Cement kiln power material scattering device and cement kiln with same

A technology of a material spreading device and a power device, applied in the field of cement kilns, can solve the problems of no effective material control, material short circuit, poor material flow control ability, etc., to achieve contact and mixed contact, improve heat exchange efficiency, and ensure normal production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

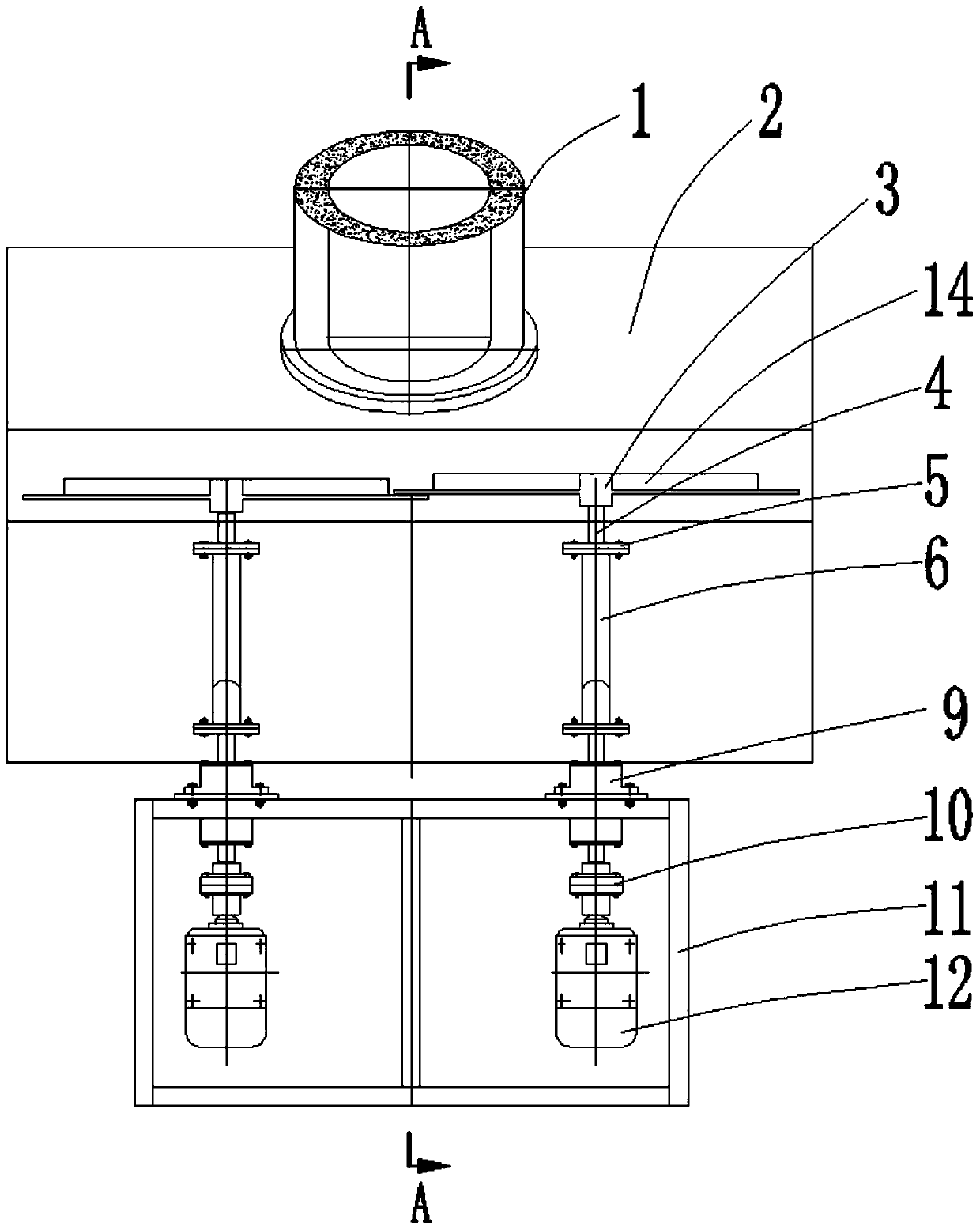

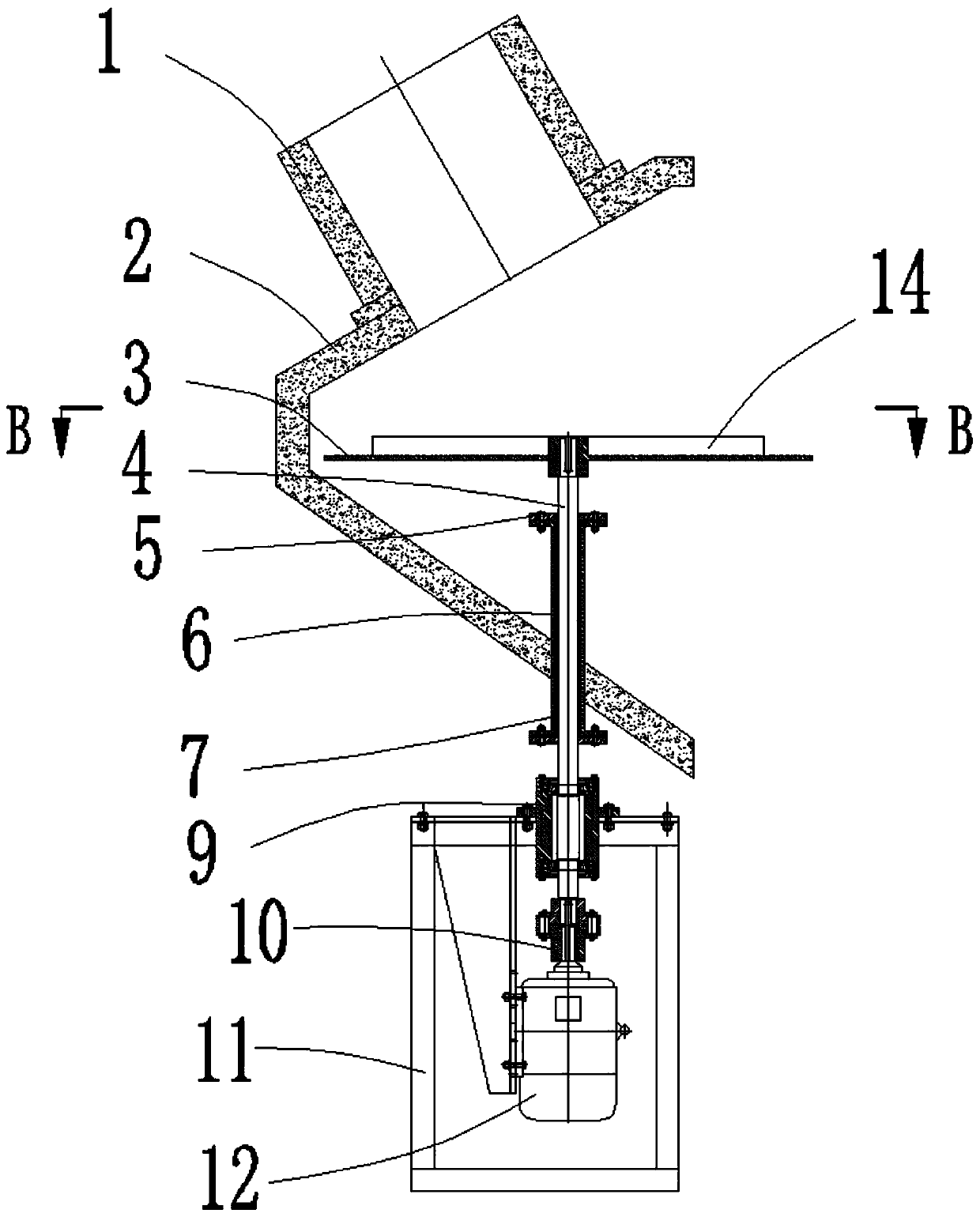

[0040] A power spreading device for cement kiln, which can disperse the material very evenly, cover the high-temperature gas flow well, and realize the full mixing and contact between the low-temperature material and the high-temperature gas, thereby greatly improving the heat exchange efficiency of the system, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, specifically set to the following structure:

[0041] It includes a material spreading box 2. The front side of the material spreading box 2 forms an opening, and the upper part has a material opening for connecting with the material discharge pipe 1 for discharging. The opening of the material spreading box 2 is used to connect with the outlet of the cyclone. The side wall of the pipe 15 is fixed and communicated with the inside of the cyclone outlet pipe 15 so as to pass the material scattered by the spreading plate 3 .

[0042] Two groups of spreading discs 3 are installed on the inner side of the sprea...

Embodiment 2

[0048] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

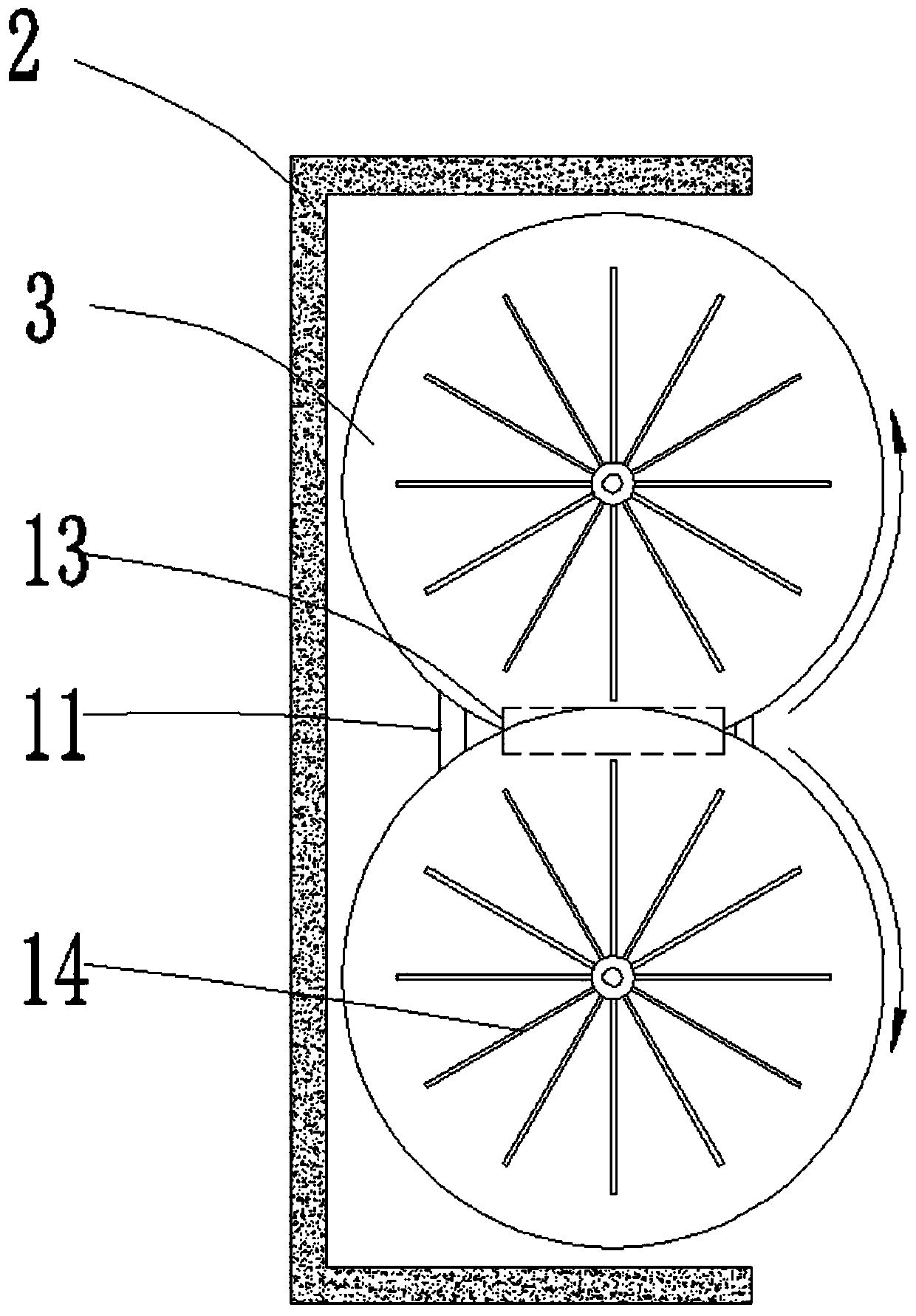

[0049] The two groups of spreading discs 3 are dislocated up and down relative to each other, and the two groups of spreading discs 3 have overlapping areas 13 in the vertical direction, image 3 The closed figure represented by the dotted line in the middle is the superposition area 13, and the axis of the feeding port intersects with the superposition area 13. In this way, the material will not completely pass between the two sets of spreading discs 3 , but will fall to the overlapping area 13 and be thrown to the opening of the spreading box 2 by the spreading discs 3 .

Embodiment 3

[0051] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0052] The top surface of every group of spreading disc 3 is all provided with at least one spreading bar 14, and spreading bar 14 is a straight plate, and the bottom surface of spreading bar 14 is connected with the disk surface of spreading disc 3 and is welded and fixed on the spreading bar. On the top surface of the disc 3 , the length direction of the spreading bar 14 is consistent with the radial direction of the corresponding spreading disc 3 . The material spreading bar 14 is used to forcibly disperse the material to improve the dispersing effect without causing excessive material accumulation and the material spreading plate 3 .

[0053] When there are multiple spreading strips 14 in each set of spreading trays 3 , the spreading strips 14 on the top surface of each set of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com