Patents

Literature

34results about How to "High efficiency, energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

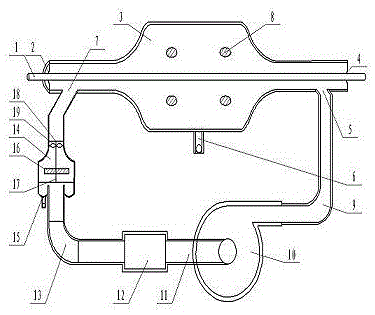

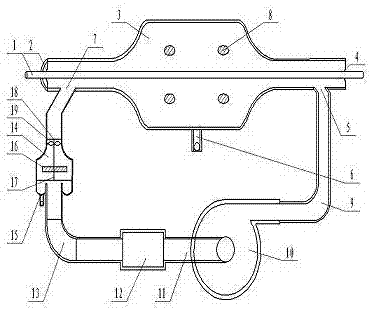

Efficient energy saving electro heating multipurpose cooker and new method of accurate temperature controlling and healthy cooking

InactiveCN101669761APlug the drainSolve technical problems that cannot withstand high temperaturesCooking-vessel lids/coversCooking utensils shields/jacketsElectricityAutomatic control

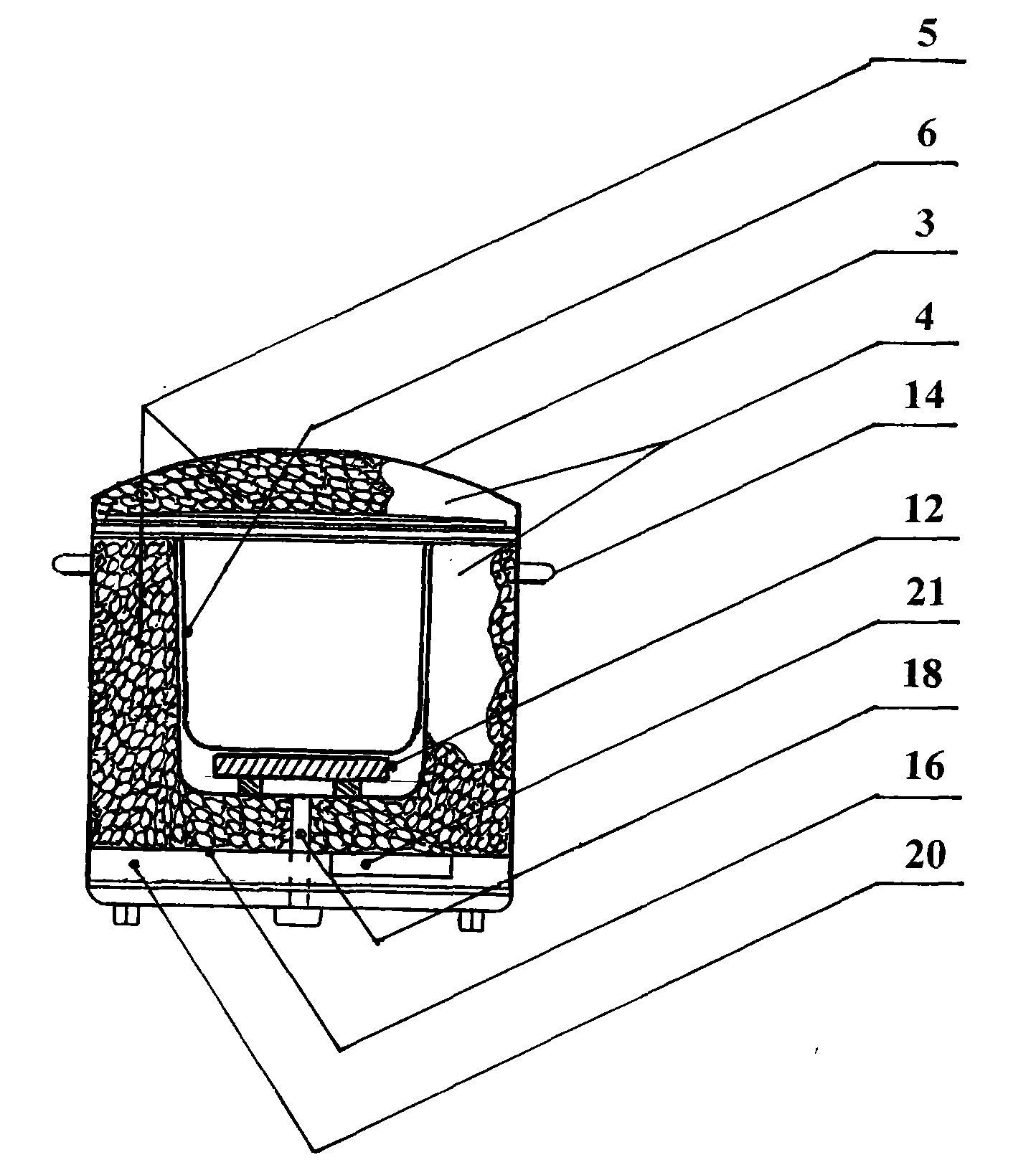

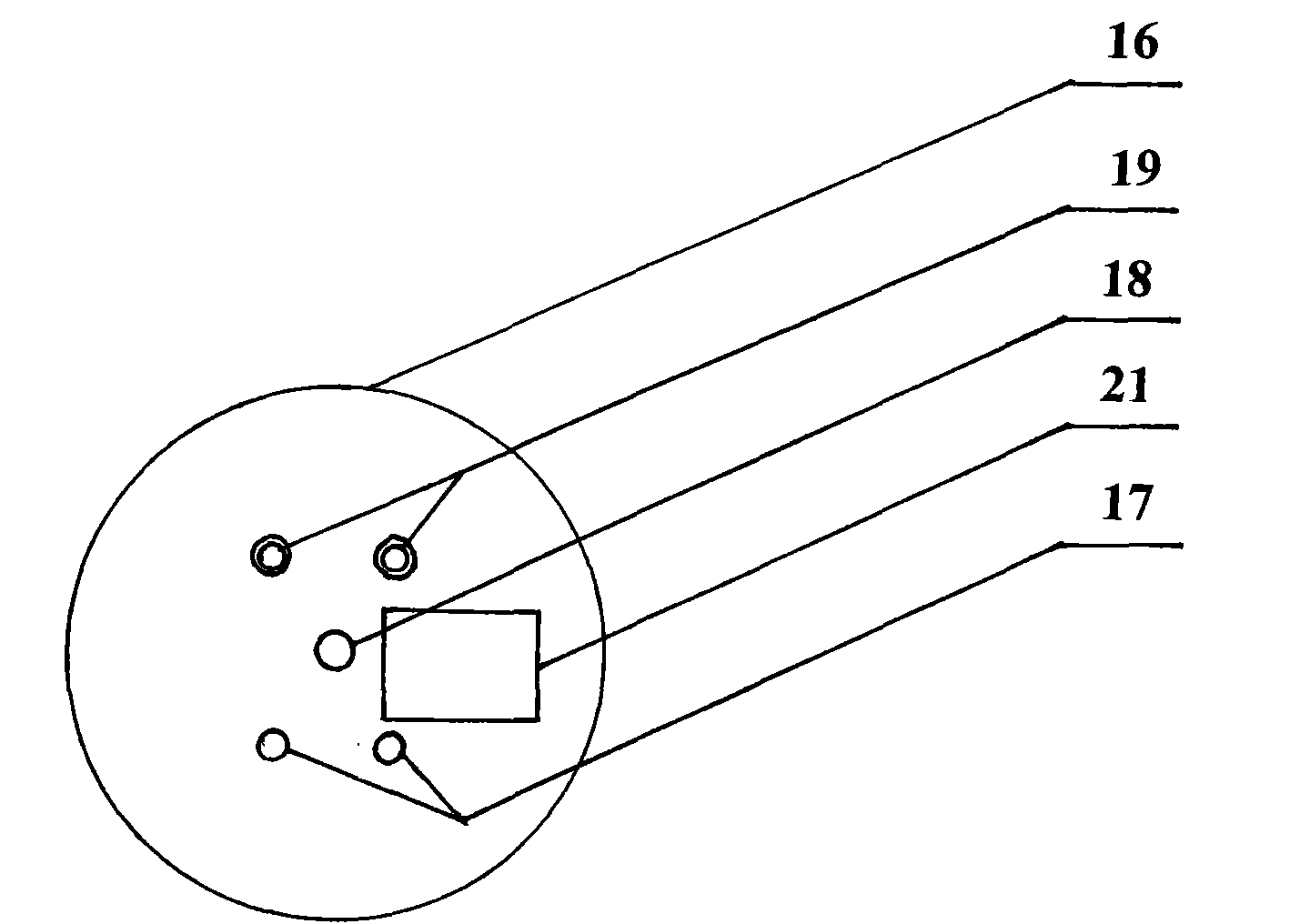

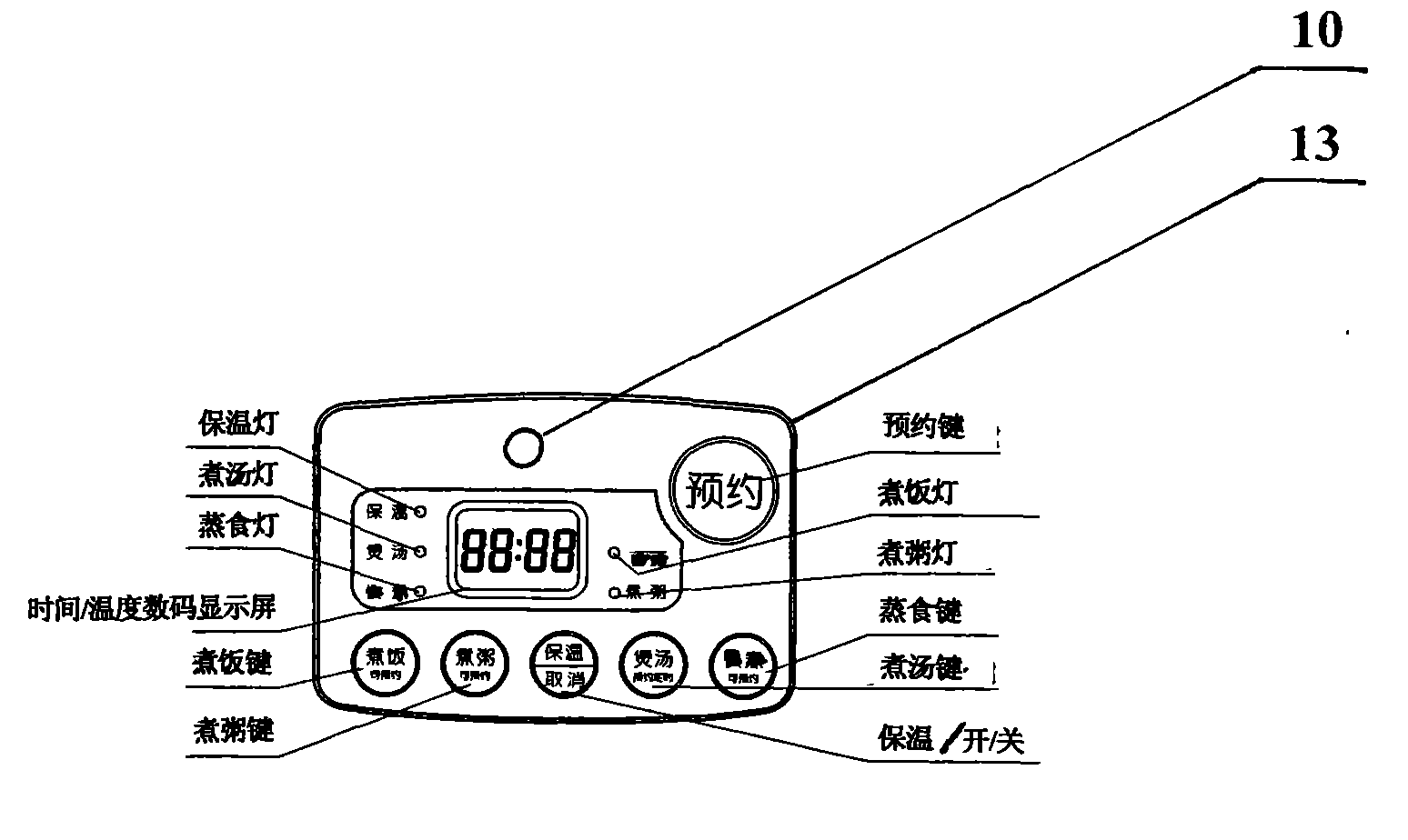

The invention discloses an efficient energy saving electro heating multipurpose cooker utilizing a new method of accurate temperature controlling and healthy cooking. The technical scheme of the invention is as follows: the outside surface of the cooker body is provided with an ambient temperature sensor; the base of the cooker is provided with an inner pot temperature sensor; the cooker body, thecooker cover and the cooker base are all set to be closed efficient heat insulation interlayers; the closed heat insulation interlayer on the cooker base is arranged between the casing of the cookerbase and the electro heating device; a hallow cavity is arranged between the casing of the cooker base and the closed heat insulation interlayer; and the purposes of energy saving, discharge reducingand healthy cooking can be realized by setting standard control values such as ambient temperature or temperature drop, cooking / steaming temperature and time and the like by an automatic control device and by comparing the ambient real-time temperature or temperature drop with the inner pot real-time temperature to control the power on and power off of the electro heating device. The efficient energy saving electro heating multipurpose cooker can be used for cooking rice, cooking congee, cooking soups and steaming food; compared with various electro rice / congee / soup cooker in the prior art, the invention can save electricity by 30%-50% and can be widely used in families, dining halls and catering enterprises in cities and towns.

Owner:郭卫康

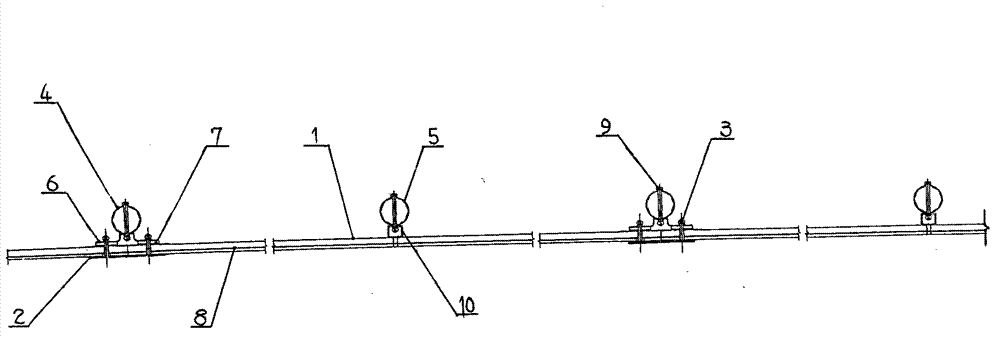

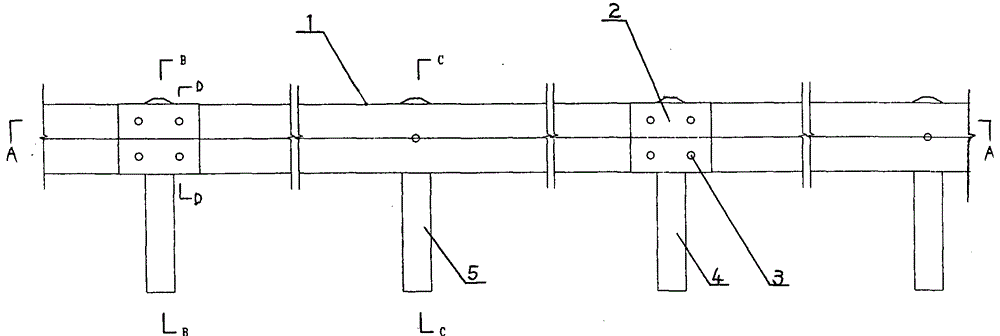

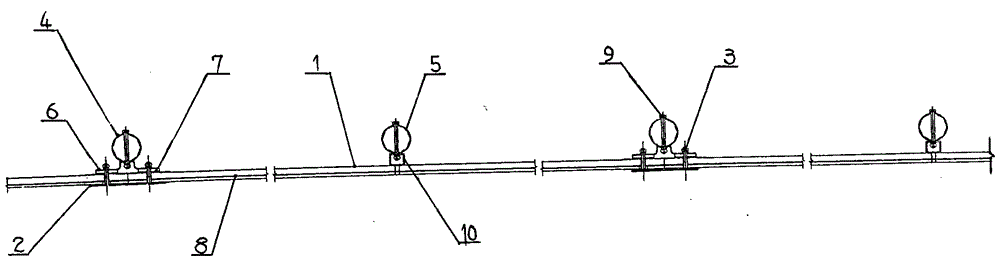

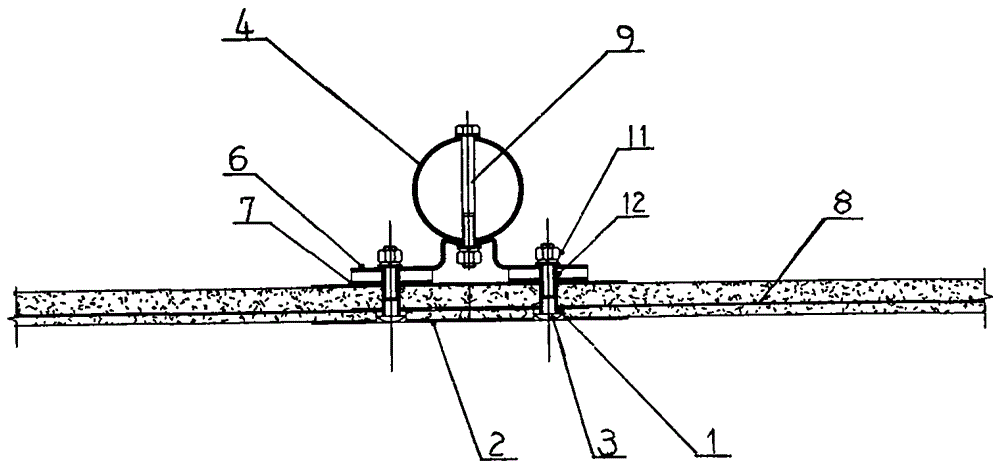

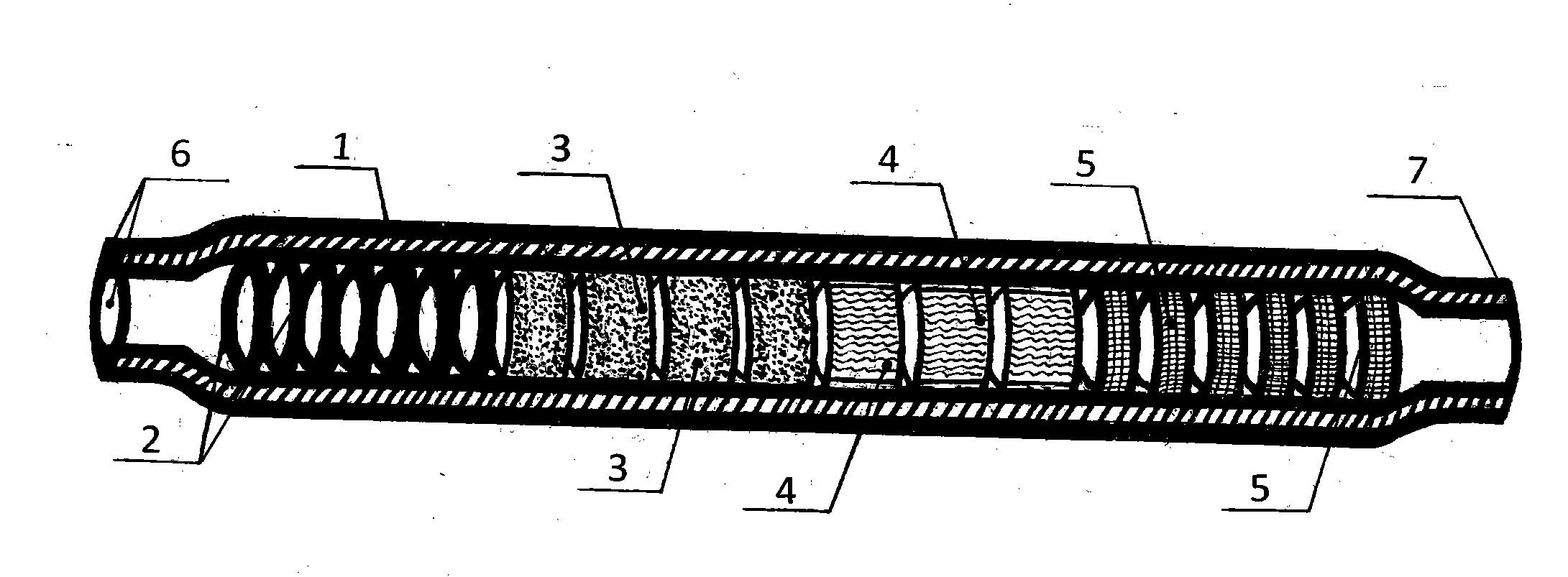

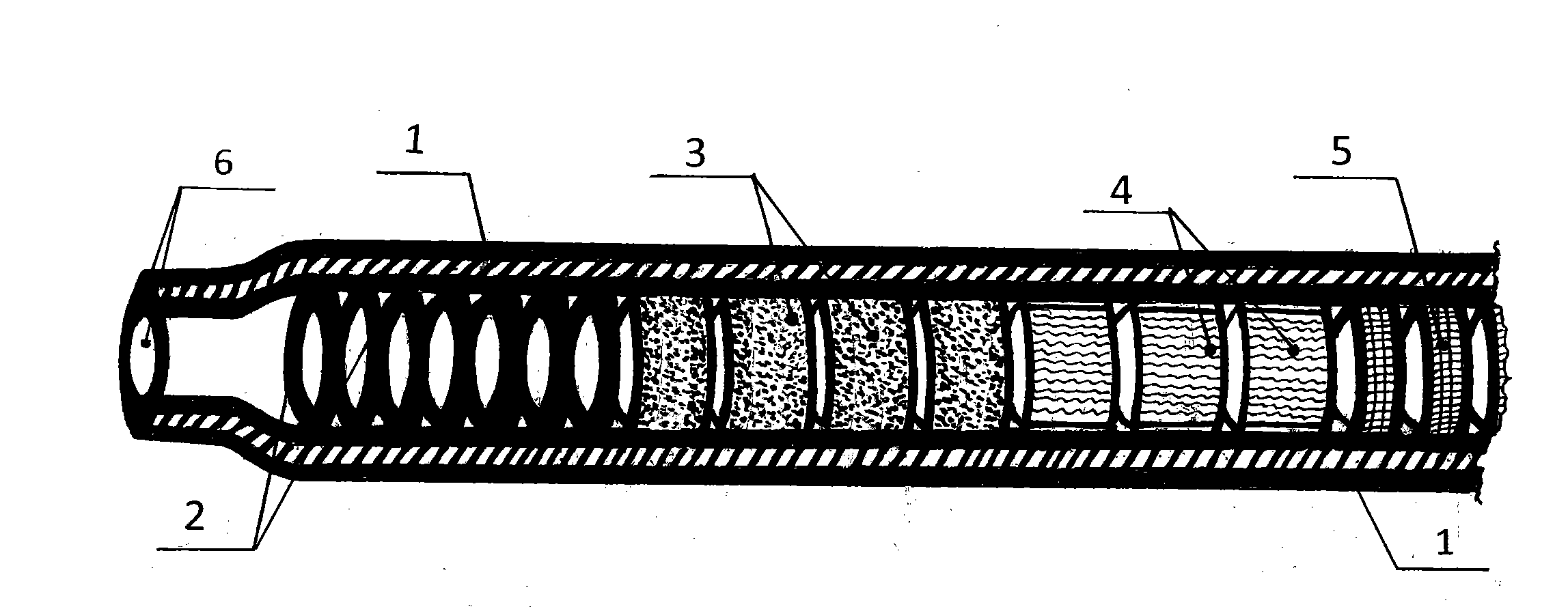

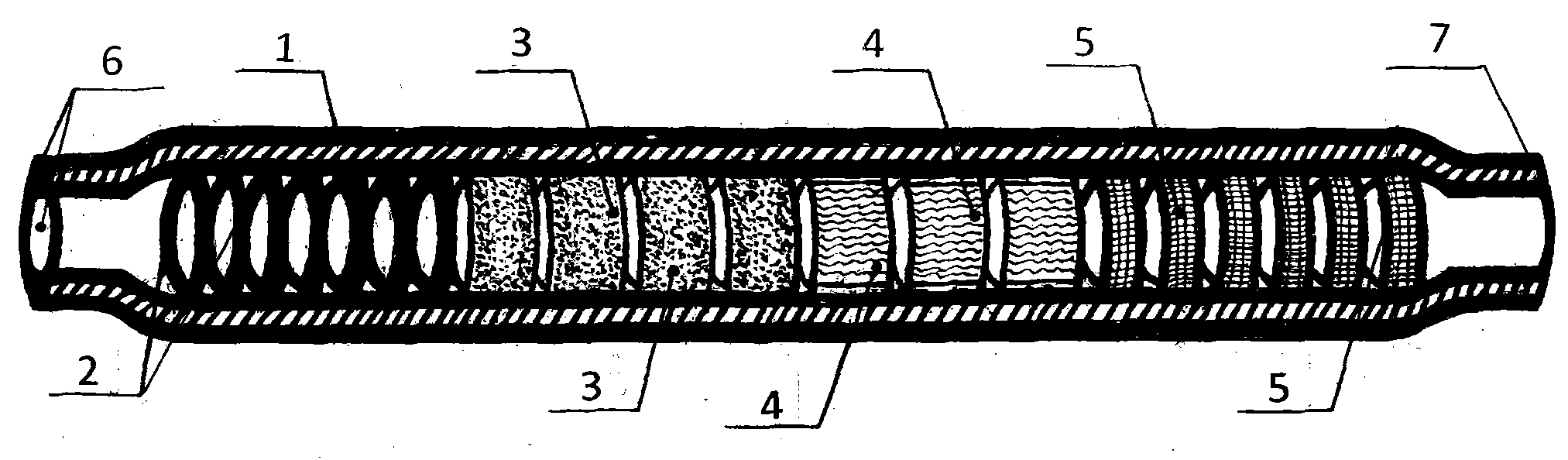

Buffering anti-collision guardrail on expressway

ActiveCN102900036AHigh strengthImprove toughnessRoadway safety arrangementsWave shapeAutomobile Accident

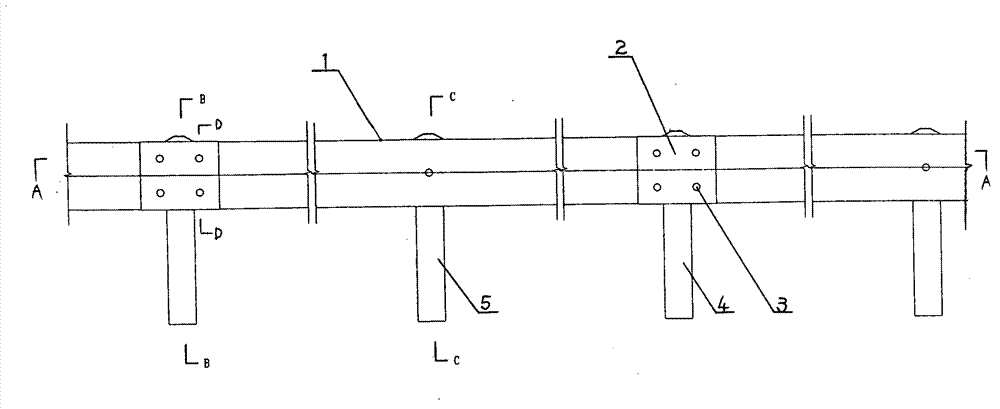

The invention discloses a buffering anti-collision guardrail on an expressway. The guardrail comprises a guardrail plate, a connection vertical column, a connection buffering tray, a reinforcing vertical column, a reinforcing buffering tray and a built-in steel plate, wherein the guardrail plate consists of an outer layer pipe plate, an inner layer pipe plate body, a steel plate clamping groove pipe body and a supporting buffer column; three layers of buffering structures are formed in the guardrail, the first layer is a three-layer pressure-reducing and buffering honeycomb, the second layer is a wave-shaped built-in steel plate manufactured in the pressure-reducing and buffering honeycomb, and the third layer is a connection buffering tray or a reinforcing buffering tray arranged between the guardrail and the vertical columns. The strength, toughness and bounciness of the guardrail are enhanced; the guard rail is connected with the vertical column elastically, so that the buffering anti-collision guardrail has high buffering capacity, bounciness, elasticity and impact resistance, phenomena that automobile accidents occur, and loss is caused by the automobile accidents can be effectively avoided; and the guardrail has the advantages of long service life and low using cost.

Owner:卞乐平

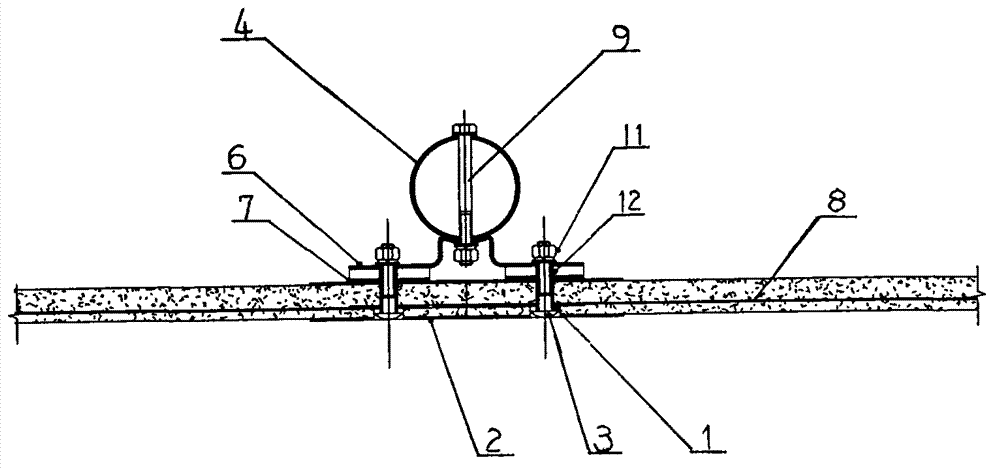

Real-time traffic flow based streetlamp energy-saving control system

InactiveCN105682311AAvoid wastingEffective intelligent energy-saving controlElectric light circuit arrangementEnergy saving control techniquesIlluminanceLight equipment

The invention provides a real-time traffic flow based streetlamp energy-saving control system. The streetlamp energy-saving control system comprises intelligent sensing probes and single-lamp controllers, wherein each intelligent sensing probe is mounted on a streetlamp pole of a road for vehicles or pedestrians to pass, used for sensing the traffic flow information of vehicles or pedestrians and the illumination intensity information of the road, and transmitting the sensed information to the corresponding single-lamp controllers; each single-lamp controller is mounted on a corresponding streetlamp separately used as the control equipment for the single streetlamp for receiving the traffic flow information and the illumination intensity information so as to control the current streetlamp to be turned on / off or to be dimmed; or the single-lamp controller transmits a control instruction to the single-lamp controllers on one or more streetlamps following the current streetlamp to request synchronous control for the one or more streetlamps following the current streetlamp so as to enable the streetlamps to be turned on / off or to be dimmed. According to the real-time traffic flow based streetlamp energy-saving control system, more effective intelligent energy-saving control can be realized according to real-time illuminance requirement; and the illuminance energy can be saved under the premise of not affecting the illuminance requirement and not affecting the illuminance equipment light source.

Owner:SHANGHAI WULING SHENGTONG INFORMATION TECH CO LTD

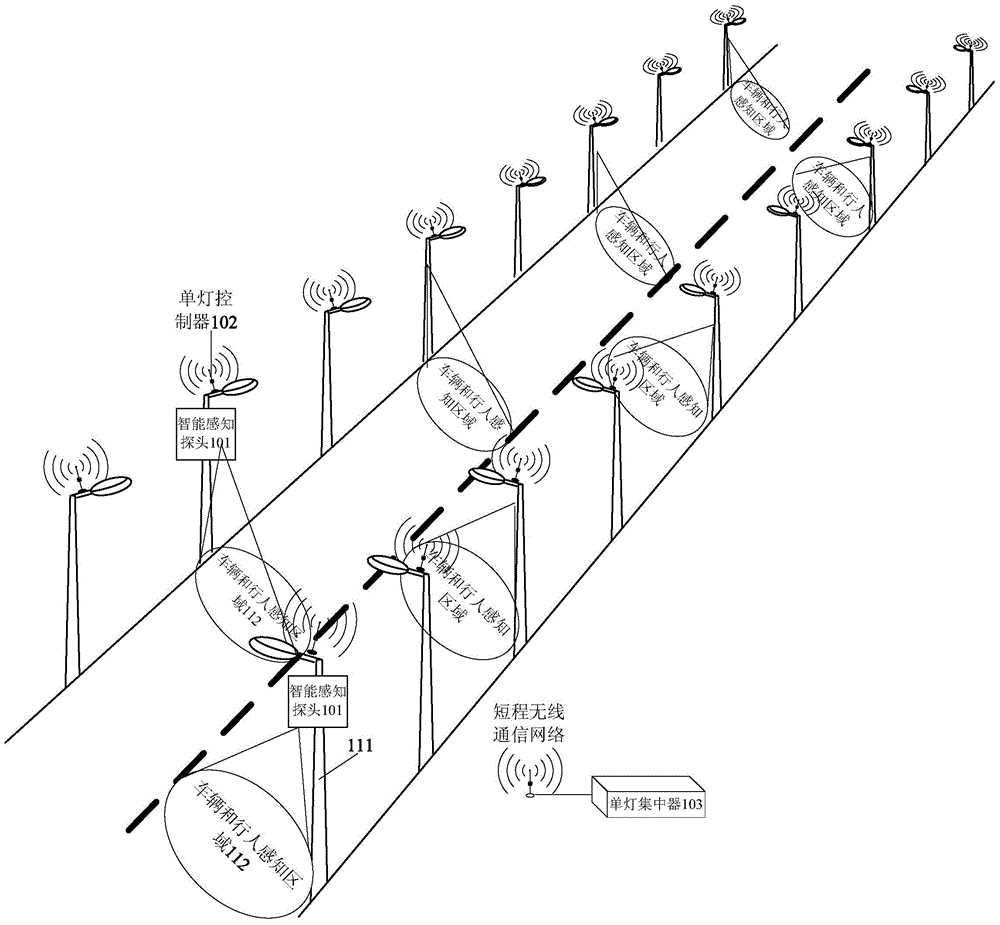

Copper coated steel wire hot air circulation drying system

ActiveCN105135862AImprove heat utilizationImprove drying qualityDrying gas arrangementsPretreated surfacesFiberTemperature control

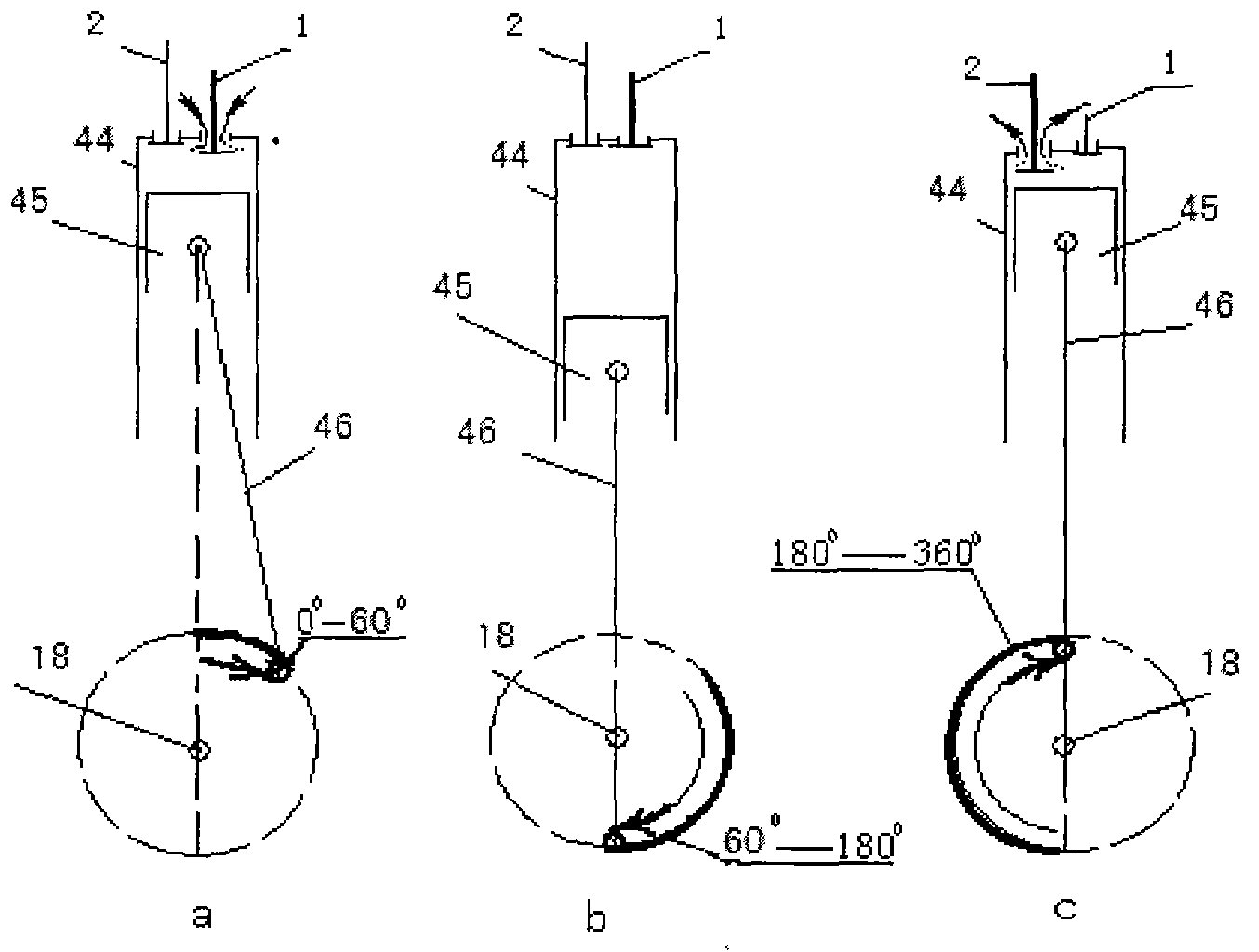

The invention discloses a copper coated steel wire hot air circulation drying system. After being heated and pressurized through an automatic temperature control hot draught fan, circulation drying air is led into a cyclone airflow drying cylinder inner cavity though a hot air duct and a tangent spiral air inlet and is exhausted through an inclined tee joint air outlet in the wire inlet ends, saturated steam formed through evaporation of a water film on the surface of a wire is taken away, and after water mist is adsorbed through a rotating filter screen device and a drying pipe adsorbs water again, the circulating drying air is fed to the automatic temperature control hot draught fan through an air returning duct to be heated and pressurized cyclically. A heat-preserving layer is arranged outside a cyclone airflow drying cylinder, and the inner cavity is provided with a turbulent flow drying segment. A low-pressure evaporation and separation segment is further provided with a drain valve. Moisture evaporation windows are distributed on the cylinder wall. A water film drive-way segment is arranged on the surface of the metal wire. According to the rotating adsorbing net device, a filter screen disk on a rotating shaft is driven by driving fan blades to rotate at high speed, and water mist is thrown to a reducing pipe shell in a centrifuging mode after being adsorbed by the filter screen disk. The rotating filter screen disk is composed of a plurality of layers of screen nets formed by interweaving fiber wires or metal and plastic monofilaments. A drying pipe is a heat-resistant and high-air-resistance pipe.

Owner:长春航天安可工业有限公司

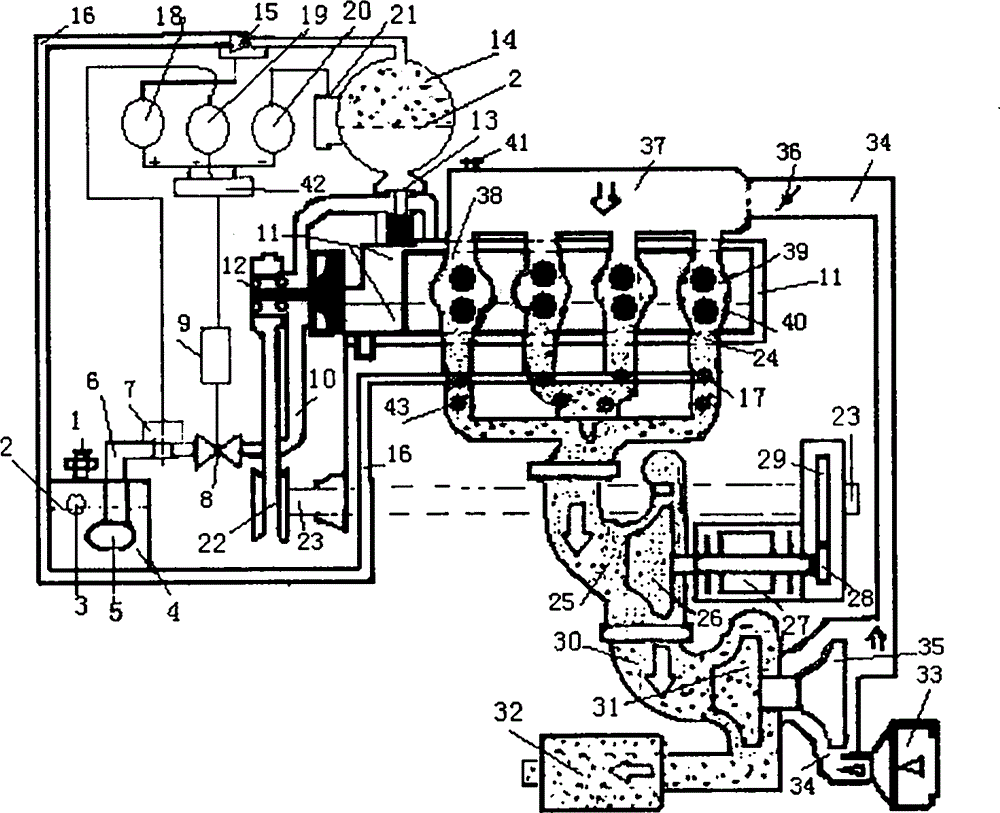

Oil water fuel composite exhaust gas powered two-stroke engine

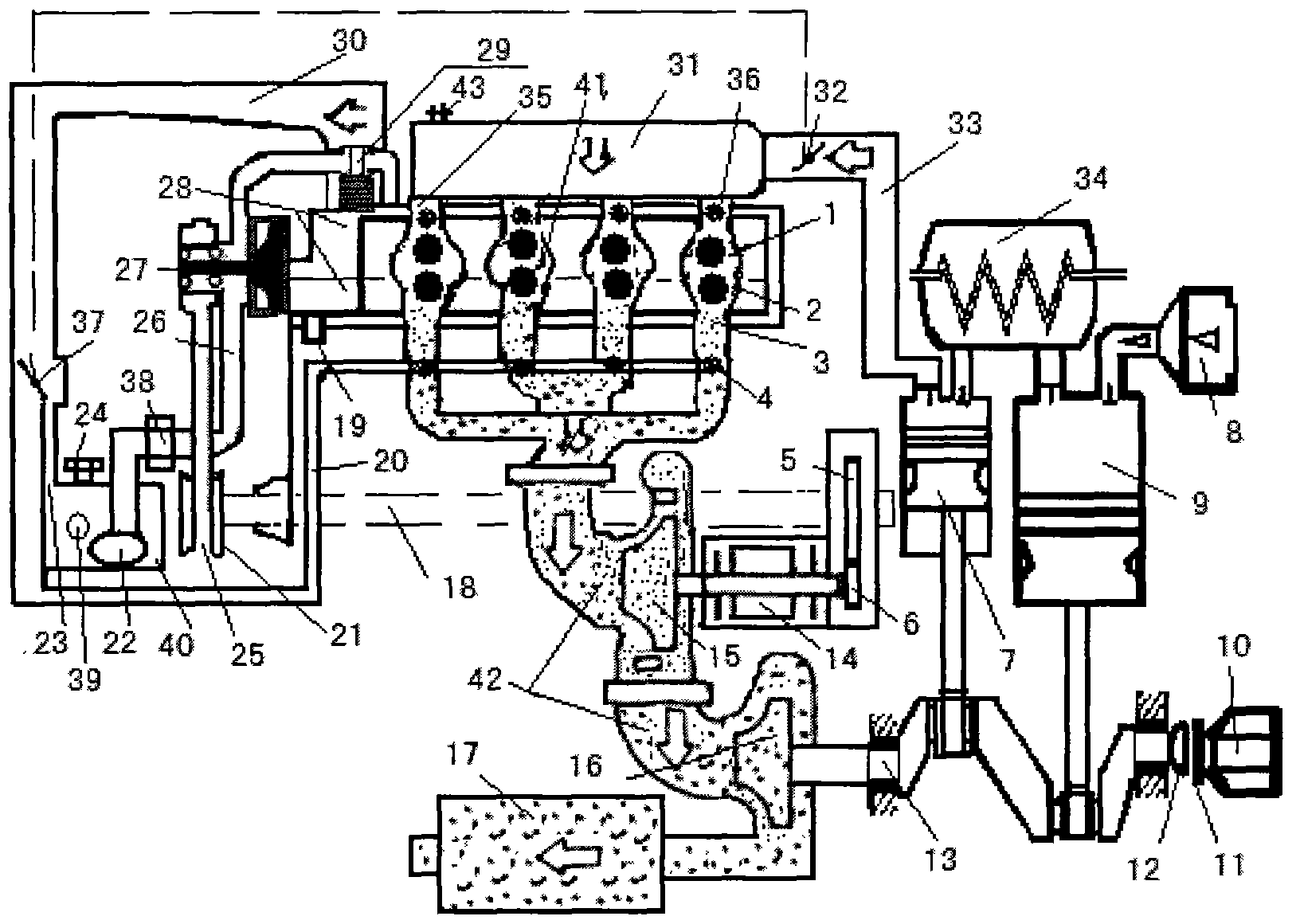

InactiveCN103266950AIncreased number of ignitionsIncrease the number of injectionsElectrical controlCoolant flow controlExhaust valveFour-stroke engine

An oil water fuel composite exhaust gas powered two-stroke engine aims at solving the problems of single fuel utilization limitation, energy losing in three interruption processes namely air exhausting, air suction and compaction, in a cooling system and of exhaust gas which is discharged outside the engine and the like of a piston type four-stroke engine in the prior art. According to the oil water fuel composite exhaust gas powered two-stroke engine, multiple advantages of technologies of an exhaust gas power turbine device, an exhaust gas double-level piston supercharging device, an electric supercharging device and the like are utilized, the number of intake and exhaust valves are increased, a cooling water tank and a cooling fan of an original engine are removed, a thermal water tank, a throttle valve water pressure regulator, a water spraying nozzle and an exhaust gas turbine combustion chamber with water as combustion fuel are increased, and expanding, working and exhaust emission are performed on an designed piston when an one third position of an upper dead center is ignited. Compared with the piston type four-stroke engine, the oil water fuel composite exhaust gas powered two-stroke engine has the advantages of being three times higher in power than the piston type four-stroke engine, large in supercharging combustion ratio, super low in exhaust gas emission, efficient in energy conservation and emission reduction and powerful in power.

Owner:刘红旗

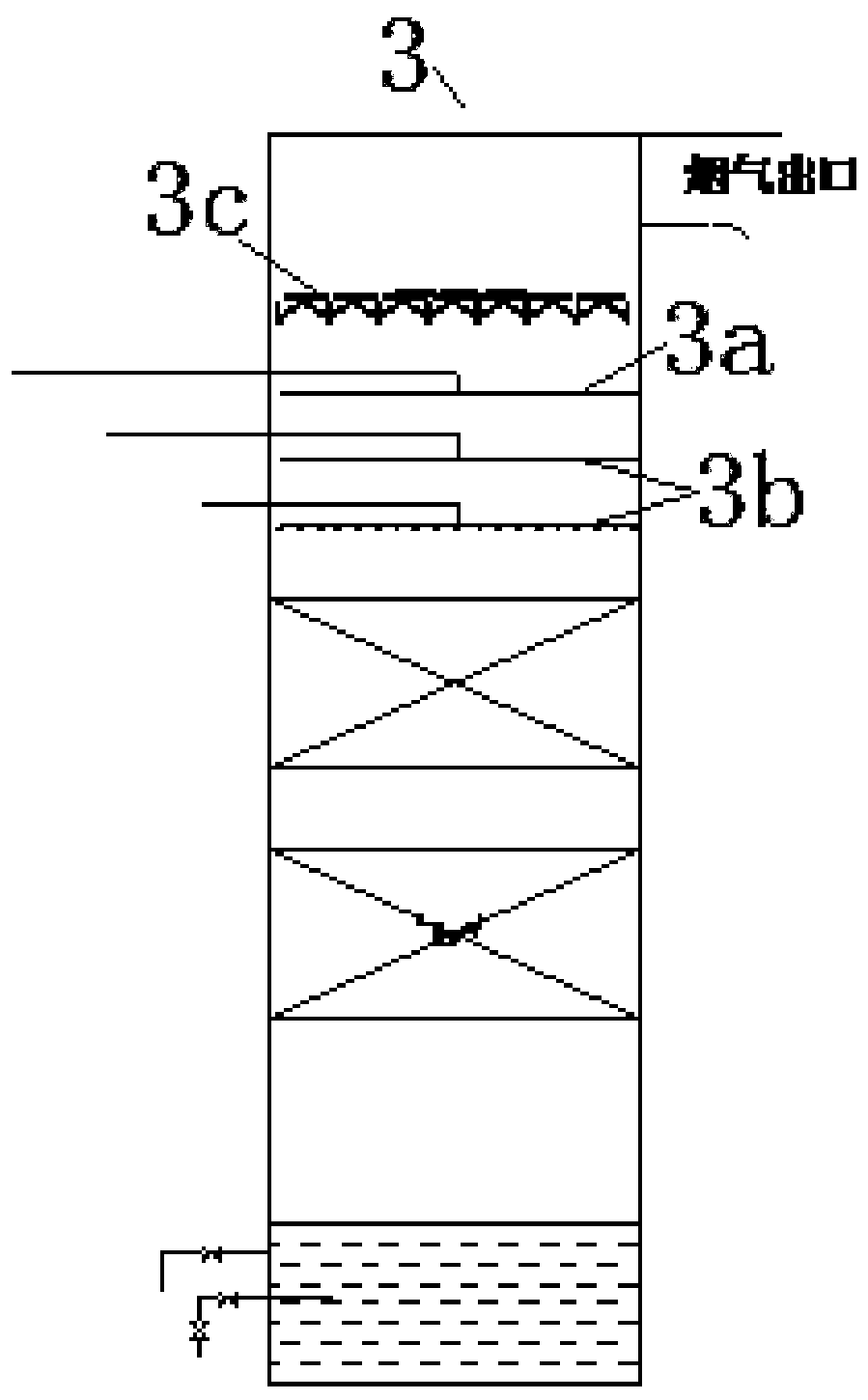

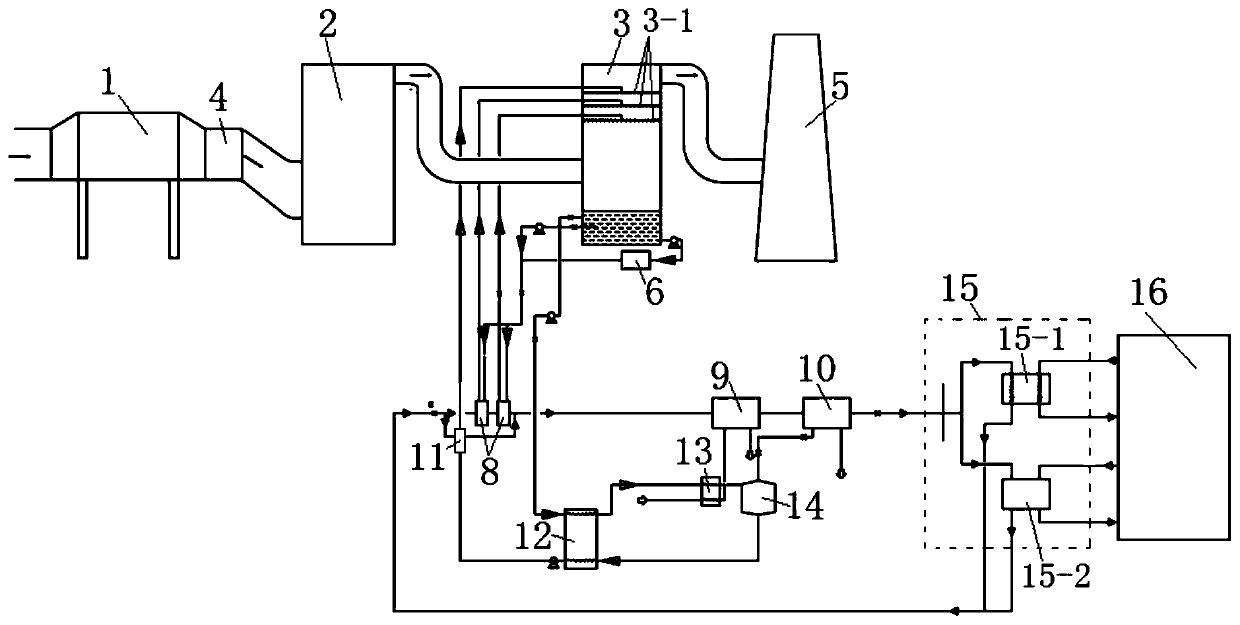

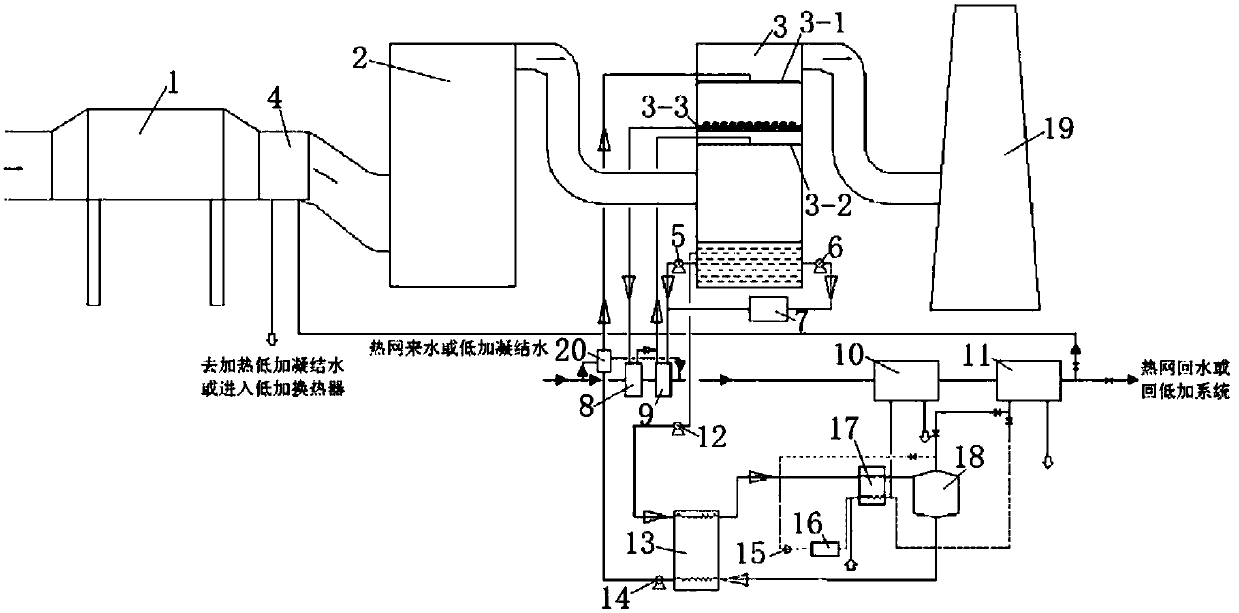

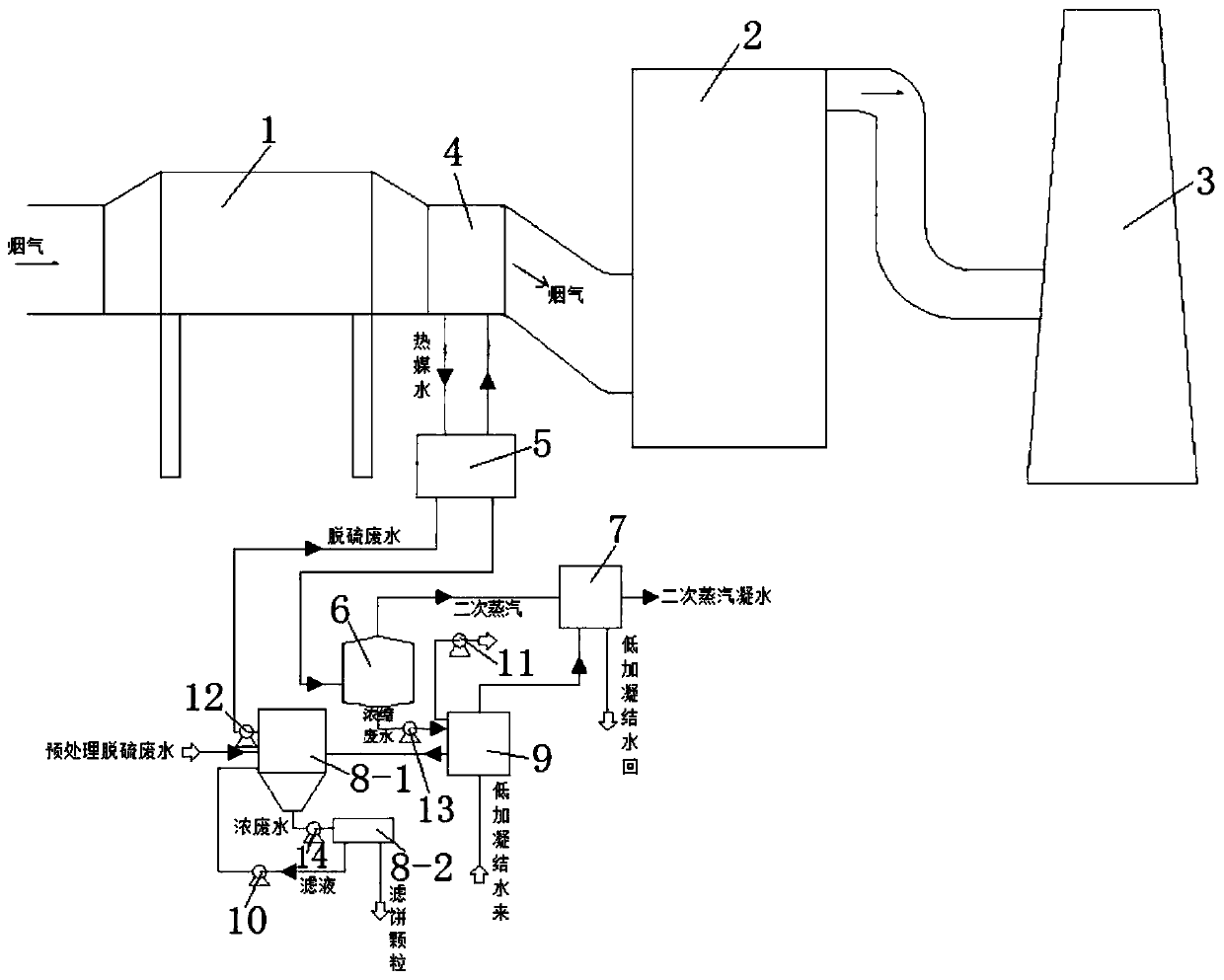

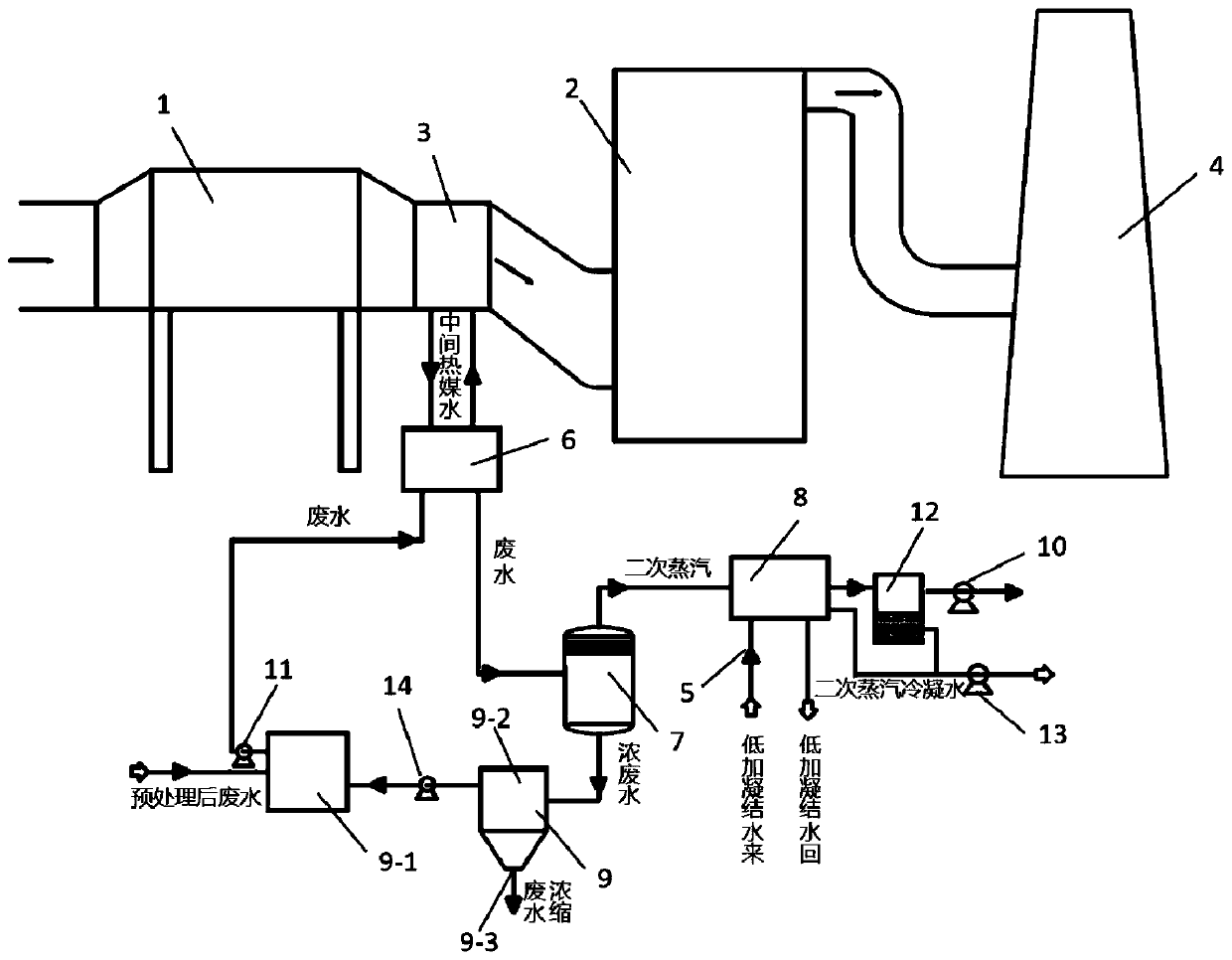

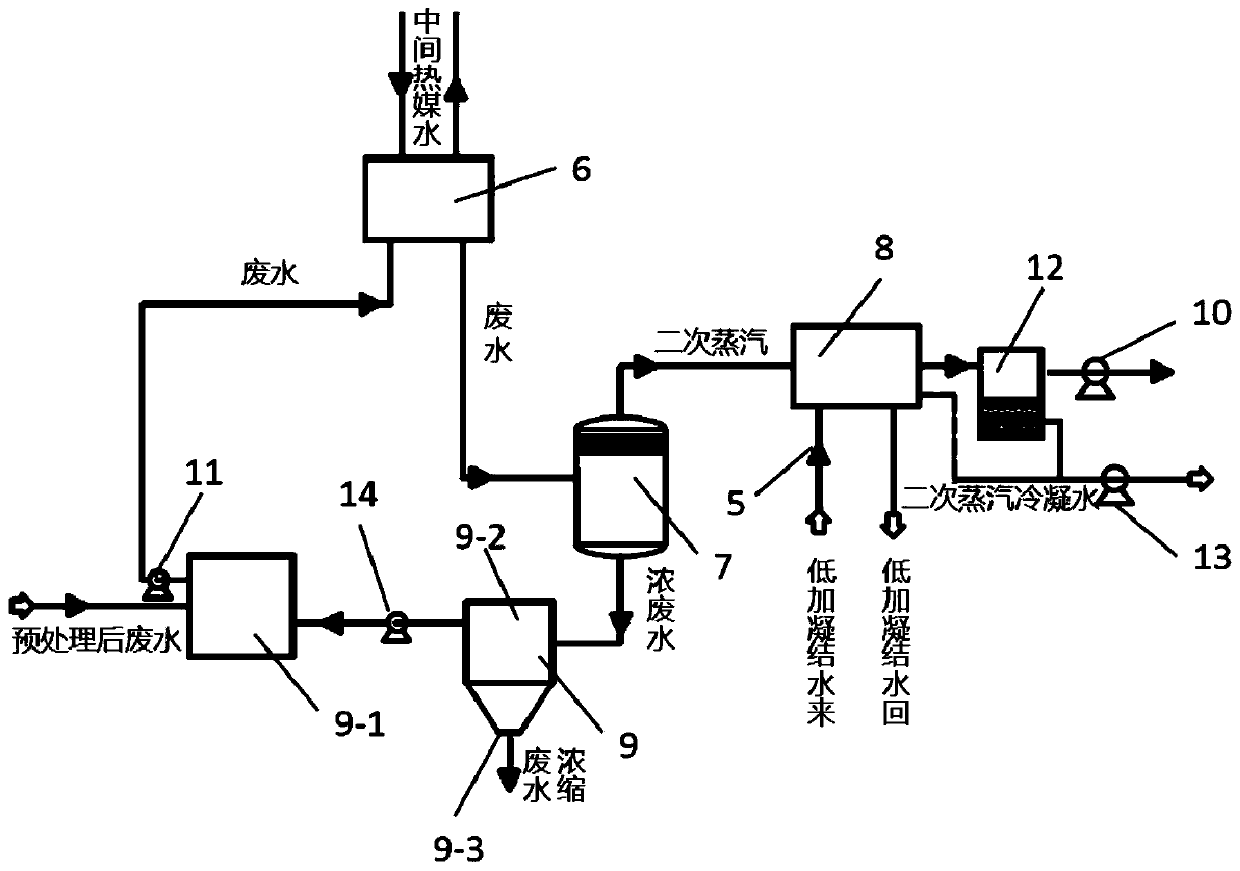

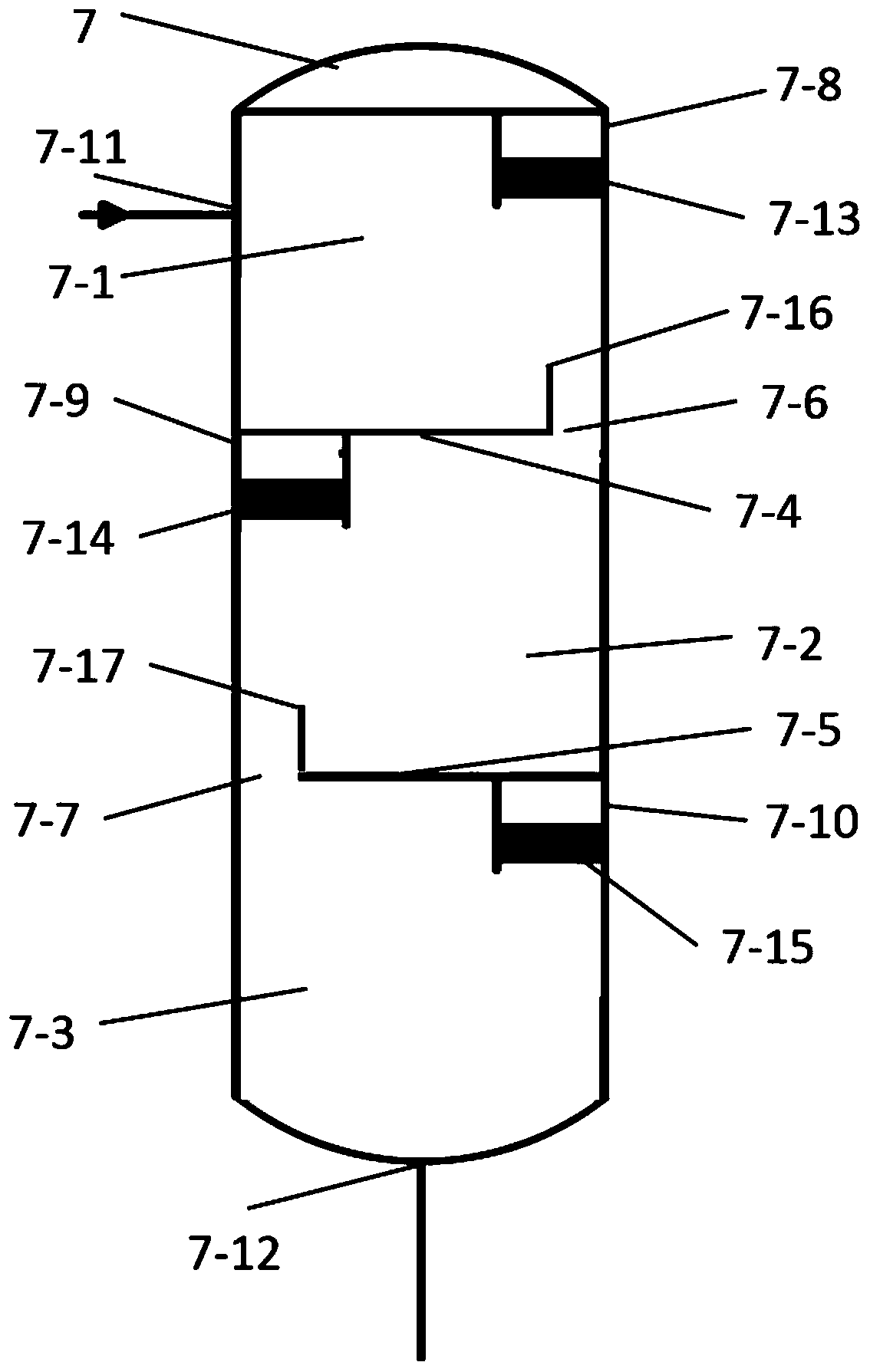

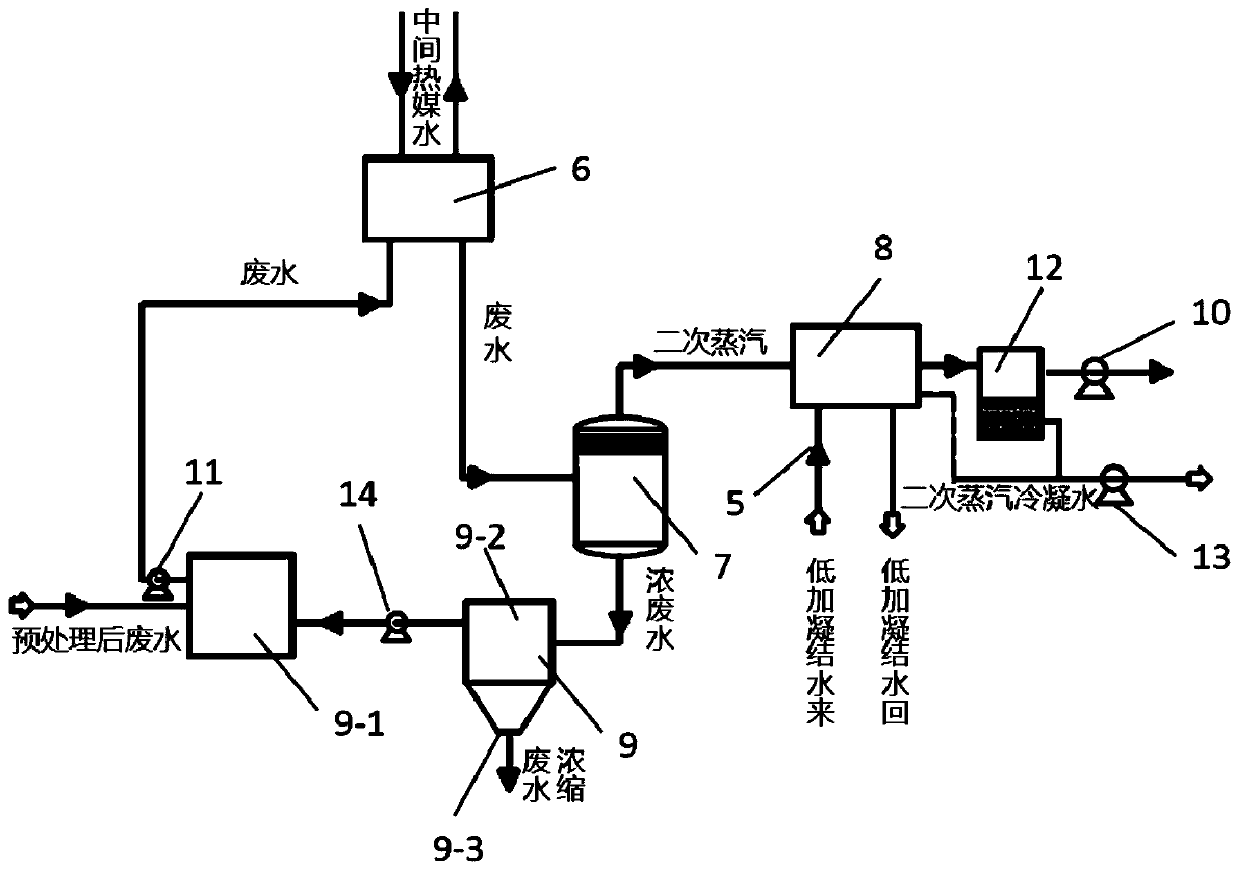

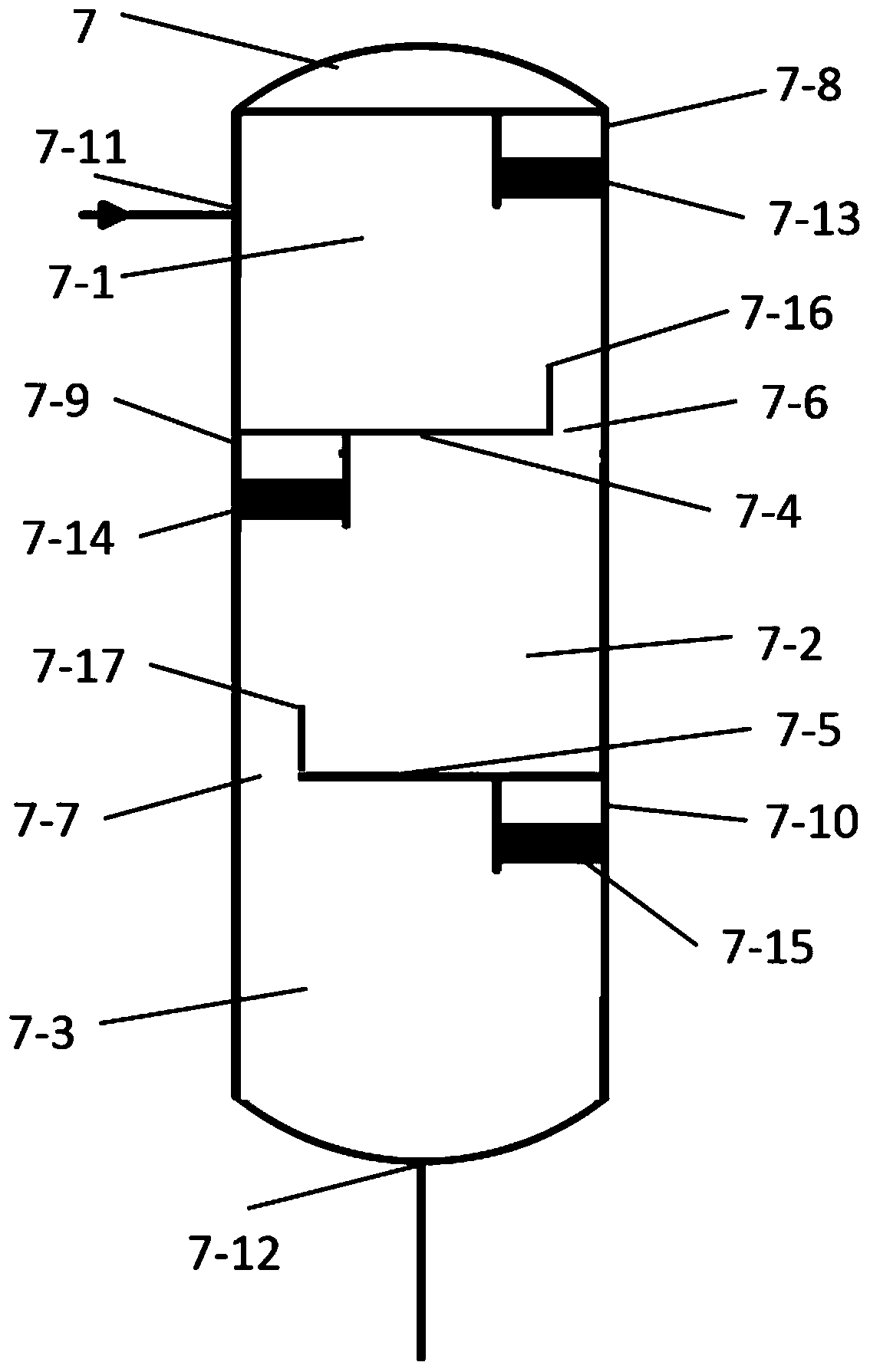

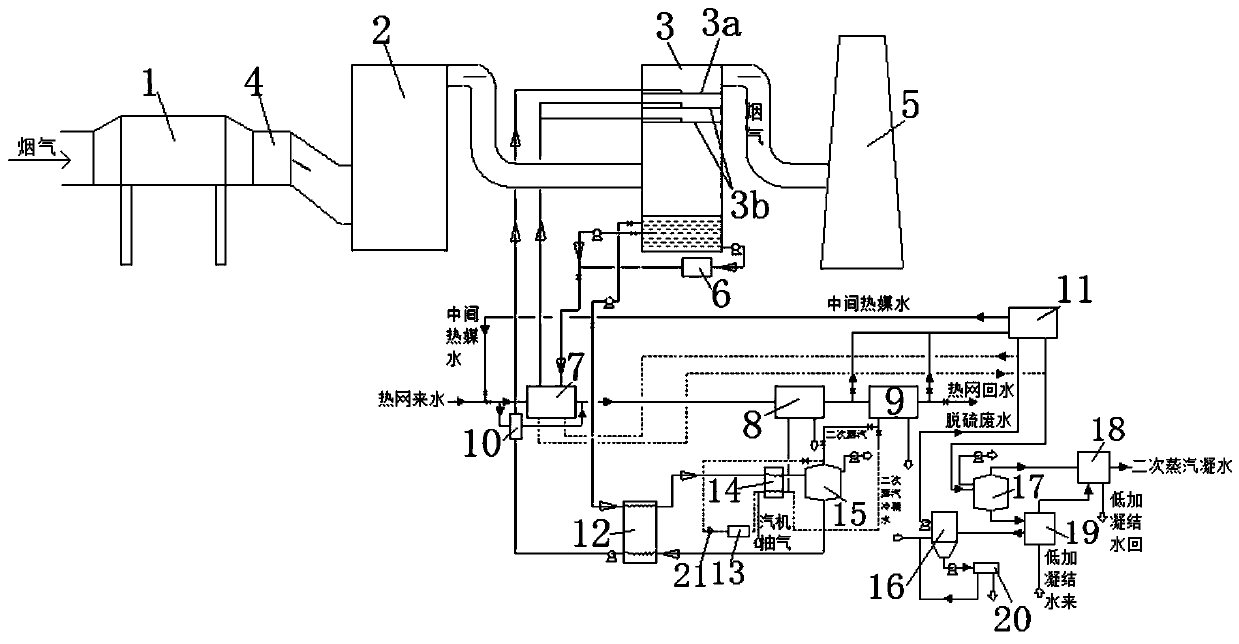

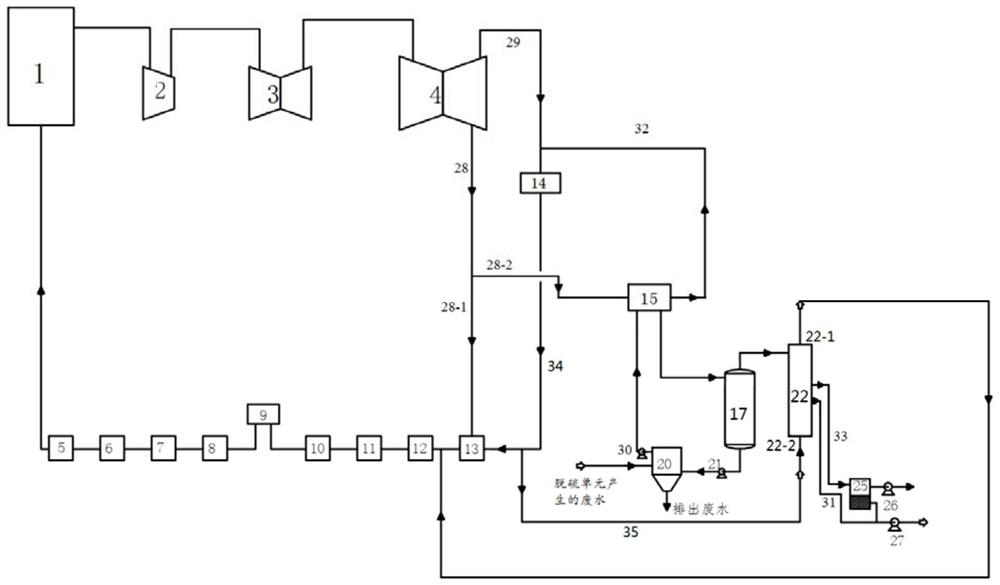

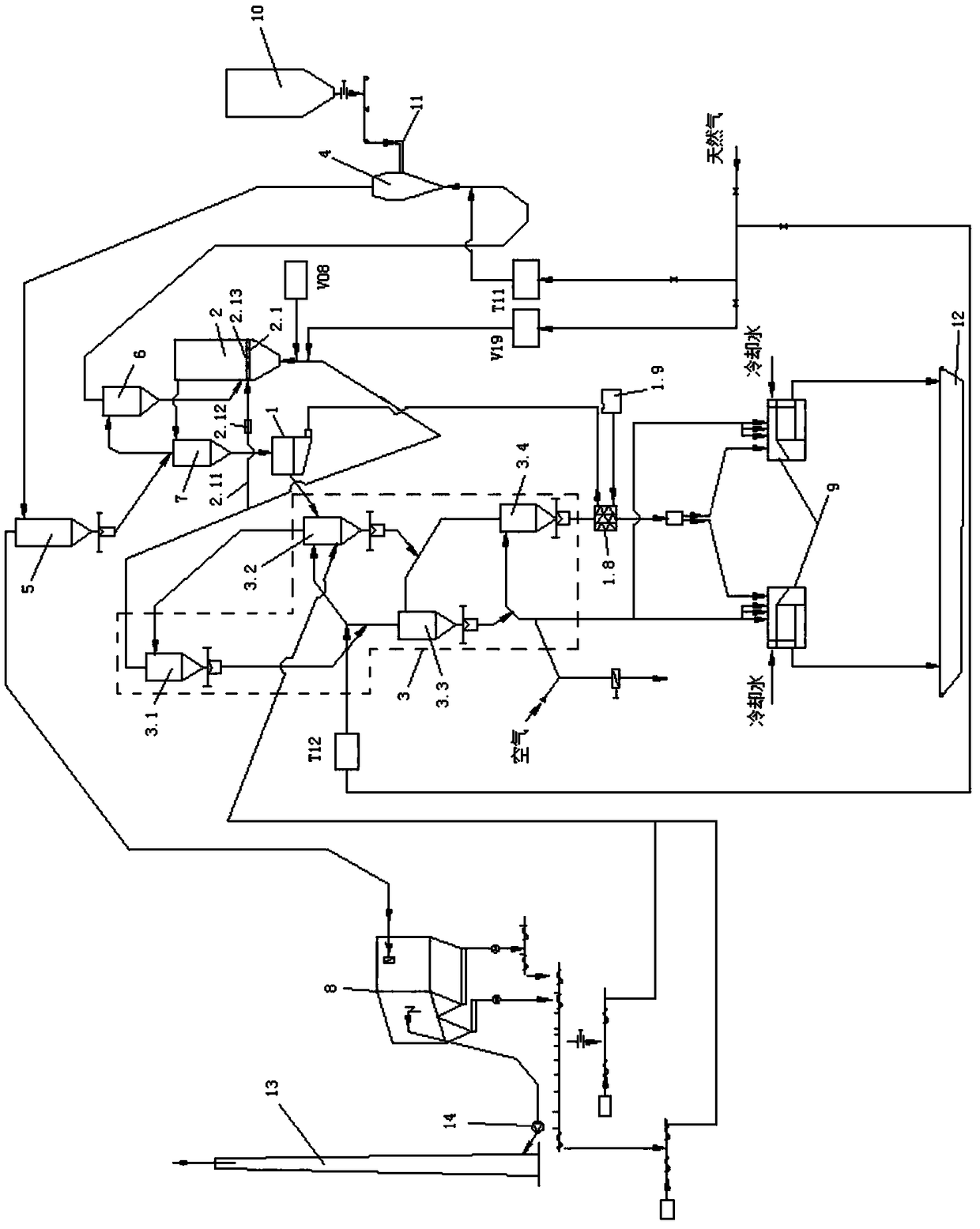

Device combining waste-heat recovery and white elimination with wastewater concentration

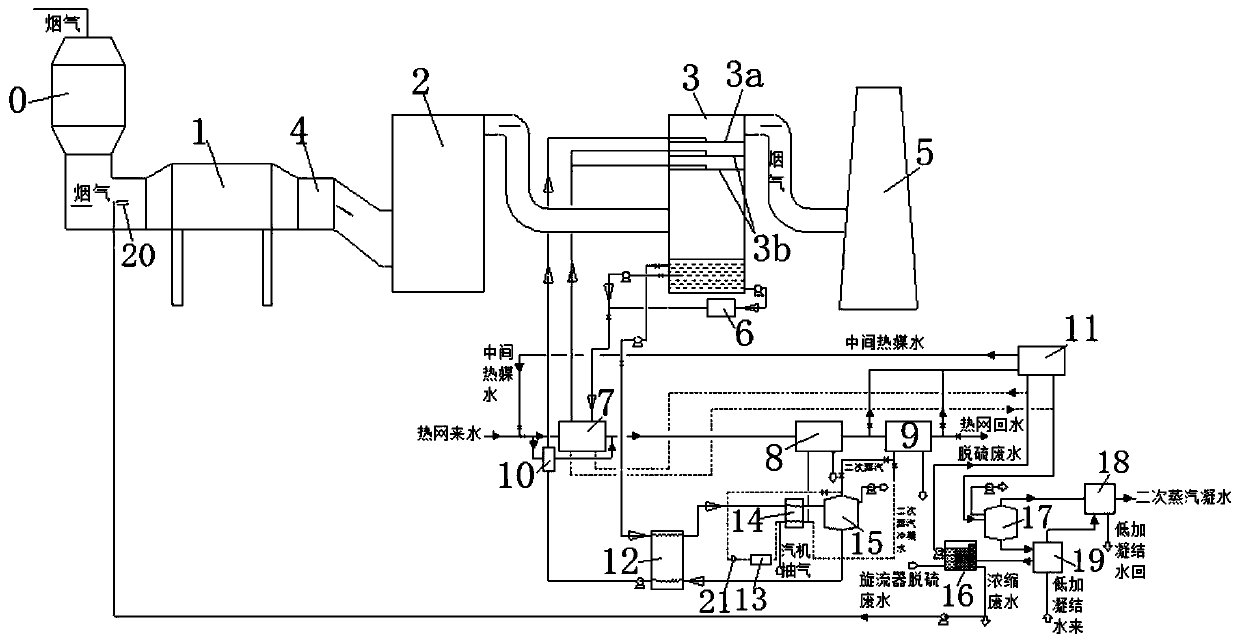

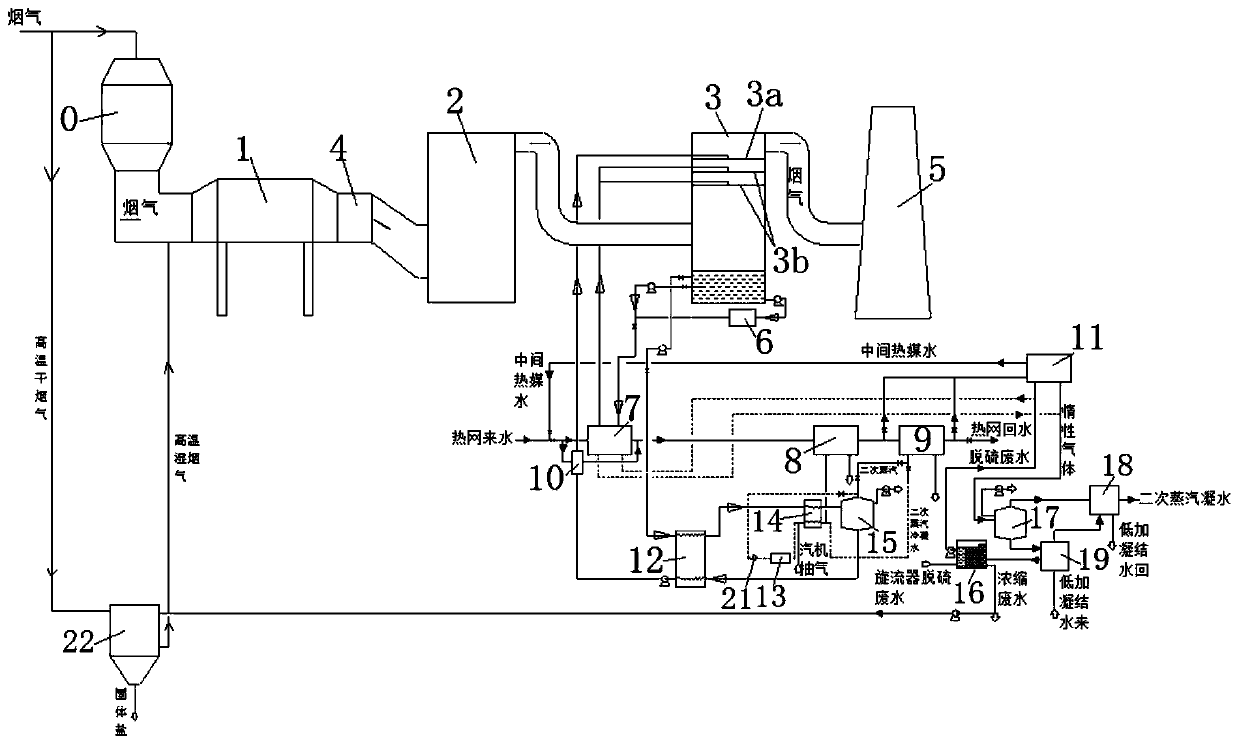

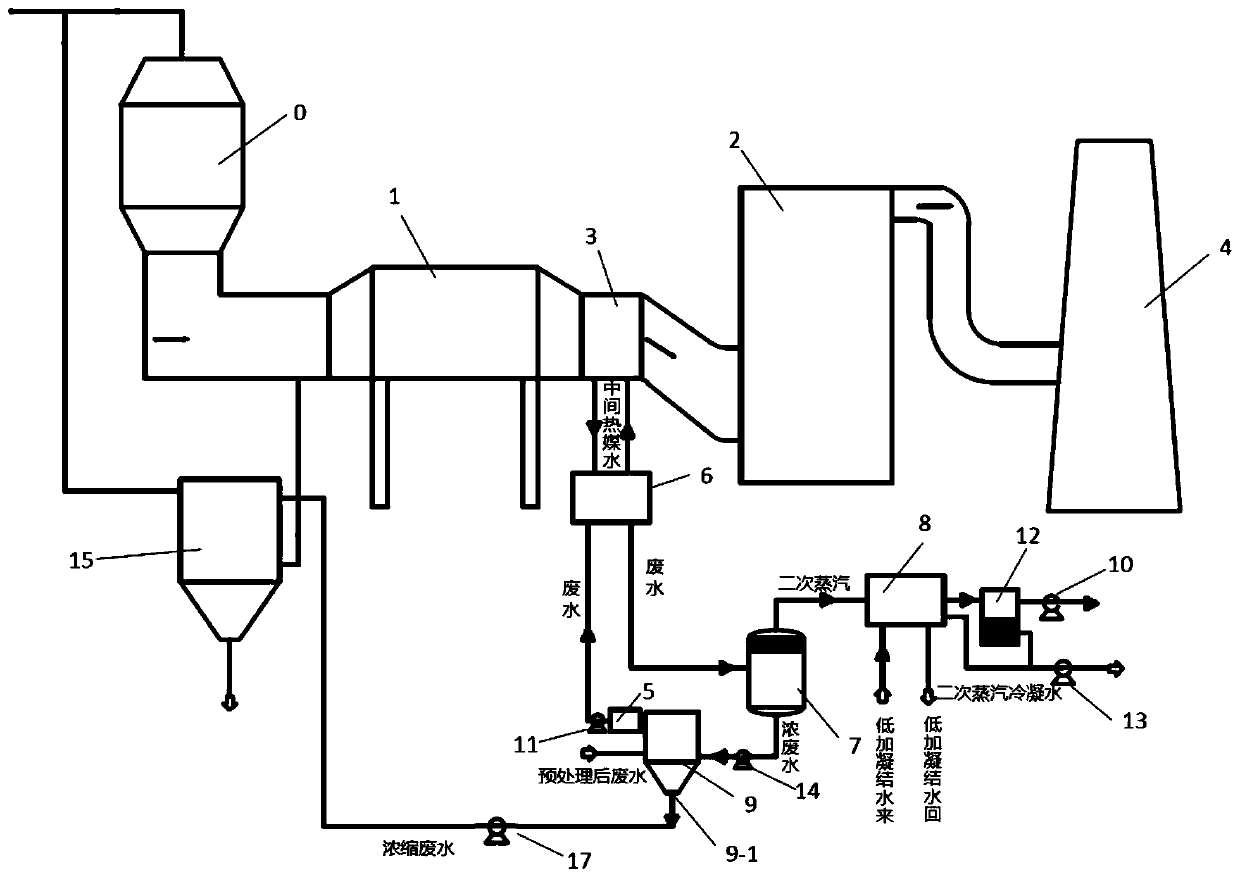

PendingCN110394031AReduce moisture contentEliminate wet plumeGas treatmentHeat recovery systemsProcess engineeringThermal energy

The invention discloses a device combining waste-heat recovery and white elimination with wastewater concentration. The device is used for solving the problems of flue gas waste-heat recovery and wastewater concentration in a power plant, and is composed of an absorption heat pump system, a wastewater concentration system, an evaporation drying system and the like. According to the device providedby the invention, the flue gas waste heat in a coal-fired power plant or other industries is utilized for wastewater concentration, the concentration process has little influence on the flue gas humidity, wastewater is turned into available water, and finally recycled flue gas heat is transmitted to a low-pressure heater system to realize gradient utilization of heat energy; and the concentratedand reduced high-concentration wastewater can be conveyed to the evaporation drying system, so that heat required by the evaporation drying system is greatly reduced, the influence on a unit is reduced, and the whole system has the advantages of low energy consumption, low investment, low operating costs and the like.

Owner:CHINA HUADIAN ENG +1

Cooker processing technology for preventing outer surface scale

InactiveCN104146593AAvoid pollutionImprove thermal conductivityCooking vesselsPretreated surfacesAlloyPowder Spray

The invention relates to a cooker processing technology for preventing outer surface scale. The technology includes the following steps that alloy materials are stretched to form a cooker body; finish turning machining is carried out on the inner surface and the outer surface of the cleaned cooker body to obtain a smooth inner surface and a smooth outer surface; non-stick cookware coating is sprayed on the inner surface of the cooker body and is sintered; plastic powder is sprayed to the outer surface of the cooker body through an electrostatic generator in an electrostatic plastic spraying mode, the thickness of the film formed by spraying powder ranges from 30 microns to 35 microns, and the film is roasted between 180 DGE C and 220 DEG C to be solidified. Priming paint is not needed for the cooker body, the paint flowing phenomenon commonly occurring in the paint spraying process cannot occur in the electrostatic powder spraying process, environmental pollution is avoided accordingly, and high efficiency, energy conservation and emission reduction are achieved. The surface of the film formed through solidification after electrostatic powder spraying is flat and smooth, adsorption capacity is weak, if the cooker is sooted in the use process, the cooker can be scrubbed and cleaned with cleaning cloth, accumulated scale cannot be formed after long-term use, the good heat conduction effect of the cooker is further guaranteed, waste of gas sources is reduced, and the service life of the cooker is prolonged.

Owner:江苏金海玛电器有限公司

Energy saving, water saving and cold and heat co-production device

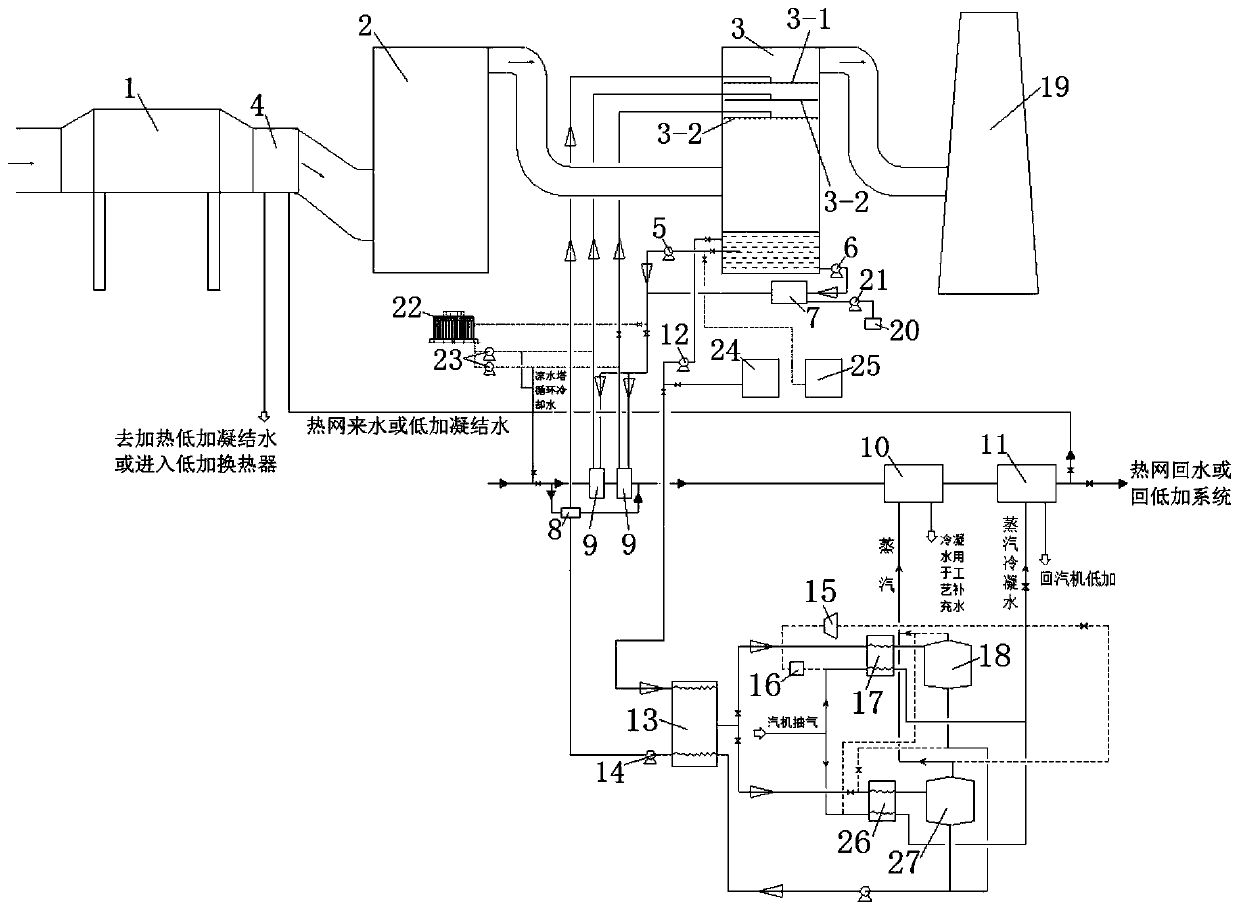

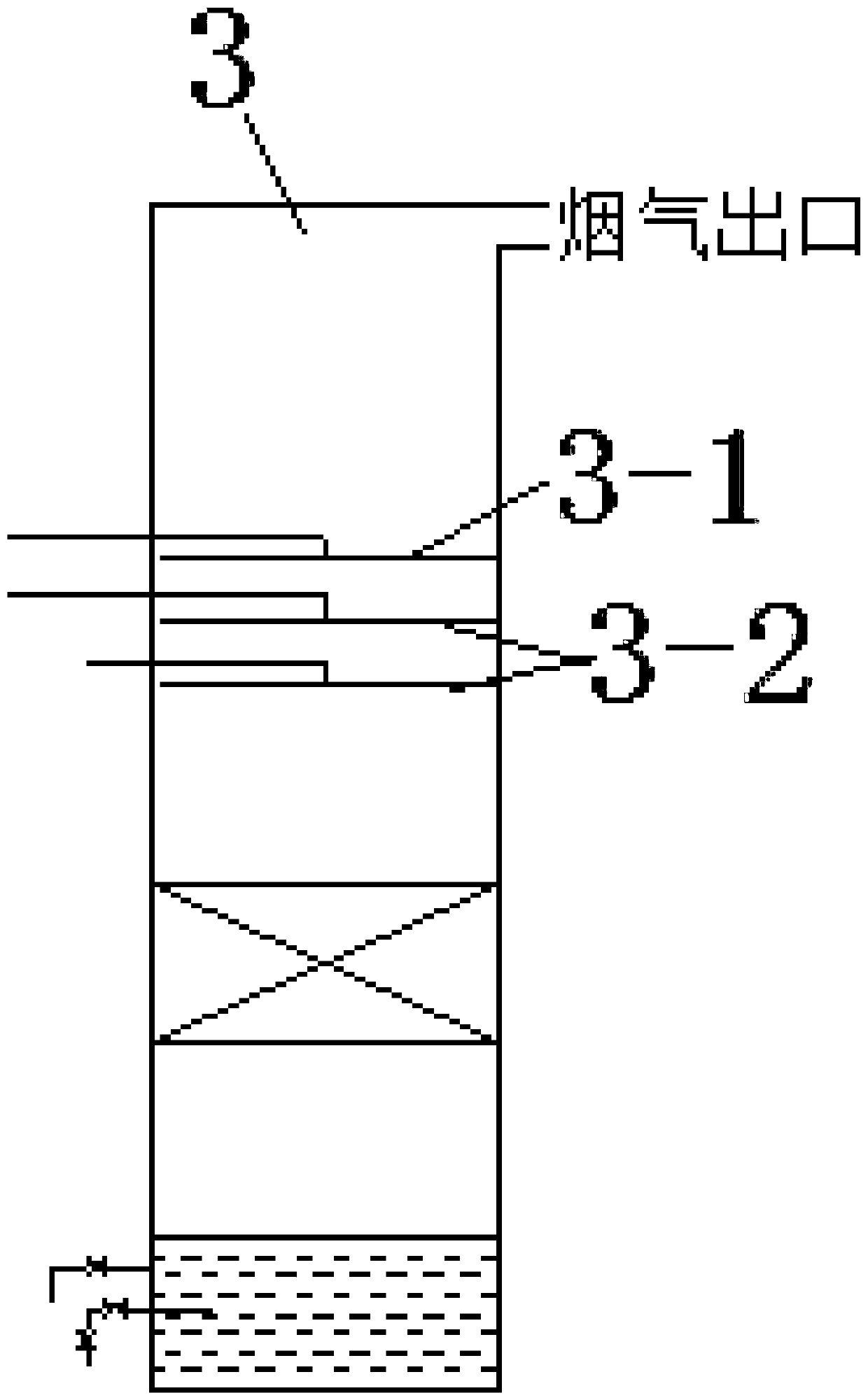

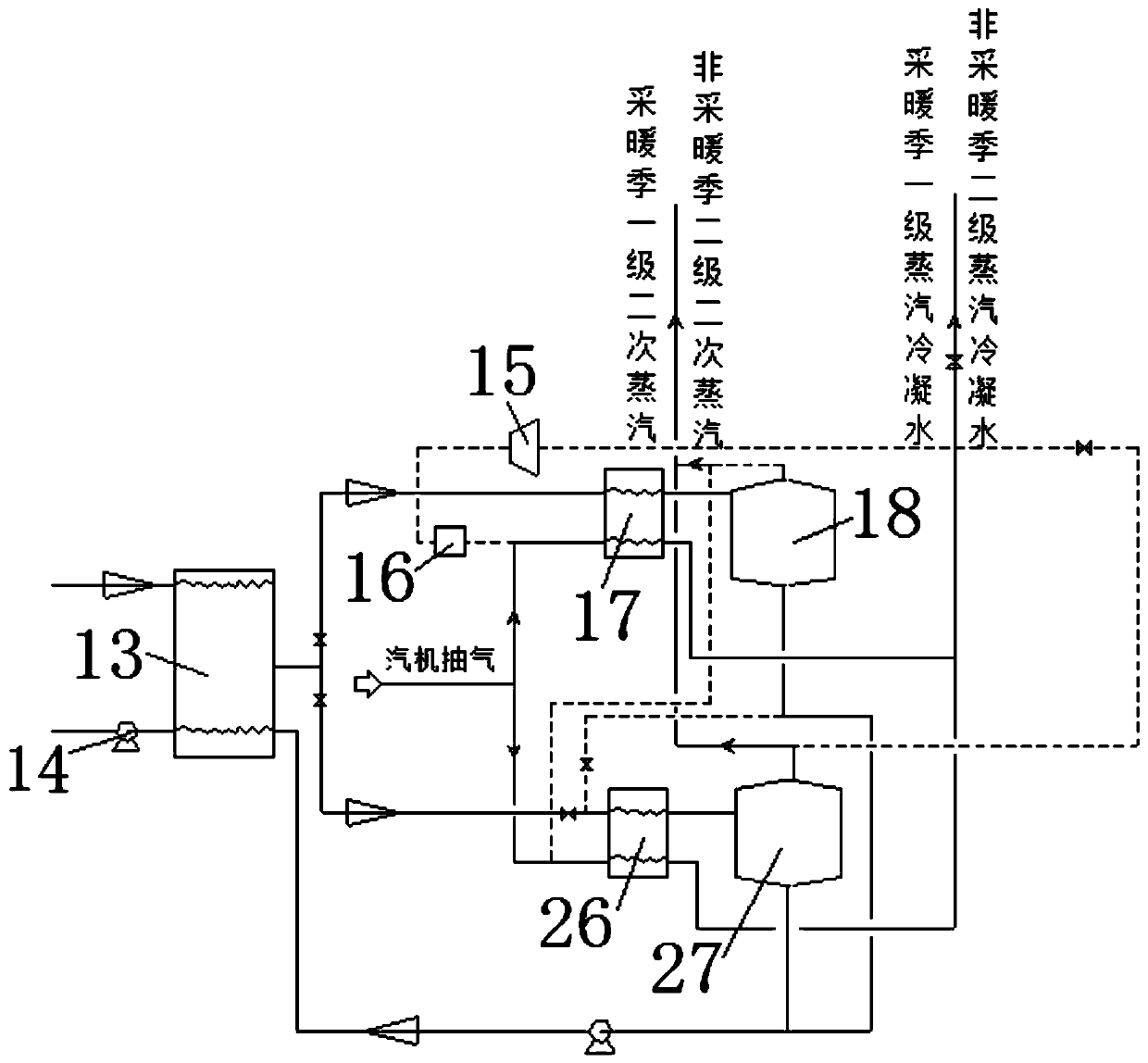

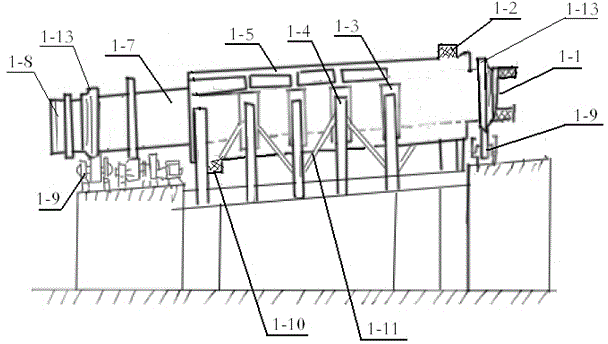

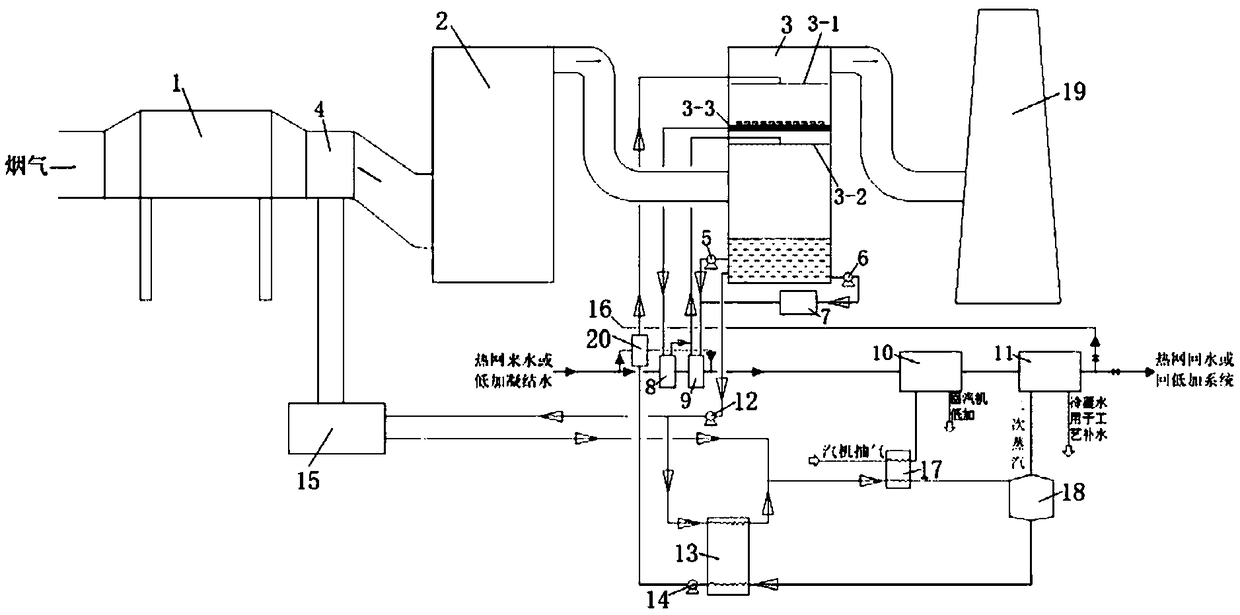

PendingCN110500602ASolve the problem of only investing but not earningSolve the disadvantages of low utilization rate and idle heating network systemEnergy efficient heating/coolingClimate change adaptationWater savingHeating season

The invention discloses an energy saving, water saving and cold and heat co-production device. By means of the device, at least one stage of first circulation loop and a circulation heat exchange pipeline are arranged so that the problem that during wet smoke plume eliminating of a coal-fired power plant or other industries, a deep water lifting system is only input, and no benefit is generated can be solved. Meanwhile, a user side refrigerating system is arranged, in addition, the user side refrigerating system is arranged on the circulation heat exchange pipeline, a LiBr heat pump is adoptedin the refrigerating system, and the LiBr heat pump and a heat exchange station in the heating season are arranged in parallel. Finally, an opening type heat pump system is used for recycling flue gas latent heat, the heat exchange station is used for heating in the heating season, the LiBr heat pump is used for refrigerating in the non-heating season, a closed heat pump is arranged at the user end in the system, a heating season heating circulation water pipe is used in the non-heating reason to send hot water to a LiBr heat pump station, the hot water is adopted as the driving heat source for refrigerating, and the defects that in summer, the utilization rate of a thermal power plant is low, and a heating network system is idle are overcome.

Owner:CHINA HUADIAN ENG +1

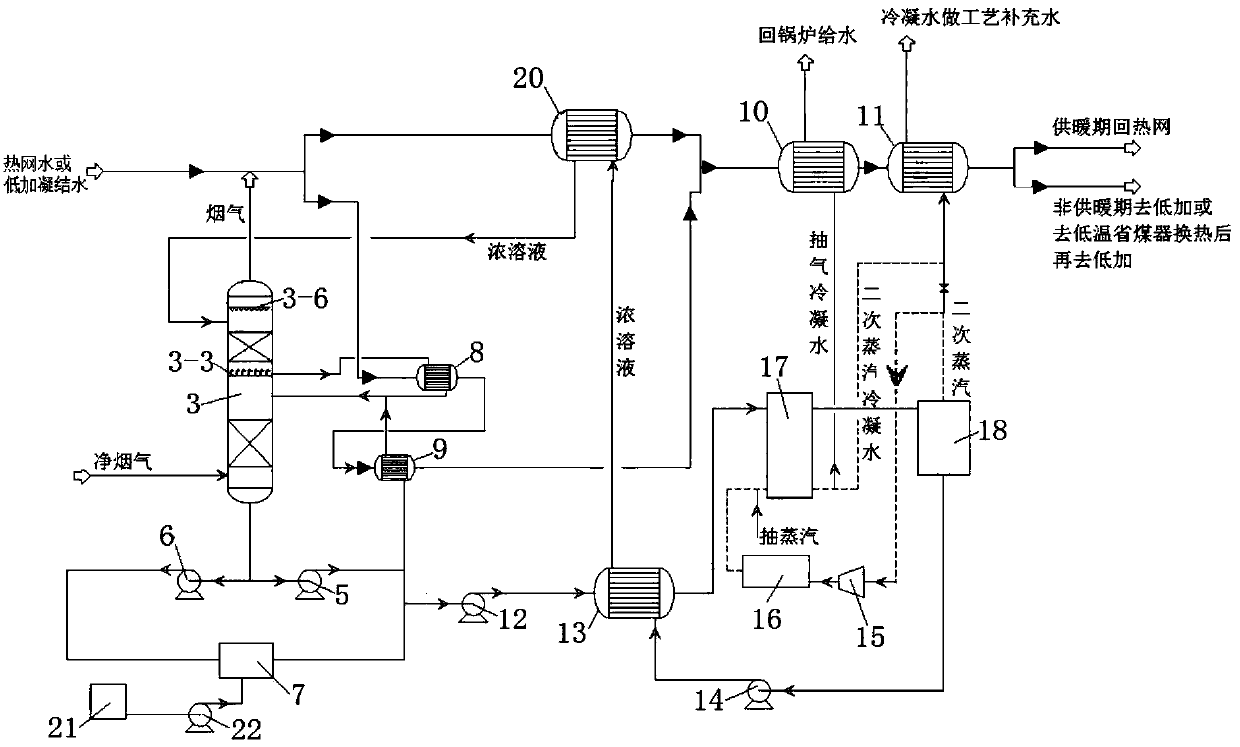

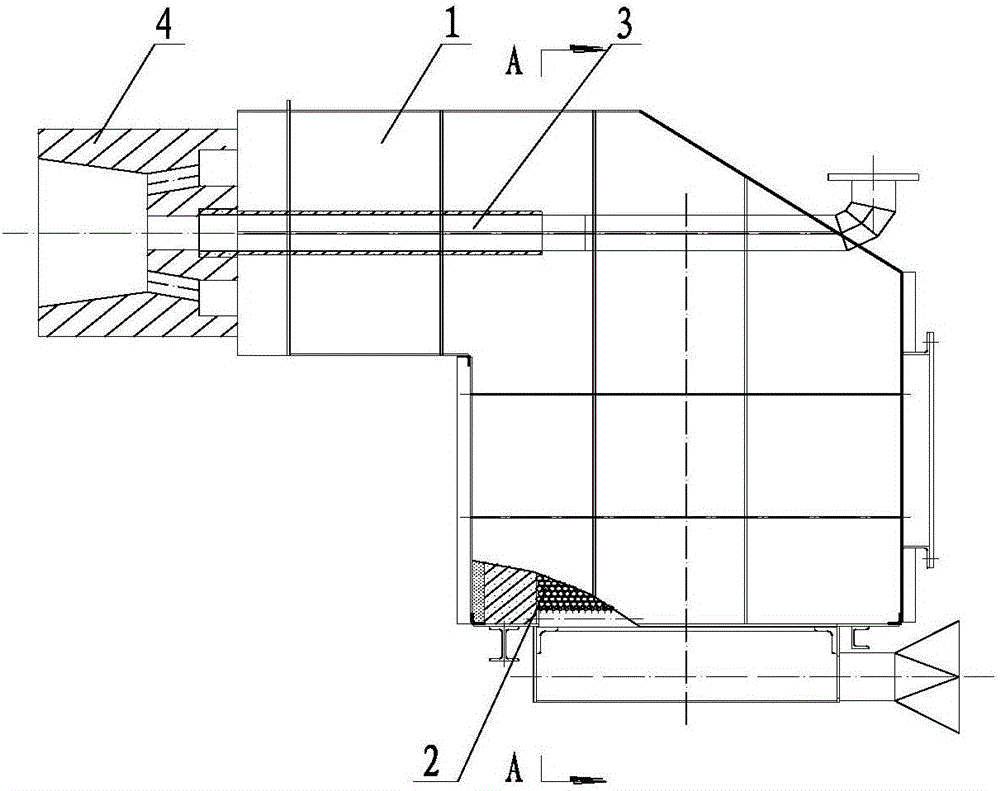

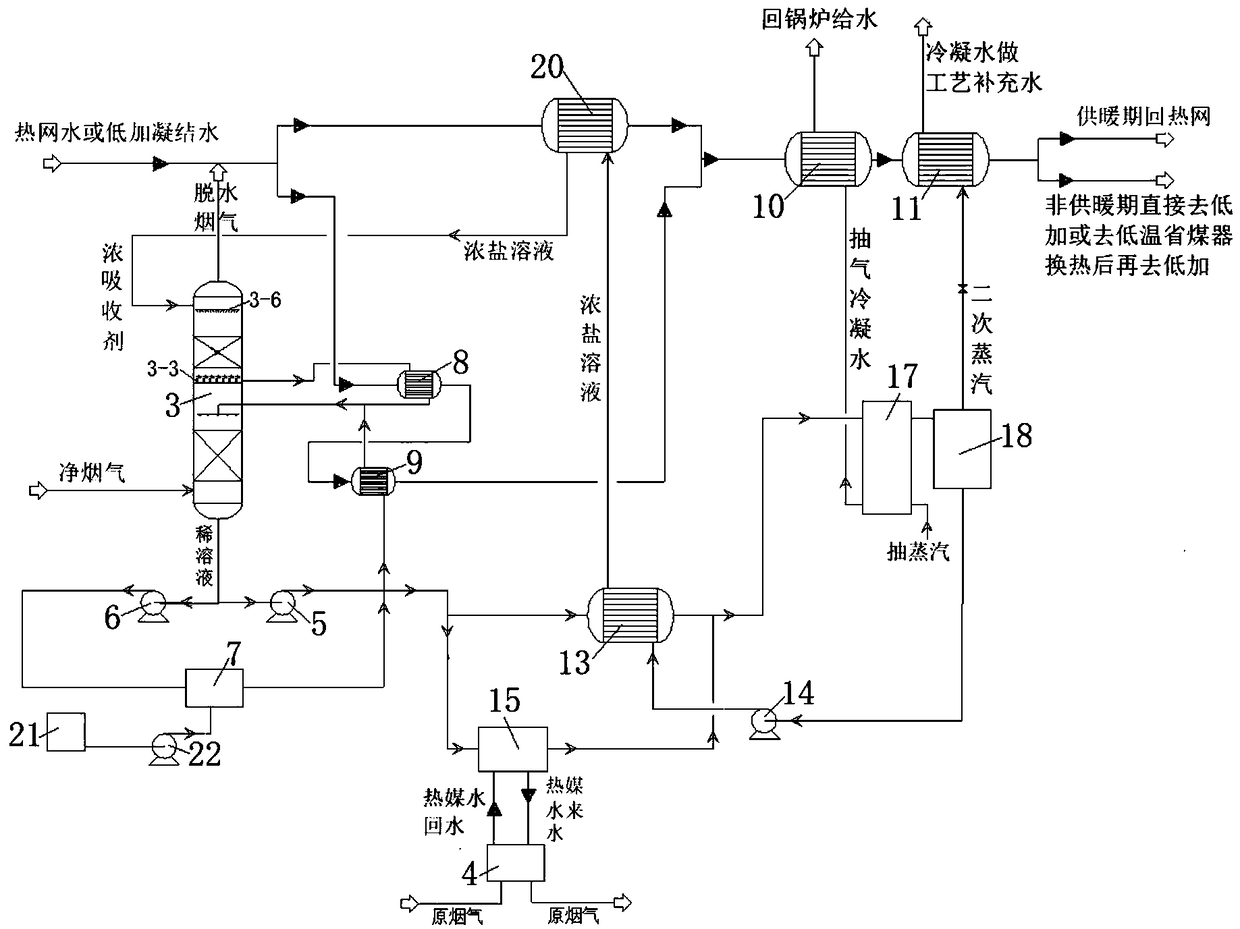

Energy-saving and water-saving flue gas treatment system

PendingCN109569200AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater savingWater vapor

The invention discloses an energy-saving and water-saving flue gas treatment system. The energy-saving and water-saving flue gas treatment system has the advantages that a liquid storage unit is arranged in an absorption device of the energy-saving and water-saving flue gas treatment system, an inner cavity is divided into a first glue gas treatment zone and a second flue gas treatment zone by theliquid storage unit, flue gas can flow into the absorption device from the bottom of the absorption device and can be in countercurrent contact with concentrated solution sprayed from the top of theabsorption device, moisture in the flue gas can be absorbed by concentrated solution in the second flue gas treatment zone, the concentrated solution in the second flue gas treatment zone can be diluted, latent heat released in moisture phase change procedures can be separated out, and the glue gas and the concentrated solution can be heated until the temperatures of the flue gas and the concentrated solution reach 55-65 DEG C; heated concentrated solution can be led out via the liquid storage unit and can be fed into a first heat exchanger, heat exchange can be carried out on the heated concentrated solution and heat exchange media (such as heat network water), the heat exchange media can be heated by the temperatures of 3-10 DEG C, the concentrated solution can be cooled until the temperature of the concentrated solution is approximately consistent with the temperature of a solution inlet in the top of the second flue gas treatment zone, then the concentrated solution can be fed intothe first flue gas treatment zone, and moisture in the flue gas can continue to be absorbed; cascade heat exchange is adopted for the first time, accordingly, the heat exchange quality can be effectively enhanced, and sensible heat in the original flue gas and latent heat in water vapor of clean flue gas can be deeply recycled and can be utilized.

Owner:CHINA HUADIAN ENG +1

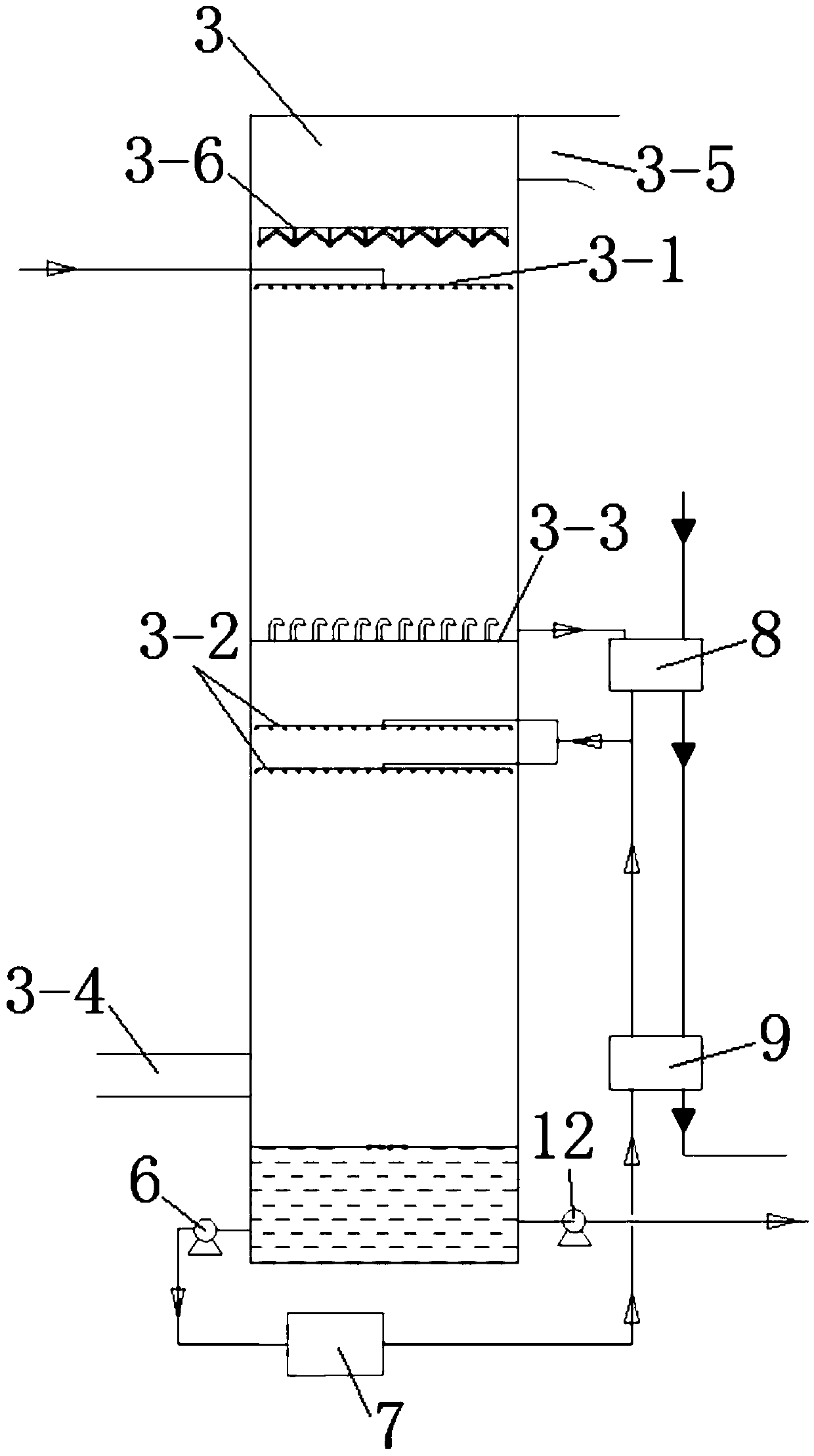

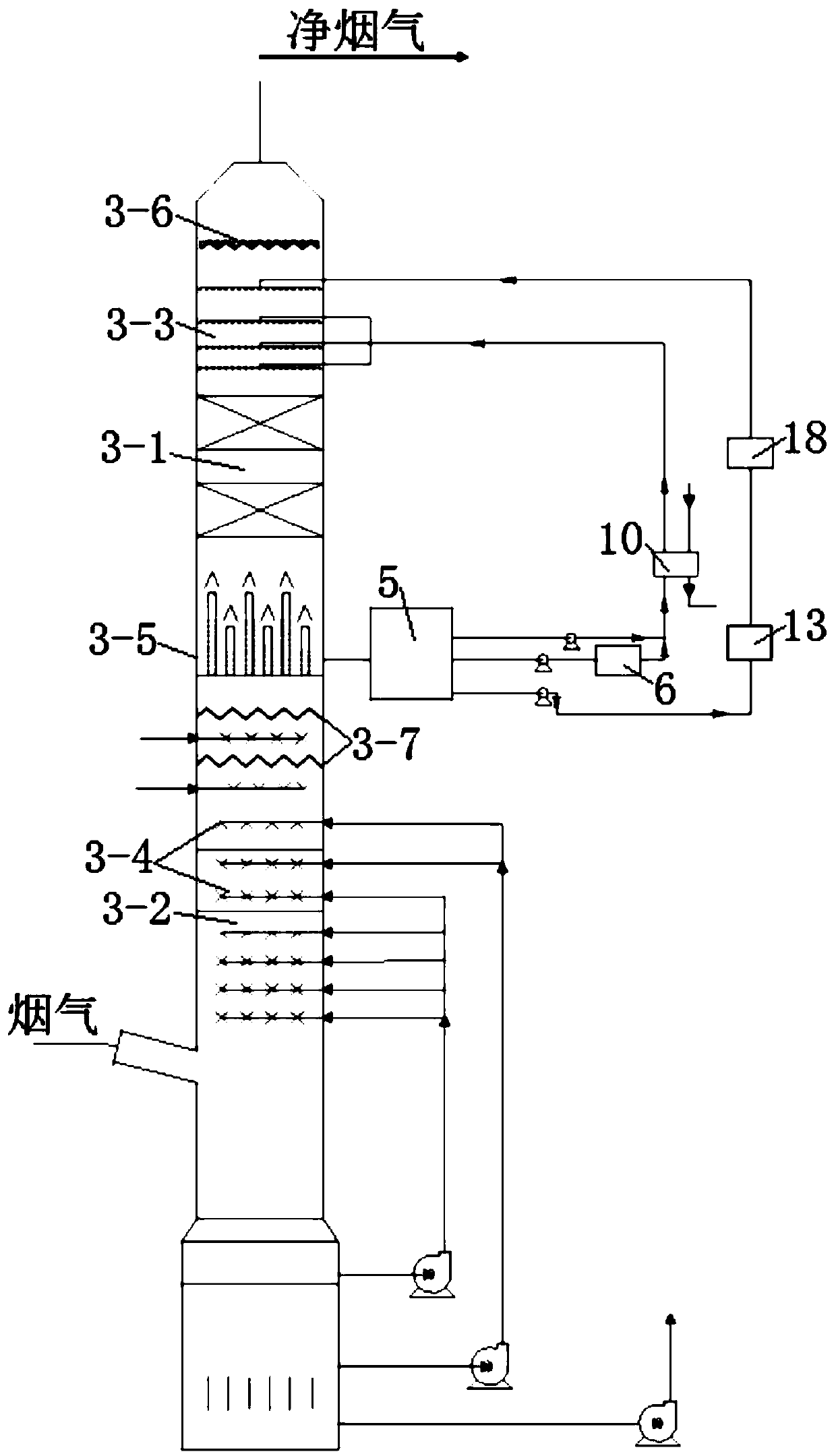

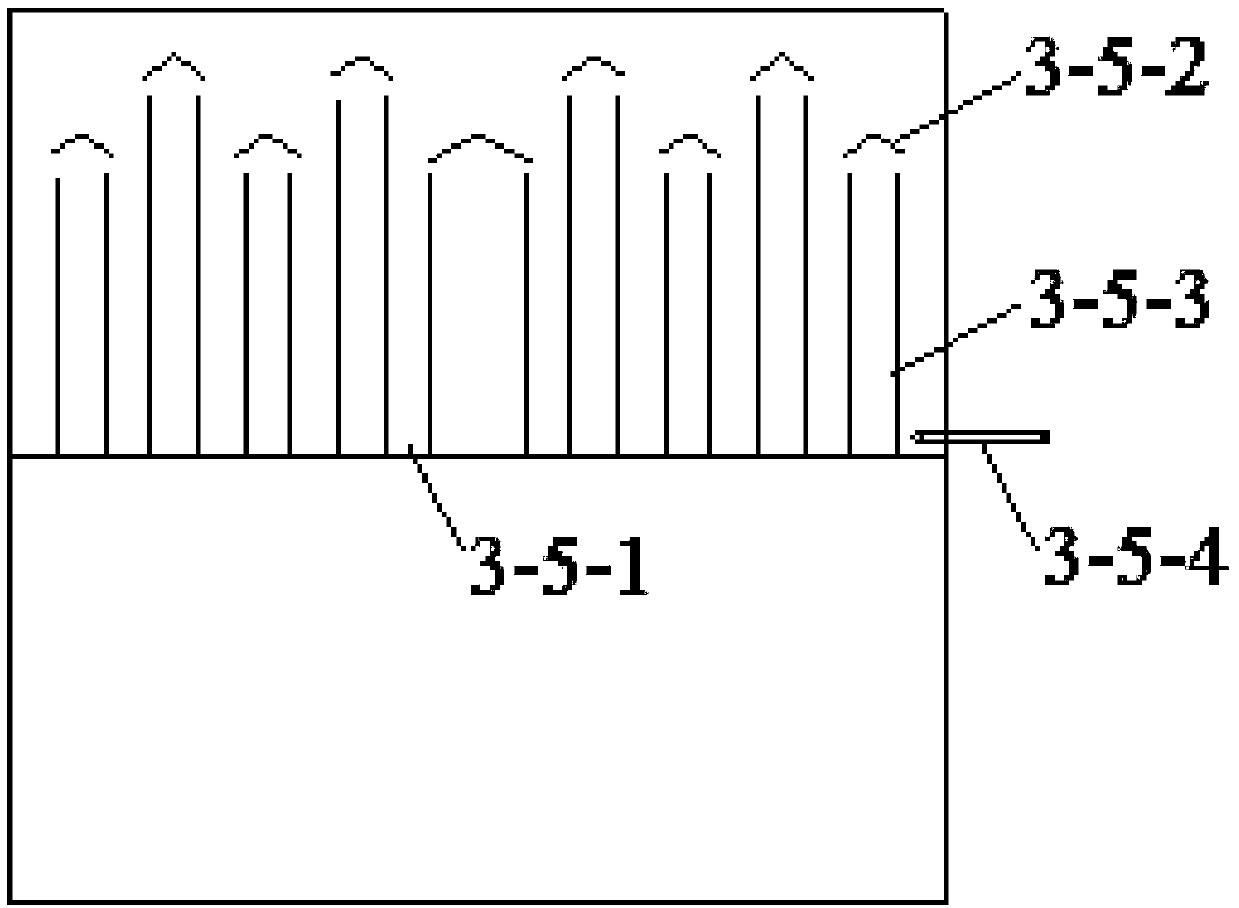

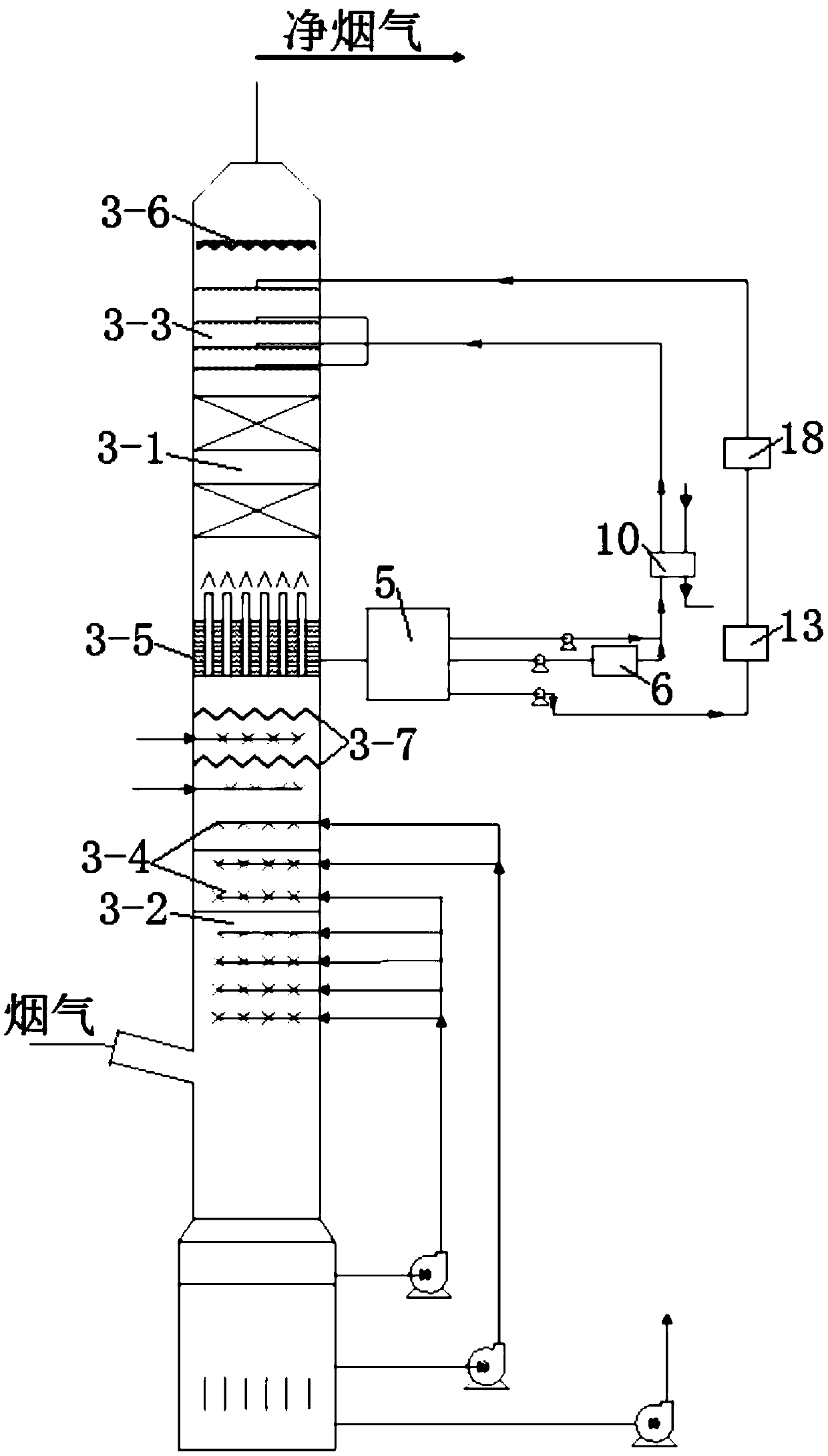

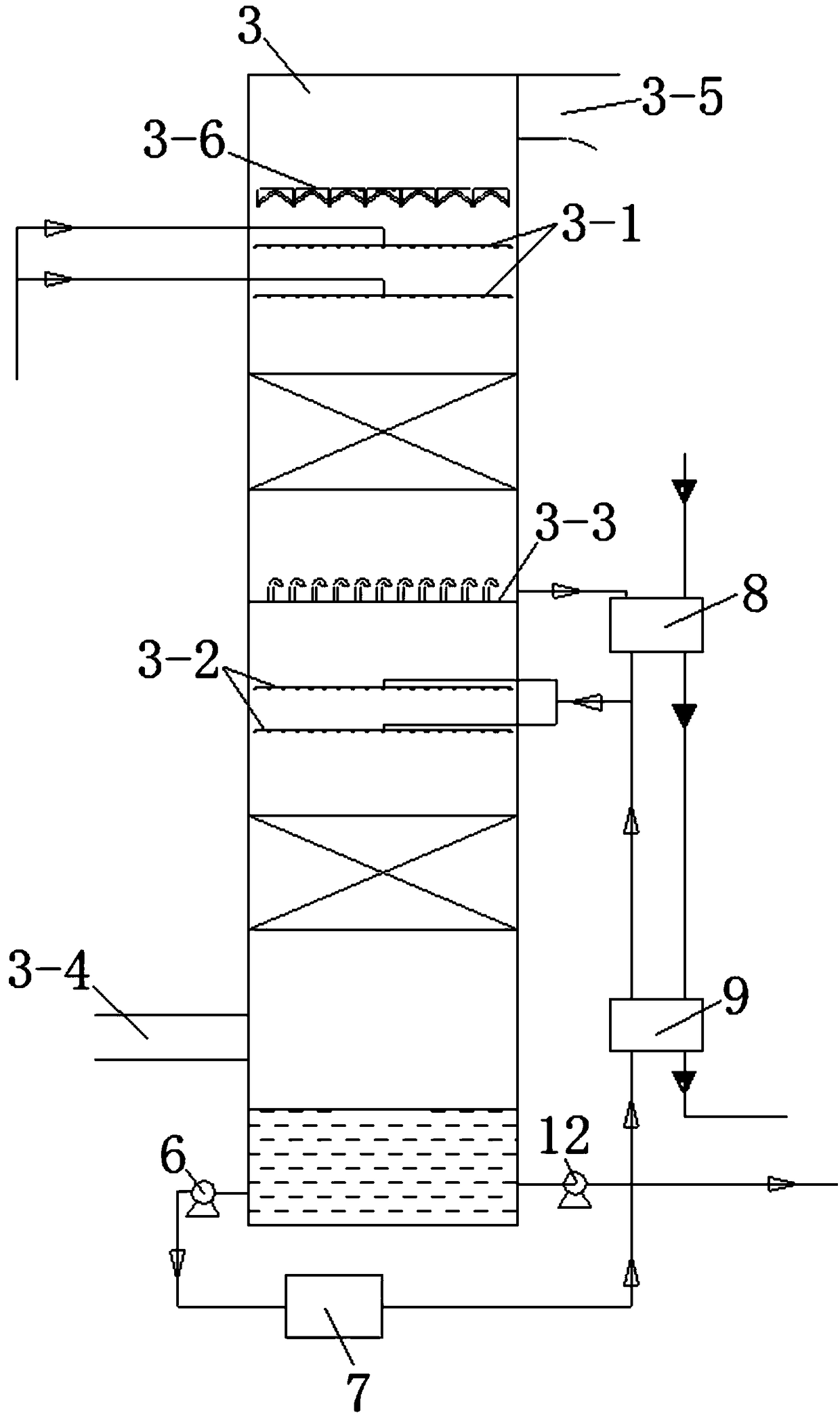

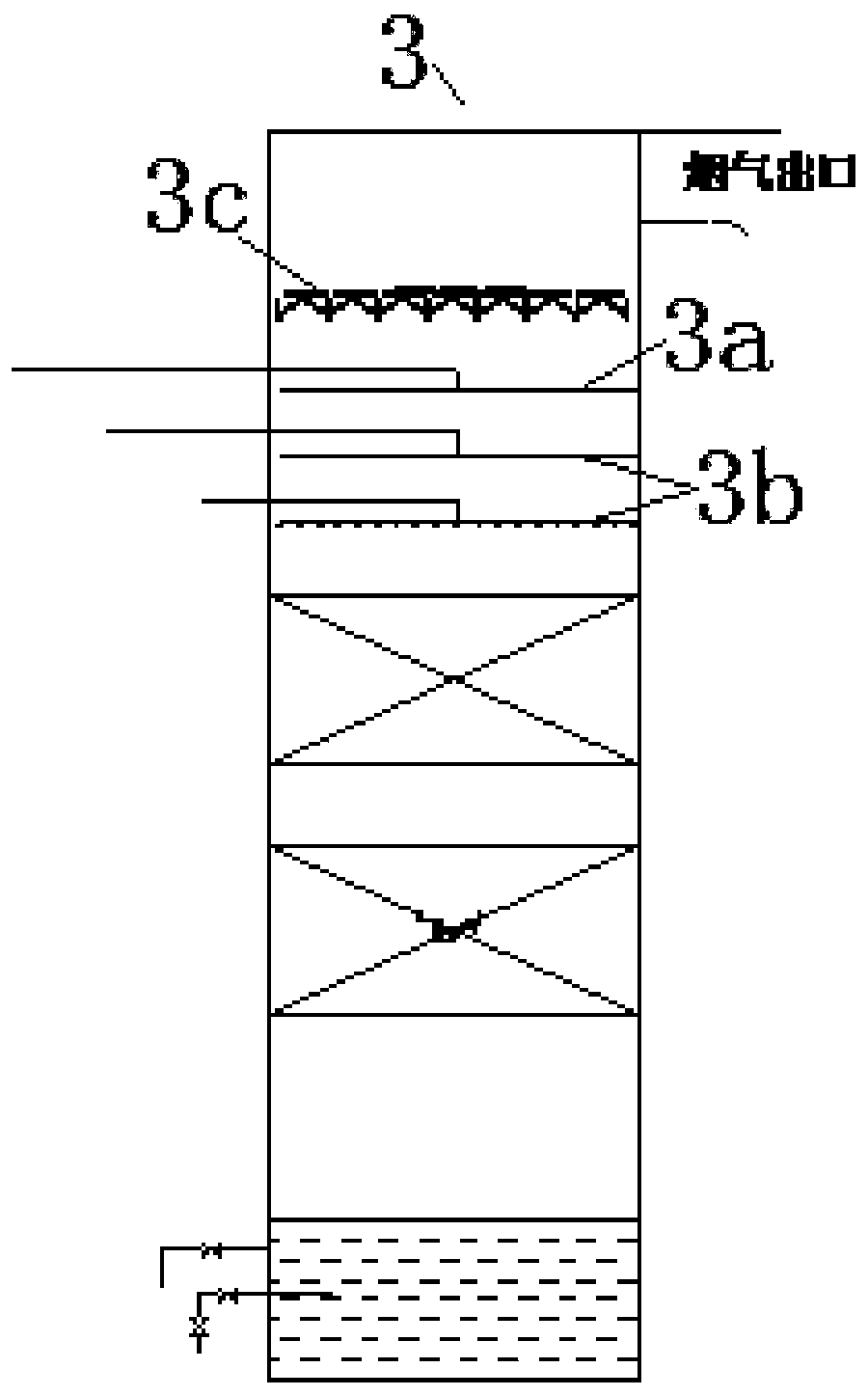

Desulfurization and white smoke elimination device

PendingCN111482058AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater vaporFlue gas

The invention discloses a desulfurization and white smoke elimination device. According to the device, a desulfurization section and an absorption section are sequentially arranged in a shell of a flue gas purification device from bottom to top, a liquid storage unit with a specific structure is arranged between the desulfurization section and the absorption section, a first spraying layer is arranged between the absorption section and the top end of the shell, and a second spraying layer is arranged between the flue gas inlet of the desulfurization section and the liquid storage unit. Flue gas enters the absorption section from the desulfurization section, and is in countercurrent contact with a concentrated solution or clear water sprayed at the top of the absorption section. In the heating season, the concentrated solution absorbs water in the flue gas and becomes thin, latent heat is released in a precipitated moisture phase change process to heat flue gas and saline solution, theheated solution is collected by the liquid storage unit, heat exchange is conducted through a first heat exchanger on the first circulation loop, the balance state in the absorption section is flexibly controlled through the amount of taken-away heat, sensible heat of raw flue gas and latent heat of purified flue gas water vapor are deeply recycled, the situation that in the prior art, a large number of cold sources are needed for flue gas cooling and condensation is avoided, and water resources are greatly saved.

Owner:CHINA HUADIAN ENG +1

Highway buffer crash barrier

ActiveCN102900036BImprove cushioning and anti-collision performanceHigh impact strengthRoadway safety arrangementsWave shapeHoneycomb

The invention discloses a buffering anti-collision guardrail on an expressway. The guardrail comprises a guardrail plate, a connection vertical column, a connection buffering tray, a reinforcing vertical column, a reinforcing buffering tray and a built-in steel plate, wherein the guardrail plate consists of an outer layer pipe plate, an inner layer pipe plate body, a steel plate clamping groove pipe body and a supporting buffer column; three layers of buffering structures are formed in the guardrail, the first layer is a three-layer pressure-reducing and buffering honeycomb, the second layer is a wave-shaped built-in steel plate manufactured in the pressure-reducing and buffering honeycomb, and the third layer is a connection buffering tray or a reinforcing buffering tray arranged between the guardrail and the vertical columns. The strength, toughness and bounciness of the guardrail are enhanced; the guard rail is connected with the vertical column elastically, so that the buffering anti-collision guardrail has high buffering capacity, bounciness, elasticity and impact resistance, phenomena that automobile accidents occur, and loss is caused by the automobile accidents can be effectively avoided; and the guardrail has the advantages of long service life and low using cost.

Owner:卞乐平

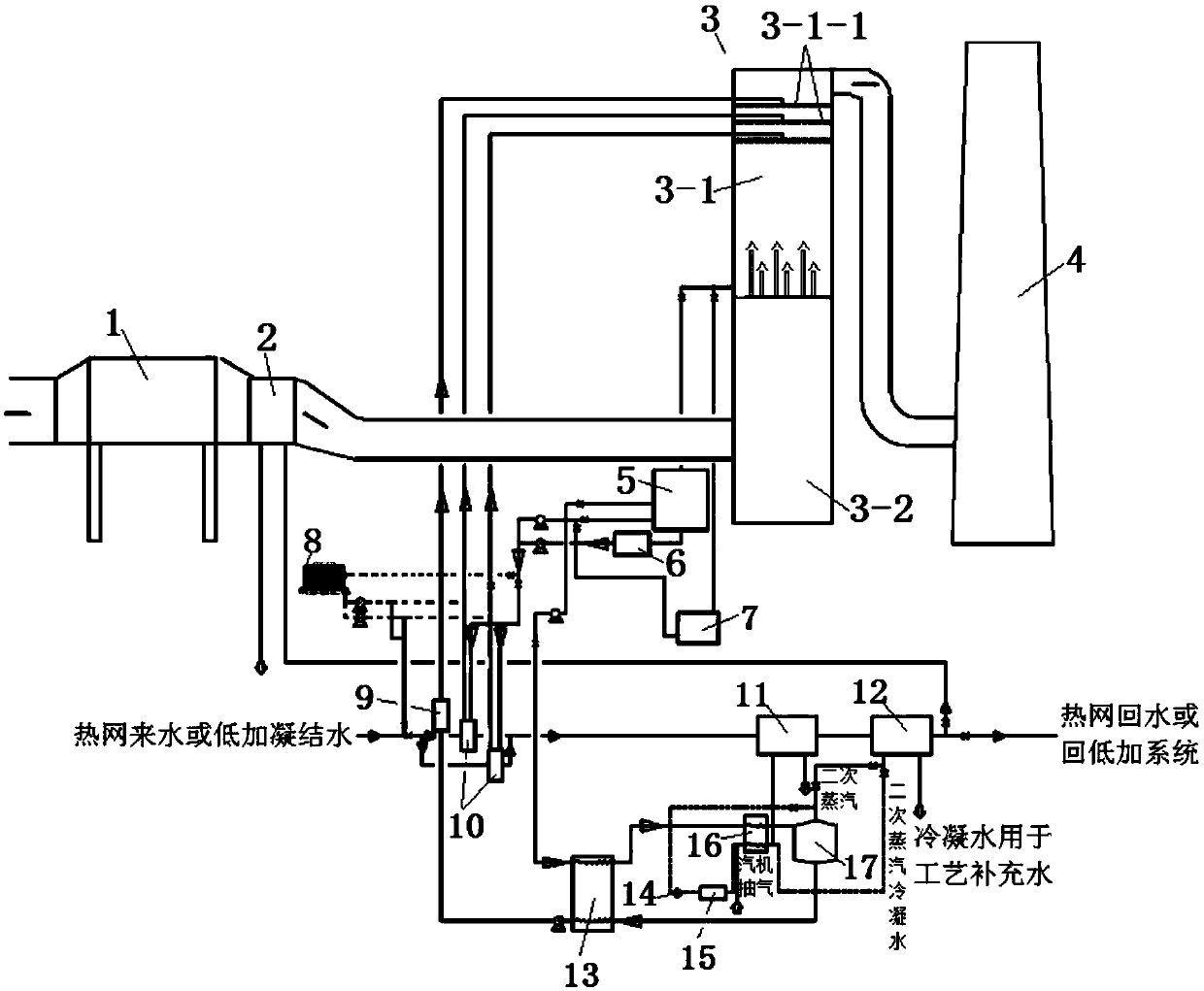

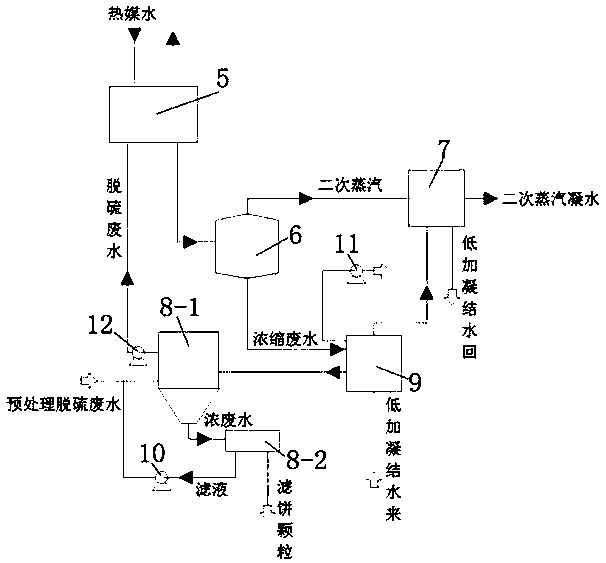

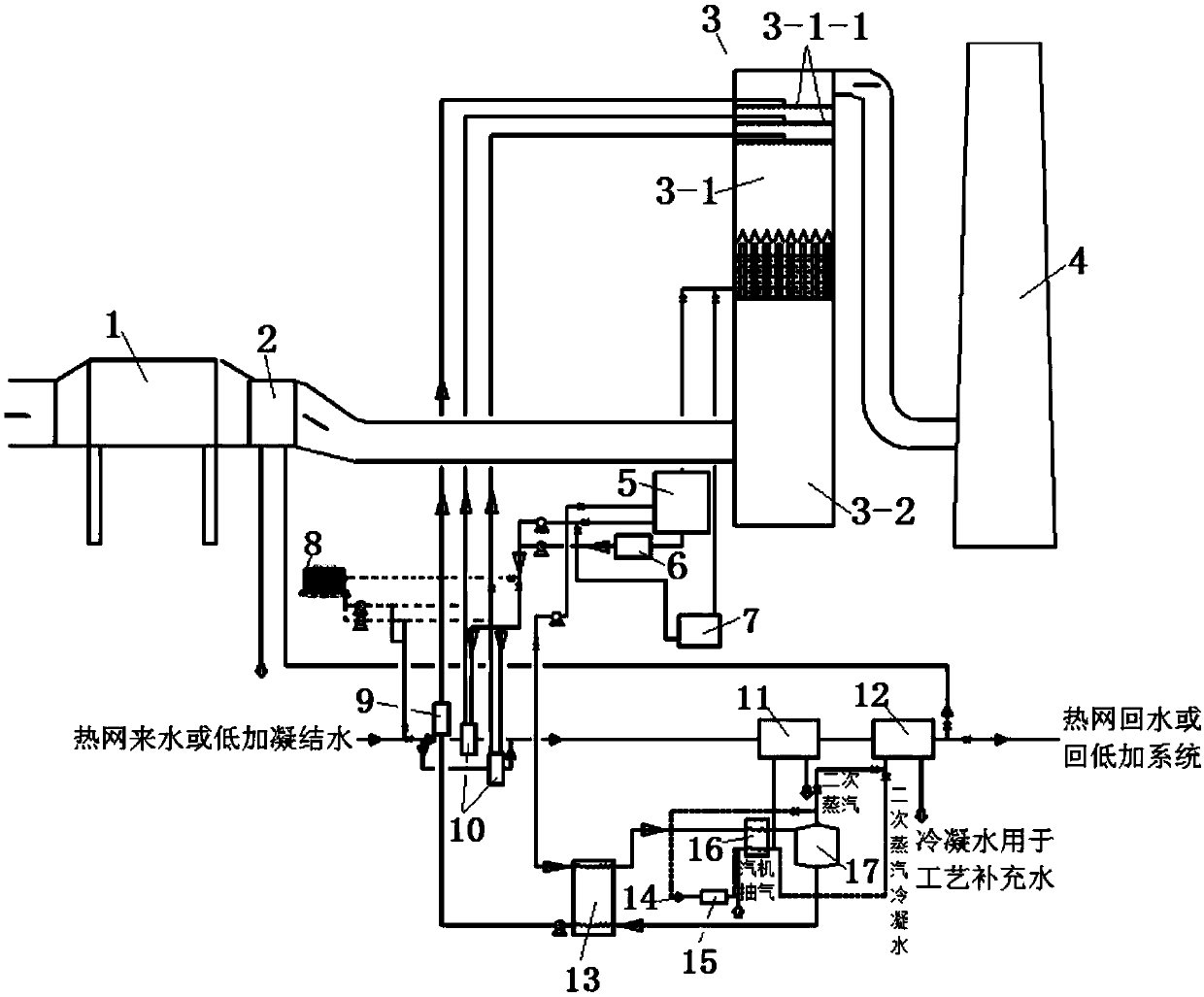

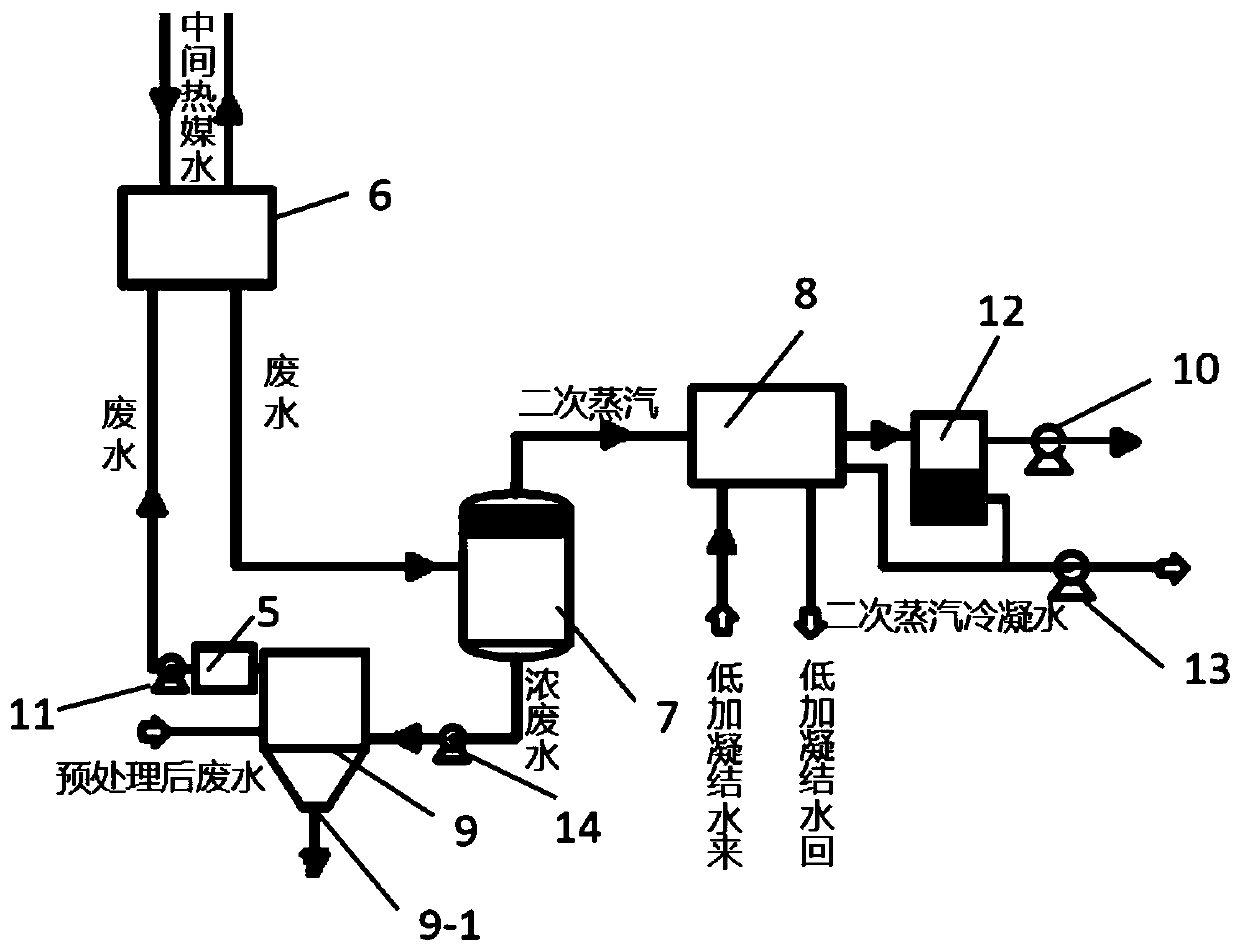

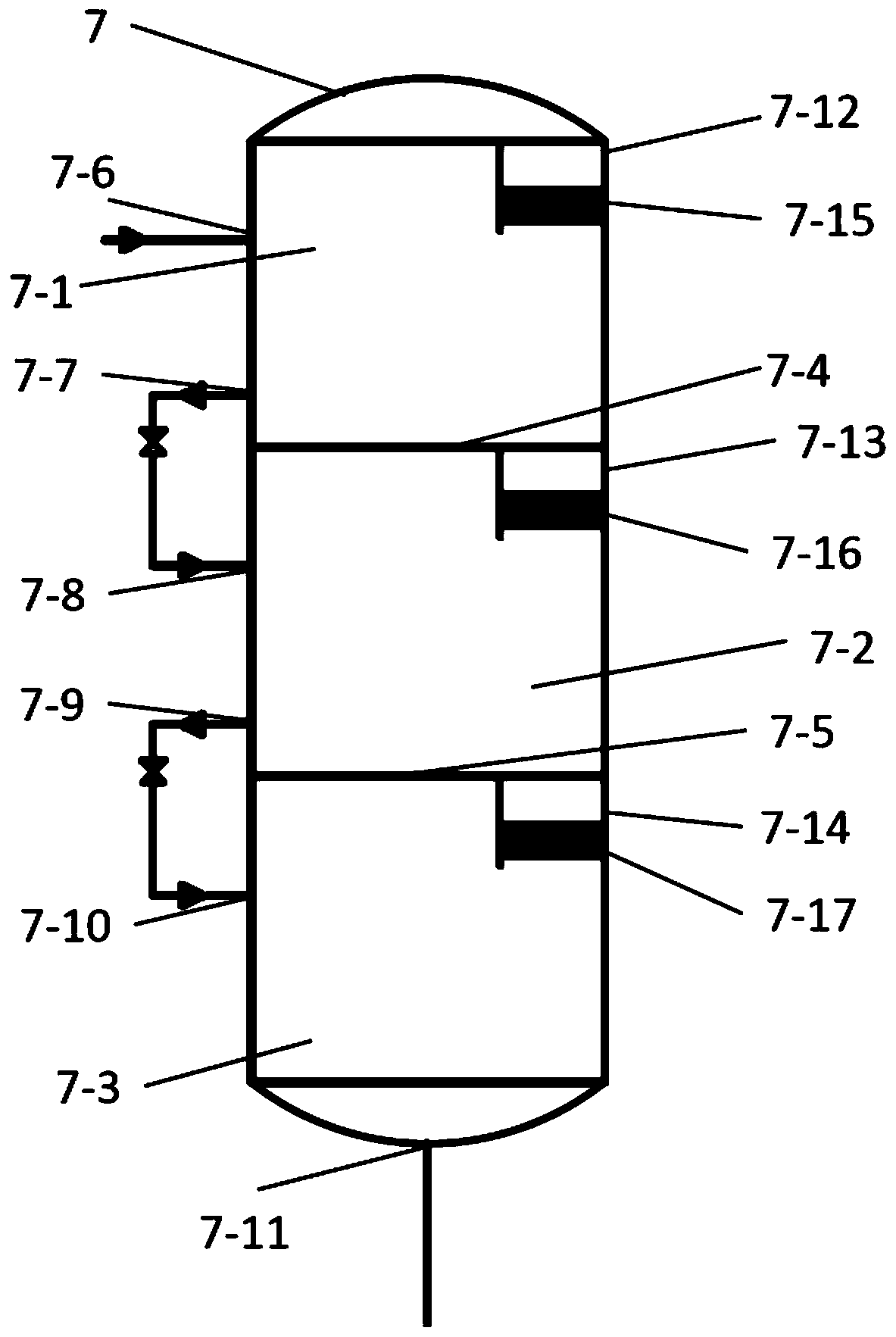

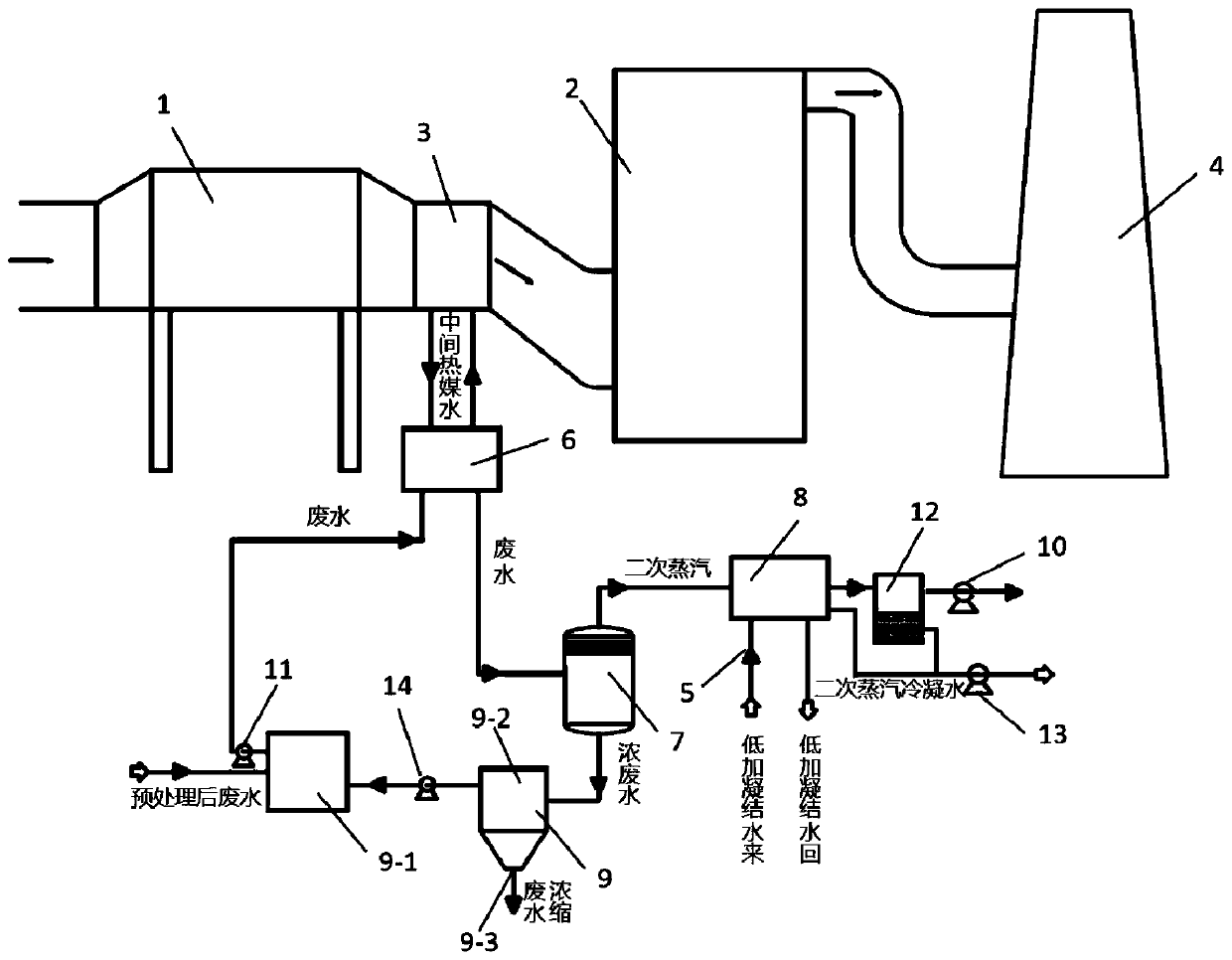

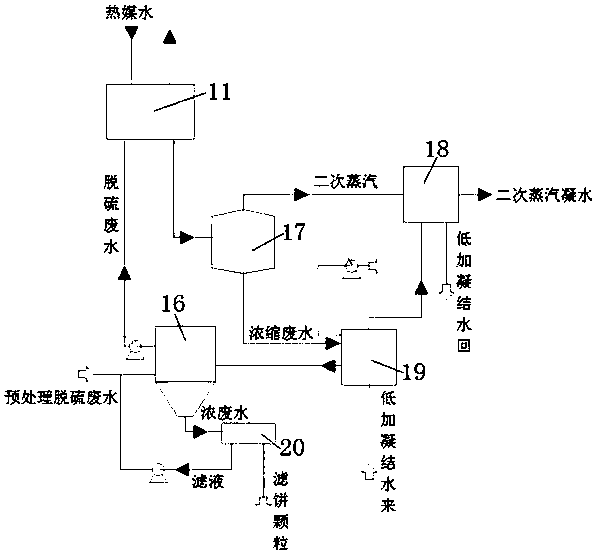

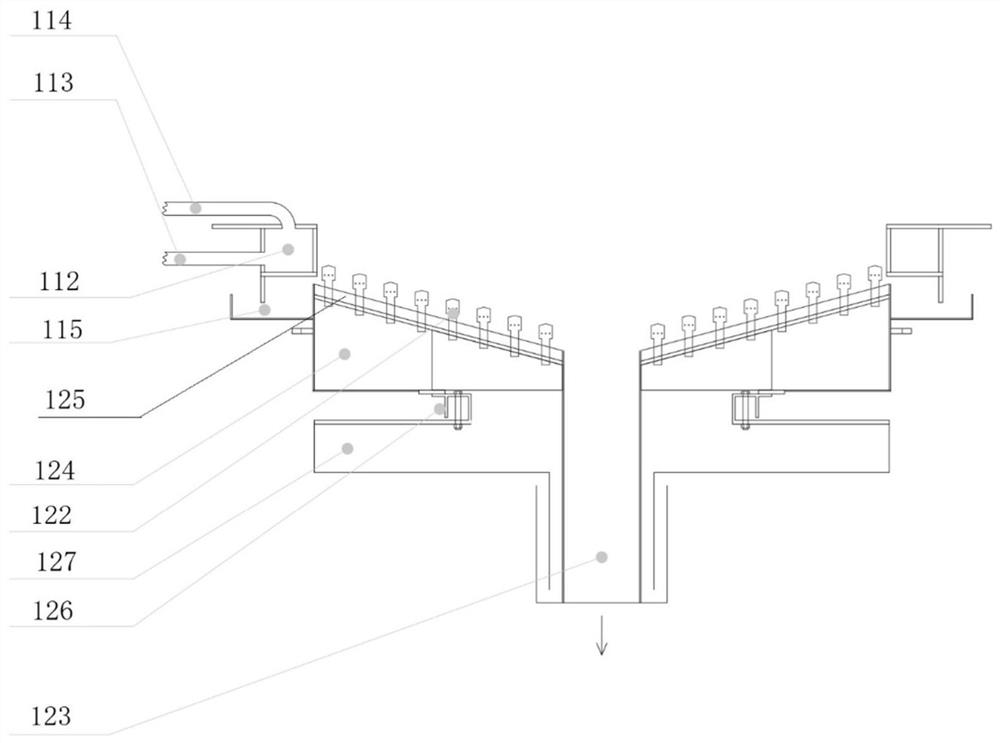

Device for treating wastewater by using low-grade flue gas

PendingCN110372142AHas zero emissionsImprove dust removal effectTreatment involving filtrationWaste water treatment from gaseous effluentsThermal energyFlue gas

The invention discloses a device for treating wastewater by using low-grade flue gas. The device is provided with a dust removal unit, an economizer and a desulfurization unit which communicate sequentially, and further comprises a first heat exchanger, a flash tank and a filter pressing device, and waste heat of the flue gas is recovered by the first heat exchanger to improve the dust removal capacity of the dust removal unit and reduce the process water replenishment of the desulfurization unit. Meanwhile, the heat recovered by the flue gas is used for increasing the temperature of the desulfurization wastewater, and the wastewater after the temperature rise is flashed in the flash tank, so that concentration of the desulfurization wastewater is realized; and the flash tank is in a negative pressure state, the recovered heat of the flue gas is taken out by the concentrated wastewater and secondary steam, the heat contained in the concentrated wastewater and the condensed secondary steam is recovered by using low pressure heater condensed water, and finally the heat is returned to a low pressure heater condensed water system to realize thermal energy cascading utilization. Meanwhile, the filter pressing device effectively treats the desulfurization wastewater. The device has low energy consumption, low investment and low operating cost, achieves efficient environmental protection effects such as energy saving and emission reduction, and has good social and economic impacts.

Owner:CHINA HUADIAN ENG +1

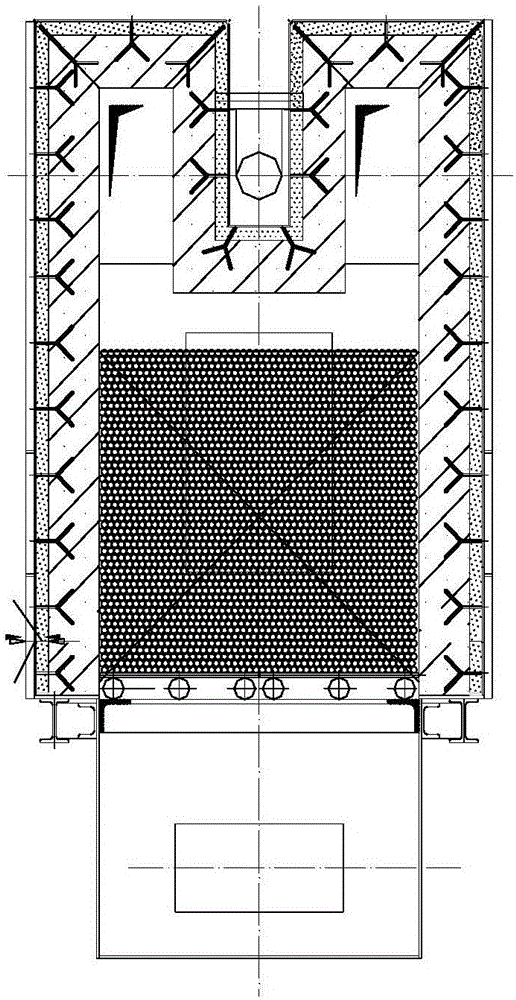

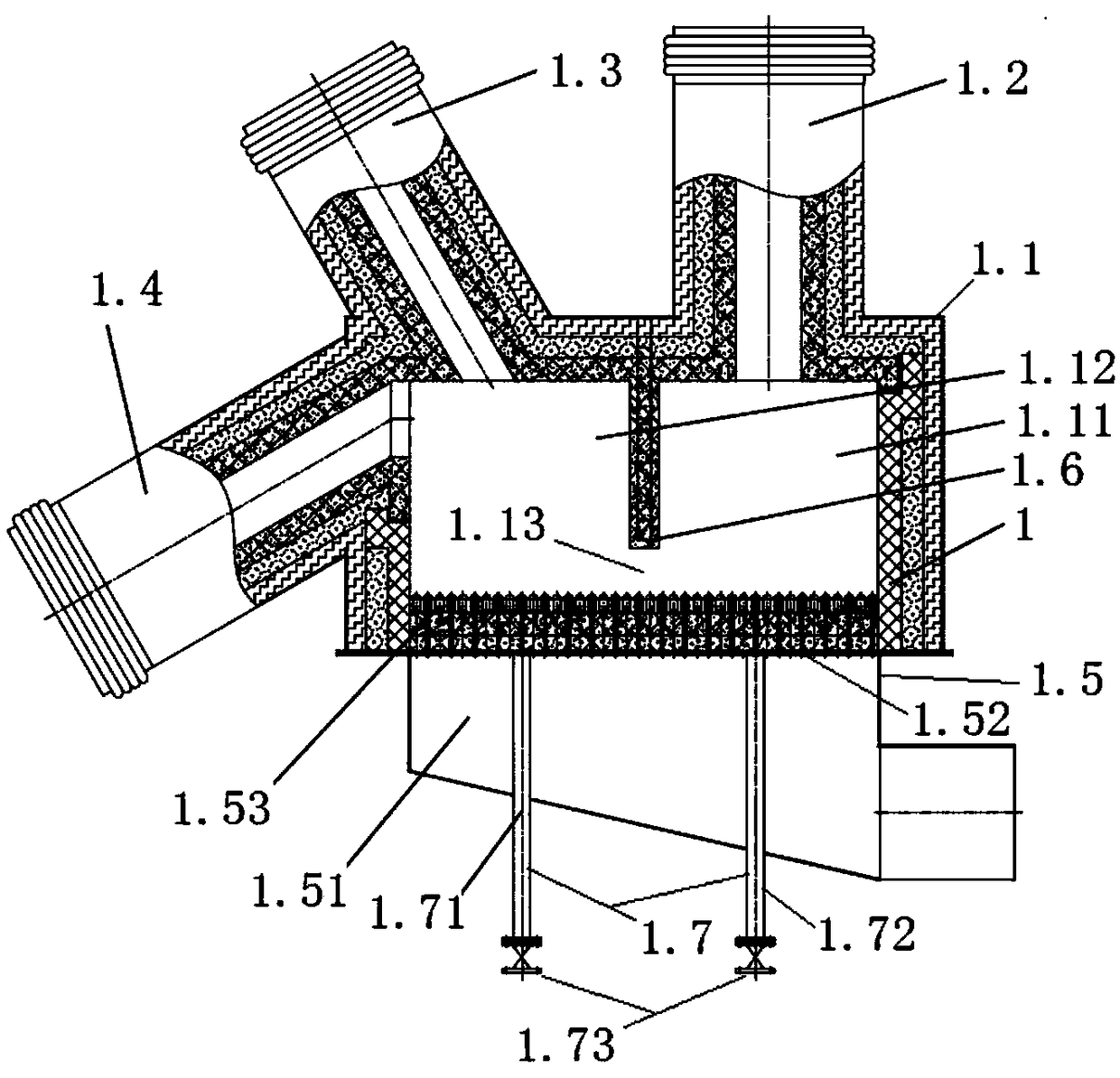

Single heat-storing nozzle device

PendingCN106765091AAvoid short-circuitingAvoid temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerFiberBrick

The invention relates to a single heat-storing nozzle device and belongs to the technical field of workpiece heating, heat treatment and burning. The single heat-storing nozzle device comprises a heat storage tank, a heat storage, a coal gas nozzle and a nozzle brick, wherein the heat storage is arranged in the heat storage tank and is used for storing heat; the coal gas nozzle is embedded between lug type air channels of the heat storage tank; the nozzle brick is connected with a channel of an external lug type heat storage tank; the heat storage tank is externally hung on the exterior of a furnace wall; the heat storage tank is composed of a section bar and a steel plate; a refractory cast material and a refractory fiber are lined in the heat storage tank; the heat storage is made from a spherical refractory material; the spherical refractory material is a cordierite, high-aluminum or mullite high-temperature refractory material; the diameter is 10-20mm; a high-temperature section of the coal gas nozzle 3 in contact with the nozzle brick 4 is made from a silicon carbide tube; a low-temperature section is made from austenitic stainless steel; the nozzle brick 4 is made from one or two of high-aluminum and mullite high-temperature refractory materials; and the use temperature is at 1200-1600 DEG C. The single heat-storing nozzle device has the advantages of convenience in mounting and overhauling and capability of realizing efficient energy conservation and emission reduction.

Owner:BEIJING SHOUGANG INT ENG TECH

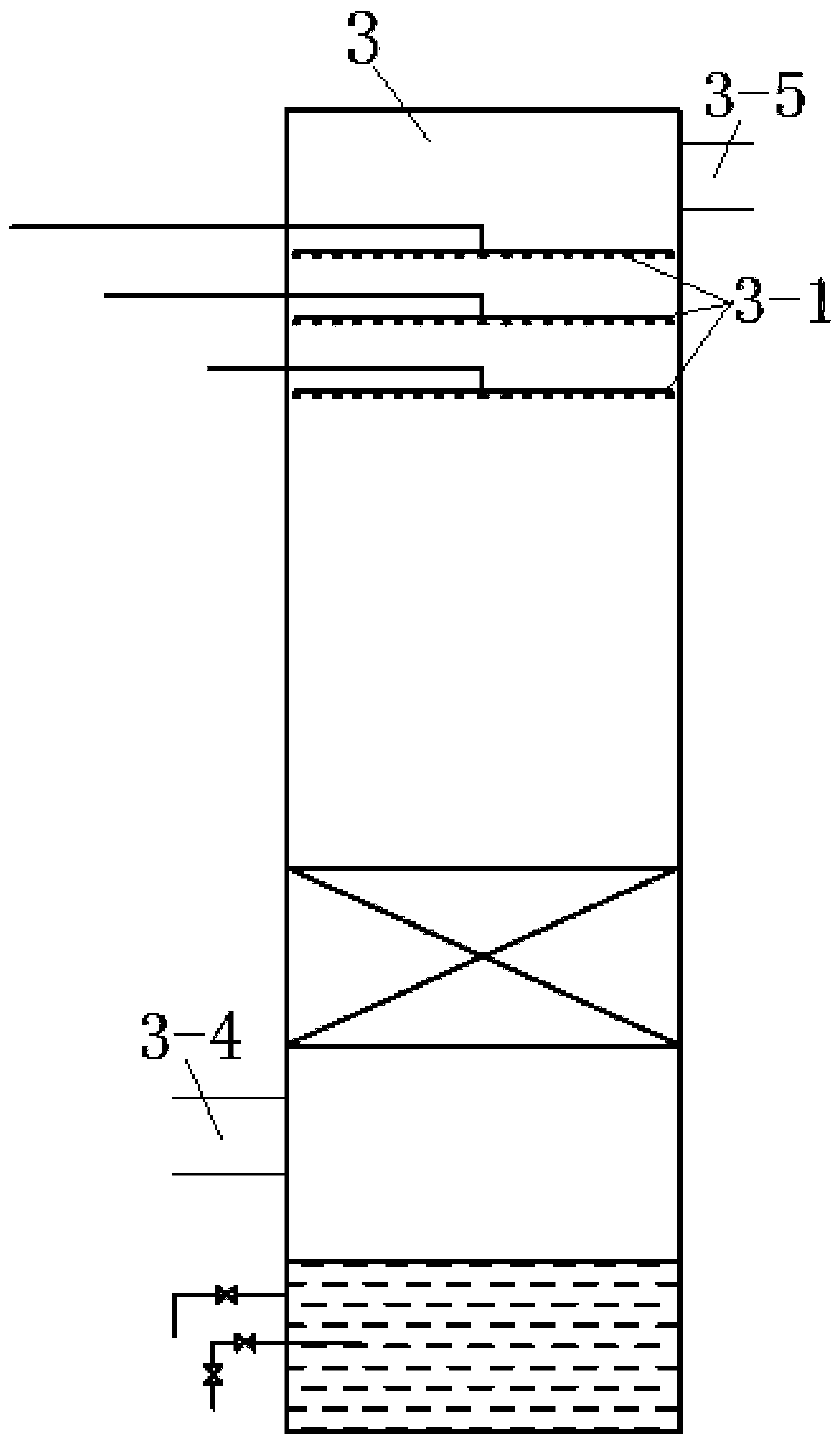

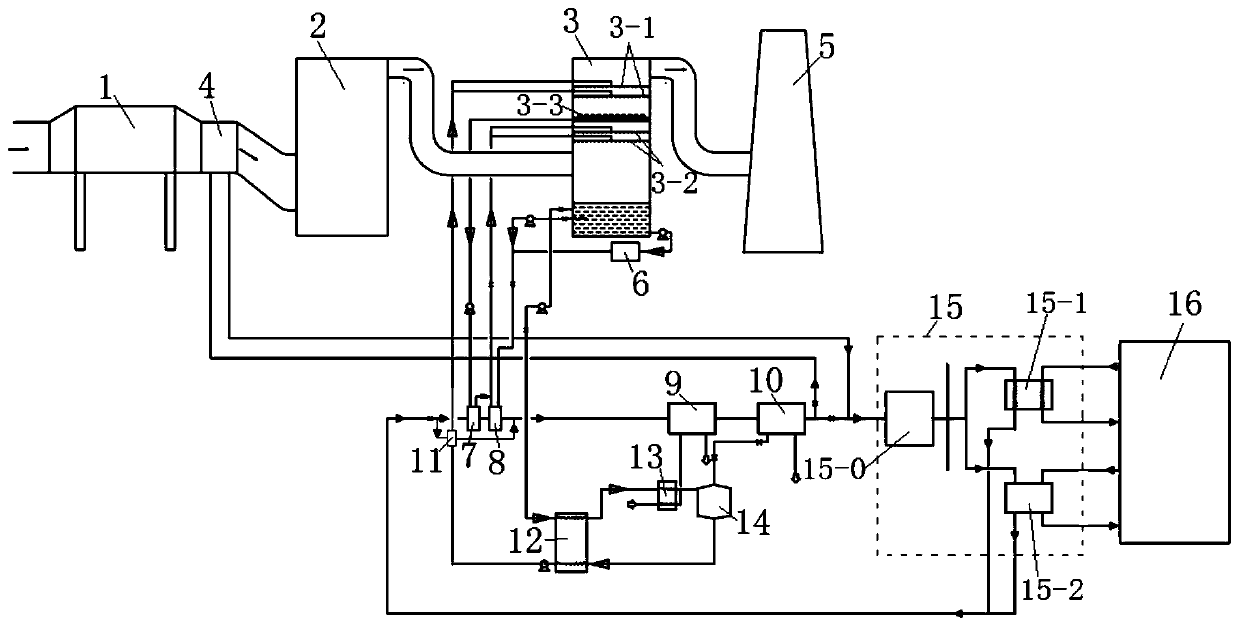

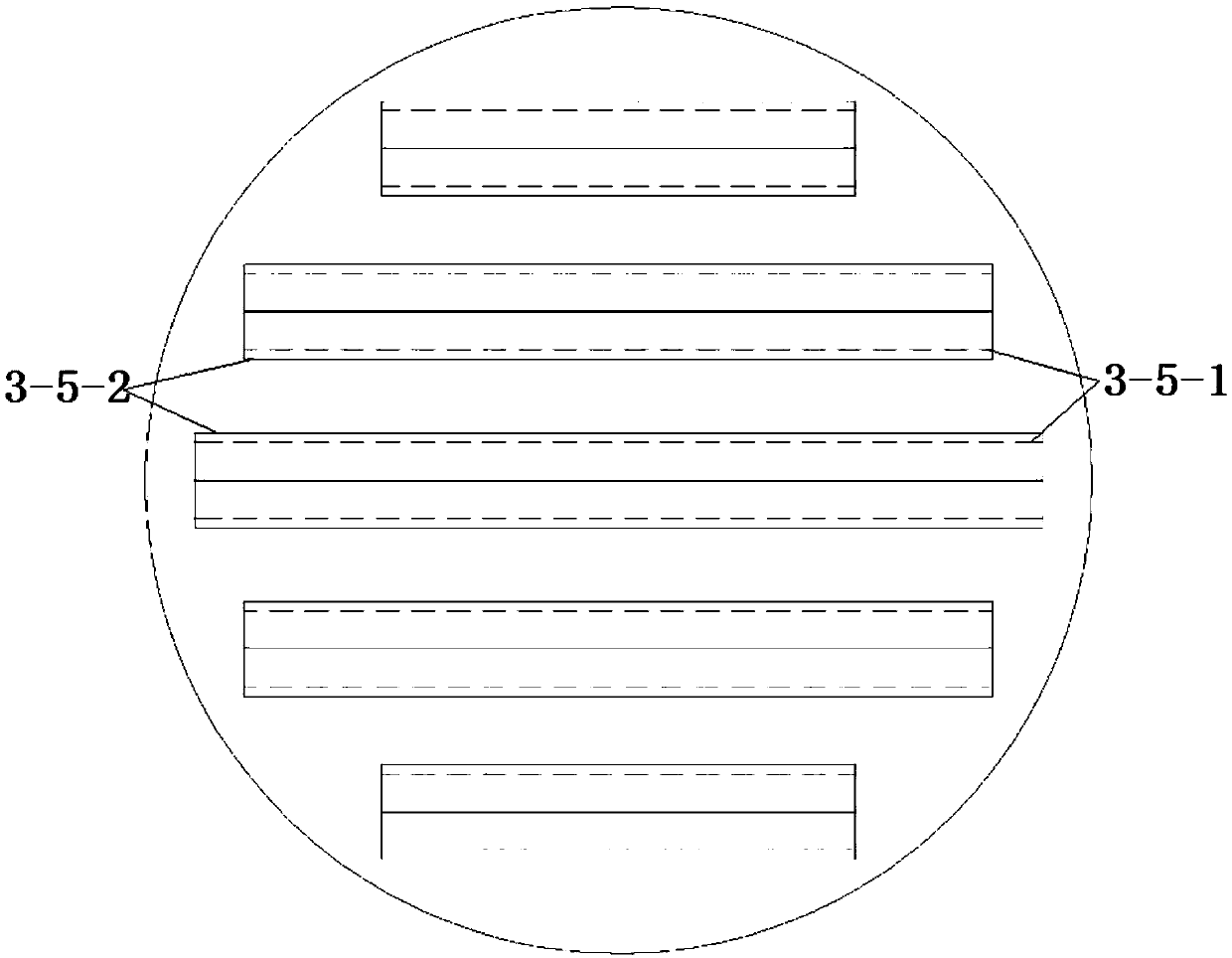

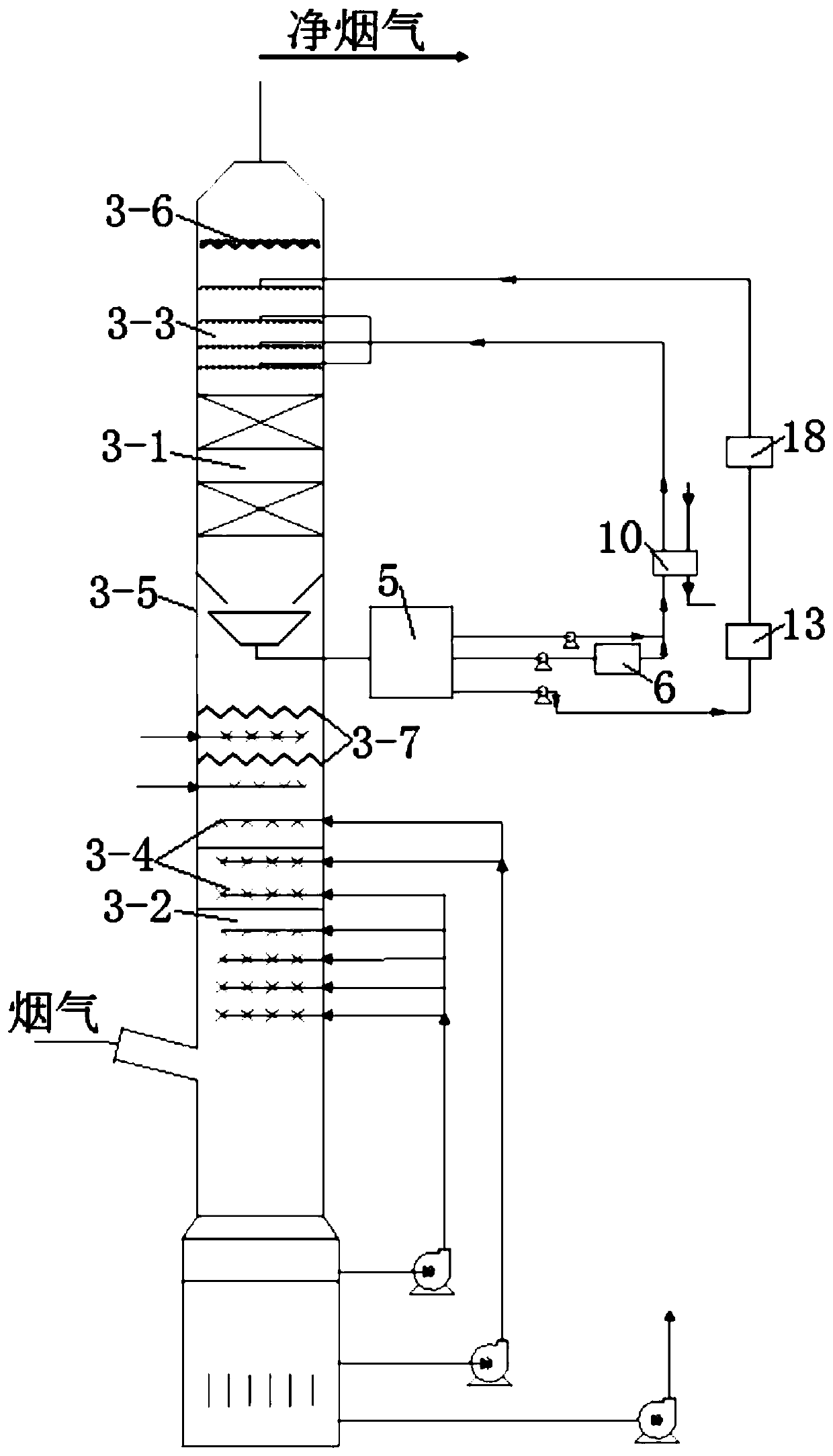

Single-tower double-circulation energy-saving white smoke elimination device

PendingCN111482056AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater vaporFlue gas

The invention discloses a single-tower double-circulation energy-saving white smoke elimination device. According to the device, a desulfurization section and an absorption section are sequentially arranged in a shell of a flue gas purification device from bottom to top, a liquid storage unit is arranged between the desulfurization section and the absorption section, a first spraying layer is arranged between the absorption section and the top end of the shell, and a second spraying layer is arranged between the flue gas inlet of the desulfurization section and the liquid storage unit. Flue gas enters the absorption section from the desulfurization section, and is in countercurrent contact with a concentrated solution or clear water sprayed at the top of the absorption section. In the heating season, the concentrated solution absorbs water in the flue gas and becomes thin, latent heat is released in a precipitated moisture phase change process to heat the flue gas and saline solution,the heated solution is collected by the liquid storage unit, heat exchange is conducted through a first heat exchanger on a first circulation loop, the balance state in the absorption section is flexibly controlled through the amount of taken-away heat, sensible heat of raw flue gas and latent heat of purified flue gas water vapor are deeply recycled, the situation that in the prior art, a large number of cold sources are needed for flue gas cooling and condensation is avoided, and water resources are greatly saved.

Owner:CHINA HUADIAN ENG +1

Dual regeneration energy saving device

PendingCN109838804AFlexible control of balance stateAvoid the needSteam generationIndirect heat exchangersWater vaporFlue gas

The invention discloses a dual regeneration energy saving device. The dual regeneration energy saving device is provided with a first circulation loop, at least a stage of second circulation loop, a refrigerating device and at least a stage of second heat exchanger, and flue gas enters from the bottom of an absorption device to be in countercurrent contact with a concentrated solution or clean water sprayed from the top of the absorption device. During a heating season, the concentrated solution absorbs the water in the flue gas to become thinner, the latent heat released in the phase change process of water is dissolved out, the flue gas and a salt solution are heated, the heated solution is subjected to heat exchange through a second heat exchanger or a refrigeration device on the secondcirculation loop, and the equilibrium state in the absorption device can be flexibly controlled by using the amount of the heat taken away; in a non-heating season, the clean water can be used for spraying to cool the flue gas except using the concentrated solution, the saturated net flue gas can be cooled and analyzed, the water lifting effect is achieved, and the heated water can be recycled after being subjected to heat exchange by the second heat exchanger or the refrigeration device; and finally, the sensible heat of the original flue gas and the latent heat of the net flue gas water vapor are deeply recovered and utilized by the above means.

Owner:CHINA HUADIAN ENG +1

Petroleum coke material calcination cooling device

InactiveCN104697326AGood for secondary useIncrease profitRotary drum furnacesWaste heat treatmentThermodynamicsPetroleum coke

The invention discloses a petroleum coke material calcination cooling device. The device comprises a cylinder and rims, wherein a material inlet, a material outlet and the rims are arranged on the cylinder respectively, the material inlet and the material outlet are located at two ends of the cylinder respectively, one rim is arranged at each of two ends where the material inlet and the material outlet are located, the cylinder further comprises a cooling body connected with the material inlet, an air inlet and an air outlet are arranged on the cooling body, and the diameter of the cooling body is larger than that of the cylinder. With the adoption of the device, heat of a calcined waste coke material can be fully and effectively utilized secondarily, the energy utilization rate and the heat recovery efficiency are increased from traditionally about 20% to more than 30%, and energy is saved.

Owner:GUANGXI HONGDA BIO ENERGY TECH

Low-temperature negative-pressure wastewater zero-discharge system

PendingCN110746025AReduce abrasionExtended service lifeRecuperative heat exchangersSpecific water treatment objectivesFlue gasMulti-stage flash distillation

The invention provides a low-temperature negative-pressure wastewater zero-discharge system. Flue gas is subjected to heat exchange with a first heat exchange medium after passing through a coal economizer, and a flash tank realizes multistage flash evaporation by utilizing gradient vacuum, so that concentration of desulfurized wastewater is facilitated; meanwhile, steam with different temperatures can be formed through multistage flash evaporation, and the steam enters a heat exchange assembly and is subjected to cascade heat exchange with a second heat exchange medium, so that the heat exchange effect is improved; through arrangement of a filter, desulfurized wastewater from a precipitation device can be effectively filtered, scale formation of a first heat exchanger and abrasion of dustin the wastewater to the first heat exchanger are reduced, and thus the heat exchange effect of the first heat exchanger is enhanced, and the service life of the first heat exchanger is prolonged; and after waste heat of flue gas increases the temperature of the wastewater, the flue gas precipitates in flash evaporation of the wastewater, and the waste heat of the flue gas is brought out along with steam, then is recovered by the second heat exchange medium, and finally returns to a low addition system. Under a condition that waste heat of the flue gas is almost not lost, cascade utilizationof heat energy is realized, the defect that high-quality heat energy is consumed in a conventional route is overcome, and energy consumption of units is reduced.

Owner:CHINA HUADIAN ENG +1

Vacuum phase change wastewater concentration and flue gas waste heat recovery system

PendingCN110642444AImprove concentrationIncrease temperatureRecuperative heat exchangersWaste water treatment from gaseous effluentsEconomizerPhysics

According to a vacuum phase change wastewater concentration and flue gas waste heat recovery system provided by the invention, flue gas exchanges heat with a first heat exchange medium after passing through a coal economizer, and a flash tank realizes multistage flash evaporation by utilizing gradient vacuum, so that the concentration of desulfurization wastewater is facilitated; meanwhile, steamwith different temperatures can be formed through multi-stage flash evaporation, the steam and a second heat exchange medium are subjected to stepped heat exchange after entering the heat exchange assembly, and the heat exchange effect is improved; due to the economizer, the flue gas waste heat is used for increasing the wastewater temperature; after wastewater flash evaporation, recovered flue gas waste heat is brought out along with steam, the second heat exchange medium recovers heat contained in the steam, and finally the heat is returned to a low-pressure heater system, so that gradient utilization of heat energy is realized under the condition that the flue gas waste heat is hardly lost, the defect that high-quality heat energy is consumed by utilizing a conventional route is overcome, and the energy consumption of a unit is reduced. By means of the mode, waste water concentration is achieved, meanwhile, the problem of flue gas waste heat recovery of a coal-fired power plant or other industries is solved, and good social and economic influences are achieved.

Owner:CHINA HUADIAN ENG +1

System for concentrating wastewater by heating via low-temperature flue gas

PendingCN110627289AImprove heat transfer effectImprove condensation effectRecuperative heat exchangersWaste water treatment from gaseous effluentsHeating systemConcentration effect

The invention provides a system for concentrating wastewater by heating via low-temperature flue gas. Multi-grade flashing is realized by using gradient vacuum through a flash tank, so that the concentration effect of desulfurization wastewater is increased; meanwhile, steam with different temperature, formed by the multi-grade flashing, enters communicated sub shell sides respectively, and is subjected to cascaded heat exchange with a secondary heat exchange medium, so that the heat exchange effect is improved; a second heat exchanger is of a tube-shell type structure, and a plurality of subshell sides are adopted, so that the complexity of the structure of the second heat exchanger and the connection of the shell sides is reduced while the condensation effect of the steam can be improved, and furthermore, the investment cost and construction period of system equipment are reduced; after the temperature of the wastewater is improved, the residual heat of the flue gas participates inwastewater flashing; and then the residual heat of the flue gas is further recycled by the second heat exchange medium after being brought out by the steam, and then returns to a low-temperature heating system. In the case that recycled heat is nearly not lost, the application of the heat is widened, and cascaded utilization of the heat is realized; and the disadvantage of a conventional route that high-quality heat is consumed is overcome and the energy consumption of units is reduced.

Owner:CHINA HUADIAN ENG +1

Method for preparing high-temperature oxidation-resistant coating with high infrared radiation rate by sol-gel method

InactiveCN102766866AImprove antioxidant capacityImprove thermal efficiencyMetallic material coating processesLithium chlorideMetallic materials

The invention relates to a method for preparing a high-temperature oxidation-resistant coating with high infrared radiation rate by a sol-gel method. The method comprises the following steps of: preparing sol by using tetraethoxysilane and zirconium oxychloride as raw materials and lithium chloride or lithium fluoride as a mineralizer, directly coating the sol on the surface of a silicon carbide or carbon-based composite matrix, drying, and sintering to obtain a layer of compact zirconium silicate high-temperature oxidation-resistant coating with high infrared radiation rate. The technology belongs to the technical field of inorganic nonmetallic materials. The coating prepared by the method has high infrared radiation rate, can be taken as a high-temperature oxidation-resistant coating, and can achieve a forced cooling effect at the same time; and the process is simple and can practically applied conveniently.

Owner:SHANGHAI UNIV

Regeneration system for achieving deep utilization of sensible heat of raw flue gas

PendingCN109395540AAvoid the needSolve the problem of only investing but not earningCombination devicesGas treatmentFlue gasWater vapor

The invention discloses a regeneration system for achieving deep utilization of sensible heat of raw flue gas. According to the regeneration system, a liquid storage unit is arranged in an absorbing device, an inner cavity is divided by the liquid storage unit into a first flue gas treatment area and a second flue gas treatment area, flue gas enters the bottom of the absorbing device to be in countercurrent contact with a concentrated solution sprayed to the top of the absorbing device, a concentrated solution in the second flue gas treatment area absorbs moisture in the flue gas and gets diluted, latent heat released in the moisture phase change process is discharged, and the flue gas and the concentrated solution are heated to 55-65 DEG C; the heated concentrated solution is guided out through the liquid storage unit and enters a first heat exchanger to exchange heat with a heat exchange medium such as heating network water, the heat exchange medium can be heated to 3-10 DEG C, the concentrated solution enters the first flue gas treatment area after being cooled to the temperature roughly coincident with that of a solution inlet of the top of the second flue gas treatment area, and the moisture in the flue gas continues to be absorbed. Firstly, gradient heat exchange is adopted, the heat exchange quality can be effectively improved, deep recycling is conducted, and the sensible heat of the raw flue gas and latent heat of water vapor of clean flue gas are deeply recycled.

Owner:CHINA HUADIAN ENG +1

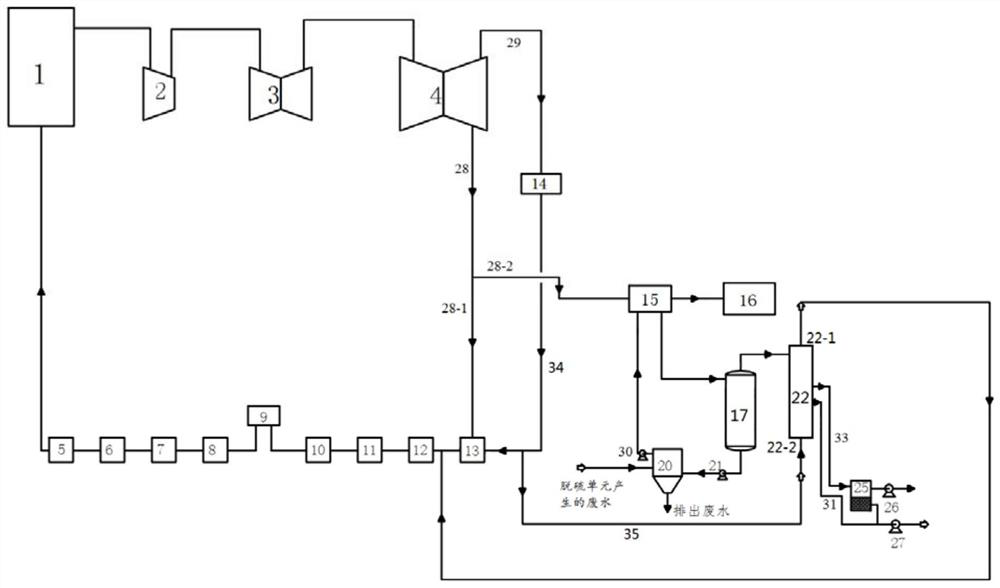

Device for waste heat recovery and smoke moisture removal combined wastewater treatment

PendingCN110407384AReduce moisture contentReduce dust contentRecuperative heat exchangersTreatment involving filtrationThermal energyHigh concentration

The invention discloses a device for waste heat recovery and smoke moisture removal combined wastewater treatment. The device is used for solving the problems of smoke waste heat recovery and wastewater concentration of a power plant, and is composed of an absorption heat pump system, a wastewater concentration system and a press filtration system. The device utilizes the waste heat of smoke of the coal-fired power plant or other industries to concentrate wastewater, the concentrating process has little influence on the humidity of the smoke, the wastewater is turned into usable water, and therecovered heat of the smoke is transmitted into a low-pressure heater system to realize the gradient utilization of the heat energy. The concentrated and reduced high-concentration wastewater can beconveyed into a evaporative drying system, so the heat required for the evaporative drying system is greatly reduced, the influences on units are reduced, and the whole device has the advantages of low energy consumption, low investment and low running cost.

Owner:CHINA HUADIAN ENG +1

Supermolecular universal fuel saving pipe capable of step-by-step superstrong activation

InactiveCN102580648APass smoothlyImprove fuel saving effectInternal combustion piston enginesCombustion-air/fuel-air treatmentDecompositionFuel oil

The supermolecular universal fuel saving pipe capable of step-by-step superstrong activation adopts the step-by-step multiple decomposition and activation and the long-effective splitting technology. Due to the adoption of the fuel saving pipe, a fuel pipe used for various small car using diesel oil or gasoline, transport vehicles, coaches, buses, engineering vans, agricultural vehicles, motorcycles, military vehicles, radio cars, tanks, airplanes, trains, steamships, warships, generators, engines and the like is not only a fuel pipe for transporting fuel oil, but also a fuel pipe type fuel economizer. The functions of the far infrared and negative ions emitted by the fuel economizer and the functions of the activation and decomposition of a plurality of radial high-intensity activation rings are applied on the fuel oil directly, so that the fuel oil molecular group achieves the micro molecularization, the sufficient burning of the fuel oil is facilitated well, and the fuel saving and emission reduction effects are superior. According to the fuel saving pipe, the fuel saving ratio generally achieves 20-40%, the exhaust contaminant, namely CO and HC+NOx is reduced by 70-90% comprehensively, the power is increased by 15-30%, and the fuel saving pipe is most effective in fuel saving ratio, is suitable for being matched with various large-size and small-size new and old cars and ships and various machines for use, and is extremely perfect.

Owner:北京中能国泰能源技术研究院 +1

Oil-water fuel combined type exhaust gas power engine

InactiveCN105443225APowerfulSupercharged combustion ratioCoolant flow controlExhaust apparatusThermal insulationFour-stroke engine

Disclosed is an oil-water fuel combined type exhaust gas power engine. In order to solve the problems of loss of energy of a cooling system and loss of energy of exhaust gas discharged out of a piston four-stroke engine and the like in the prior art, multiple advantages of technologies such as a power turbine and a charging turbine of a combined type exhaust gas supercharging device and feed-water three-impulse regulating are adopted; a cooling water tank and a cooling fan of the original engine are omitted; a thermal insulation water tank, an overheated steam water tank, an overheated steam spray nozzle, a water level sensor, a water feed flow sensor, a water feed adjusting valve, a water feed actuator, a proportion integration differentiation (PID) adjuster, a water feed flow transmitter, a steam flow transmitter, a water level transmitter and an overheated steam flow sensor are additionally arranged; therefore, the oil-water fuel combined type exhaust gas power engine which adopts an exhaust manifold to inject overheated steam serving as fuel and adopts the power turbine and the charging turbine of the combined type exhaust gas supercharging device for working is designed. Compared with the original piston four-stroke engine technology, the oil-water fuel combined type exhaust gas power engine has the functions of larger pressurized combustion ratio, more efficient energy saving and emission reduction and higher power.

Owner:TAIYUAN UNIV OF TECH

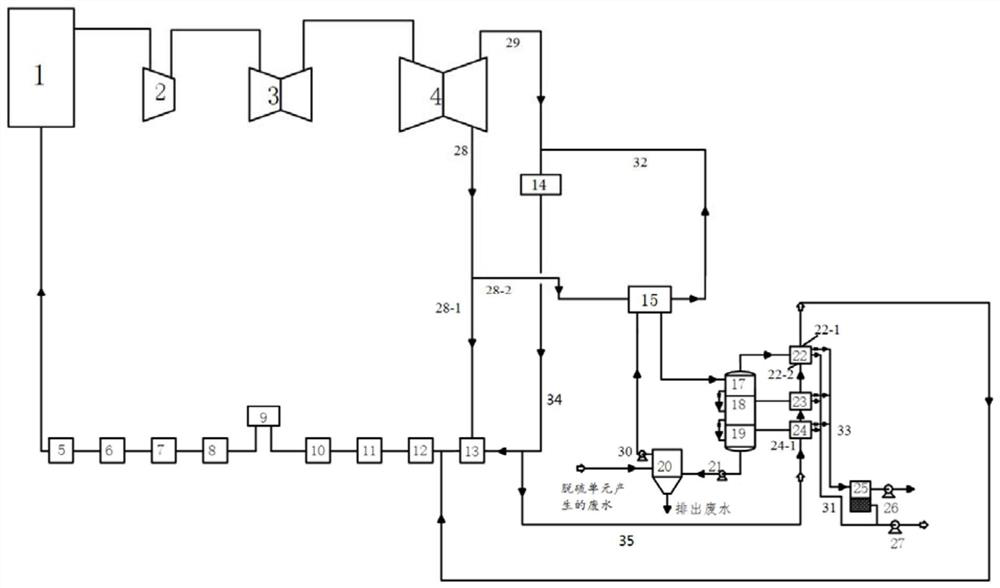

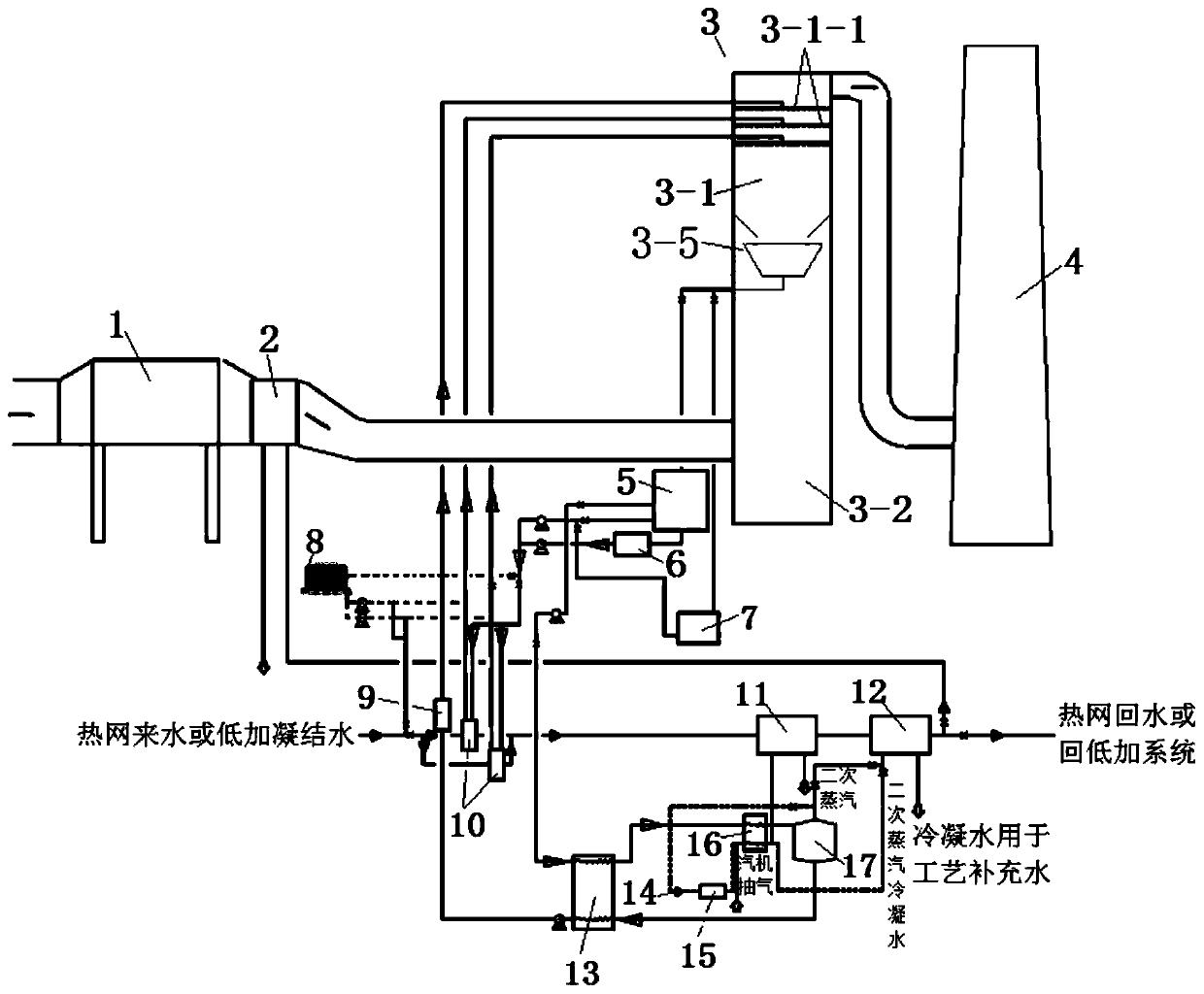

Wastewater concentration and waste heat recycling device and method

PendingCN112097542AAchieving zero emissionsReduce heat lossLiquid degasificationSteam/vapor condensersCondensed waterGenerating unit

The invention belongs to the technical field of wastewater treatment, and particularly relates to a wastewater concentration and waste heat recycling device and method. The wastewater concentration and waste heat recycling device comprises a desulfurization unit and a wastewater concentration system which communicate. The wastewater concentration system comprises a wastewater pool, a wastewater heater, a flash tank, a condenser and a low-pressure condensed water system which communicate. The low-pressure condensed water system communicates with the wastewater concentration system. The low-pressure condensed water system comprises a generator set, a condenser, a first low-pressure heater and a high-pressure heater. Heat discharged by the generator set can be used for heating wastewater in the wastewater heater, condensed water at an outlet of the condenser serves as a refrigerant to recycle heat of secondary steam, gradient utilization of the heat is achieved, the heat is returned to the low-pressure condensed water system through the wastewater concentration system, almost no heat is lost in the process, the heat required by desulfurization wastewater treatment is also satisfied, wastewater concentration is realized, and the defect that high-quality heat energy is consumed by utilizing a conventional route is overcome.

Owner:CHINA HUADIAN ENG +1

Copper-plated steel wire hot air circulation drying system

ActiveCN105135862BImprove heat utilizationImprove drying qualityDrying gas arrangementsPretreated surfacesFiberInsulation layer

The invention discloses a hot air circulation drying system for copper-plated steel wires. After the circulating drying air is heated and pressurized by an automatic temperature-control hot air blower, it is introduced into the inner cavity of a cyclone airflow drying cylinder through a hot air channel and a tangential spiral air inlet. The outlet of the oblique tee at the inlet end of the line is discharged, and the saturated steam evaporated by the water film on the surface of the line is taken away. After the water mist is absorbed by the rotary filter device, the drying pipe absorbs the water again, and then sent to the automatic temperature control system through the return air duct. The air inlet of the hot air blower is circulated to heat and pressurize. There is an insulation layer on the outside of the cyclone airflow drying cylinder, and a turbulent drying section in the inner cavity; there is a steam trap in the low-pressure evaporation and separation section, and moisture evaporation windows are distributed on the wall of the cylinder; the water film drive-off section on the surface of the metal wire. The rotary adsorption net device drives the fan blades to drive the filter disc on the rotary shaft to rotate at high speed. After the water mist is absorbed by the filter disc, it is centrifugally thrown to the variable diameter tube shell and discharged by the drain valve; the rotary filter disc is made of fiber Wire or metal, plastic monofilament woven multi-layer composition. The drying tube is a heat-resistant, high air resistance tube.

Owner:长春航天安可工业有限公司

Crystal form transformation energy-saving device, alumina roasting system and production method thereof

PendingCN108726549ASimple structureEasy to makeAluminium compoundsChemical industryNitrogen oxidesRetention time

The invention provides a crystal form transformation energy-saving device, which comprises a main box body, a blanking pipe, a pressure equalizing pipe, a return pipe and a wind distribution mechanism. The crystal form transformation energy-saving device has the effects of simple structure and convenient making, is convenient to control an appropriate retention time of materials in the main box body, ensures the completion of material crystal form transformation, and enables the product to reach the quality requirements of high-quality metallurgical grade alumina. The invention also provides an alumina roasting system, which includes a main roasting furnace, a cyclone separation device and the crystal form transformation energy-saving device. Through combination of the crystal form transformation energy-saving device and an existing alumina roasting system, the alumina roasting system provided by the invention has the characteristics of lowering the temperature of the main roasting furnace, reducing the unit consumption of fuels or increasing the productivity of the roasting furnace, reducing the initial nitrogen oxide concentration of the roasting furnace and the like, and throughthe design of a secondary air supply apparatus, the initial nitrogen oxide emission of the roasting furnace is greatly reduced. The invention also discloses a production method of alumina, the methodhas the advantages of simplified technological process, high efficiency, energy saving and emission reduction, and is easy for industrial production.

Owner:HUNAN SIWEI ENERGY ENVIRONMENT ENG

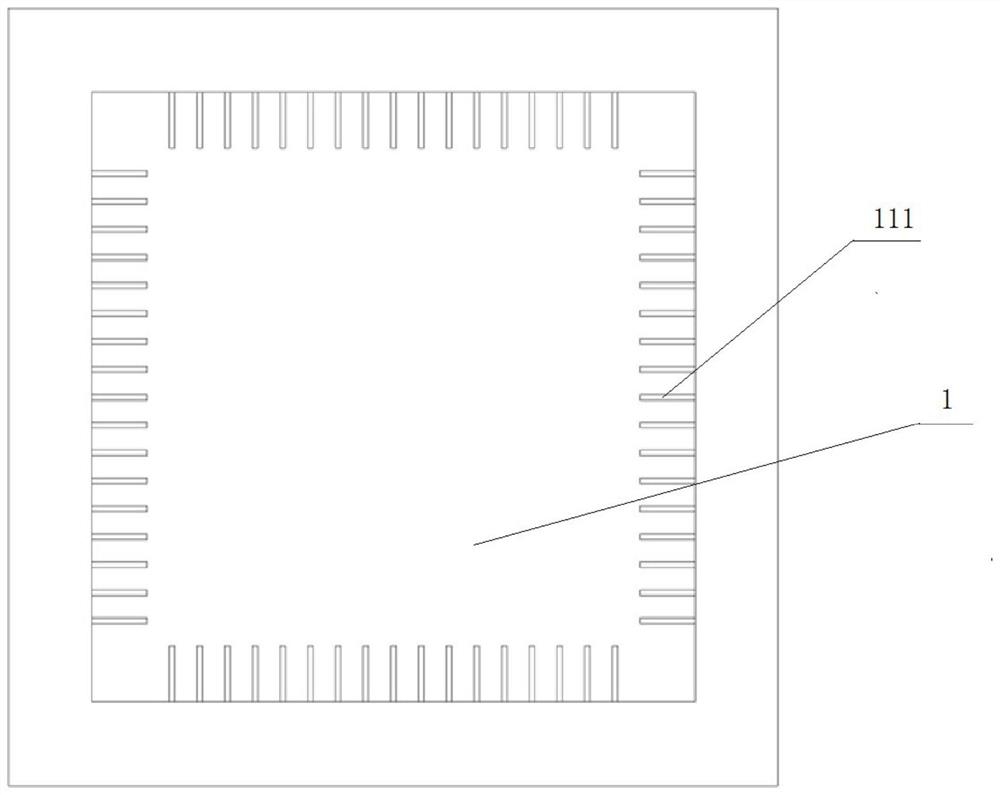

Sensing type piano recording technical scheme

InactiveCN109903741ASimple structureReasonable designElectrophonic musical instrumentsPianoSoftware system

The invention relates to a sensing type piano recording technical scheme. The sensing type piano recording technical scheme is characterized in that a recording device comprises a main control box anda sensor guide rail, the main control box is provided with a sensor interface and a USB interface, and the sensor guide rail is connected with the sensor interface on the main control box through a strip-shaped cable; four PCBs are mounted on the sensor guide rail, and each PCB is provided with 22 photoelectric sensors; the PCBs are connected with telescopic flexible flat cables; the main controlbox is connected with a computer installed with a recording software system through the USB interface and outputs data to the computer; the upward face of each photoelectric sensor is provided with alight-emitting diode and a phototransistor. The sensing type piano recording technical scheme has the advantages that the technical scheme is convenient in operation and simple in principle, the system can precisely capture a playing process by the aid of the high-sensitivity photoelectric sensors, and each moment of the playing can be precisely recorded and flexibly saved.

Owner:孔晓芳

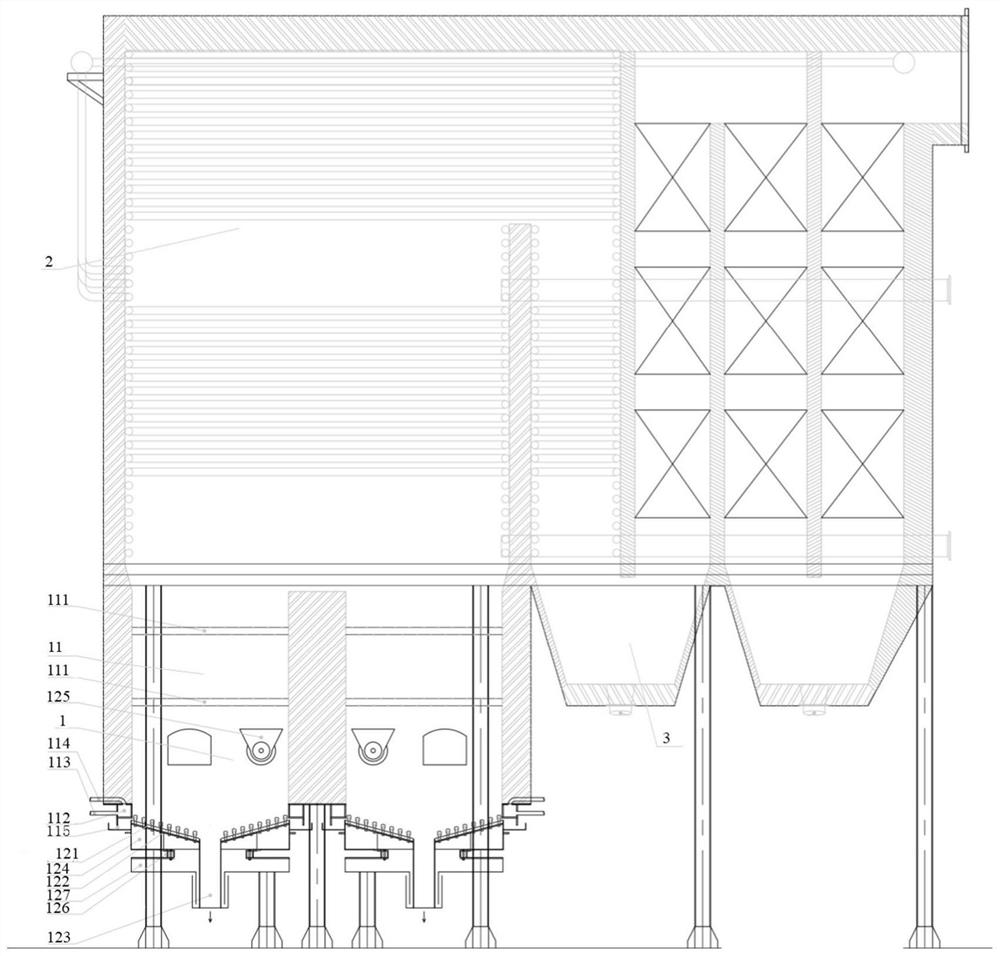

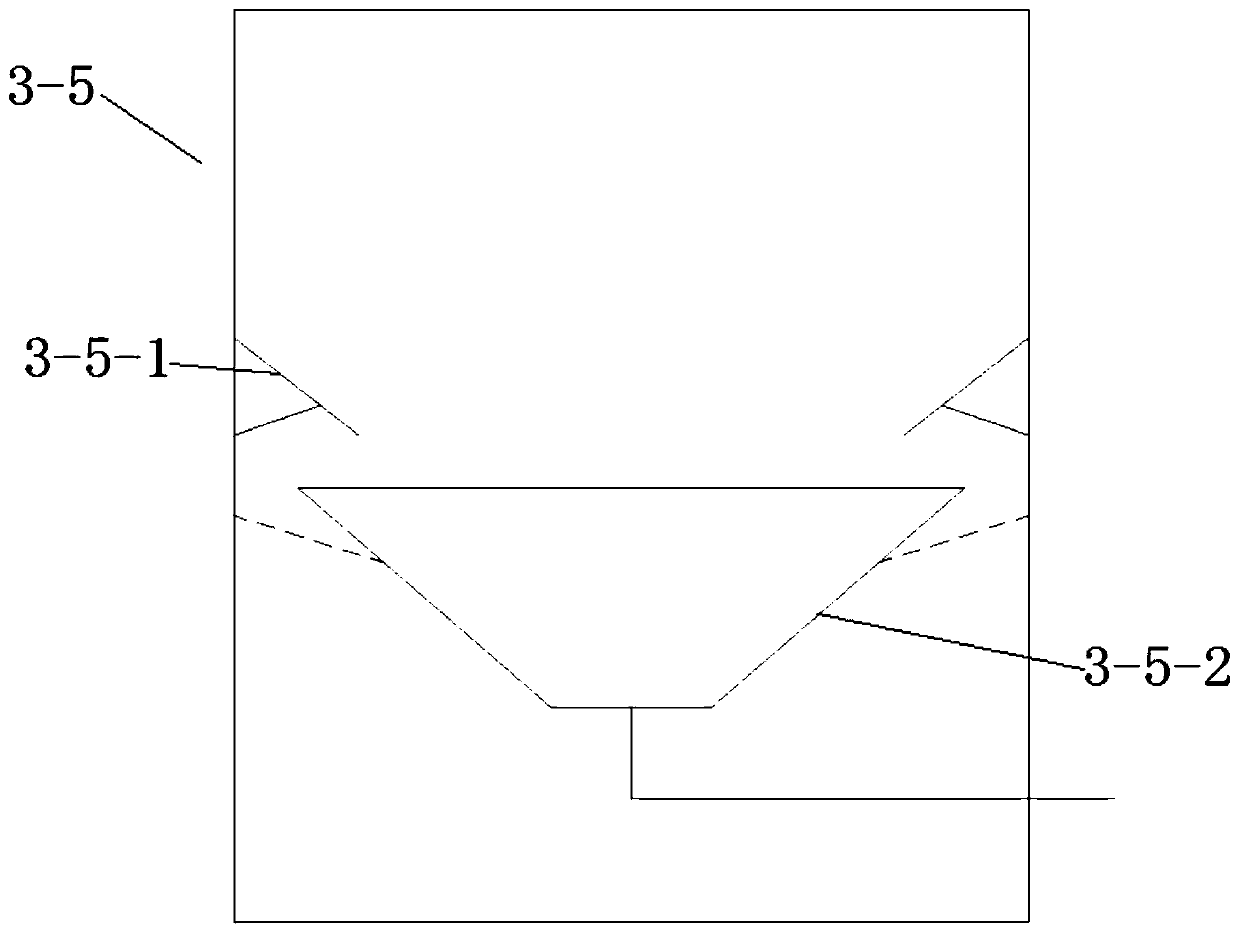

Integrated biomass gasification low-nitrogen oxygen-deficient combustion boiler

PendingCN111720815AEasy to installIncrease spacingGratesSolid fuel combustionThermodynamicsCombustion chamber

The invention discloses an integrated biomass gasification low-nitrogen oxygen-deficient combustion boiler. The low-nitrogen oxygen-deficient combustion boiler comprises a gasification combustion area, a heat exchange area and an ash deposition area which are arranged in the same combustion boiler body. The gasification combustion area comprises a combustion chamber and a rotary combustion bed layer, the rotary combustion bed layer is arranged below the gasification combustion area, the rotary combustion bed layer comprises a rotary combustion bed, a fixed gear is arranged on the outer ring ofthe rotary combustion bed, and a motor drives the rotary combustion bed to rotate through the fixed gear; the rotary combustion bed is a conical plate, and the air cap is arranged on the conical plate; the central position of the conical plate is hollow and is connected with the ash falling pipe; a primary air duct is arranged below the conical plate, a fixed air duct is arranged below the primary air duct, and the fixed air duct is connected with a primary fan air outlet; the combustion chamber is a cylindrical cavity connected with the rotary combustion layer, an air pipe surrounding the inner wall of the cavity is arranged in the cavity, the heat exchange area is arranged above the gasification combustion area, a heat exchange layer is arranged in the heat exchange area, and the heat exchange layer is formed by evenly arranging heat conduction oil pipelines or steam pipelines; and the ash deposition area is communicated with the heat exchange area.

Owner:TAICANG XINRUI ENERGY SAVING EQUIP +1

Single-tower desulfurization white removal device

PendingCN109821382AAvoid the needSolve the problem of only investing but not earningDispersed particle separationWater sourceEngineering

The invention discloses a single-tower desulfurization white removal device. According to the device, a desulfurization section and an absorption section are sequentially arranged in a shell of a fluegas purification device from bottom to top, a liquid storage unit with a specific structure is arranged between the desulfurization section and the absorption section, a first spraying layer is arranged between the absorption section and the top end of the shell, a second spraying layer is arranged between a flue gas inlet of the desulfurization section and the liquid storage unit, and flue gas enters the absorption section from the desulfurization section and contacts with concentrated solution or clear water sprayed from the top of the absorption section in a reverse flow manner. In the heating season, concentrated solution absorbs moisture in flue gas and is thinned, latent heat is released in the moisture separating out and phase changing process, the flue gas and the saline solutionare heated, heated solution is collected by the liquid storage unit, heat is exchanged by a first heat exchanger on a first circulation loop, an equilibrium state in the absorption section is flexiblycontrolled by the taken away heat, sensible heat of original flue gas and latent heat of clean flue gas are deeply recycled and utilized, a lot of cold sources needed by cooling and condensing of theflue gas in the prior art are avoided, and water sources are greatly saved.

Owner:CHINA HUADIAN ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com