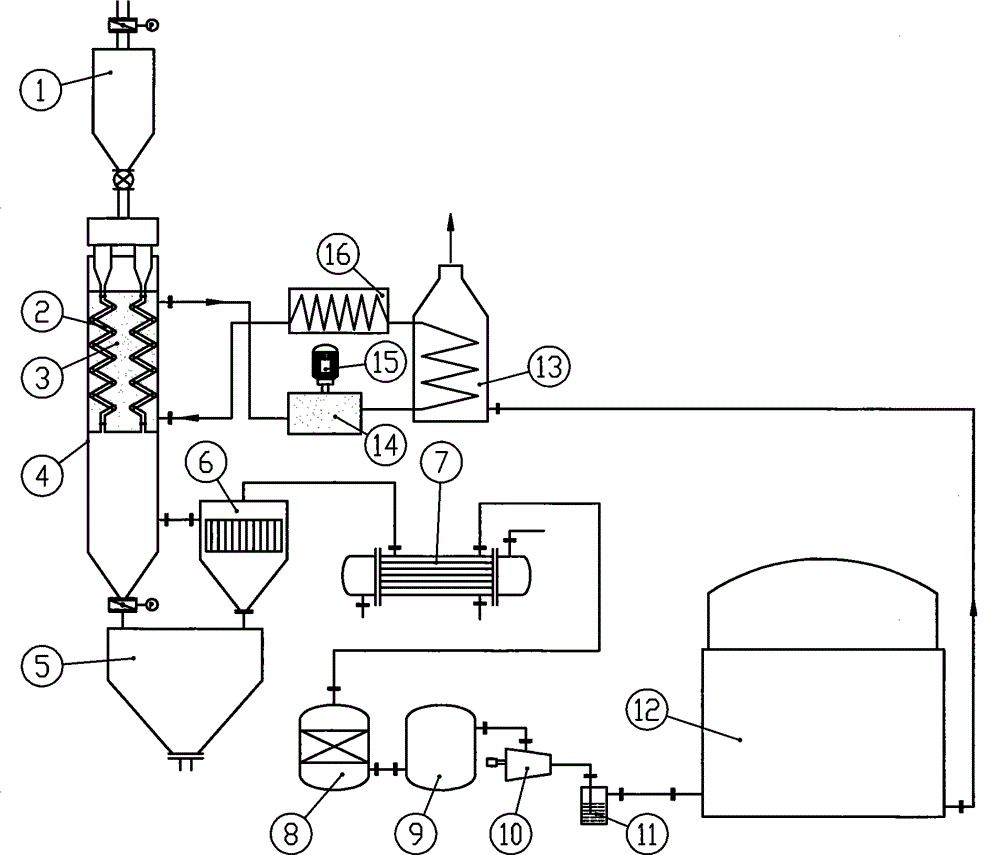

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

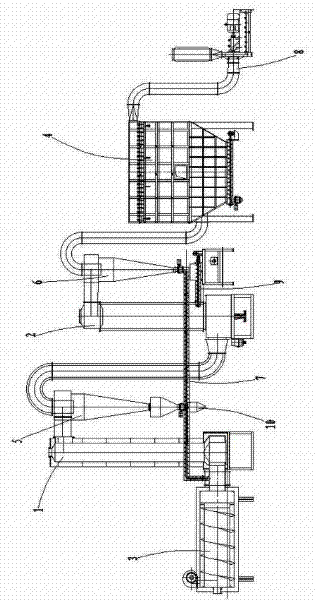

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

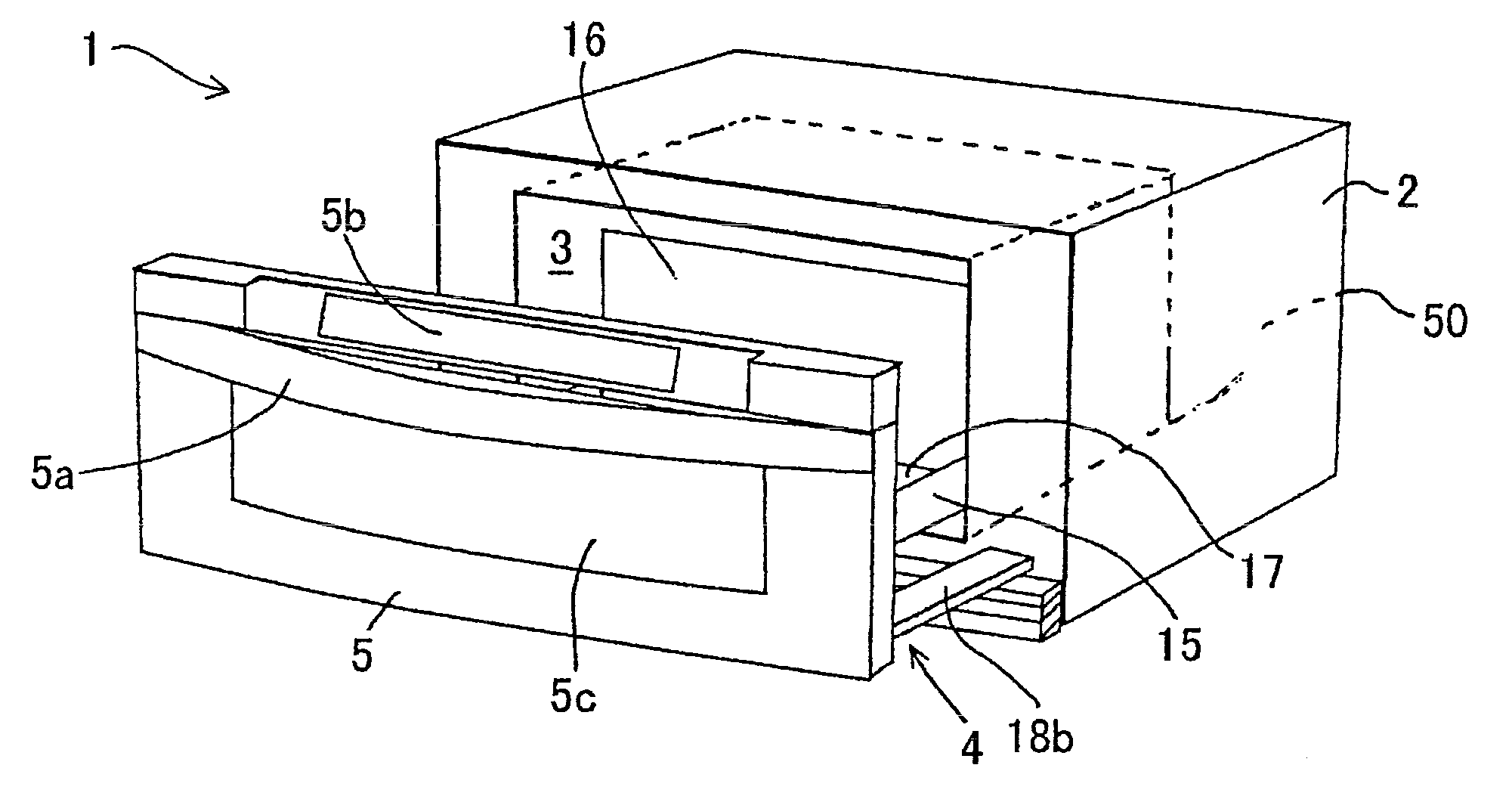

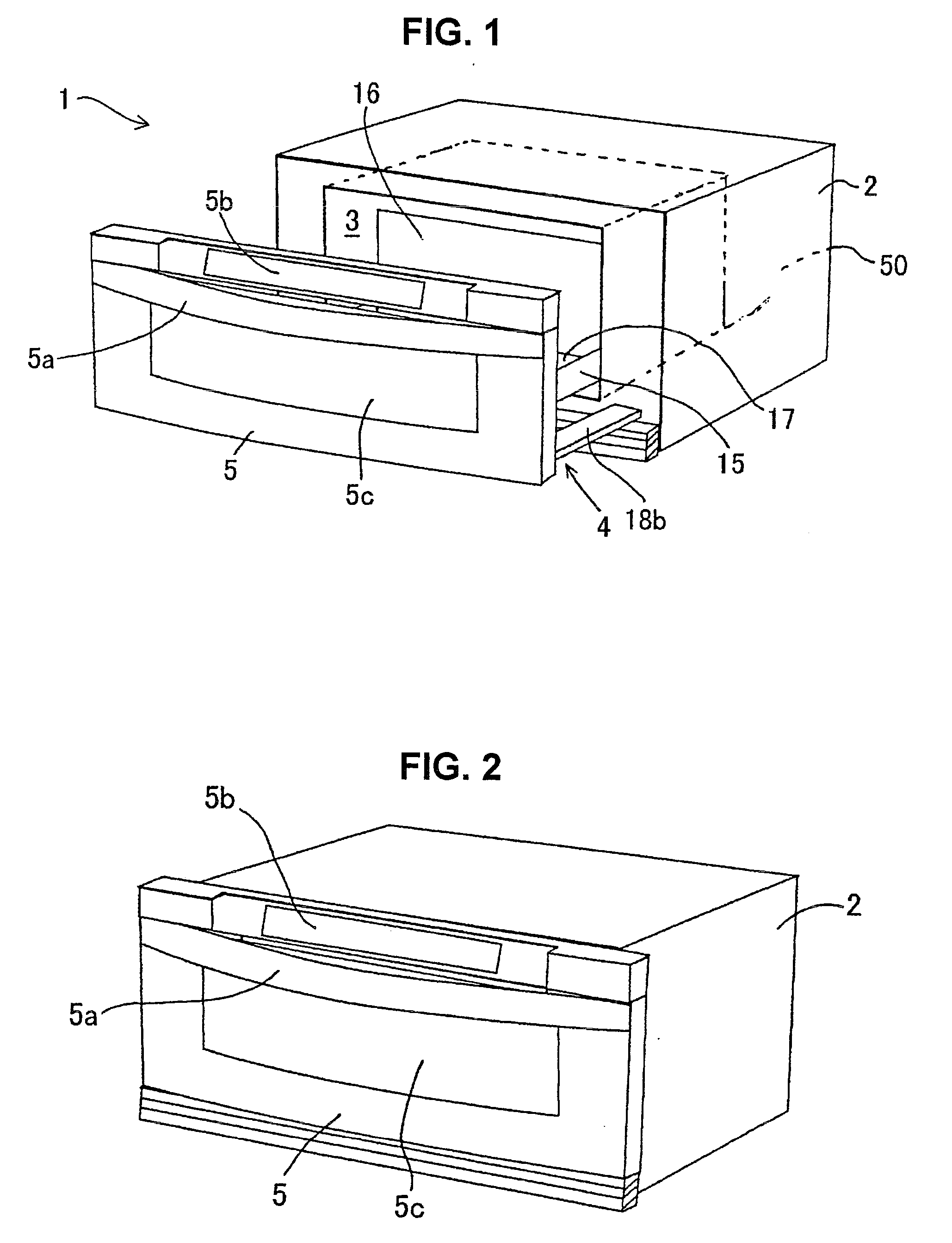

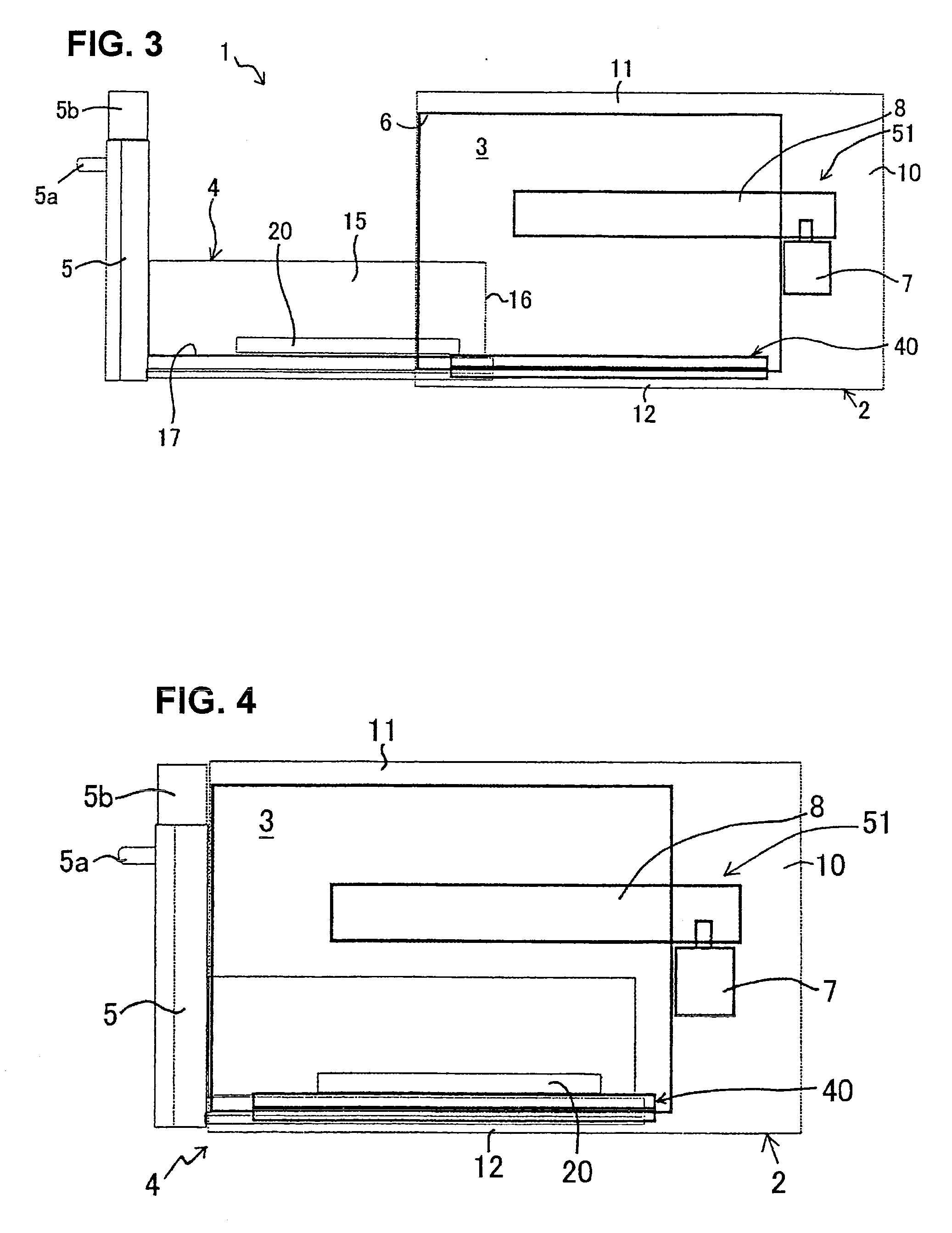

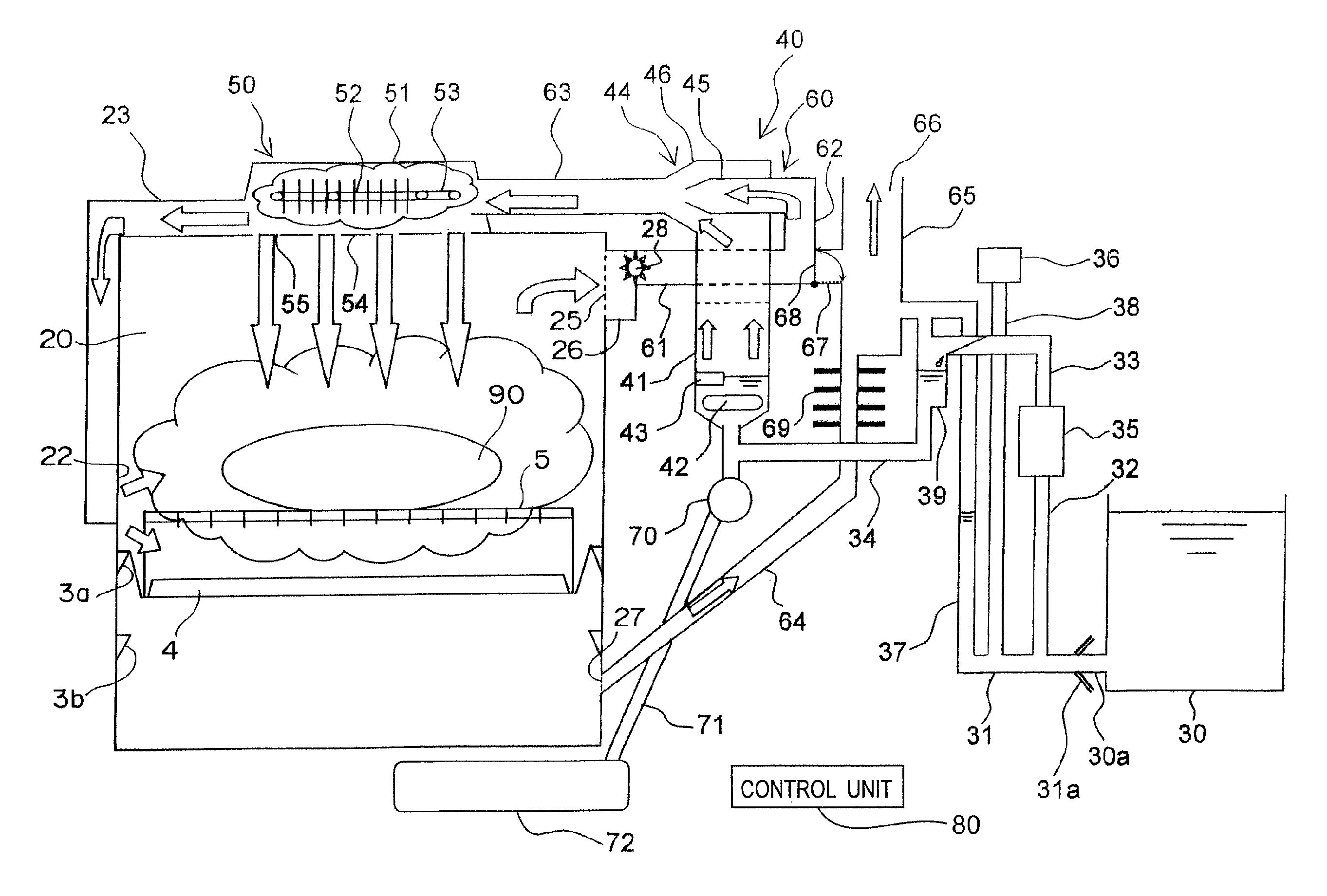

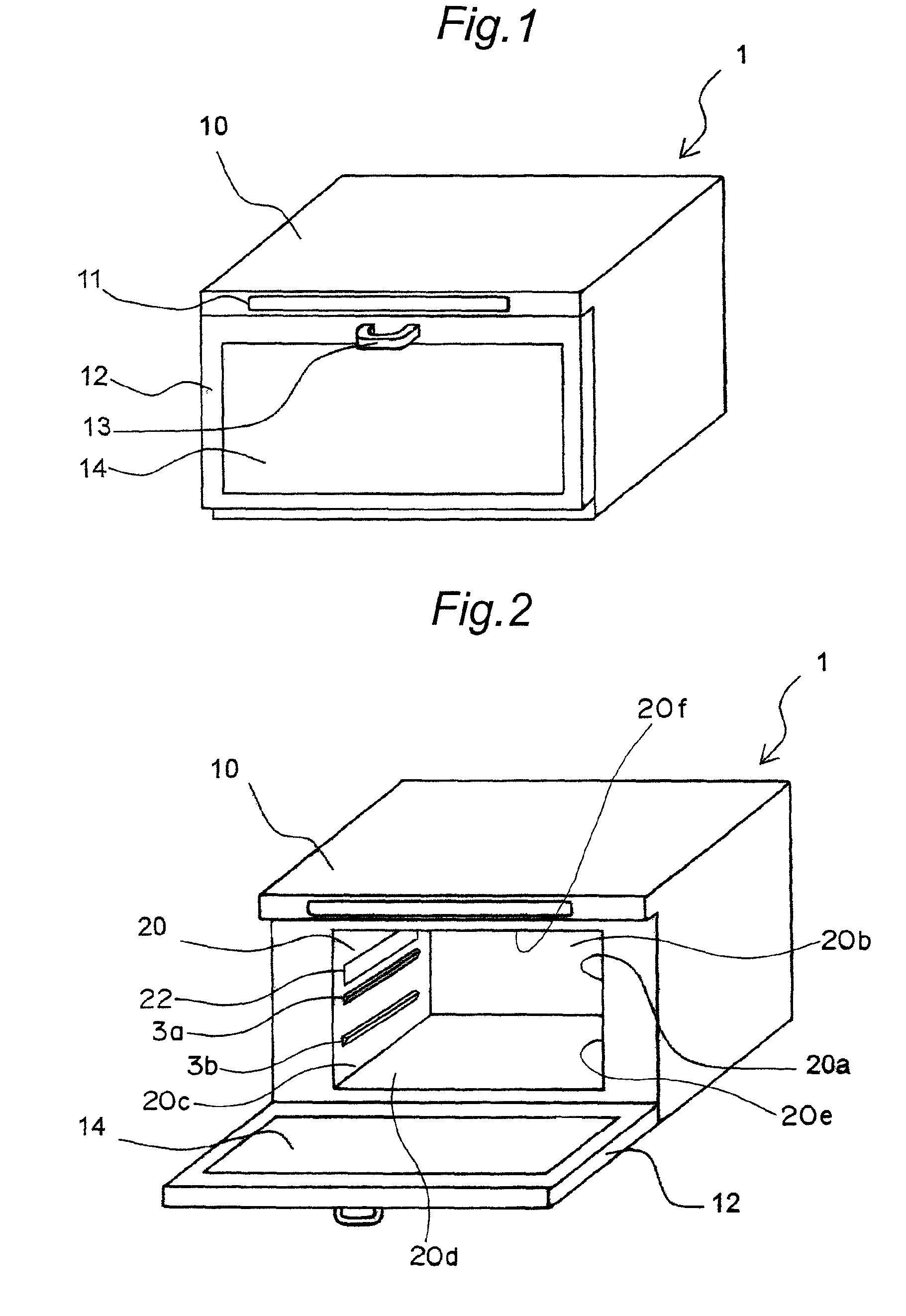

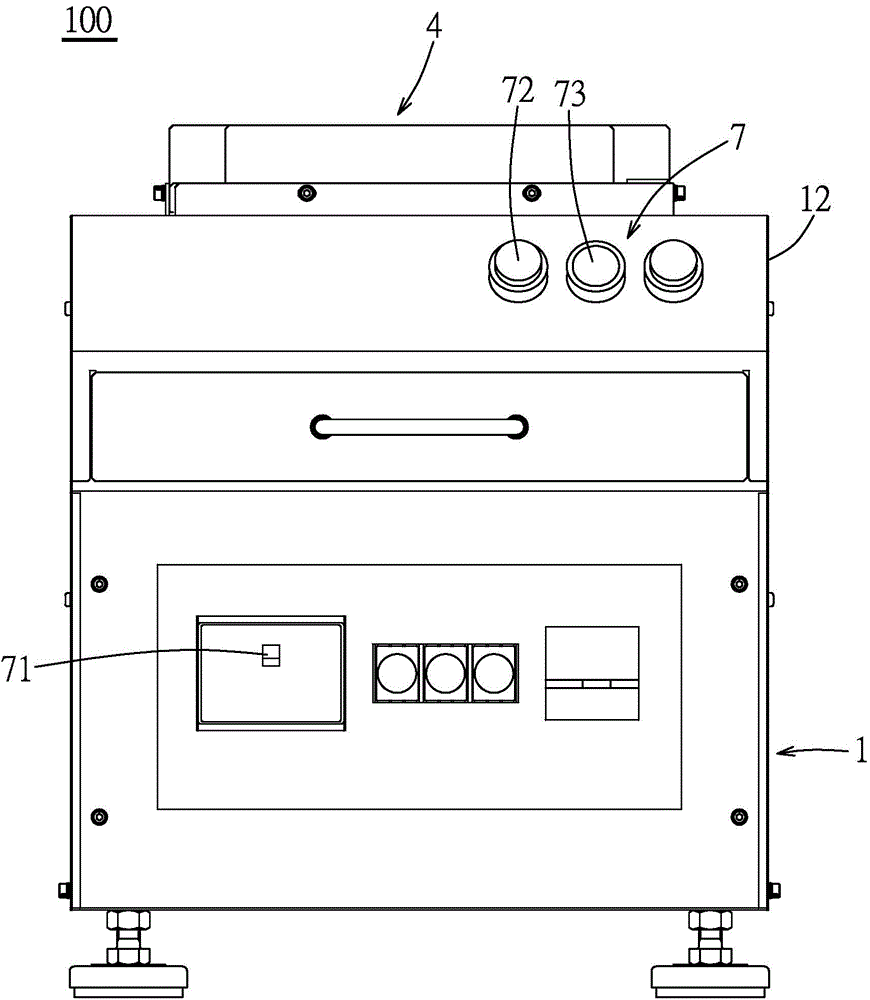

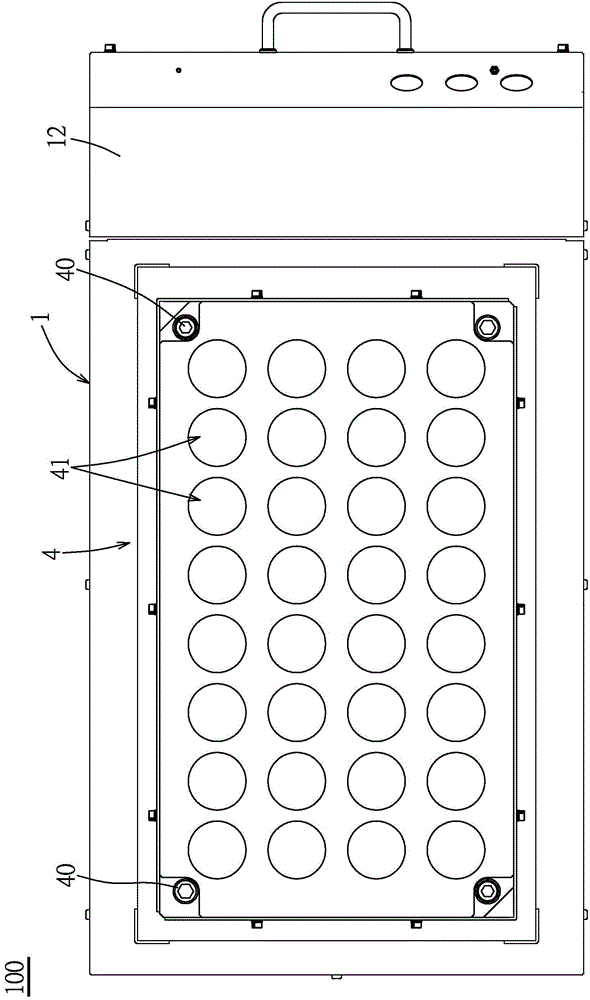

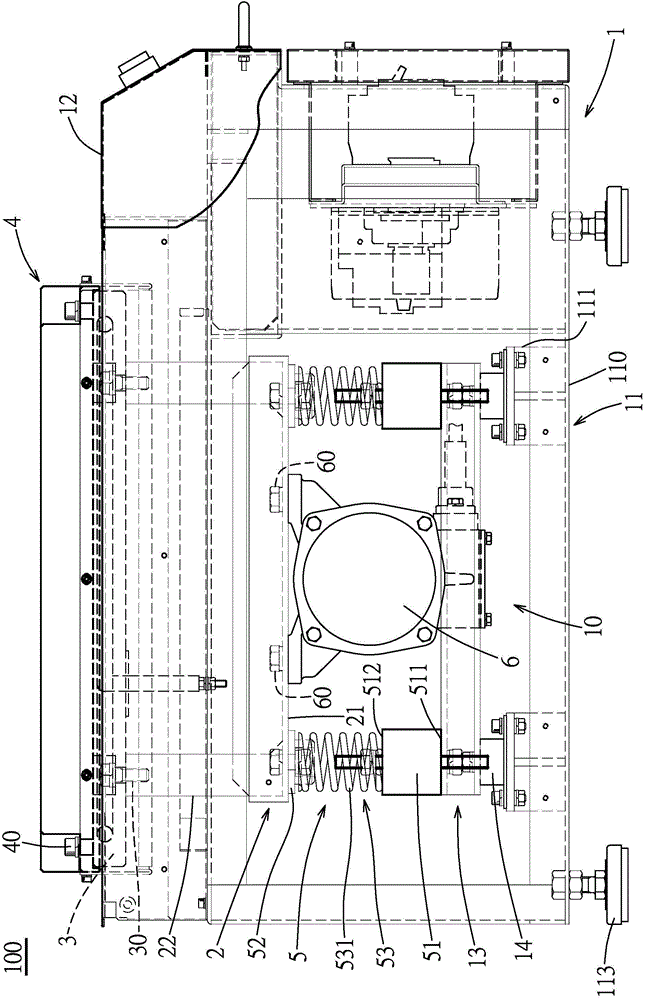

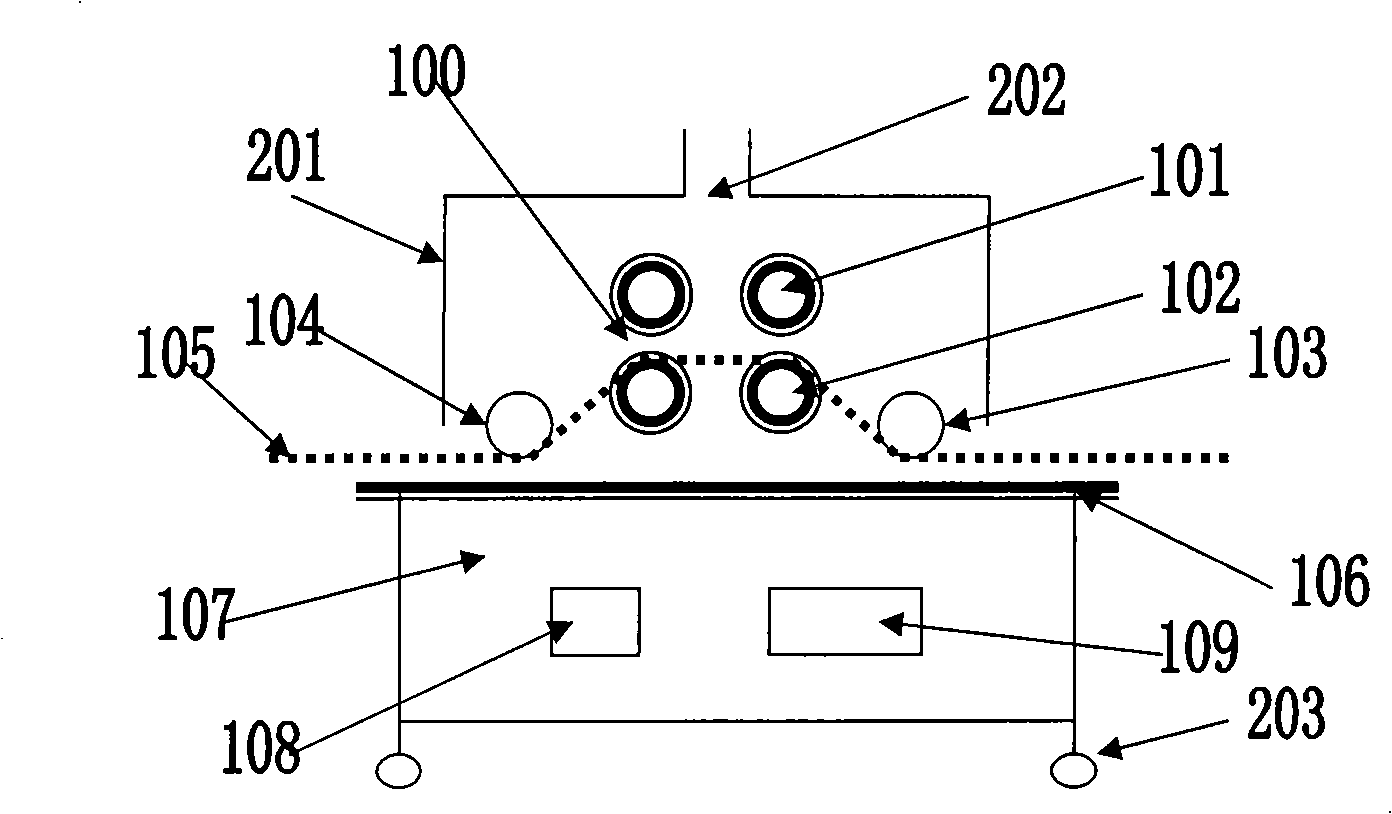

Drawer type cooking device having turntable mechanism

ActiveUS20100133263A1Avoid uneven heatingIncrease heightDomestic stoves or rangesCooking fumes removalMicrowave ovenEngineering

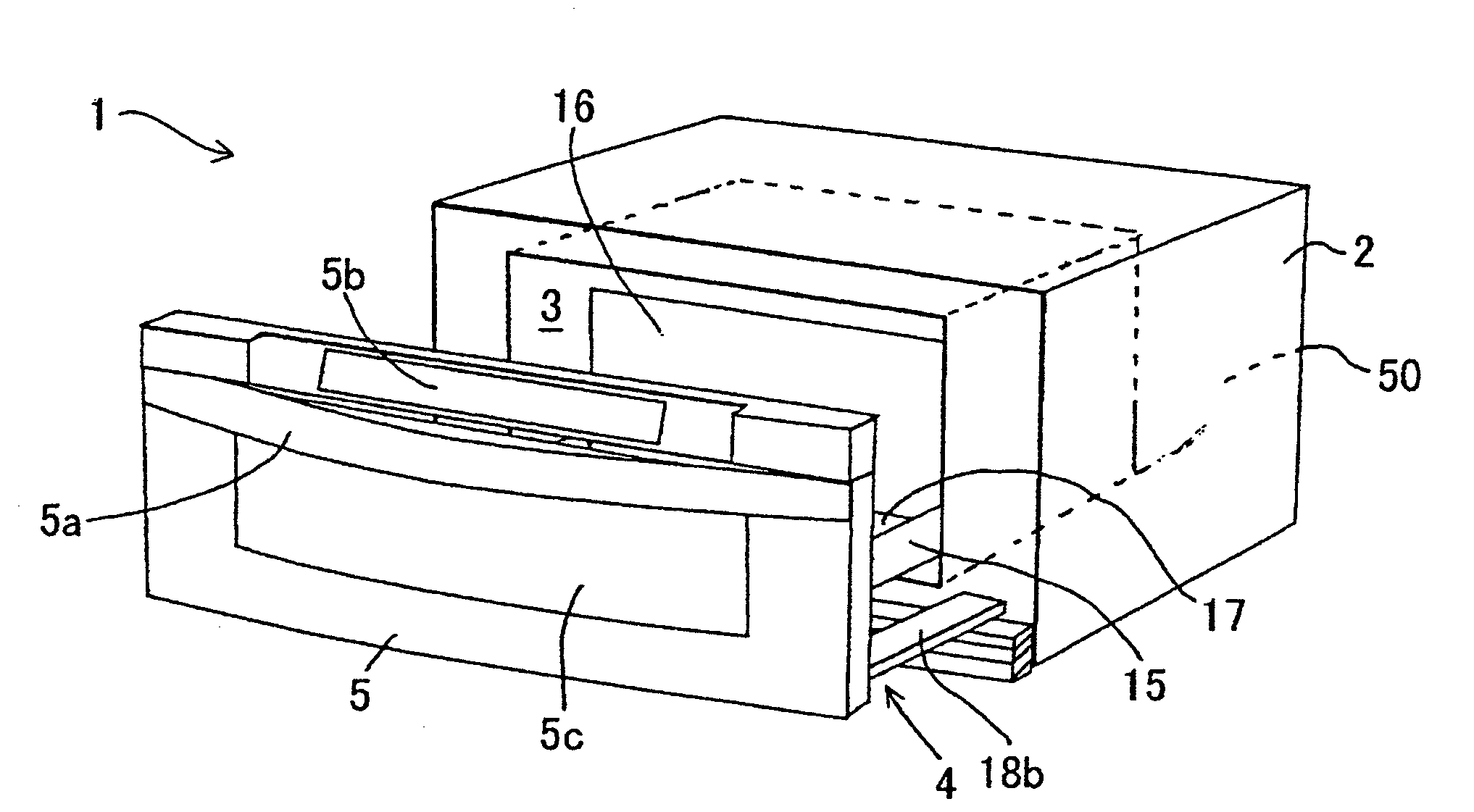

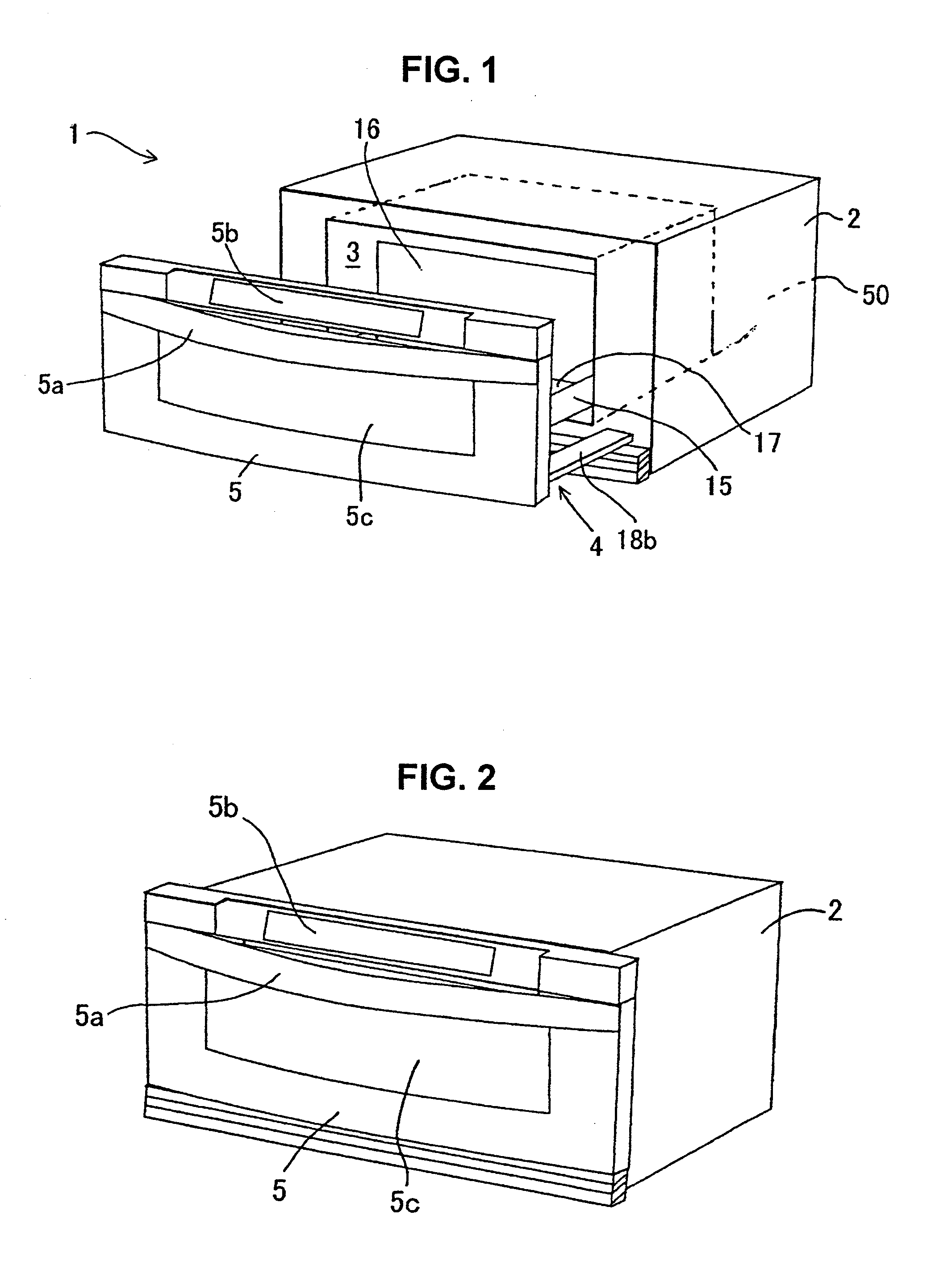

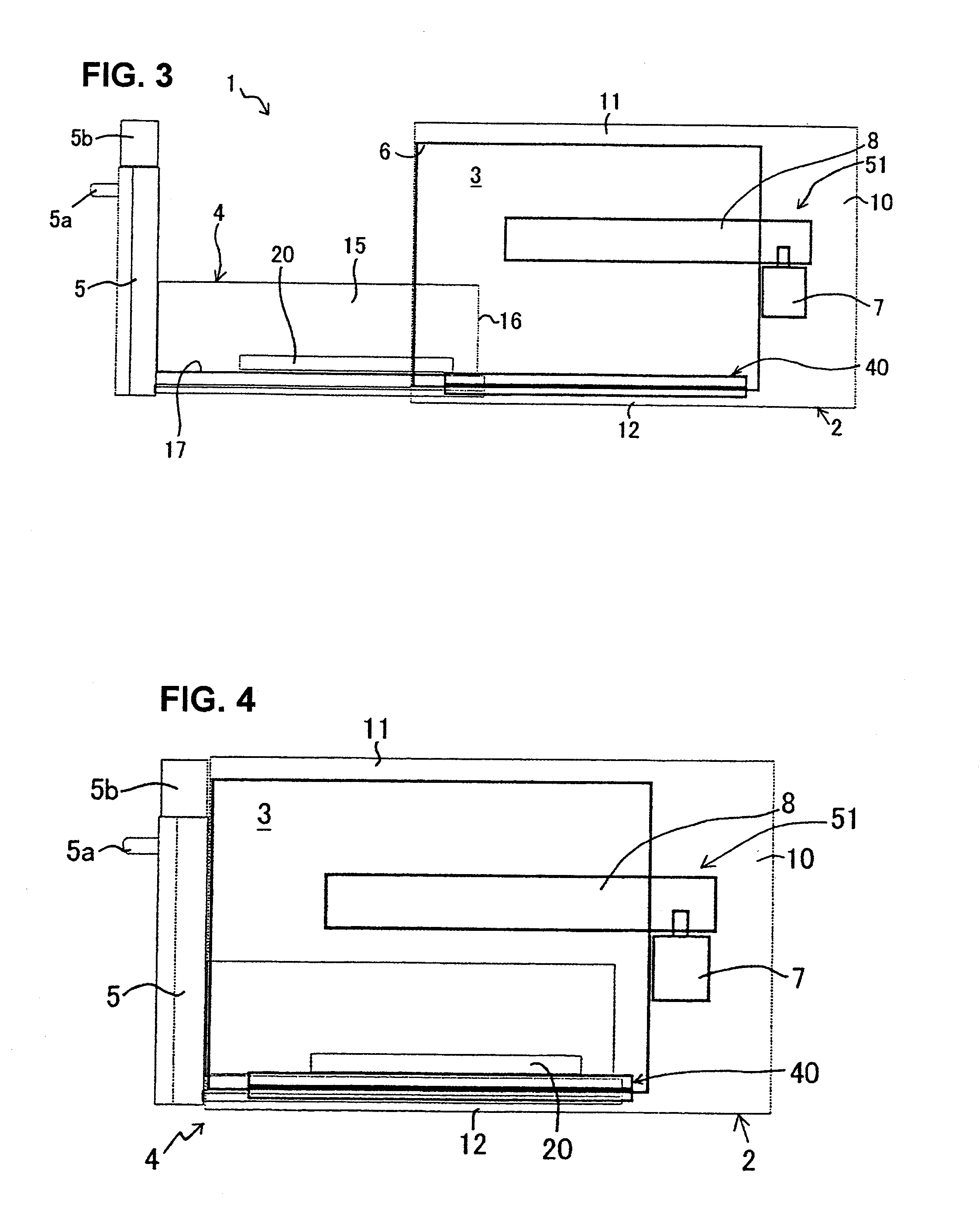

The invention provides a drawer type microwave oven having a turntable functioning as a uniform heating mechanism with a visual effect, while maintaining the ceiling height of a heating chamber and having improved usability. A turntable drive mechanism 40 utilizing a thin deceleration mechanism and a pivot mechanism is disposed in a space 19 formed between a bottom wall 17 of the drawer body 4 and a bottom wall 12 of the heating chamber 3, and a power transmission mechanism is engaged in a detachable manner in conjunction with the movement of the drawer body 4 together with the door. Thus, a drawer type microwave oven capable of performing uniform heating by pivot rotation while maintaining the ceiling height of the heating chamber is realized.

Owner:SHARP KK

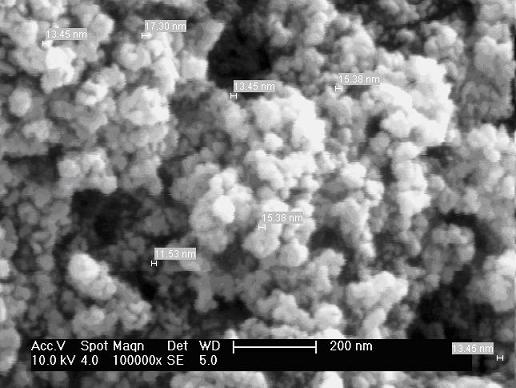

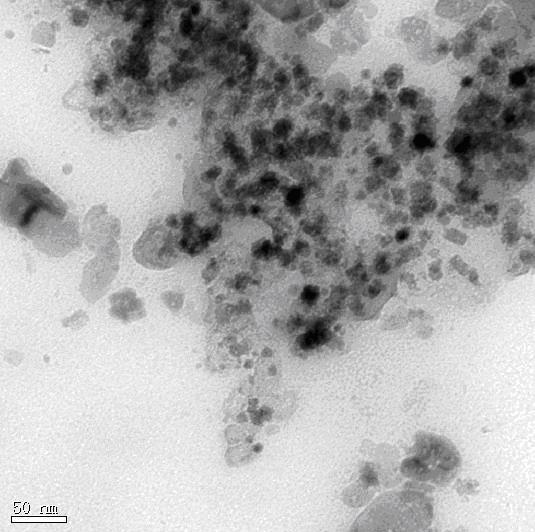

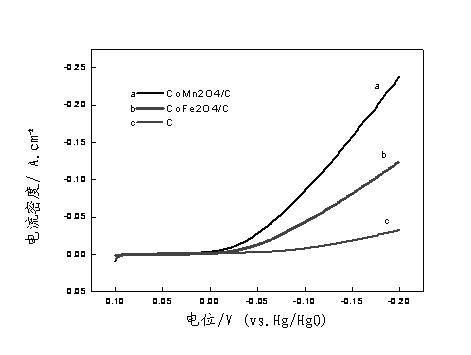

Transition metal composite oxide catalytic material and microwave preparation method thereof

InactiveCN101908628AAvoid uneven heating inside and outsideAvoid uneven heatingCell electrodesCatalyst activation/preparationHigh current densityComposite oxide

The invention discloses a transition metal composite oxide catalytic material and a microwave preparation method thereof, can output larger working voltage under higher current density, and has simple preparation method, easily controlled preparation process and rich raw material resources. The preparation method comprises the following steps: taking the nitrates of two transition metals according to the stoichiometric ratio of two metal elements, adding distilled water to prepare a solution, adding carbon black, stirring for reaction, and centrifuging to obtain the precipitate; washing the precipitate; drying at 50-80 DEG C and pulverizing to obtain a precursor, wherein the mass ratio of the transition metal composite oxide to the carbon black is 6:4, the A transition metal is one of Co, Mn, Fe and Ni, and the B transition metal is one of Co, Mn and Fe; and calcining the precursor by microwave to obtain the transition metal composite oxide catalytic material. The microwave calcining method of the invention has simple process and high efficiency, and the prepared spinel has a nano crystal form, small particle size and even distribution.

Owner:TIANJIN JIUJU ENERGY TECH DEV

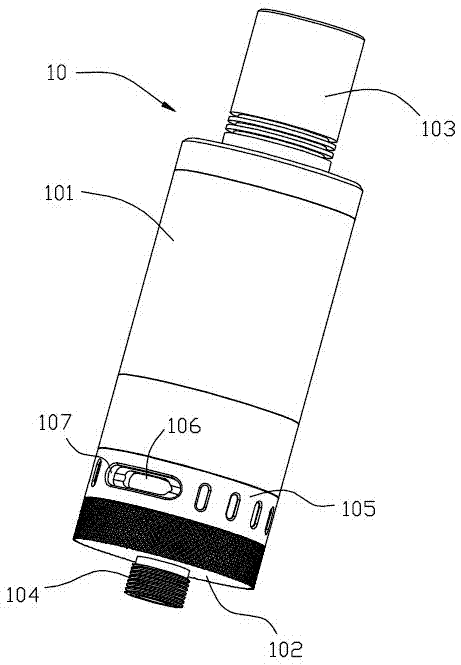

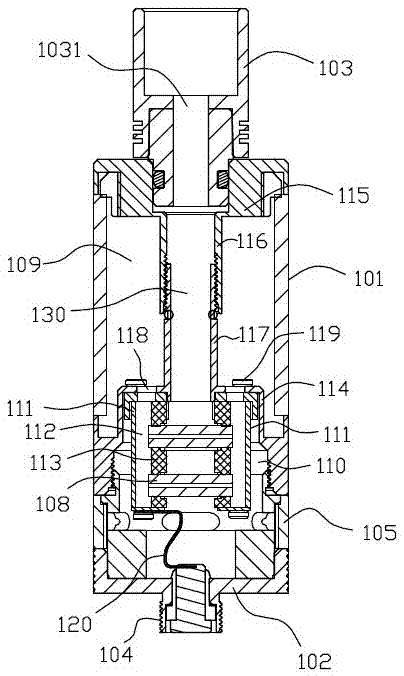

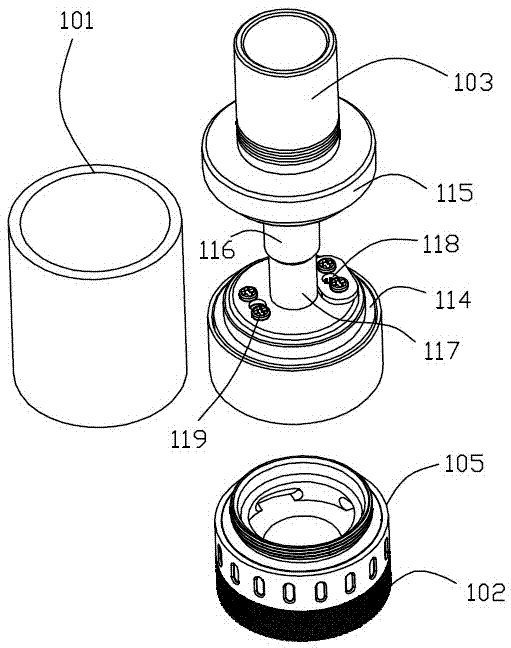

Atomizer and electronic smoking device

PendingCN105433443AWith heating functionEasy to assembleAdditive manufacturingOhmic-resistance waterproof/air-tight sealsCapillary actionLiquid storage

The invention discloses an atomizer and an electronic smoking device. The atomizer comprises a shell, an electric conduction part arranged on the shell and a suction nozzle with a gas outlet, a liquid storage cavity used for containing tobacco liquid is formed in the interior of the shell, the shell is further internally provided with at least one heating element which is electrically connected with the electric conduction part, each heating element comprises a liquid conduction carrier with a micropore structure and a heating part which forms an integral structure with the liquid conduction carrier, and the liquid conduction carrier can make contact with the tobacco liquid; the heating elements heat and atomize the tobacco liquid sucked by the liquid conduction carrier through the capillary action. The heating elements in the atomizer have the functions of sucking the tobacco liquid and heating simultaneously, and the atomizer is simple in structure and capable of being applied to high-power electronic smoking devices.

Owner:SHENZHEN FIRST UNION TECH CO LTD

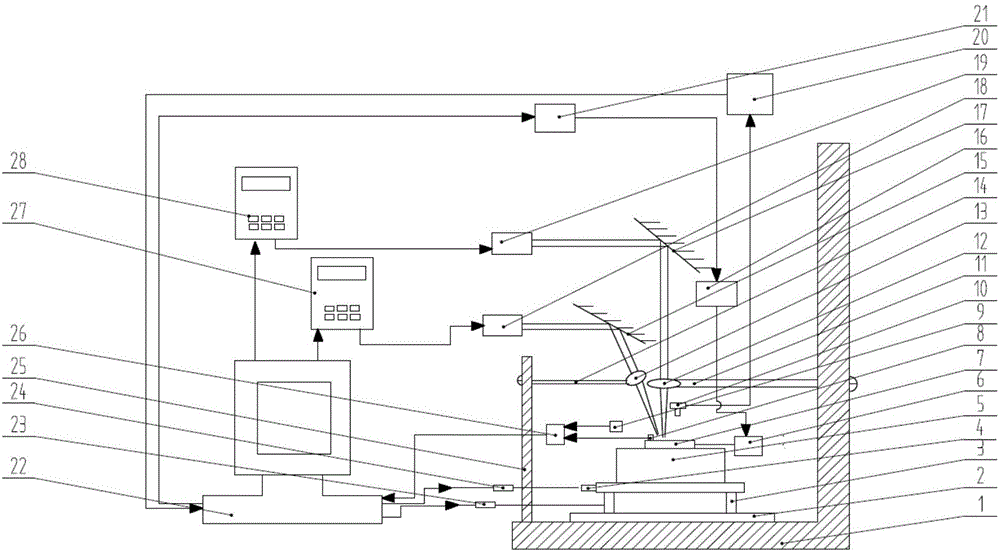

Novel laser indirect impact micro-forming device and method

InactiveCN107520538AGuaranteed forming qualityReduce scrap rateLaser beam welding apparatusControl systemContact type

The invention discloses a novel laser indirect impact micro-forming device and method. The device and method are mainly applied to plastic forming technique and manufacturing of fine micro parts. The device and method solve the problem that a conventional laser impact micro-forming method is difficult in forming, and materials cannot be formed. The device comprises a mold-debug light spot centering assembly, a workpiece positioning assembly, a workpiece assembly, an Nd:YAG pulsed laser system used for impact forming, a CW optical fiber laser system used for heating, an ultrasonic vibration system and a control system. The device can achieve the aim that pulsed laser impact force is adopted to serve as an energy source, meanwhile, ultrasonic vibration is applied to a mold and a workpiece, or, a laser beam sent out by a CW optical fiber laser is used for carrying out non-contact type quasi-static heating on the surface of the workpiece, or, under the joint effect, workpiece micro-forming is achieved; due to the design, work efficiency is improved, design is reasonable, control performance is good, quality and precision of micro-forming parts are ensured, and the device is suitable for industrialized application.

Owner:JIANGSU UNIV

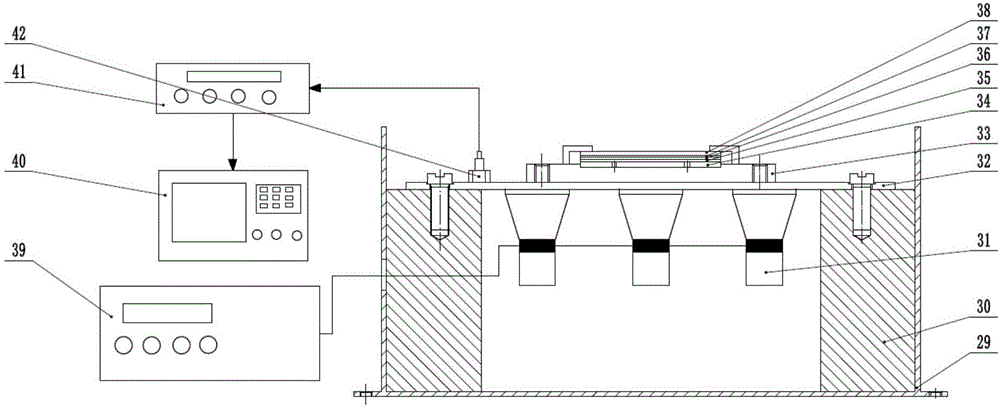

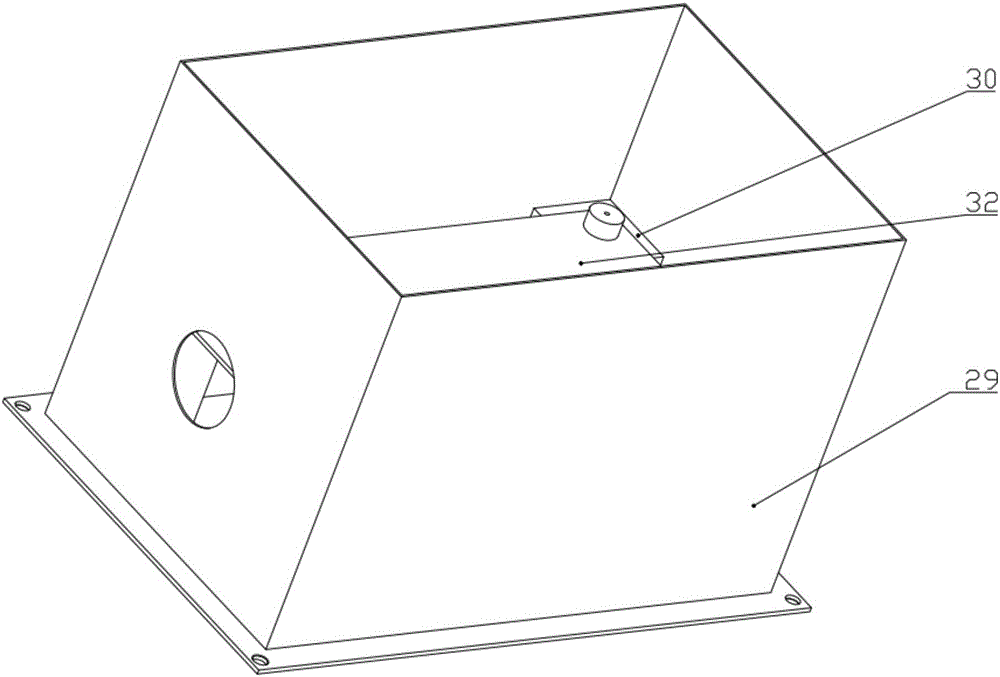

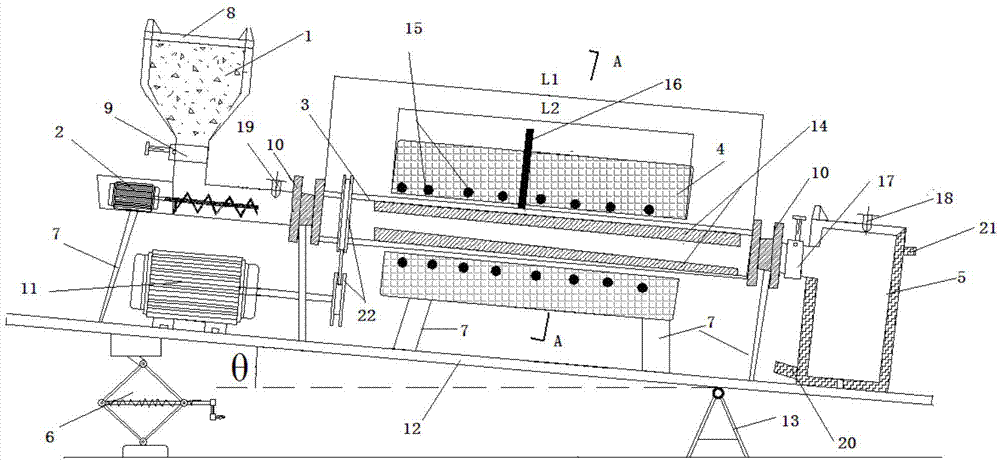

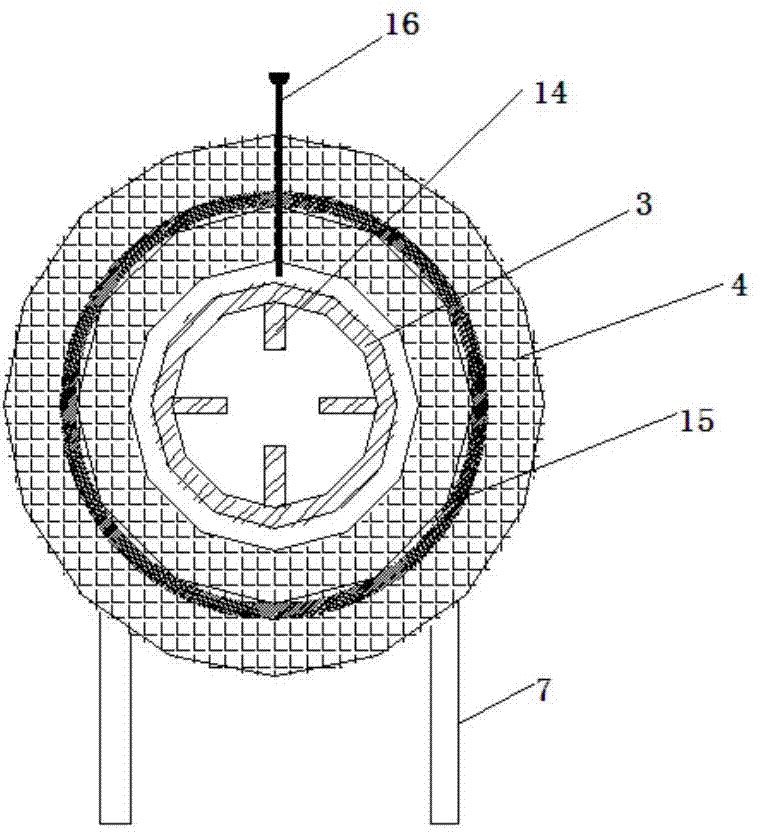

Dynamic continuous preparation method of Ti4O7 powder and dynamic continuous sintering device

InactiveCN104760993AEvenly heatedGuaranteed uniformityTitanium oxides/hydroxidesMaterials preparationChemical reaction

The invention provides a dynamic continuous preparation method of Ti4O7 powder. The dynamic continuous preparation method comprises the following steps: (1) material preparation: computing the weight percents of raw materials including TiO2 powder and reducing agents according to the chemical formula of the Ti4O7 powder and chemical reaction between the used raw materials; (2) material mixing and drying; (3) sintering: heating furnace tubes in a sloping state in which discharge holes of the furnace tubes are lower than feeding holes of the furnace tubes and in a rotating state of the furnace tubes in an open system or a closed system or under negative pressure, continuously feeding the mixed powder obtained in the step (2) into the furnace tubes when the temperatures in the furnace tubes reach the reaction temperature, enabling the mixed powder to pass through heating zones of the furnace tubes in a form of screw motion after the mixed powder enters the furnace tubes to complete reaction to form a reaction product, enabling the reaction product to fall into a collecting chamber, and cooling the reaction product, thus obtaining the Ti4O7 powder. A dynamic continuous sintering device used in the method comprises a material storage chamber, a screw feeder, the furnace tubes, a furnace tube driving mechanism, a heating furnace, the collecting chamber, a support frame, a threaded lifter and a bracket.

Owner:CHENGDU DELIAN MINOTECH CO LTD

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

Drill welding system and drill welding method

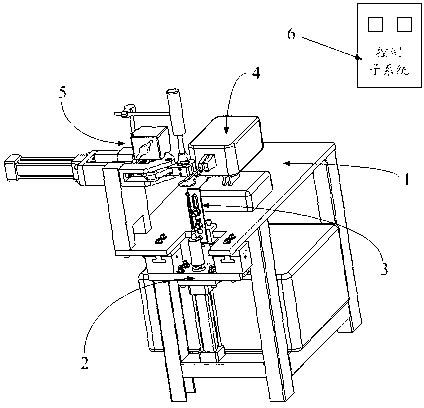

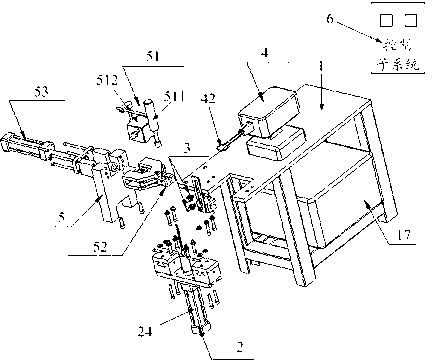

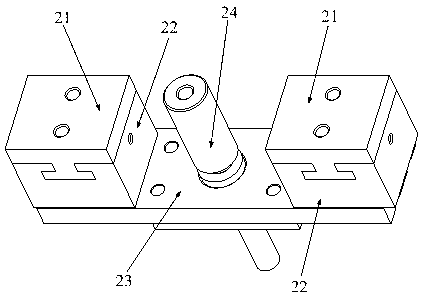

ActiveCN103028832AClear structureReasonable settingWelding/cutting auxillary devicesAuxillary welding devicesRadial positionUltimate tensile strength

The invention discloses a drill welding system, the drill welding system comprises a cutter bar moving device, a welding and heating device, a tool bit adjusting device and a controlling subsystem, the cutter bar moving device is used for placing and moving the cutter bar placed a tool bit and welding materials on the top portion; the welding and heating device is used for heating the welding materials to melt to an end portion of the cutter bar; the tool bit adjusting device is used for adjusting the axial position and radial position of the tool bit and the cutter bar, thereby guaranteeing the concentricity and compactness of the cutter bar and the tool bit; the cutter bar moving device, the welding and heating device and the tool bit adjusting device are respectively connected with the controlling subsystem, the cutter bar moving device used for a controlling positioning pre-added drill returns to seat after sequentially passing the welding and heating device and the tool bit adjusting device. The invention further provides a drill welding method. The drill welding system and drill welding method has the advantages of improving accuracy as well as speed of welding, greatly improving the quality of welding and productivity and lowering the labor intensity of workers. The drill also has high concentricity and firm connection.

Owner:SHANGHAI KUNJEK HANDTOOLS & HARDWARE

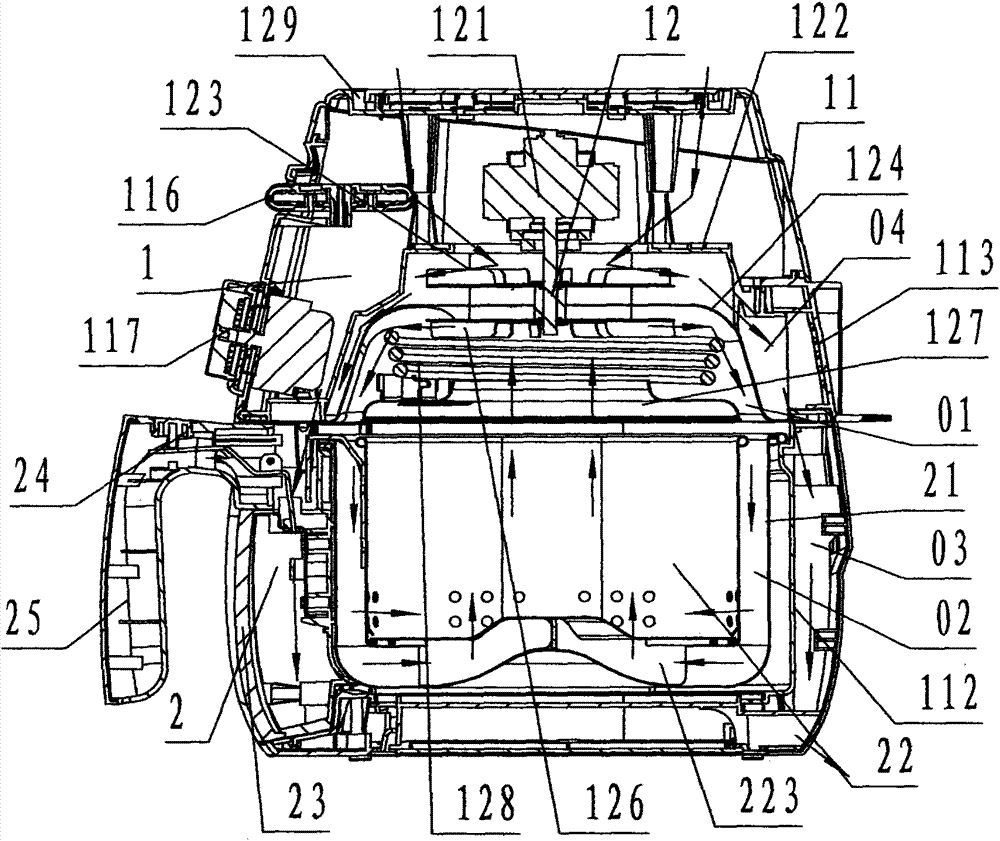

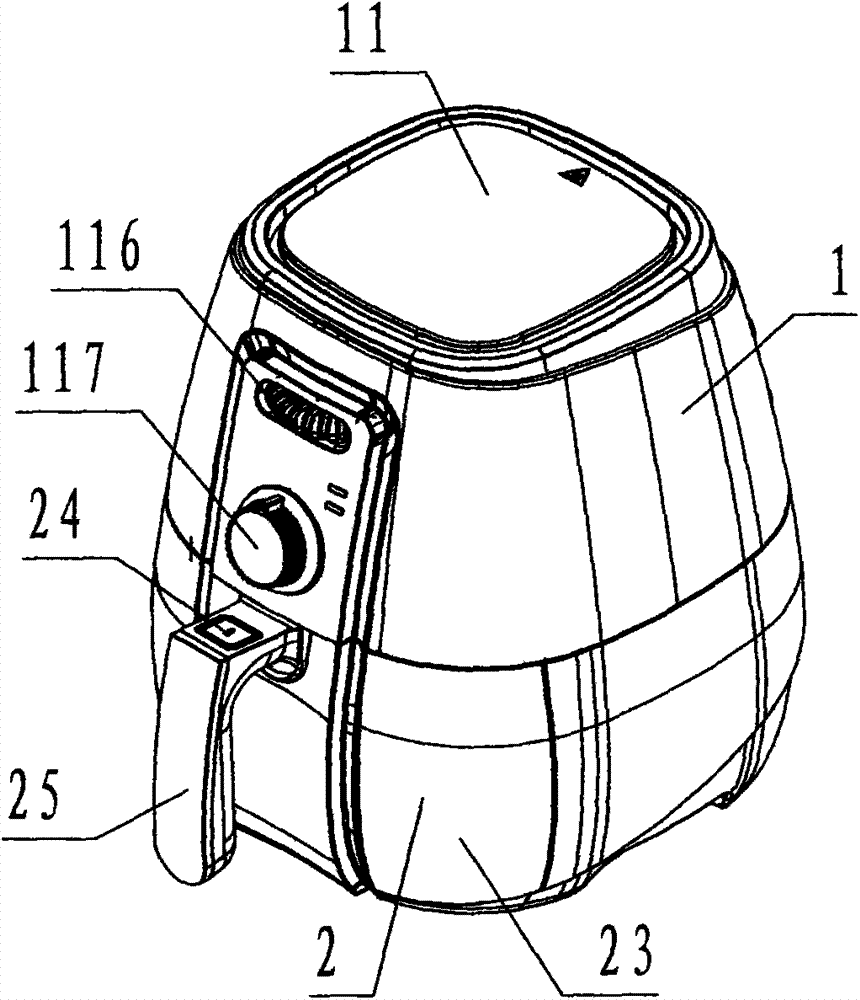

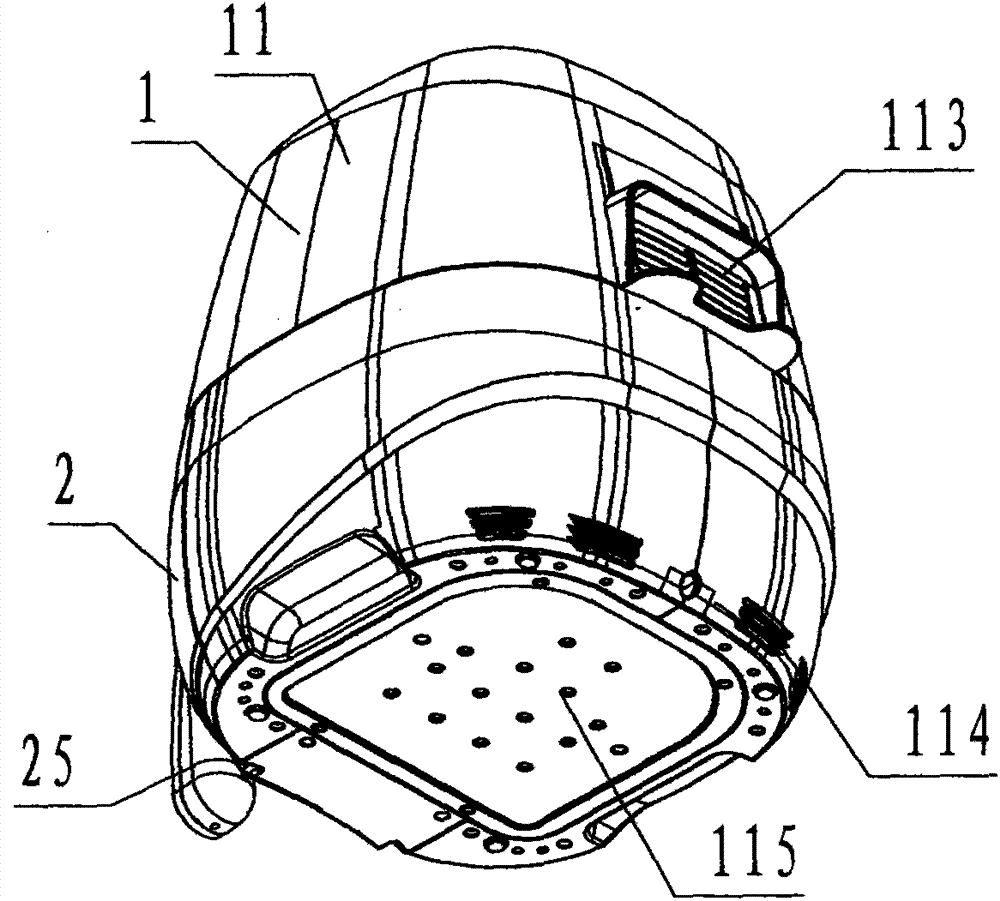

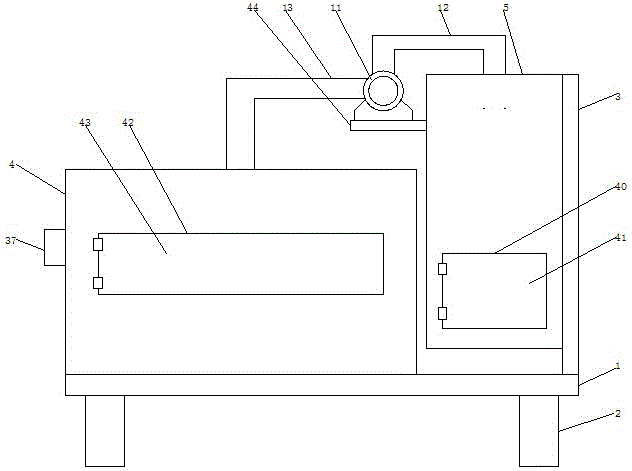

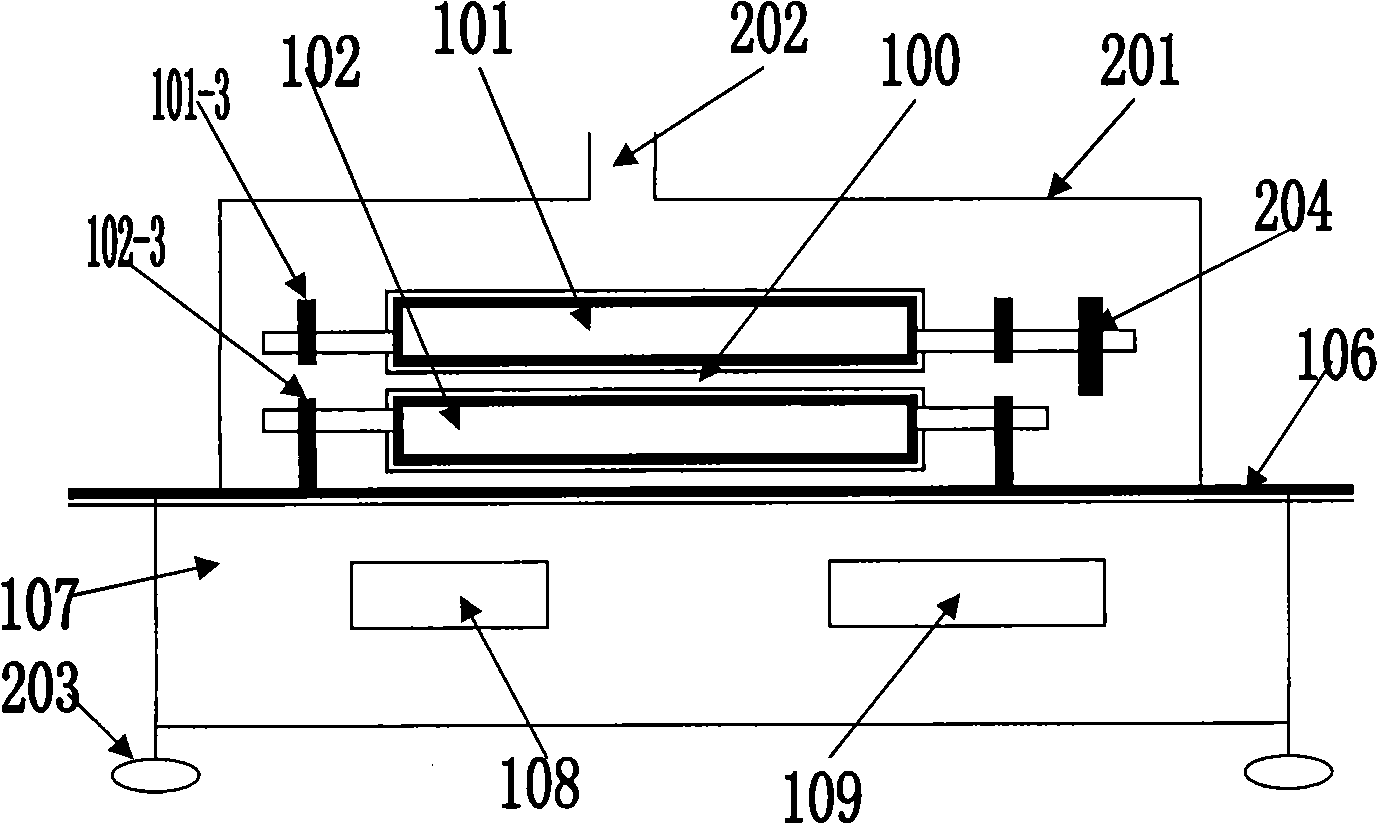

Household electric-heating air heat baking pot

The invention discloses a household electric-heating air heat baking pot which comprises a hot air generating portion (1) and a drawer pot (2). A device composed of the hot air generating portion and the drawer pot is adopted, a drawer pot socket used for inserting of the drawer pot is arrange on the lower portion of the hot air generating portion, a fan and electrical heated tubes are arranged on the upper portion of the hot air generating portion, the fan is downwardly provided with a fan cover, an upper blade, a hot air guiding hood, a lower blade and a hot air suction hood, a motor is located above the fan cover, and a gap formed between side walls of the hot air guiding hood and the hot air suction hood is called as an upper hot air channel; the drawer pot is internally provided with a hot air pot and a net basket, and a gap formed between the hot air pot and the net basket is called as a lower hot air channel. The technical scheme includes that when in use of the baking pot, the drawer pot is located in the drawer pot socket, food is placed in the net basket, the fan and the electrical heated tubes are started, and the lower blade drives hot air to enter the net basket via the lower hot air channel form the upper hot air channel to have the food cyclically heated, so that requirements of a household kitchen on hot air cookers are met.

Owner:NINGBO FENGYA ELECTRICAL APPLIANCES

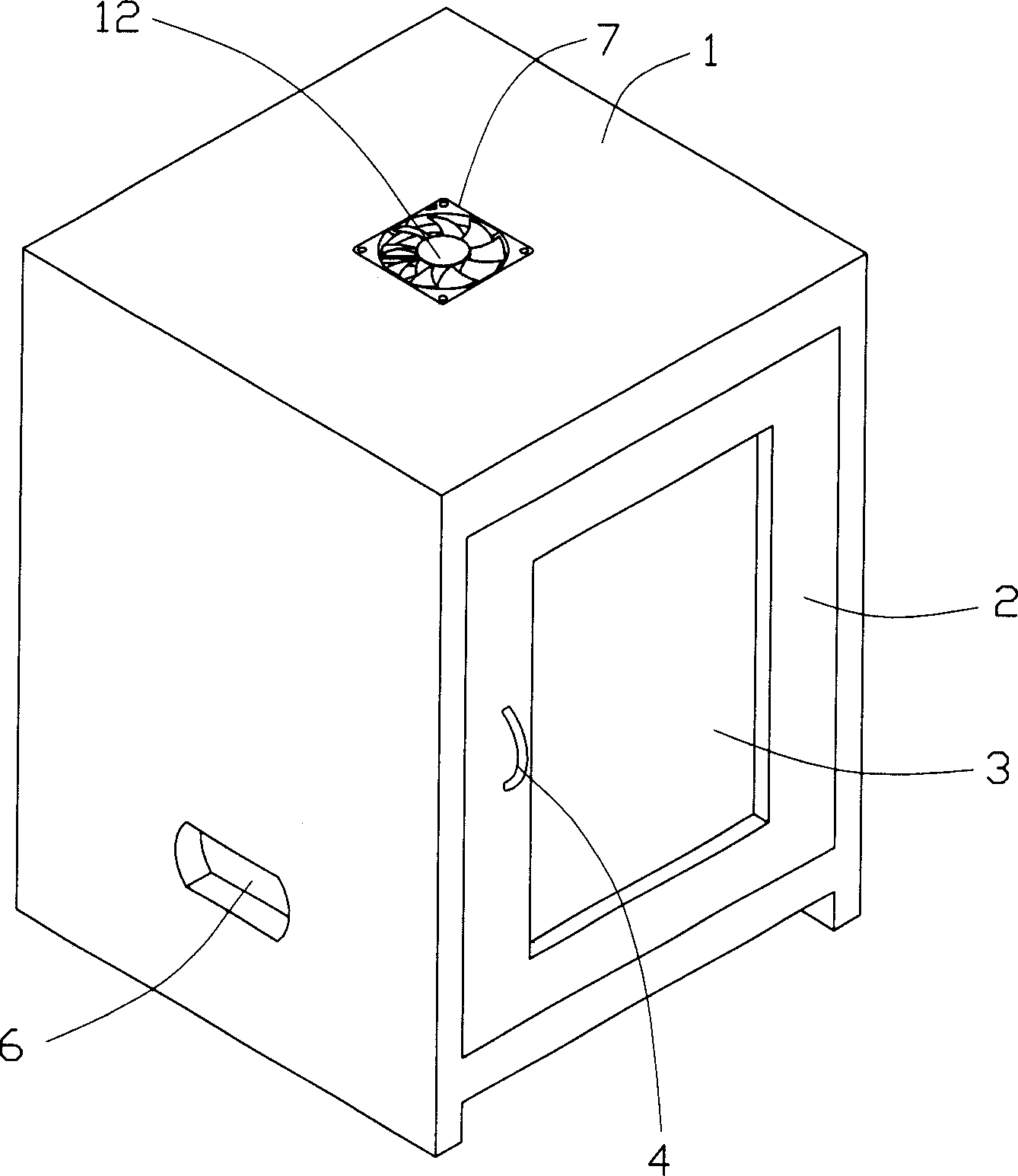

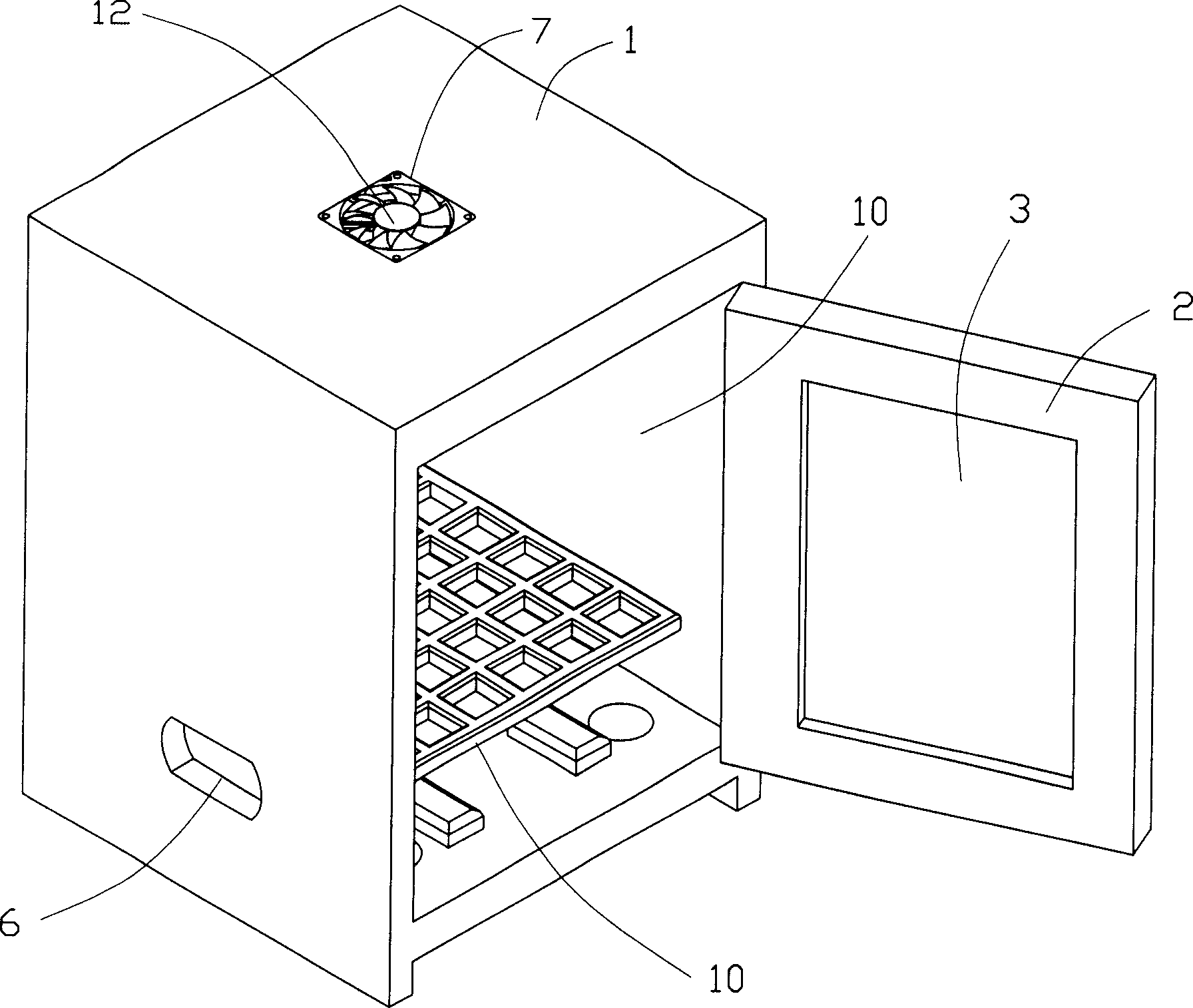

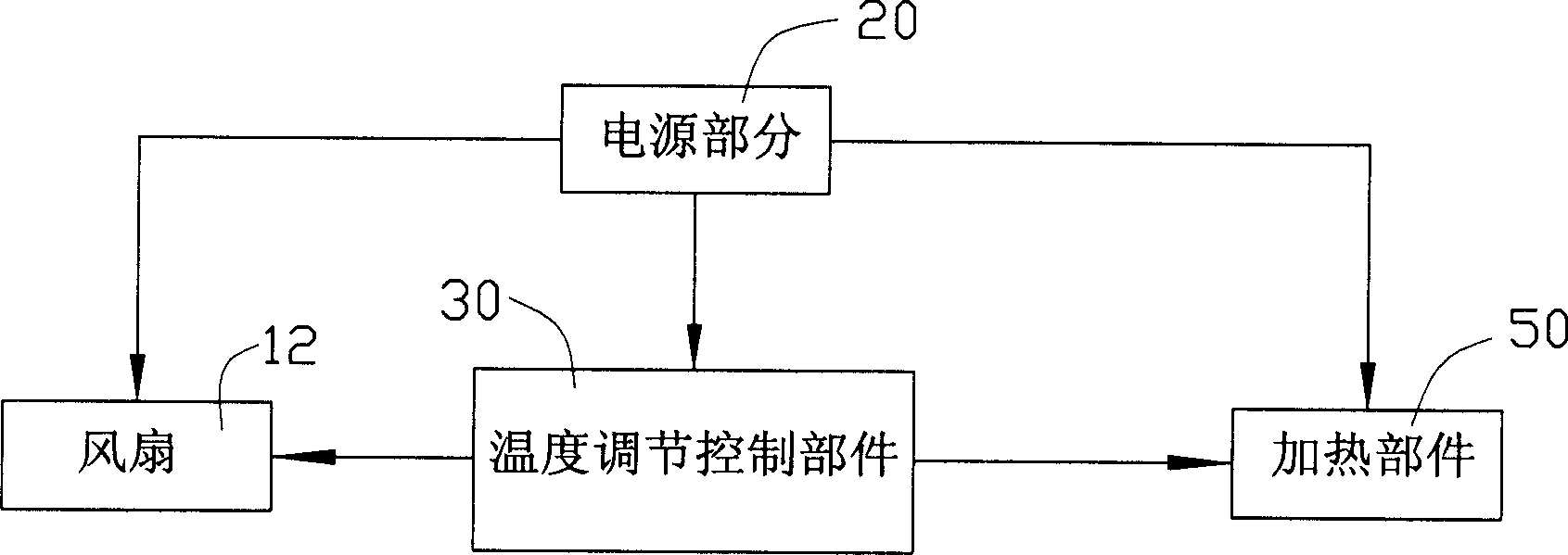

Automatic regulation type constant temperature box

InactiveCN1752880AAvoid uneven heatingTo achieve the purpose of simulating the natural environmentFurnace typesTemperature control using electric meansAuto regulationElectrical resistance and conductance

The present invention relates to an automatic regulated thermostat. It includes a tank body, a fan mounted on the top of said tank body and a bearing plate mounted in the interior of said tank body. The control circuit of said thermostat includes a power supply portion, a temperature regulation control component and a heating component placed in the interior of said tank body, the temperature regulation control component includes a T-type temperature-sensing thermowire, a temperature controller, a double-control relay and several single-control relays.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

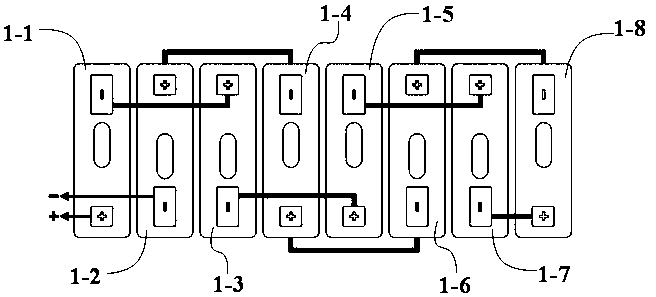

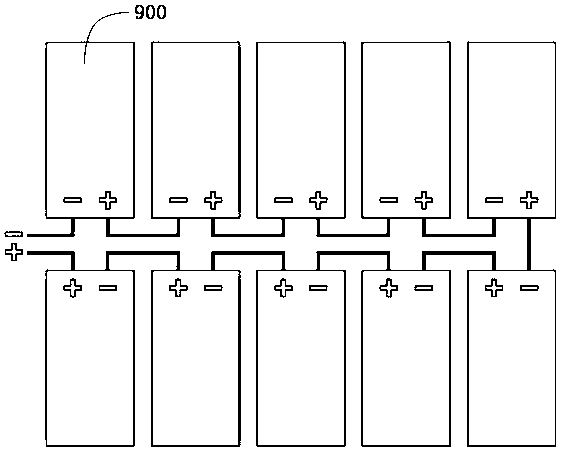

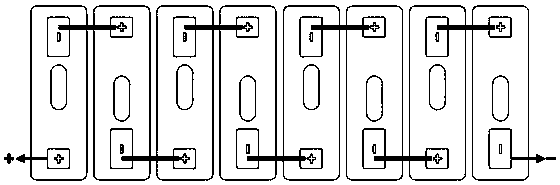

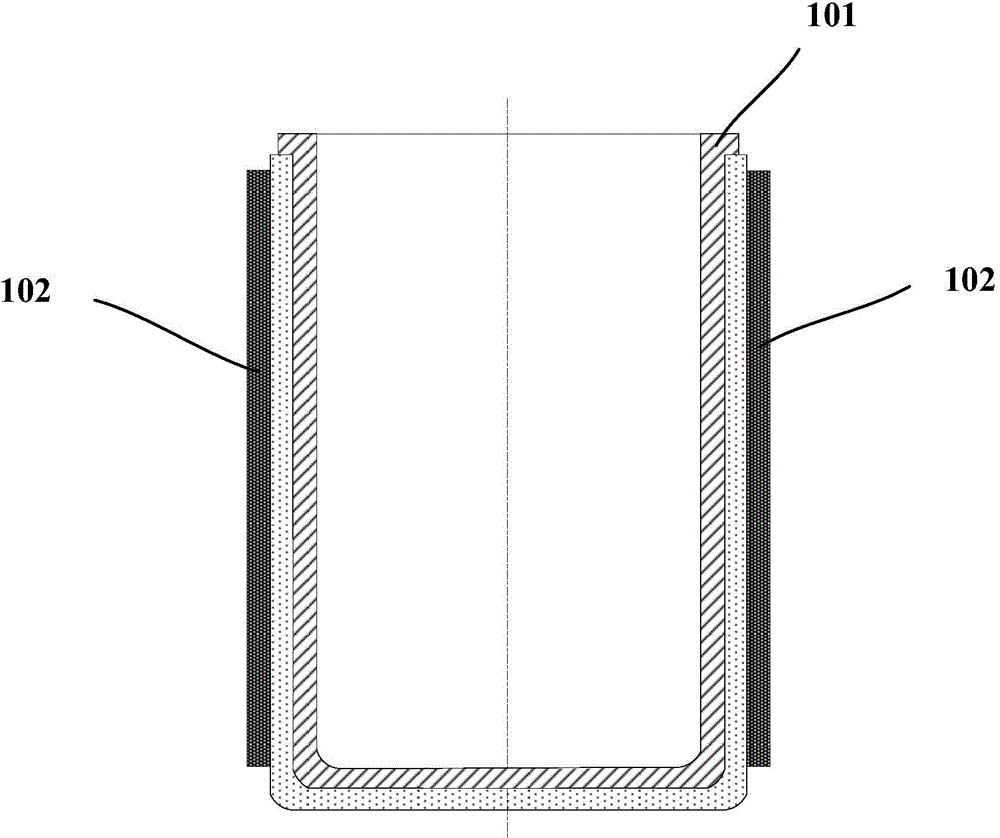

Battery module with same-side electrode output

PendingCN110931694AReduce complexityImprove physical performanceCurrent conducting connectionsCells structural combinationElectrical batteryHemt circuits

The invention discloses a battery module with same-side electrode output, which comprises a plurality of square batteries arranged in sequence, and the positive electrodes and the negative electrodesof the batteries are positioned at the top and are respectively arranged at two sides of the central axis of the arrangement direction of the batteries. Along the arrangement direction of the batteries, the positive and negative electrodes of the first battery and the second battery are arranged on different sides, and then the positions of the positive and negative electrodes of every two batteries are changed. The positive electrode of the first battery is connected with the positive output electrode of the battery module, and the negative electrode of the second battery is connected with the negative output electrode of the battery module; the negative electrode of the first battery is connected to the positive electrode of the third battery, and the positive electrode of the second battery is connected to the negative electrode of the fourth battery, and so on. The bus connection mode of the series batteries in the battery module can reserve enough space for the monitoring circuitboard, and when the module package is formed, the low-voltage line connected with the monitoring circuit can be separated from the bus high-voltage wiring harness connected with the positive electrodeand the negative electrode of the battery module, so that the electromagnetic interference of the bus to the low-voltage line is greatly reduced.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

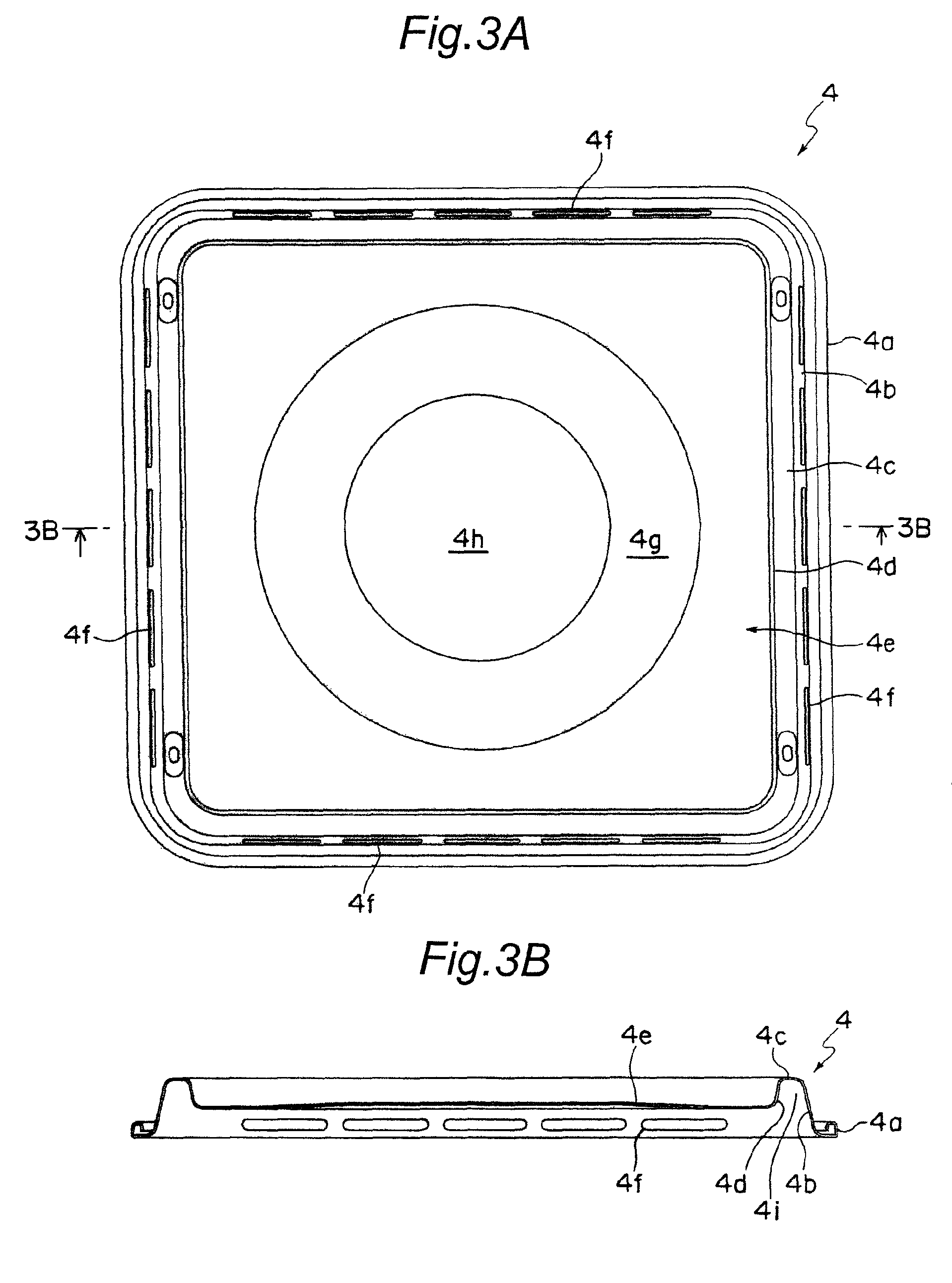

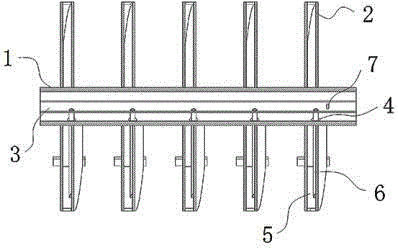

Heating cooker and tray therefor

InactiveUS8042458B2Reduce in quantityReduce effortAir-treating devicesDomestic stoves or rangesEngineeringCooker

A heating cooker has a side wall of a heating chamber (20) formed with an outlet (22) for discharging a heating fluid and an engagement portion (3a). A tray (4) has an edge portion (4a), a side wall portion (4b) having a thorough hole (4f), a flat surface portion (4c), an inner wall portion (4d), and a bottom portion (4e). When the tray is engaged with the engagement portion with its front surface side facing up, the through hole faces the outlet. A part of the discharged heating fluid is fed to the rear surface side of the tray through the through hole, and the remaining fluid is fed to the front surface side. When the tray is engaged with the engagement portion with its rear surface side facing up, an opening in a groove portion (4i) defined between the side wall portion and the inner wall portion faces upward.

Owner:SHARP KK

Prepn. of polyacrylonitrile-base high-performance raw carbon fiber

InactiveCN1167838CReduce gel particlesReduce intensityFibre chemical featuresItaconic acidMineralogy

The present invention relates to the preparation of high-performance polyacrylonitrile-based carbon fiber. Acrylonitrile, itaconic acid and methyl methacrylate in a certain weight proportion are reacted to obtain spinning dope, and the spinning dope is made into greign fiber of high-performance carbon fiber through filtering, solidification, water washing, drafting in hot water, oiling, drying and densifying, re-oiling, drying and densifying for the second time, steam drafting and drying setting. The present invention has the advantages of high drafting rate, homogeneous fibre structure, and small mechanical performance variation coefficient.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

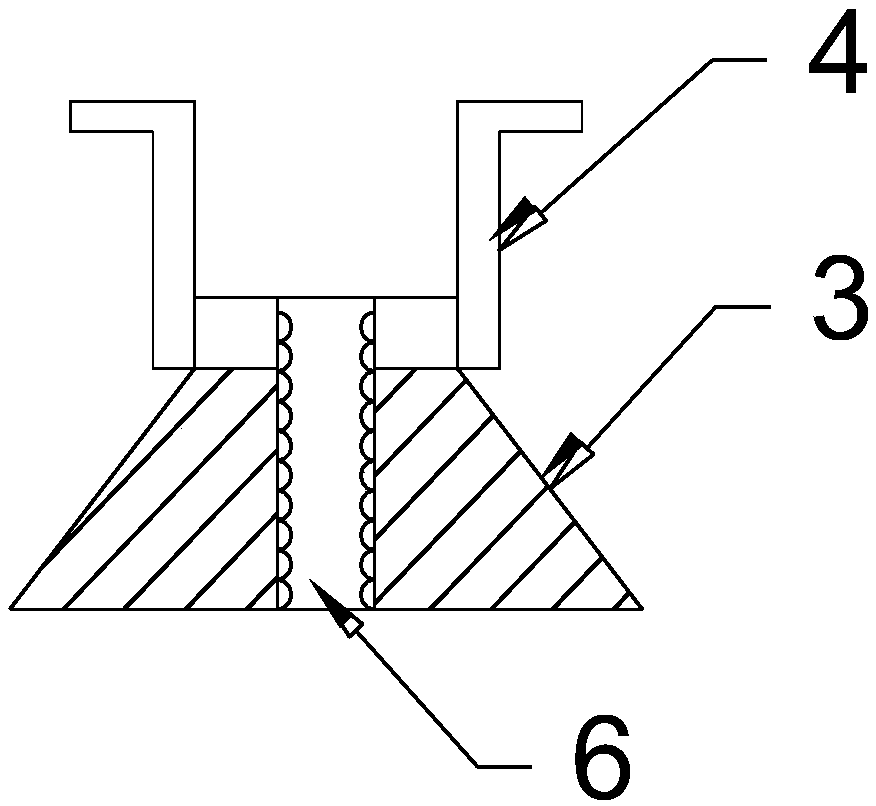

Food roasting device

InactiveCN105286649AInfluence of baking qualityAvoid uneven heatingRoasters/grillsFood materialEngineering

A food roasting device comprises a base, an upper bearing frame, a heating plate, a roasting tray, a buffering mechanism and a vibration motor. The base comprises a lower bearing frame below the upper bearing frame, the roasting tray provided with a plurality of holding grooves is arranged on the heating plate which is arranged on the upper bearing frame, and the holding grooves are used for holding to-be-roasted food materials. The buffering mechanism is arranged between the lower bearing frame and the upper bearing frame and comprises a plurality of lower connecting parts, a plurality of upper connecting parts and a plurality of compression springs, the lower connecting parts are arranged on the lower bearing frame, the upper connecting parts are arranged on the upper bearing frame, and upper and lower ends of each compression spring are abutted against the corresponding upper connecting part and the corresponding lower connecting part respectively. The vibration motor in operation is capable of driving the upper bearing frame, the heating plate and the roasting tray to vibrate.

Owner:陈谷光 +1

Heater for crucible, crucible and evaporation source

ActiveCN104357797AHigh purityAvoid uneven heatingVacuum evaporation coatingSputtering coatingDeposition temperatureCrucible

The invention provides a heater for a crucible, a crucible and an evaporation source. The heater comprises a containing cavity for containing the crucible and a middle heating unit arranged in the contain cavity, wherein the middle heating unit is used for heating a vapor deposition material in the middle of the crucible. The side heating unit positioned on the periphery of the crucible can be utilized to heat the vapor deposition material on the periphery of the crucible, and the middle heating unit of the heater can be utilized to heat the vapor deposition material in the middle of the crucible, thereby avoiding the phenomenon of nonuniform heating of the middle material and peripheral material of the crucible, enhancing the vapor deposition temperature uniformity, and further enhancing the purity of the vapor deposition material and the properties of the vapor deposition film.

Owner:BOE TECH GRP CO LTD +1

Steel bar for high-ductility and superhigh-strength pre-stressed concrete and machining method thereof

ActiveCN103484789AReduce intensityImproved resistance to hysteresis fractureUltra high pressurePre stress

The invention discloses a steel bar for high-ductility and superhigh-strength pre-stressed concrete and a machining method of the steel bar. The steel bar comprises, by weight, 0.3-0.5% of C, 0.3-1.8% of Si, 0.6-1.5% of Mn, 0.02-0.2% of Nb, 0.01-0.1% of V, 0.01-0.2% of Ni, 0.1-0.5% of Cr, 0.01-0.1% of Mo, 0.001-0.005% of B and the balance Fe, wherein the Ceq is smaller than 0.8%. Because an online continuous superhigh-pressure quenching control technology is adopted, the strength of the steel bar can be larger than 1860MPa or even larger than 2000MPa; because an online continuous quenching heat insulation and control technology is adopted, the ductility of the steel bar can be larger than 7%, the structural state of few ultra fine ferrites and tempered troostite is kept, and the steel bar has the advantages of being good in ductility and resistant to delayed fractures.

Owner:江苏森林建筑新材料股份有限公司

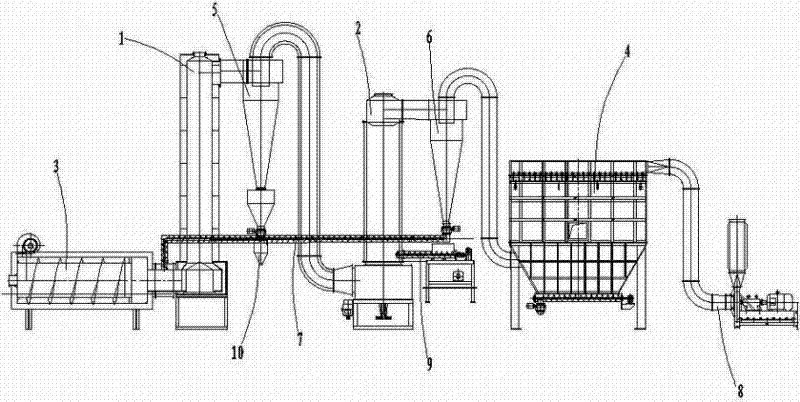

Calcination and flash drying cyclic energy saving technology for intermediate wet carbonate from soft magnetic manganese zinc iron composite material prepared through precipitation method

ActiveCN102249657AAvoid uneven heatingStable on ignitionInorganic material magnetismExcess heatCyclonic separation

The invention discloses a calcination and flash drying cyclic energy saving technology for an intermediate wet carbonate from a soft magnetic manganese zinc iron composite material prepared through a precipitation method. First, a calcining and expansion drying cyclic energy saving system is set up. Wet carbonate is added into a flash dryer, dried rapidly by waste heat in the dryer, and then sent to a secondary cyclone by system negative pressure, and enters to a calciner bottom from the cyclone bottom through a spiral. Depending on heat provided by an air heater and system negative pressure, the material fully contacts with heat and is treated with ebullience calcination in the calciner. After calcination, calcined material, together with superfluous heat, is introduced into a primary cyclone by the system negative pressure, treated with cyclone separation and falls into a hopper collector; and residual heat is introduced into a flash drying furnace bottom. According to the invention, an integral utilization of waste heat after calcination drying is realized; and the calcined material has stable physical ignition lost and is sieved by a 160 mesh screen, leaving riddling no more than 1%, to obtain black brown powder.

Owner:CHONGQING SHANGJIA ELECTRONICS

Waste recycling device and method for plastic product production

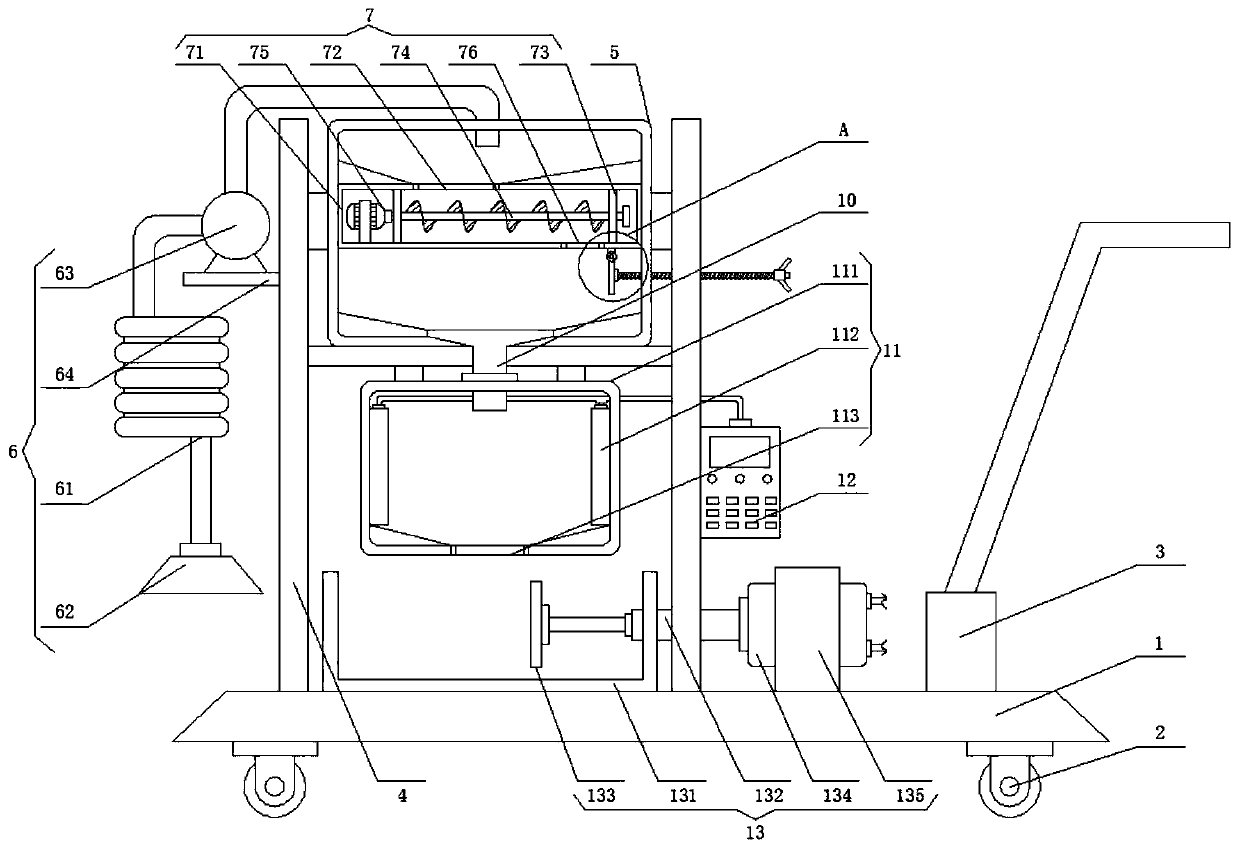

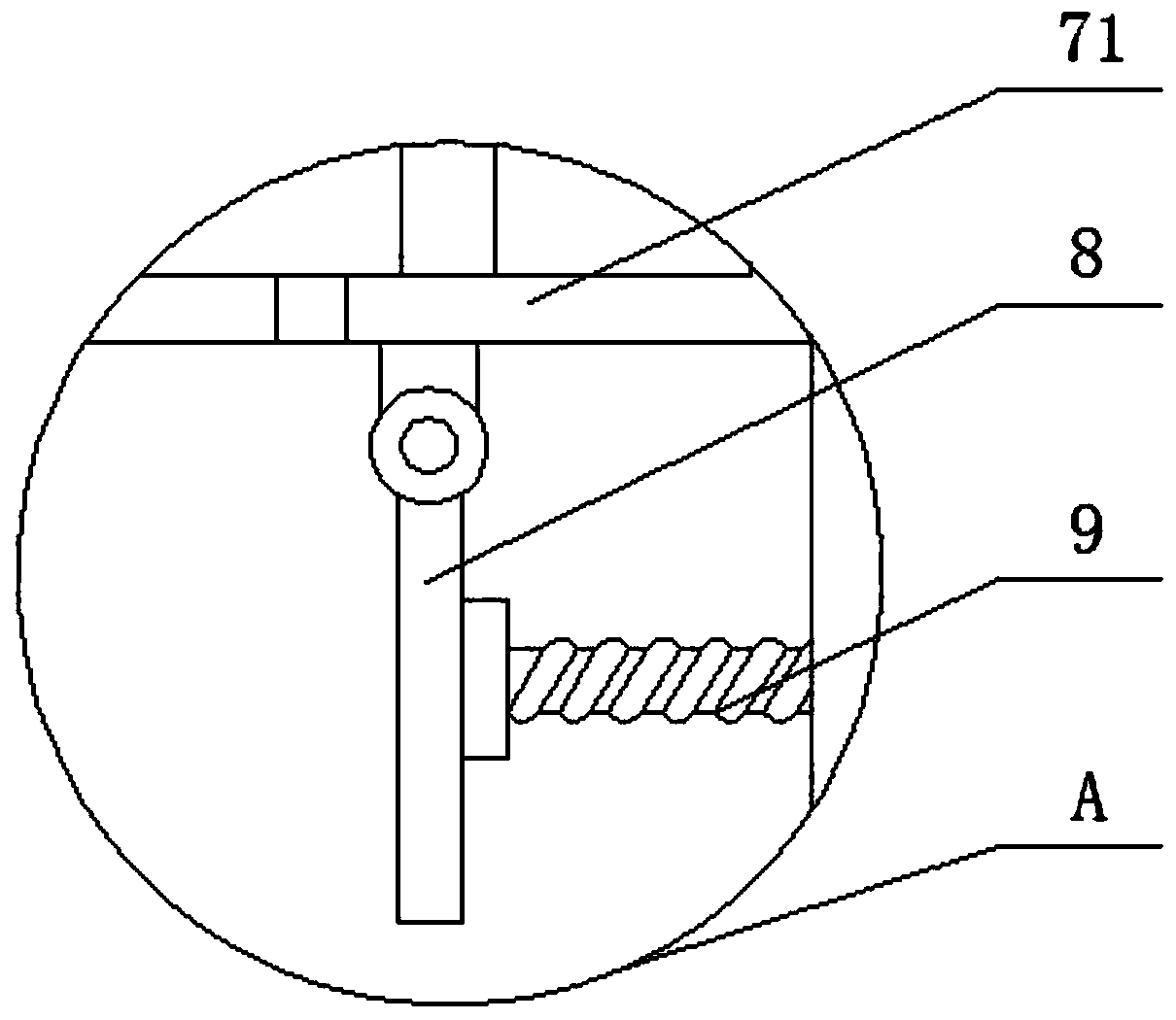

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

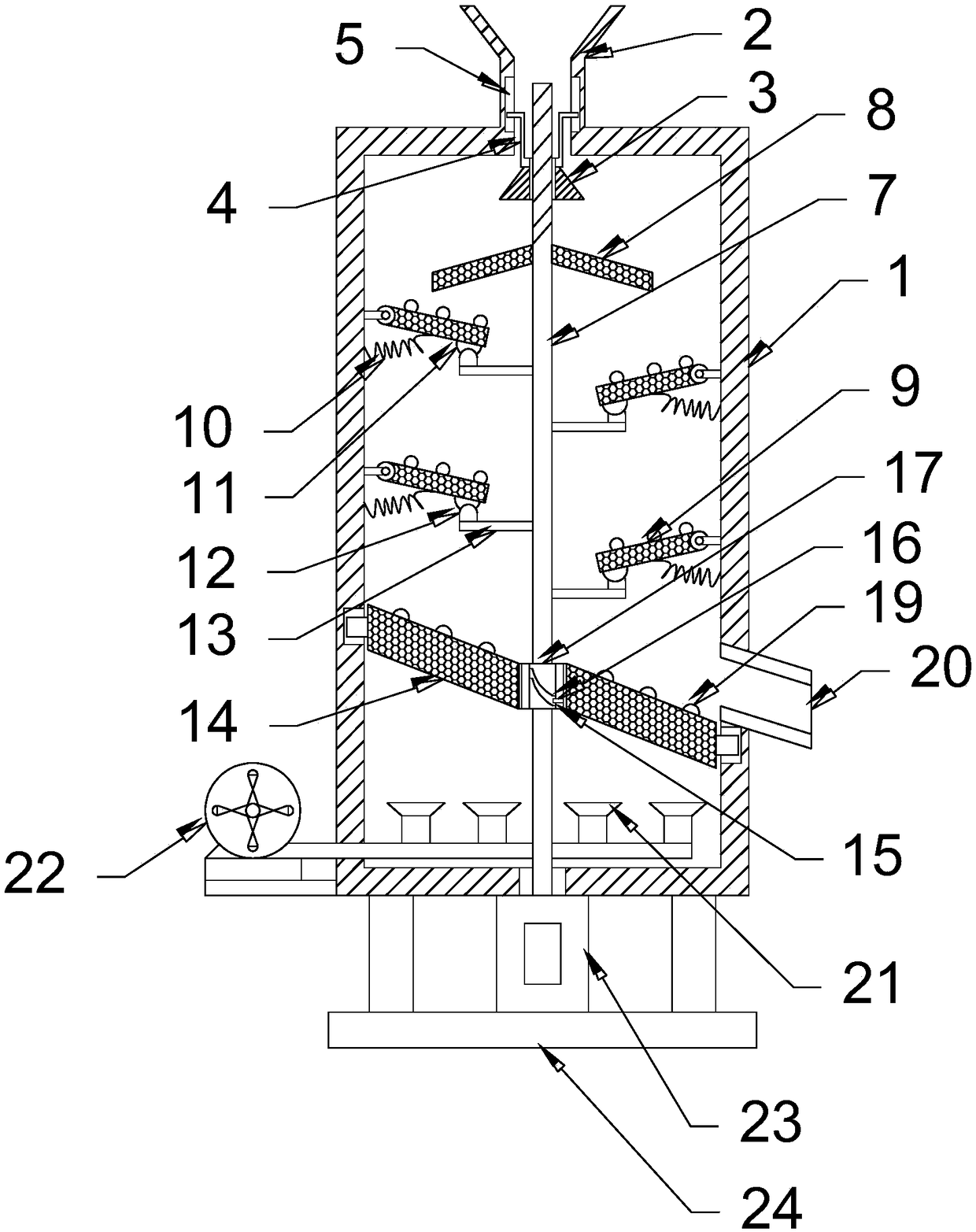

Tea drying box capable of conducting drying uniformly

The invention discloses a tea drying box capable of conducting drying uniformly. The tea drying box comprises a box body. A feeding pipe is connected to the top of the box body. A movable piston is arranged at the position, below the feeding pipe, inside the box body. Overturning plates are hinged to the positions, below a dispersing plate, of the inner walls of the left side and the right side ofthe box body, wherein the overturning plates are distributed in a staggered manner. A discharging plate is arranged below the overturning plates. According to the tea drying box, by means of the dispersing plate and the overturning plates with the surfaces being provided with protruding strips, tea is dispersed and then shaken to fall; the tea is uniformly dried by hot air through mesh holes in the overturning plates; meanwhile, the overturning plates ceaselessly shakes the tea, so that nonuniform heating is avoided; the tea drying box is provided with the movable plug, the movable plug movesup and down, so that intermittent discharging is achieved, and the drying effect is guaranteed; and the tea drying box is provided with the discharging plate which moves up and down, so that discharging is conducted uniformly.

Owner:南安市科联专利应用服务有限公司

Hollow stirring shaft for oil bath heating of sludge hydrolysis treatment equipment

PendingCN106746442AAvoid uneven heatingThorough thermal hydrolysis treatmentRotary stirring mixersTransportation and packagingSludgeThermal water

The invention relates to a hollow stirring shaft for oil bath heating of sludge hydrolysis treatment equipment. The hollow stirring shaft comprises a shaft body and stirring blades, a plurality of stirring blades are arranged on the shaft body in the axial direction of the shaft body, a hollow structure penetrating in the axial direction is arranged in the shaft body, a cavity is formed in the stirring blade, and through holes communicating the cavities with the hollow structure are formed in the side wall of the shaft body connected with the stirring blades. The hollow stirring shaft has the advantages that the shaft body and the stirring blades are of hollow structures, the hollow structures are filled with high temperature liquid (e.g., high temperature oil), and the high temperature liquid flows in the hollow structures, so that heat is transferred between the surfaces of the shaft body and the stirring blades and the interior of sludge, stirring heating on the interior of the sludge is completed, the situation that the sludge is not heated uniformly due to heating of a tank interlayer is avoided, the heating efficiency is improved, and simultaneously, the sludge heat hydrolysis treatment is more thorough.

Owner:SICHUAN GAOBO ENVIRONMENTAL PROTECTION ENG CO LTD

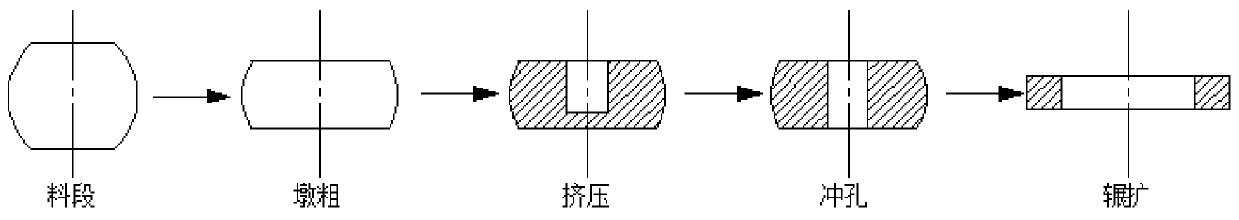

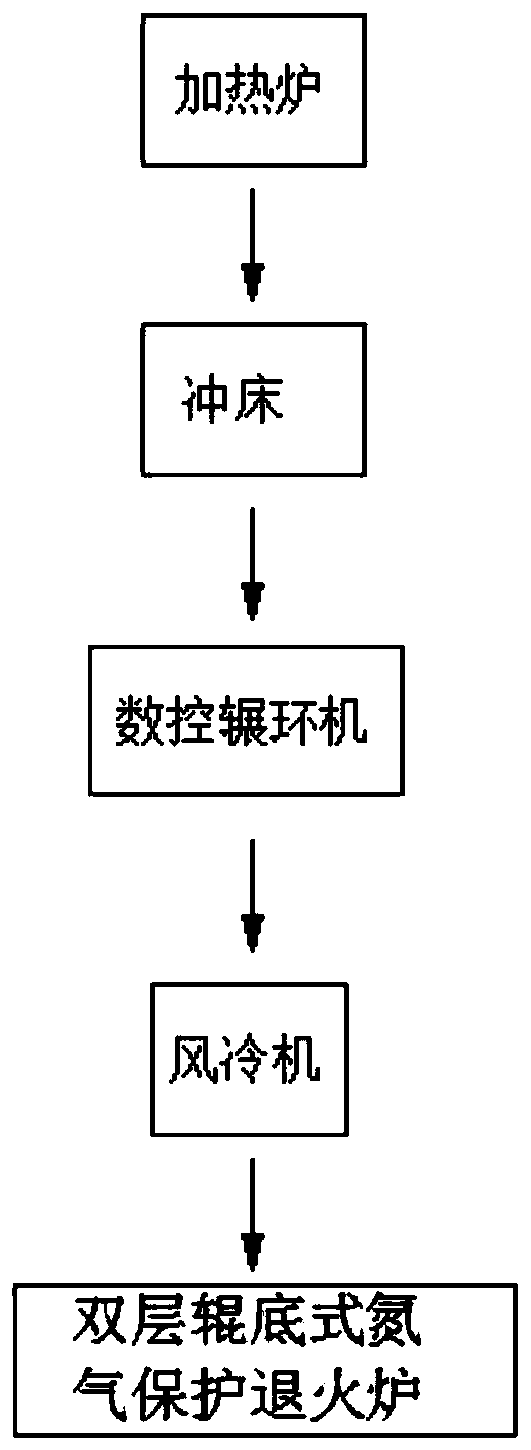

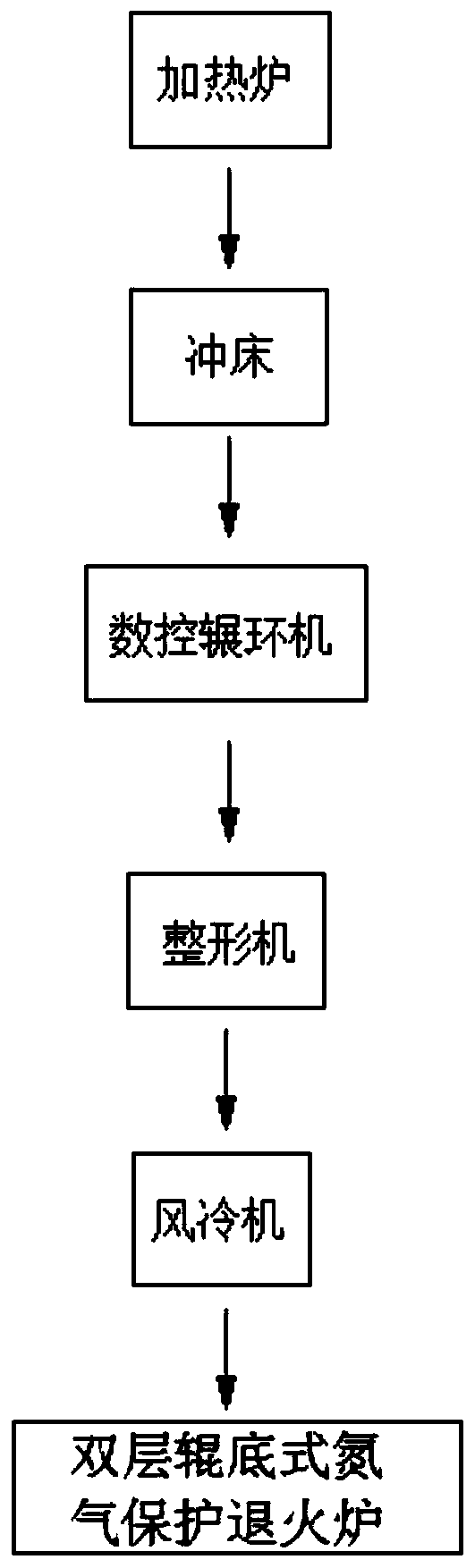

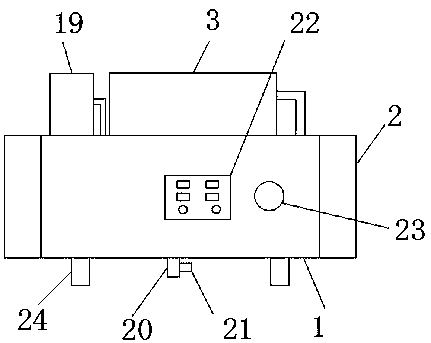

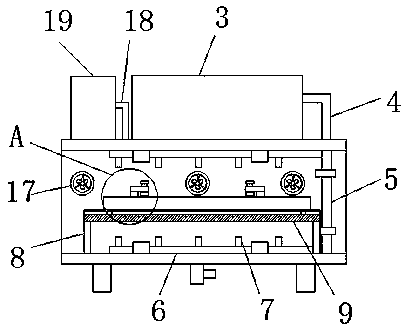

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

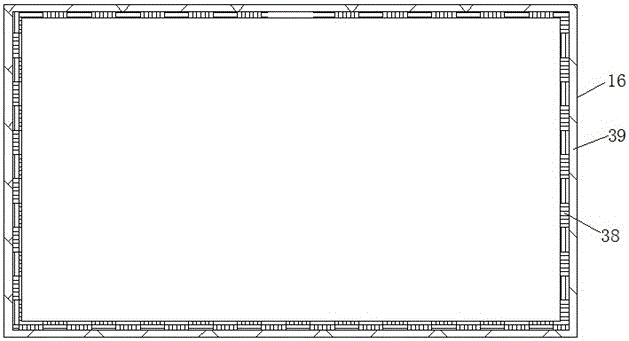

Wood processing drying machine with sterilizing function

InactiveCN109323543AWith bactericidal functionIncrease pressureDrying gas arrangementsDrying solid materialsPulp and paper industryHigh pressure

The invention discloses a wood processing drying machine with a sterilizing function. The wood processing drying machine with the sterilizing function comprises a drying box; box doors are locked at the two ends of the drying box in a sealed manner; the top of the drying box is fixedly connected with a steam generating tank; an output end of the steam generating tank communicates with the drying box through a steam conveying pipe; one end, extending into the drying box, of the steam conveying pipe fixedly communicates with an arc-shaped pipe; the upper end and the lower end of the arc-shaped pipe fixedly communicate with a steam discharging pipe; the arc-shaped pipe and the steam discharging pipe are fixedly connected to the inner wall of the drying box through clamping hoops; the steam discharging pipe is fixedly connected with a plurality of spraying heads which are distributed uniformly; the inner bottom of the drying box is fixedly connected with a plurality of supporting rods which are arranged symmetrically; the tops of the plurality of the supporting rods are fixedly connected with a railway plate; the railway plate is connected with a fixed plate in a sliding manner; and the fixed plate is fixedly connected with a plurality of fastening mechanisms which are arranged symmetrically. According to the wood processing drying machine with the sterilizing function, high-temperature high-pressure drying of a wood plate can be realized; the wood plate can be dried and sterilized better; and the wood plate can be prevented from deforming when the wood plate is dried.

Owner:柳州市千山木业有限公司

Drawer type cooking device having turntable mechanism

InactiveUS20120187115A1Avoid uneven heatingIncrease heightDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention provides a drawer type microwave oven having a turntable functioning as a uniform heating mechanism with a visual effect, while maintaining the ceiling height of a heating chamber and having improved usability. A turntable drive mechanism 40 utilizing a thin deceleration mechanism and a pivot mechanism is disposed in a space 19 formed between a bottom wall 17 of the drawer body 4 and a bottom wall 12 of the heating chamber 3, and a power transmission mechanism is engaged in a detachable manner in conjunction with the movement of the drawer body 4 together with the door. Thus, a drawer type microwave oven capable of performing uniform heating by pivot rotation while maintaining the ceiling height of the heating chamber is realized.

Owner:TOYODA TAKASHI +1

Down feather dryer capable of preventing down feathers from being stacked

ActiveCN106500468AAvoid accumulationEvenly distributedDrying gas arrangementsDrying solid materialsCombustion chamberAir pump

The invention provides a down feather dryer capable of preventing down feathers from being stacked and relates to the field of down feather processing. The down feather dryer capable of preventing the down feathers from being stacked comprises an operating table. Supporting legs are fixedly connected with the four corners of the bottom of the operating table. A fixing column and a machine body are fixedly connected to the top of the operating table from right to left in sequence. The left side of the fixing column is fixedly connected with a heat supply box. A partition plate is arranged in the heat supply box. Air holes are formed in the surface of the partition plate. The interior of the heat supply box is partitioned into a combustion chamber and a hot gas chamber through the partition plate. The combustion chamber is located at the bottom of the hot gas chamber. A combustion box is arranged in the combustion chamber. The bottom of the combustion chamber is fixedly connected with the bottom of the inner wall of the heat supply box. A gas pump is arranged on the left side of the heat supply box. An air inlet of the gas pump communicates with a U-shaped exhaust tube. Through the down feather dryer capable of preventing the down feathers from being stacked, the problem of uneven heating due to the fact that the down feathers are stacked is solved, and the drying speed is increased.

Owner:无锡锡东新农村投资发展有限公司

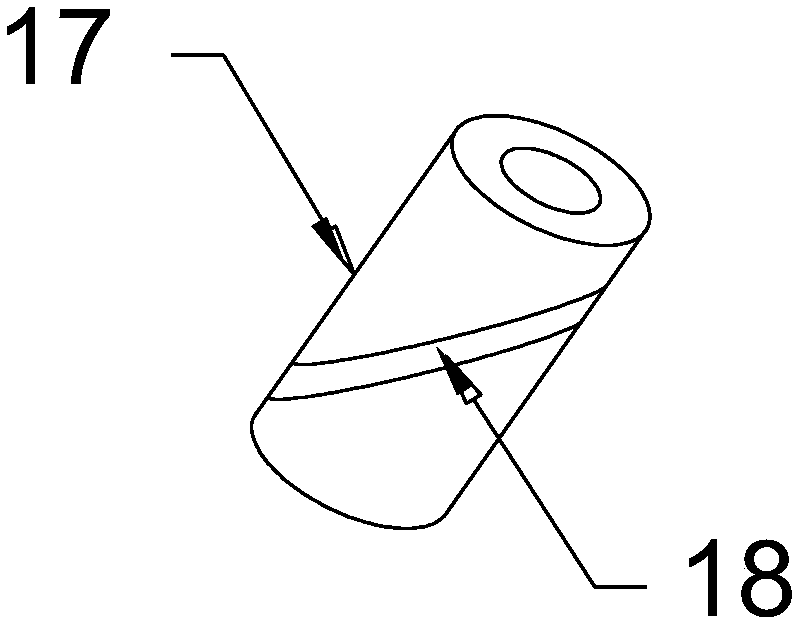

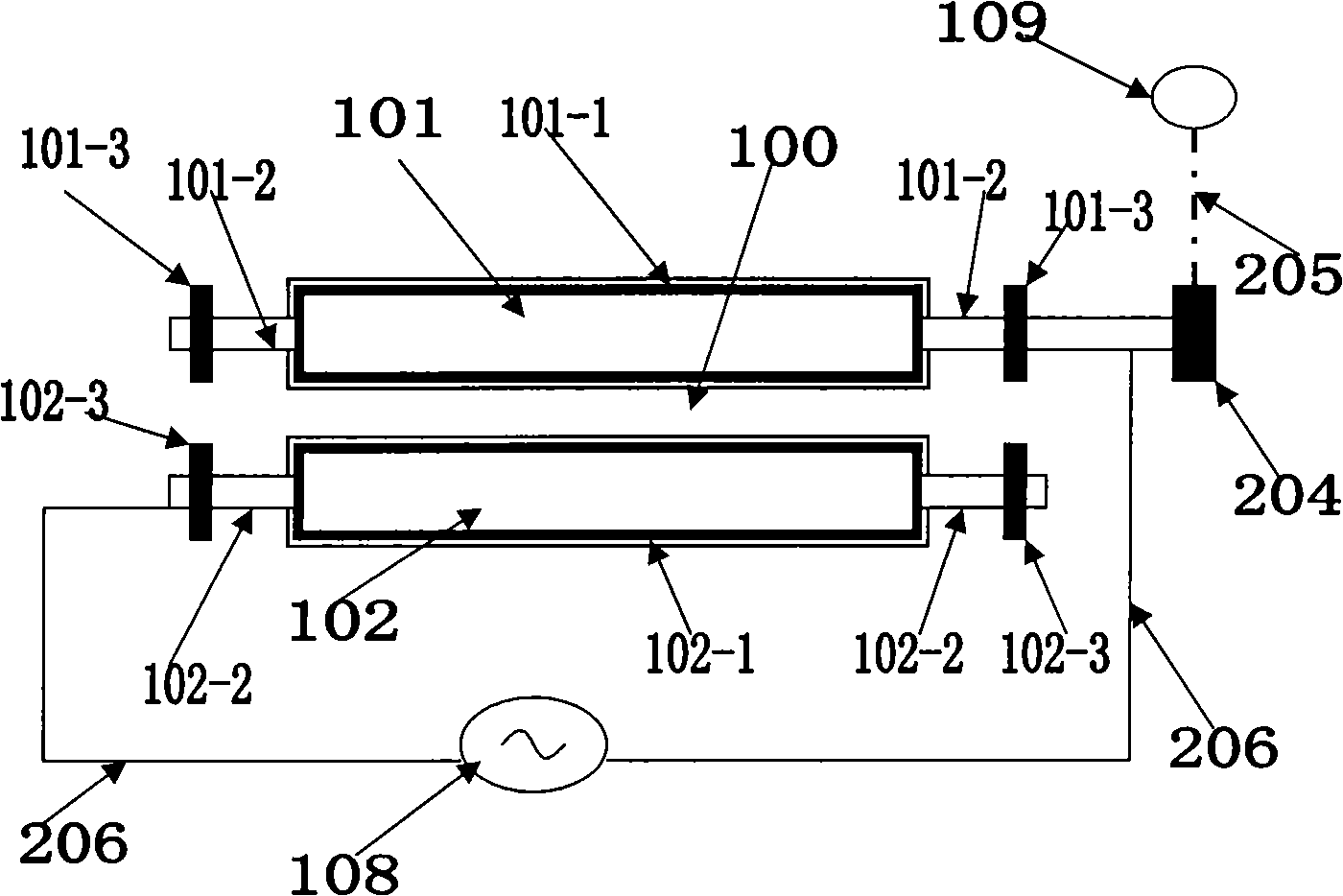

System for processing thin-film material surface using bi-medium to block electric discharge

The present invention provides a system of processing film material surface by a dual dielectric barrier discharge, including a high frequency power supply, a motor, discharge electrodes and an electrode casing, the discharge electrodes are composed by upper and lower metal tube electrodes which are multi-group parallel, covered by glass tubes or ceramic tubes and has same gap between electrodes, the two insulation material tubes covering the upper and lower metal tube electrodes form a dual dielectric between electrodes, the two ends of the upper and the lower electrode tubes are connected with a bearing respectively, the upper electrode tube is rotary driven by the motor, the lower electrode tube is rotary driven by the film penetrating through two electrodes, the upper and the lower metal tubes are connected with the high frequency power supply respectively, the upper and lower electrode tubes are placed in one casing, when the film material penetrates through the upper and lower metal tube electrodes, the surface is processed with modification treatment by plasma.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI +1

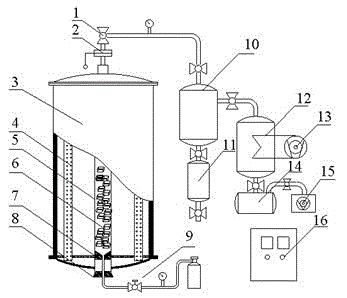

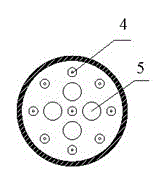

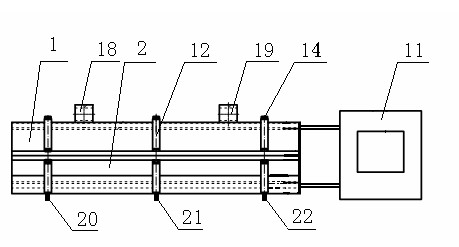

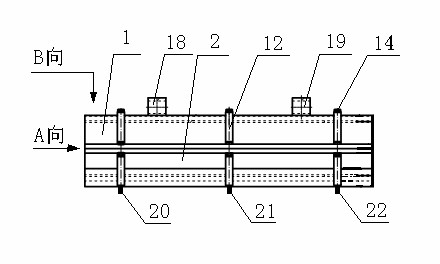

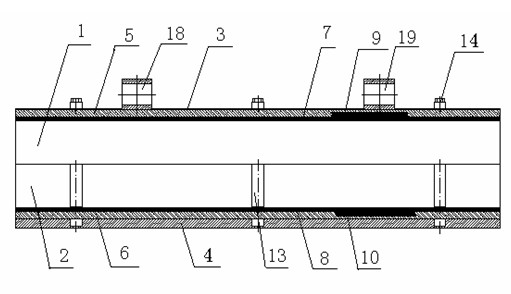

Intermediate wave infrared and pulse vacuum draying integrated device of granulate prepared food and using method thereof

ActiveCN102972848AImprove efficiencyLow costDrying solid materials with heatDrying solid materials without heatProcess engineeringIntegrated devices

The invention discloses an intermediate wave infrared and pulse vacuum draying integrated device of granulate prepared food and a using method thereof, belonging to the field of food dehydration and drying machinery. The intermediate wave infrared and pulse vacuum draying integrated device consists of a feed valve, a baffle valve, an intermediate wave infrared heating cavity, intermediate wave infrared transmitting tubes, drying tubes, a gas distributor, a drying tube plug, a gas flow adjuster, a gas-solid separator, an unloader, a cooler, a refrigerator, a vacuum storer, a vacuum pump and a control panel, wherein a material enters the drying tubes through the feed valve and the baffle valve; the baffle valve is machined to be a hole plate to prevent particle loss during drying; the drying tubes are material drying and flowing channels; the intermediate wave infrared heating cavity is a cylindrical vacuum container; the intermediate wave infrared transmitting tubes are uniformly distributed in the cavity; the drying tubes are uniformly arranged between the intermediate wave infrared transmitting tubes. By the device, the material can spray and rotate under the condition of intermediate wave infrared vacuum draying, so that the purpose of high-efficiency and uniform drying is reached, the drying period is shortened by over 40%, and the production cost is reduced.

Owner:JIANGNAN UNIV +1

Rapid rice husk pyrolysis apparatus and matching system thereof

ActiveCN105400528AFast pyrolysisAchieve self-sufficiencyBiofuelsSpecial form destructive distillationScrew conveyorPyrolysis

The present invention discloses a rapid rice husk pyrolysis apparatus. According to the rapid rice husk pyrolysis apparatus, the main body of a reactor is a stainless steel housing, the upper portion is tightly provided with an vacuum material feeder through a material inlet on the upper end, the lower portion, a screw conveyor and two pneumatic gate valves maintain the reactor and outside air isolation state through a material outlet, multiple groups of molten salt heaters are vertically and densely arranged inside the reactor, a fuel gas outlet is arranged above the right side of the main body, the external is connected to a vacuum pump, a condenser and a filter, and separated combustible gas enters a combustor to combust so as to heat high temperature molten salt adopted as a thermal carrier, such that the energy self-sufficiency can be achieved. With the apparatus of the present invention, the rapid rice husk pyrolysis at the temperature of 450-650 DEG C under the total pressure of 5-15 kPa can be achieved, the natural nanometer structure of the silica inside the rice husk is not damaged, and the complete oxidation of the subsequent combustion oxidation unit impurity carbon is easily achieved.

Owner:王开辉

Heating device of lining

InactiveCN102497680AReduce difficultyEvenly distributedOhmic-resistance heating detailsFiberInsulation layer

The invention discloses a heating device of an over-long lining. The heating device comprises a heater, thermocouples and a control cabinet. The heater is divided into an upper part and a lower part. A metal casing, an alumina silicate fiber heat-insulation layer, and a rope shaped electric heating band are provided from an external layer to an internal layer in order. The rope shaped electric heating band is controlled by an electrical control cabinet. Double thermocouples are employed to measure temperature. When using, the upper part and the lower part are connected into one body through abolt and a nut, simultaneous heating and assembling of the lining can be realized. In an assembling process, the heater and the lining move together, constant temperature of the lining in the assembling process is ensured, and an aperture is prevented from deformation. The heating device has the advantages of simple structure and small energy consumption loss, and is especially suitable for heating a large scale over-long lining with the length of more than two meters.

Owner:WUHAN MARINE MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com