Wollastonite powder surface wet modification method assisted by microwave

A wollastonite powder and microwave-assisted technology, which is applied in microwave heating, chemical instruments and methods, climate sustainability, etc., can solve the problems of low heating efficiency and inability to heat, improve thermal efficiency and heating speed, overcome low thermal efficiency, The effect of maintaining physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

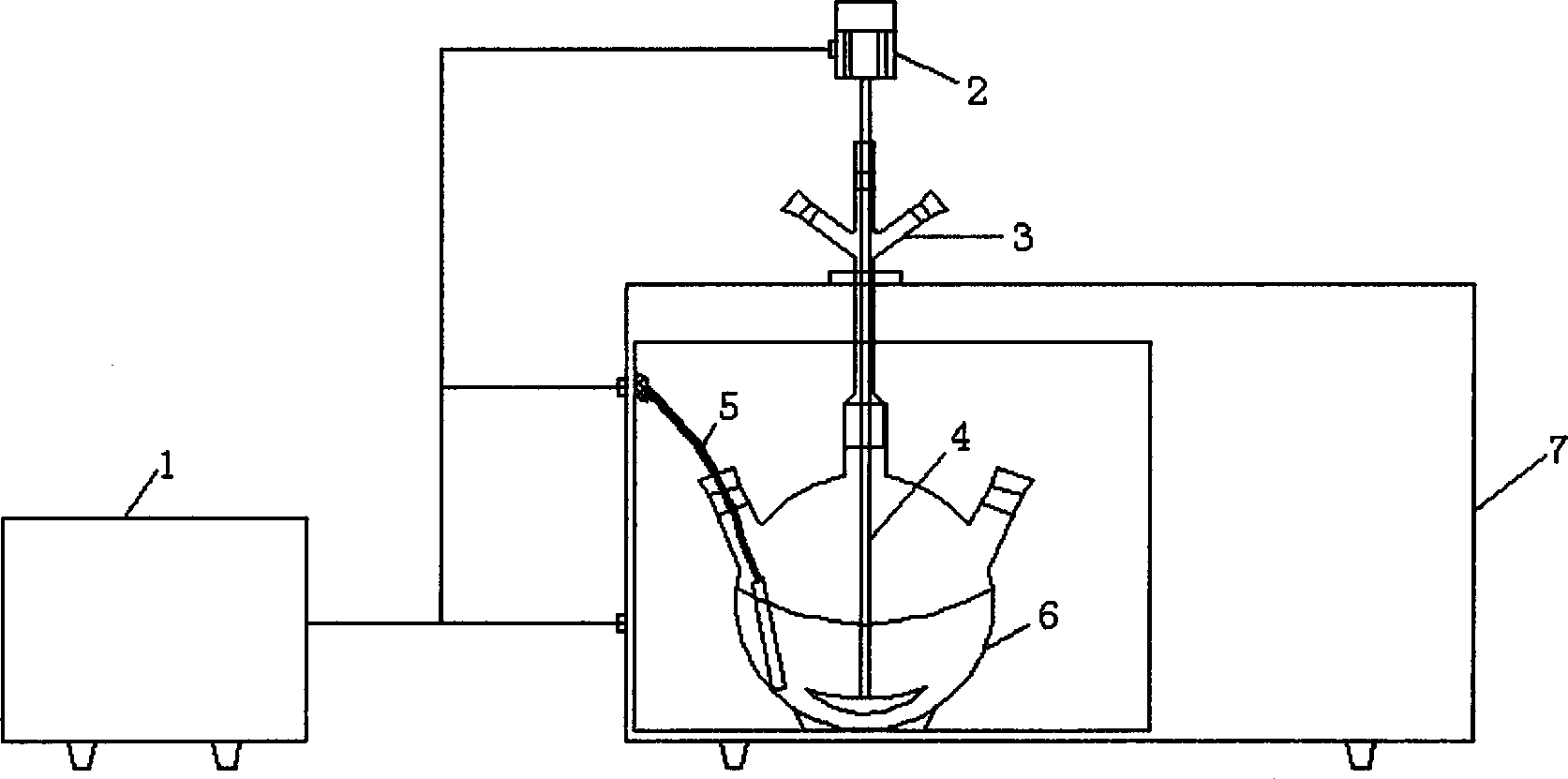

[0035] Example 1 Microwave-assisted wollastonite powder surface wet modification device:

[0036] (1) Microwave oven structure

[0037] a) Simple devices for laboratory use such as figure 1As shown, 1 is an electric control device; 2 is a stirring motor; 3 is a three-way glass tube; 4 is a stirrer, which is composed of a stirring shaft and paddle blades; 5 is a temperature sensor; 6 is a glass container; 7 is a constant temperature microwave oven. Connect thermocouples and relays to the constant temperature microwave oven circuit, open a round hole in the center of the top of the constant temperature microwave oven 7, and set a copper mesh or metal ring with a height of about 5 to 10 cm around the hole (to prevent microwave leakage), and a three-way glass tube 3 Sealed connection with the slurry glass container 6 in the constant temperature microwave oven 7 through the round hole, the stirring rod with the paddle enters the slurry through the polytetrafluoroethylene stirring ...

Embodiment 2

[0040] Embodiment 2 The best process and process conditions of the present invention

[0041] Take 0.9 g of γ-aminopropyltriethoxysilane (KH550) as a coupling agent, mix it by volume ratio coupling agent: deionized water: ethanol = 1:1:3, adjust the pH value to 3.5 with acetic acid, and hydrolyze 60 minutes, dubbed hydrolyzate.

[0042] In the flask, add 10g of wollastonite powder into 100ml of ethanol to form a slurry; put the flask into a constant temperature microwave oven, stir and heat to 80°C; then slowly add the hydrolyzate into the slurry, and stir for 30 Minutes; After the sample was suction filtered, it was dried in a constant temperature microwave oven at 115°C for 30 minutes.

[0043] The dried sample was extracted in acetone solution for 8 hours, and then dried to obtain a chemically grafted sample. The grafting rate was measured to be 3.75%.

Embodiment 3

[0044] Embodiment 3 The preferred process and process conditions (1) of the present invention:

[0045] Take 0.9 g of γ-aminopropyltriethoxysilane (KH550) as the coupling agent, mix the coupling agent by volume: deionized water: ethanol = 1:1:2, adjust the pH value to 3.5 with acetic acid, and hydrolyze 60 minutes, dubbed hydrolyzate.

[0046] In the flask, add 10g of wollastonite powder into 60ml of ethanol to form a slurry; put the flask into a constant temperature microwave oven, stir and heat to 70°C; then slowly add the hydrolyzate into the slurry, and stir for 15 Minutes; After the sample was suction filtered, it was dried in a constant temperature microwave oven at 130°C for 60 minutes.

[0047] The dried sample was extracted in acetone solution for 8 hours, and then dried to obtain a chemically grafted sample. The grafting rate was measured to be 2.38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com