Inorganic material hybrid hard melamine polyurethane foam heat insulation material, preparation method thereof and combined polyether used therein

A technology of melamine polyurethane and foam insulation material, which is applied in the field of polymer materials, can solve the problems that the addition ratio is too small to achieve fire resistance and the physical properties of the foam are degraded, and achieve the effects of good adhesion, stable physical properties and low viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

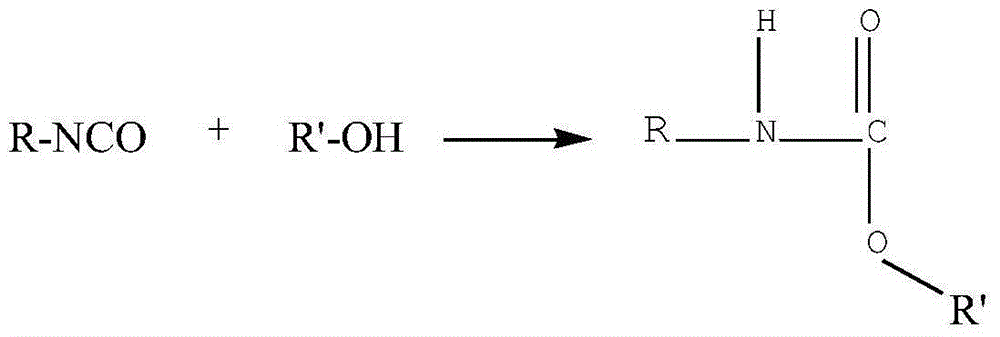

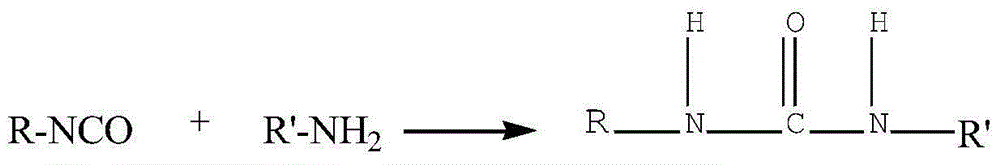

Method used

Image

Examples

Embodiment 1

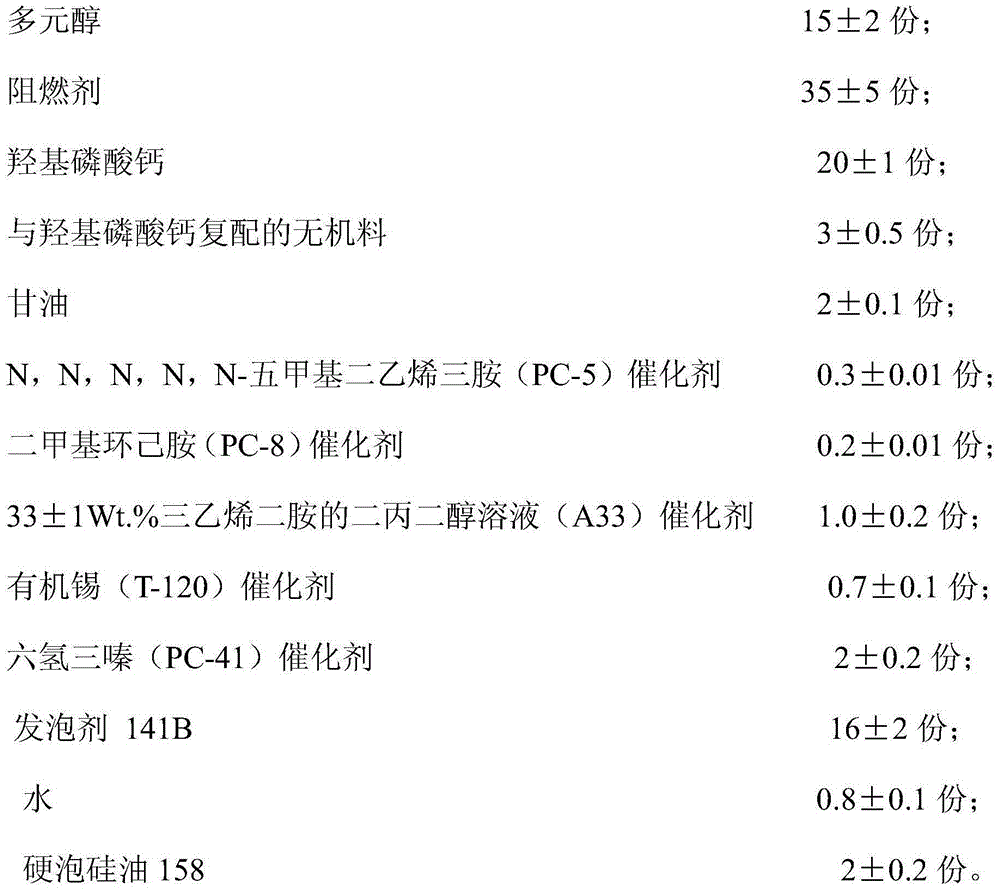

[0054] The combined white material is configured according to the mass parts:

[0055]

[0056]

[0057] The mass ratio of combined white material and isocyanate (MDI) is 1:1, and airless spraying is carried out with a spray gun. The thickness of the obtained polyurethane energy-saving thermal insulation foam is 50mm, and the obtained foam density is 43Kg / m 3 ; Oxygen index: 30.4%, the flame retardant level reaches (GB8624-2012 standard) B1 level.

Embodiment 2

[0059] The combined white material is configured according to the mass parts:

[0060]

[0061]

[0062] The mass ratio of combined white material and isocyanate (MDI) is 1:1, and airless spraying is carried out with a spray gun. The thickness of the obtained polyurethane energy-saving thermal insulation foam: 50mm, and the obtained foam density: 45Kg / m 3 ; Oxygen index: 35.4%, the flame retardant level reaches (GB8624-2012 standard) B1 level.

Embodiment 3

[0064] The combined white material is configured according to the mass parts:

[0065]

[0066]

[0067] The mass ratio of combined white material and isocyanate (MDI) is 1:1, and airless spraying is carried out with a spray gun. The thickness of the obtained polyurethane energy-saving thermal insulation foam: 50mm, and the obtained foam density: 46Kg / m 3 ; Oxygen index: 33.1%, the flame retardant level reaches (GB8624-2012 standard) B1 level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com