Polymeric compositions containing nanotubes

A technology of polymers and compositions, applied in the direction of carbon nanotubes, single-walled carbon nanotubes, multi-walled carbon nanotubes, etc., can solve the problems of unsatisfactory practical applications, decreased mechanical strength and impact strength, and difficulty in obtaining sheets with satisfactory properties. Materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

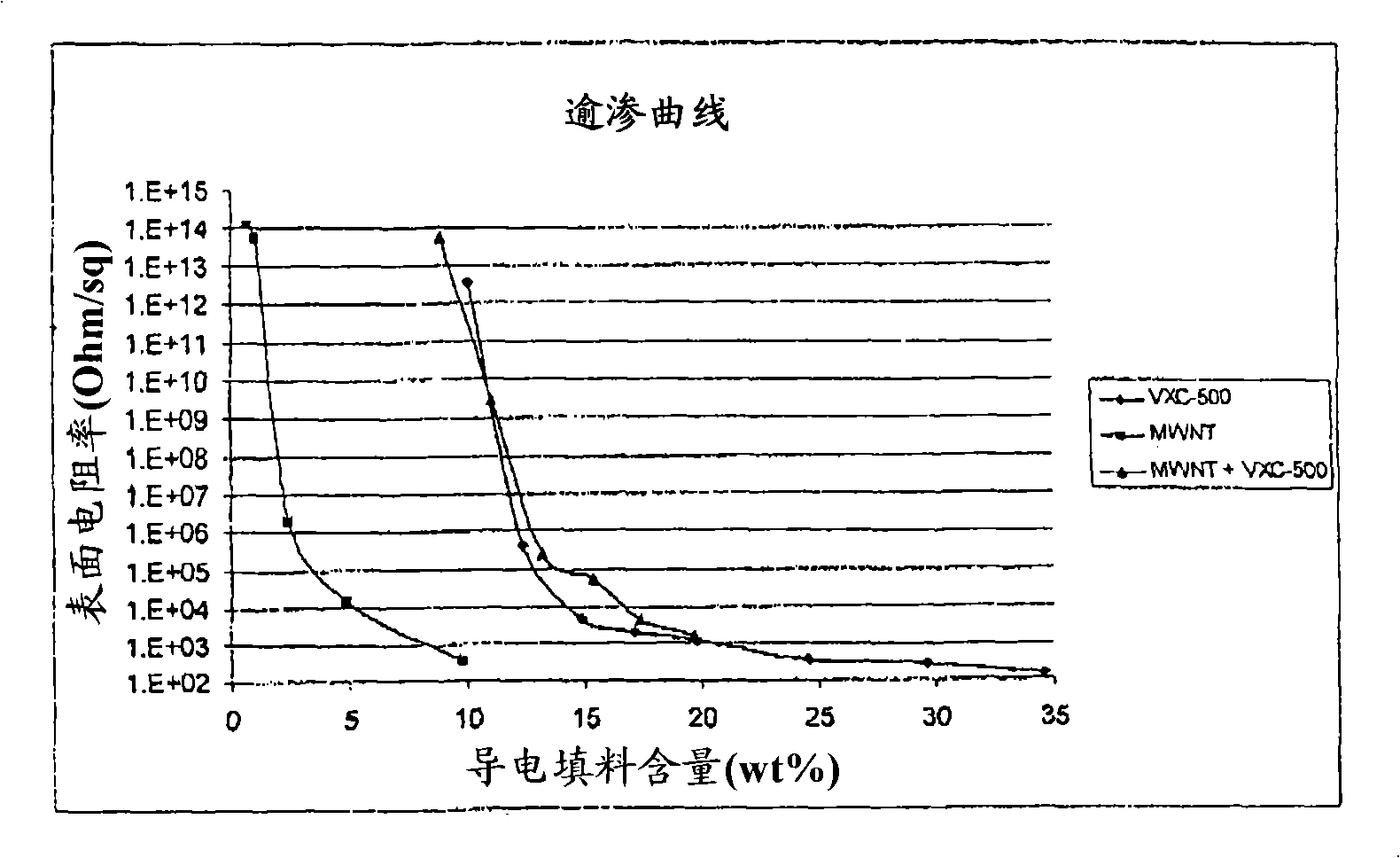

[0133] The compounding equipment was a high shear internal mixer Haake Rheocord 90 equipped with a mixing chamber with two counter-rotating Brabender-shaped blades. For each compound, the following method was used. The granular polymer is first introduced into the mixing chamber. Carbon black (Vulcan XC-500 carbon black) or thin thick multi-walled carbon nanotubes (MWNTs) are introduced into the mixing chamber.

[0134] At the end of the mixing cycle (1 minute at 40RPM / 40RPM to 200RPM in 3 minutes / 2 minutes at 200RPM), the compound was removed from the mixer and passed between two Mylar sheets on a hydraulic press Press down and flatten. The material was then cut into small pieces for a second mixing cycle to ensure good filler dispersion and a uniform compound.

[0135] Several compounds were prepared at different loadings (wt%) in EEA LE5861 obtained from Borealis with a nominal MFI of 6 g / 10 min at 190°C / 2.16 kg:

[0136] Carbon black: 35-30-25-20-17.5-15-12.5-10%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com