Patents

Literature

1050results about How to "Accurate temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

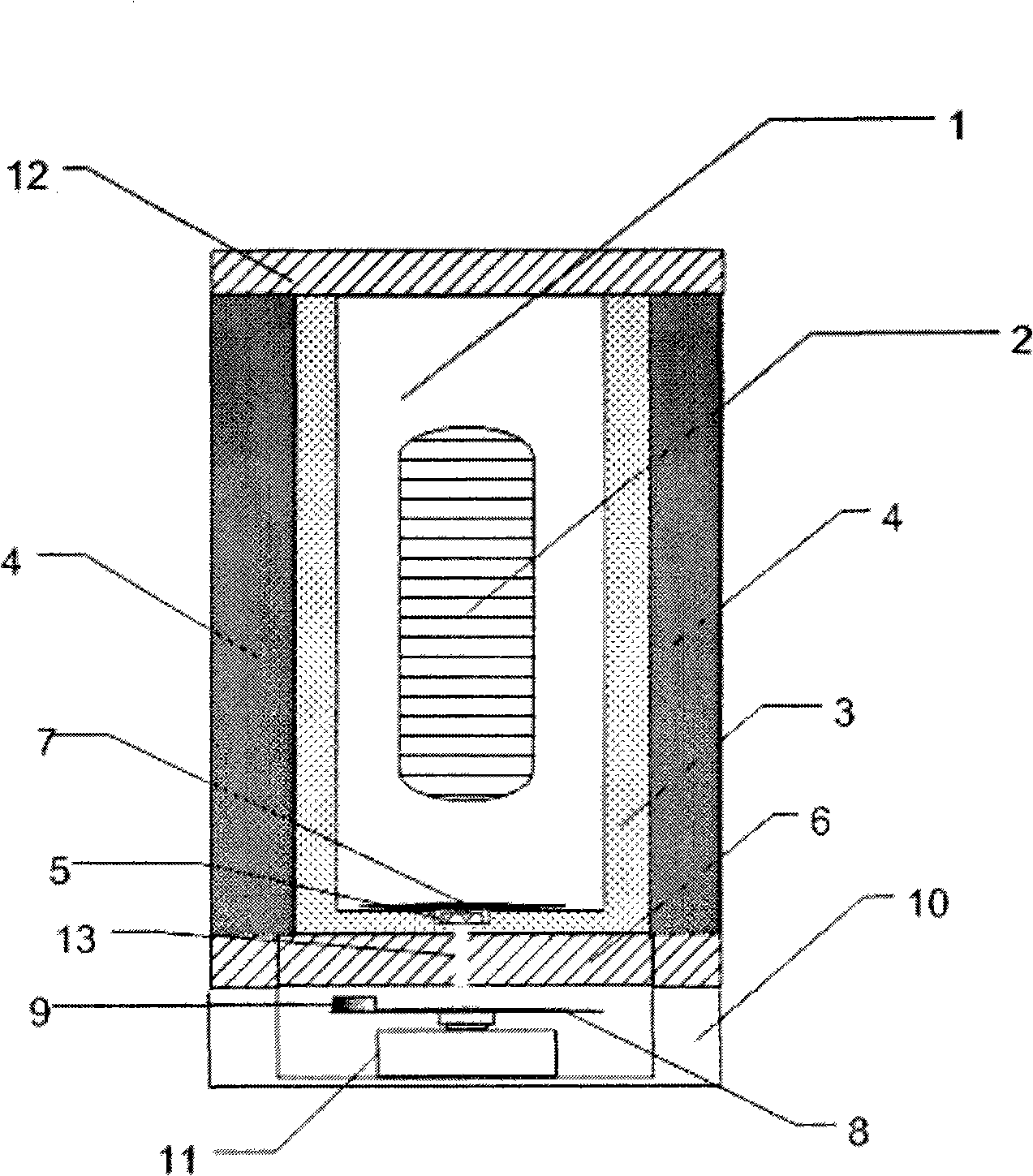

Efficient energy saving electro heating multipurpose cooker and new method of accurate temperature controlling and healthy cooking

InactiveCN101669761APlug the drainSolve technical problems that cannot withstand high temperaturesCooking-vessel lids/coversCooking utensils shields/jacketsElectricityAutomatic control

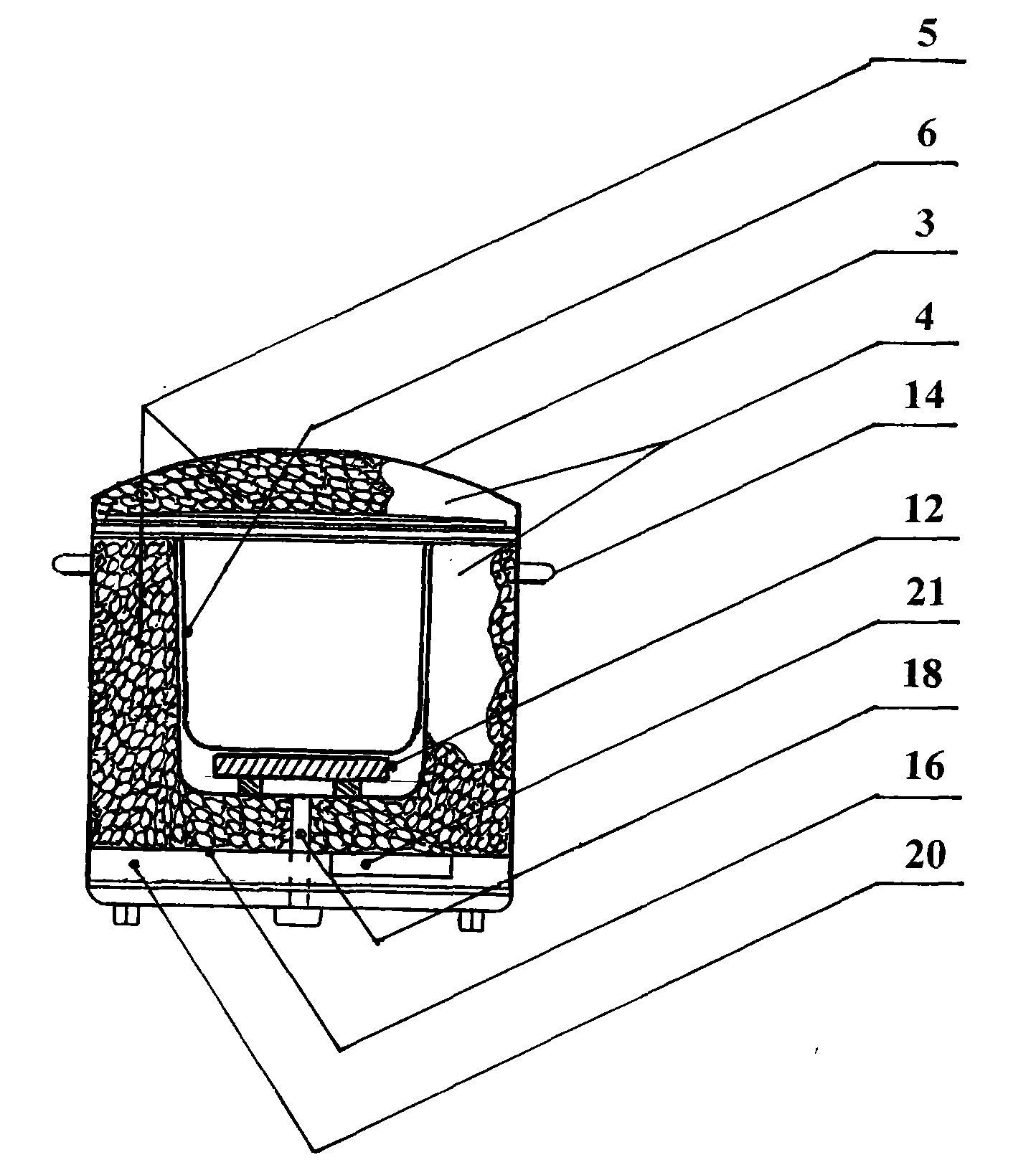

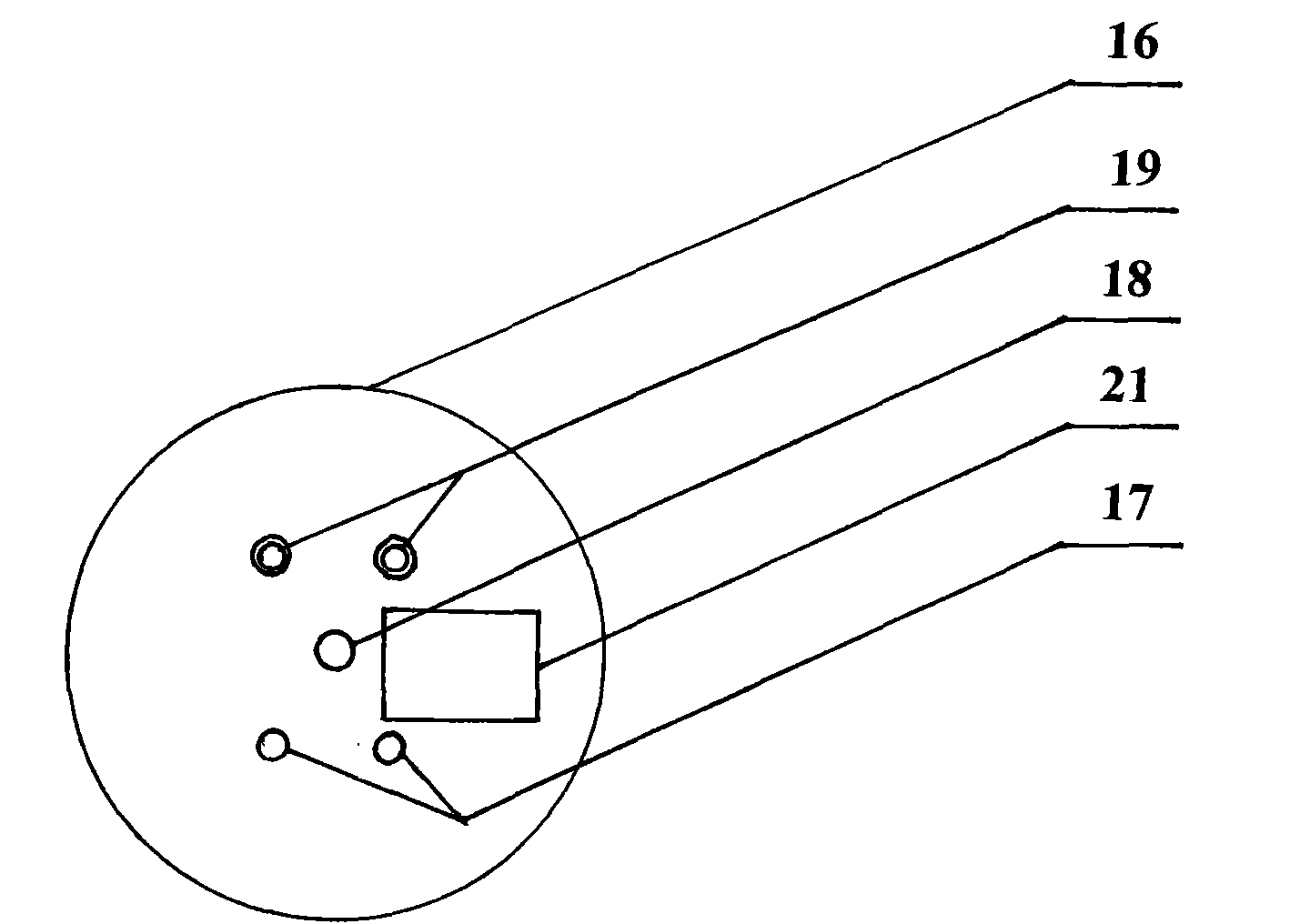

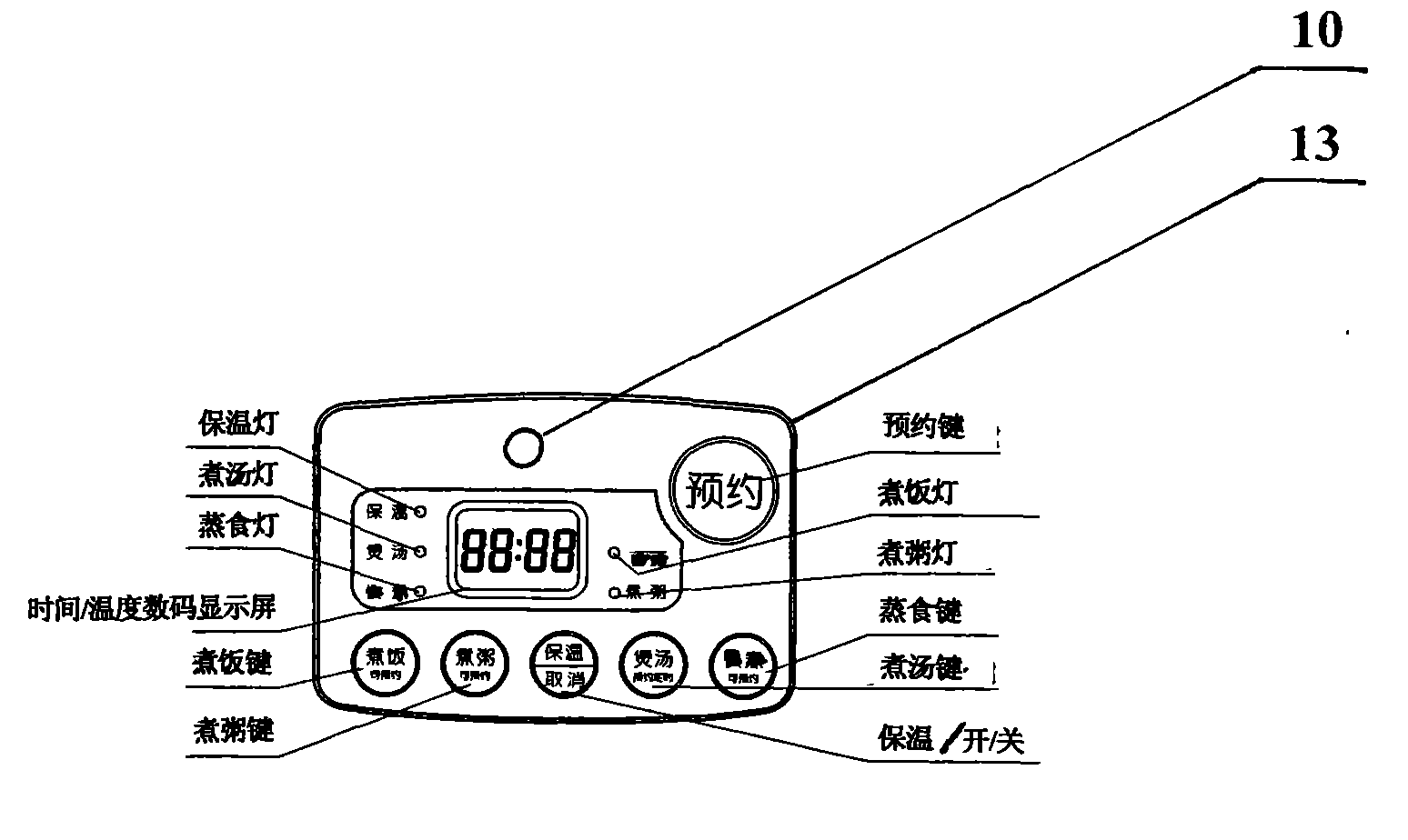

The invention discloses an efficient energy saving electro heating multipurpose cooker utilizing a new method of accurate temperature controlling and healthy cooking. The technical scheme of the invention is as follows: the outside surface of the cooker body is provided with an ambient temperature sensor; the base of the cooker is provided with an inner pot temperature sensor; the cooker body, thecooker cover and the cooker base are all set to be closed efficient heat insulation interlayers; the closed heat insulation interlayer on the cooker base is arranged between the casing of the cookerbase and the electro heating device; a hallow cavity is arranged between the casing of the cooker base and the closed heat insulation interlayer; and the purposes of energy saving, discharge reducingand healthy cooking can be realized by setting standard control values such as ambient temperature or temperature drop, cooking / steaming temperature and time and the like by an automatic control device and by comparing the ambient real-time temperature or temperature drop with the inner pot real-time temperature to control the power on and power off of the electro heating device. The efficient energy saving electro heating multipurpose cooker can be used for cooking rice, cooking congee, cooking soups and steaming food; compared with various electro rice / congee / soup cooker in the prior art, the invention can save electricity by 30%-50% and can be widely used in families, dining halls and catering enterprises in cities and towns.

Owner:郭卫康

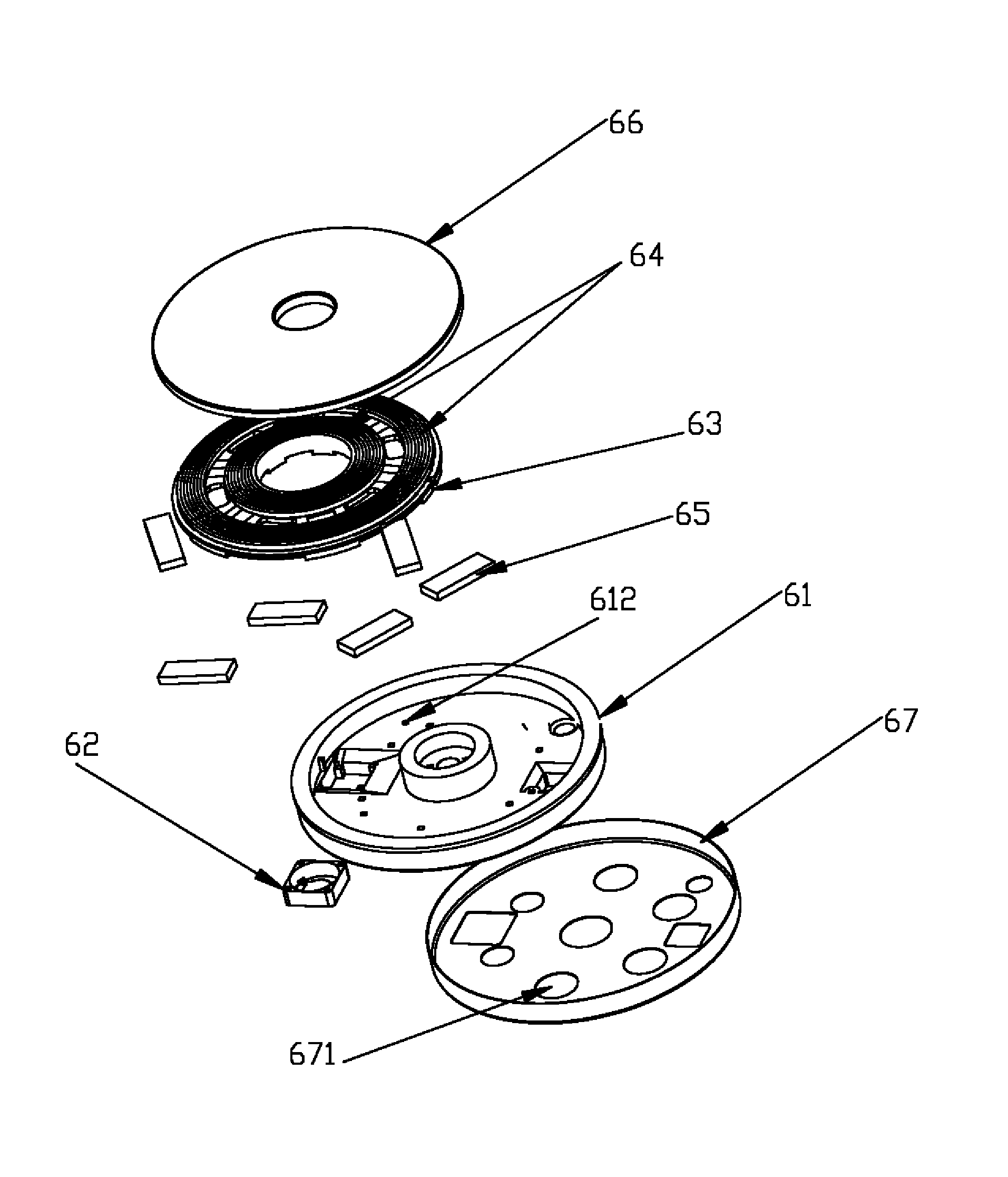

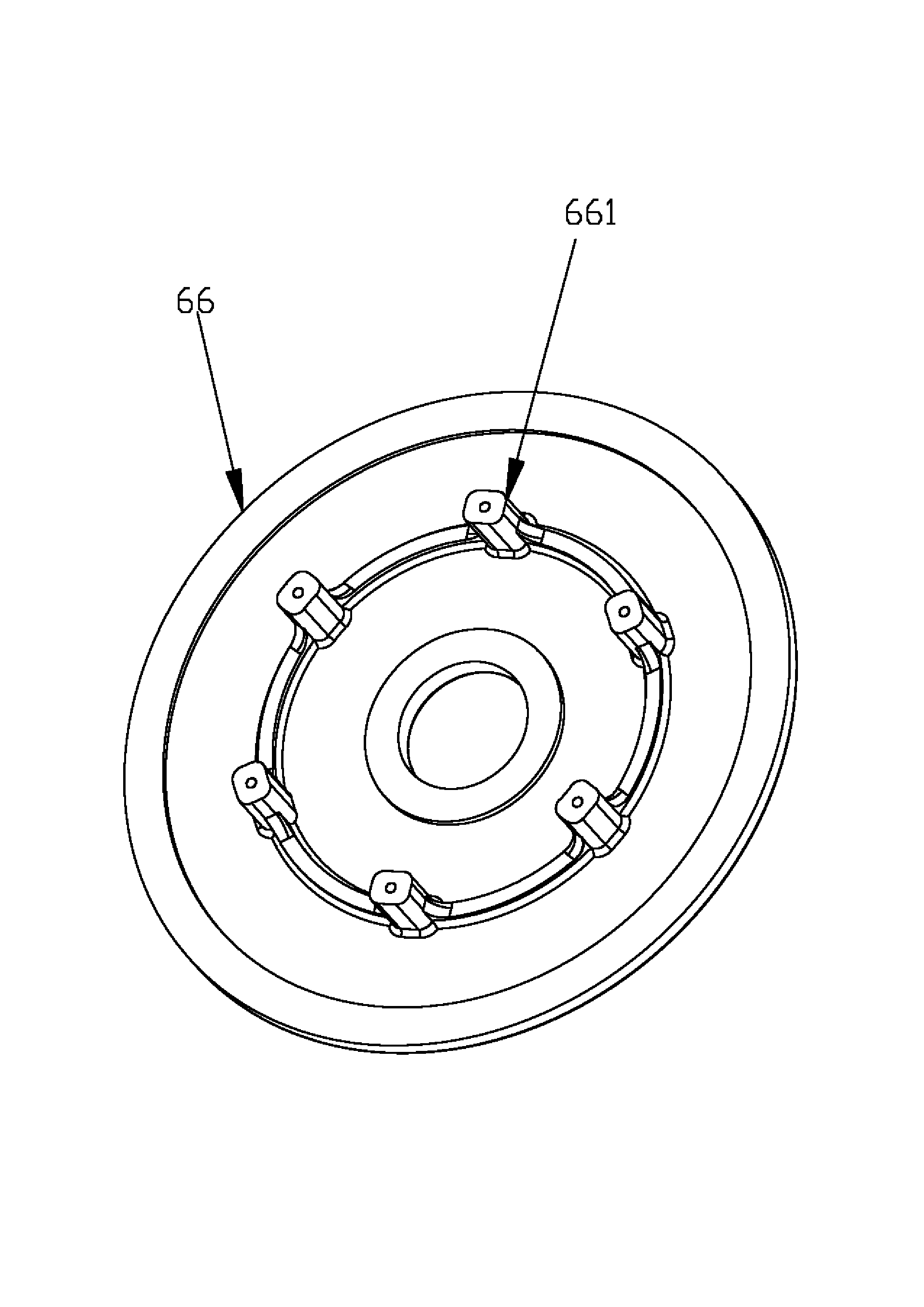

Electromagnetic heating electric pressure cooker

InactiveCN103006045ASolve potential safety hazardsImprove cooling effectCooking vesselsMagnetic heatingEngineering

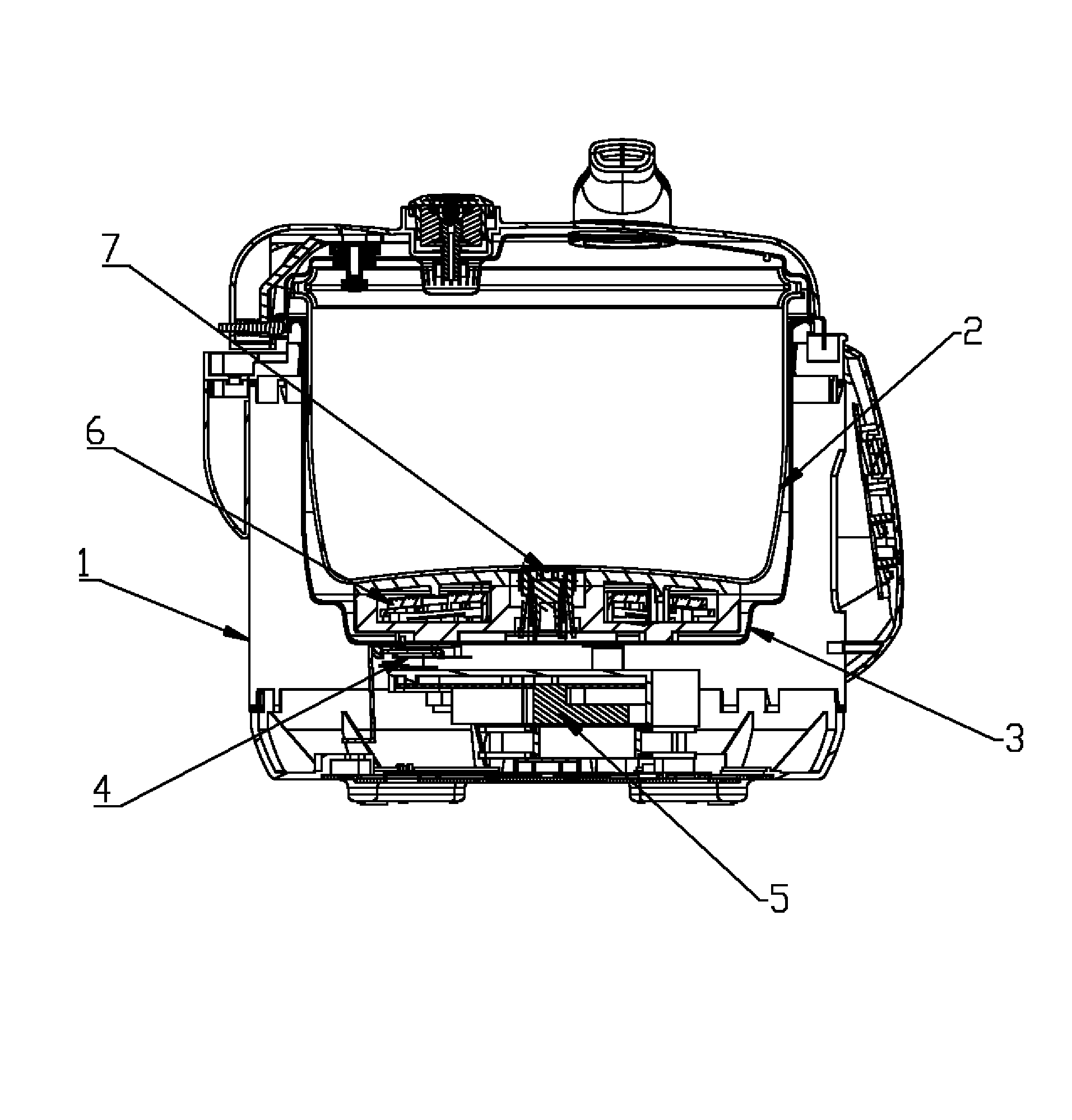

The invention relates to the technical field of electric pressure cookers, in particular to an electromagnetic heating electric pressure cooker. The electromagnetic heating electric pressure cooker structurally comprises a shell, an inner pot and an outer pot, wherein a pressure switch and a control device are arranged at the bottom of the outer pot; an annular heating disk component and a sensor component are arranged between the inner pot and the outer pot; a through hole is formed in the middle of the heating disk component; the sensor component is mounted in the through hole; the heating disk component comprises an electromagnetic heating outer disk, a radiating fan, an electromagnetic heating wire coil, an electromagnetic coil, a plurality of magnetic strips, an electromagnetic heating disk cover and an anti-magnetic disk; the sensor component comprises a fixed frame, a spring arranged on the fixed frame in a sleeving manner, a sensor cap and a thermistor; and the thermistor is electrically connected with the control device. Compared with the prior art, the electric pressure cooker has the advantages of simple structure, high radiating performance, capacity of precisely controlling pressure and temperature and long service life, truly realizes application of an electromagnetic heating technology to the electric pressure cooker, and has a wide market prospect.

Owner:GUANGDONG LUBY ELECTRONICS

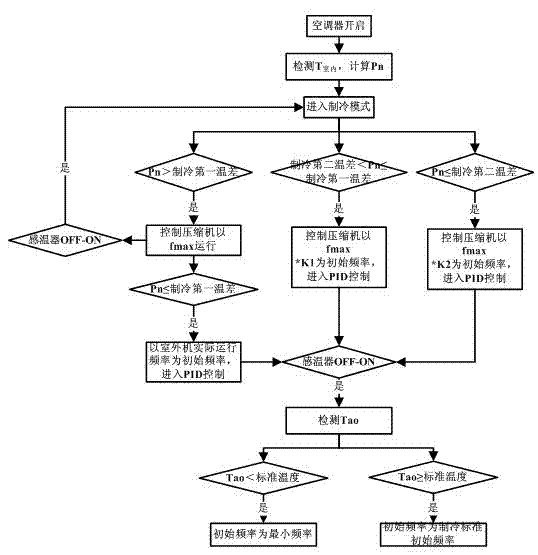

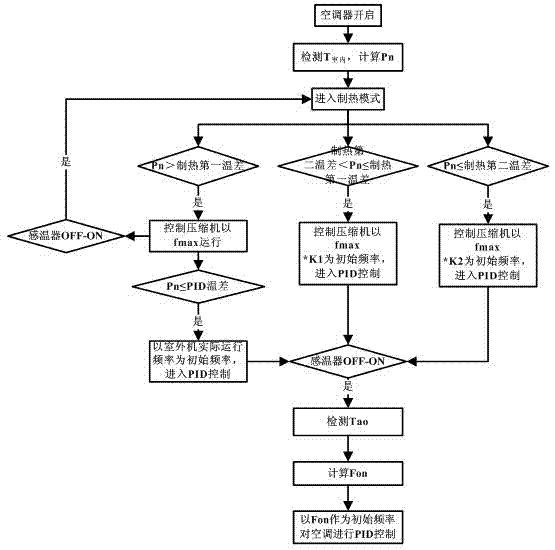

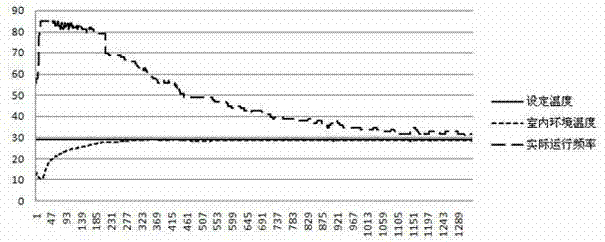

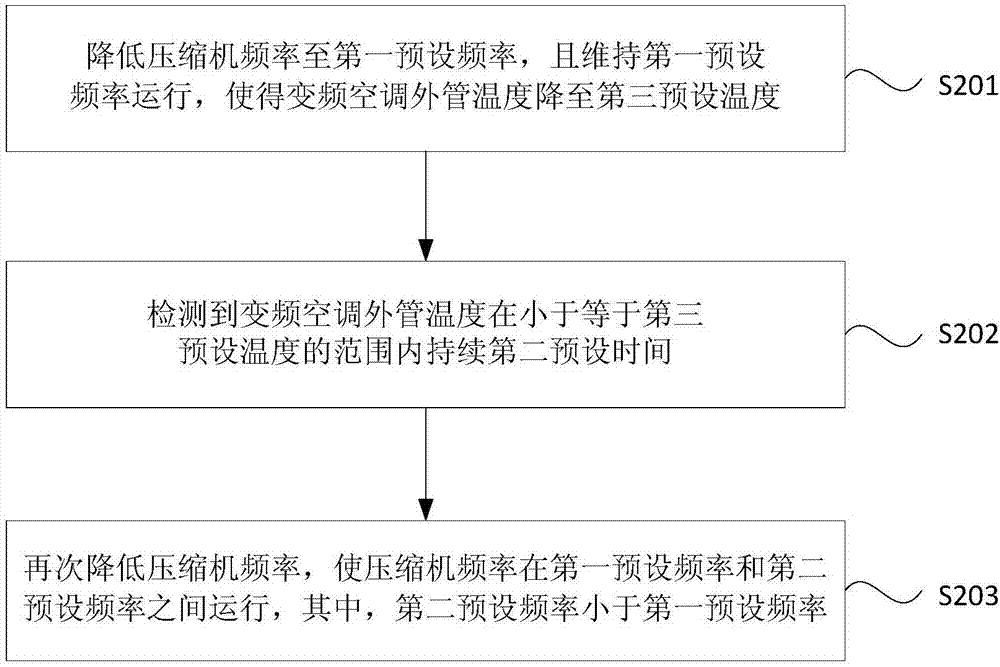

Air conditioning compressor frequency control method

ActiveCN104515254ARapid cooling and heatingAccurate temperature controlMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind speed

The invention provides an air conditioning compressor frequency control method. The method comprises that an air conditioning detects the indoor temperature T [indoor], wherein Pn= T [set]-T [indoor]; Pn is compared with a preset temperature difference, the air conditioning runs at the highest frequency when the temperature difference is large, and the work frequency of the compressor is corrected through an increment PID algorithm when the temperature difference is small, accordingly, rapid refrigeration and heating can be achieved. By the aid of the method, the frequency is controlled to be reduced stably through the PID algorithm, the temperature is kept at a 0.5-degree static difference and is kept at the set temperature finally, the problems of stopping caused by temperature over-regulation can be solved, the air conditioning runs stably, and the user experience is good; when the set temperature and the air speed are changed, the compressor running frequency can respond to changes of the temperature timely, and the frequency is improved and reduced effectively; moreover, the frequency can be adjusted according to the environment temperature, so that the air conditioning stable running can be guaranteed, and the temperature can be adjusted rapidly.

Owner:HAIER GRP CORP +1

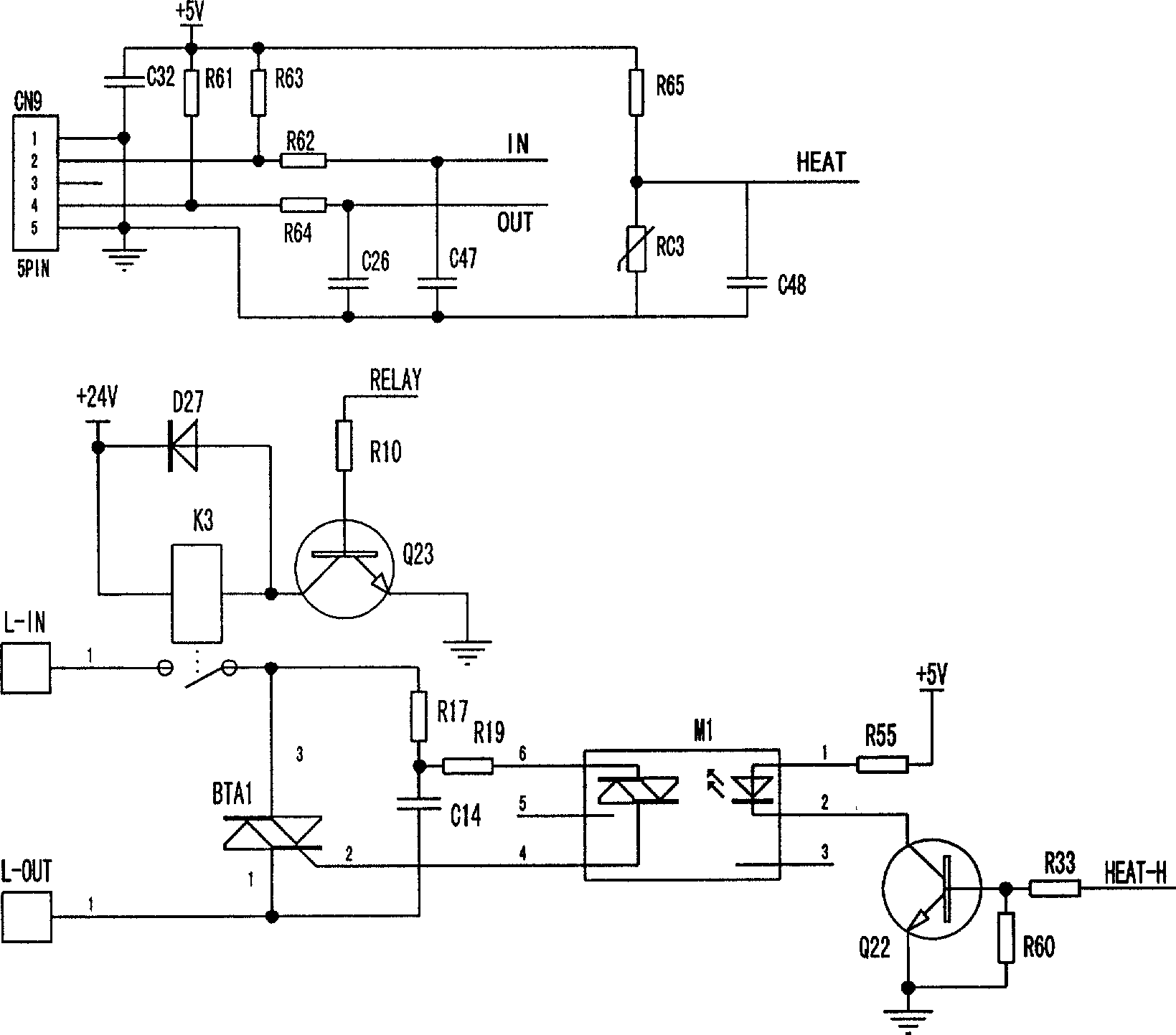

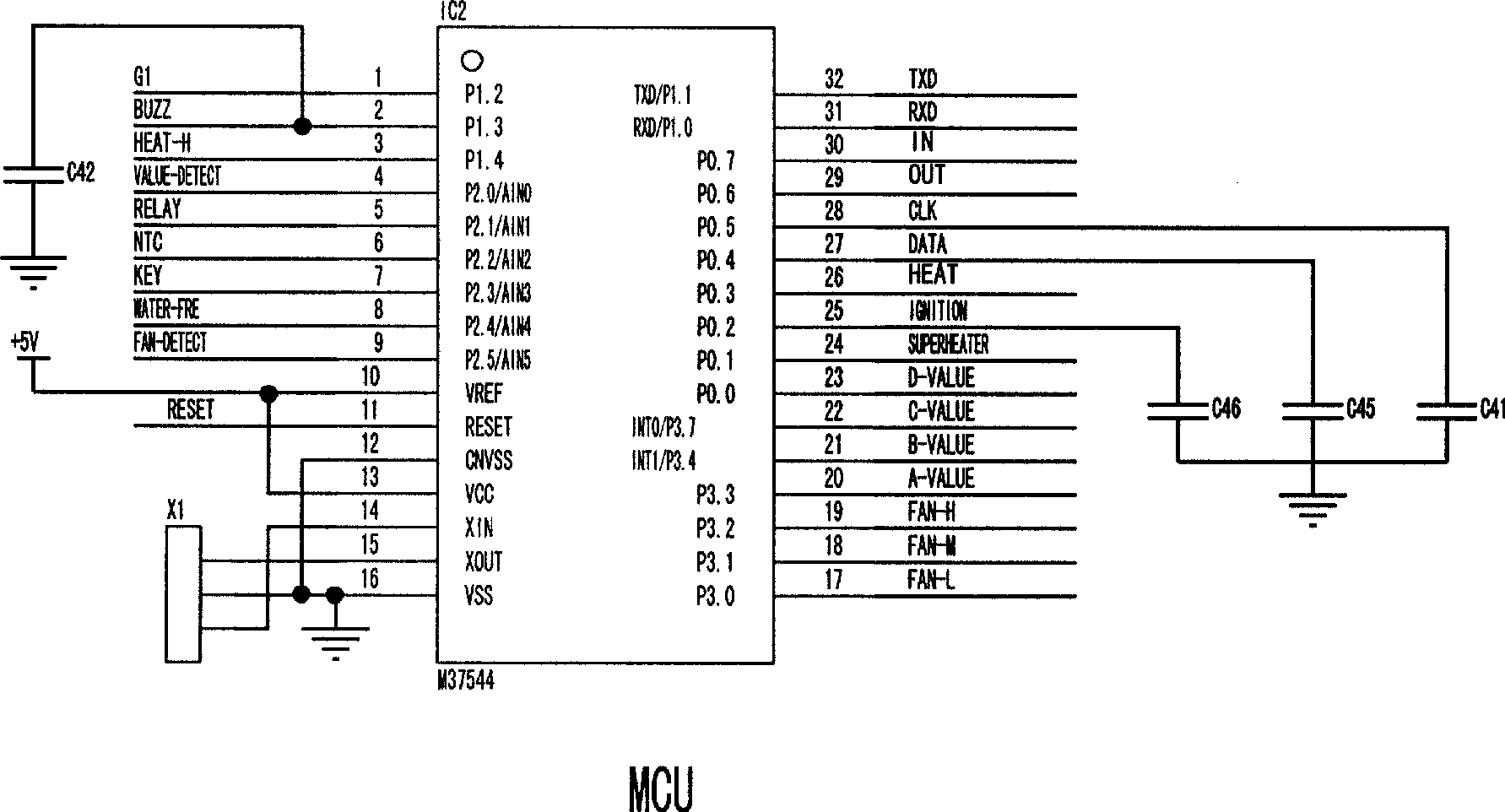

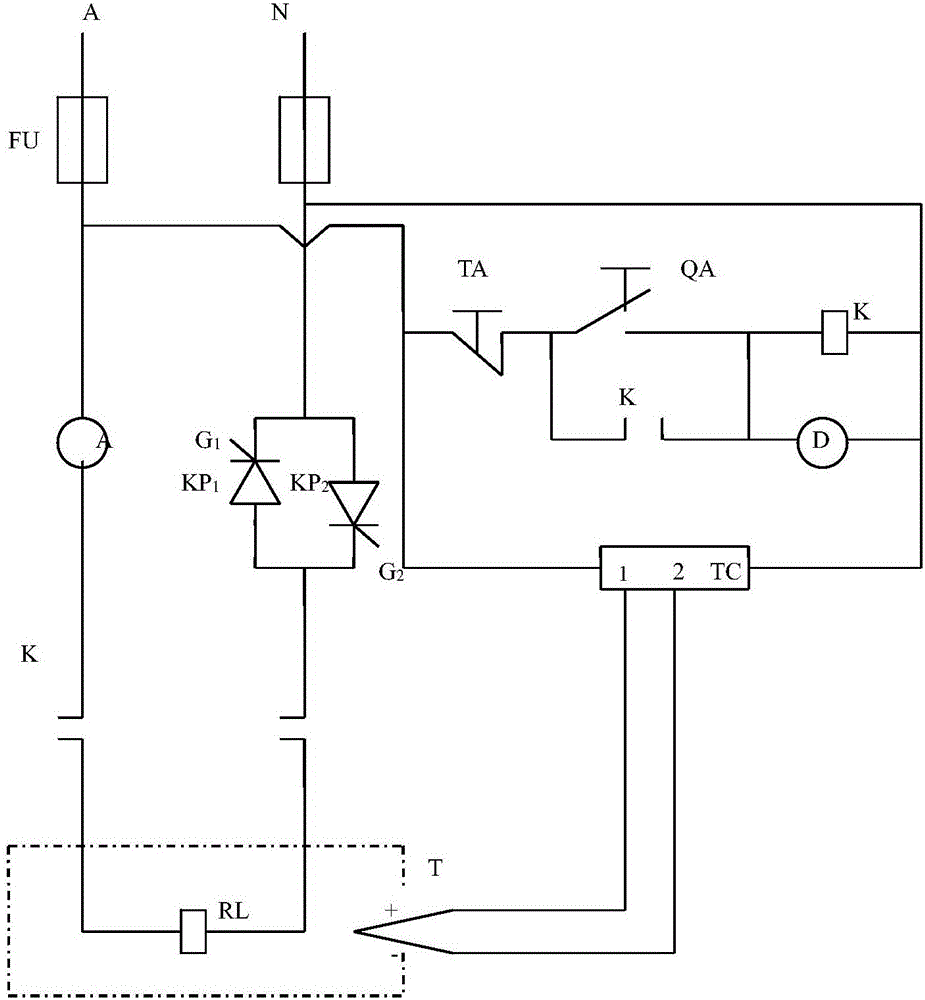

Mixed energy thermostatic control water heater

InactiveCN101424447ASimple structureReduce startup timeSpace heating and ventilation detailsWater heatersElectricityWater flow

The invention relates to a hybrid-energy thermostatic control water heater, which belongs to the technical field of water heaters. The water heater comprises a gas heating part, an electric heating part and a control circuit, wherein the control circuit comprises an electric energy output control device; the electric heating part consists of a water flow channel and an electric heating device arranged in the water flow channel; the gas heating part and the water flow channel of the electric heating part form a series or parallel flow passage; an ultimate water outlet of the flow passage is provided with a temperature sensor; the output end of the temperature sensor is connected with the signal input end of the control circuit; the signal input end is connected with the controlled end of the electric energy output control device through the control circuit; and the output end of the electric energy output control device is connected with the electric heating device. The water heater has the advantages that the water heater is very sensitive and accurate in temperature regulation, and can effectively guarantee the temperature constancy of effluent water.

Owner:A O SMITH CHINA WATER HEATER CO LTD

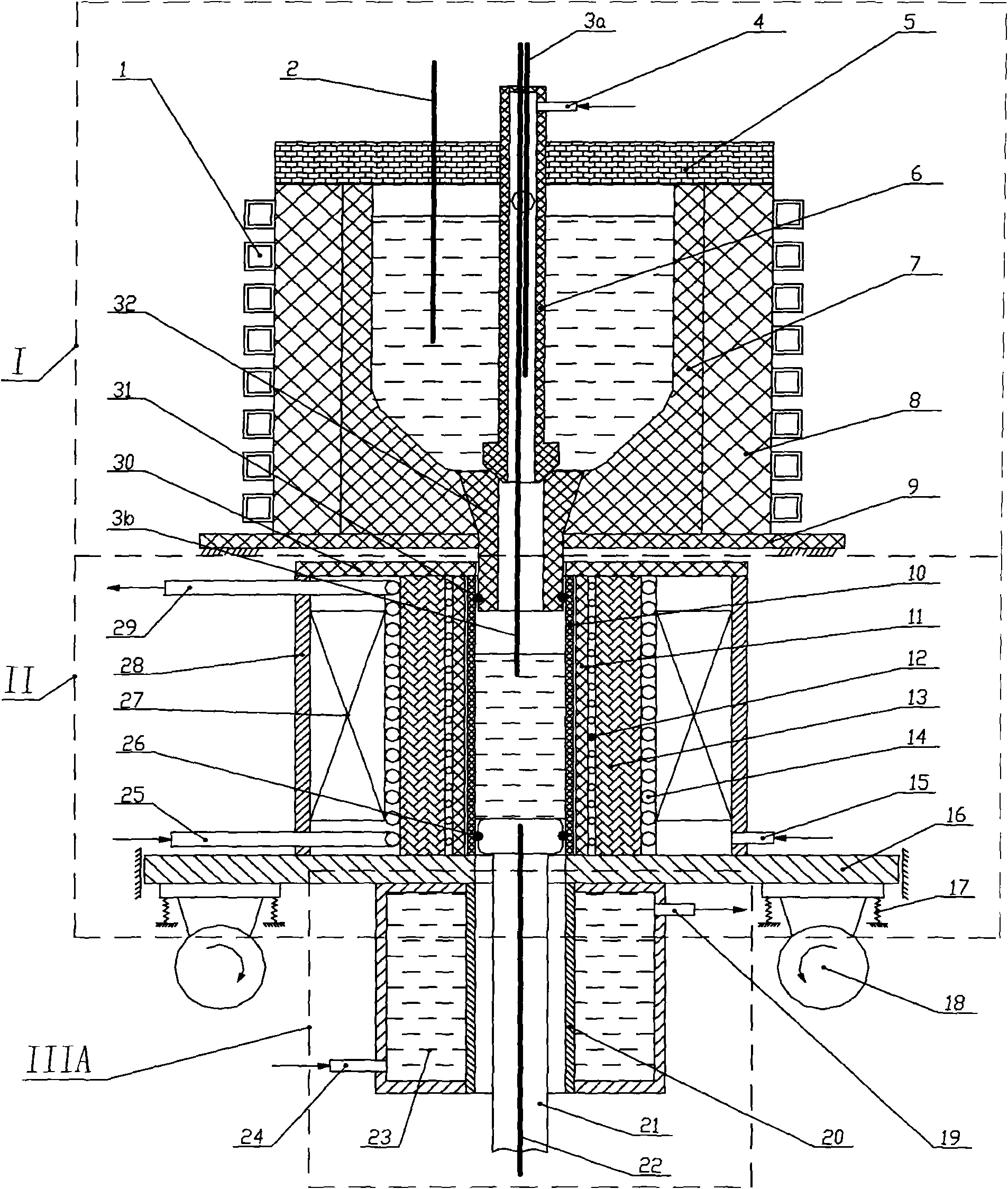

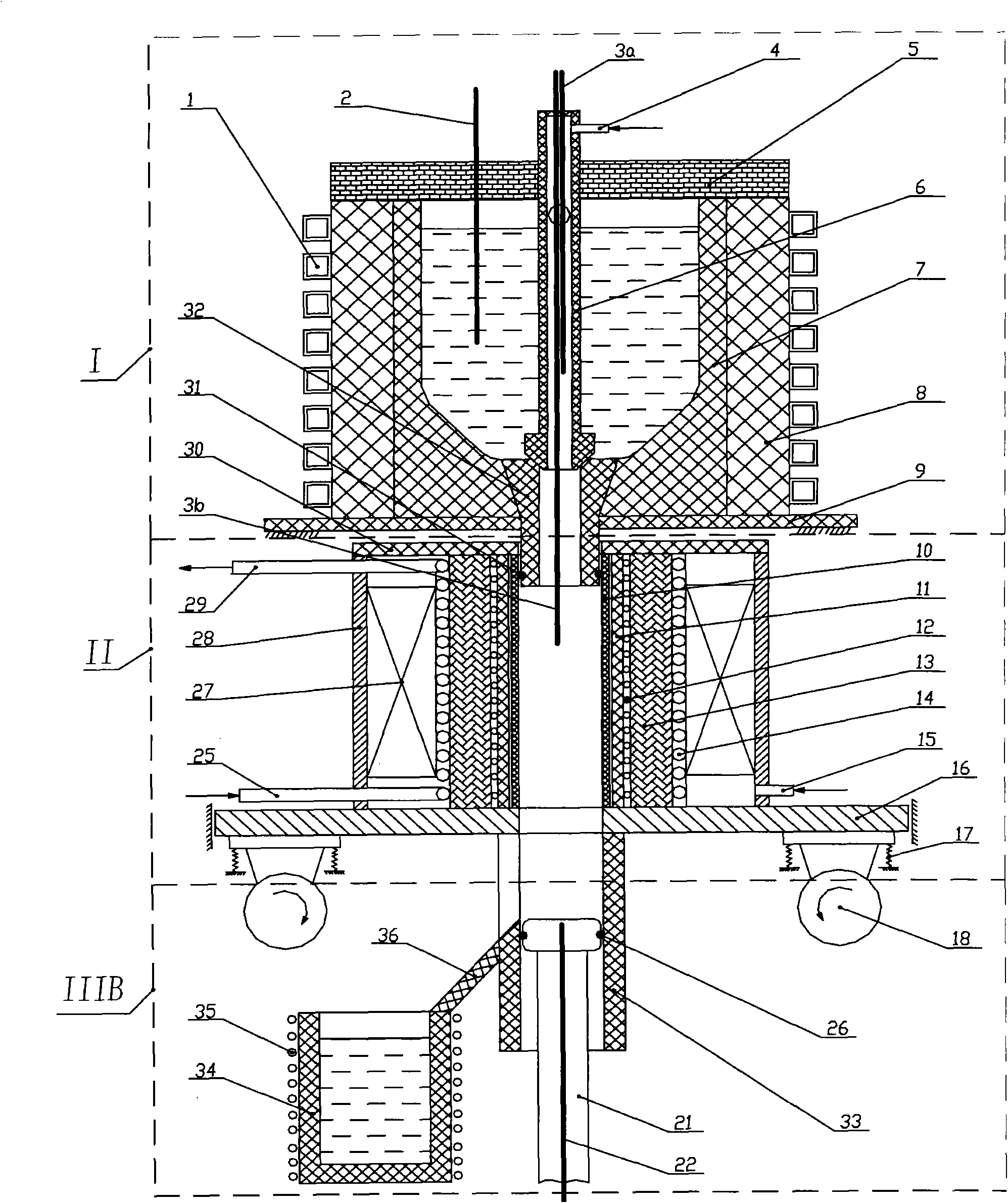

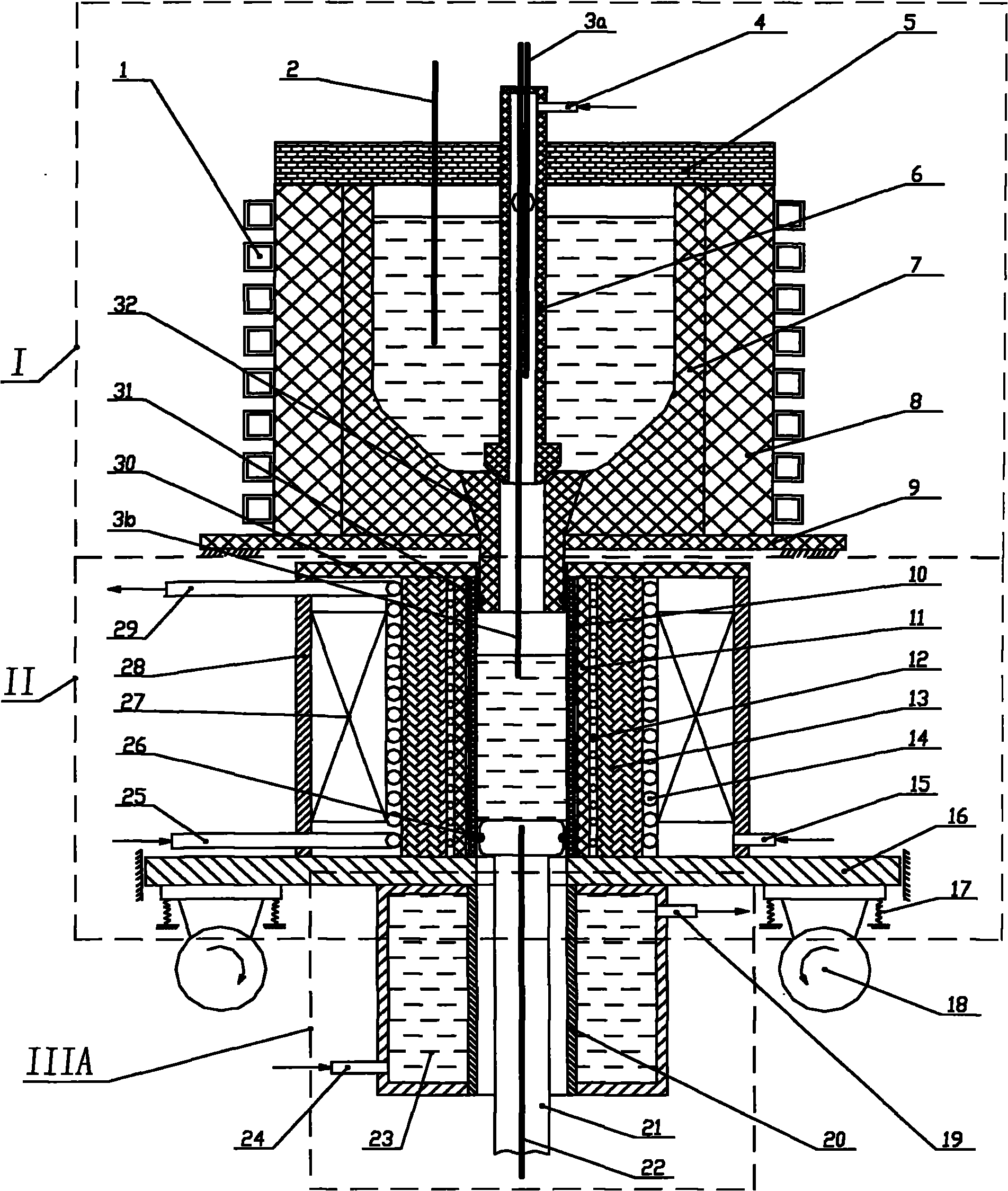

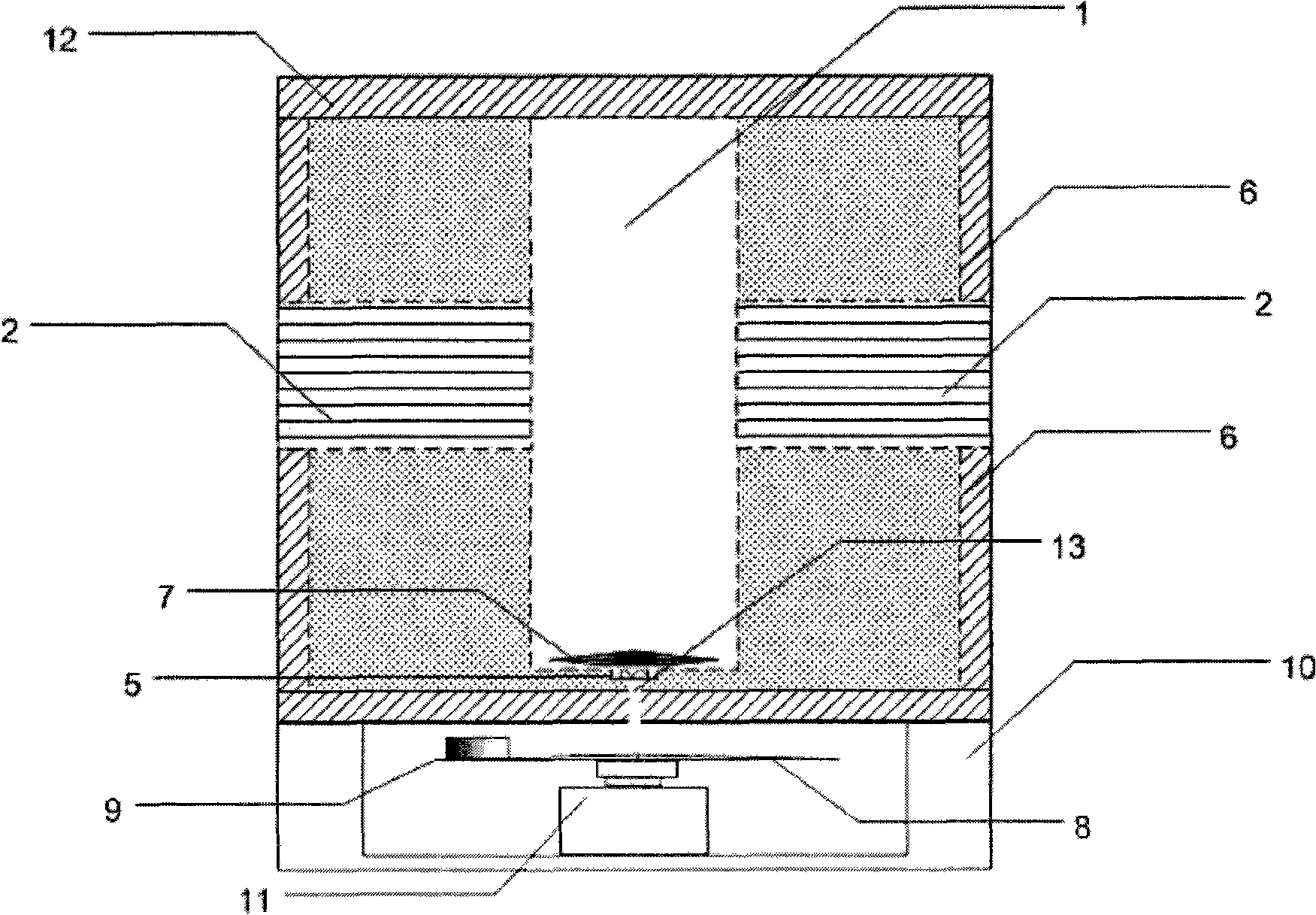

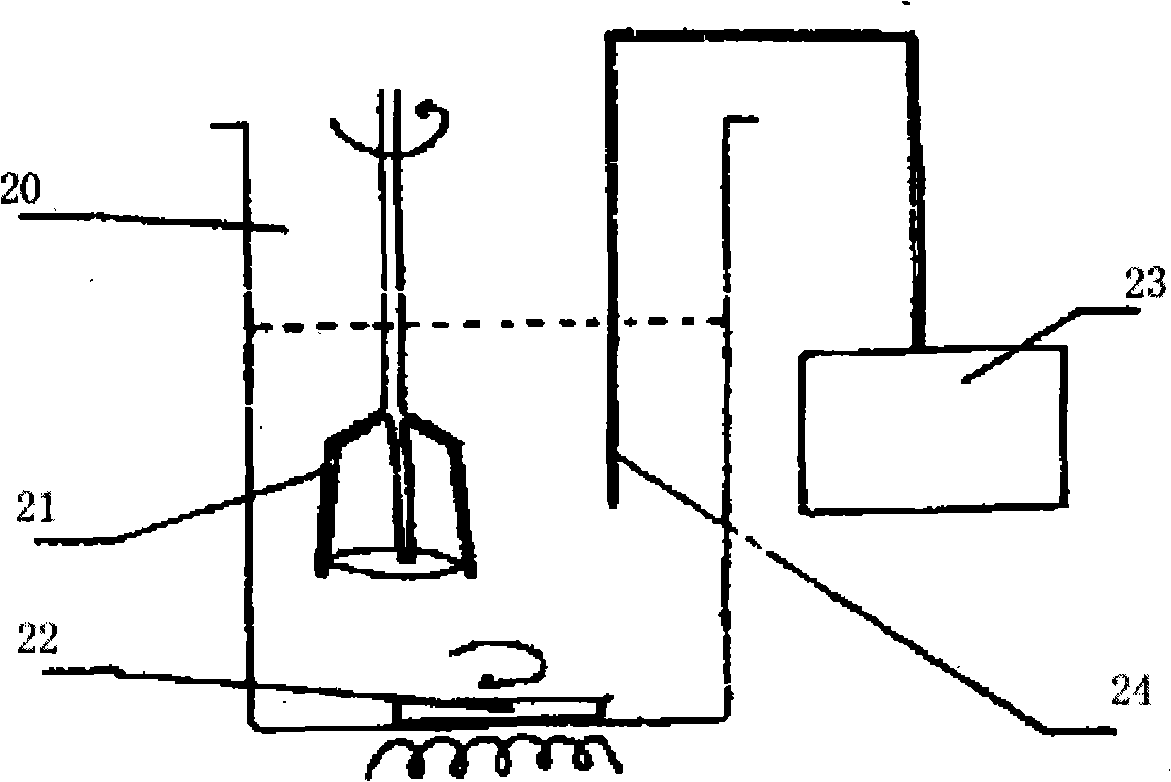

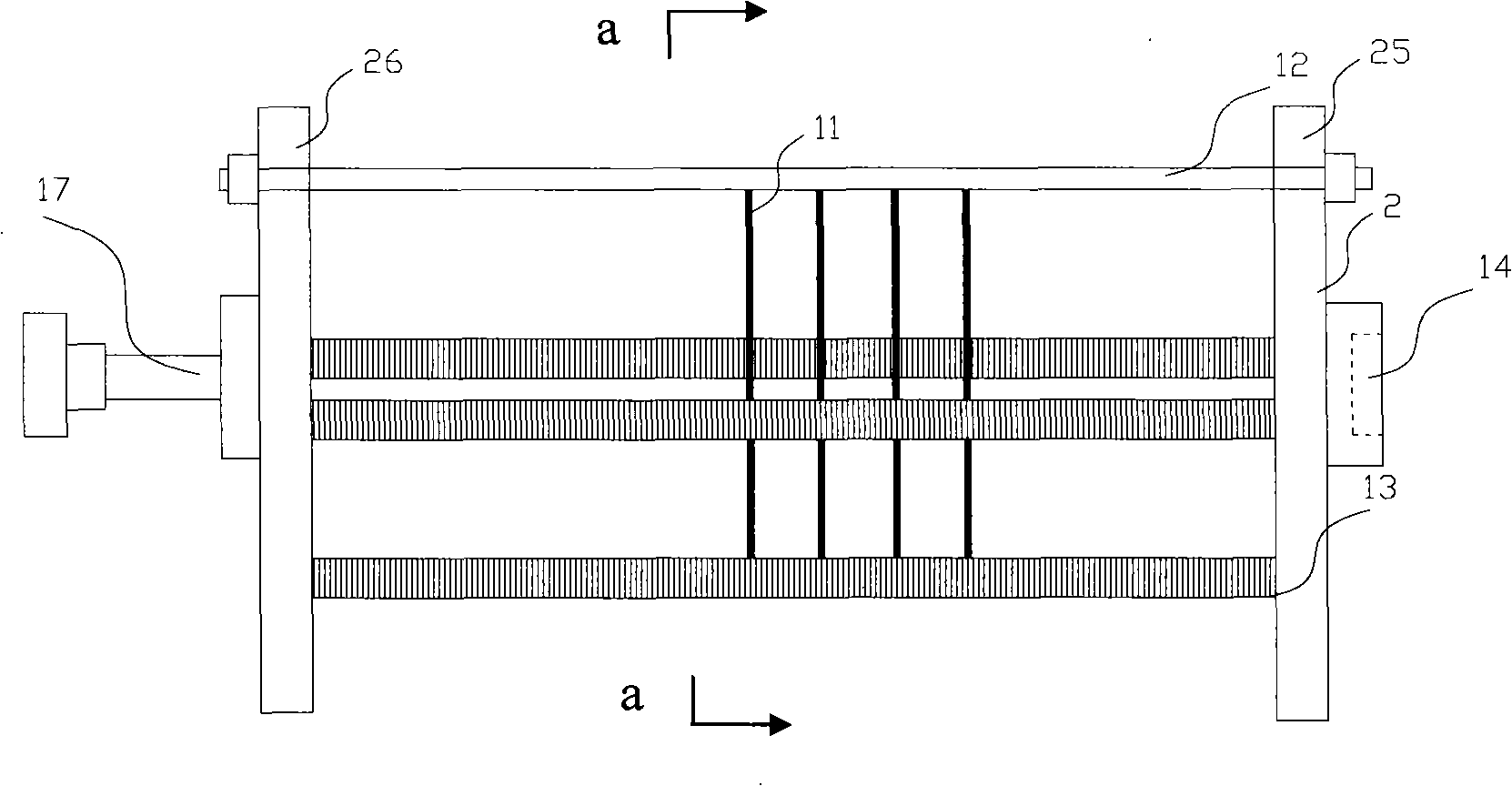

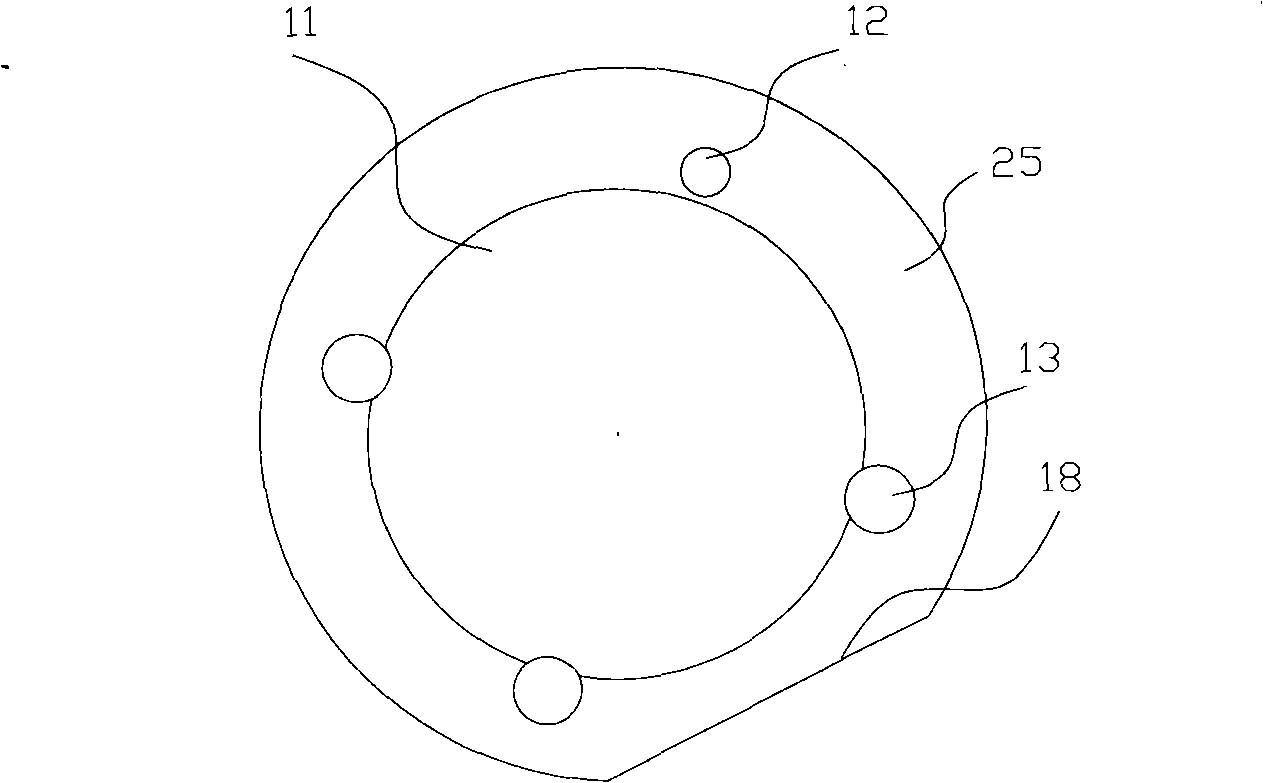

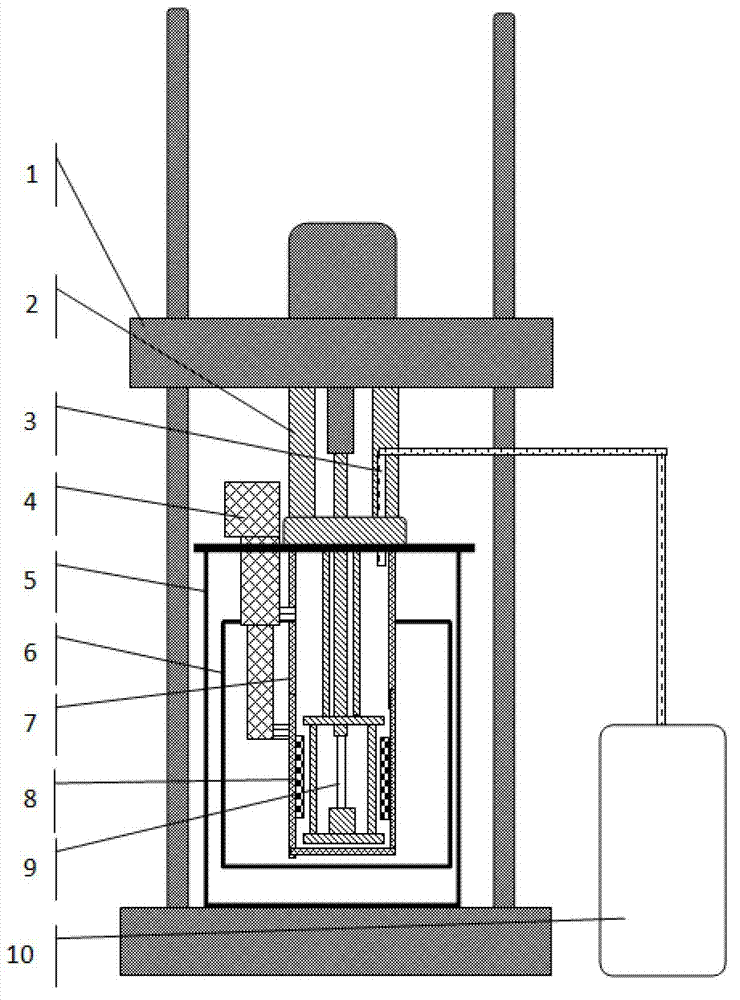

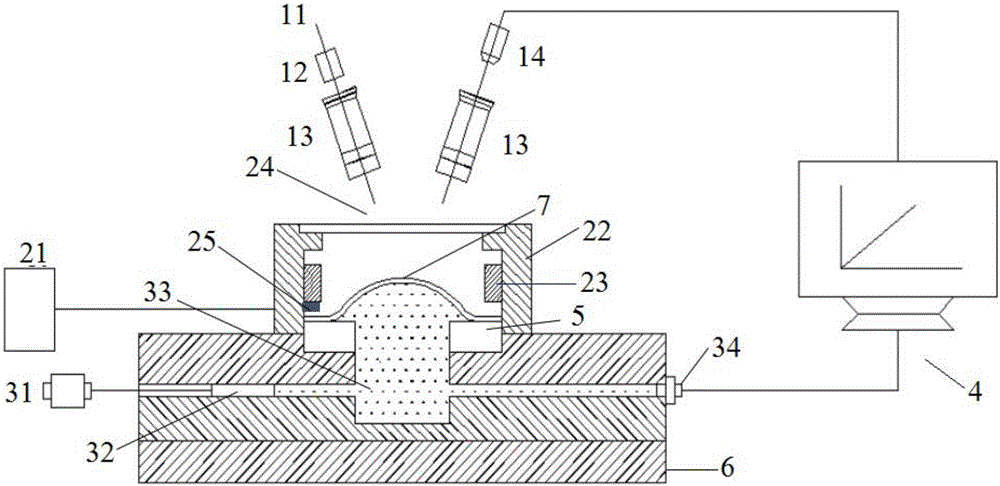

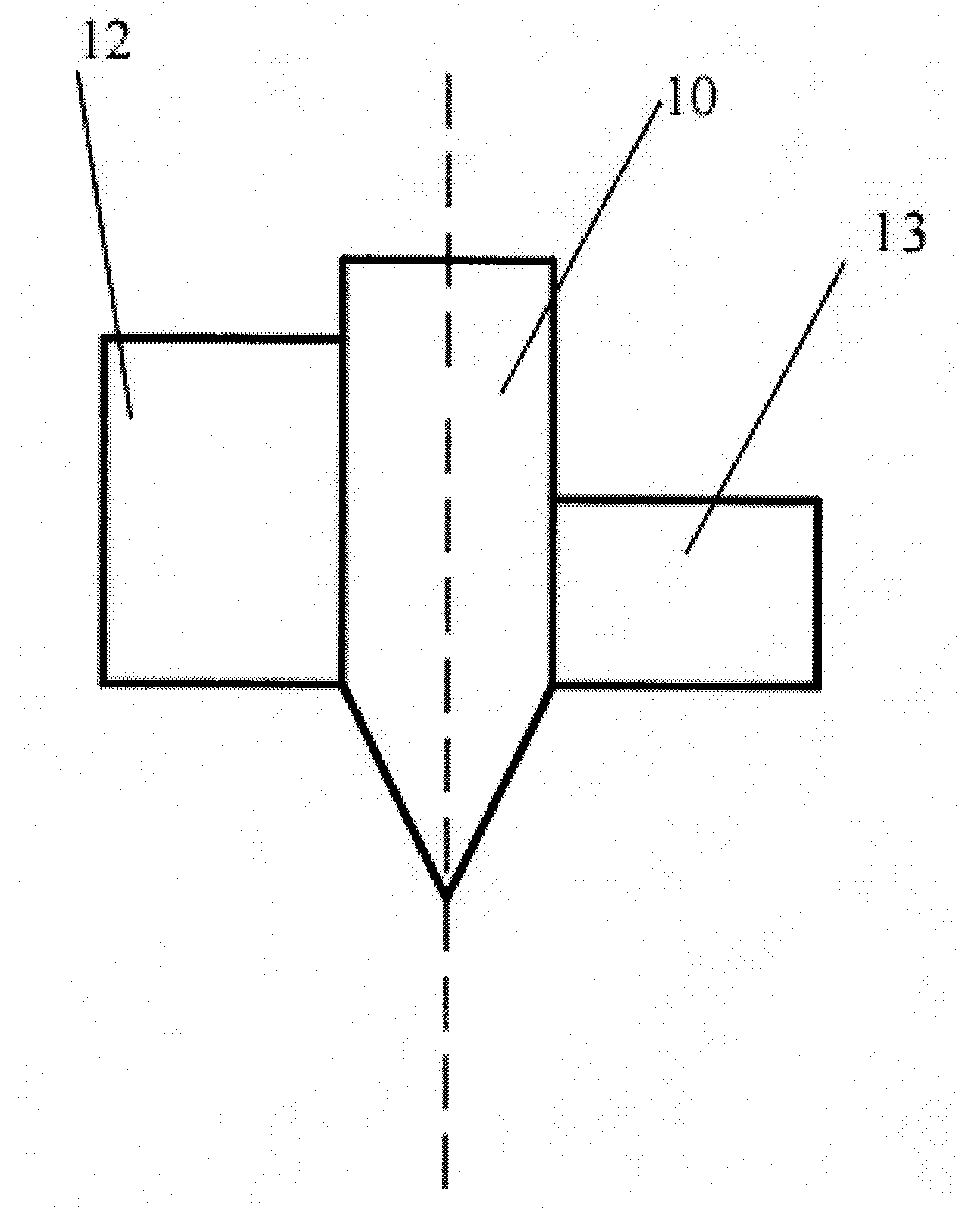

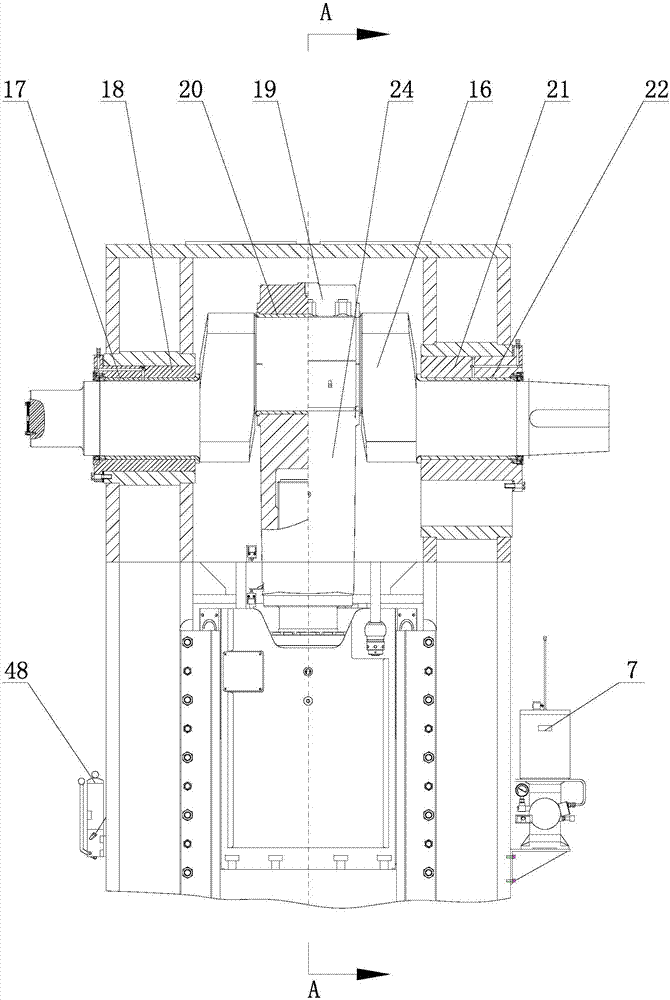

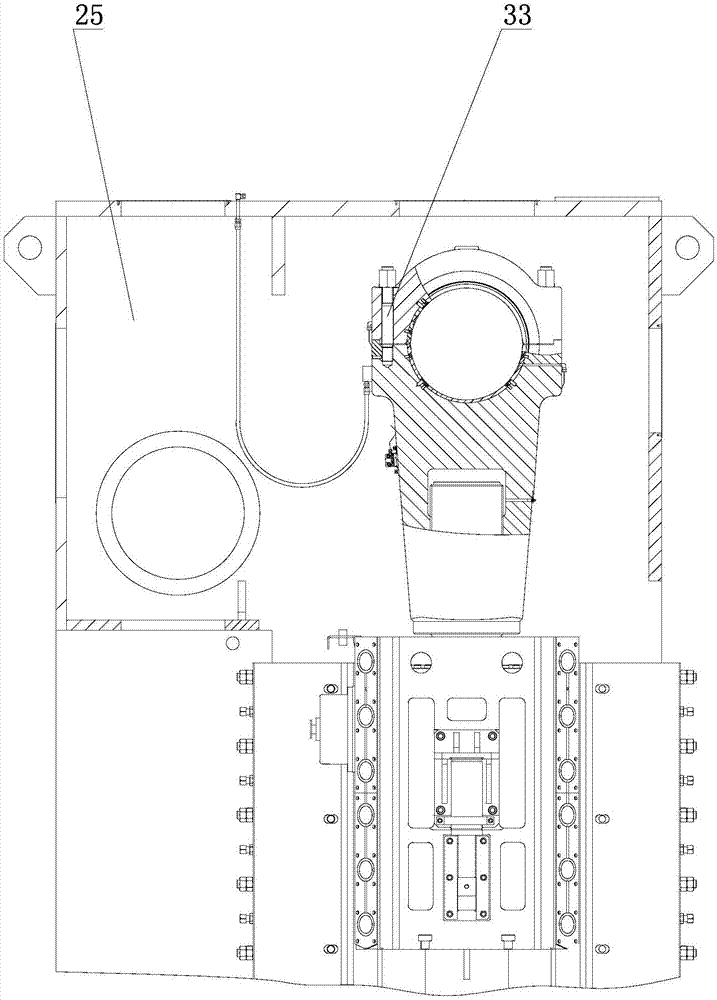

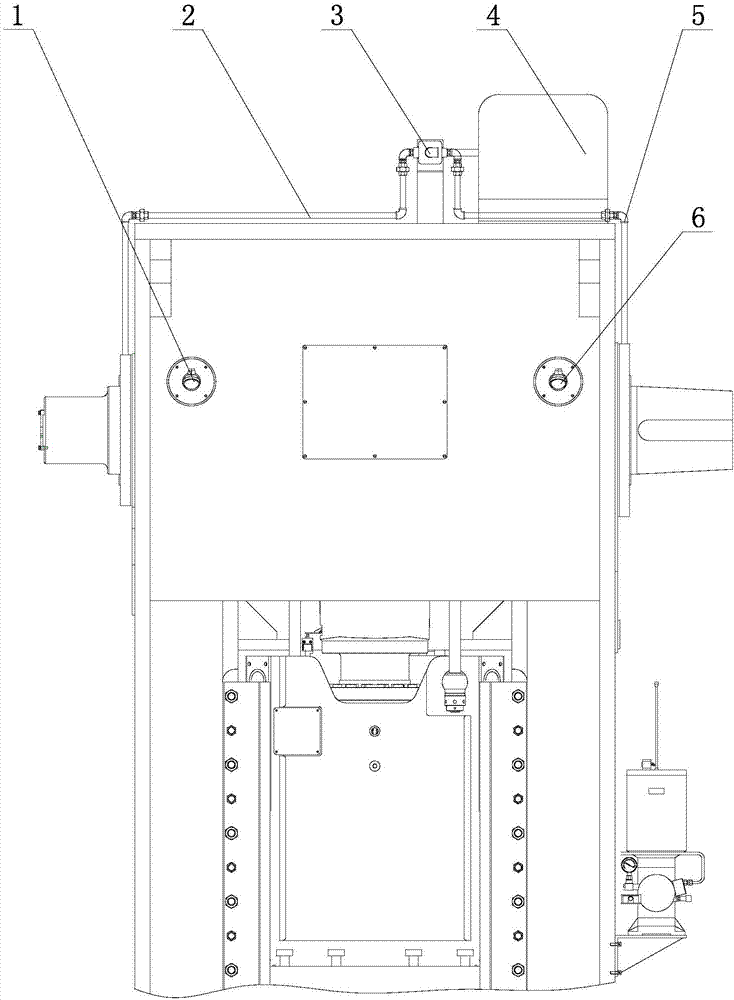

Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

The invention relates to an electromagnetic stirring and vibration combined device for preparing semi-solid slurry of a black metal. The device comprises three main sections: a melting furnace, a stirring chamber, and a crystallizer or a rheologic conveyor, wherein the melting furnace is arranged at the upper part of the stirring chamber, and the crystallizer or the rheologic conveyor is arranged at the lower part of the stirring chamber. When molten metal is poured into the melting furnace, a medium-frequency induction heater is used for maintaining temperature and uniformly heating; when the temperature of the molten metal is within the liquidus temperature range, the molten metal is poured into a stirring crucible in a quantitative amount, and a non-dendritic fine equiaxial spherical or nearly spherical microstructure is obtained by electromagnetically stirring and mechanically vibrating the molten metal; and the prepared fine nearly spherical semi-solid slurry is poured into the crystallizer, then cooled and solidified into a blank, or the slurry is poured into the rheologic conveyor and then is rapidly conveyed to a forming mold for rheoforming. The device can be used for preparing semi-solid slurry of a black metal and nonferrous metal, which improves the efficiency and the quality for preparing metal semi-solid slurry and shortens the preparation time. The device is especially suitable for rheoforming.

Owner:XI AN JIAOTONG UNIV

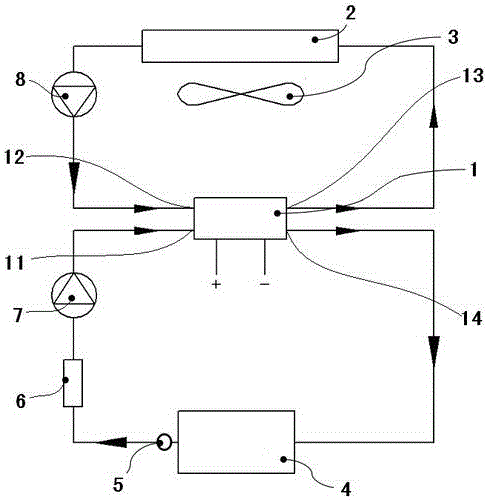

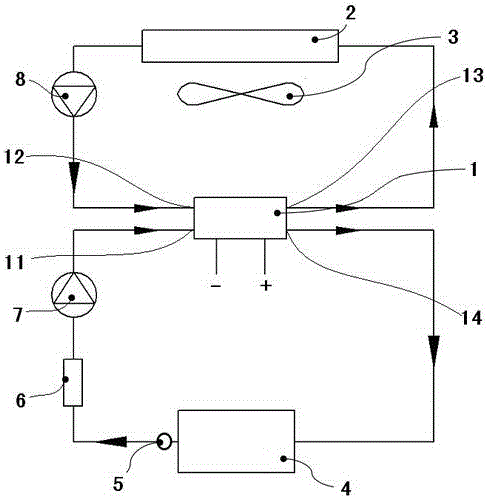

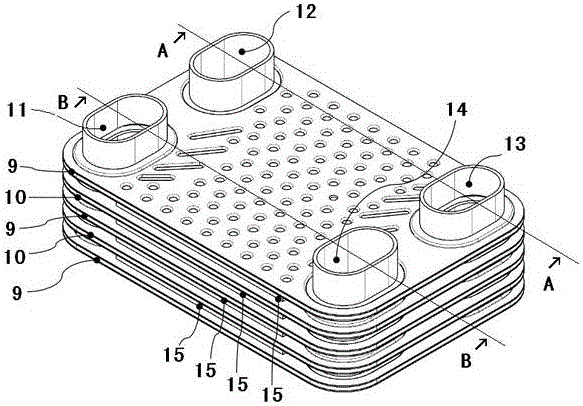

Electric car power battery thermal management system

InactiveCN105870544AEffective and reliable thermal management structureReduce in quantitySecondary cellsPower batteryPlate heat exchanger

The invention provides an electric car power battery thermal management system. The electric car power battery thermal management system comprises a thermoelectric plate heat exchanger, a radiator, a fan, a battery pack, a kettle, a first circulating water pump, a second circulating water pump and connecting pipelines. The thermoelectric plate heat exchanger comprises a first fluid channel, a second fluid channel, a first fluid inlet, a second fluid inlet, a first fluid outlet, a second fluid outlet, a thermoelectric module, a positive electrode and a negative electrode. One closed and independent fluid circulating system is formed by the thermoelectric plate heat exchanger, the battery pack, the kettle, the first circulating water pump and one connecting pipeline. The other closed and independent fluid circulating system is formed by the thermoelectric plate heat exchanger, the radiator, the fan, the second circulating water pump and the other connecting pipeline. The two closed and independent fluid circulating systems can circulate two kinds of fluid at different temperatures to cool or heat a power battery. The thermoelectric plate heat exchanger is adopted for heating and refrigerating the battery pack, a heating mode or a refrigeration mode can be switched only by switching the positive electrode and the negative electrode of a power source of the thermoelectric plate heat exchanger, and the electric car power battery thermal management system is of a practical and reliable heat management structure.

Owner:上海松芝酷能汽车技术有限公司

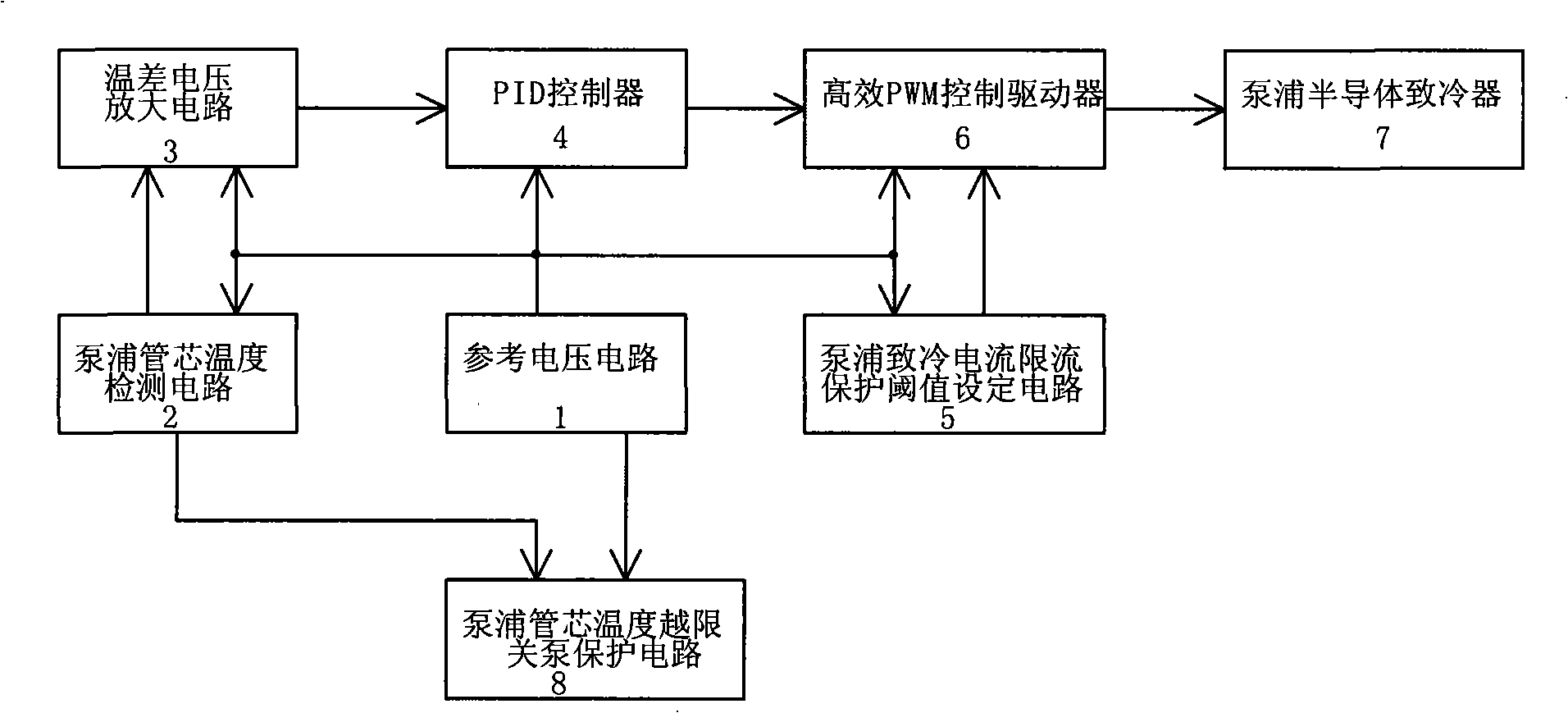

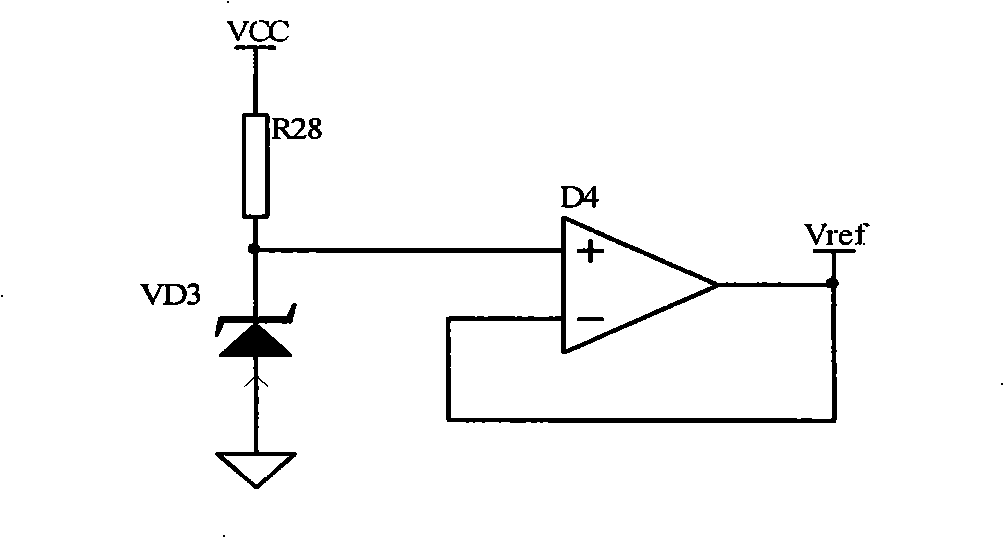

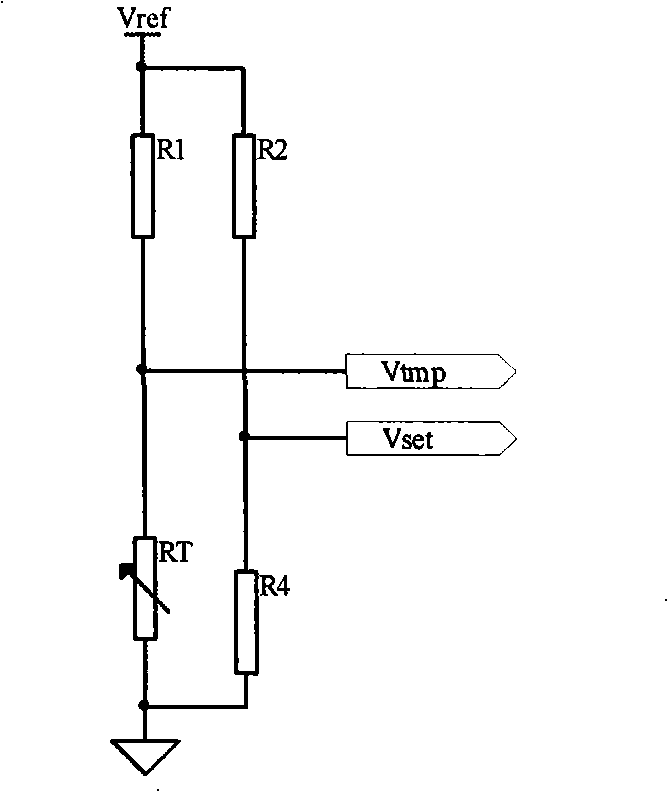

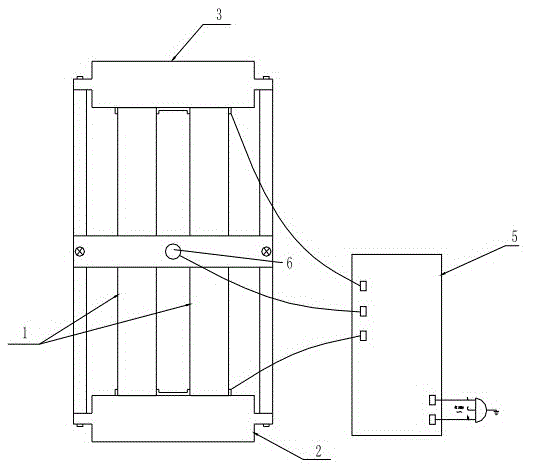

Automatic temperature control apparatus of pump laser for ASE broadband light source

ActiveCN101404376ACompact designImprove reliabilityTemperatue controlLaser cooling arrangementsAutomatic controlControl signal

The invention designs an automatic temperature control circuit which has exact control, reliable and stable performance and complete protective measures, and is used for executing effective real time control on the temperature of a tube core of a pump laser in ASE broadband light source. The control device adopts the design proposal of a temperature control system based on Proportion Integration Differentiation (PID) control and pulse-width modulation (PWM) braking mechanism and realizes the designs by adopting a pure hardware circuit; the control device comprises a reference voltage circuit, a pumping tube core temperature testing circuit, a thermoelectric voltage amplifier circuit, a PID controller, a pumping refrigeration current limiting protective threshold set circuit, an efficient PWM control driver, a pumping semiconductor refrigerator and a pumping tube core temperature out-of-limit close protective circuit. The whole circuit has simple and compact design, high reliability as well as heating and refrigerating efficiency, and little self heating, thereby greatly reducing the power consumption and volume of a pumping temperature controller; as the control device has the complete protective function, when the temperature of the pumping tube core exceeds the set range of operating temperature, the circuit sends out the gang control signal to automatically close a drive circuit of the pumping. The pumping refrigeration current limiting protective circuit limits the refrigeration current within the range of the preset maximum refrigeration current range to prevent the pumping from being damaged.

Owner:WUXI TACLINK OPTOELECTRONICS TECH CO LTD

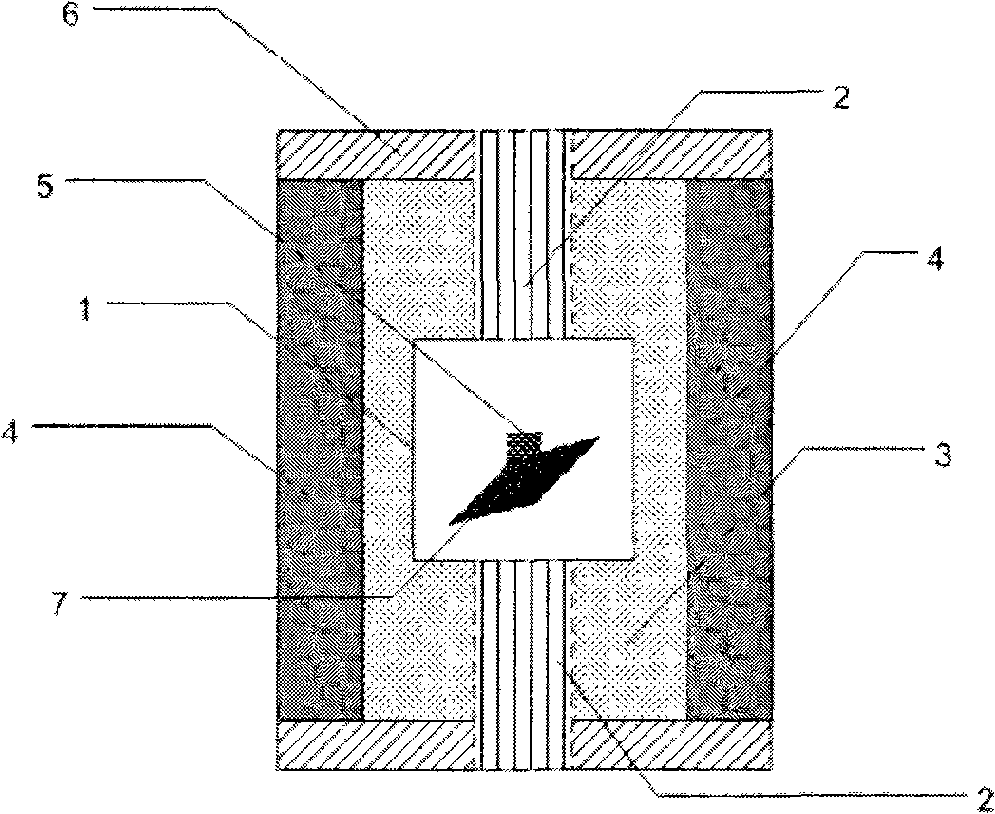

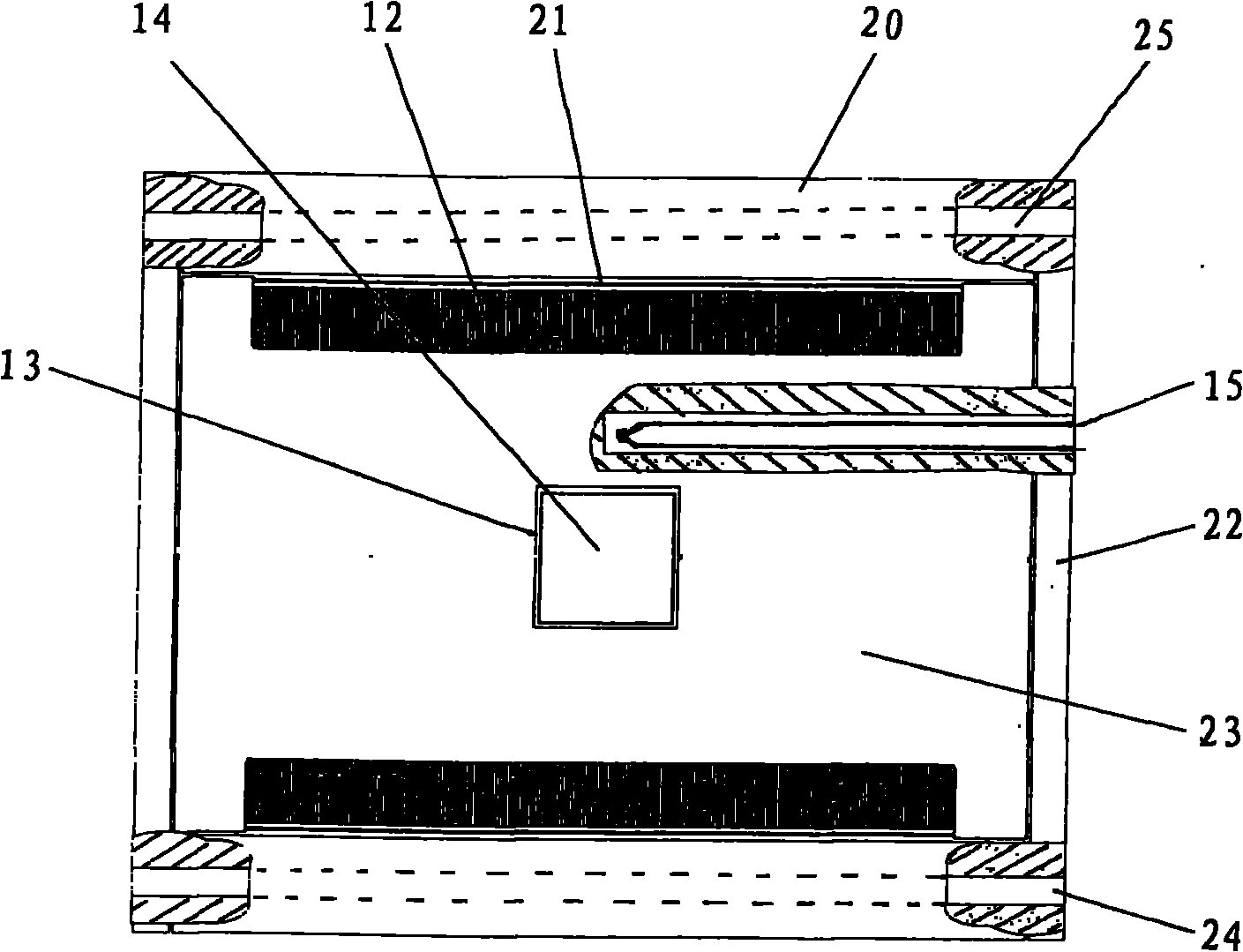

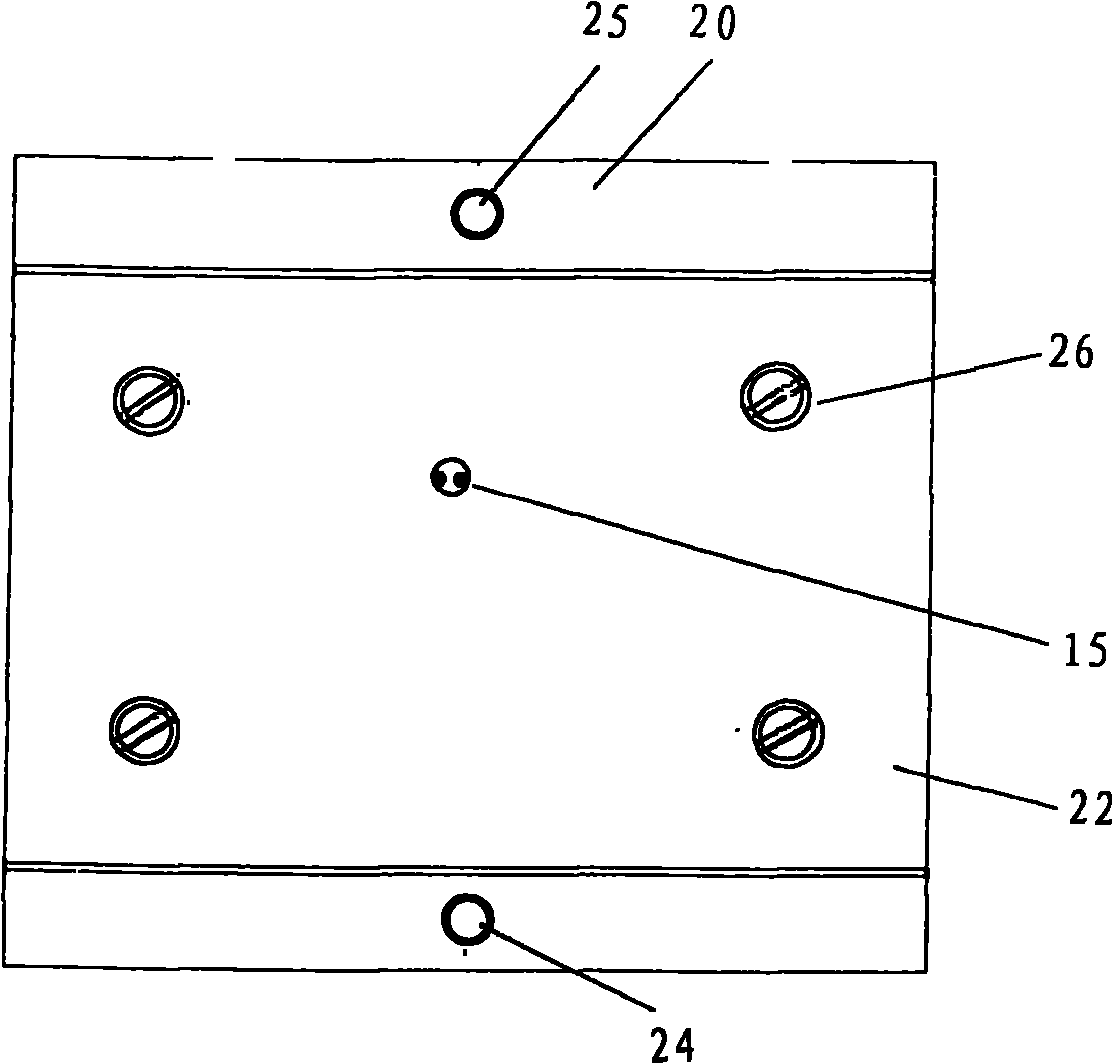

Quick changeable temperature small-sized constant temperature sample pool

InactiveCN101281121APrecise and fast temperature controlMeet the requirements of constant temperatureMaterial analysis by optical meansWater/sand/air bathsTemperature controlMetallic materials

The invention relates to a quick variable temperature miniature thermostatic sample cell, which is made of metallic material, an opening is formed in the center of the metallic material and is used as a sample cavity, a light through hole is formed on a metallic shell along the center of the sample cavity, a transparent material is embedded in the light through hole, a Peltier temperature control element is glued on the non-light surface of the metallic material, a groove is arranged on the bottom of the metallic shell for laying aside a temperature sensor, the coat of the metal shell has a heat insulation outer frame, the center of a base connected with the bottom of the heat insulation outer frame is provided with a miniature motor, a small magnet is arranged at the edge of the leaf of a spiral leaf on the shaft of the motor, a stirring magneton is laid aside at the bottom in the sample cavity, the inner wall of the sample cavity and the outer faces of the sensor and the stirring magneton is carried on chemical inertia processing. The invention replaces the water heat conduction with the metal, and changes the system temperature with a thermo-element; the sensor directly observes the temperature of the sample, the heat conduction is speeded up by a miniature electromagnetic stirring system has accelerated; the invention is characterized in having small volume, accurate the temperature measurement, quick variable temperature, and good stability, etc, being able to be placed in analytical instrument such as spectrophotometer, etc., and realizing the quick variable temperature and the accurate thermostatic control of the temperature of the sample.

Owner:SHANGHAI JIAO TONG UNIV

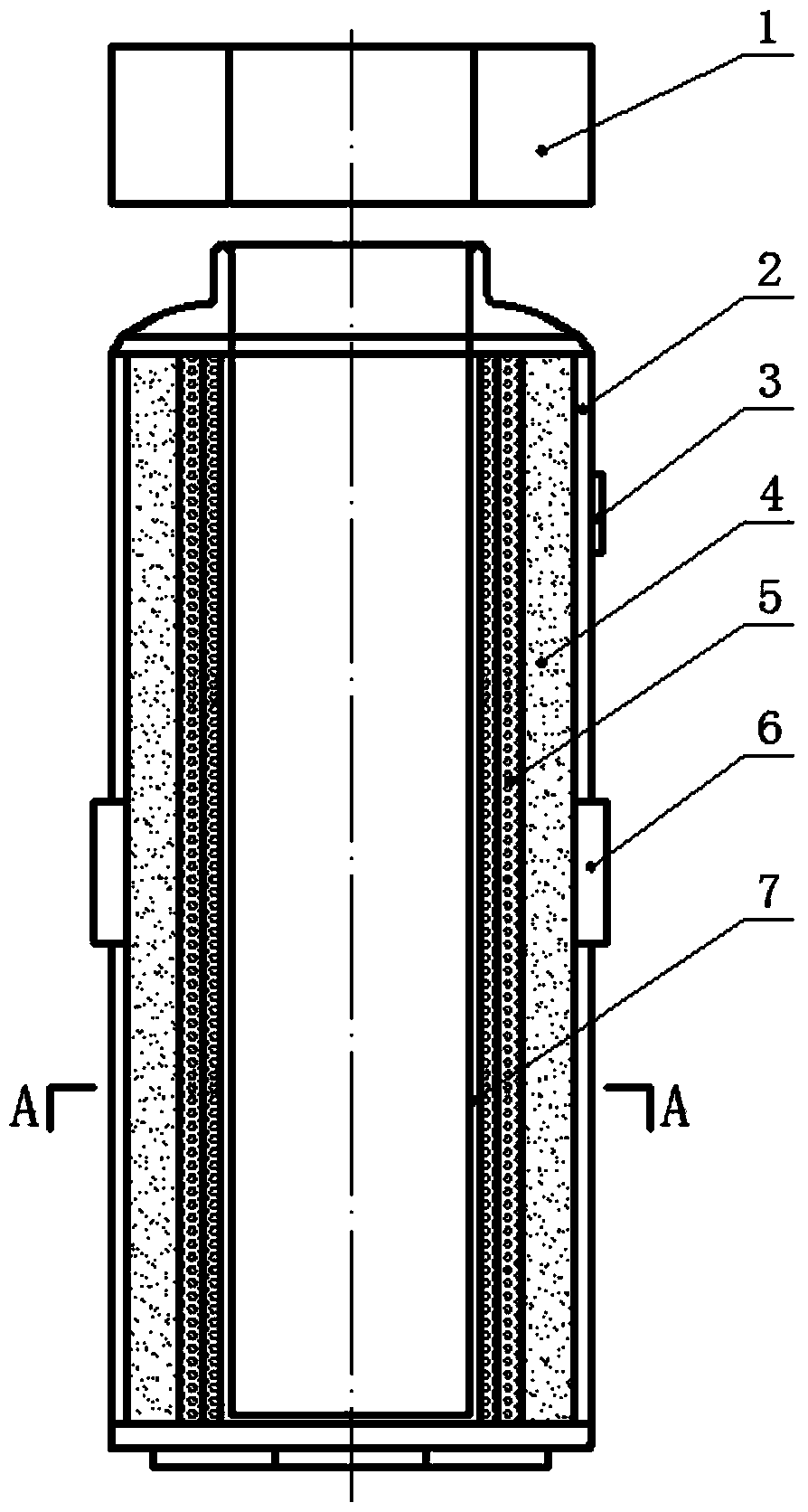

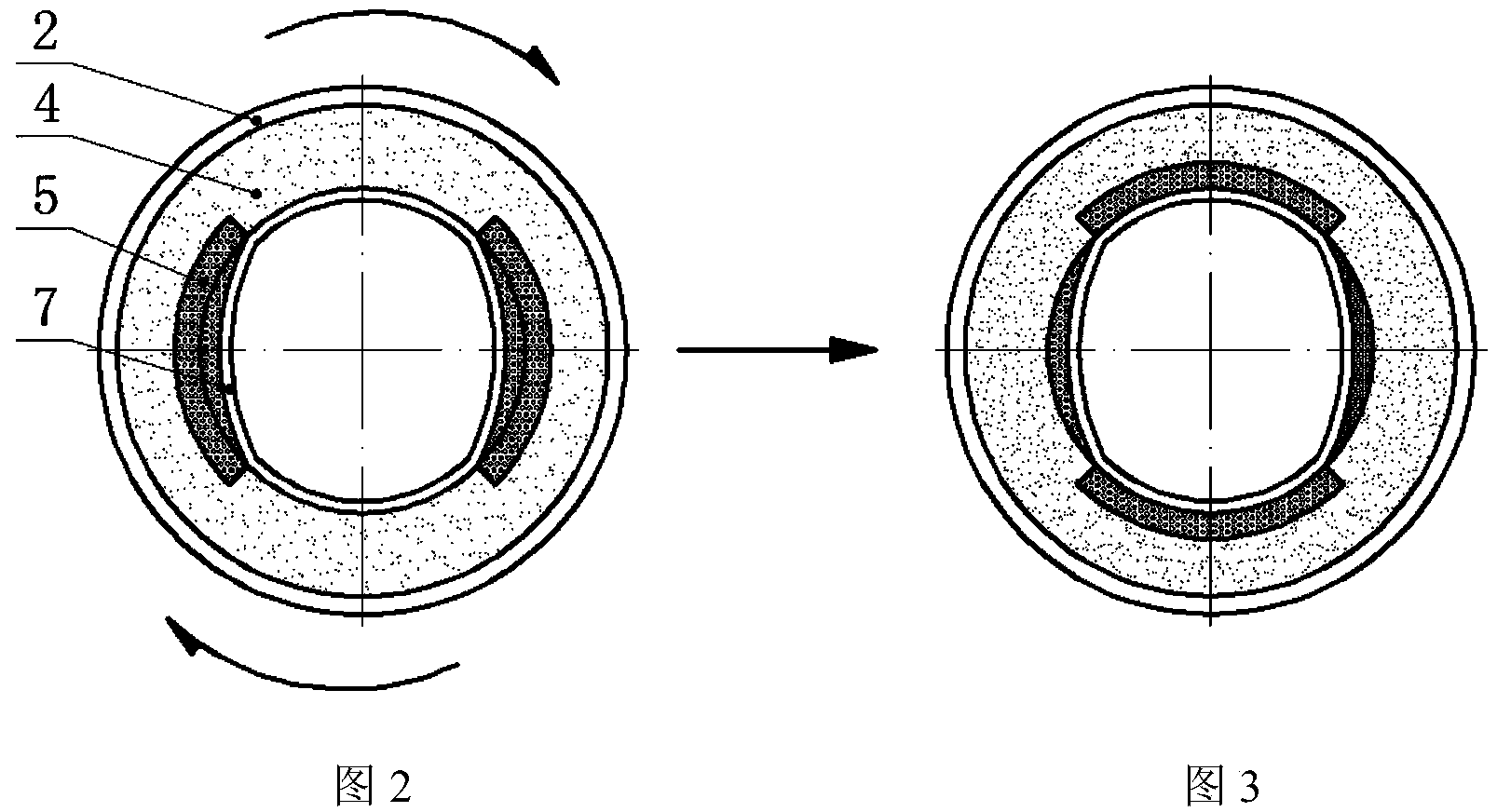

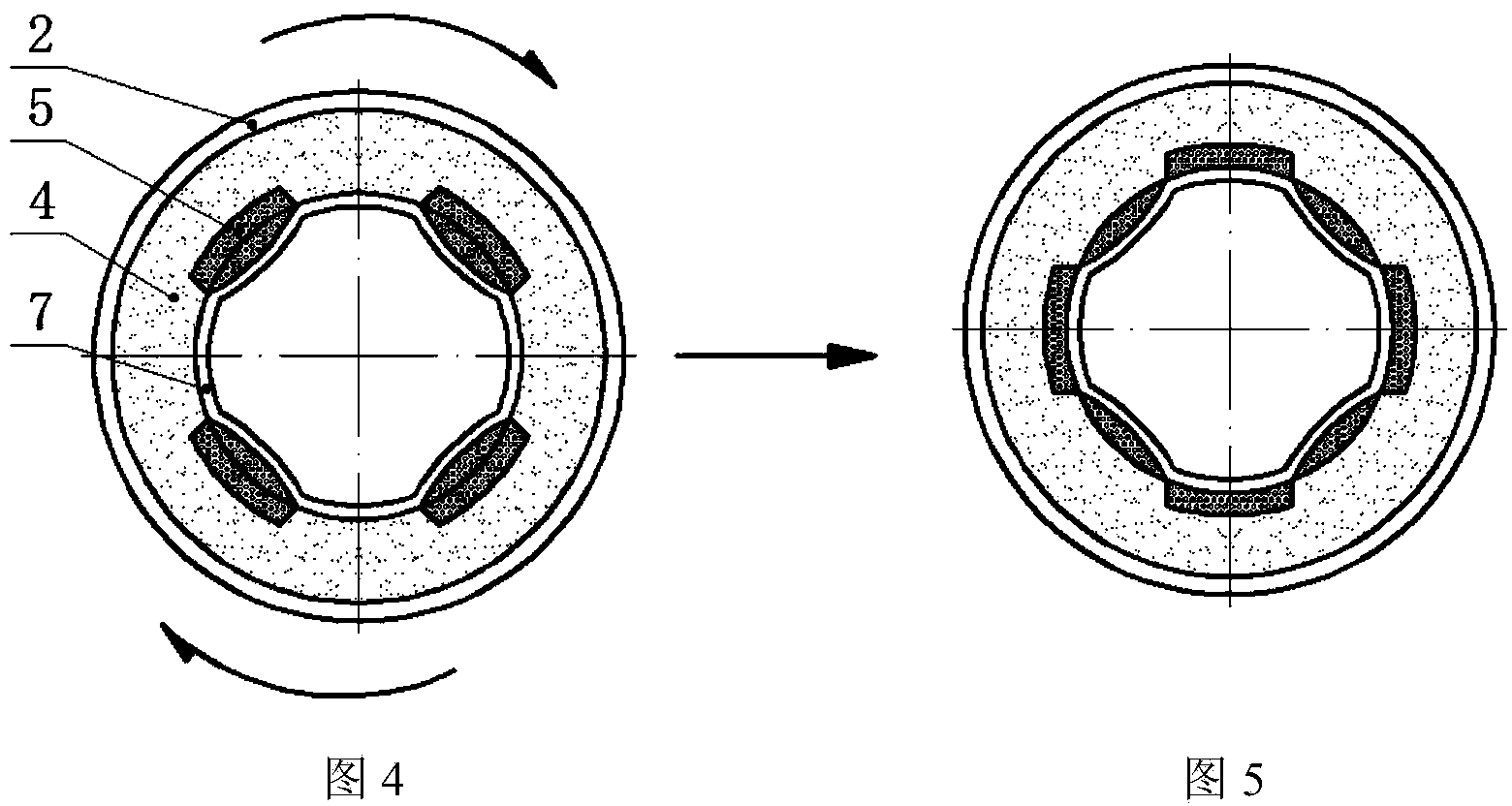

Intelligent temperature control cup

ActiveCN104161430AAccurate temperature controlSmall temperature differenceDrinking vesselsEngineeringPhase-change material

The invention relates to an intelligent temperature control cup which comprises a cup body and a cup cover. The cup body is sealed by the cup cover. The cup body comprises an inner container and an outer shell. Heat insulation materials and phase-changing materials are arranged between the inner container and the outer shell. Grooves are formed in the outer wall of the inner container in the radial direction at intervals. Each groove is filled with heat insulation materials. A phase-changing material layer is arranged between the inner container and the outer shell in a sleeved mode. Grooves are evenly distributed in the radial direction of the inner edge column face of the phase-changing material layer at intervals. Each groove is filled with heat insulation materials. A rotating ring is coaxially and fixedly arranged on the outer edge column face of the phase-changing material layer. According to the rotating ring, the phase-changing material layer rotates in the axial direction, and when the phase-changing material layer rotates to the position where the heat insulation materials arranged in the phase-changing material layer grooves in a filling mode and the heat insulation materials arranged in the inner container grooves in a filling mode are crossed and are not overlapped, the heat insulation materials can right seal and surround the inner container. According to the temperature control cup, temperature controlling and preservation can be carried out at multiple points and multiple time periods, and the intelligent, convenient, quick and human-friendly designing concept is reflected.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Whirl etching system and method for large area silicon chips

InactiveCN101275287AAccurate temperature controlIncrease productivityAfter-treatment detailsSemiconductor/solid-state device manufacturingIonSilicon chip

The invention discloses a whirl etching system for large-area silicon chip and a method thereof, comprising an autorotation etch fixture, a revolution arm, an etch bath, a de-ionized water rinse bath, a bubbling agitating device, a condensing and temperature control device; the etch fixture is installed on the arm for uniform autorotation driven by a rotating motor; the etch bath contains chemical corrosive liquid; the bubbling agitating device is located at bottom of the bath; the condenser pipe and the temperature control thermoelectric couple are installed at side wall of the etch bath; the de-ionized water rinse bath is located adjacent to the etch bath; when etching the silicon chip, the arm drives autorotation fixture into dip into the chemical corrosive liquid in the etch bath, while the arm undergoes uniform revolution; after that, the autorotation fixture driven by the arm is dipped into the de-ionized water rinse bath for cleaning; controlling the temperature of the corrosive liquid, and mixing the corrosive liquid evenly by the agitating device, so as to ensure that the concentration, the temperature of the corrosive liquid is substantially uniform, and that etch speed on the surface of the silicon chip is consistent, so as to enhance uniformity of silicon chip etching.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

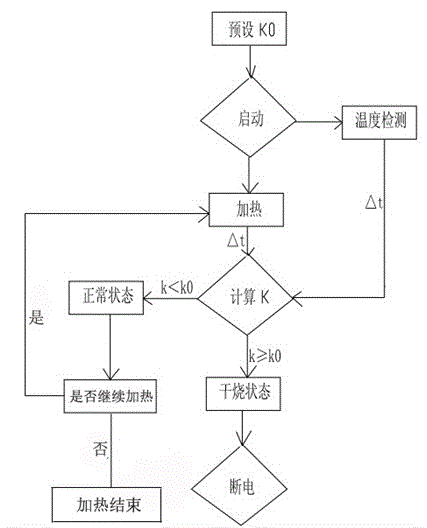

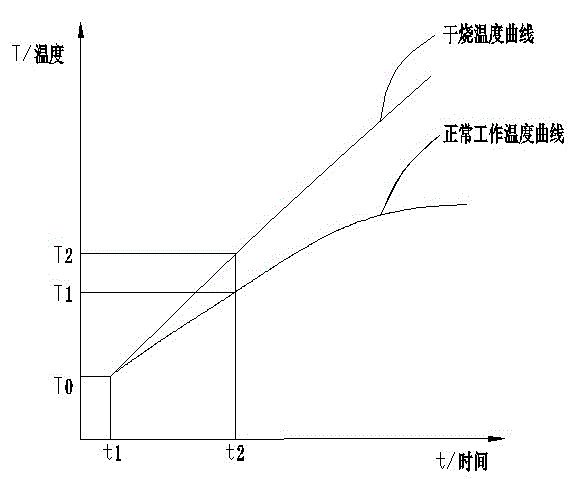

Dry heating prevention method of liquid heating device and heating device using dry heating prevention method

InactiveCN102914053APrevent dry stateAccurate temperature controlFluid heatersTemperature controlElectrical resistance and conductance

The invention relates to the field of liquid heating, in particular to a dry heating prevention method of a liquid heating device and a heating device using the dry heating prevention method. The dry heating prevention method comprises the following steps that a temperature sensing part is used for detecting the temperature of the surface of a heating element and then transfers a temperature signal to a control unit, and the control unit calculates a temperature change rate of the surface of the heating element by two or more temperature spots so as to judge the working state of the heating element. Compared with the traditional method for judging the working state of the heating element by a single-spot temperature, the dry heating power-off time is not affected by the response delay of a temperature controller or a temperature sensor, so that the dry heating prevention method of a liquid heating device is more accurate in temperature control and can effectively prevent the heating element from being in a dry heating state for a long time. In addition, the temperature sensing part such as a thermistor or a thermocouple is used for directly detecting the temperature of the surface of the heating element so that the temperature sensing is fast and sensitive; and compared with the traditional metal temperature-sensing piece, the response delay time is greatly reduced so as to prevent the temperature of the heating element from being over-high and prolong the service life of the heating element.

Owner:MIDEA GRP CO LTD

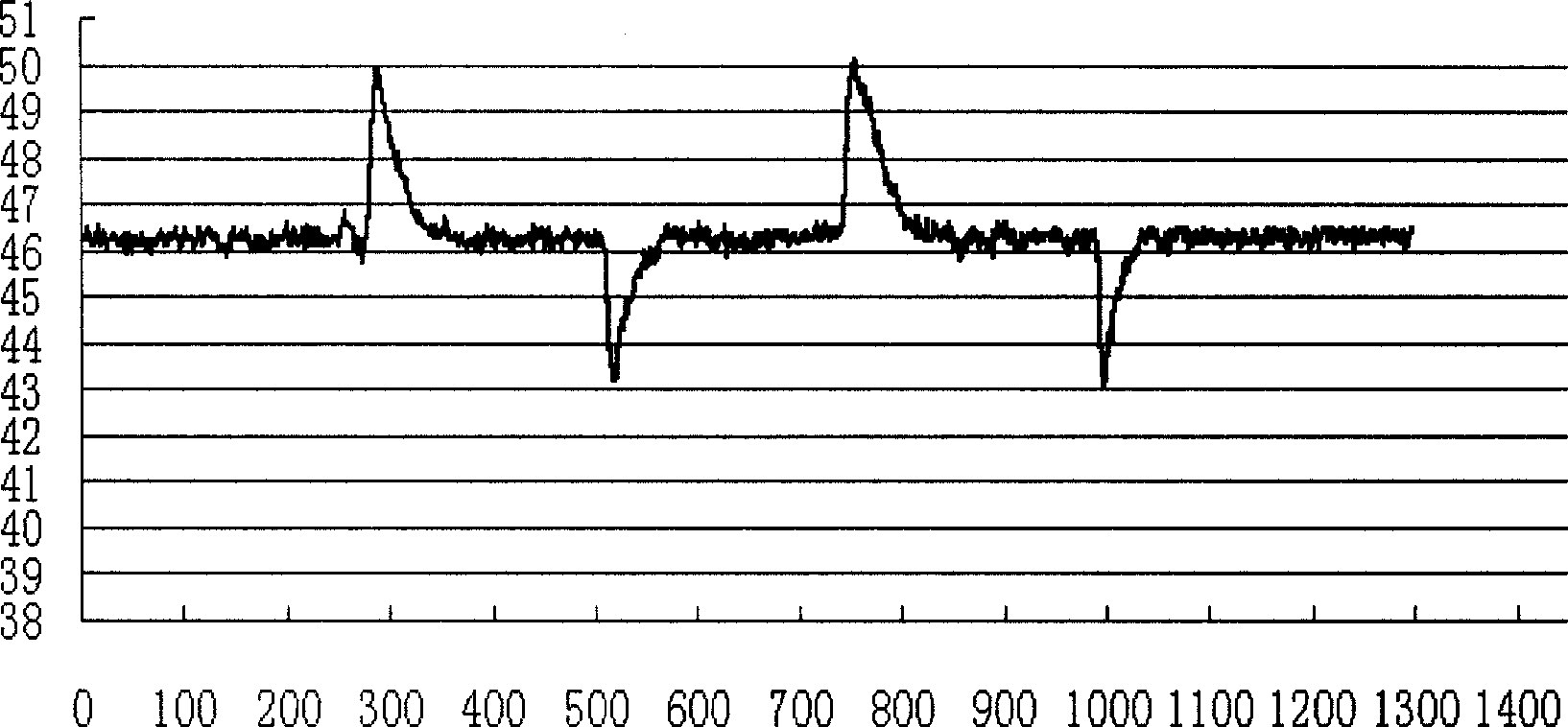

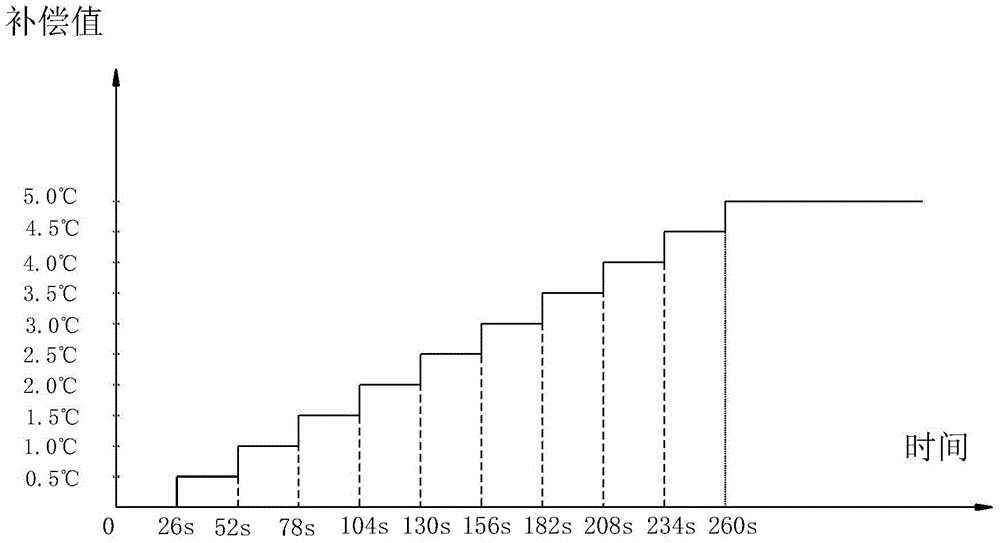

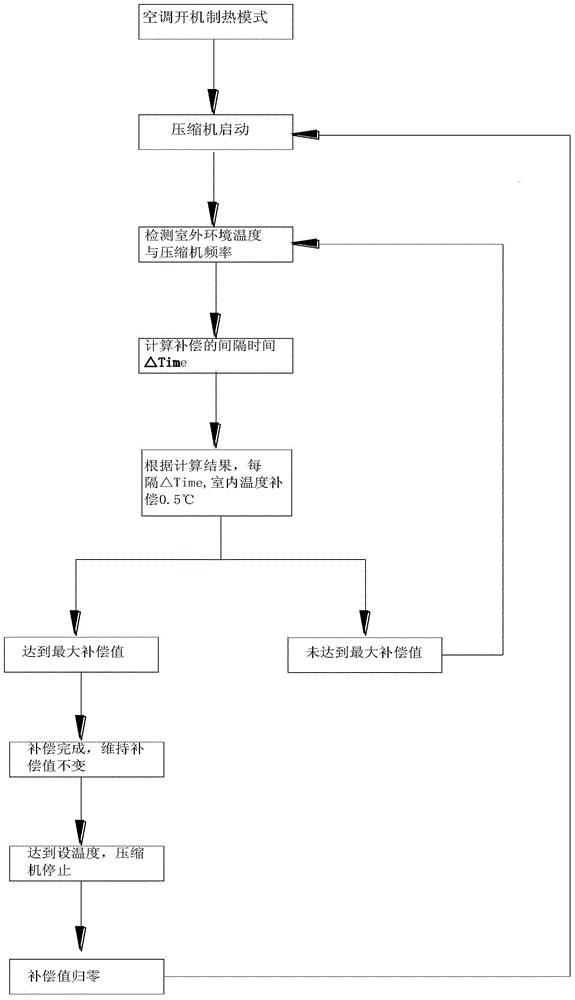

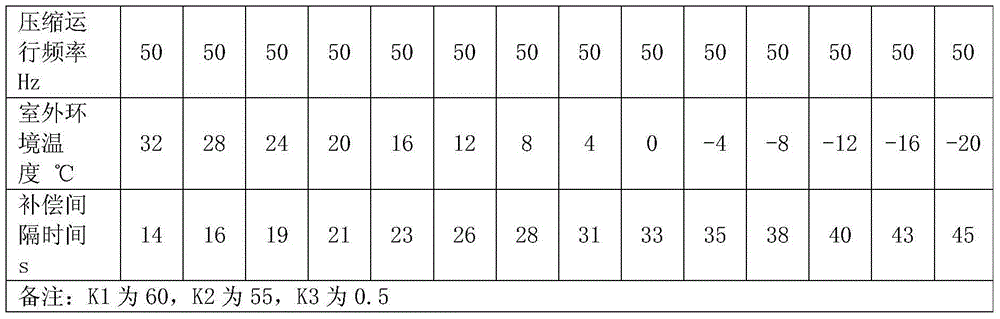

Control method for indoor temperature compensation during heating operation of variable frequency air conditioner

ActiveCN104654528AComply with heat loadAccurate temperature controlMechanical apparatusSpace heating and ventilation safety systemsTemperature controlReturn-to-zero

The invention discloses a control method for indoor temperature compensation during heating operation of a variable frequency air conditioner. After a compressor is started, sectional cumulative compensation is adopted to cumulate an indoor temperature compensation value according to set interval time and a set temperature compensation step value until to a set indoor temperature total compensation value; the compressor stops when the indoor temperature reaches the set temperature, and the compensation value is returned to zero; the compensation is restarted after the indoor temperature is lower than the set temperature and the compressor is restarted. By using the sectional cumulative compensation method, the temperature in a room can be reflected more really. Thus, the frequency calculation of the compressor conforms to real room heat load well, so the temperature control of the air conditioner is more accurate and the comfort of a user can be improved.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

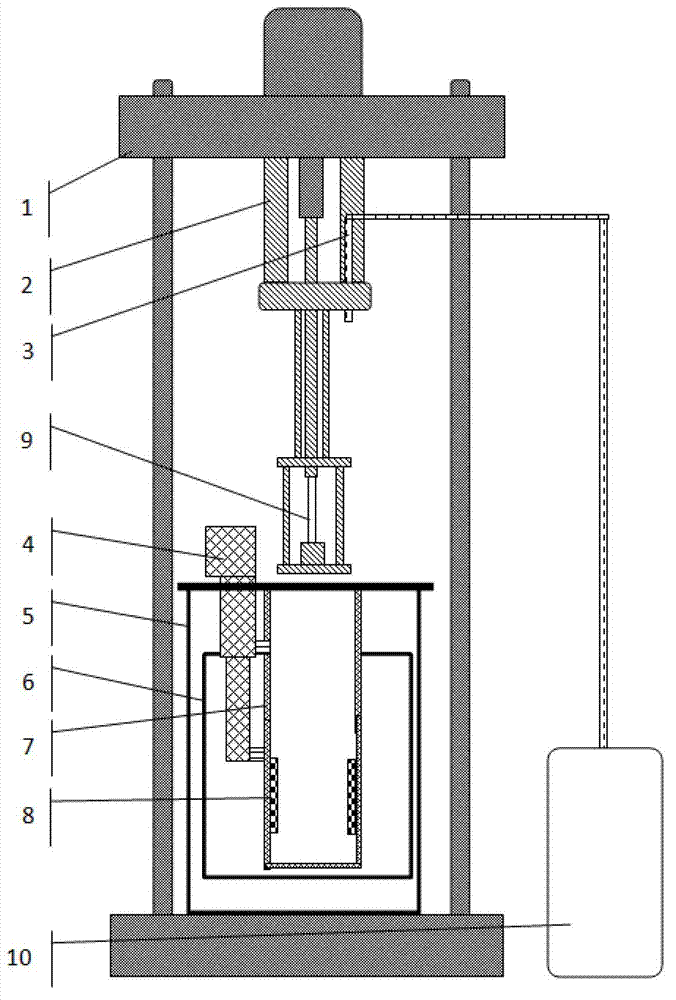

Material low-temperature mechanics performance testing device using refrigerator as cold source

InactiveCN102854056AAccurate temperature controlSimple structureStrength propertiesMaterials testingTest sample

The invention discloses a material low-temperature mechanics performance testing device using a refrigerator as a cold source. The device comprises a vacuum heat preservation barrel, a test sample cavity, a heat radiation preventing barrel, an outer gas storage bag and the refrigerator, wherein the vacuum heat preservation barrel is placed on a base in a universal material testing machine; the test sample cavity is arranged in an internally-built temperature controller which is arranged in the heat preservation barrel; the test sample cavity covers the heat radiation preventing barrel which is positioned in the heat preservation barrel; helium is arranged in the outer gas storage bag which is communicated with the test sample cavity; a sample to be tested is rigidly connected with a mechanics support frame by a measuring clamp and moves up and down; the testing machine is provided with a mechanics and displacement sensor and supplies the mechanics power source for the test sample to be tested; the mechanics support frame transmits a mechanics signal and a displacement signal of the test sample to be tested to a mechanics sensor and a displacement sensor; the refrigerator is arranged in the heat preservation barrel; a cooling head is in contact with the test sample cavity by virtue of bridge connection; and cold energy is supplied to the test sample cavity. By utilizing the device, the refrigerator is used as the cold source, liquid helium or liquid nitrogen are not needed to be consumed, so that the material mechanics test of any of the temperature points in the temperature area of 4.2-300K can be realized; and moreover, the temperature is accurately controlled, and the device has a simple structure, and is easy to operate and high in efficiency.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

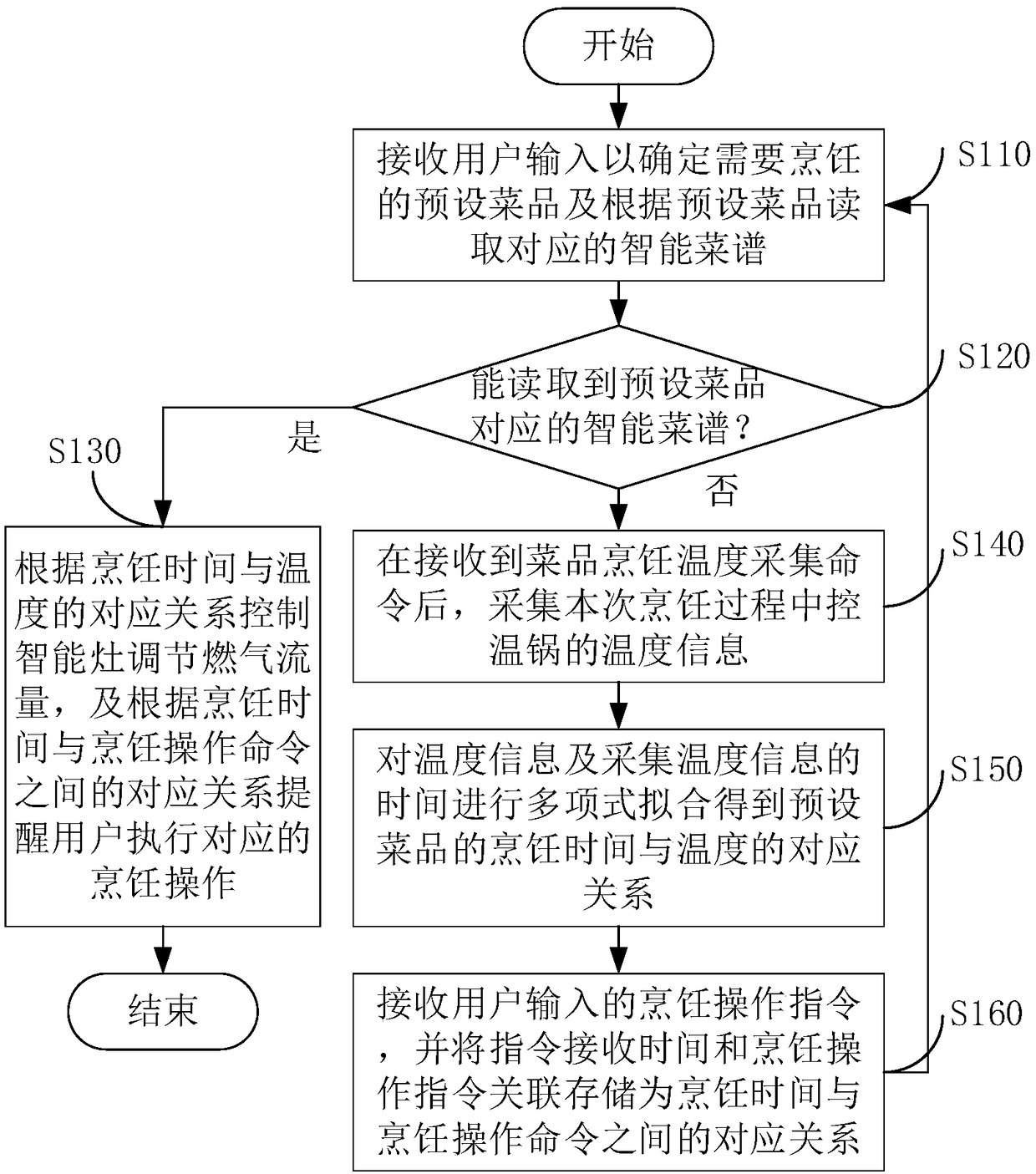

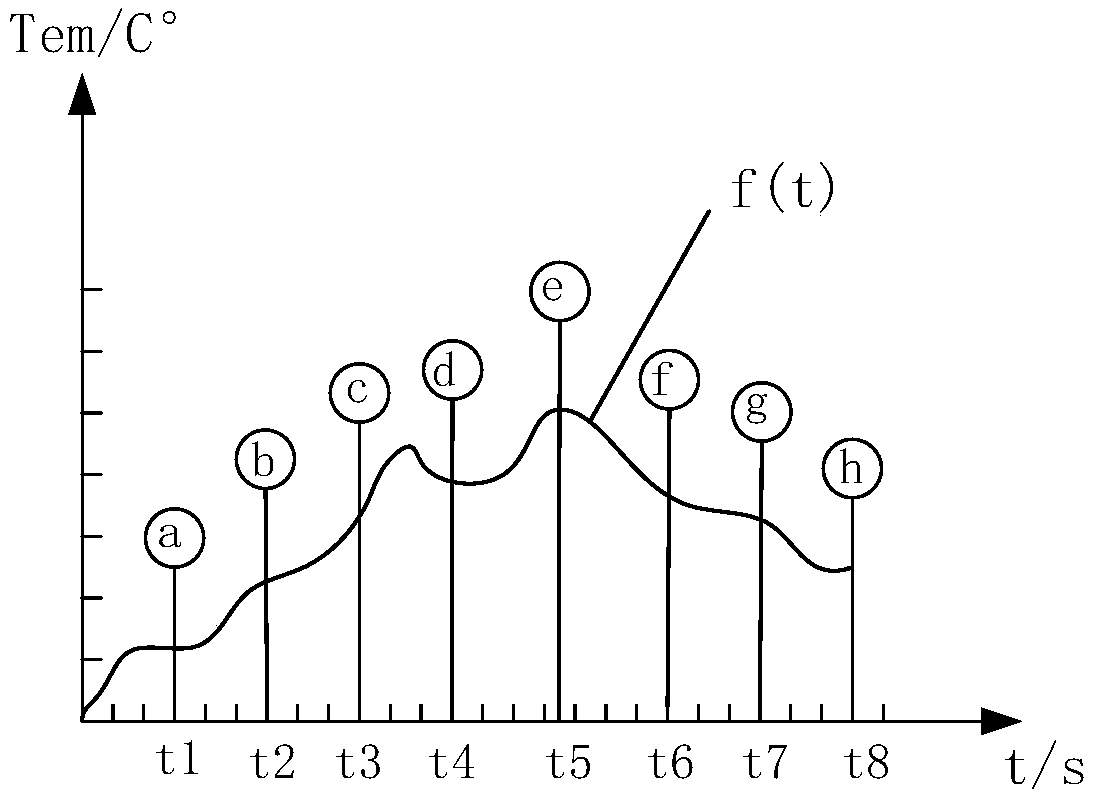

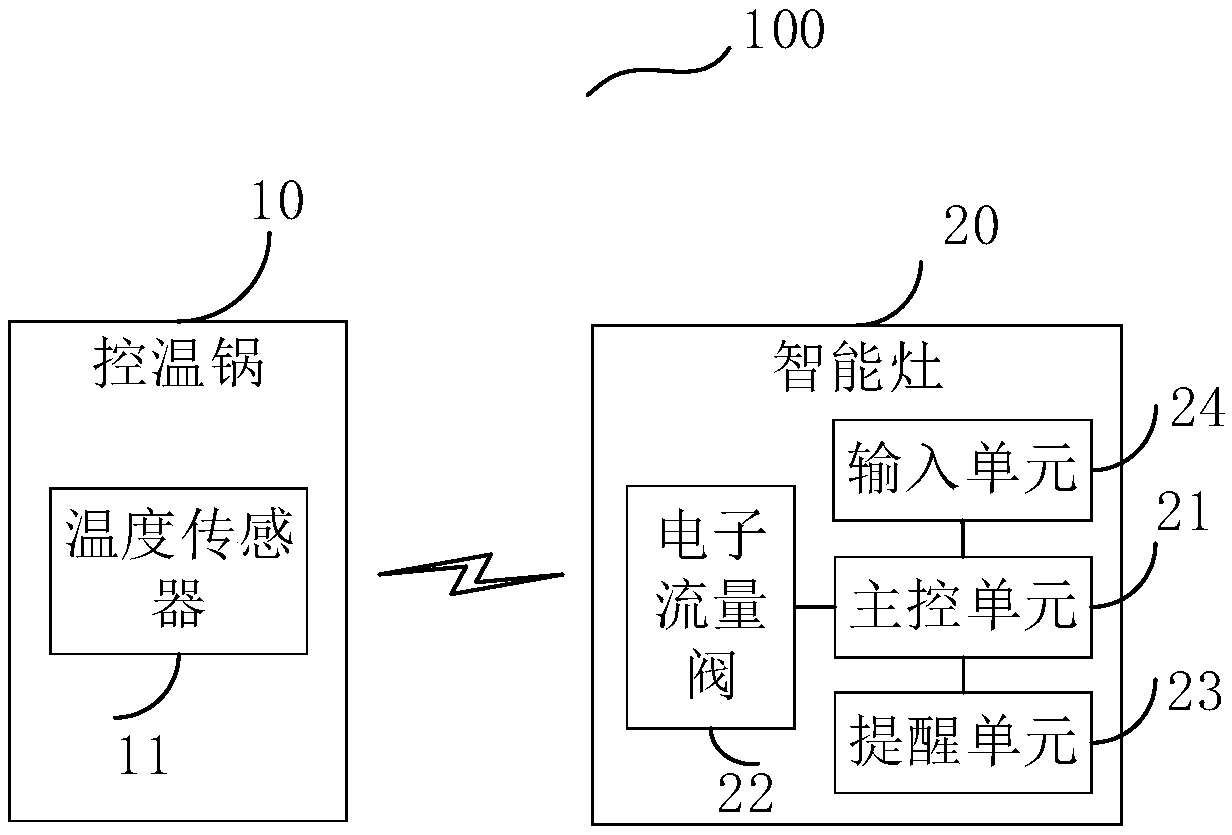

Intelligent cooking method and intelligent cooking type pot and stove combination product

ActiveCN108980915AAccurate temperature controlDomestic stoves or rangesLighting and heating apparatusTemperature controlUser input

The invention discloses an intelligent cooking method and an intelligent cooking type pot and stove combination product. The intelligent cooking method comprises the following steps that the user input is received so as to determine a preset dish, and an intelligent menu is read according to the preset dish; if the preset dish is read from the intelligent menu, an intelligent stove is controlled to adjust the gas flow according to a corresponding relationship between the cooking time and the temperature, and a user is reminded to execute corresponding cooking operation according to the corresponding relationship between the cooking time and the cooking operation instruction; if the preset dish is not read from the intelligent menu,, temperature information of a temperature control pot is collected after an collection instruction is received; the temperature information and the collection time are subjected to polynomial fitting so as to obtain the corresponding relationship between thecooking time and the temperature; and the cooking operation instruction input by the user is received, and the instruction receiving time and the cooking operation instruction are stored in an associative mode as the corresponding relationship between the cooking time and the cooking operation instruction. According to the intelligent cooking method and the intelligent cooking type pot and stovecombination product, the temperature and cooking operation information of each time node in cooking are recorded so as to form the intelligent menu, in the follow-up cooking process, the cooking duration and degree are controlled and the cooking operation of the user is guided according to the intelligent menu, and therefore the problems that the user cannot do the cooking and cannot do the cooking well can be solved.

Owner:深圳北鱼信息科技有限公司

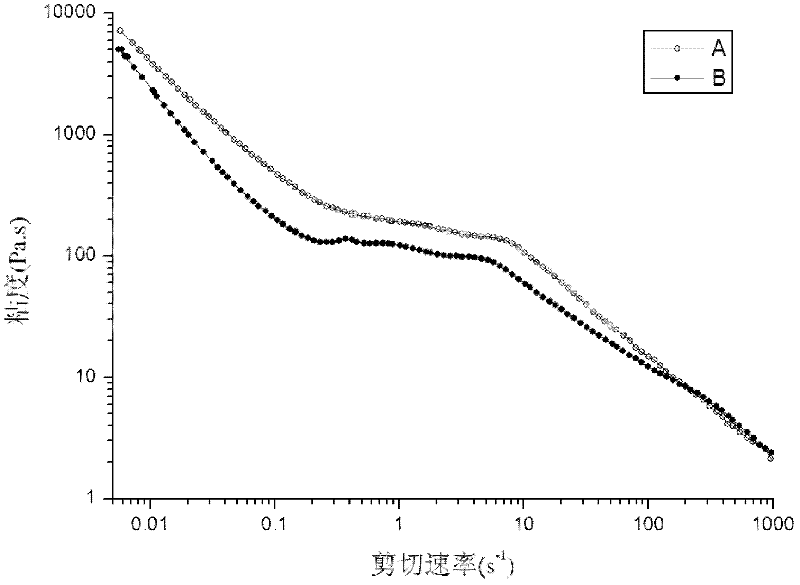

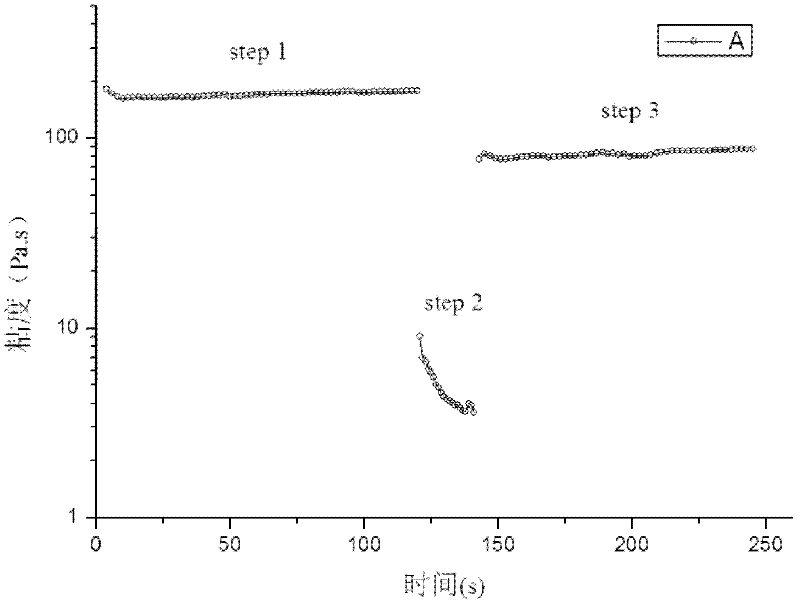

Method for testing rheological property of conductive slurry

InactiveCN102393348AComprehensive Rheological CharacterizationRheological CharacterizationFlow propertiesTemperature controlPhotovoltaic industry

The invention relates to the photovoltaic industry and in particular relates to a method for testing the rheological property of a conductive slurry. The method comprises the following steps: calibrating the instrument accuracy; setting a temperature; selecting and calibrating a clamp; loading and testing a sample; and determining the rheological property. Compared with a viscometer, the test method provided by the invention has a measurement accuracy which is one order of magnitude higher than that of the viscometer, needs a few samples, can be used for realizing accurate temperature control and quick experiment operations, and can represent the rheological property of the conductive slurry more comprehensively.

Owner:TRINA SOLAR CO LTD

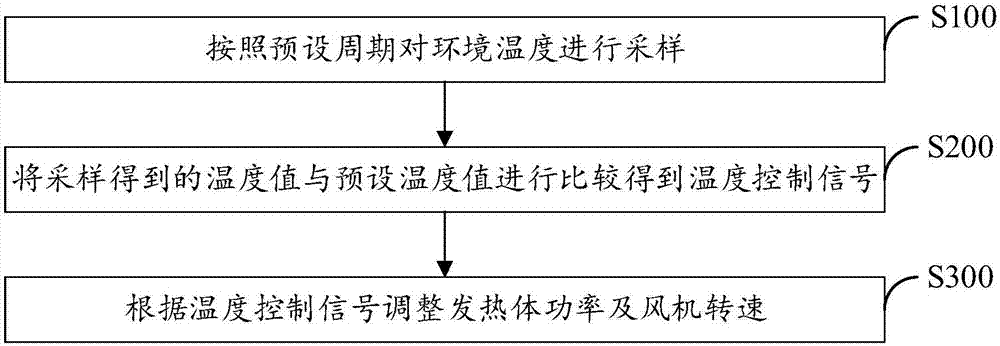

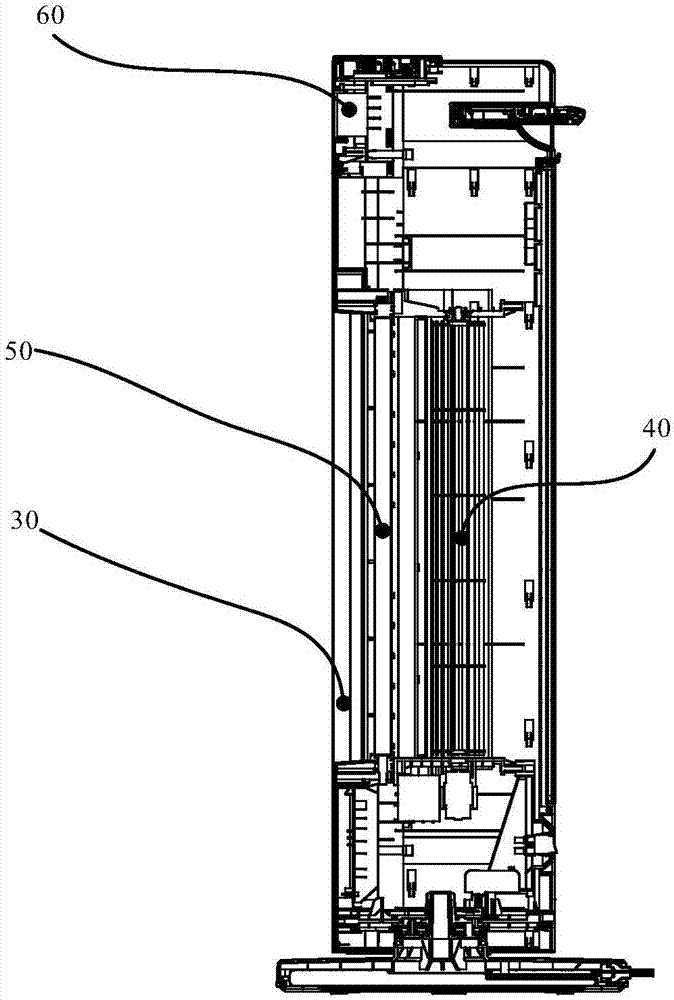

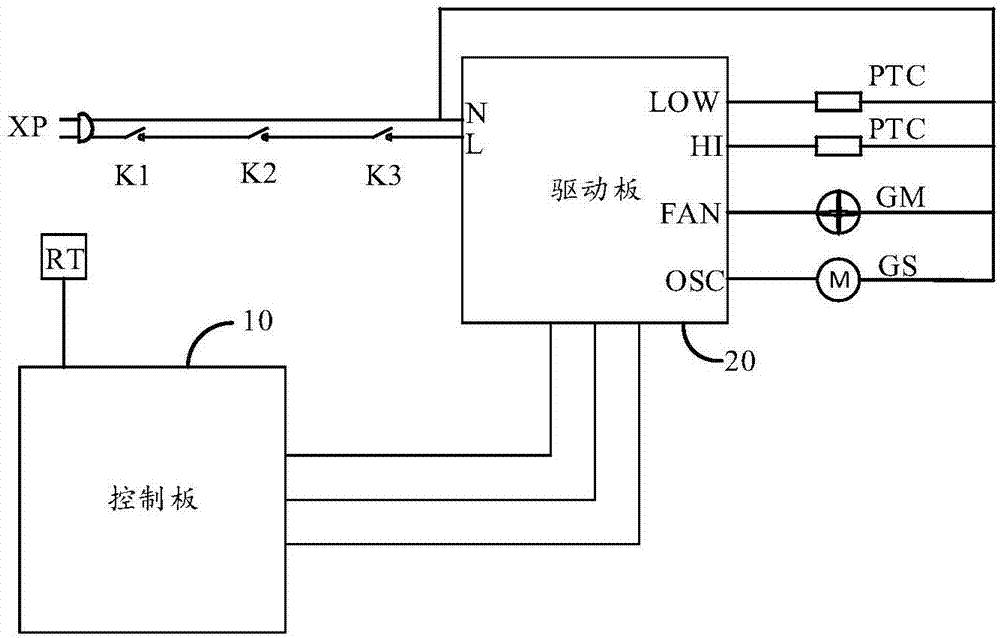

Fan heater control method and device, fan heater and storage medium

InactiveCN107289634AIncrease temperature rise ratePrecise constant temperature controlAir heatersTemperature control using electric meansEngineeringTemperature control

The invention discloses a fan heater control method and device, a fan heater and a storage medium. The method comprises the steps that the ambient temperature is sampled according to the preset period; the temperature value obtained after sampling is compared with the preset temperature value, and a temperature control signal is obtained; and the heating body powder and the fan rotating speed are adjusted according to the temperature control signal. By the adoption of the technical scheme, the temperature rising speed is increased, the control accuracy is improved, and the control frequency is lowered.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

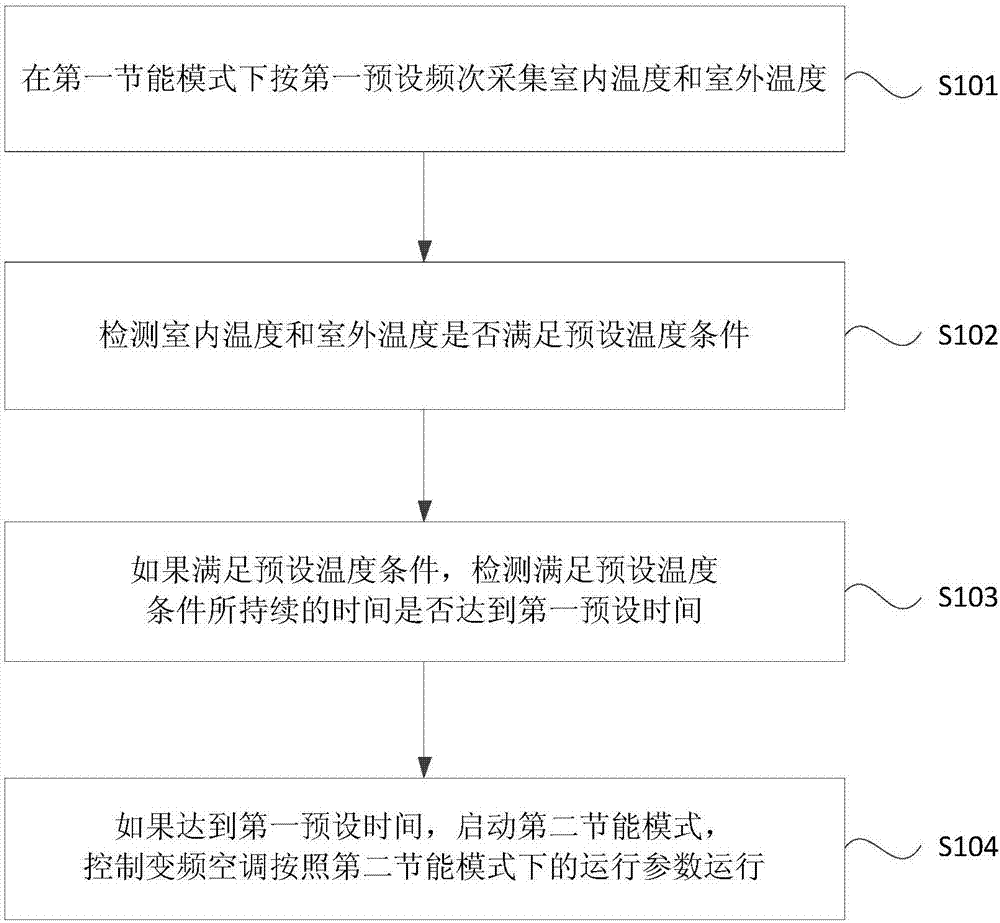

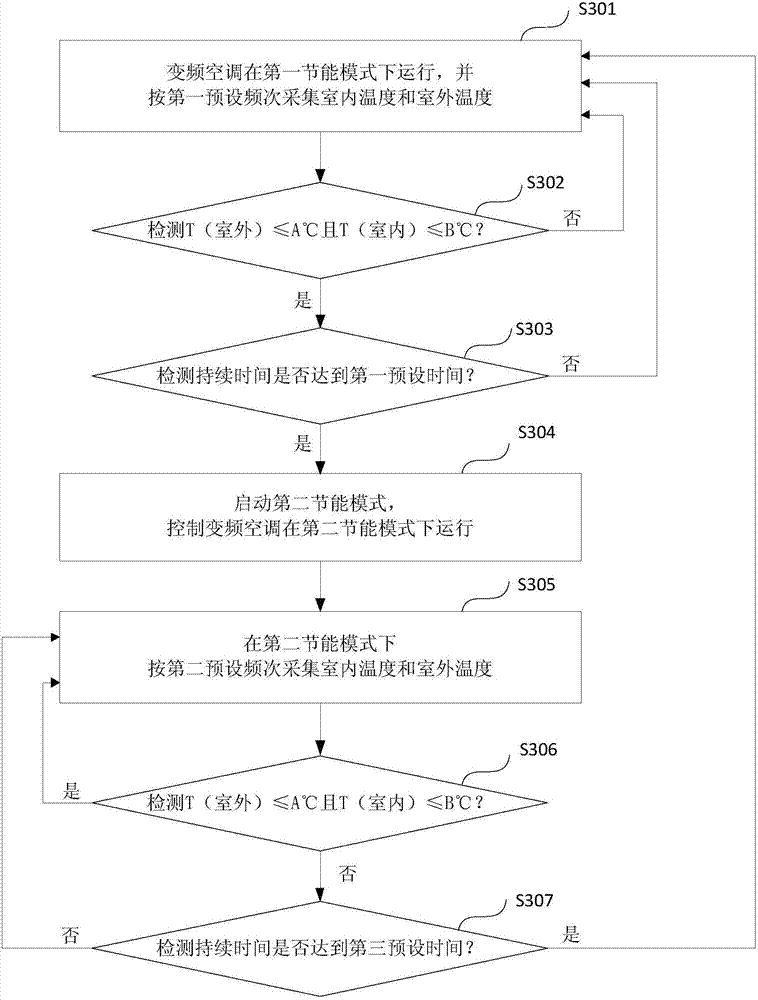

Variable-frequency air conditioner control method and device

ActiveCN107401817AImprove comfortFeel comfortableSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlProcess engineering

The embodiment of the invention discloses a variable-frequency air conditioner control method and device. The method comprises the steps that under a first energy saving mode, the indoor temperature and the outdoor temperature are collected according to a first preset frequency; whether the indoor temperature and the outdoor temperature meet preset temperature conditions or not is detected; if yes, whether the duration that the indoor temperature and the outdoor temperature meet the preset temperature conditions reaches first preset time or not is detected; and if yes, a second energy saving mode is started, and a variable-frequency air conditioner is controlled to operate according to operation parameters under the second energy saving mode. According to the variable-frequency air conditioner control method and device, the variable-frequency air conditioner can select the proper energy-saving operation parameters according to the change of the indoor temperature and the outdoor temperature, accurate temperature control is achieved while energy is saved, the user comfort is improved, especially under the conditions that after a user falls asleep at night, both the energy consumption amount and the amount of generated heat are low, more energy is saved through the variable-frequency air conditioner, and the user feels comfortable.

Owner:SHENZHEN SKYWORTH AIR CONDITIONING TECH CO LTD

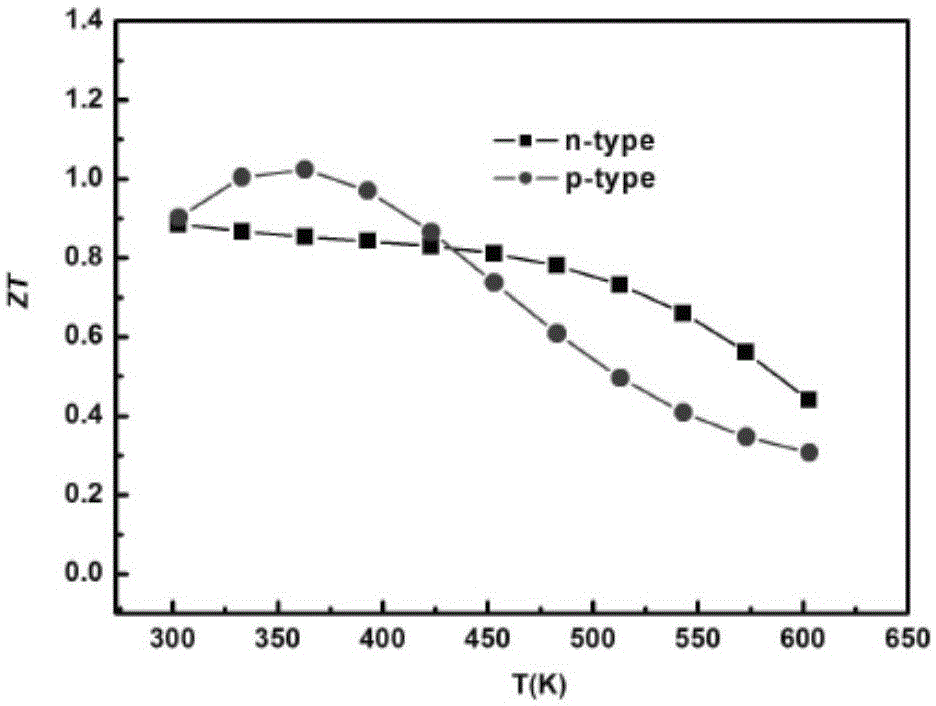

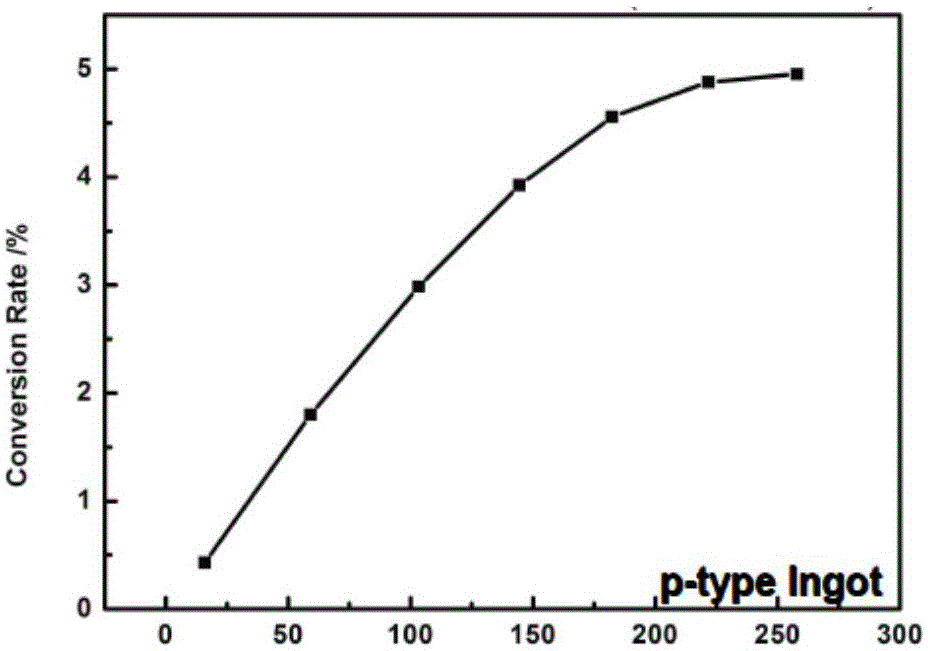

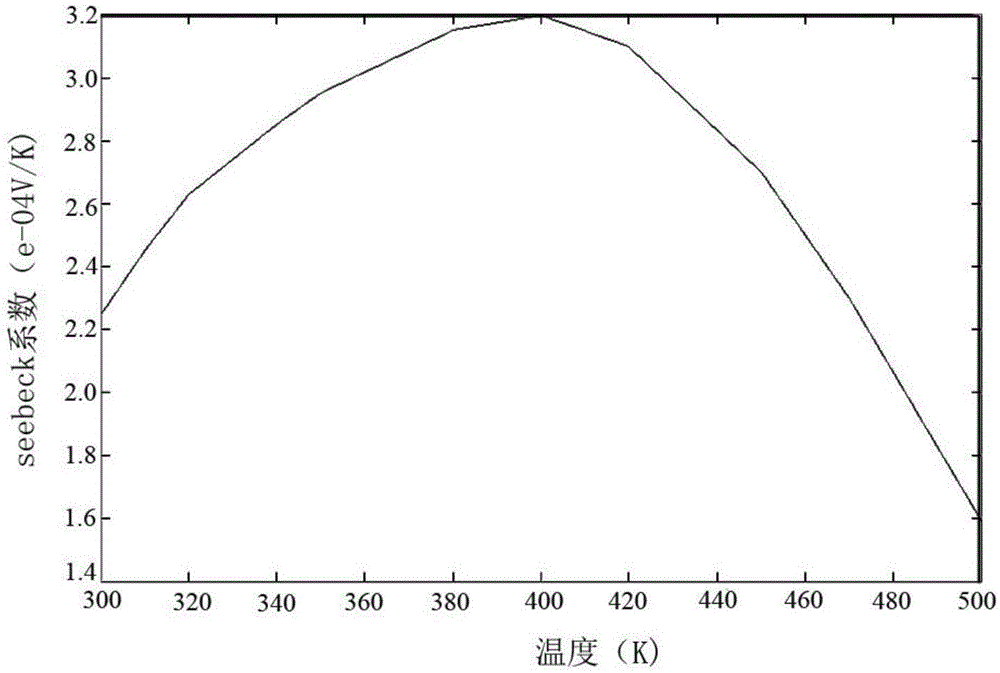

BiSbTeSe-based thermoelectric material

InactiveCN105047808ALow thermal conductivityImprove thermoelectric performanceSelenium/tellurium compounds with other elementsThermoelectric device junction materialsThermoelectric materialsAlloy

The invention discloses a BiSbTeSe-based thermoelectric material. The formula of the BiSbTeSe-based thermoelectric material is Bi<m>Sb<n>Te<x>Se<y>M<z>, wherein m=0.4-0.6, n=1.4-1.6, x=2.7-2.9, y=0.075-0.3, z=0.02-0.15, and M is one or two kinds of elements selected from S, Si, P, Ge, Sn, Ce, Li, I, Br, Al, Cu, Ag, Yb, Tm, La, Gd and Dy. Steps such as powder mixing and alloy smelting are adopted to prepare the BiSbTeSe-based thermoelectric material. The BiSbTeSe-based thermoelectric material of the invention has the advantages of low thermal conductivity, excellent thermoelectric properties, extended application range and the like.

Owner:LEIZIG GUANGDONG THERMOELECTRIC TECH CO LTD

Device and method for measuring mechanical property of film under high temperature

InactiveCN106198206ALoading and unloadingUniform furnace temperatureMaterial strength using tensile/compressive forcesFull fieldOptical measurements

The invention discloses a device and a method for measuring mechanical property of a film under high temperature. The measuring device comprises an optical measurement component, a data processing and displaying component, a dynamic loading component, a heating component and a sample platform, wherein the optical measurement component, the heating component, the sample platform and the dynamic loading component are successively arranged; light sources and light spots sent during measurement are unchanged; due to the bulging effect, the film is deformed; a reflection angle of a light path transmitted to the film is changed due to the deformation of the film; the optical measurement component for receiving a reflected light path is remotely connected to the data processing and displaying component; the received light path is obtained by the optical measurement component; and the data processing and displaying component is used for visually displaying the measurement process and recording the change of the received light path. Through the measuring device, a heating device and a bulging device are combined together to measure the mechanical property of the film under high temperature; the measuring device is compact in structure, is applied to the films of various elasto-plastic systems, and is capable of achieving real-time and full-field measurement of the change of the mechanical property in the heating process.

Owner:XIANGTAN UNIV

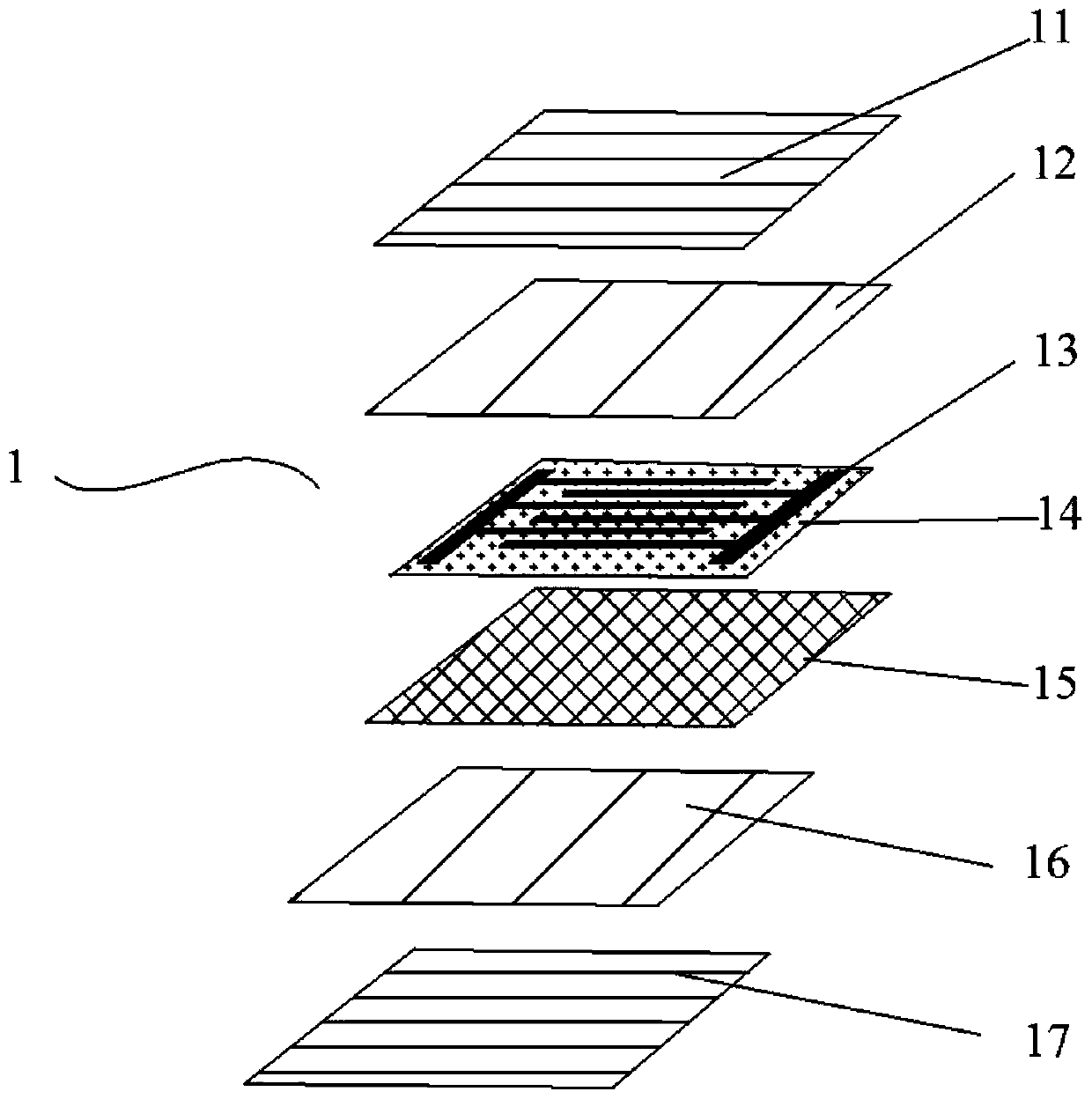

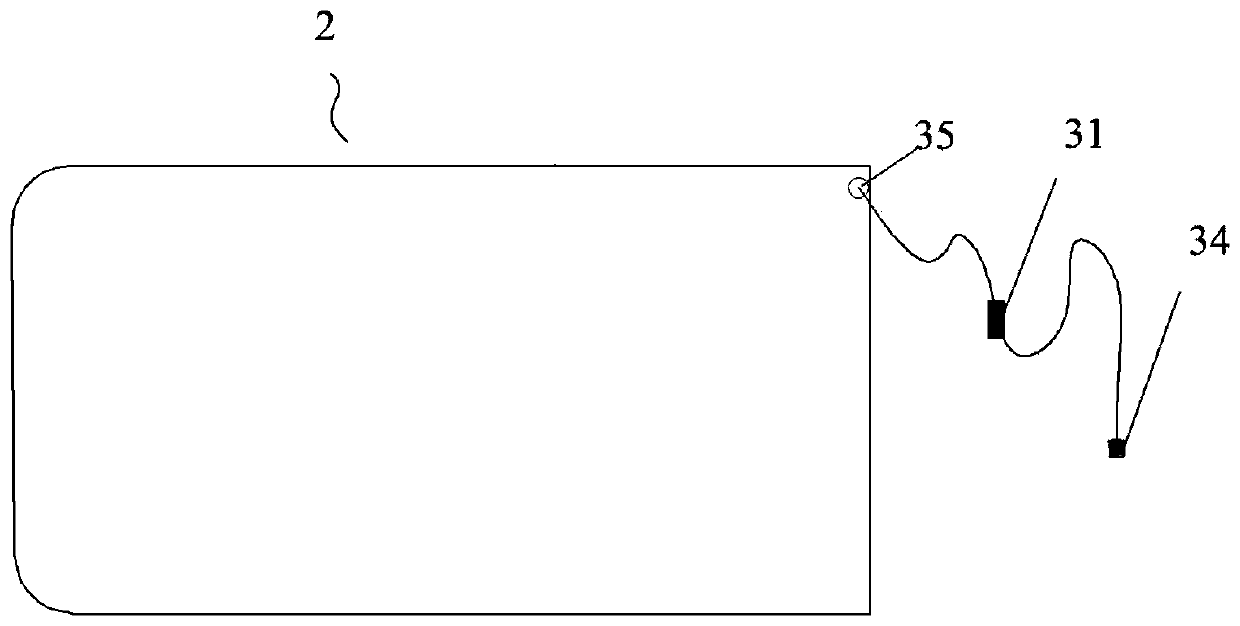

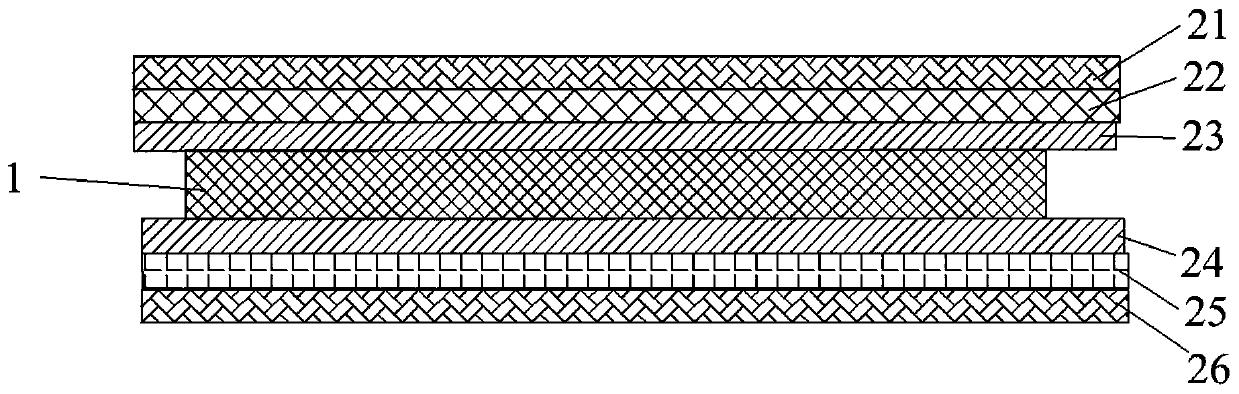

Graphene heat-emitting film assembly with single-side far infrared radiation function and bed warmer based on graphene heat-emitting membrane assembly

PendingCN110475396AUniform and stable heatingImprove the effect of physical therapyOhmic-resistance electrodesChemical industryBlood circulationFar infrared

The invention discloses a graphene heat-emitting film assembly with a single-side far infrared radiation function and a bed warmer based on the graphene heat-emitting film assembly. According to the graphene heat-emitting film assembly of the invention, one surface of a graphene heat-emitting film layer, which is far away an electrode layer, is provided with a far infrared reflecting layer. The graphene heat-emitting film assembly disclosed by the invention has an excellent infrared reflection effect and is more energy-saving; the bed warmer based on the graphene heat-emitting film assembly has the advantages of good heat-emitting stability, high temperature rise speed, uniform heat emission and soft material, and can realize the physical therapy functions of promoting blood circulation, repairing cells, preventing diseases and the like..

Owner:合肥微晶材料科技有限公司

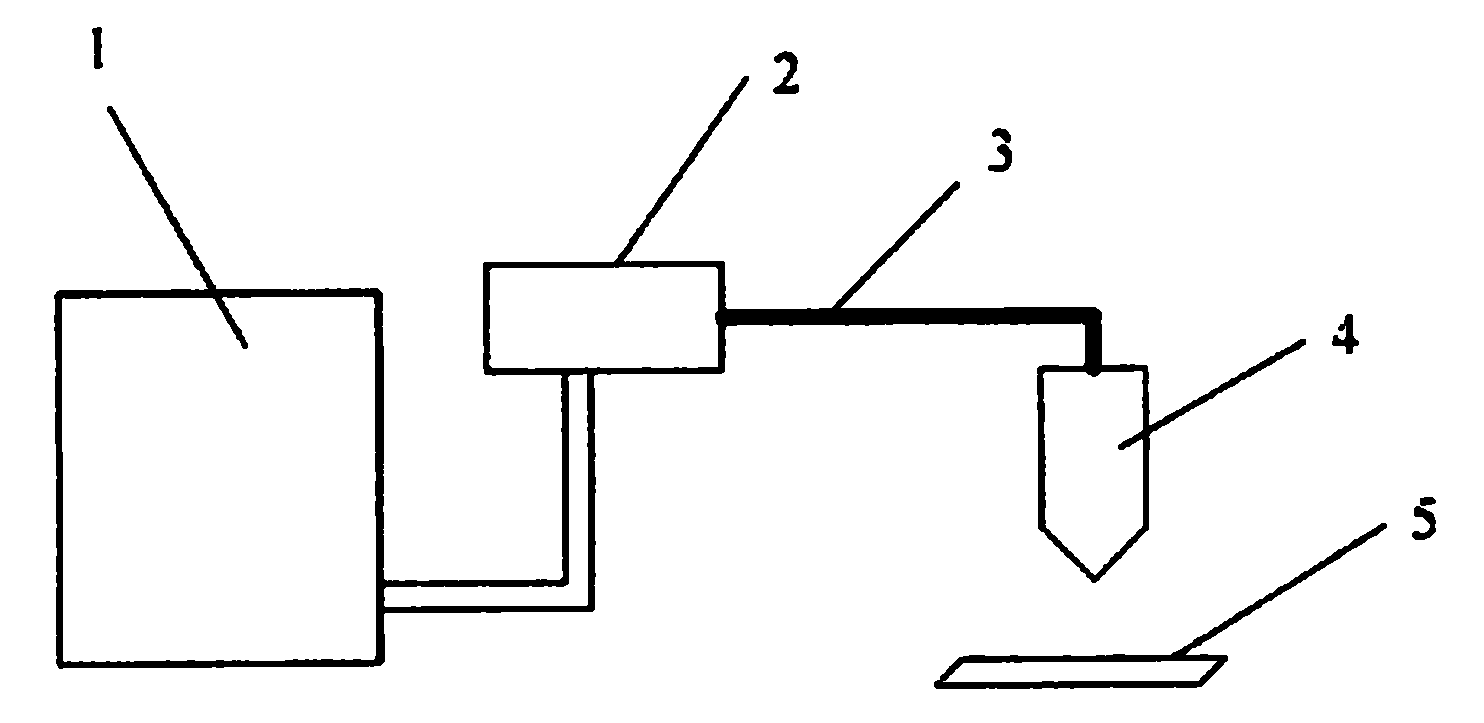

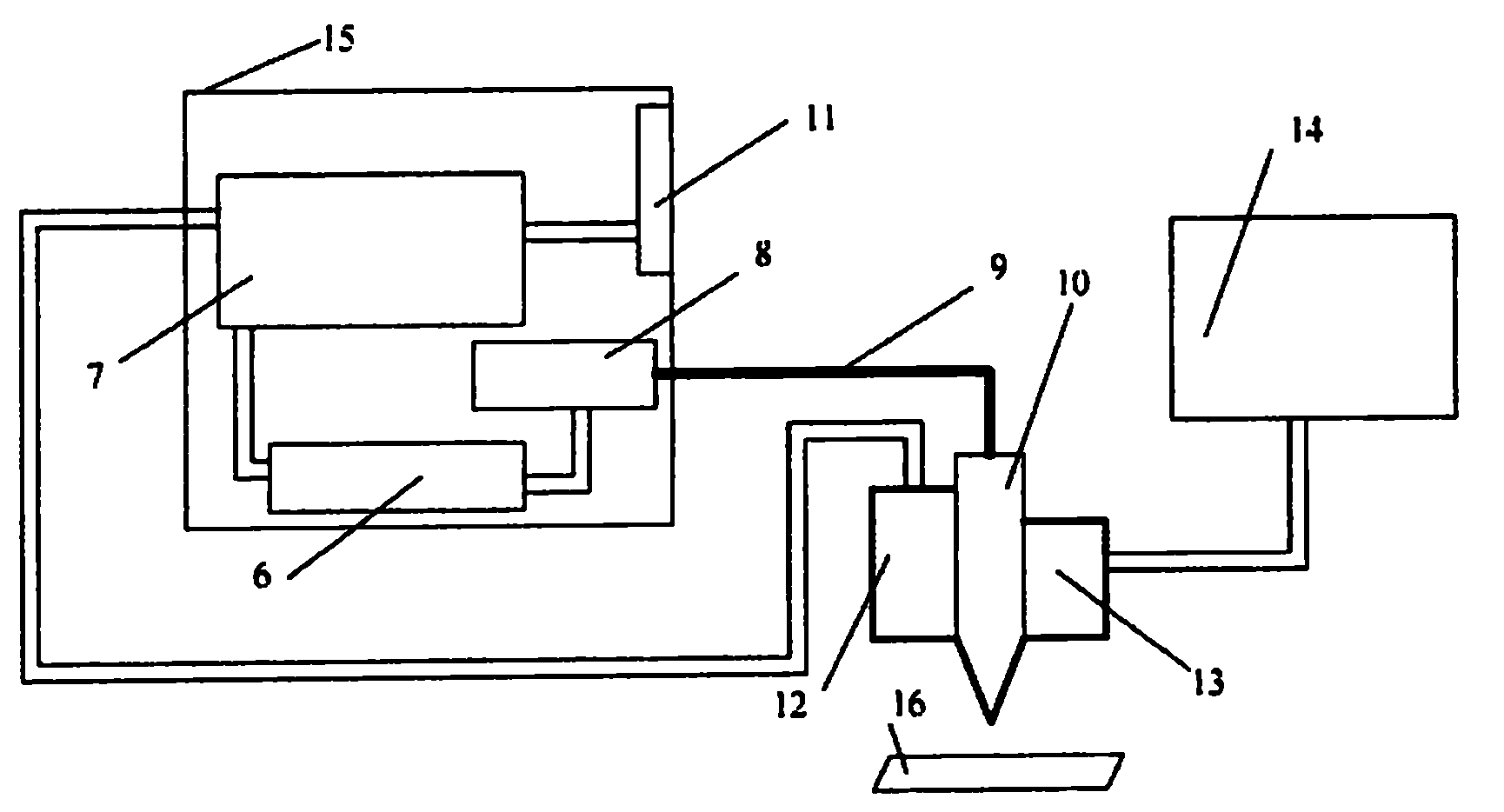

High-power semiconductor laser constant-temperature welding device

InactiveCN101774090ACompact structureImprove performanceLaser beam welding apparatusProgrammable logic controllerDisplay device

The invention relates to a high-power semiconductor laser constant-temperature welding device which comprises a laser power supply, a programmable logic controller, a laser module, an optical fiber, a laser focus head, an infrared high-temperature detector, a charge coupling apparatus, a display and a bottom plate. The welding device is characterized in that the programmable logic controller is connected with the laser power supply, the high-temperature detector and a touch screen respectively; the optical fiber is connected with the laser module and the laser focus head; the charge coupling apparatus is connected with the display; a part of apparatus are fixed on the bottom plate; and the high-temperature detector, the charge coupling apparatus and the laser focus head are assembled. The device has the advantages of compact structure, accurate temperature, convenient installation, good control performance, easy industrial batch production and the like, and can be widely applied to the fields of laser material processing, laser printed circuit board welding and the like.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Automatic temperature rise control device for crankshaft and bearing bushes of mechanical press

ActiveCN107097452AReduce the temperatureImprove the sliding friction environmentPress ramTemperature controlAutomatic control

An automatic temperature rise control device for a crankshaft and bearing bushes of a mechanical press comprises a machine body, the crankshaft, a first supporting sleeve, a second supporting sleeve, a connecting rod cover, a connecting rod, a first shaft end bearing bush, a second shaft end bearing bush and a connecting rod bush; an air circuit temperature control system and a temperature detection and control system are arranged on the machine body; the air circuit temperature control system comprises an air cooling machine arranged on the machine body; the air cooling machine is connected with an air distributor; the air distributor communicates with spiral grooves formed in inner walls of the first supporting sleeve, the second supporting sleeve, the connecting rod cover and the connecting rod through multiple air inlet pipes; the temperature detection and control system comprises a controller and multiple temperature sensors for detecting the temperatures of the first shaft end bearing bush, the second shaft end bearing bush and the connecting rod bush; the temperature sensors are connected with the controller through circuits; and the controller is connected with the air cooling machine through a circuit. The control device has the advantages that the working temperature of the bearing bushes is automatically controlled, the design clearance is reduced, the service life of the crankshaft and the service life of the bearing bushes are prolonged, the operation speed and precision of the crankshaft is improved, the production efficiency is high, the product quality is high, and the like.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

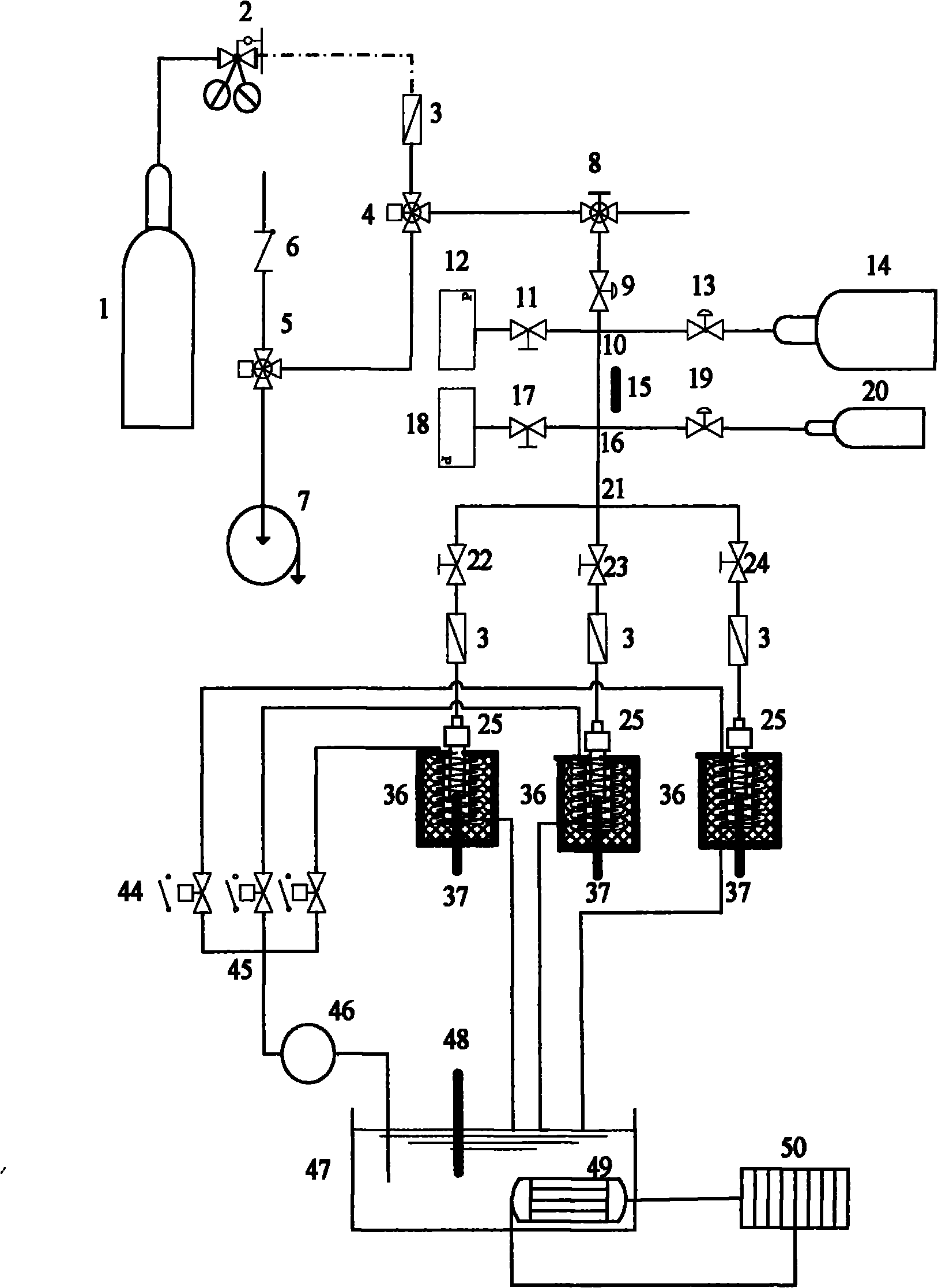

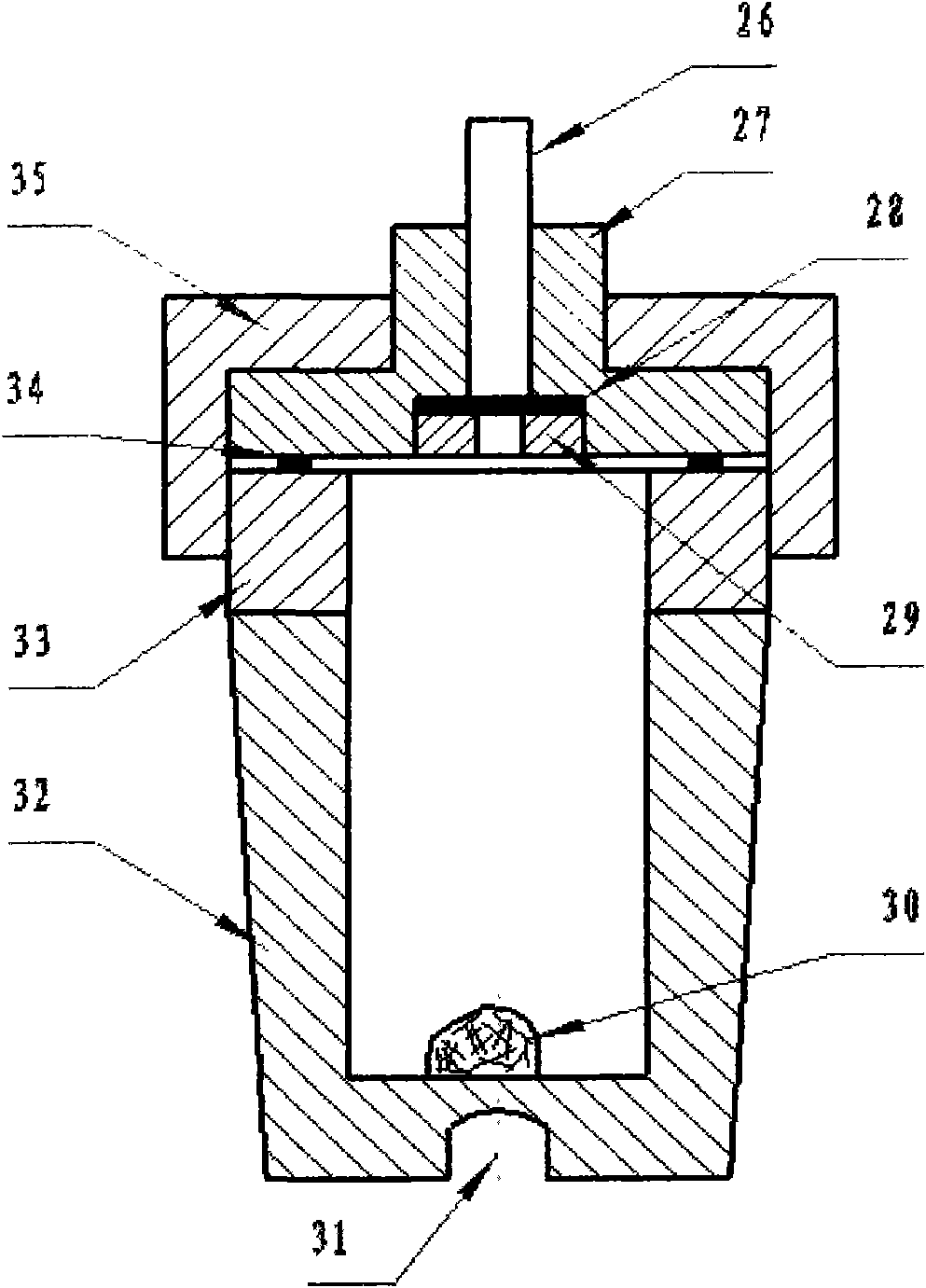

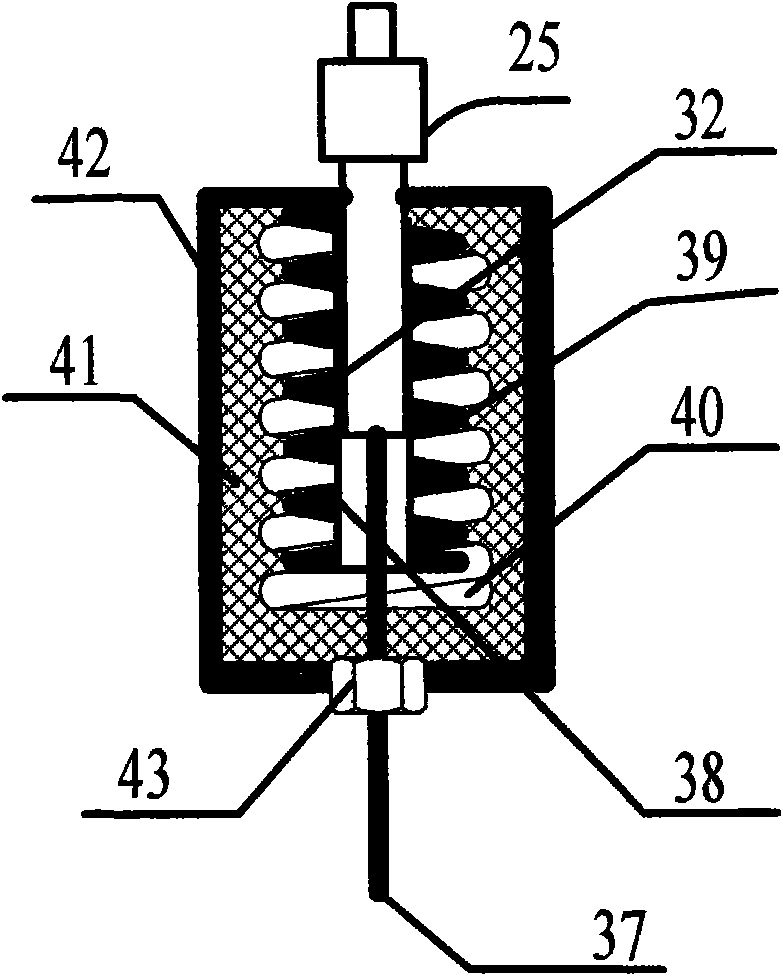

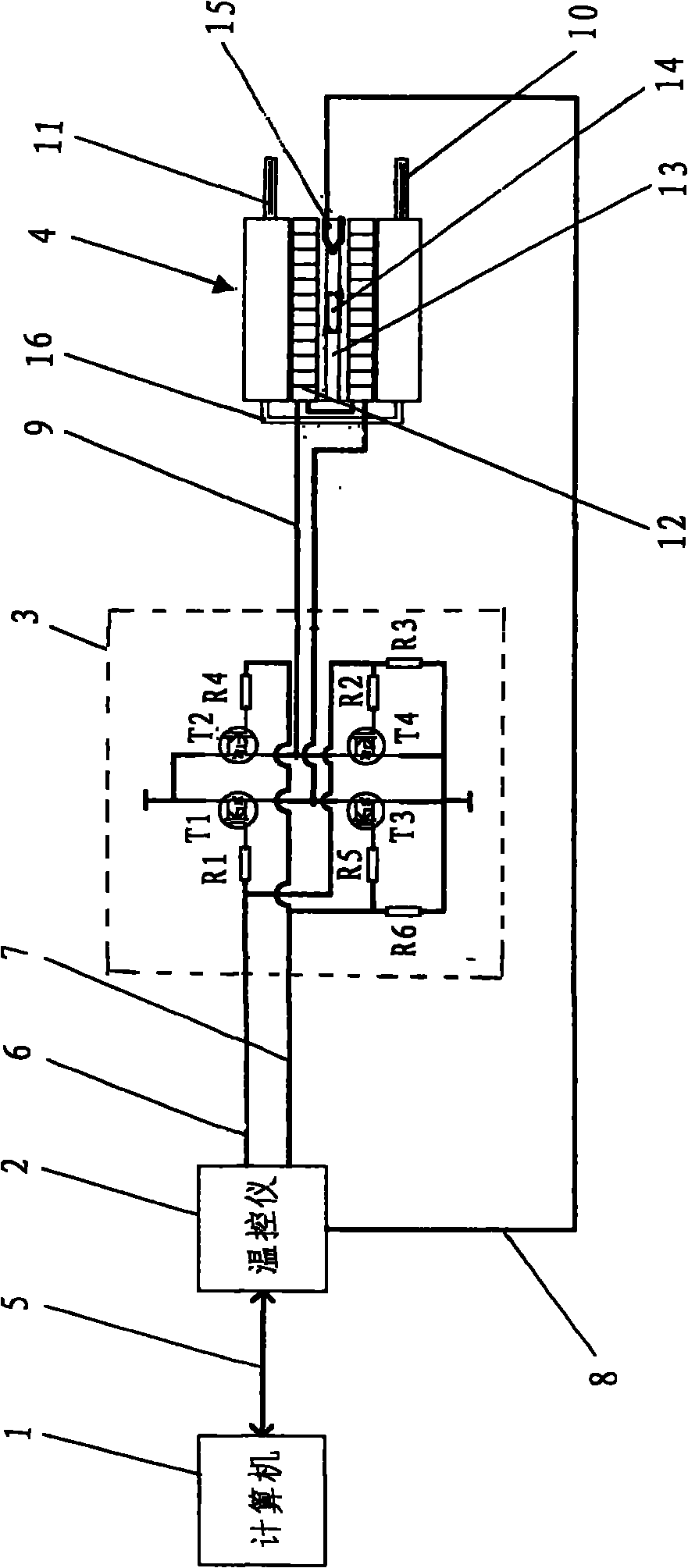

Test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and special device thereof

InactiveCN101858842AAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

The invention discloses a test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and a special device thereof. The test device consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

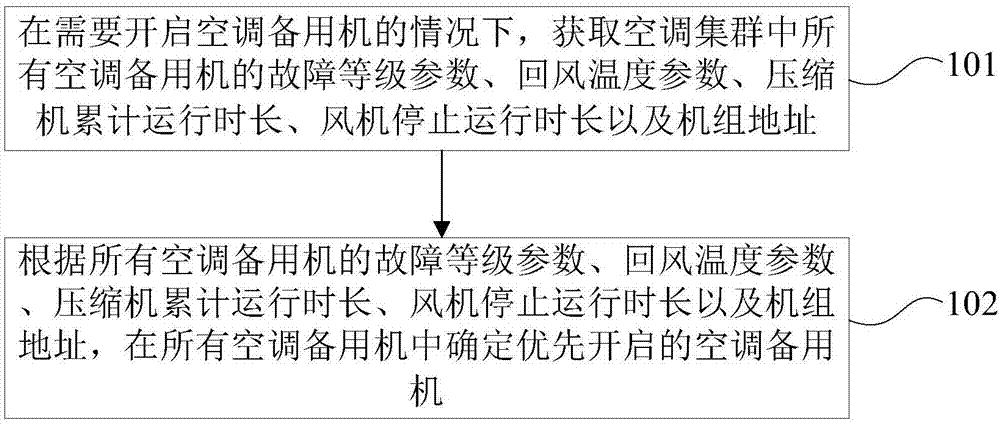

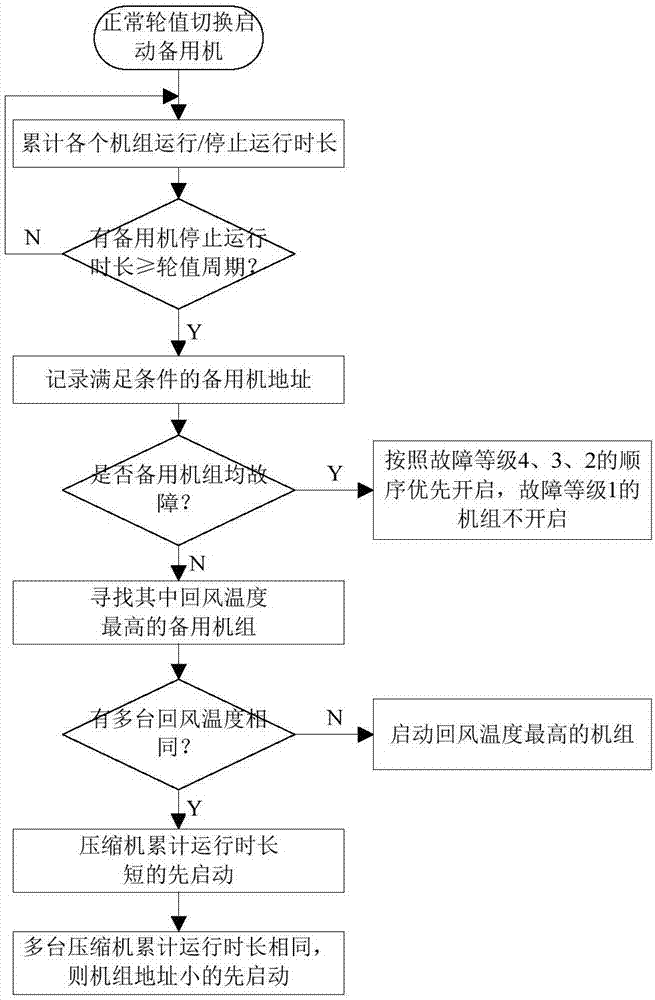

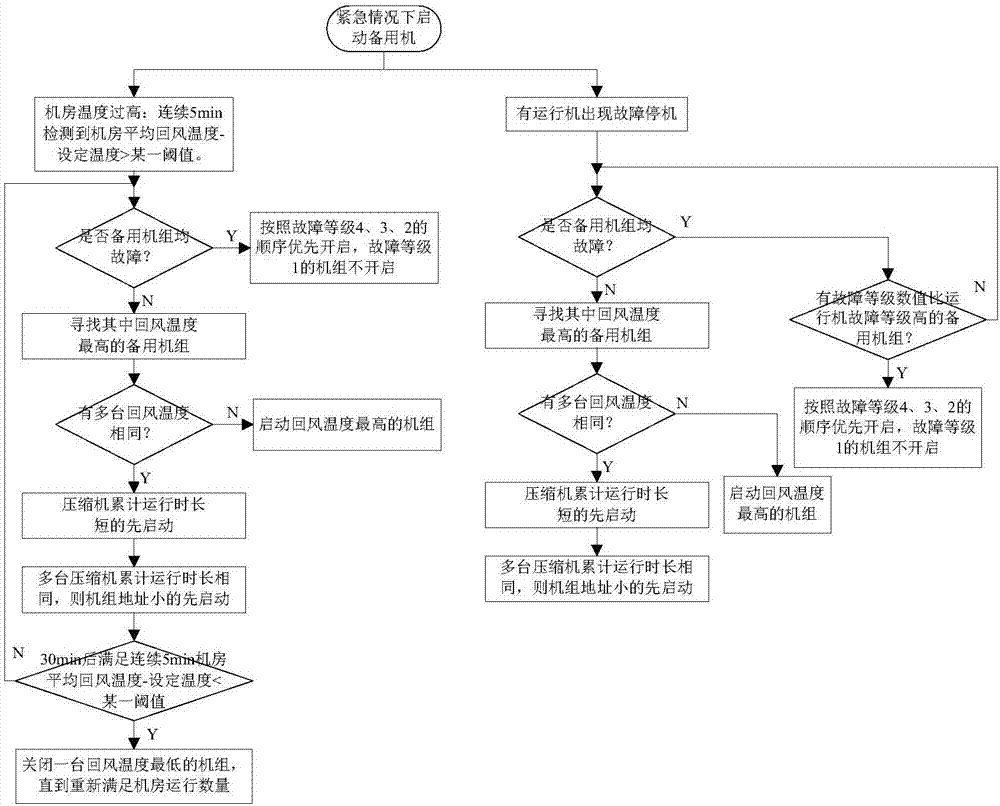

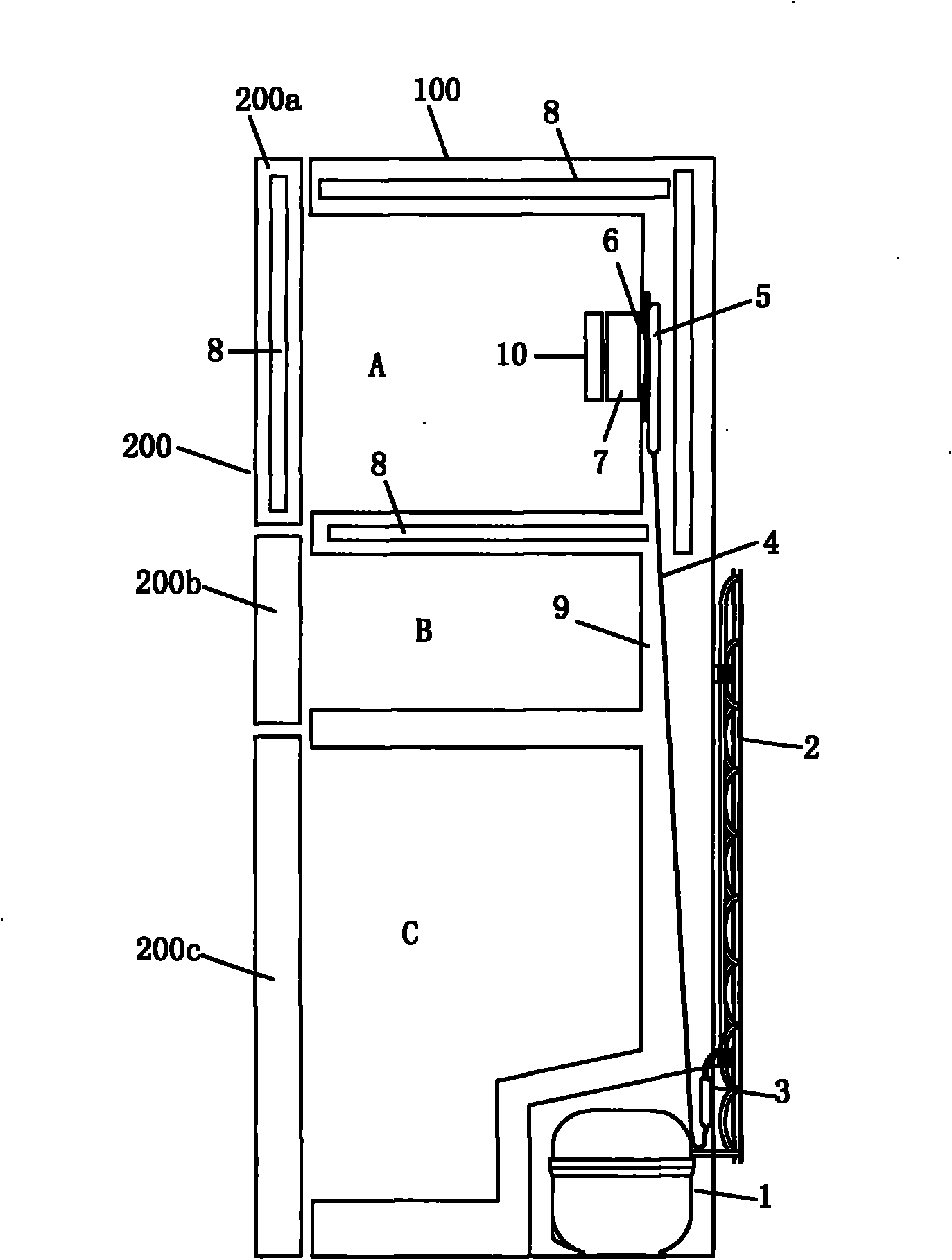

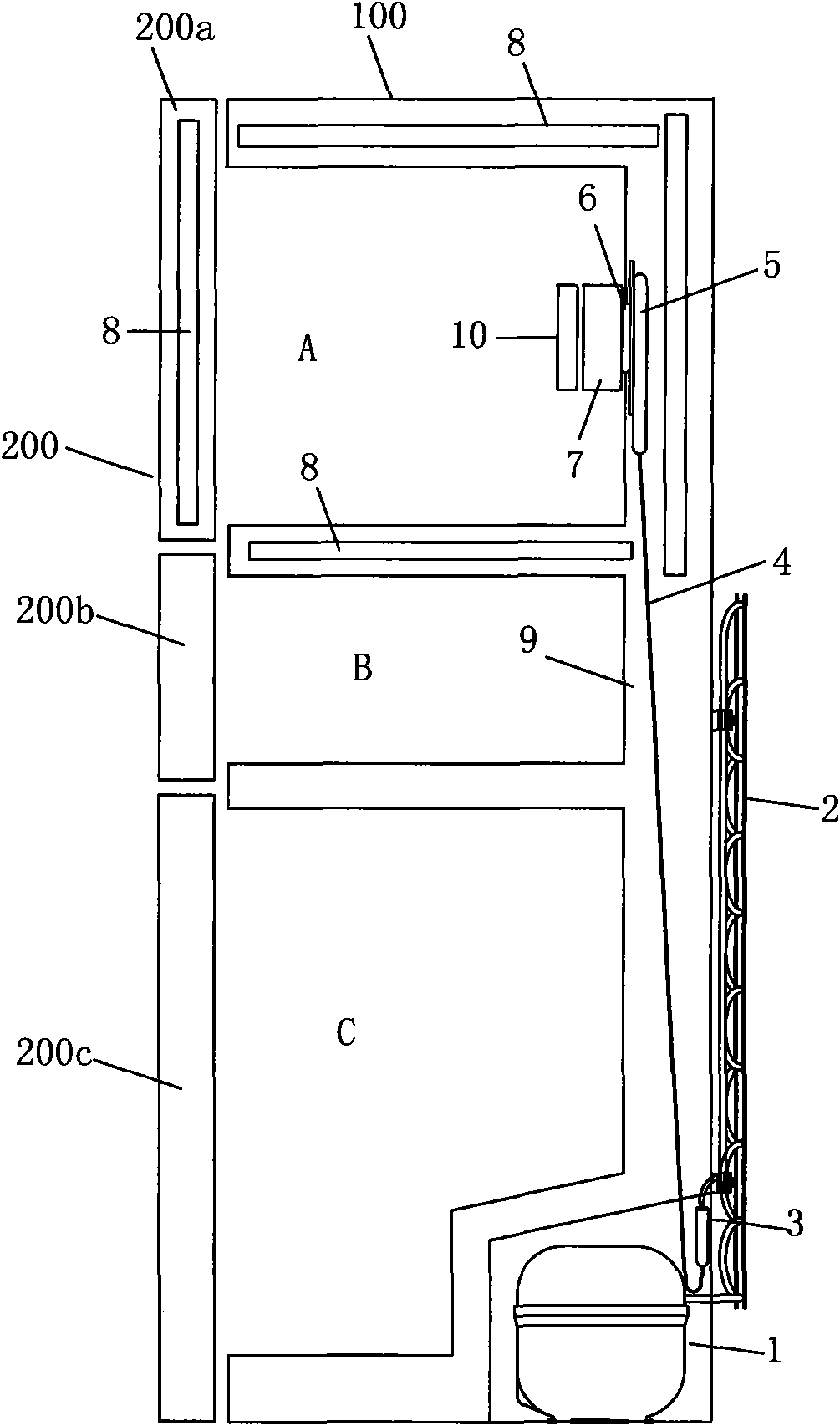

Air conditioner spare machine opening control method and device and computer readable storage medium

ActiveCN107975909AAverage usage timeExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusComputer engineering

The invention discloses an air conditioner spare machine opening control method and device and a computer readable storage medium. The method comprises the steps of obtaining failure level parameters,air returned temperature parameters, compressor accumulation running duration, draught fan running stop duration and the unit address of all air conditioner spare machines in an air conditioner cluster under the condition that the air conditioner spare machines need to be opened; according to the failure level parameters, the air returned temperature parameters, the compressor accumulation running duration, the draught fan running stop duration and the unit address of all air conditioner spare machines, determining the air conditioner spare machines, preference to be opened, in the all air conditioner spare machines.

Owner:GREE ELECTRIC APPLIANCES INC

Low temperature refrigerator

ActiveCN101865587AReduce volumeSimple structureLighting and heating apparatusDomestic refrigeratorsTemperature controlTemperature difference

The invention discloses a low temperature refrigerator, comprising a refrigerator body, a refrigerator door, an evaporator and a semiconductor refrigeration plate. A refrigerating chamber and a freezing chamber are respectively defined in the refrigerator body, the front side of the refrigerator body is provided with an opening, the refrigerator door is installed on the refrigerator body and used for opening and closing the opening, the evaporator is arranged in the back wall of at least one of the refrigerating chamber and the freezing chamber, the hot end of the semiconductor refrigeration plate is in contact with the evaporator, and the cold end is located in at least one of the refrigerating chamber and the freezing chamber. In the low temperature refrigerator, by using the high temperature difference characteristics at two ends of the refrigeration plate, a refrigerating system of the refrigerator is used for dissipating heat at the hot end of the refrigeration plate, thereby achieving the purpose of low temperature at the cold end of the refrigeration plate, and cooling the temperature in a low temperature chamber to 40 to 50 DEG C below zero. Therefore, the low temperature refrigerator has low production cost, small refrigerator volume, and simplified structure of the refrigerating system, can achieve accurate temperature control and has wide adaptability.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Constant temperature control device of frequency doubling crystals of solid laser

ActiveCN101916958ABest multiplier conversion efficiencyAccurate temperature controlLaser detailsTemperature controlDriving current

The invention discloses a constant temperature control device of frequency doubling crystals of a solid laser, comprising a temperature control unit, wherein the temperature control unit is connected with the input end of a power drive circuit via refrigeration control signals and heating control signals, and the output end of the power drive circuit is connected with a semiconductor refrigeration film in a gripper via a drive current line. A light inlet window is used for accommodating the frequency doubling crystals and the gripper is internally provided with a cooling water tunnel. The invention can realize accurate and stable temperature control with the temperature difference range of + / -0.1 DEG C, and has the characteristics of easy implementation and operation. Under the condition of high precision and high stability temperature control, frequency doubling crystals can achieve optimum frequency doubling conversion frequency by matching temperature with phase. The temperature control unit also can be interconnected with a computer via an RS485 interface, thus realizing remote control and parameter management on the temperature of the frequency doubling crystals of the solid laser by a computer.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

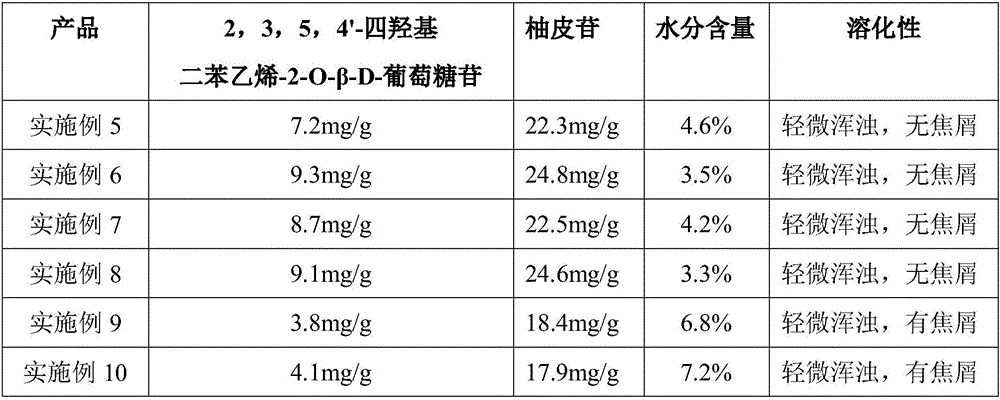

Drying method for Chinese medical extract

InactiveCN106123496AKeep the fragranceModerate colorDrying solid materials with heatDrying solid materials without heatMedicinal herbsMedicine

The invention relates to a drying method for Chinese medical extract, in particular to a vacuum drying method for Shouhui cathartic extract. The vacuum drying method adopts circulating hot water with the temperature being controlled automatically to serve as a medium for heating of the Chinese medical extract, and the purpose of low-temperature drying of the Chinese medical extract is achieved. Through the method, the defects, occurring to traditional vacuum drying and the like, that thermosensitive components of extract are decomposed due to high temperature, the energy consumption is high, the heat efficiency is low, the extract is dried and burnt, drying is insufficient can be overcome. According to the dried Chinese medical extract obtained through the drying method, the content of effective components is high, the quality of finished products is good, the water content is low, and preparation processing and storage of the finished products are facilitated; fresh scent of medicinal materials is maintained, the color and lustre are natural, the texture is loose and uniform, the extract is easy to crush; and continuous and automatic production can be achieved, and the method has quite high operability and practicability.

Owner:LUNAN PHARMA GROUP CORPORATION

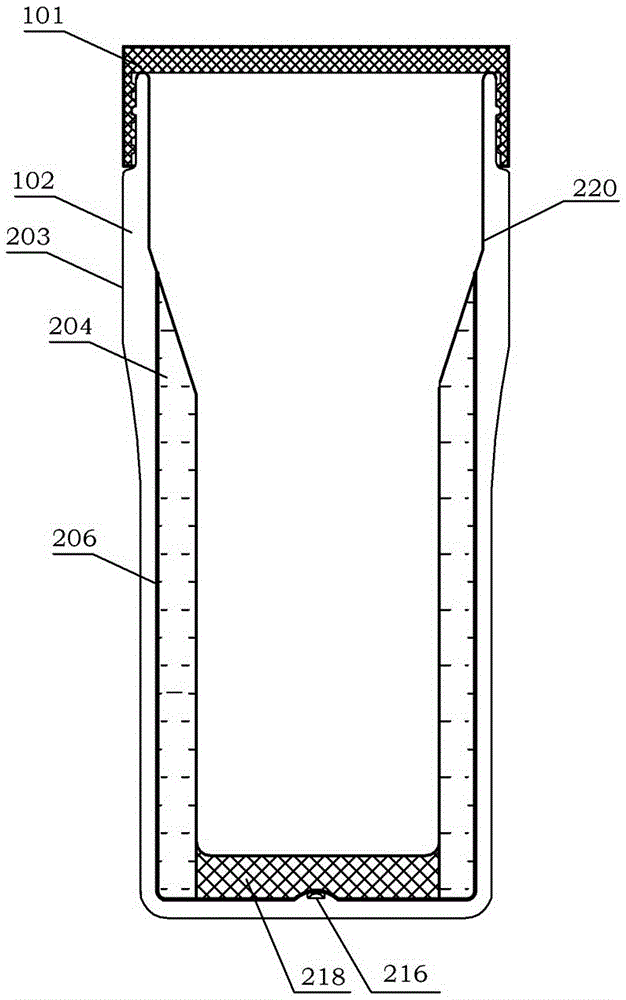

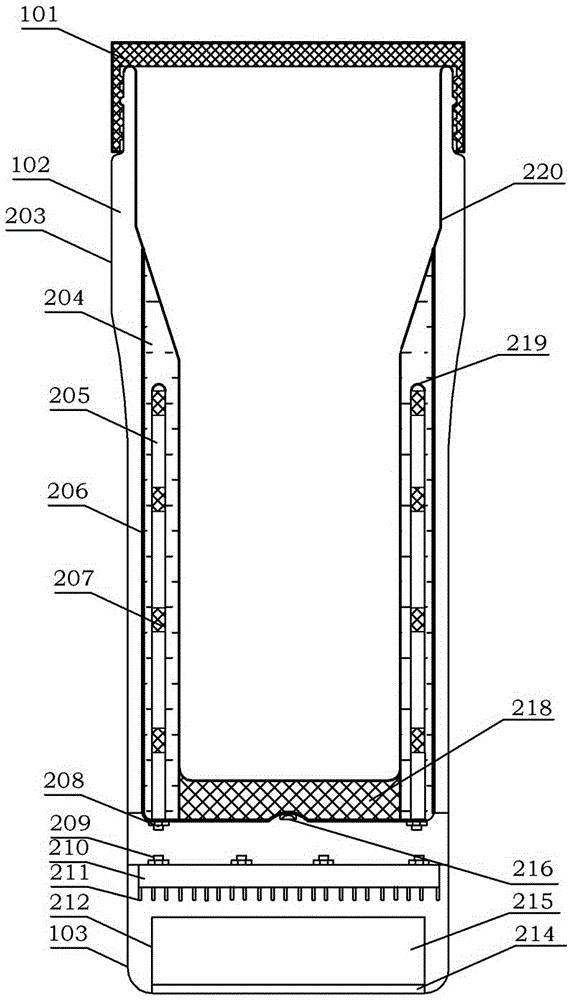

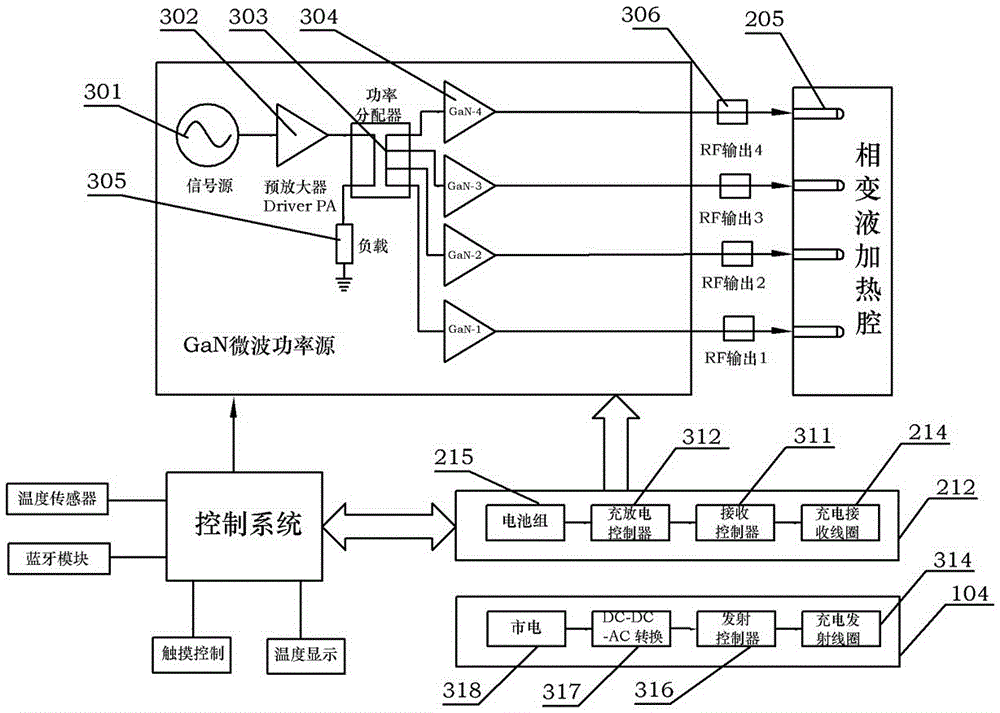

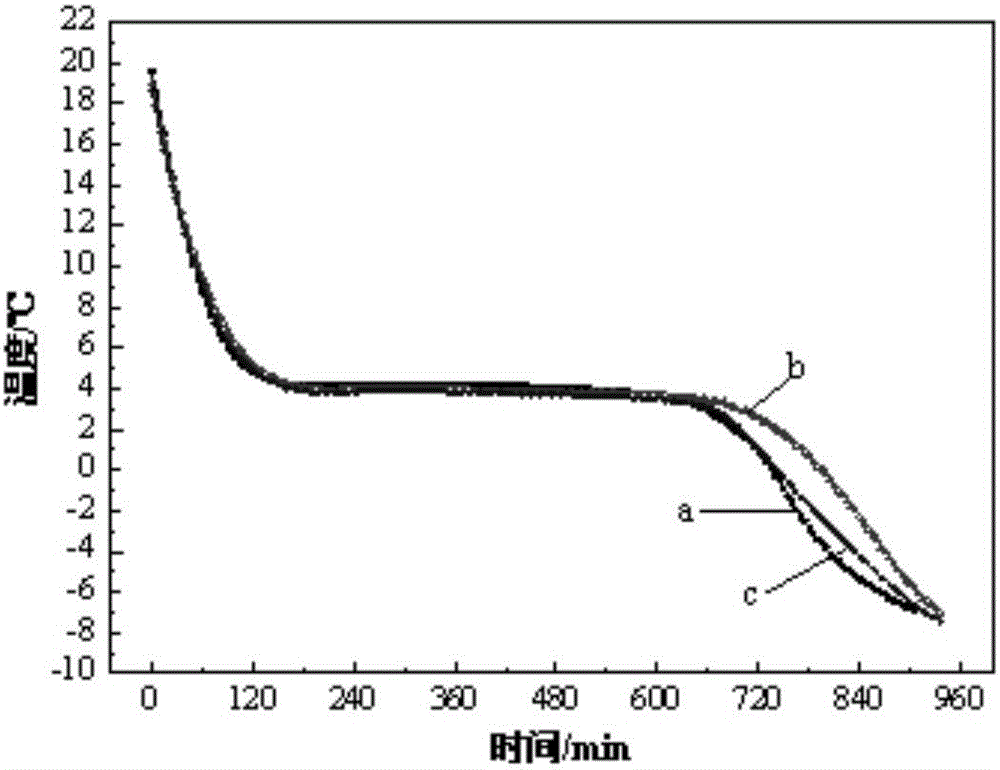

Solid-liquid compound-phase variable-speed cooling constant-temperature cup and microwave heating constant-temperature cup

ActiveCN106361101AEasy to useLarge latent heat of phase changeDwelling equipmentWarming devicesSolid-stateInternal cavity

The invention relates to a daily used vacuum cup, in particular to a compound-phase variable-speed cooling constant-temperature cup. The solid-liquid compound-phase variable-speed cooling constant-temperature cup comprises a cup lid and a cup body, wherein the cup lid is in sealed connection with the cup body, the cup body comprises an inner cup wall, a middle cup wall and an outer cup wall, the internal cavity of the inner cup wall forms a beverage containing cavity, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid, the airtight cavity between the bottom of the inner cup wall and the bottom of the middle cup wall is designed into a phase change alloy rapid-cooling interlayer, and the phase change alloy rapid-cooling interlayer is provided with built-in low-melting-point phase change alloy. In a solid-liquid compound-phase variable-speed cooling microwave heating constant-temperature cup, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid to form a phase change liquid heating cavity, one or more distributed rod-like microwave antennae are arranged in the phase change liquid heating cavity, and a solid-state microwave power source, a power supply part and a control system are arranged in a cup base.

Owner:陈鹏

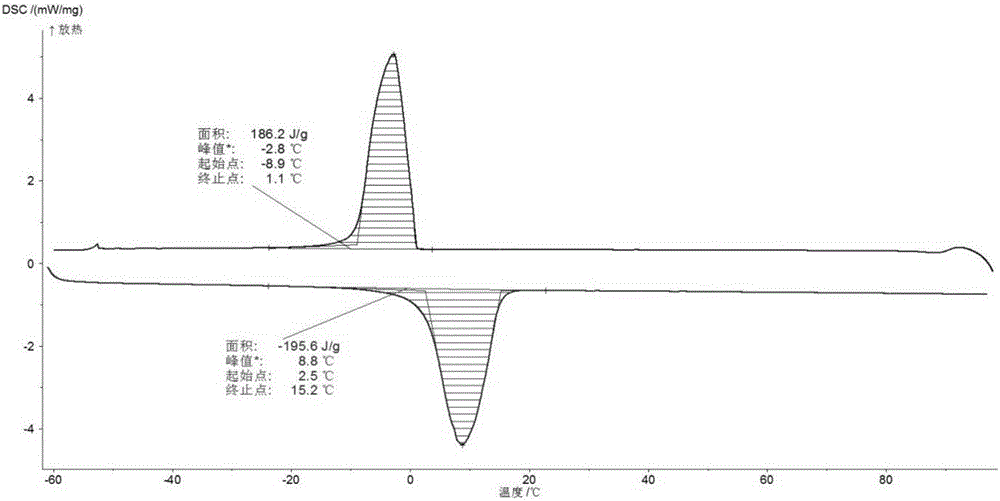

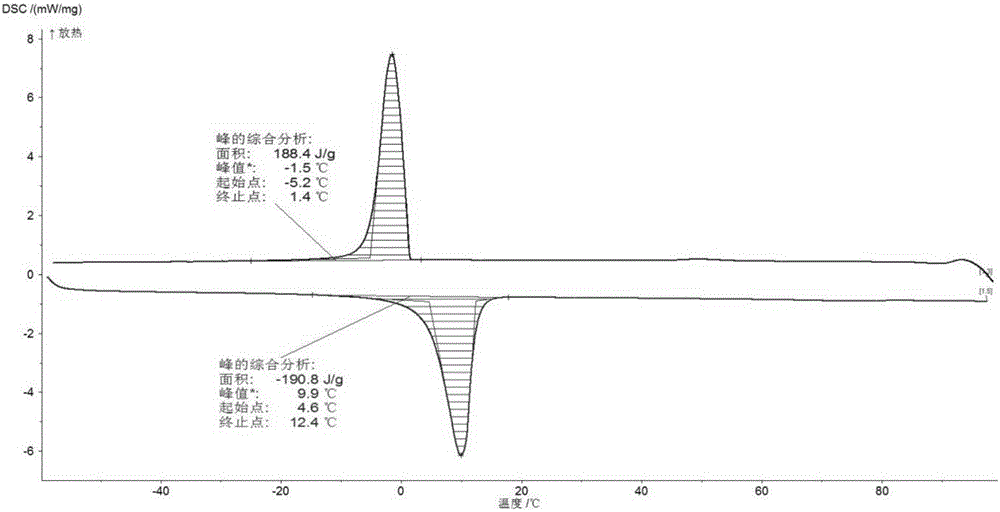

Novel solid phase change cold storage agent for cold chain transportation at temperature of 2-8 DEG C and preparing method and application of novel solid phase change cold storage agent

InactiveCN106520076AStable temperatureAccurate temperature controlHeat-exchange elementsSolid phasesAntioxidant

The invention belongs to the field of cold chain transportation, and particularly relates to a novel solid phase change cold storage agent for cold chain transportation at the temperature of 2-8 DEG C and a preparing method and application of the novel solid phase change cold storage agent. The solid phase change cold storage agent comprises, by mass percent, 84.5%-90.6% of n-tetradecane, 8.8%-14.9% of thermoplastic elastomer SEBS and 0.6% of antioxidant. The solid phase change cold storage agent is transparent gel and is in a solid state before and after phase change, and the problems of inorganic cold storage agent supercooling, phase separation and liquid phase leakage do not need to be worried. The phase change temperature of the solid phase change cold storage agent ranges from 4 DEG C to 5 DEG C, and the phase change latent heat ranges from 170 J / g to 200 J / g. The solid phase change cold storage agent has the beneficial effects that temperature control is accurate, and the temperature can be kept stable for a long time; the cold storage agent serves as a cold source, the stable and accurate temperature environment of 4-5 DEG C can be provided for biological medicine cold chain transportation, and the cold storage agent is extremely suitable for meeting the requirement for cold chain transportation of 2-8 DEG C in the biological medicine field.

Owner:SOLEE WUHAN SCI & TECH +1

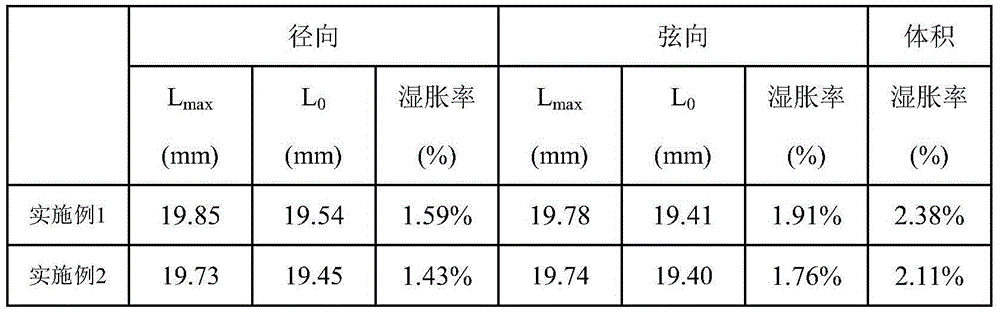

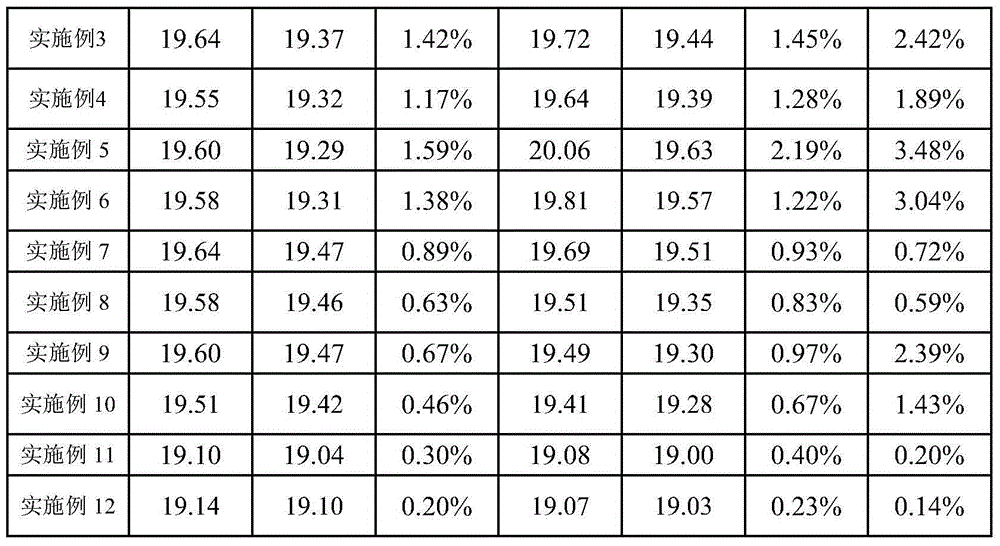

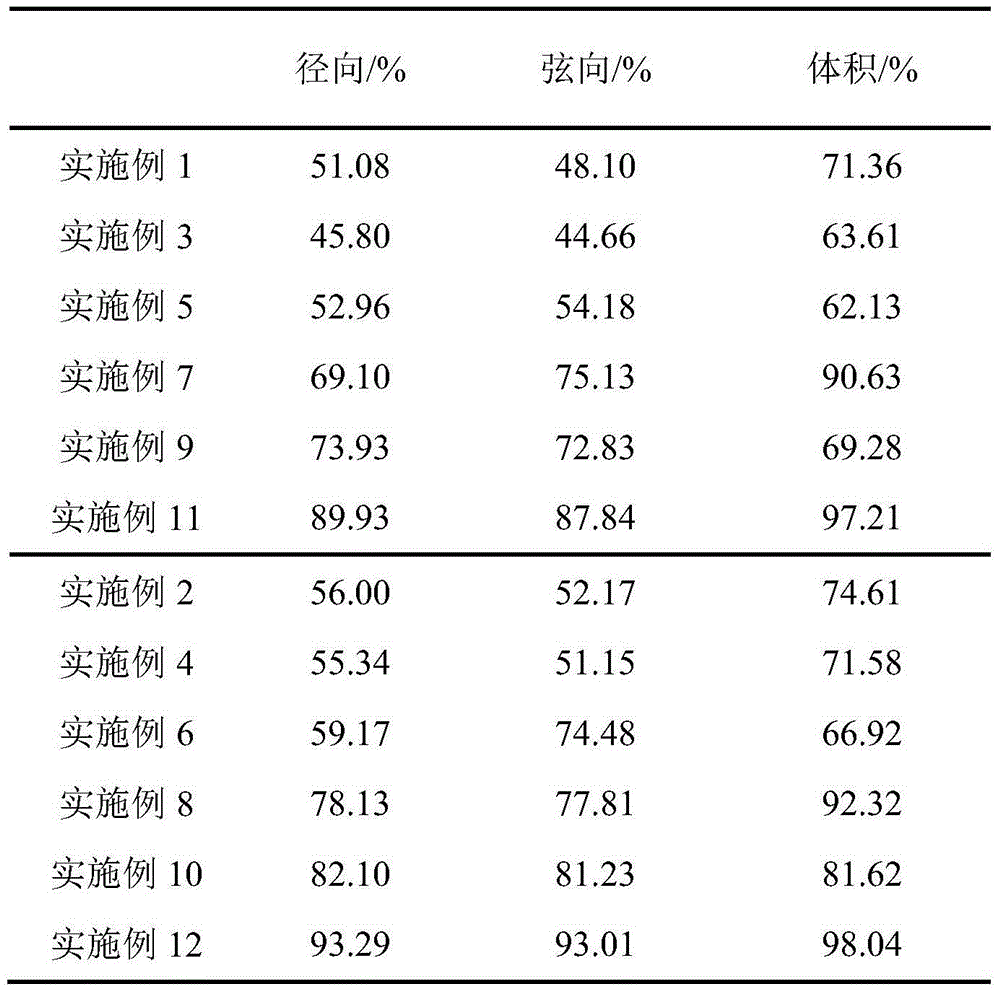

Method for improving dimensional stabilization of wood

InactiveCN105082282AGood dimensional stabilityEven contactWood impregnation detailsWaxProcess conditions

The invention discloses a method for improving the dimensional stabilization of wood. The method comprises the steps of soaking wood in petroleum wax, carrying out soaking process on the wood and making wood absorbing petroleum wax to obtain wood with good dimensional stabilization. According to the method, wax injection process is carried out on the wood in the normal pressure condition, and the petroleum wax is injected into the wood on the premise without damaging performance of the wood. Thus, redundant moisture in the wood can be drained out. Meanwhile, pipe holes of the wood and gaps between cells can be sealed, and the purpose of improving the dimensional stabilization of the wood is achieved. Furthermore, the method is simple in equipment, convenient to operate, controllable in processing condition and suitable for processing various kinds of wood.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com