Battery module with same-side electrode output

A battery module and side electrode technology, which is used in battery pack components, secondary battery repair/maintenance, circuits, etc., can solve the problem that aluminum alloy profiles cannot be operated in an open environment, and there is no elastic buffer space for the frame frame. The problem of high manufacturing cost is to avoid uneven voltage difference between cells, simple wiring, and avoid welding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the drawings.

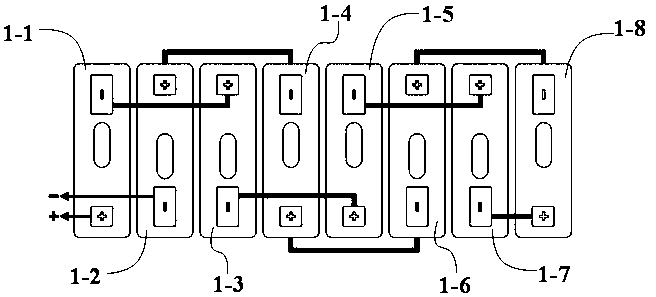

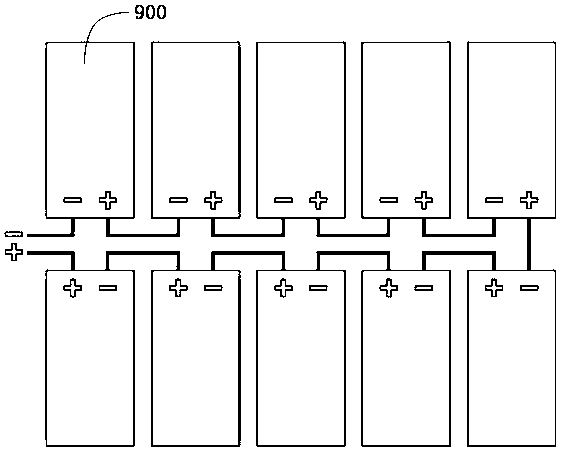

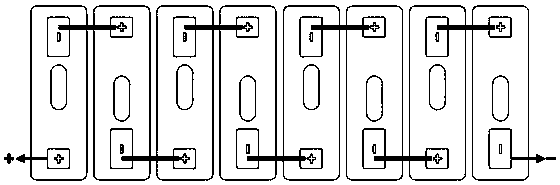

[0053] Such as figure 1 As shown, a battery module with electrode output on the same side includes a number of square batteries arranged in sequence. figure 1 There are 8 batteries in the battery, which are batteries 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7, 1-8. Among the 8 batteries, battery 1 -1 is the first battery, battery 1-2 is the second battery, and so on. Those skilled in the art understand that the number of batteries in the battery module can be 4, 5, 6, 7, 9, or other numbers. The positive and negative electrodes of each battery are located on the top of the battery and are arranged on both sides of the central axis in the battery arrangement direction.

[0054] The arrangement of the batteries of the battery module is as follows:

[0055] Along the battery arrangement direction, the positive electrode of the first battery and the negative electrode of the second battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com