Patents

Literature

395results about How to "Guaranteed physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for producing ultra high-strength terylene industry filament yarn

InactiveCN101144195AGuaranteed purityGuaranteed viscosity uniformityArtificial filament heat treatmentMelt spinning methodsSetting timeFilament yarn

The present invention discloses a production process for an ultra high tenacity polyester industrial filament. The production process adopts a one-step method of spinning and stretching, and the method comprises the solid state tackifying, the melt spinning, the high temperature stretching, the heat setting, and the winding forming. The present invention adopts the innovative five-pair hot roll stretching heat setting process, compared with the traditional four-pair hot roll stretching heat setting, the the present invention adopts two-stage heat stretching, the processing method of the two-stage heat setting effectively reduces the stretching speed of fiber, and prolongs the heat setting time of the fiber, so that the fiber has an even stable orientation structure while the physical performance of products is ensured, the spinning condition is optimized. The ultra high tenacity polyester industrial filament prepared by utilizing the method of the present invention has the advantages that the intensity is high, the stretching and the dry heat shrinkage are reasonable, the heat resistant performance is good, and the impact resistant performance and the fatigue resistant performance are good.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

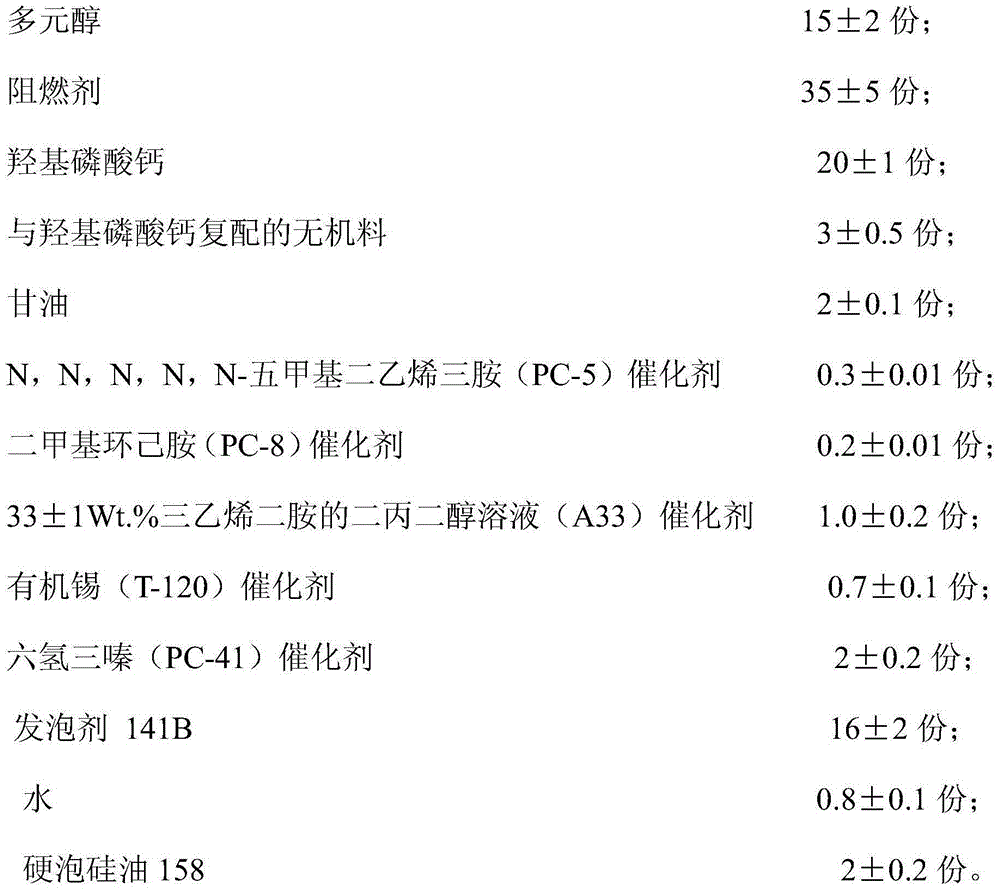

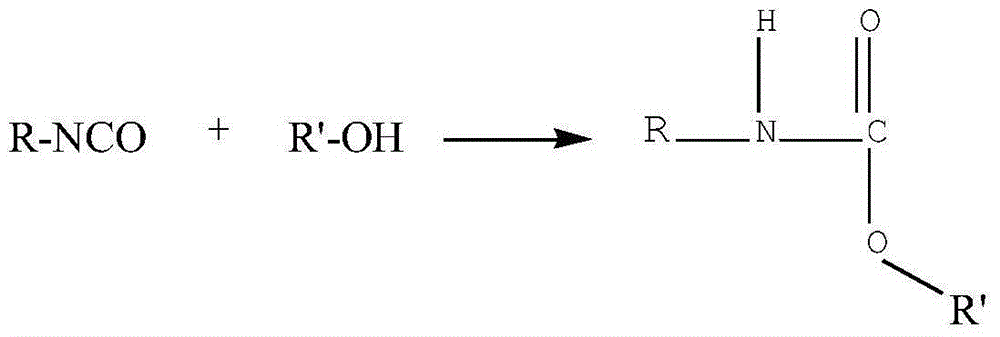

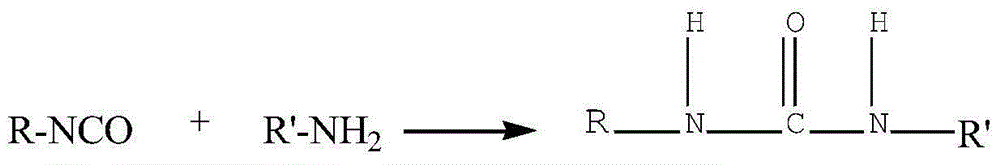

Inorganic material hybrid hard melamine polyurethane foam heat insulation material, preparation method thereof and combined polyether used therein

The invention discloses an inorganic material hybrid hard melamine polyurethane foam heat insulation material, a preparation method thereof and combined polyether used therein. The combined polyether comprises: a polyol flame retardant, hydroxyl calcium phosphate, an inorganic material compounded with hydroxyl calcium phosphate, glycerin, N, N, N, N, N-pentamethyl diethylenetriamine, dimethyl cyclohexyl amine, 33+ / -1Wt.% triethylene diamine's dipropylene glycol solution, organic tin, hexahydro triazine, a foaming agent 141B, water, and silicone oil AK-158. The preparation method includes: mixing the combined polyether with isocyanate in ratio, and then carrying out spraying or casting foaming moulding, thus forming the heat insulation material. The heat insulation material has the characteristics of stable physical performance, no deformation, no shrinkage, strong bonding force, low thermal conductivity, an oxygen index up to over 30%, and a combustion heat release rate increase index of less than 250W / S.

Owner:ZHANGJIAGANG DIMENGDE ENERGY SAVING TECH CO LTD

Preparation method of halogen-free flame-retardant polyurethane (PU) sealant

ActiveCN102181260AGuaranteed physical propertiesGood adhesionNon-macromolecular adhesive additivesOther chemical processesScavengerAntioxidant

The invention relates to a preparation method of a halogen-free flame-retardant polyurethane (PU) sealant. The preparation method comprises the following steps: dewatering and drying the following materials, namely a filler, a thixotropic agent, a halogen-free flame retardant, a flame-retardant synergist, a plasticizer, a light stabilizer and an antioxidant in vacuum; stirring a PU prepolymer and the materials for dispersion in a double planet mixer with a high-speed dispersion disk or a tri-roller grinder at the temperature of 30-50 DEG C for 2-5 hours under the condition that the vacuum degree is not less than 0.092Mpa; under normal pressure and protection of high-purity nitrogen, adding a catalyst A, a silane adhesion promoter and a water scavenger, and stirring for 0.1-1 hour for dispersion; and removing small molecules and stirring for 0.3-1 hour under the condition that the vacuum degree is not less than 0.092Mpa to finally obtain the halogen-free flame-retardant PU sealant. The halogen-free flame-retardant PU sealant effectively overcomes the disadvantages of the PU sealant such as big flame, fast burning speed, severe drippage and the like in the prior art on the premise of ensuring the original physical properties of the PU sealant, thus the PU sealant has the advantages of flame retardance, no drippage during the burning process, good adhesive property and the like.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN1904153AAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

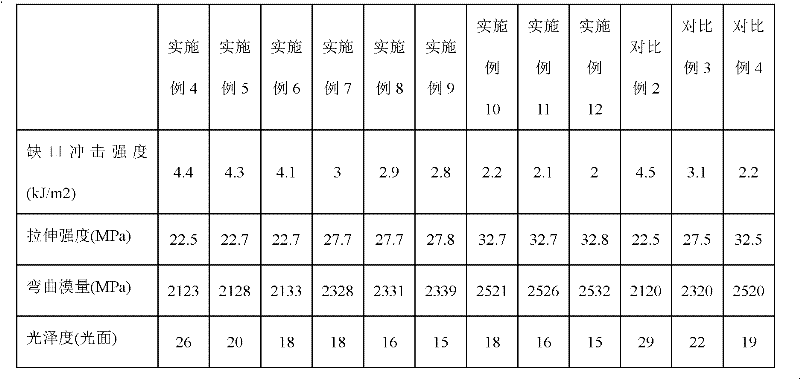

Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

The present invention relates to a glass fiber reinforced flame retardant polypropylene material for household appliance products, and belongs to the field of modified polypropylene plastic. The material comprises the following raw materials, by weight: a high-impact-resistance copolymer polypropylene resin, a bromine-based flame retardant agent, antimony trioxide, a flame retardant synergist, alkali-free continuous long glass fibers, a compatibility agent, a toughening agent, a lubricant, a UV absorber and an antioxidant. The present invention provides the glass fiber reinforced flame retardant polypropylene material with higher tensile strength, bending modulus and hardness as well as high impact-resistance, low molding shrinkage, aging resistance and the like. The glass fiber reinforced flame retardant polypropylene material has a high heat deformation temperature, good oxidation resistance at high temperature, and the flame retardant performance up to the level of UL94 V-2, and passes the glow wire test of GWIT: 700 / 3.0. The glass fiber reinforced flame retardant polypropylene material has a low cost and a light weight, and can be used instead of metal or plastic material to produce the household appliance products which need flame retardation and high temperature resistance.

Owner:GUANGDONG JUSHI CHEM CO LTD

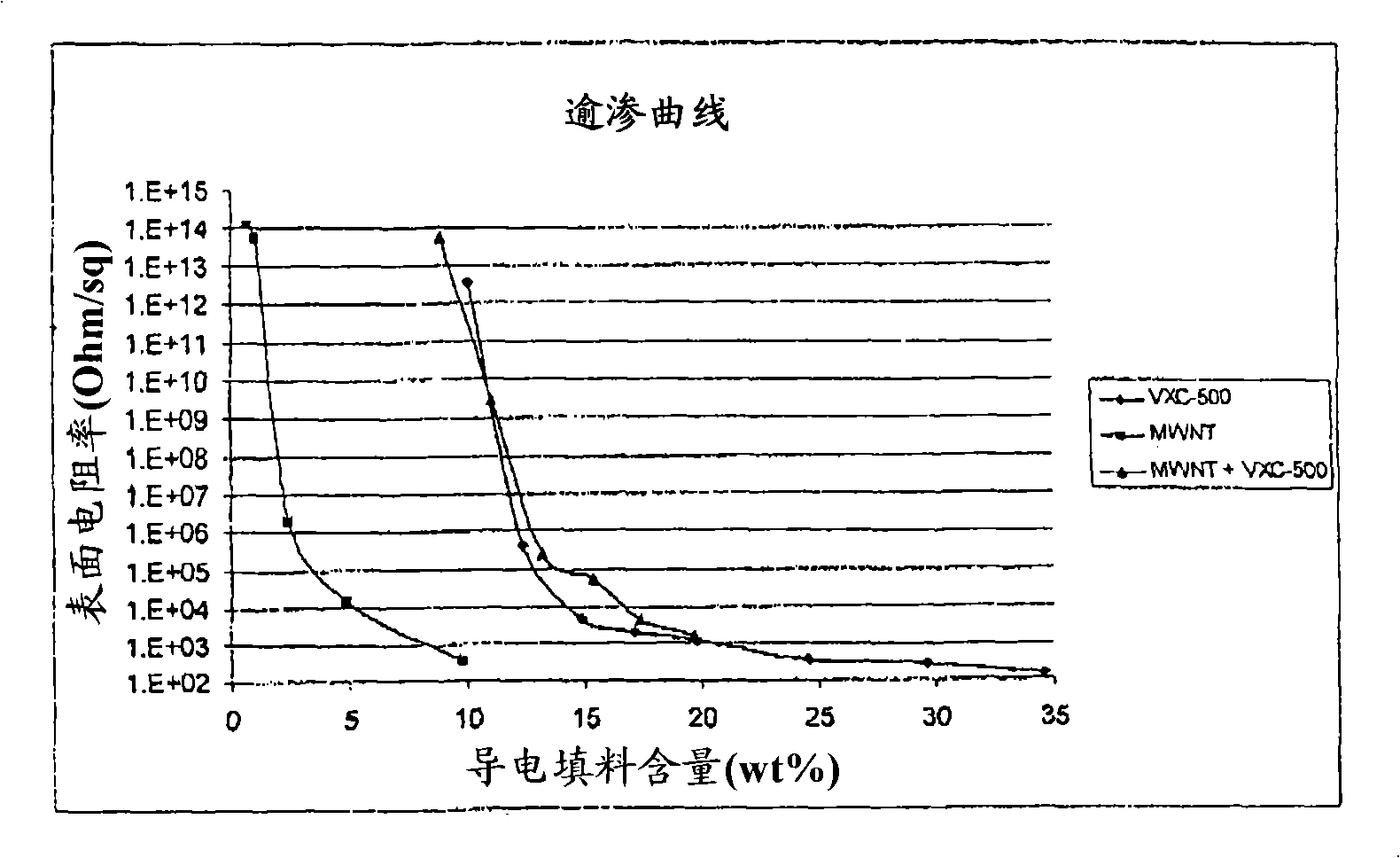

Polymeric compositions containing nanotubes

InactiveCN101283027AHigh conductivity rangeImprove smoothnessMaterial nanotechnologyNon-conductive material with dispersed conductive materialPolymer sciencePolymer chemistry

A polymeric composition containing at least one polymer and carbon nanotubes is described. The polymeric composition can have carbon nanotubes that are multi-wall carbon nanotubes and / or single-wall carbon nanotubes. The compositions can also contain carbon black. Also described are various articles made from the polymeric compositions including cables and other articles.

Owner:CABOT CORP

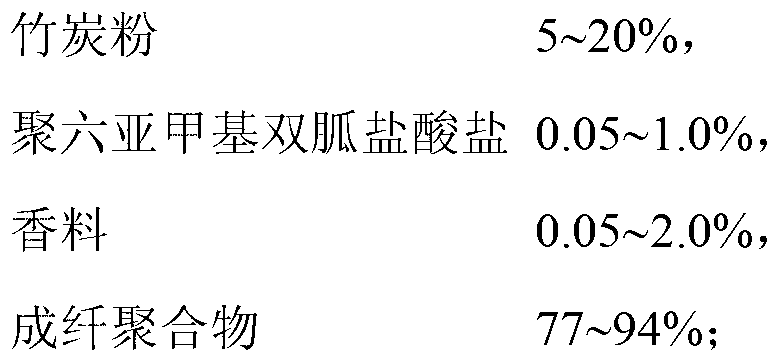

Health-care spandex fiber and preparation method thereof

ActiveCN103194819AGuaranteed stabilityGuaranteed physical propertiesFilament forming substance formingMelt spinning methodsMoistureMelt spinning

The invention provides a health-care spandex fiber which is formed by combining a wrapper and a core part, wherein the section of the fiber is solid; the mass percentage of the core part accounts for 30-70% of that of the fiber and the mass percentage of the wrapper accounts for 30-70% of that of the fiber; and a preparation method of the health-care spandex fiber comprises the following steps of: 1, preparing a health-care spandex core part by utilizing a melt spinning technology according to a formula proportion; 2, preparing a health-care spandex fiber wrapper by utilizing a dry-method spinning technology according to the proportion; and 3, spinning by utilizing a special spinneret plate combined piece through a conventional dry-method spinning equipment process so as to obtain a health-care spandex. The health-care spandex disclosed by the invention has the effects of eliminating the peculiar smell, absorbing the moisture and proofing moulds, and inhibiting bacteria and expelling parasites; the health-care spandex can be contacted with a human body to remove the humidity and absorb the sweat so as to accelerate the blood circulation and the metabolism of the human body and relieve fatigues; and the health-care spandex also has the aroma of plant essences, and furthermore is good in utilization performance and can meet the requirements on homespun in processes of spinning, weaving, dyeing and finishing.

Owner:ZHEJIANG HUAFENG SPANDEX

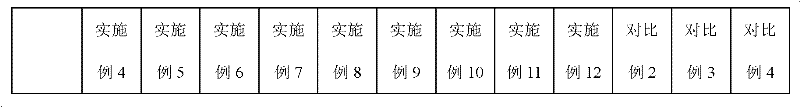

Low-gloss polypropylene composite material and preparation method thereof

The invention discloses a low-gloss polypropylene composite material which is prepared from the following raw materials by weight percent: 45-99% of polypropylene, 0-42% of inorganic filling material, 0-10% of flexibilizer POE (polyolefin elastomer), 0.5-4% of organic delustering agent, 0.1-2% of antioxidant and 0-3% of other additives. The preparation method comprises the following steps: weighing the raw materials in proportion; mixing polypropylene, the inorganic filling material, the flexibilizer, the organic delustering agent, the antioxidant, a light stabilizing agent and the other additives in a high-speed stirrer; putting the obtained mixture in a two-screw extruder for melt extrusion; and after extrusion, cooling, drying and grain-sized dicing to obtain a finished product. According to the invention, a method of adding a proper amount of styrene-acrylonitrile crosslinking copolymer into polypropylene is adopted, thus the prepared polypropylene composite material has the characteristic of low gloss, and simultaneously the polypropylene composite material basically has original physical property. The low-gloss polypropylene composite material disclosed by the invention is suitable for being applied to inner decorative materials for home appliances, automobiles and the like.

Owner:SHANGHAI PRET COMPOSITES

Method for preparing melt spun chlorine-resistance high resilient polyurethane fiber

InactiveCN102011211AIncrease elasticityGuaranteed physical propertiesFilament/thread formingArtificial filament heat treatmentFiberCross-link

The invention discloses a method for preparing melt spun chlorine-resistance high resilient polyurethane fiber, comprising the following steps: 1) a thermoplastic polyurethane slice is prepared by a one-step method; 2) the slice is uniformly mixed with chlorine-resistance cross-linking agent; 3) melt extrusion is carried out; 4) spinning moulding is carried out; and 5) post curing is carried out. By utilizing the invention, the requirement on higher chlorine resistance and resilience in special fields is met, combination of the chlorine-resistance cross-linking agent and polyurethane fiber is good, and the physical performance of fiber can be effectively maintained when being used in a chlorine-containing environment; and besides, diamine is adopted as chain extension agent, the hard section of the formed polyurethane urea has higher cohesive energy, three-dimensional hydrogen bonds can be formed, and the microphase separation degree is improved, thus improving the resilience of fiber.

Owner:奥斯汀新材料(张家港)有限公司

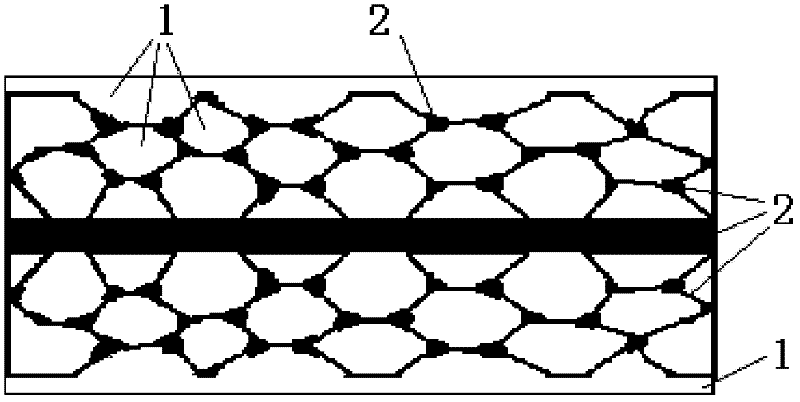

Elastic compound metal heat interface material and preparation method thereof

The invention belongs to the technical field of a heat interface material and discloses an elastic compound metal heat interface material. The elastic compound metal heat interface material is formed by compounding indium and a through-hole porous metal sheet, wherein the indium is filled in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet. The invention also discloses a preparation method of the elastic compound metal heat interface material. The method comprises the following steps: preparing the through-hole porous metal sheet at first; adding a proper amount of indium; heating for smelting indium so that smelted indium fills in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet; and finally cooling, thereby obtaining the elastic compound metal heat interface material. The two surfaces of the through-hole porous metal sheet are both through-hole porous metal and the middle core of the through-hole porous metal sheet is a metal solid. The compound material of the through-hole porous metal sheet and indium has higher elasticity and flexibility in the direction vertical to a mounting surface, so that the compound material can be quickly filled in bigger gaps caused by heat sink and an uneven silicon surface, the interface can be completely filled and the heat resistance of the interface can be kept.

Owner:SOUTHEAST UNIV

Sweet potato saccharified potato paste and method for processing instant product series thereof

ActiveCN101347219AGuaranteed Physical PropertiesMechanizationFood preparationReady to eatAlpha-amylase

The invention discloses a processing method of a saccharified mashed sweet potato and series mashed sweet potato ready-to-eat products, and belongs to the technical field of food processing. The method comprises the steps as follows: (1) pretreatment of sweet potatoes of raw material; (2) preparation of the saccharified mashed potatoes: prepared mashed potato and high-temperature-resistant alpha-amylase are evenly mixed with the proportion of 100kg:5-50ml and stewed for 10-30min at the temperature of 90-100 DEG C, and then are rapidly heated to 105 DEG C to inactivate enzyme, thus obtaining the saccharified mashed potatoes; (3) preparation of the series saccharified mashed sweet potato ready-to-eat products. The processing method adopts the high-temperature-resistant alpha-amylase and is complemented with a two-step heating process to saccharify partial starch in the mashed sweet potato, and the method provides the saccharified mashed sweet potato with naturally saccharified flavor and taste and prolongs the processing period. The processing method overcomes great amount loss in natural saccharification in long term storage in the conventional process as well as reduces production cost. The processing method can be popularized in food processing enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

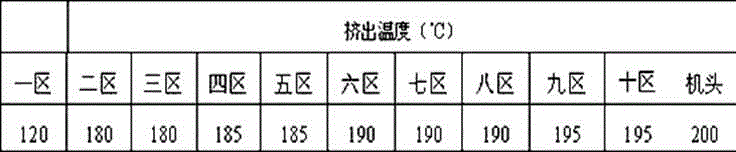

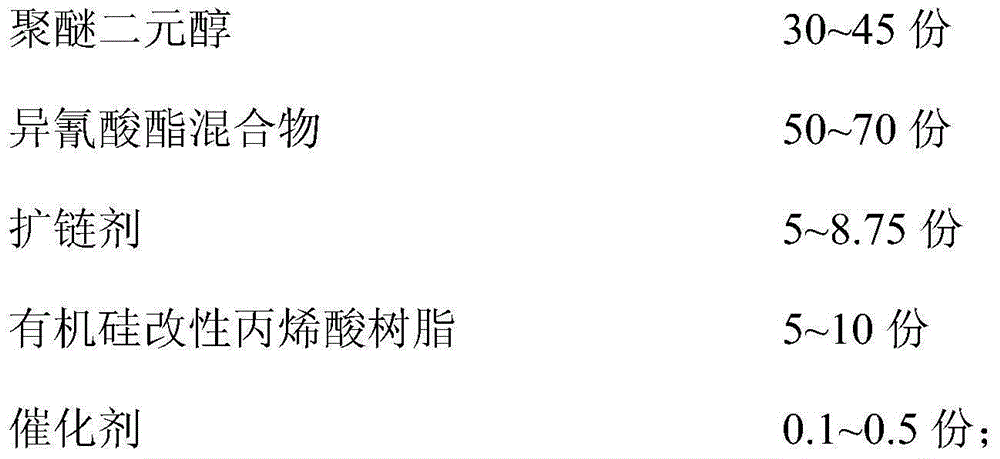

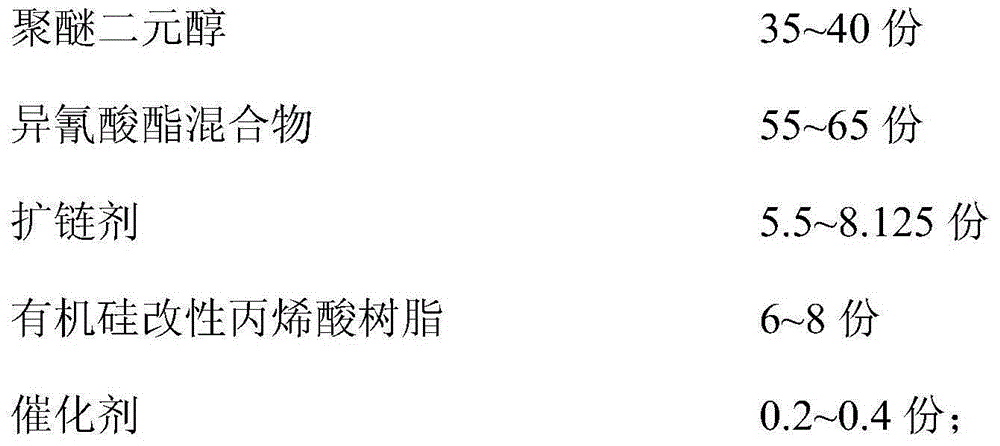

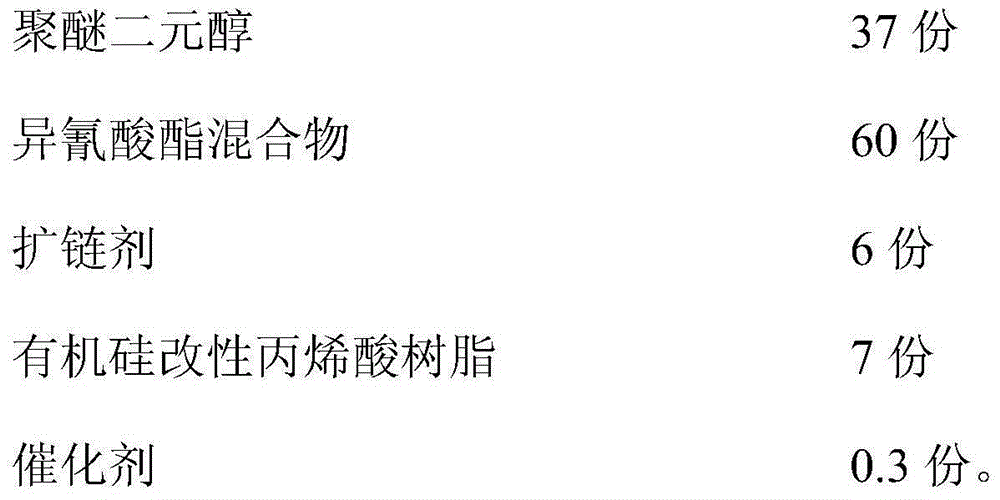

Extrusion grade thermoplastic polyurethane elastomer and manufacturing method thereof

InactiveCN105001626AImprove extrusion fluidityImprove mechanical propertiesAcrylic resinThermoplastic polyurethane

The invention provides an extrusion grade thermoplastic polyurethane elastomer and a manufacturing method thereof. The extrusion grade thermoplastic polyurethane elastomer is manufactured from, by weight, 30-45 parts of polyether diol, 50-70 parts of isocyanate mixtures, 5-8.75 parts of chain extender, 5-10 parts of silicone-modified acrylic resin and 0.1-0.5 part of catalyst. The manufacturing method includes the steps that the polyether diol and the catalyst are mixed to form a mixed material A; the isocyanate mixtures and the chain extender are fused and then mixed with the mixed material A, and the formed mixture is granulated through a double-screw extruder and then cured to manufacture the extrusion grade thermoplastic polyurethane elastomer. The manufactured thermoplastic polyurethane elastomer has high mechanical properties, the tensile strength can reach over 52 MPa, the elongation can reach over 775%, the hardness range can be 60-86A, and therefore the manufactured thermoplastic polyurethane elastomer meets the industrial requirement.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

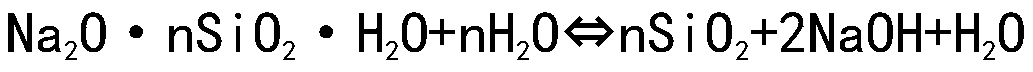

Preparation method of baking-free high-strength fly ash ceramsite

The invention discloses a preparation method of baking-free high-strength fly ash ceramsite. The preparation method comprises four stages of preparation of a mixed alkaline excitant, uniform mixing ofthe excitant and raw materials, balling by a balling disc, and maintenance and molding, wherein the mixed alkaline excitant is prepared by mixing and crushing dried desulfurized gypsum, fly ash and quick lime according to a certain ratio. The baking-free high-strength fly ash ceramsite has the advantages of low construction cost, convenience in preparation, simple process, light weight, high strength and the like, and can replace part of sandstone to prepare lightweight aggregate concrete and produce prefabricated parts; the fly ash is used as a main raw material, cement, quicklime and desulfurizing gypsum are a mixed alkaline activator and a curing agent, and sodium silicate is a binder; the comprehensive utilization approach of industrial solid waste fly ash and industrial by-product gypsum is expanded while unfired high-strength fly ash ceramsite is prepared, and the concept of the green circular economy and the sustainable development of a building material is enhanced.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

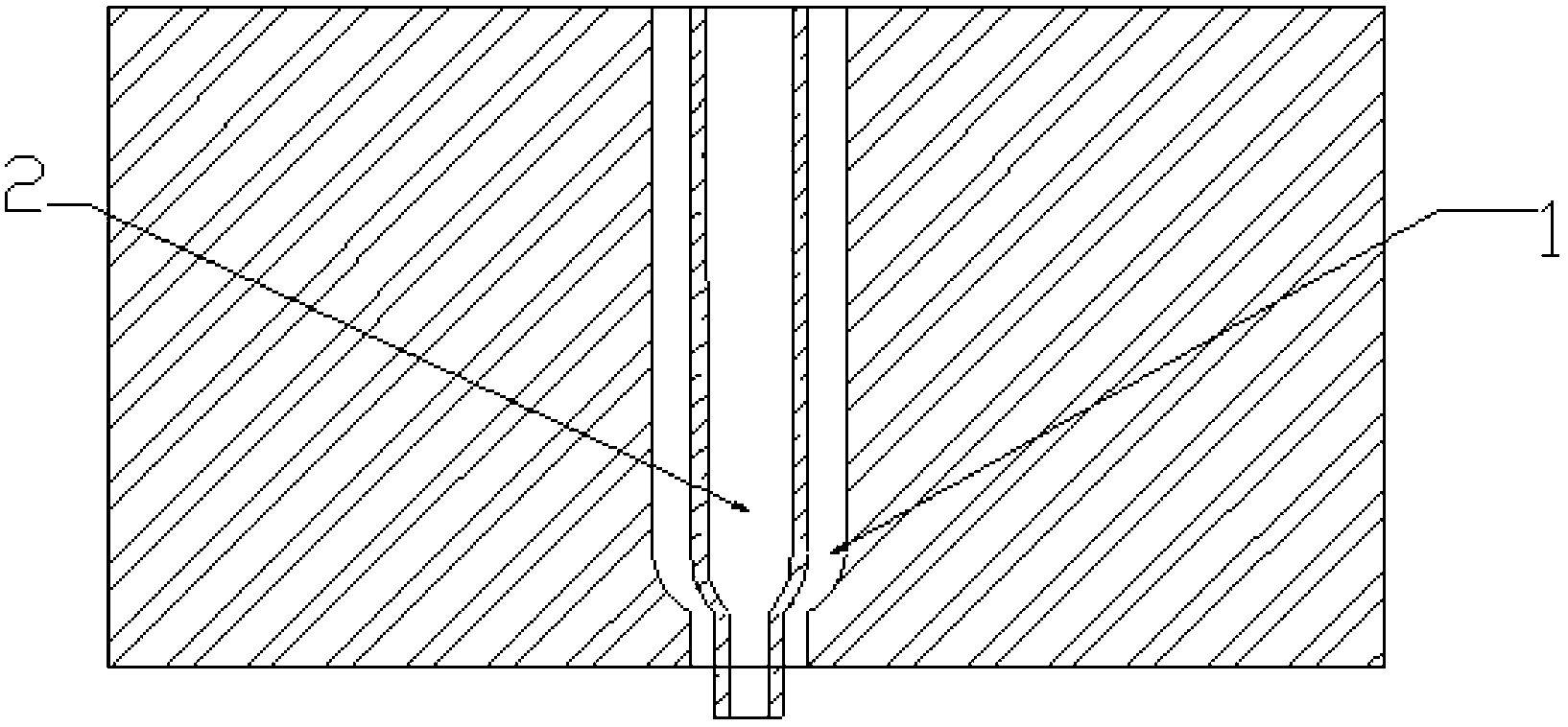

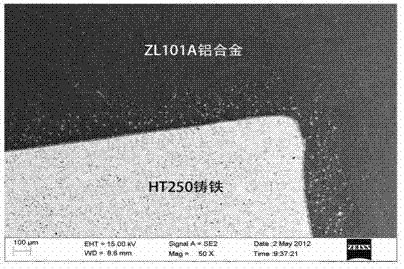

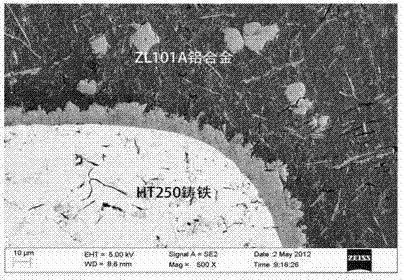

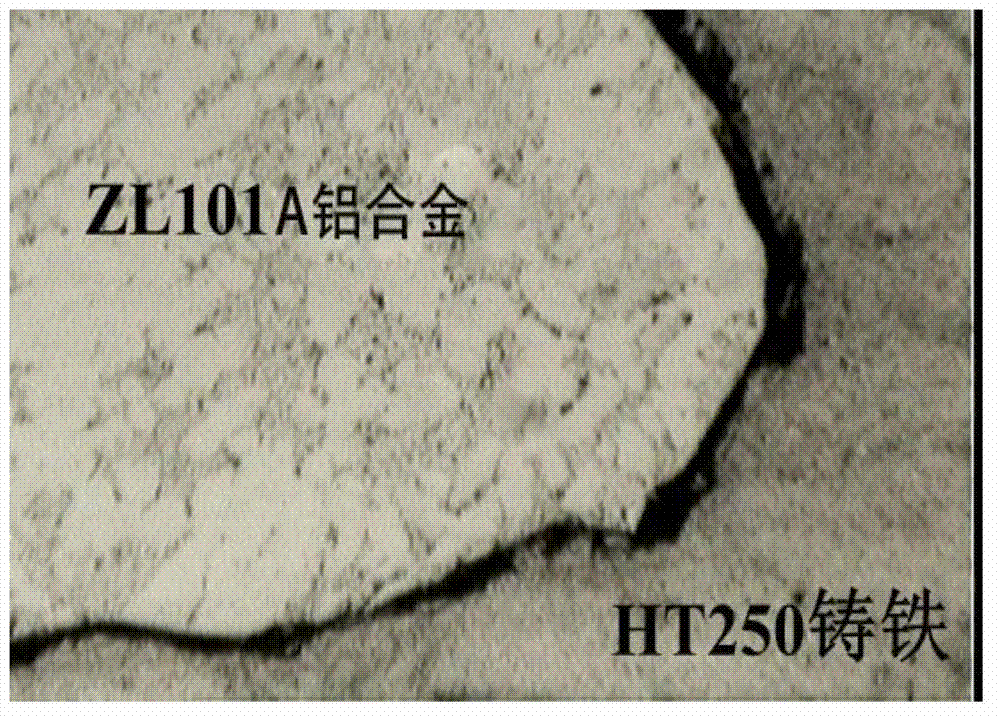

Preparation process of dual-metal engine cylinder composite material

InactiveCN102773463AGuaranteed physical propertiesEnhanced interface bindingPotassium fluorideMetallic materials

The invention relates to a preparation process of a dual-metal engine cylinder composite material, the preparation process comprises the following steps of: firstly, acid-washing a HT250 cast iron cylinder liner and carrying out surface degreasing and derusting treatment on the HT250 cast iron cylinder liner; then dipping the HT250 cast iron cylinder liner into a prepared proportional saline solution, so that the surface of the HT250 cast iron cylinder liner is soaked in the saline solution; then drying the HT250 cast iron cylinder liner, and putting the HT250 cast iron cylinder liner in a ZL101A aluminum alloy melt body for hot immersion plating; fixing the immersion-plated HT250 cast iron cylinder liner in a mold cavity of a metal mold casting mold, casting, melting and cooling a ZL101A aluminum alloy, wherein concentration of the saline solution is 100-200g / L, the saline solution is prepared by mixing water together with potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF2, and calcium chloride CaC12 according to a mass ratio of 39-46:16-26:15-21:6-15:5-10. According to the preparation process, the engine cylinder composite material is obtained through treating the ZL101A aluminum alloy and HT250 cast iron by a self-prepared surfactant and implementing a dual-metal composite casting process on the ZL101A aluminum alloy and the HT250 cast iron, wherein two metal materials of the ZL101A aluminum alloy and the HT250 cast iron are not mixed and kept with original physical properties; but the ZL101A aluminum alloy and the HT250 cast iron obtain an extremely perfect combination interface, so that casting metallurgical bonding of 99.5 percent and above is achieved.

Owner:烟台路通精密科技股份有限公司 +1

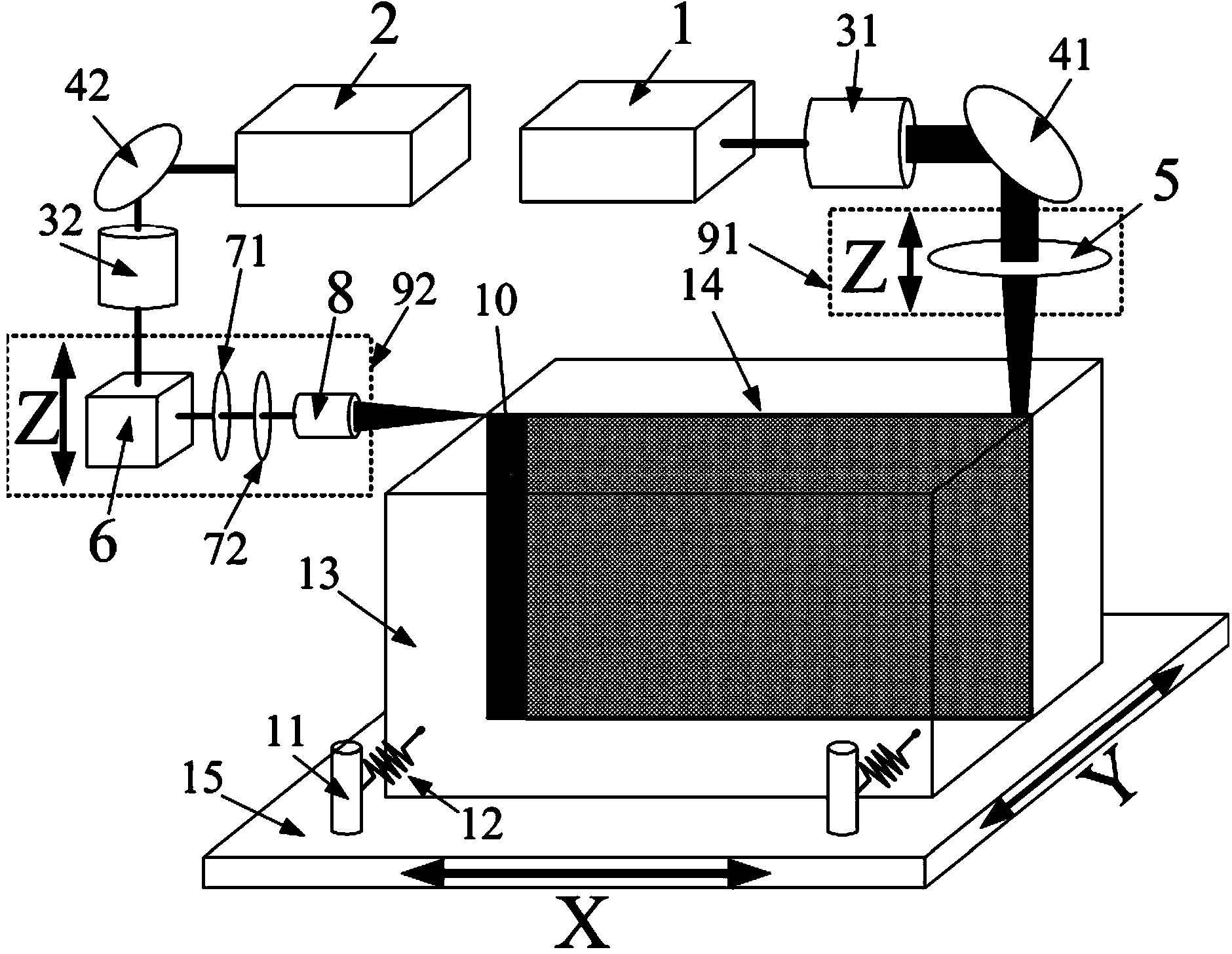

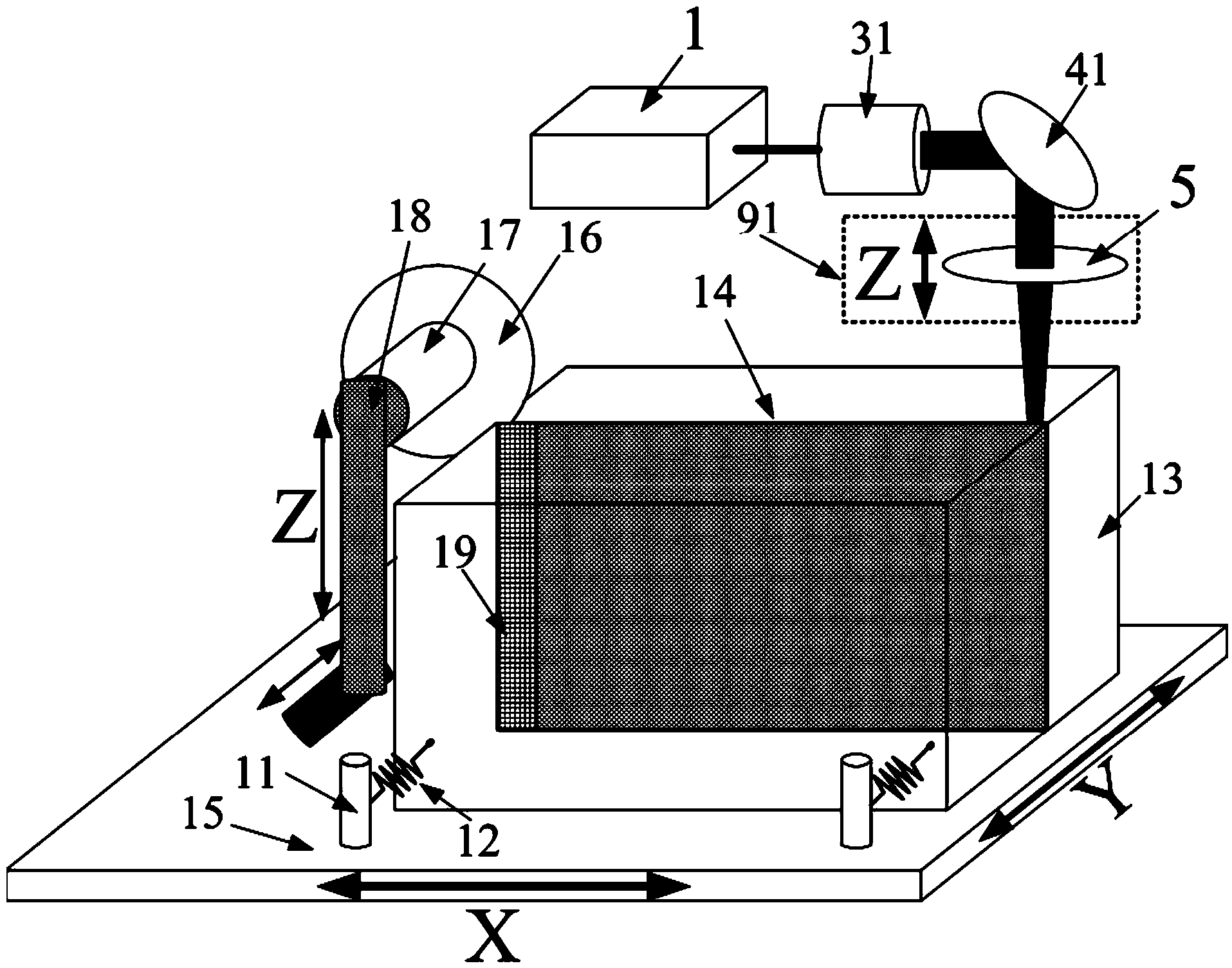

Method and device for quickly separating optical crystals by using laser light

ActiveCN103831527ARelieve mechanical stressPrecise Separation SizeWelding/soldering/cutting articlesLaser beam welding apparatusLaser lightThermal expansion

The invention discloses a method for quickly separating optical crystals by using layer light. The method comprises the following steps of setting the separating direction of the optical crystals by using ultrafast laser light or a miniature diamond grinding wheel; forming a precast microcrack with the direction along a to-be-separated path at a separation starting end; performing scanning heating on the preformed microcrack by using focusing laser light to form a laser-induced microcrack; quickly moving the focusing laser light along the to-be-separated path until the laser moving speed is the same with the crack expansion speed; enabling the focusing laser light to always follow the foremost end of the microcrack; performing thermal expansion effect on materials on two sides of the microcrack; generating forward squeezing force and lateral pulling stress on the tip of the microcrack; and pulling materials of the crystals so as to realize high-quality separation of the crystals. A device comprises a microcrack preforming mechanism, a single-focus-point laser machining system and a two-dimensional worktable. By using the method and the device, the separation speed, the separation accuracy, the machining safety and the machining quality of the optical crystals can be improved, non-loss separation of the optical crystals is realized, and a quasi-polishing-level finishing separation surface is formed.

Owner:武汉飞能达激光技术有限公司

Large-capacity steam turbine generator rotor copper alloy slot wedge and its preparing method

InactiveCN1776997AHigh strengthImprove pass rateWindingsManufacturing dynamo-electric machinesSolution treatmentExtensibility

Slot wedge material is copper base alloy containing following elements: (in weight percent) Ni 1.35-2.05úÑ, Si 0.40-0.80úÑ, Cr, 0.05-0.25úÑ, Be 0.15-0.40úÑ, other as Cu. Using following processes makes alloy possess allround performance: hot forging, solution treatment, cold deformation, primal ageing strengthening process. The said allround mechanical and physical performances are: tensile strength larger than and equal to 760Mpa, yield strength larger than and equal to 640Mpa, extensibility larger than and equal to 15úÑ etc. Supersonic inspection shows that the disclosed alloy is accorded with operation requirement as well as reaches or exceeds specification of CuCo2BeZr copper alloy. Advantages are: lowering cost more than 30úÑ, saving resources of noble element.

Owner:JIANGSU UNIV OF SCI & TECH

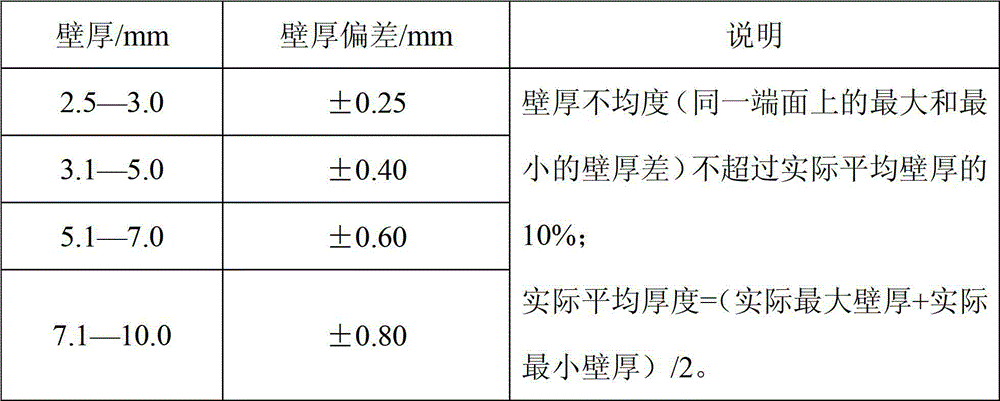

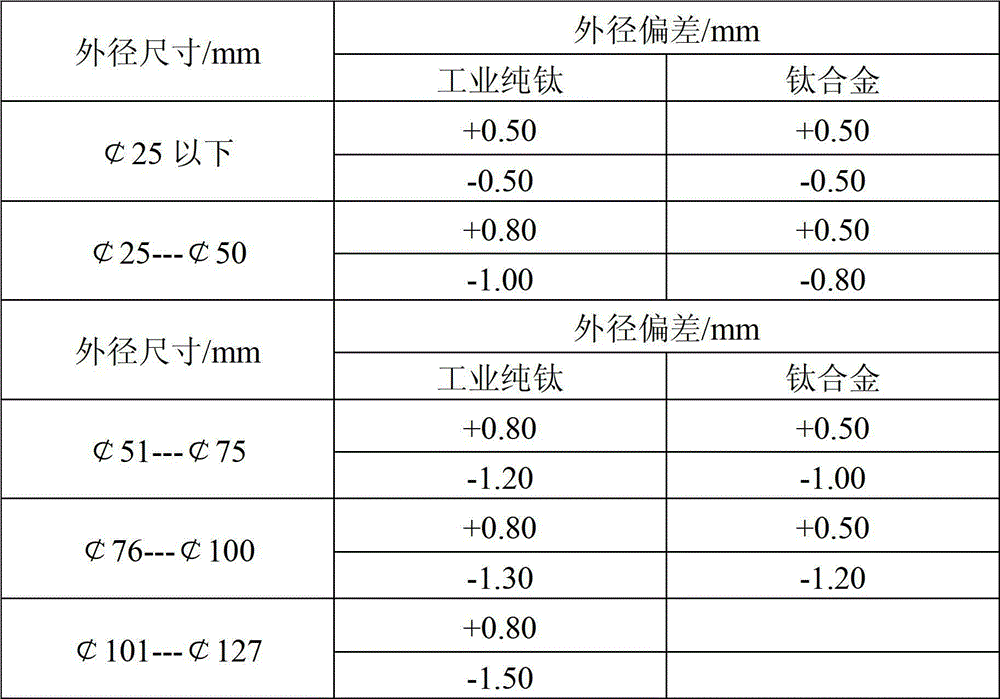

High-accuracy TA18 titanium alloy pipe preparation method

The invention provides a high-accuracy TA18 titanium alloy pipe preparation method comprising the steps of preparing material, melting, putting a titanium alloy ingot into a resistance furnace to heat until temperature reaches up to 850 DEG C to 900 DEG C, forming a titanium alloy sheared billet after preserving heat for one to three hours and mounding and drawing for several times, rolling a titanium alloy pipe blank, rolling roughly, rolling precisely, and annealing. A titanium alloy pipe produced by utilizing the high-accuracy TA18 titanium alloy pipe preparation method is high in finished product rate, low in production cost, good in fineness which can reach h6, reasonable in crystal structure, and pretty high in practical value.

Owner:宝鸡市西部三联钛材有限责任公司

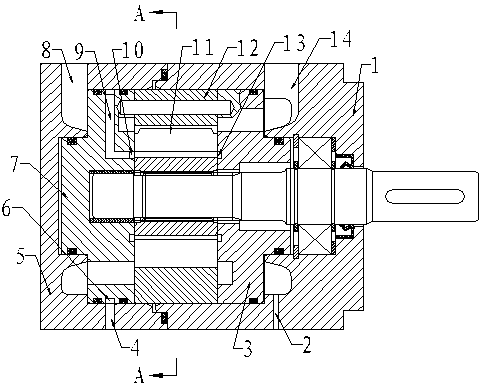

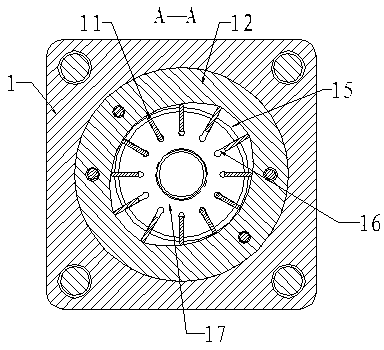

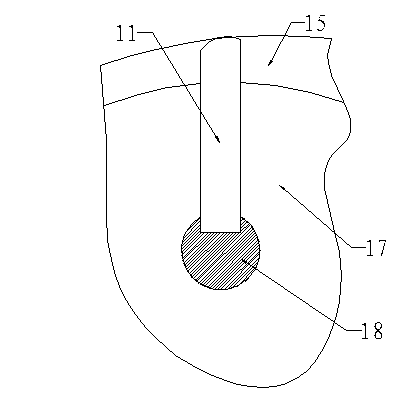

Hydraulic control mechanism for vanes

ActiveCN102840134AReduce work energy consumptionReduce feverRotary piston pumpsRotary piston liquid enginesEngineeringEnergy consumption

The invention discloses a hydraulic control mechanism for vanes. The hydraulic control mechanism for the vanes solves the problem that vanes can still extend to the outside of a rotor when the existing common vane pump does not work, so that the energy consumption of the vane pump is large. The vane pump structurally comprises a shell, a stator and a rotor, wherein the rotor is arranged in the stator in a rotatable mode, a plurality of vane grooves are radially arranged in the rotor, the vane grooves are internally provided with the vanes in a sliding way, and the vanes can partially extend out of the radial outside of the rotor, or retract into the rotor. A cavity is formed between the rotor and the stator, and is provided with a fluid suction zone, a fluid compression zone and a vane retraction zone, the shell is internally provided with a chamber communicated with the cavity, and the chamber is communicated with the outside through a fluid inlet and a fluid outlet. When the rotor is required to idle, pressure fluid is introduced into the chamber so as to enable the vanes to stably retract into the rotor.

Owner:胡阳

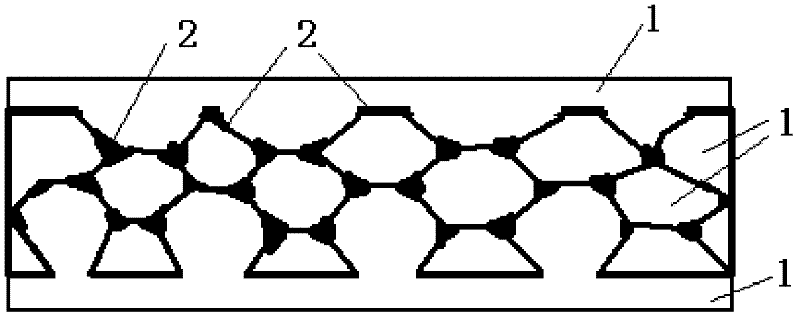

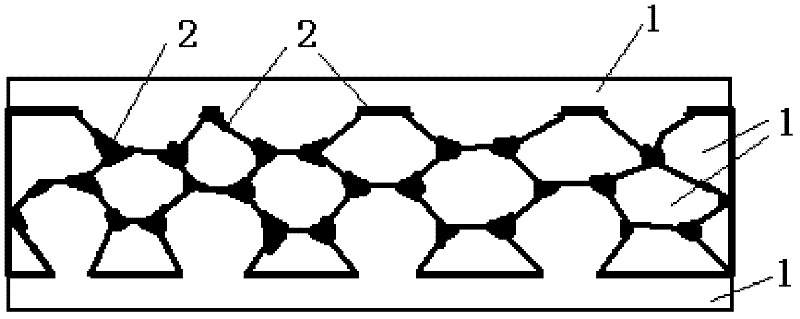

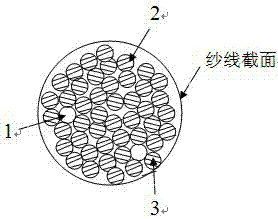

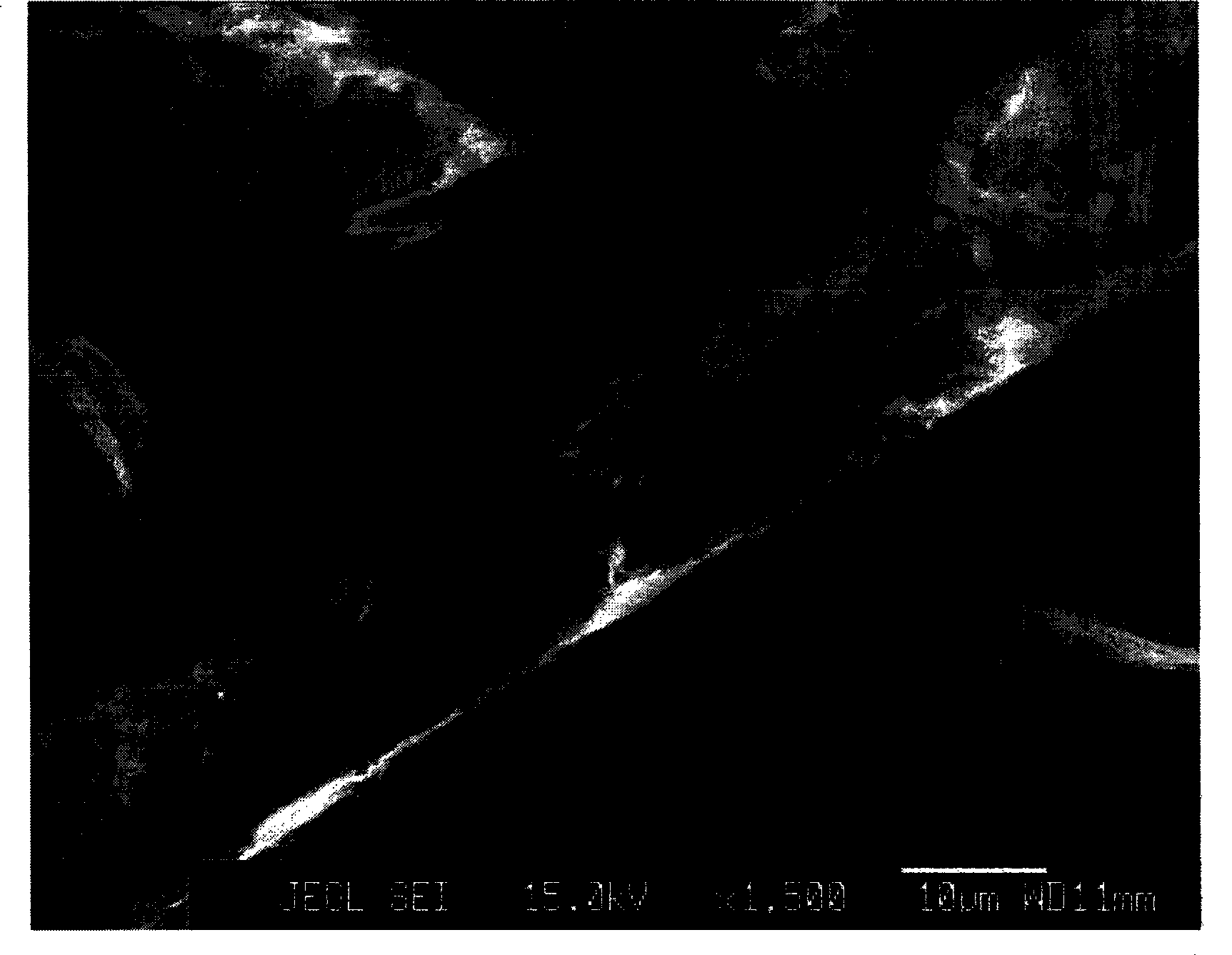

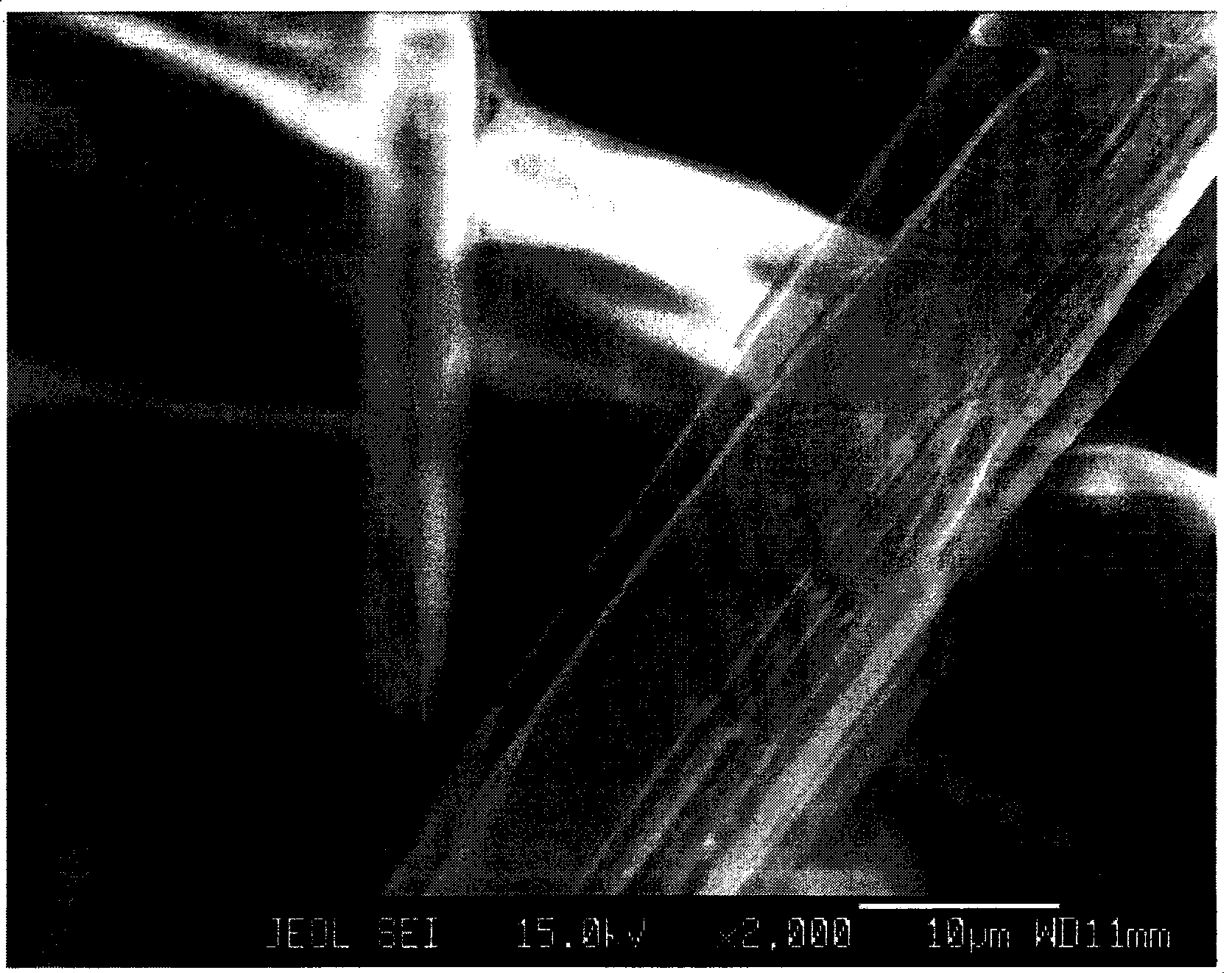

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

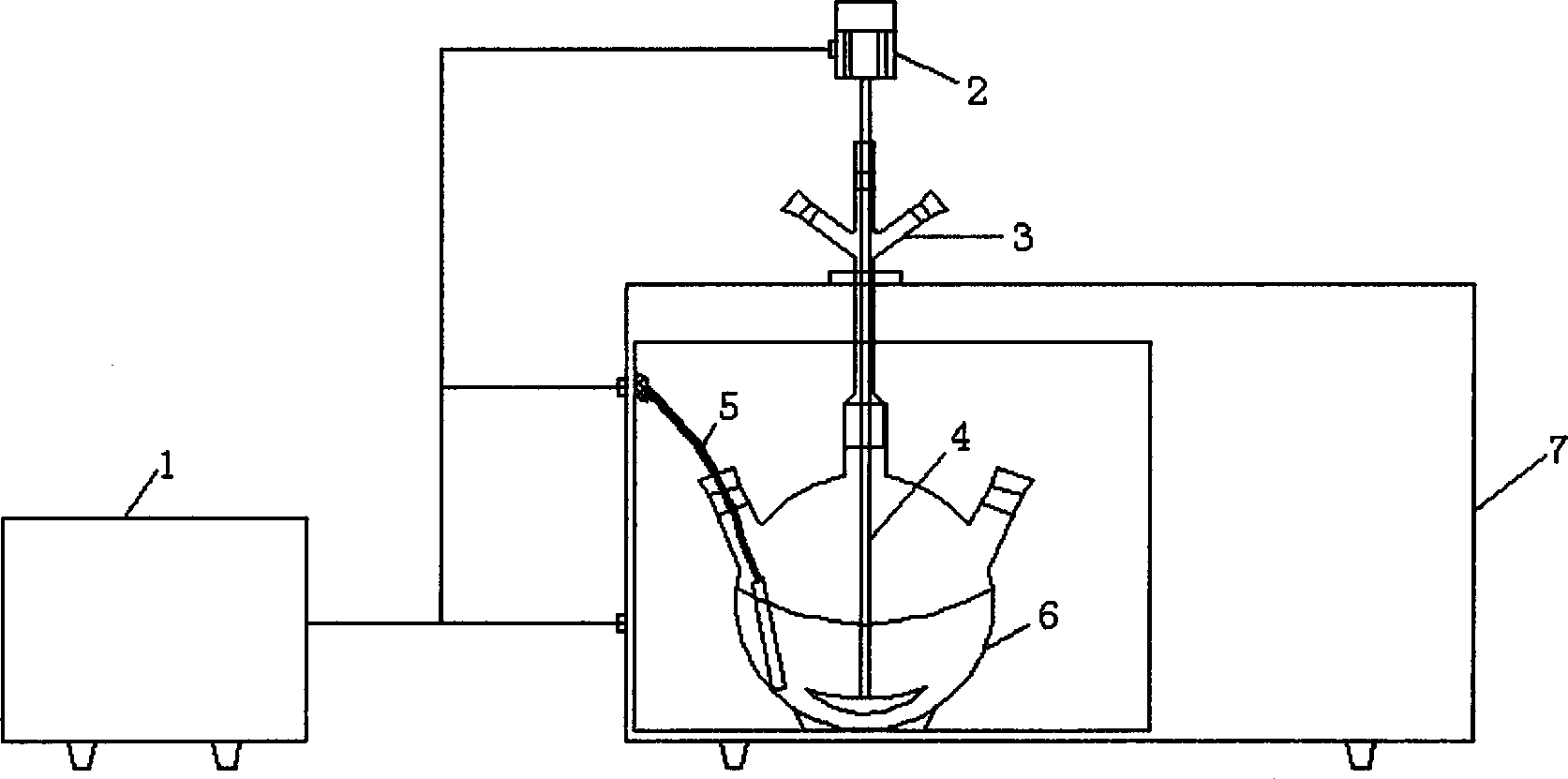

Wollastonite powder surface wet modification method assisted by microwave

InactiveCN101531835AGood modification effectImprove efficiencyChemical industryMicrowave heatingFiltrationHydrolysate

The invention relates to a wollastonite powder surface wet modification method assisted by microwave, which belongs to the technical field of powder surface modification. KH550 is used as coupling agent. The method comprises the processes of hydrolysate solution preparing, microwave-assisted coupled reaction, extraction and drying. The process of the microwave-assisted coupled reaction is as follows: wollastonite powder and ethanol are prepared into slurry to be put a constant-temperature microwave oven and stirred and heated to 50-80 DEG C; the hydrolysate solution is dripped into the slurry slowly and is stirred to react for 15 to 60 minutes; and a sample is dried in the constant-temperature microwave oven under the temperature of 90-130 DEG C after suction filtration. Compared with the prior wollastonite powder surface wet modification method, the invention uses the characteristic of heating by the microwave completely and realizes the goals of being assisted by microwave radiation and intensifying modification; the invention does not change the wollastonite crystal structure and the molecular structure of the coupling agent; and the invention can control the temperature exactly and ensures that the thermal efficiency and the heating speed during the modifying process are improved greatly.

Owner:JILIN UNIV

Processing process of lemon jelly dried molassed tablets

The invention provides a processing process of a lemon jelly dried sugar curing tablets. The process comprises the following steps of: cleaning separated fresh lemons, washing, disinfecting, airing, dewatering, freezing, slicing, vacuum freezing and drying, dipping molasses and drying to prepare a lemon jelly dried sugar curing tablets. The processed tablets has the advantages of high quality, good mouthfeel, convenient storage, convenient use and great commercial value.

Owner:四川小炊事实业有限公司

Method for producing thinned ceramic tile by recycling of waste incineration fly ash

InactiveCN104891961AEasily damagedLower sintering temperatureCeramic materials productionClaywaresBrickEngineering

The invention discloses a method for producing a thinned ceramic tile by recycling of waste incineration fly ash and realizing the innocent treatment of waste incineration fly ash. The method comprises the following steps of treating waste incineration fly ash by using a smoke carbonation stable chemical process, blending the ash with the raw materials, and carrying out the work sequences of ball-milling, sieving, pelleting, molding, glazing, sintering and the like, so as to obtain a high-quality thinned ceramic tile which has the indexes such as the green brick thickness of 4.5-6mm, the shrinking percentage within 2%, the water absorption rate of 11%-13% and the rupture modulus of 15-20MPa. According to the invention, hazardous wastes, namely rubbish incineration fly ash, can be recycled as a raw material for developing thinned ceramic tiles, heavy metals in fly ash are solidified by the smoke carbonation stable chemical process, and dioxin in the fly ash can be thoroughly destroyed by calcination, thereby achieving the aims of innocent treatment and resourceful treatment of waste incineration fly ash.

Owner:内江博达科技有限公司 +2

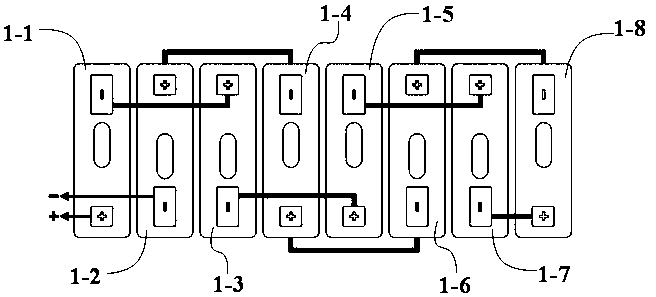

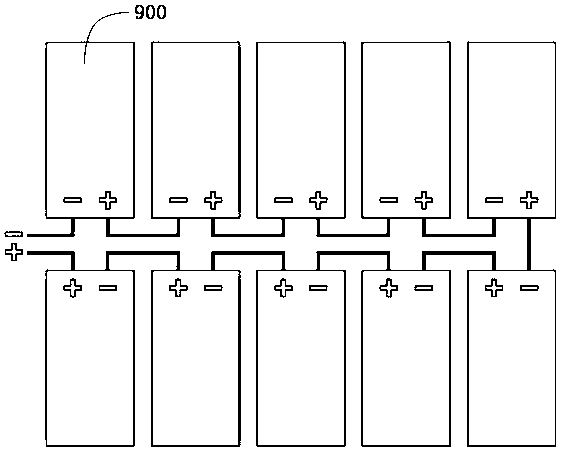

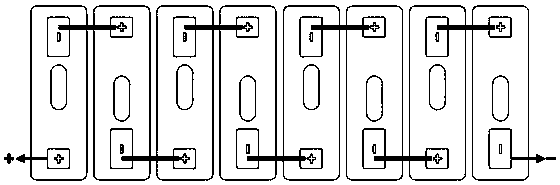

Battery module with same-side electrode output

PendingCN110931694AReduce complexityImprove physical performanceCurrent conducting connectionsCells structural combinationElectrical batteryHemt circuits

The invention discloses a battery module with same-side electrode output, which comprises a plurality of square batteries arranged in sequence, and the positive electrodes and the negative electrodesof the batteries are positioned at the top and are respectively arranged at two sides of the central axis of the arrangement direction of the batteries. Along the arrangement direction of the batteries, the positive and negative electrodes of the first battery and the second battery are arranged on different sides, and then the positions of the positive and negative electrodes of every two batteries are changed. The positive electrode of the first battery is connected with the positive output electrode of the battery module, and the negative electrode of the second battery is connected with the negative output electrode of the battery module; the negative electrode of the first battery is connected to the positive electrode of the third battery, and the positive electrode of the second battery is connected to the negative electrode of the fourth battery, and so on. The bus connection mode of the series batteries in the battery module can reserve enough space for the monitoring circuitboard, and when the module package is formed, the low-voltage line connected with the monitoring circuit can be separated from the bus high-voltage wiring harness connected with the positive electrodeand the negative electrode of the battery module, so that the electromagnetic interference of the bus to the low-voltage line is greatly reduced.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

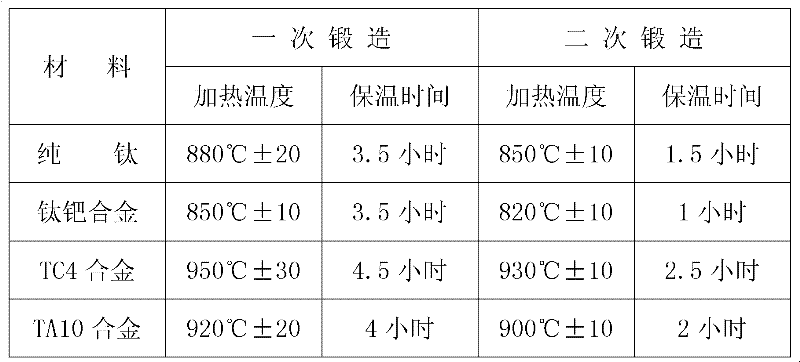

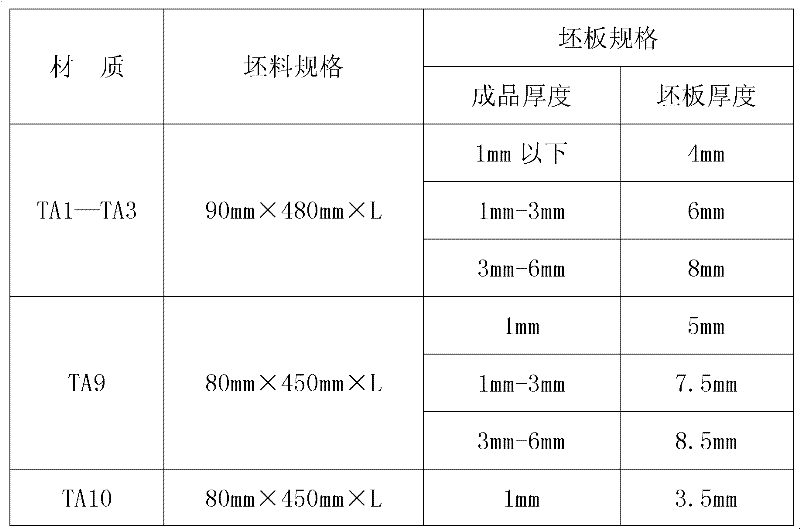

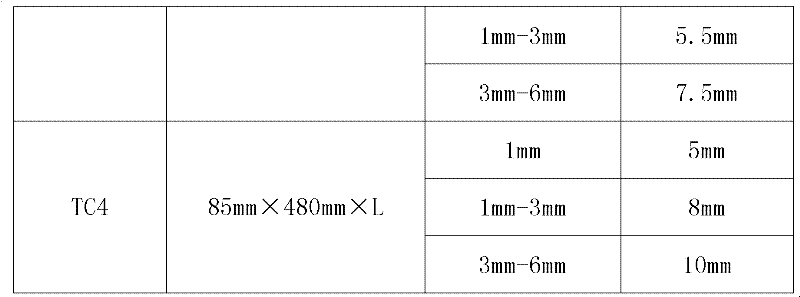

Process for fabricating high precision titanium and titanium alloy plates

InactiveCN102225504AGuaranteed permutation rulesGuaranteed physical propertiesTitaniumTitanium alloy

The invention provides a process for fabricating high precision titanium and titanium alloy plates, employs the processes of material selection, smelting, forging, plate milling, mechanical grinding, composite electropolishing and the like, and solves the difficult problems of titanium and titanium alloy plates of which the surface can not be a mirror surface in precision and roughness, so that the average roughness of the titanium and titanium alloy plates can reach about 0.03 mu m, an oxide film can be formed on the surface during the polishing process, and the corrosion resistance of the plates can be improved effectively.

Owner:BAOJI XINZE TITANIUM NICKEL

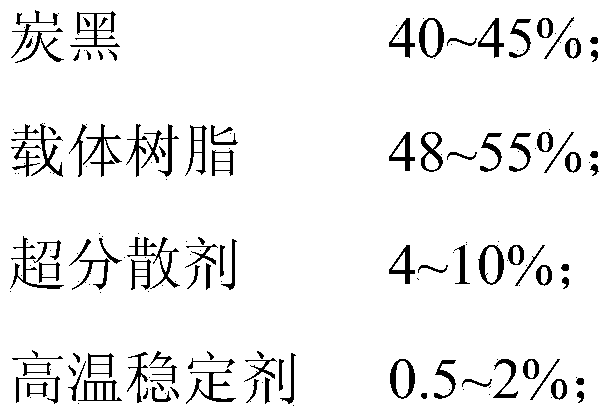

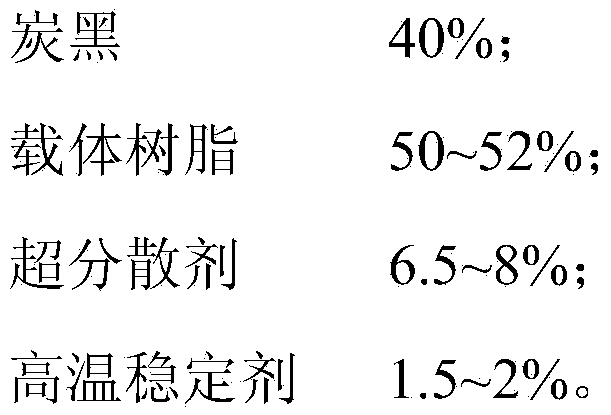

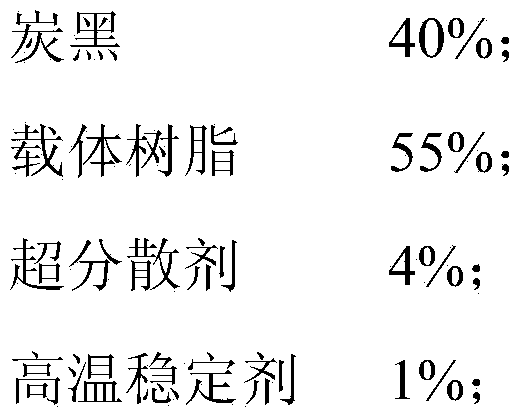

High-lightness and high-brightness black masterbatch and preparation method thereof

The invention belongs to the technical field of plastic coloring, and discloses high-lightness and high-brightness black masterbatch and a preparation method thereof. The high-lightness and high-brightness black masterbatch comprises components in percentage by weight as follows: 40%-45% of carbon black, 48%-55% of carrier resin, 4%-10% of hyperdispersant and 0.5%-2% of a high-temperature stabilizing agent. The preparation method comprises steps as follows: the carbon black, the carrier resin, the hyperdispersant and the high-temperature stabilizing agent are prepared according to content of a formula, the components of raw materials are totally put in a low-speed mixer for pre-mixing treatment, and then the obtained mixture is transferred to a pressurizing mixer for pressurizing mixing; materials obtained through pressurizing mixing are sliced and placed in a double-roll extruding machine for extrusion forming; materials obtained through extrusion are broken and transferred into a spiral granulator for granulation; and obtained materials are cooled, dried and sub-packaged to obtain the high-lightness and high-brightness black masterbatch. The high-lightness and high-brightness black masterbatch has high carbon black content, high blackness degree and good dispersity.

Owner:HUIZHOU HAOYING NEW MATERIAL TECH

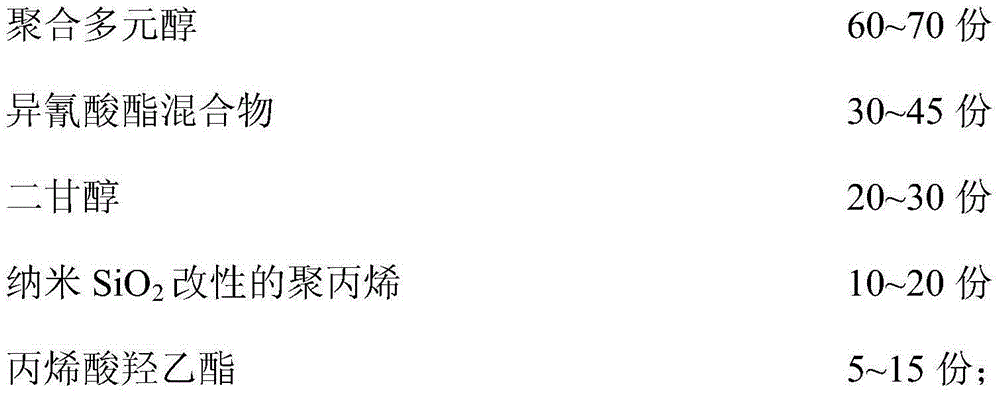

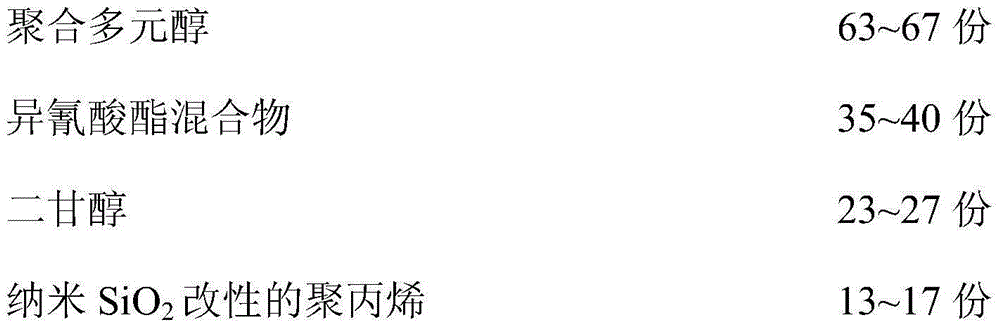

Rolling level thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a rolling level thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer is mainly prepared of the following components in parts by weight: polymeric glycol, isocyanate mixture, diethylene glycol, nano SiO2 modified polypropylene and hydroxyethyl acrylate, wherein the polymeric glycol is a polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol mixture; the isocyanate mixture is a toluene diisocynate and hexamethylene diisocyanate mixture. Under the synergistic effect of polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol and the synergistic effect of toluene diisocynate and hexamethylene diisocyanate, the prepared rolling level thermoplastic polyurethane elastomer is high in processing performance and resilience performance due to nano SiO2 modified polypropylene and hydroxyethyl acrylate serving as a crosslinking agent; meanwhile, the phenomenon of roll bonding can be avoided in a working process.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Conductive polyformaldehyde material

InactiveCN1389513AImprove conductivitySimple structureOrganic conductorsPlasticizerConductive materials

The invention refers to a kind of electric polyformaldehyde amterial made up of polyformaldehyde, charcoal blacks and the plasticizer according a certain proportion. The invention can make the common non-electric polyformalhyde material augment the electric capability, and it can retain the proper physical capability of the original polyformaldehyde material, and at the same time, it can be used as the electric of the original polyformaldehyde material, and at the same time, it can be used as the electric material and gain more application. The application of the electric material can make the construct of the electrical-apparatus products, such as the portfire of the lighter, simplify, and accordingly enlarge the applied range of the polyformaldehyde material.

Owner:吴建业

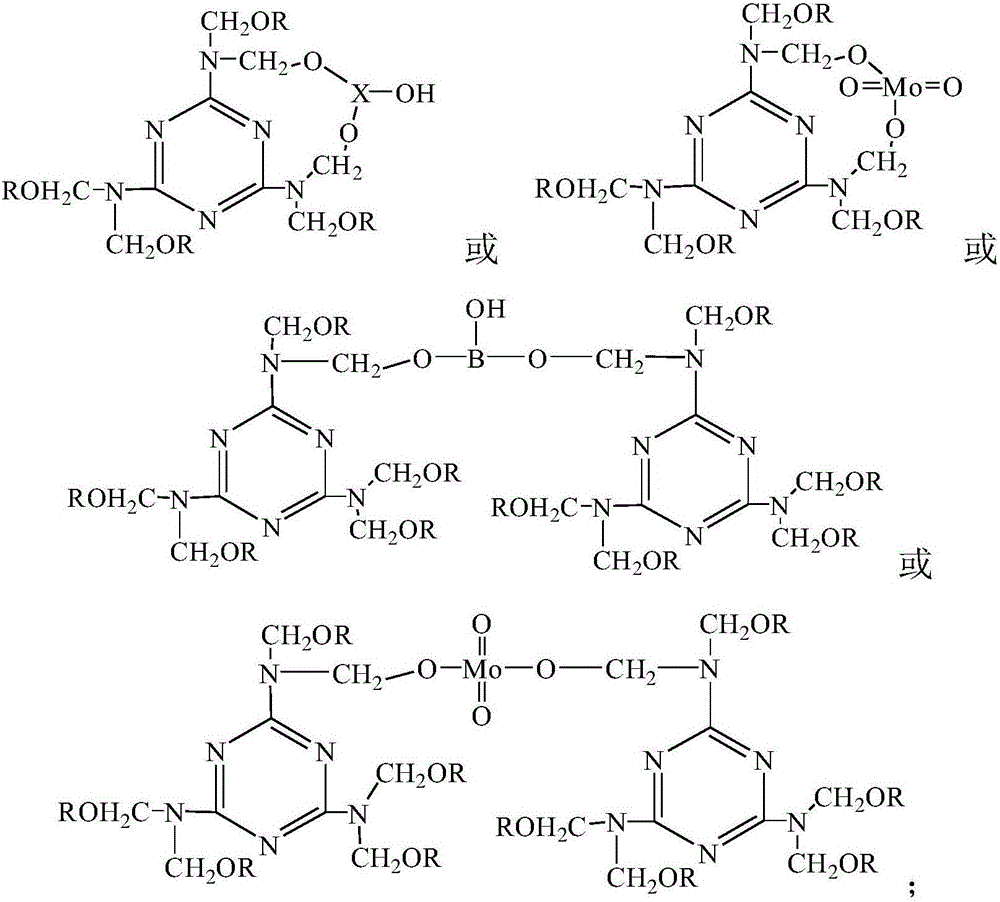

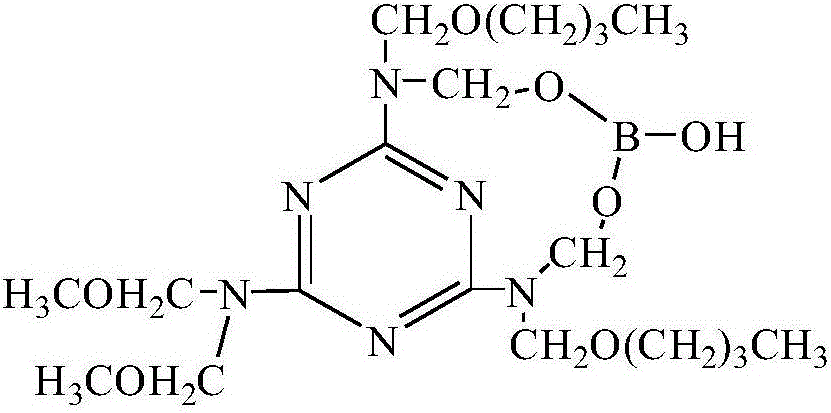

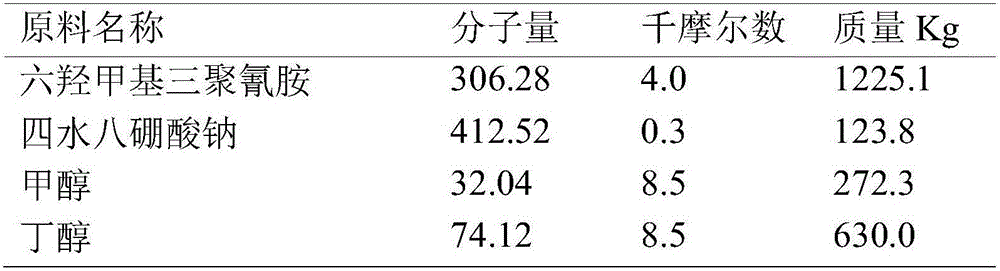

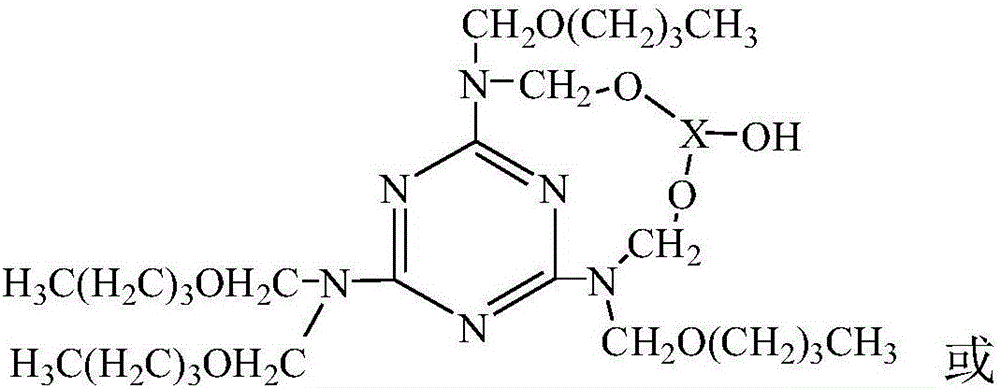

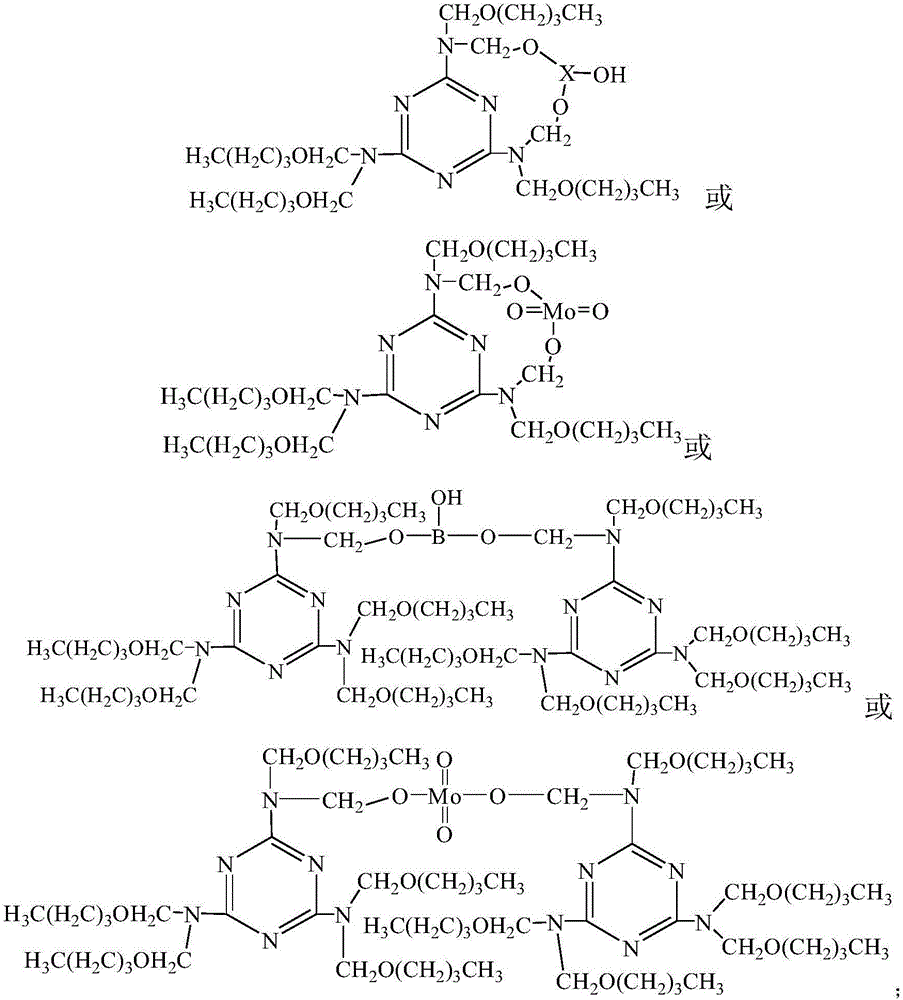

Inorganic hybridized mixed-etherified melamine resin and preparation method thereof

ActiveCN106349267AImprove high temperature resistanceImprove flame retardant performanceGroup 3/13 element organic compoundsGroup 6/16 organic compounds without C-metal linkagesCross-linkHybrid compound

The invention belongs to the technical field of inorganic hybridized polymer materials and particularly relates to inorganic hybridized mixed-etherified melamine resin and a preparation method thereof. The preparation method mainly includes steps: (1) etherification reaction, to be more specific, adding hexamethylol melamine, methyl alcohol and butyl alcohol into a reactor, and performing thermal reaction to obtain tetra-etherified or penta-etherified melamine resin; (2) alkali neutralization; (3) hybridization reaction; (4) distillation for removing residual methyl alcohol and butyl alcohol; (5) cooling and filtering to obtain a finished product. The inorganic hybridized mixed-etherified melamine resin prepared according to the method has advantages that by hybridization cross-linking reaction with inorganic hybrid compounds, high-temperature flame-retardant elements such as boron, molybdenum and stibium are added into amino resin generated finally, and accordingly high temperature resistance and flame retardation of the amino resin are improved, and the resin is mainly applied to preparation of combined polyether and paint.

Owner:重庆派昂科技发展有限公司

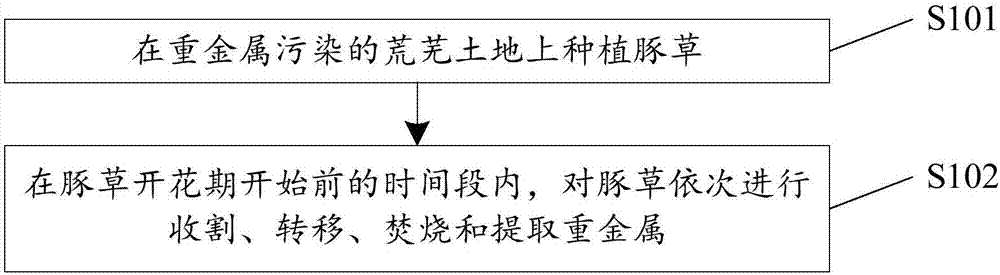

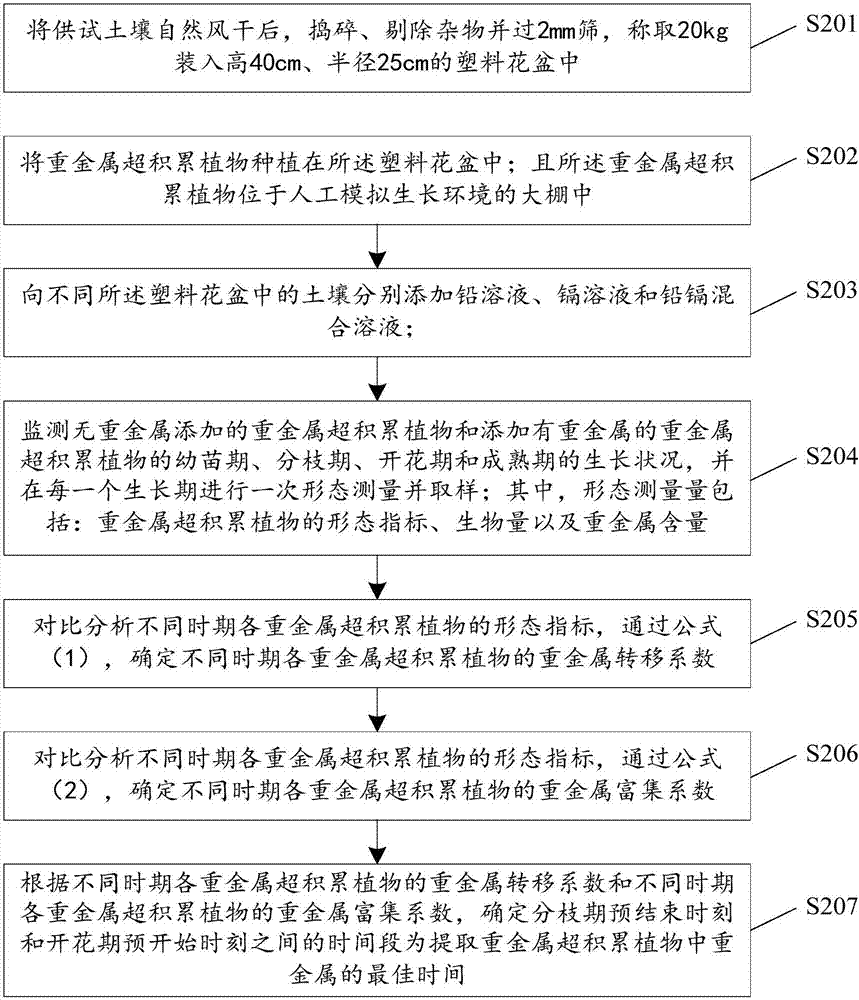

Remediation method for heavy-metal-contaminated soil

InactiveCN107159694APromote growthLarge biomassContaminated soil reclamationEcological environmentHigh absorption

The invention discloses a remediation method for heavy-metal-contaminated soil and relates to the field of ecological environment remediation. The method comprises the steps that ragweed is planted on the heavy-metal-contaminated barren land; and the ragweed is reaped, transferred, incinerated and subjected to heavy metal extraction sequentially in the period before the start of the flowering period of the ragweed. According to the remediation method, the heavy-metal-contaminated soil is remedied through the ragweed, the ragweed grows fast in the growing period and branching period, and the ragweed has the high absorption function and enrichment function on the heavy metal pollution in the soil; and the ragweed has the beneficial effects of being high in growth speed, large in biomass, high in adaptability, low in cost, wide in distribution and the like, a lot of lead, cadmium and the like in the soil, especially in the overground part, can be transferred into the plants, the ragweed is reaped and transferred manually before the flowering period and is incinerated, then heavy metals are extracted, and therefore the soil pollution such as lead and cadmium is remedied, and the higher economic value and economical environment value are provided for the effective utilization of heavy metal soil remediation by the plants and invasive alien species.

Owner:LIAONING PROVINCIAL ENVIRONMENTAL PROTECTION SCI INST

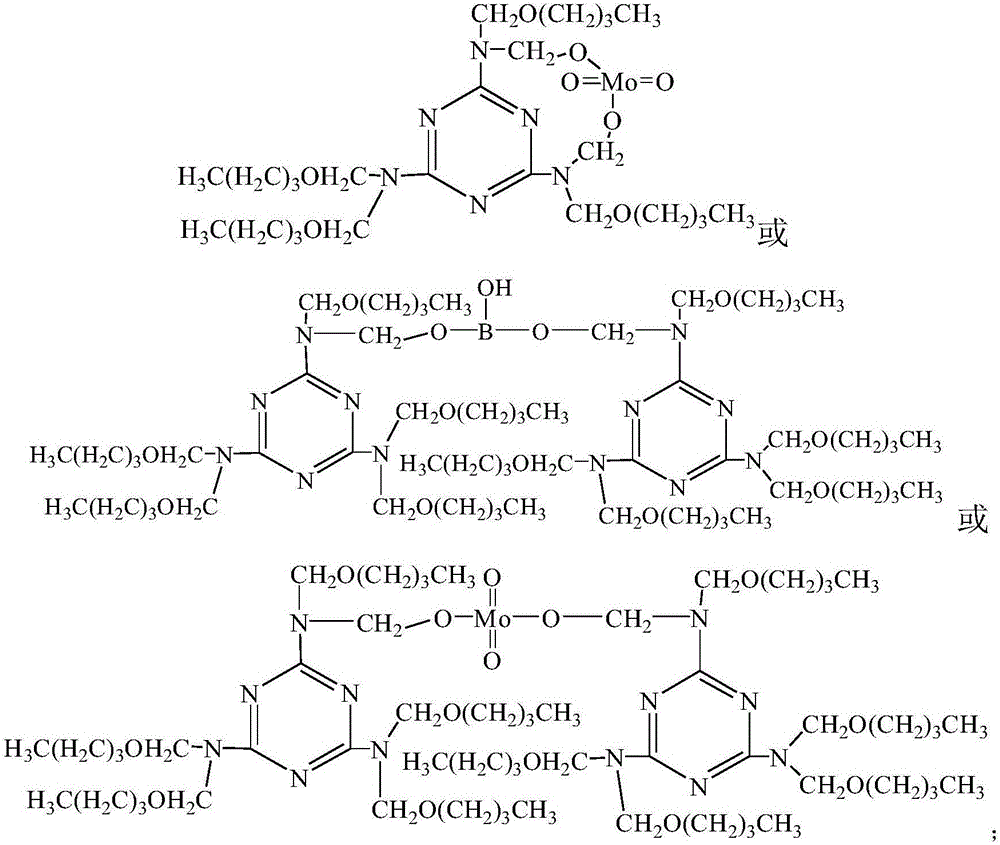

Inorganic hybrid butylated melamine resin and production method thereof

ActiveCN106243300AImprove high temperature resistanceImprove flame retardant performancePolyurea/polyurethane coatingsEpoxy resin coatingsCross-linkHybrid compound

The invention belongs to the technical field of inorganic hybrid polymeric materials, and especially relates to an inorganic hybrid butylated melamine resin and a production method thereof. The production method mainly comprises the following steps: 1, carrying out an etherification reaction: adding hexamethylolmelamine and butanol to a reaction kettle, and carrying out a heat insulation reaction to obtain tetraetherified or pentaetherified melamine resin; 2, neutralizing with an alkali; 3, carrying out a hybrid reaction; 4, distilling to remove residual butanol; and 5, cooling and filtering to obtain the finished product. A hybrid cross-linking reaction with an inorganic hybrid compound makes boron, molybdenum, antimony and other high temperature-resistant flame retardation elements be introduced to finally generate amino resin, so the high temperature resistance and the flame retardation performance of the amino resin are improved, and the obtained amino resin is mainly used to prepare combined polyether, paints and coatings.

Owner:重庆派昂科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com