Zero-sintering and hydrogen-expansion nano-diffusion reinforced Cu-Al2O3 alloy and its production

A dispersion-strengthening, cu-al2o3 technology, applied in the field of Cu-Al2O3 alloy and its preparation, can solve the problems of inability to use electric vacuum devices, expansion, etc., and achieve the effects of high electrical conductivity and high temperature resistance annealing softening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

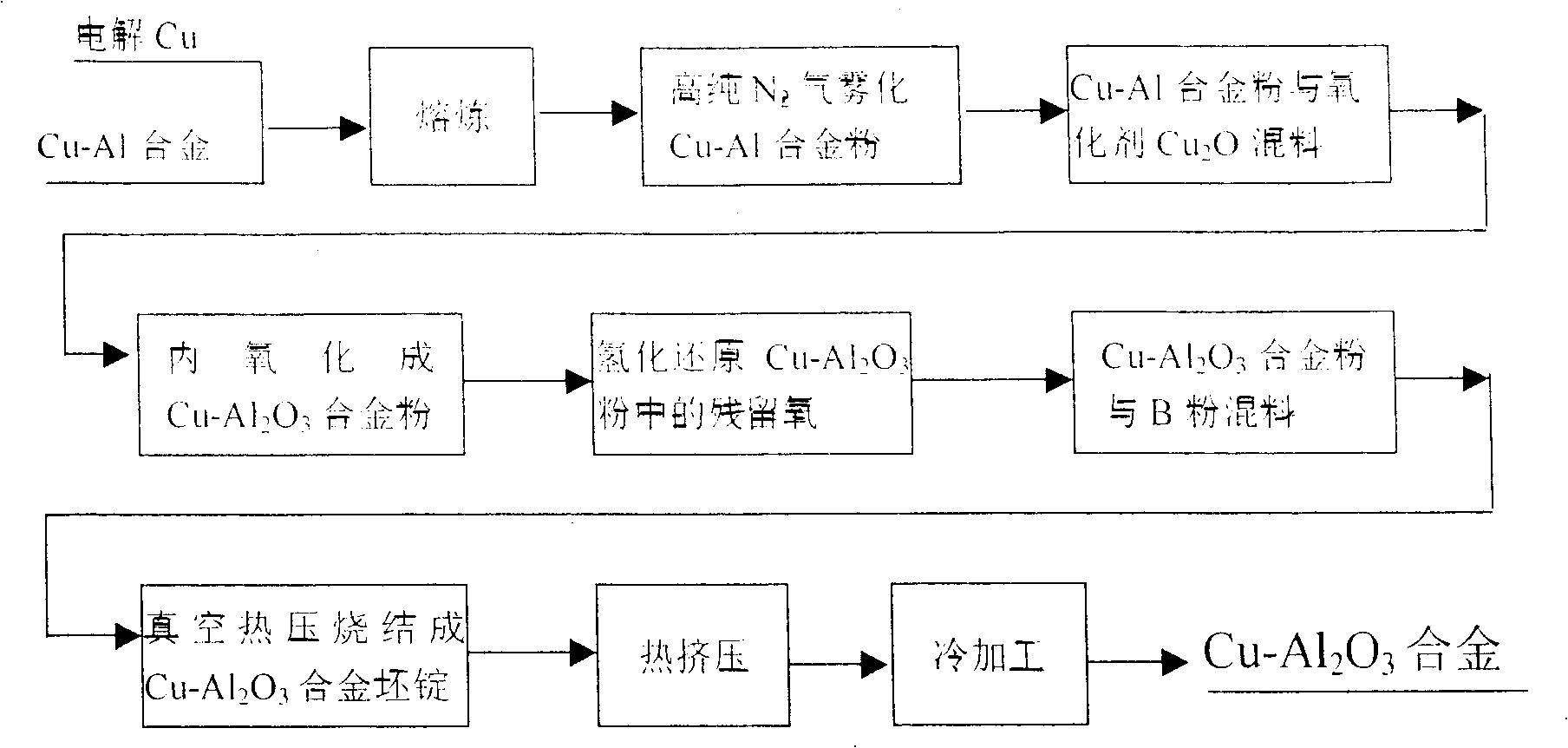

Method used

Image

Examples

Embodiment 1

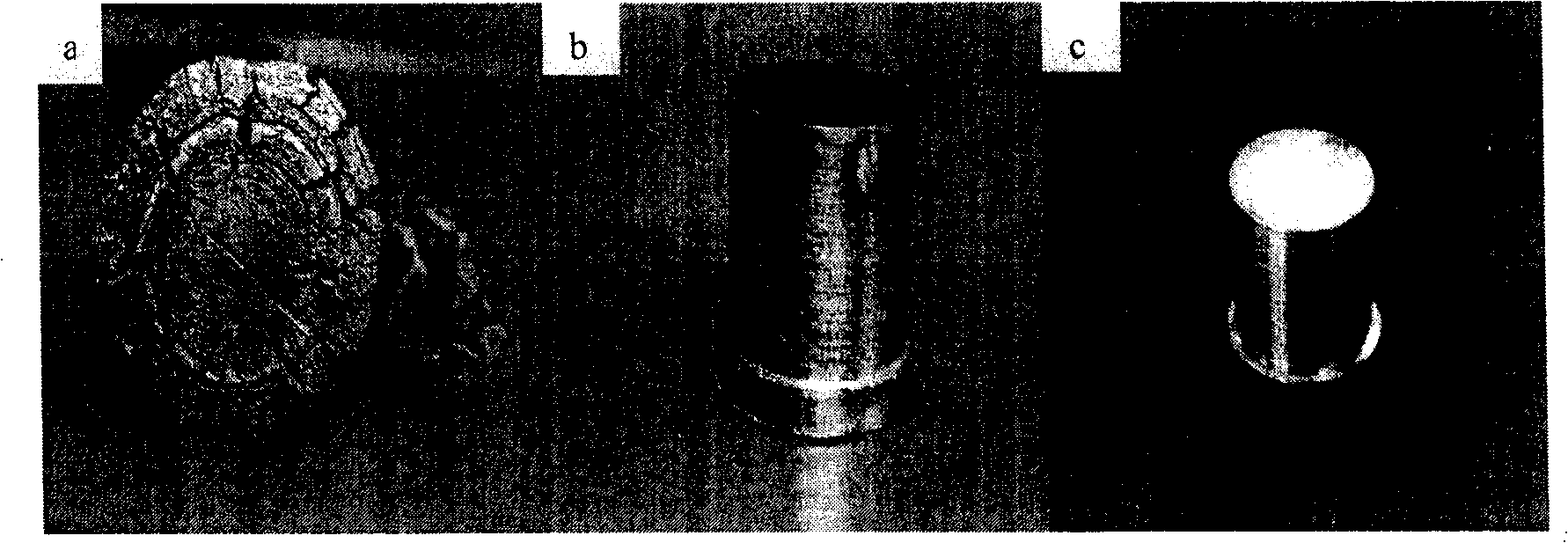

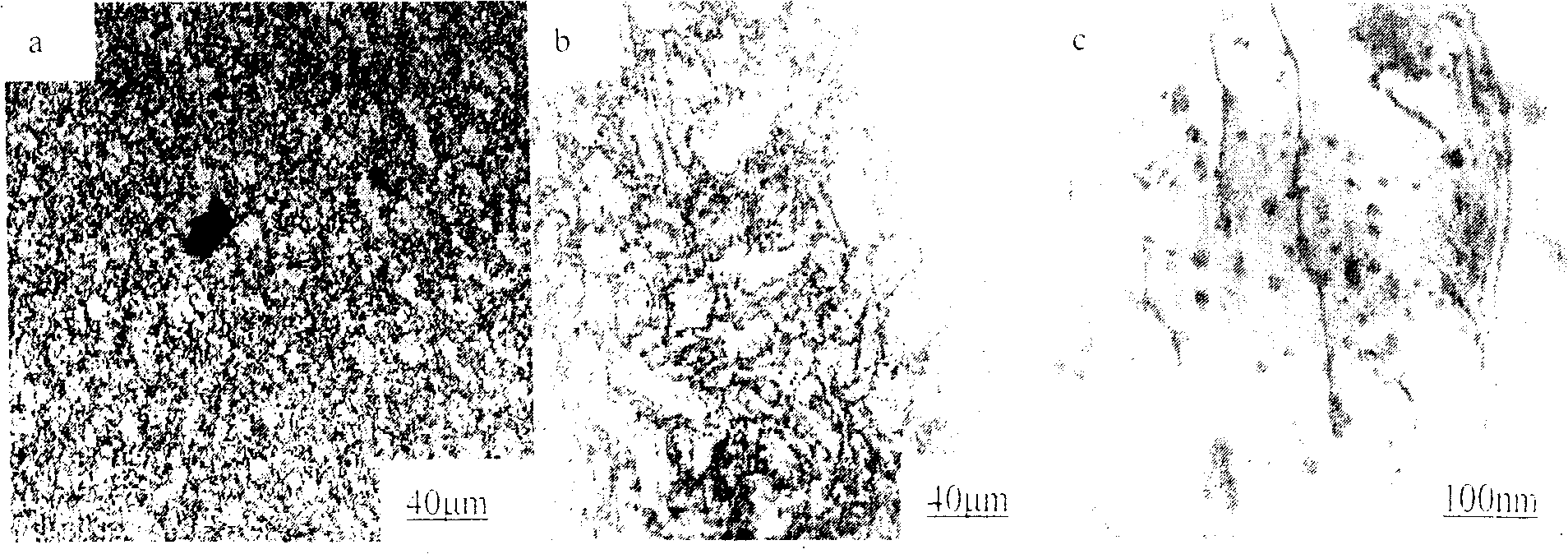

[0026] Embodiment 1: Alloy composition is Al 2 o 3 -0.22wt%, B-300ppm, the rest is Cu. According to the method (1)~(6) described in the "invention details", the hot-pressed ingot of Φ100 is made, and then heated to 930 °C under the protection of hydrogen to be hot-extruded into a rod of Φ20 (extrusion ratio 25 : 1), and cold-drawn to Φ14 bar (deformation 50%), the cold-drawn bar is annealed by hydrogen protection at 900°C for 1h, and the measured alloy performance data are shown in Table 1. It can be seen that the measurement accuracy is Under the condition of μm, the alloy does not observe hydrogen burning expansion phenomenon. The metallographic structure, TEM structure and appearance of the sample after burning hydrogen in this embodiment are shown in image 3 (b), (c) and figure 2 (c). It can be seen that the alloy in this example is in a fully dense and fully metallurgical state, and 5-20nm Al is dispersed inside the alloy. 2 o 3 Particles, particle anchors to dis...

Embodiment 2

[0029] Embodiment 2: Alloy composition is Al 2 o 3 -0.22wt%, the rest is Cu. Compared with Example 1, only the secondary reducing agent B is not added, and the rest of the preparation and processing methods are the same as in Example 1, and the experimental conditions are also the same. The measured performance data of the alloy are shown in Table 2. It can be seen that even without the addition of the secondary reducing agent B, the C in the graphite mold still has a secondary reduction effect during vacuum autoclaving, and the vacuum can remove the gas in the alloy powder. The alloy also undergoes little hydrogen expansion (measured maximum size increase of only 3 μm).

[0030] Table 2 Cu-0.22wt% Al in this example 2 o 3 Alloy property data

[0031]

Embodiment 3

[0032] Embodiment 3: Alloy composition is Al 2 o 3 -0.22wt%, the rest is Cu and unavoidable impurities. Same as Example 2, no secondary reducing agent B was added. In addition to heat pressure is slightly greater than 10 5 Except carrying out in the high-purity Ar gas protection of Pa, all the other preparation methods are the same as in Example 2, and the experimental conditions are also the same. The measured alloy performance data are shown in Table 3. It can be seen that hot pressing in high-purity Ar gas will make Cu-Al 2 o 3 The alloy contains gas, resulting in slight hydrogen expansion (about 8-15 μm).

[0033] Table 3 Cu-0.22wt% Al in this example 2 o 3 Alloy property data

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com