Single heat-storing nozzle device

A single regenerative and regenerative box technology, applied in single regenerative burner device, multi-stream, swirling single regenerative burner device, and external mounting ear type field, can solve the problem of low air preheating temperature, gas The problems of short tube life and insufficient heating capacity can reduce pollution emissions, reduce fuel consumption and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

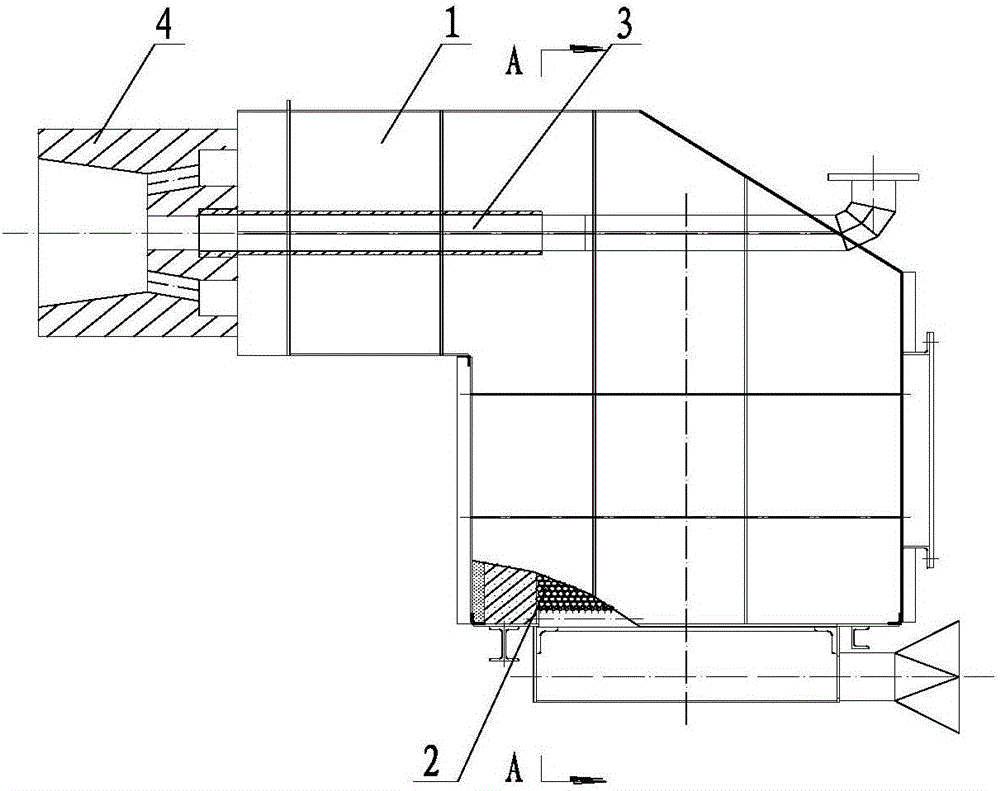

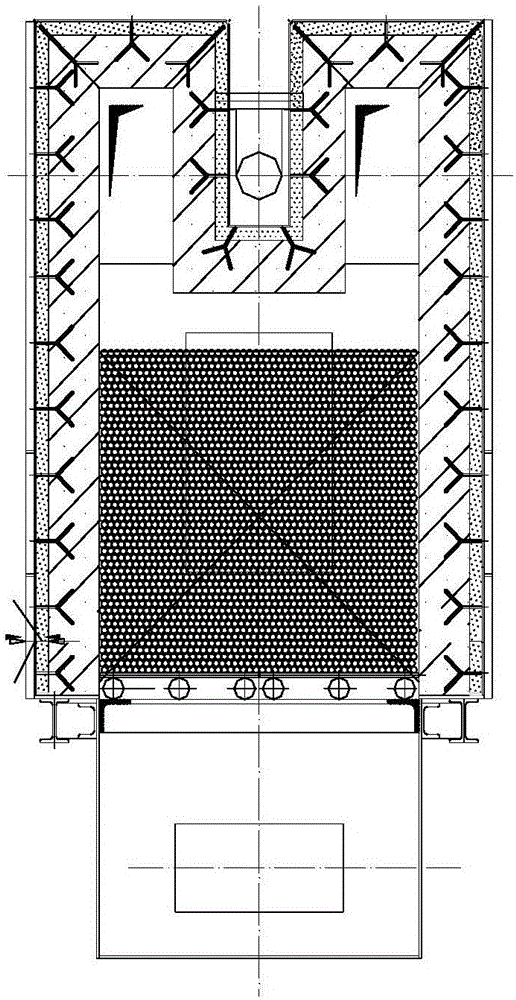

[0018] A single heat storage burner device, comprising a heat storage box 1, a heat storage body 2, a gas burner 3 and a burner brick 4. The heat storage box 1 is equipped with a heat storage body 2 for heat storage, the gas burner 3 is embedded between the ear-type air channels of the heat storage box 1, and the burner brick 4 is connected with the channel of the external ear-type heat storage box 1.

[0019] The heat storage box 1 is hung outside the furnace wall, and the two ear-type air passages are separated on both sides, and the airflow flows in an up-and-down interchangeable manner, and the combustion-supporting air is preheated to 950°C. The shell of the heat storage box 1 is composed of section steel and steel plate, lined with refractory castables and refractory fibers, so as to ensure the service life and heat preservation effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com