Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

A semi-solid slurry, electromagnetic stirring technology, applied in stirring devices, lighting and heating equipment, furnaces, etc., can solve the problems of large quantitative error and unstable flow, and achieve convenient temperature control, small vibration power, and small error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

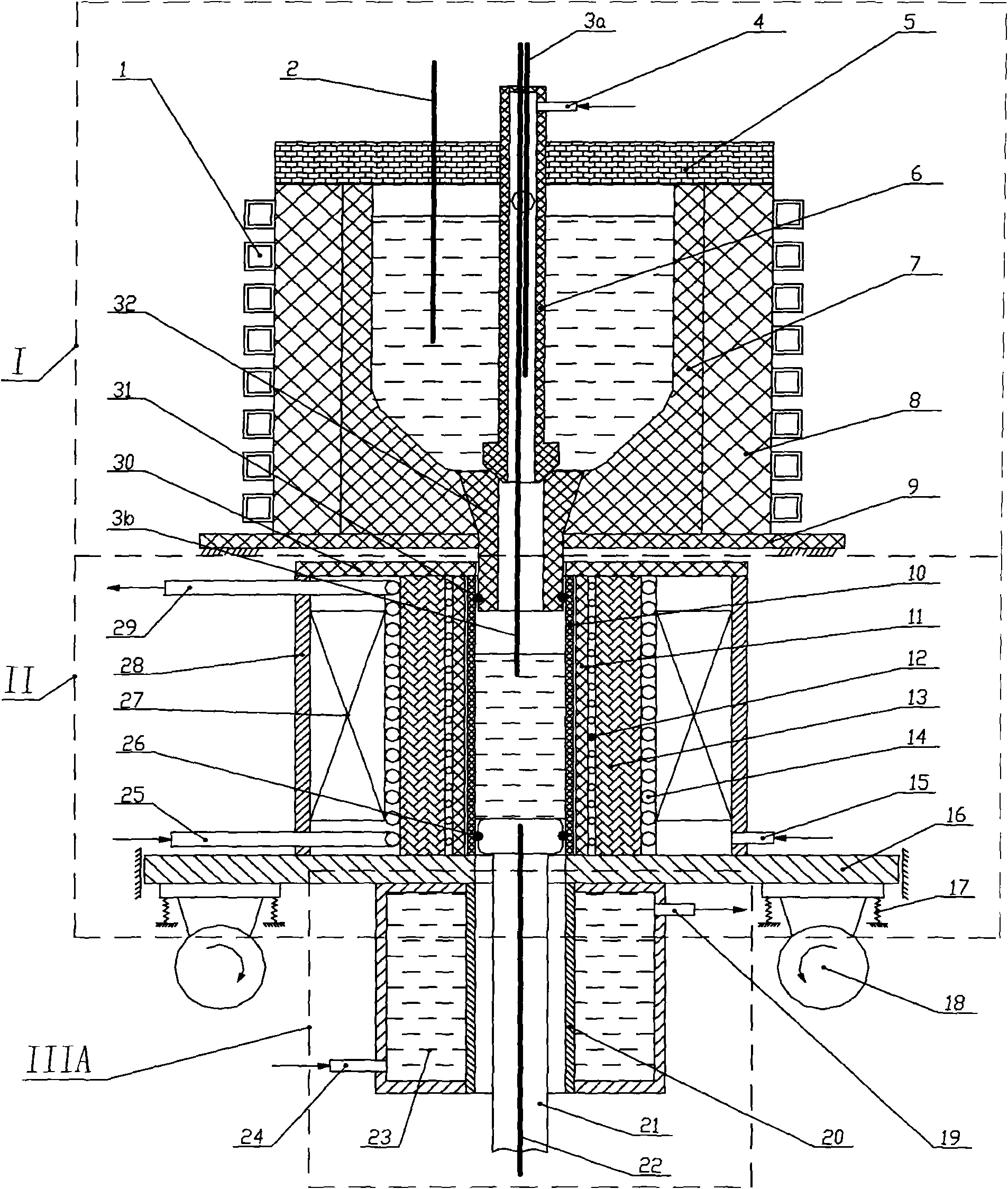

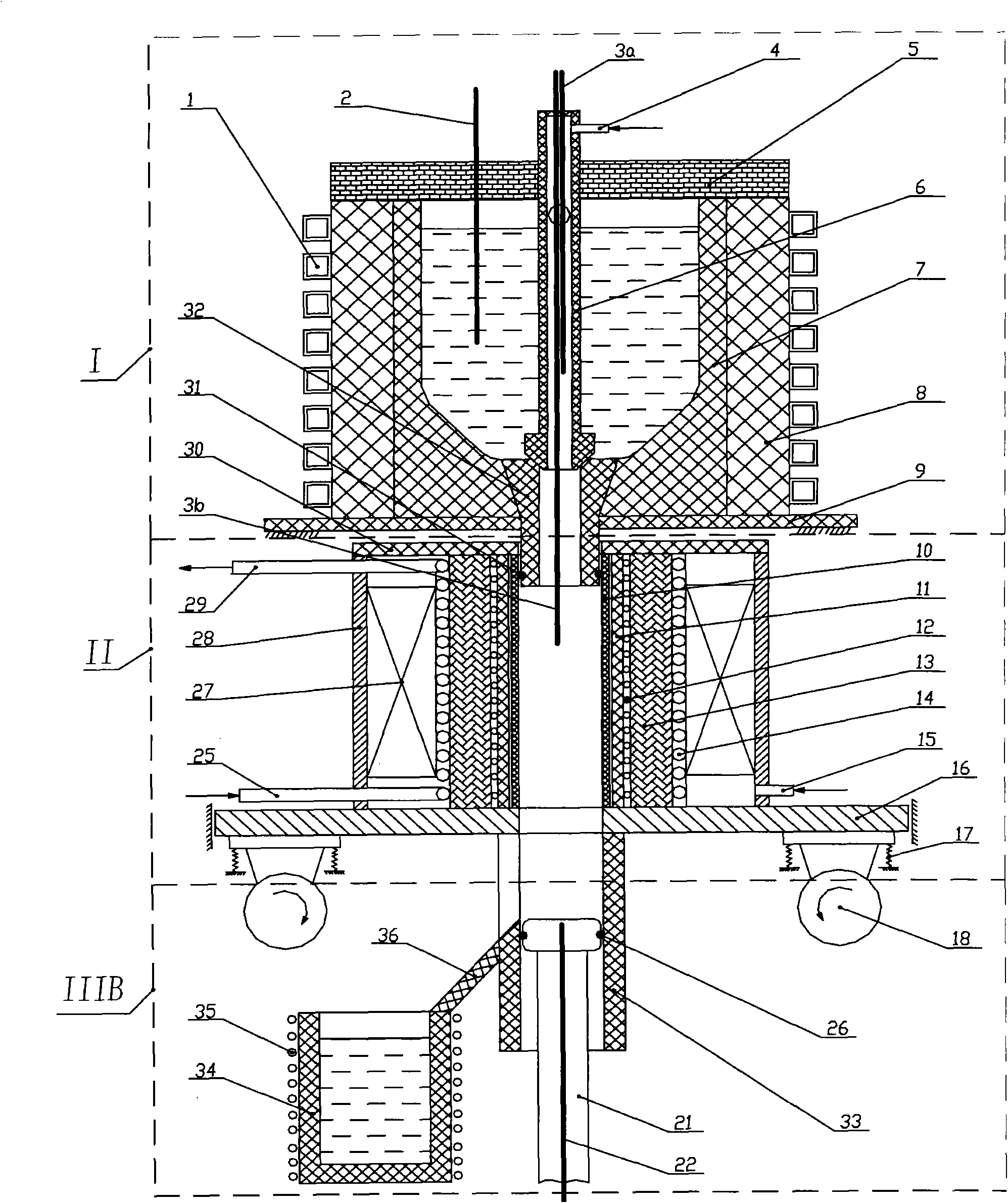

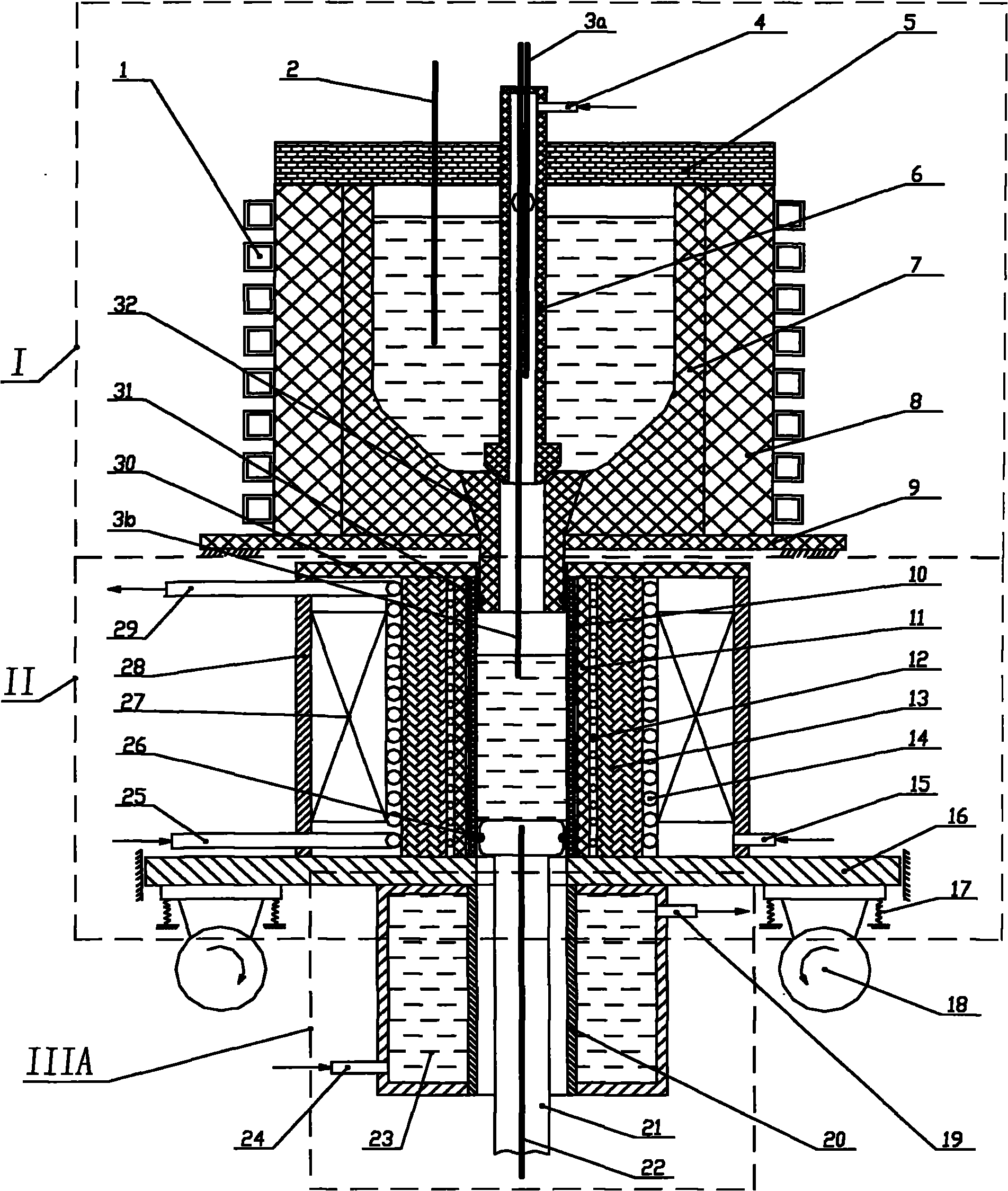

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] Such as figure 1 , figure 2As shown, an electromagnetic stirring and vibration composite device for ferrous metal semi-solid slurry preparation is composed of three parts: melting furnace I, stirring chamber II, crystallizer IIIA or rheological conveyor IIIB, and melting furnace I is installed in the stirring chamber The upper part of II, but the two are separated independently. The purpose is to make only the stirring chamber II receive the exciting force during mechanical vibration, but the melting furnace I does not vibrate, so as to improve the working stability and life of the parts of the melting furnace I. The melting furnace The bottom of the melting crucible substrate 32 of I extends into the stirring crucible 10 of the stirring chamber II. When used for thixotropic slurry, the crystallizer IIIA is installed in the lower part of the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com