Patents

Literature

138results about How to "Well mixed contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

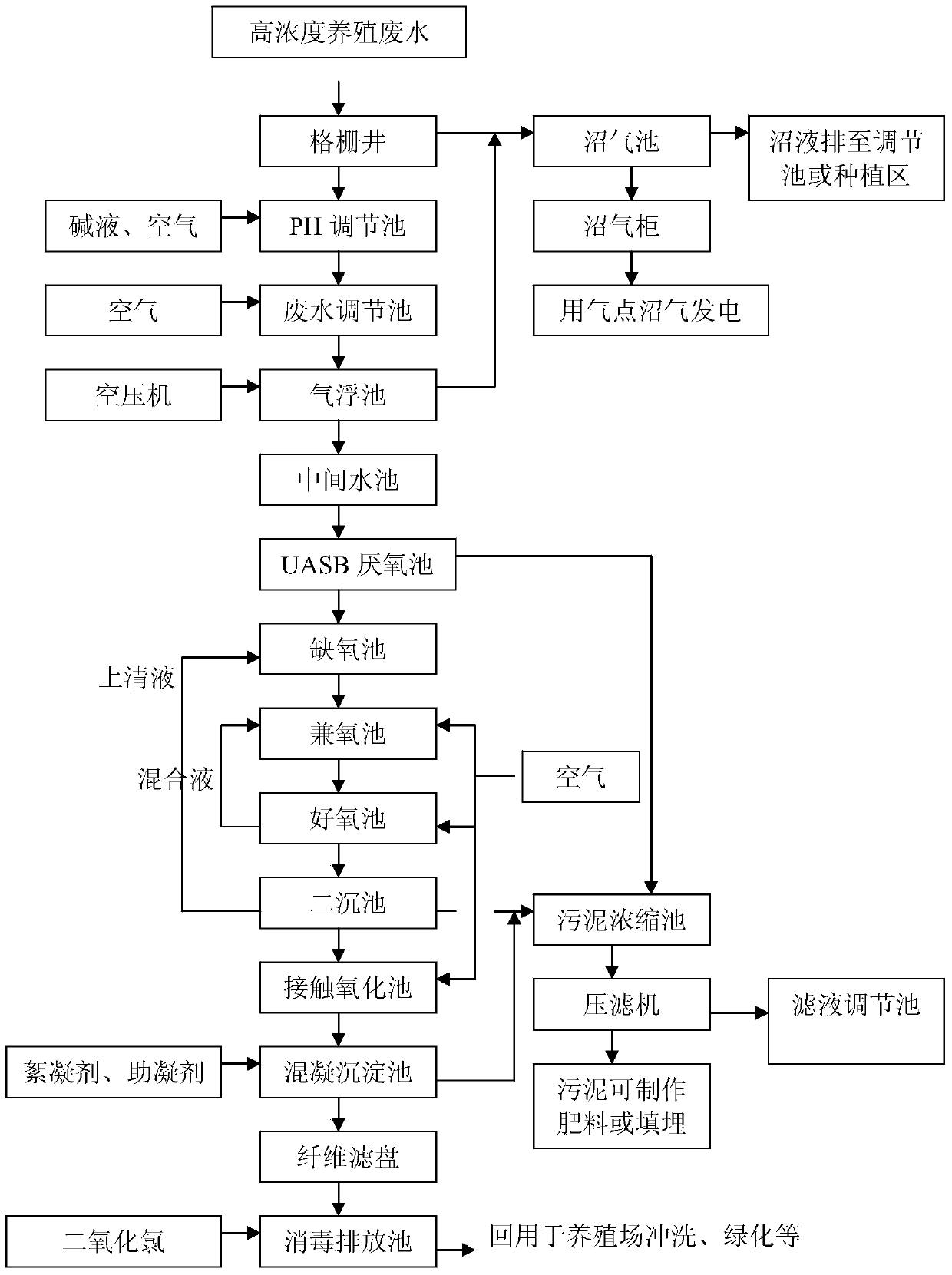

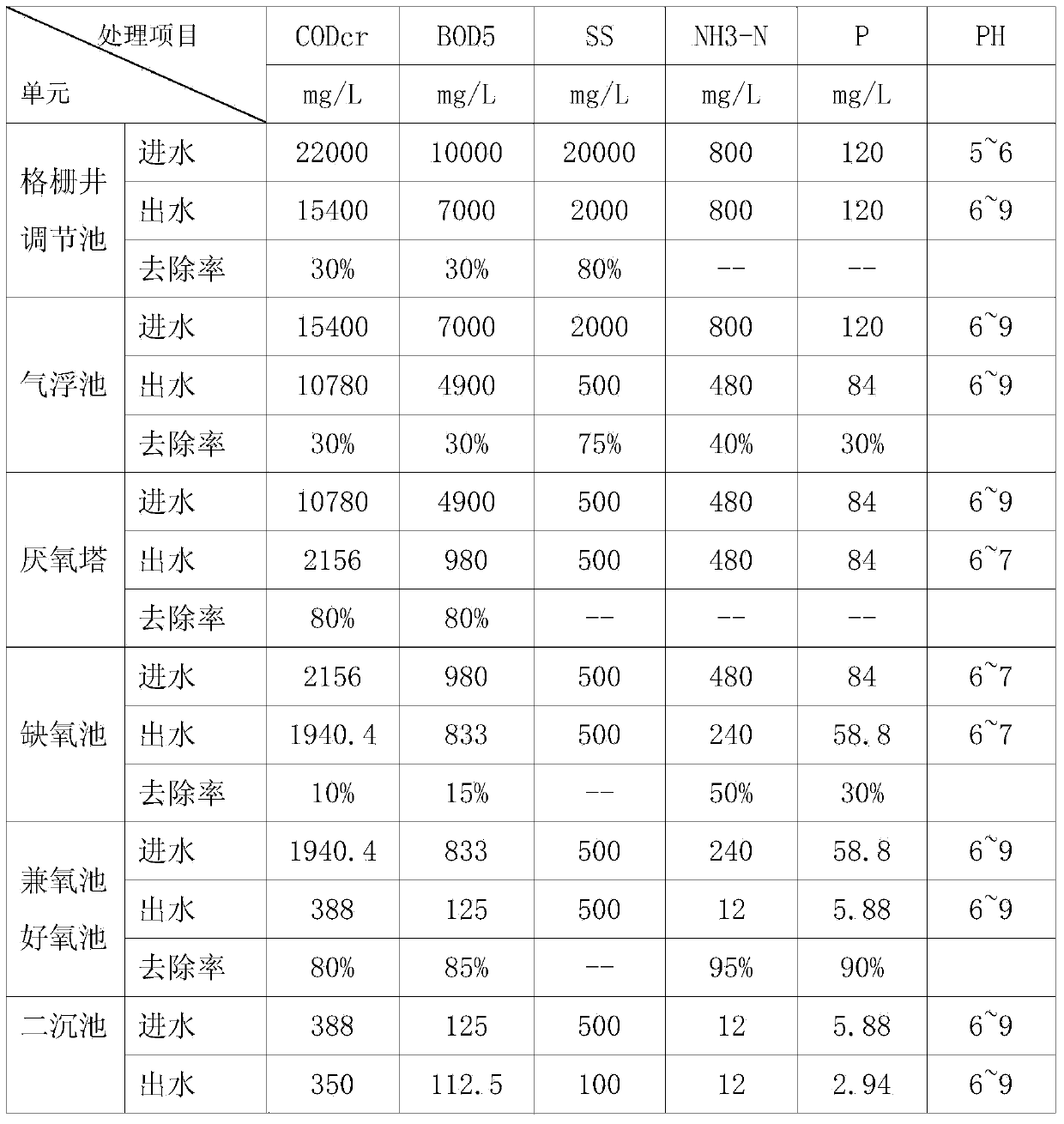

Waste water treatment technology for livestock breeding

InactiveCN103435224AHigh organic loadImproved resistance to shock loadsMultistage water/sewage treatmentLivestock breedingWastewater

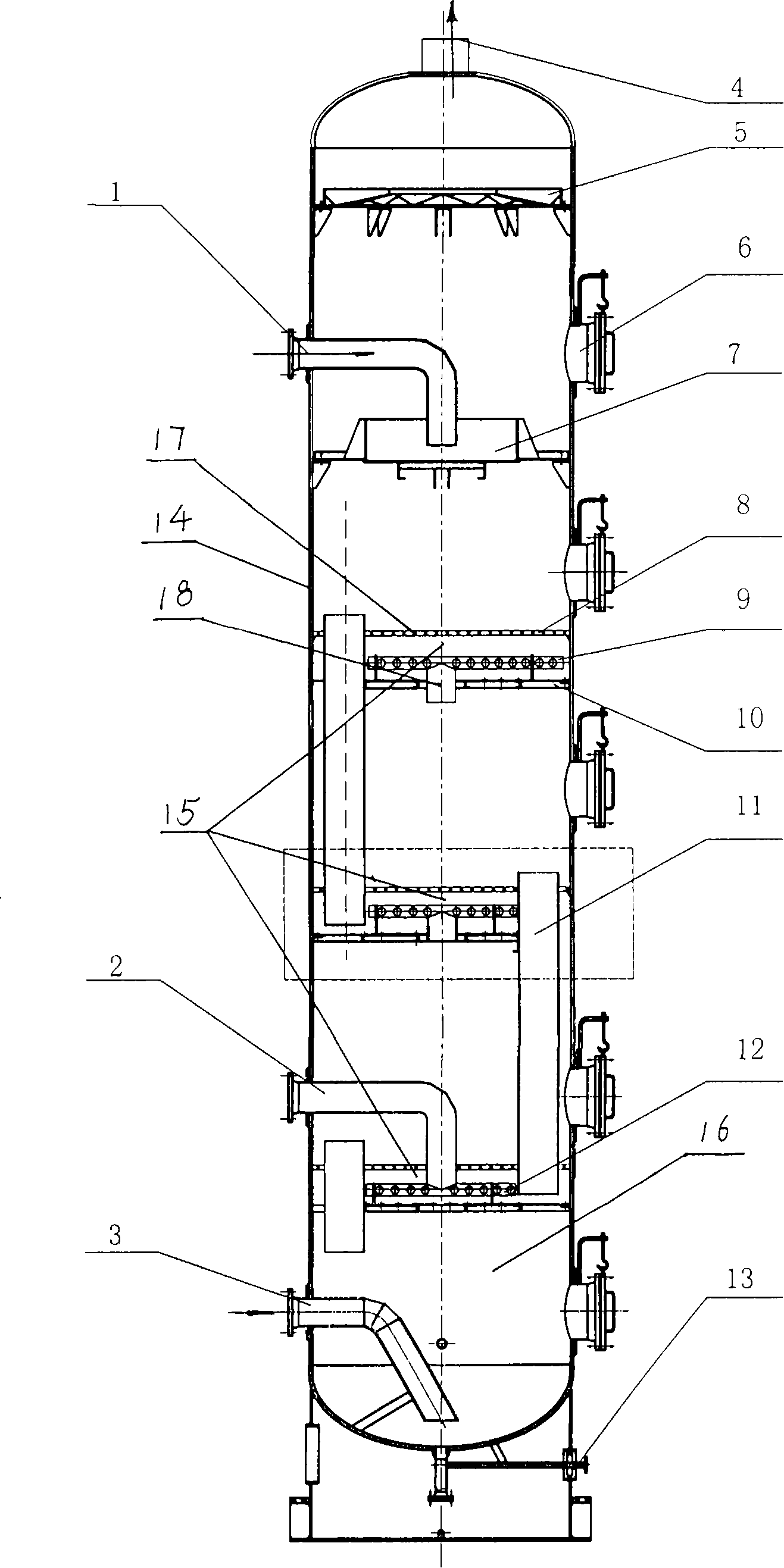

The invention discloses a waste water treatment technology for livestock breeding. The waste water treatment technology comprises the following steps: 1) pretreating the waste water; 2) biochemically treating the waste water; 3) posttreating the waste water, wherein the pretreatment of the waste water mainly comprises a grating well, a pH regulating tank, a regulating tank, floatation equipment and a middle water tank; the waste water biochemical treatment mainly comprises an anaerobic tank, an anoxia and aerobic tank, an aerobic tank, a secondary sedimentation tank, and a contact aeration tank; the waste water posttreatment mainly comprises a coagulating sedimentation tank, a fiber filter disc and a disinfection drain tank. The waste water treatment technology can efficiently and conveniently perform purification treatment on the waste water, effectively reduce the manufacturing cost for the waste water purification treatment industry, and increase the production efficiency through the reasonable wastewater treatment process procedure arrangement.

Owner:江苏鑫林环保设备有限公司

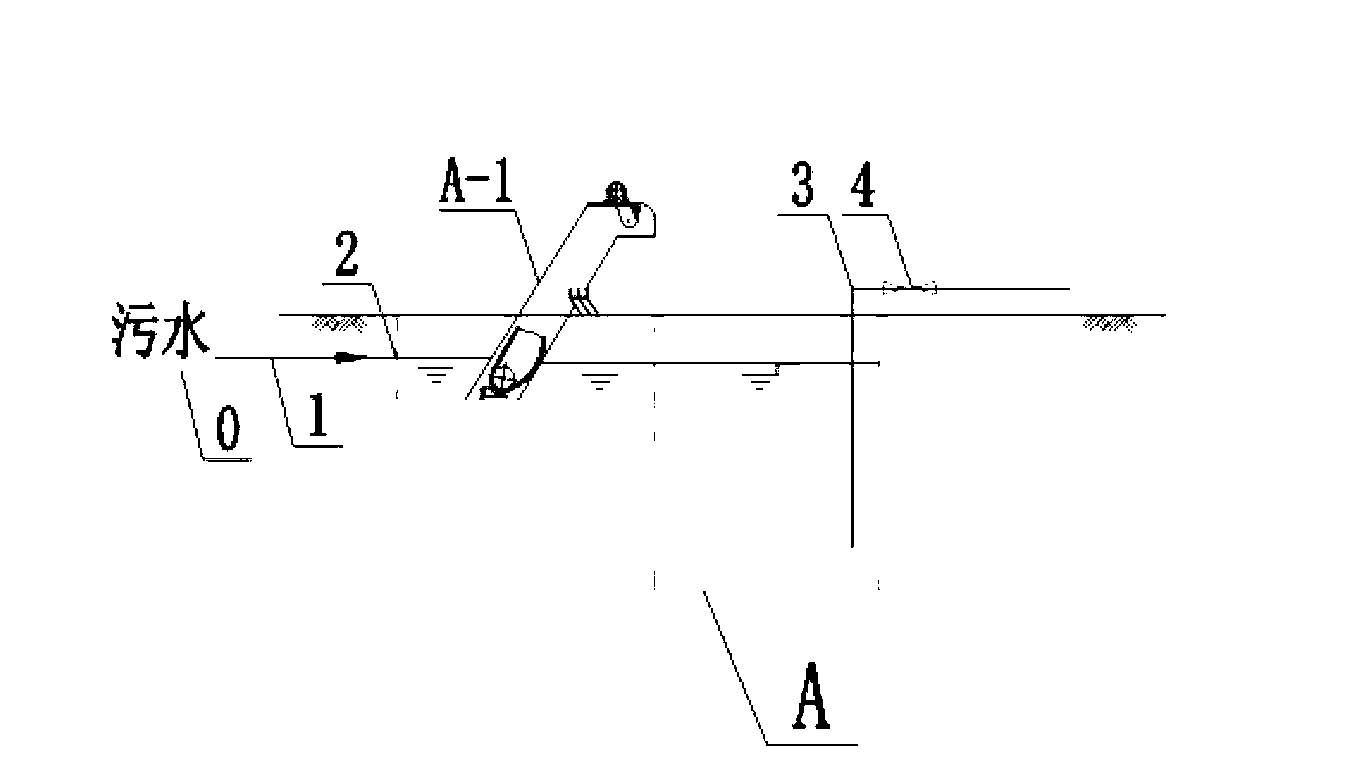

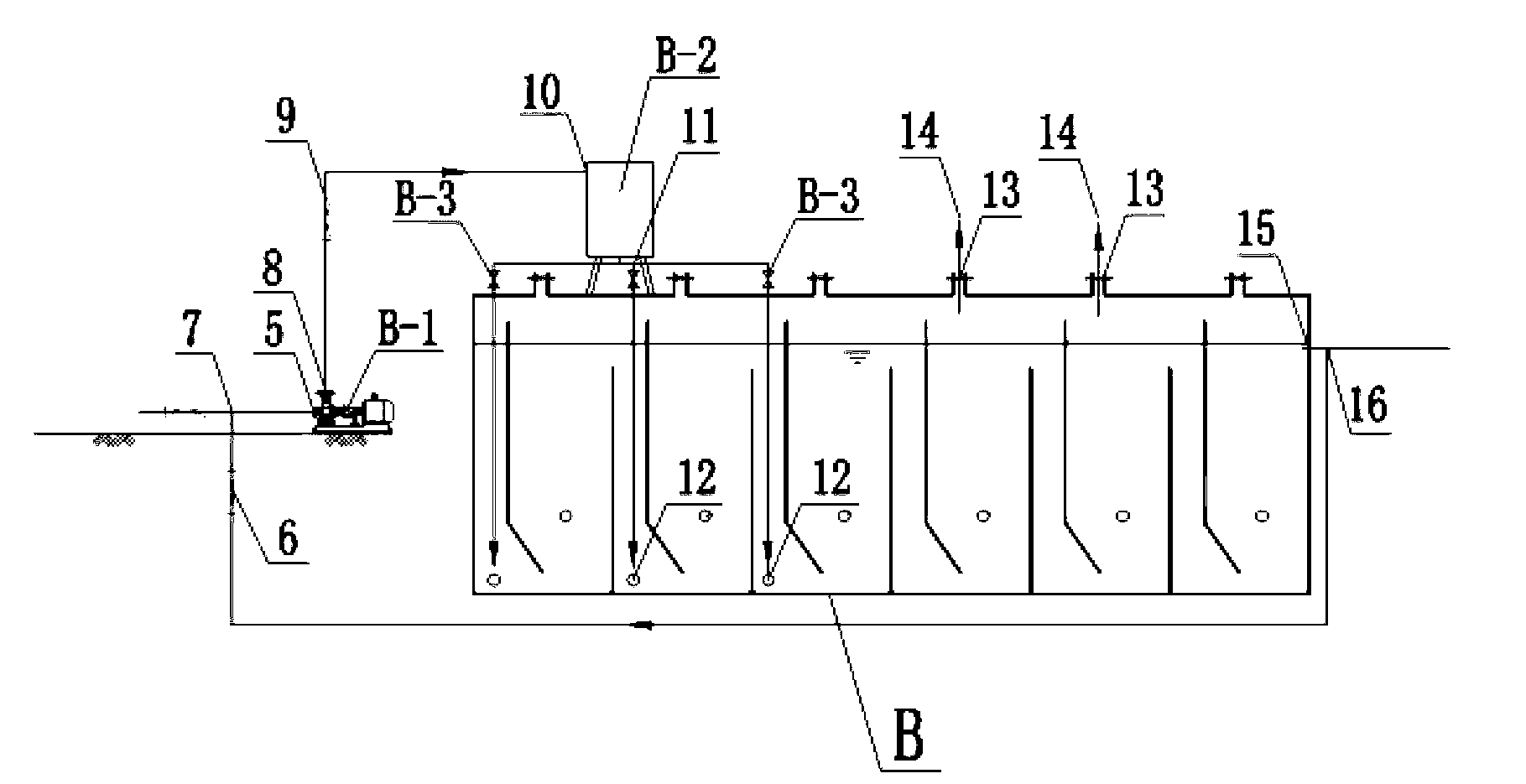

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

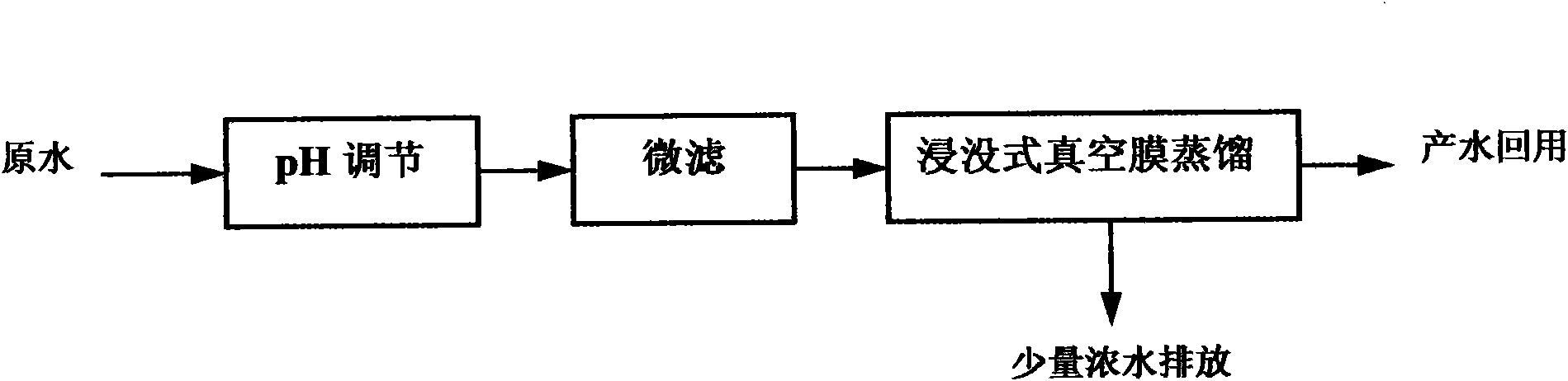

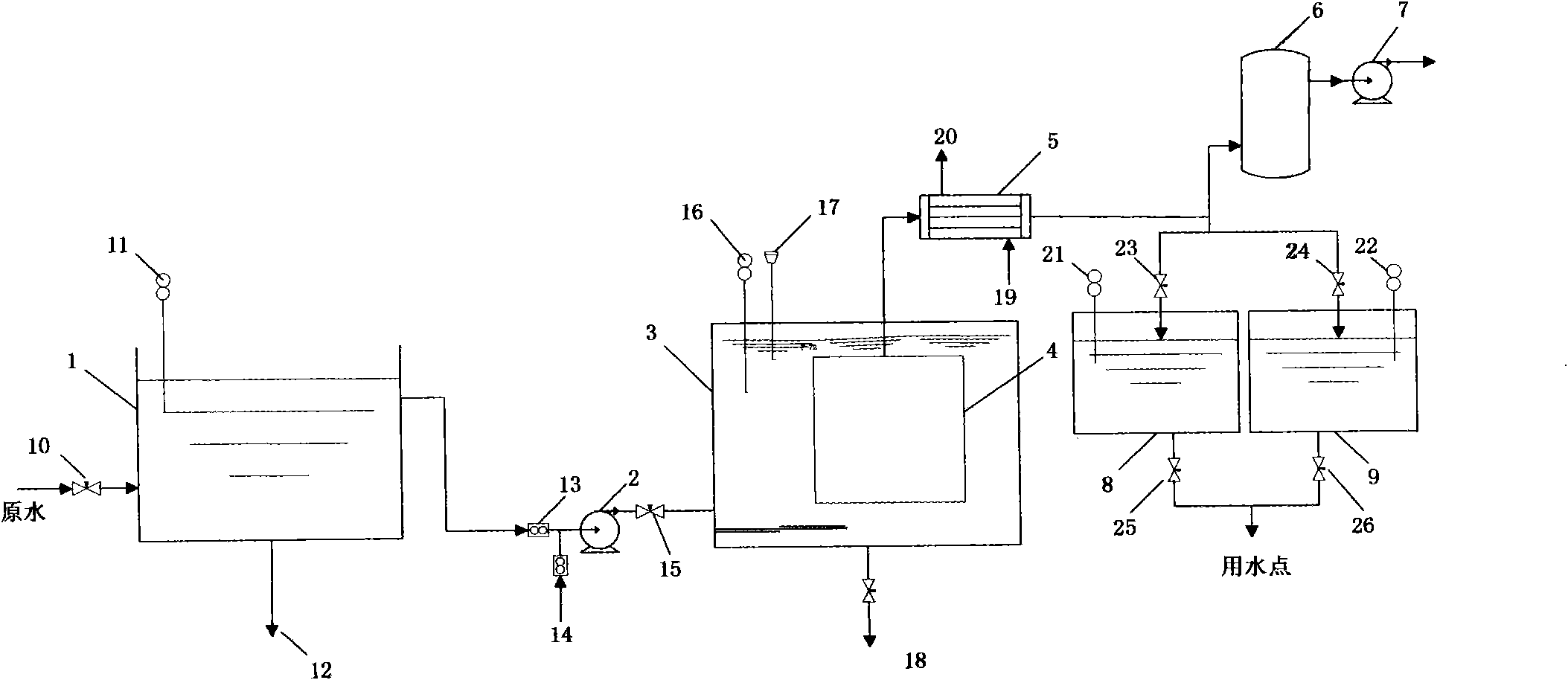

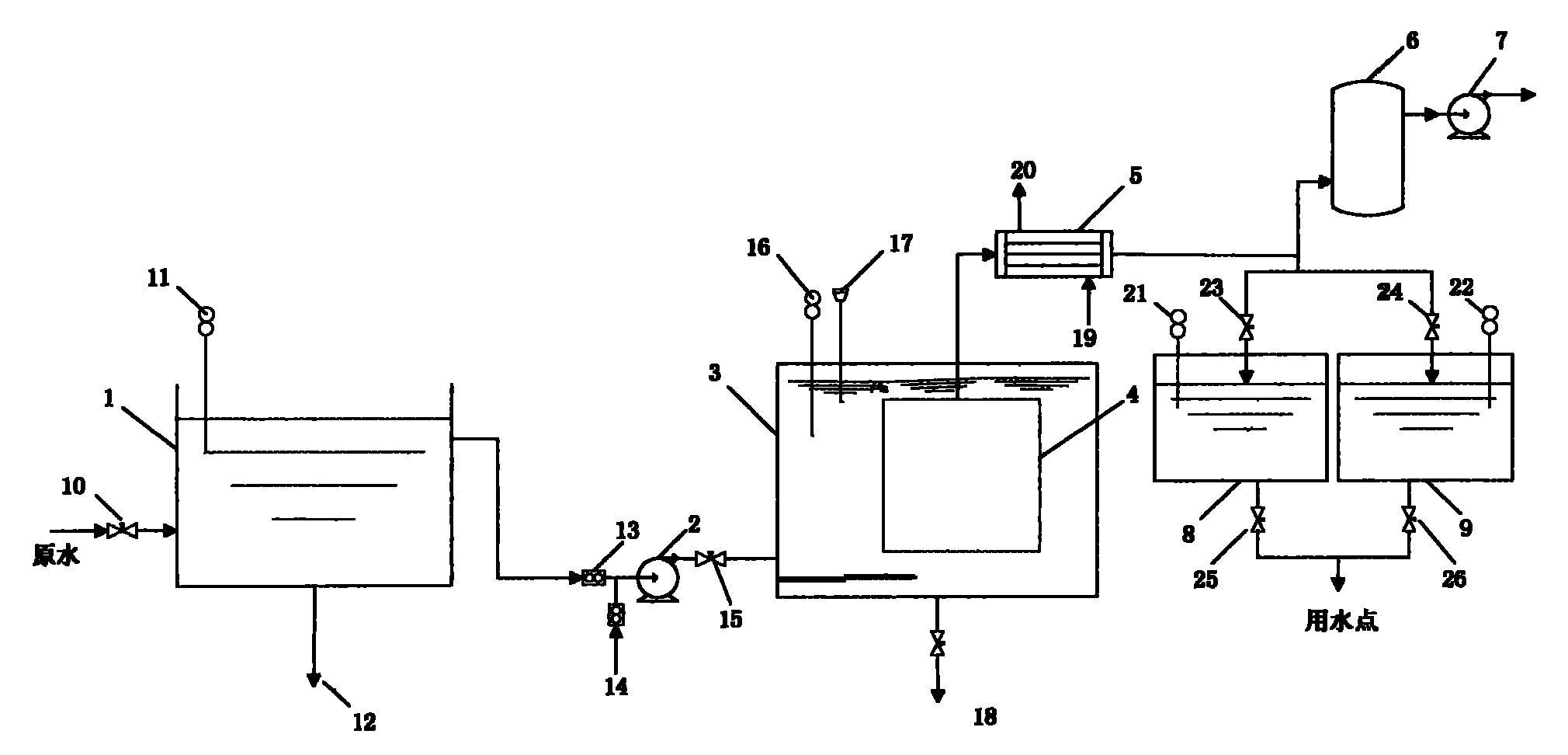

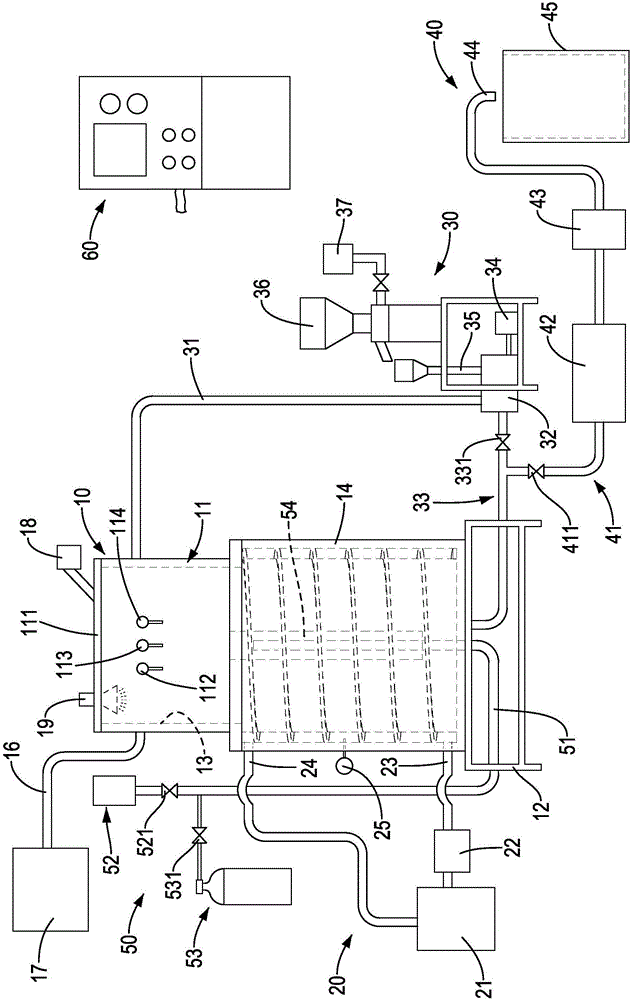

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

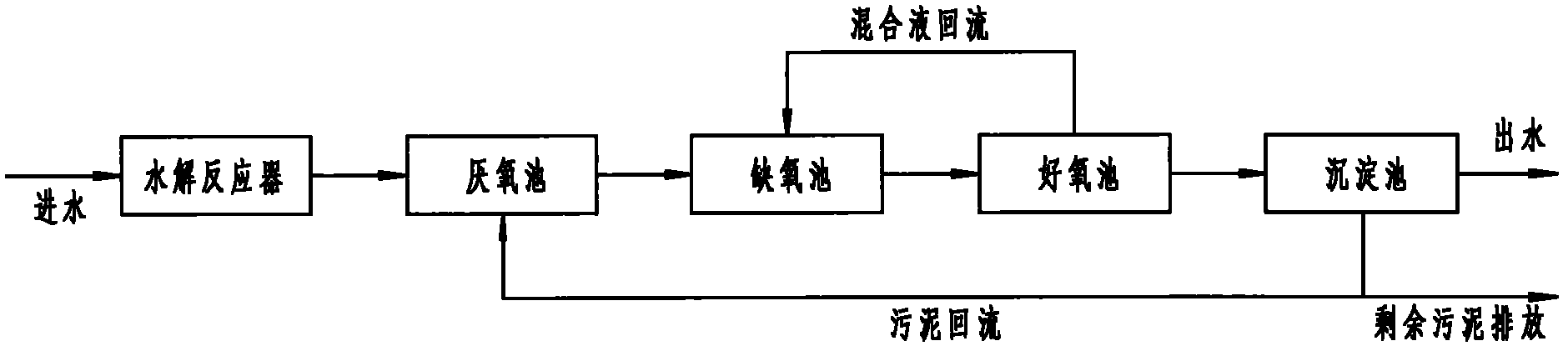

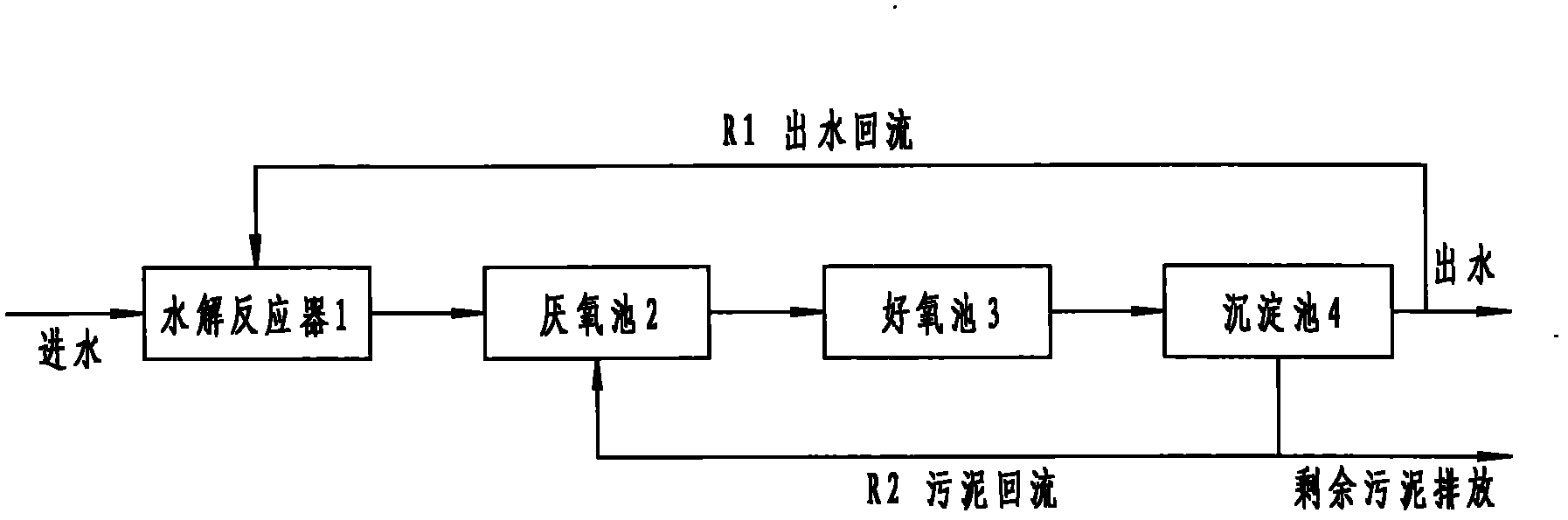

Hydrolysis denitrification denitrification system and method

InactiveCN102276061AHigh degree of removalImprove biodegradabilityTreatment with aerobic and anaerobic processesChemistryOxidation ditch

A hydrolysis denitrification denitrification system and method. The system replaces the traditional anoxic tank with an upflow sludge bed hydrolysis reactor. The hydrolysis reactor includes: an effluent return channel, which is arranged between the sedimentation tank and the hydrolysis reactor, so that the discharged water from the sedimentation tank contains The nitrate supernatant is used as reflux to flow back into the hydrolysis reactor for hydrolysis, denitrification and denitrification. In the present invention, the hydrolysis reactor is used as the functional area of pre-denitrification denitrification, and the good anaerobic environment in the hydrolysis reactor, the rapid recovery ability of the denitrification bacteria function and the sufficient supply capacity of organic matter are used to realize efficient and stable hydrolysis reaction. Nitrification and denitrification. The invention makes full use of the carbon source in the sewage, improves the denitrification efficiency, and reduces the energy consumption of the whole sewage treatment process. The invention can be combined with common urban sewage treatment processes such as AAO and oxidation ditch, and is convenient for upgrading and reforming existing facilities of sewage treatment plants.

Owner:贾立敏 +7

High-efficient gas-liquid mass transferring device

ActiveCN101108299AIncrease contact areaImprove the degree of purificationDispersed particle separationChemical reactionProduct gas

The invention discloses a high efficient gas and liquid mass transfer rig. A defoaming plate, a liquid distributor and a multilevel gas and liquid exchanging device is arranged in a tower body up and down, the bottom of the tower body is a liquid collecting chamber, the top of the tower body is an air gate; the invention uses the character of H2S and aqueous alkali which can proceed chemical reaction quickly and adopts gas and liquid direct contact, makes liquid and gas moving contact, turbulent motion mass transfer, the contact area between the liquid and the gas is increased greatly, makes the gas realize full mixing contact with the liquid and improves the purifying degree. The invention doesn't use filling, which solves the blocking problem in the filling desulfurizer and has simple structure, convenient installation, large operating flexibility, low tower resistance, low production cost and remarkable practical application effect.

Owner:CHANGCHUN DONGSHI TECH & TRADING INDAL

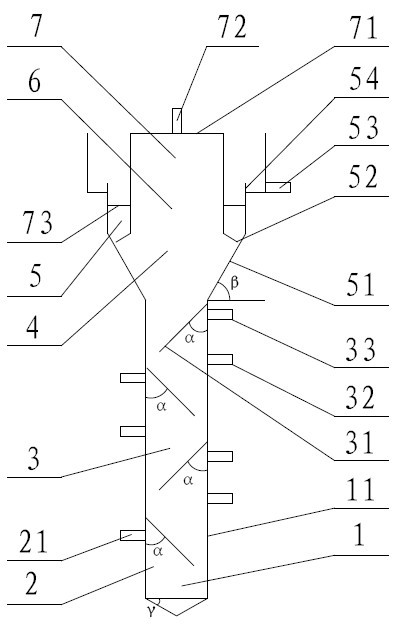

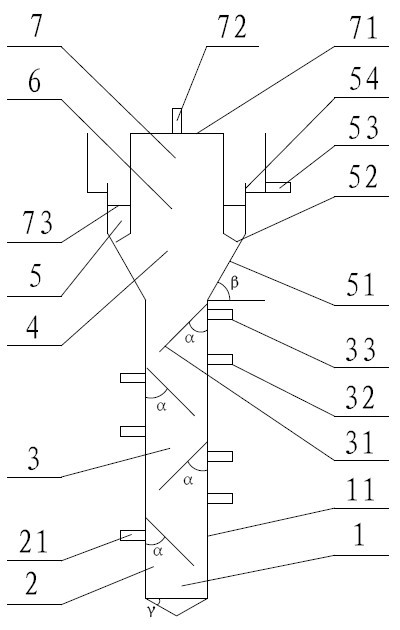

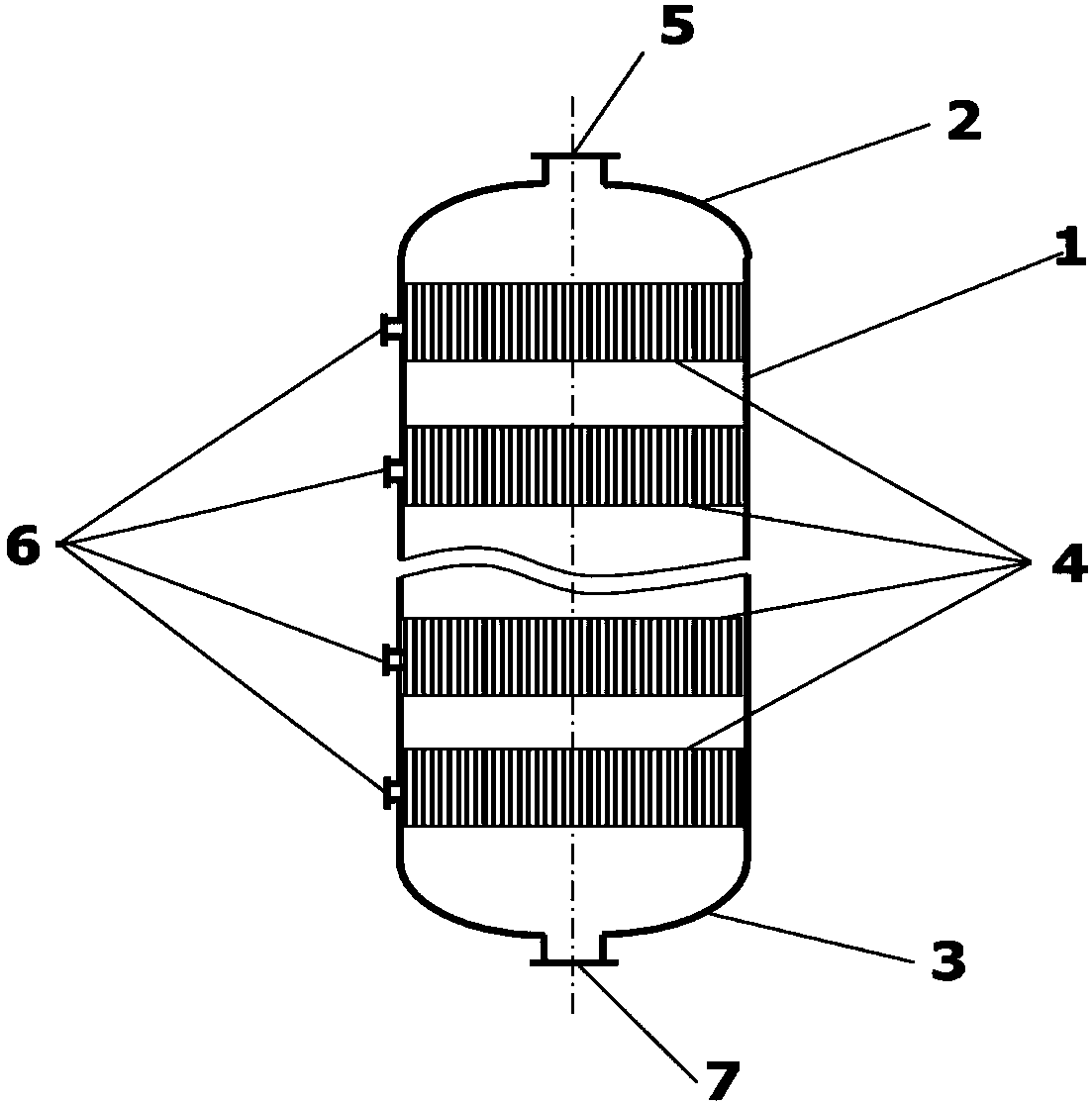

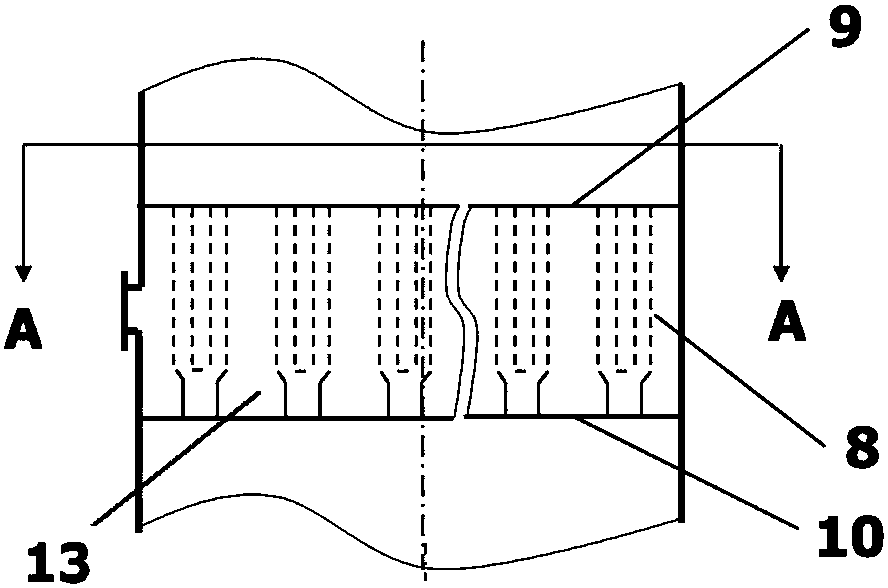

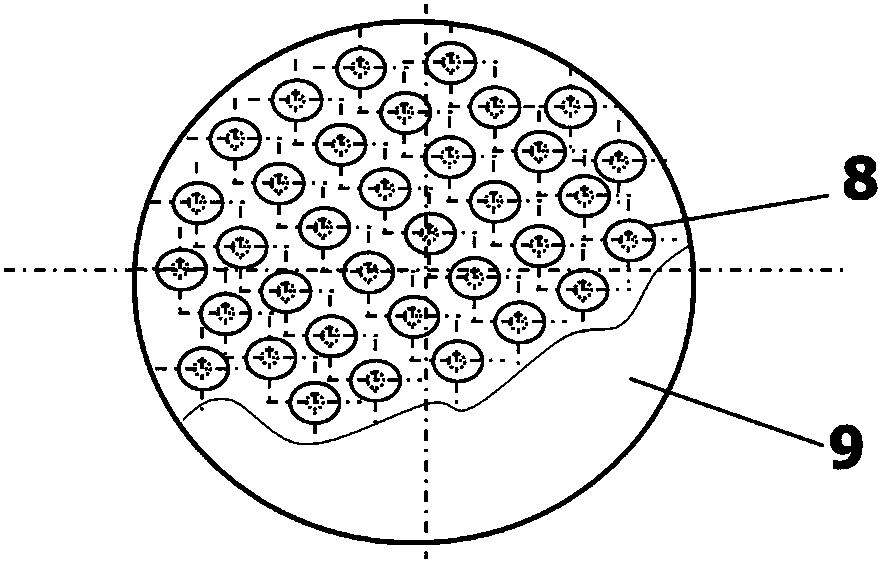

Upflow subregion anammox bioreactor

ActiveCN102153194AEfficient separationReduce churnTreatment with anaerobic digestion processesCouplingSludge

The invention relates to an upflow subregion anammox bioreactor, comprising a reactor body, wherein the reactor body is divided into a water inlet buffer region, an upflow reaction chamber and a three-phase separation region from bottom to top; the water inlet buffer region comprises a water inlet pipe arranged at one side of the bottom of the reactor body, the upflow reaction chamber is connected with a settling chamber of the three-phase separation region by virtue of an increasing coupling, an outer barrel of the settling chamber is internally provided with a three-phase separation chamber, a gas collecting chamber is arranged above the three-phase separation chamber, a gas collecting hood separated from the settling chamber is arranged at the top of the gas collecting chamber, an air outlet is arranged at the top end of the gas collecting hood, the upflow reaction chamber comprises a plurality of subregion reaction chambers which are separated by semi-opened baffles, the openings of the baffles are downward, and the baffles are connected to the wall of the reactor body in a left-right cross connecting way, the subregion reaction chambers are communicated by virtue of the baffles, and the side of the reactor body at the upper part of each subregion reaction chamber is provided with an exhaust port used for escaping part of nitrogen. By adopting the bioreactor provided by the invention, effective separation of water, gas and mud is realized, sludge loss is reduced, short circuit is avoided, and effective working space of the bioreactor is increased.

Owner:江苏清材智能制造有限公司

Fluidized bed thermal desorption device

ActiveCN105817472AEasy to handleEasy to separateContaminated soil reclamationIncinerator apparatusSlagQuenching

The invention discloses a fluidized bed thermal desorption device. The fluidized bed thermal desorption device is used for treating polluted soil, and comprises a thermal desorption device, a tail gas treatment device, a screening machine, a quenching tower, an oil-water separator, a cyclone dust collector, a slag extractor, a fluidized bed, a first burner and a second burner, wherein a feed inlet of a thermal desorption chamber communicates with a sand outlet of the fluidized bed and a polluted soil feed hopper; a feed outlet and an air outlet of the thermal desorption chamber respectively communicate with a feed inlet of the screening machine and an air inlet of the quenching tower; a sand outlet of the screening machine communicates with a sand inlet of the fluidized bed; an air outlet of the quenching tower communicates with an inlet of the second burner; a water outlet of the quenching tower communicates with a water inlet of the oil-water separator; a water outlet of the oil-water separator communicates with a water inlet of the quenching tower; a smoke outlet of the fluidized bed communicates with an air inlet of the cyclone dust collector; a smoke outlet of the cyclone dust collector communicates with an inner cavity defined by the thermal desorption chamber and a smoke clamping sleeve; the tail gas treatment device communicates with the inner cavity; and a feed inlet of the slag extractor communicates with a dust outlet of the cyclone dust collector. According to the thermal desorption device, the treatment capacity is high, the pollutant removal rate is high, and the device is economic and practical.

Owner:ZHEJIANG EASYCLEAN ENVIRONMENTAL TECH CO LTD

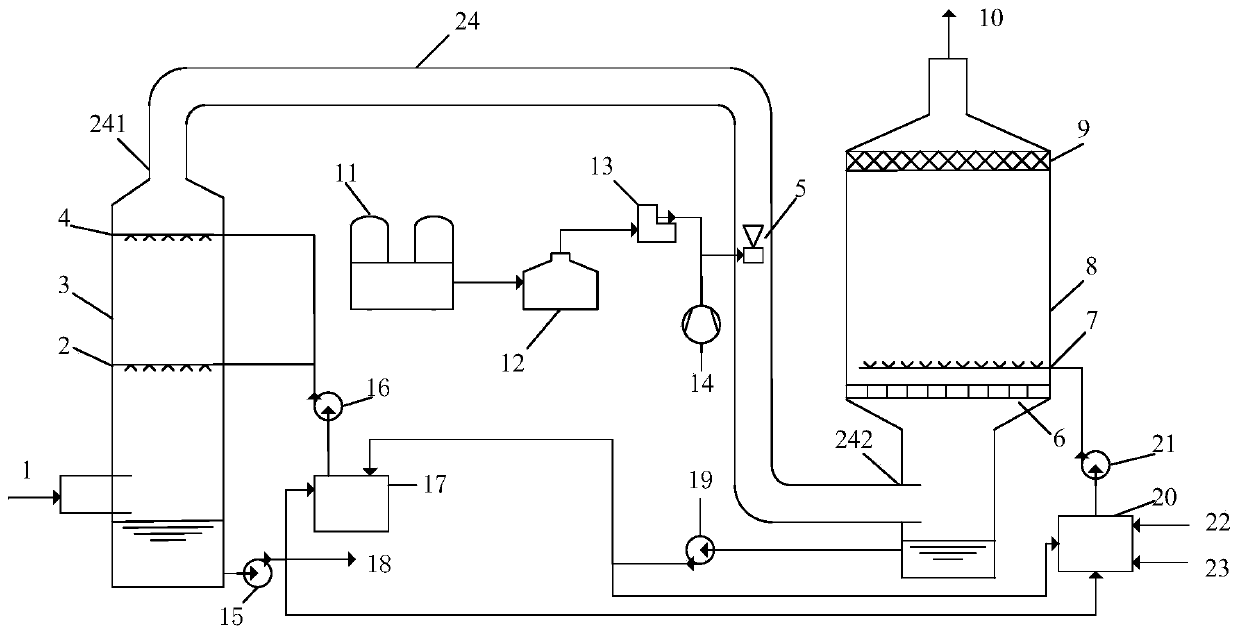

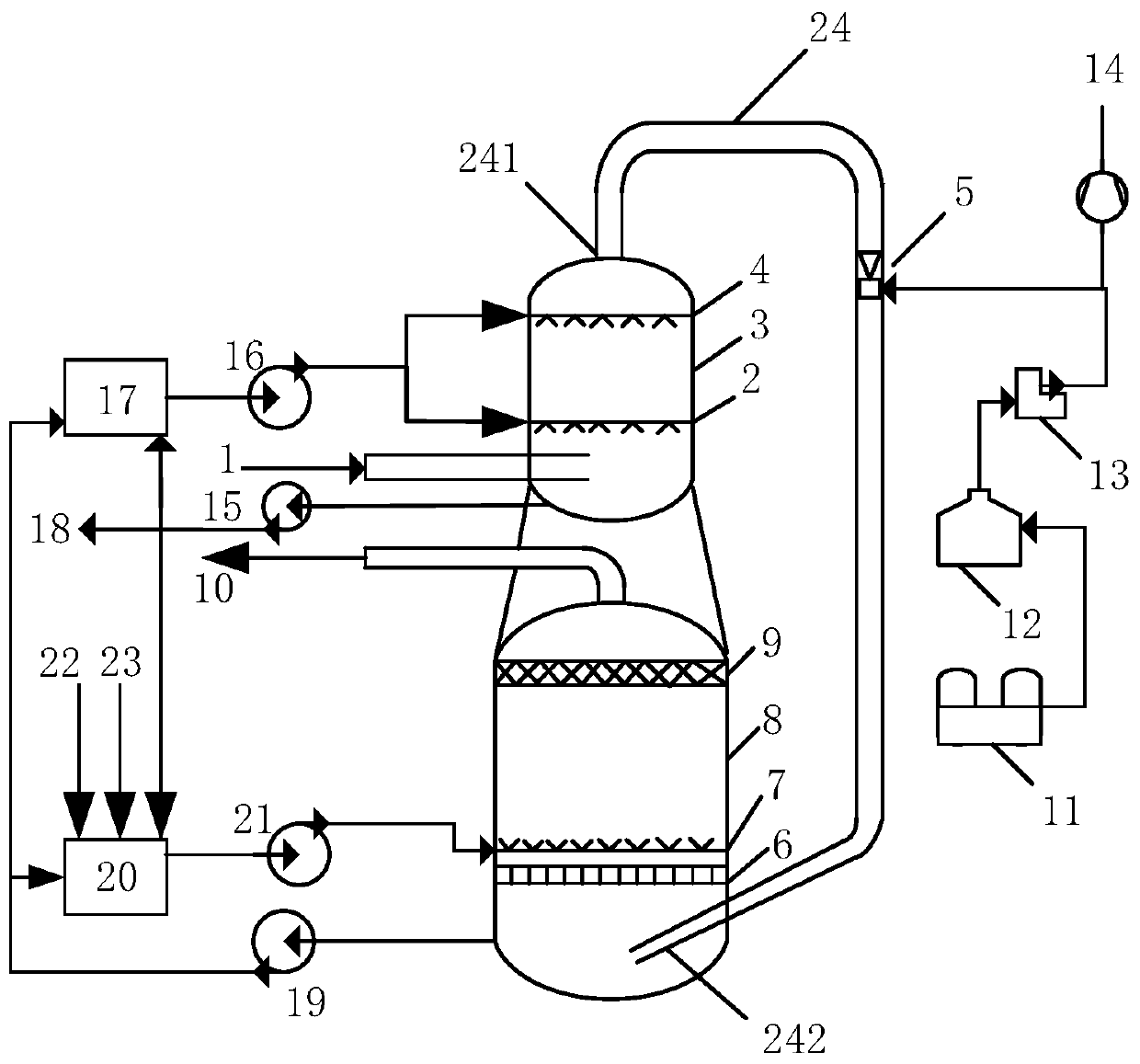

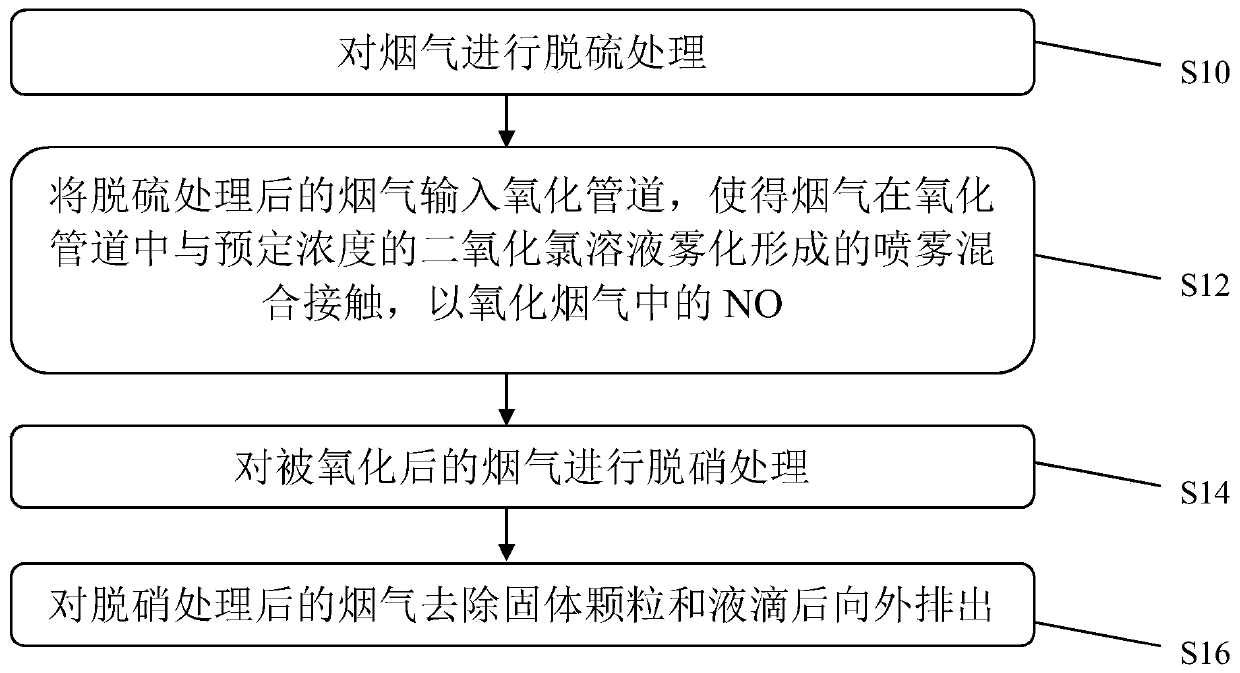

Flue gas desulfurization and denitration device and method

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

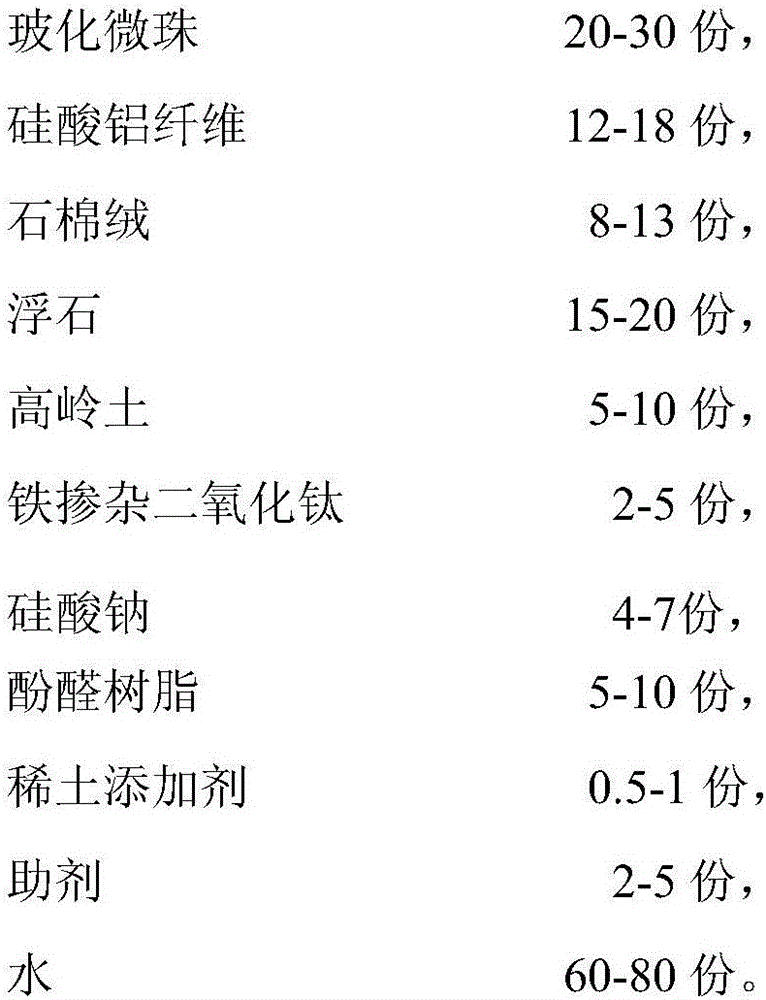

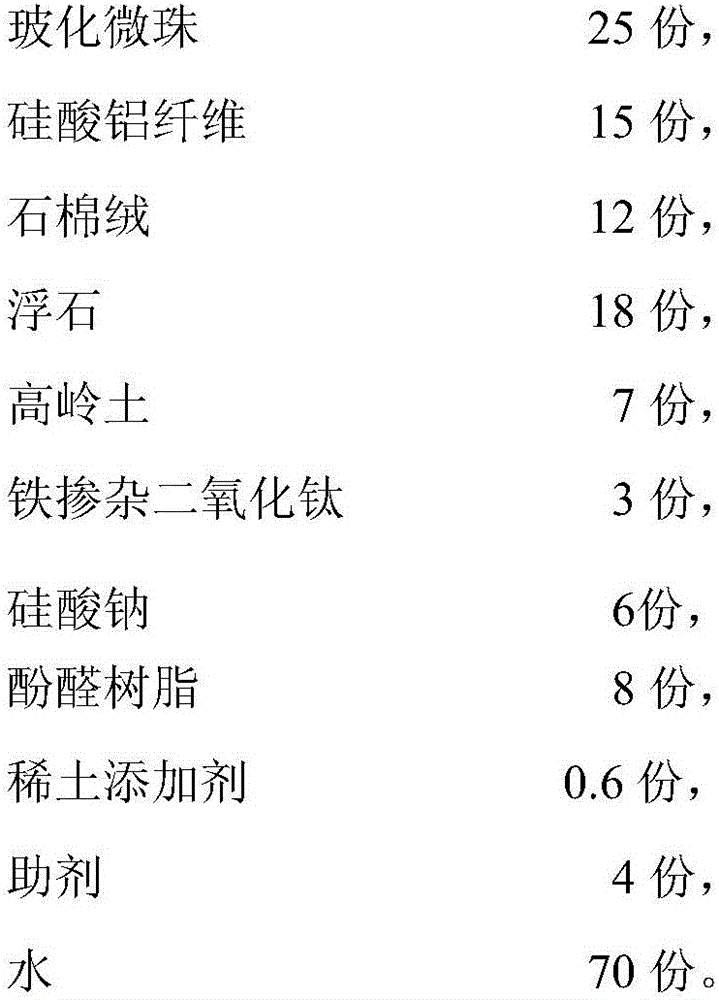

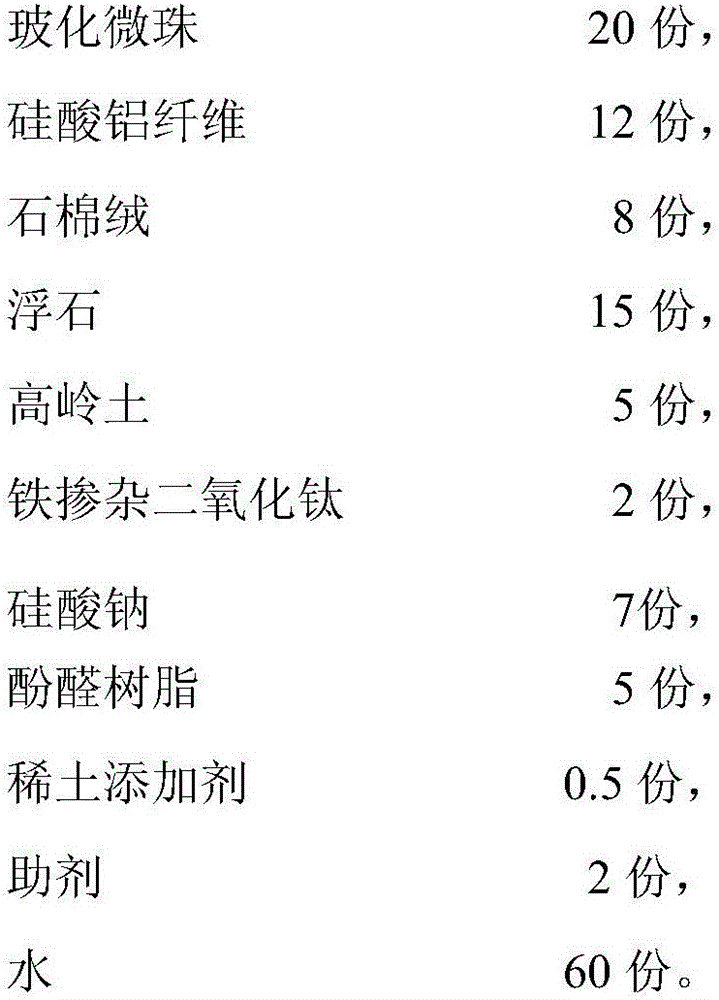

Rare-earth fireproof heat-insulating material and preparation method therefor

ActiveCN106365582AExtended service lifeImprove fire performance and thermal insulation performanceSodium silicateAsbestos

The invention relates to heat-insulating materials and particularly discloses a rare-earth fireproof heat-insulating material. The rare-earth fireproof heat-insulating material contains the following ingredients in parts by mass: 20-30 parts of vitrified microbeads, 12-18 parts of aluminum silicate fibers, 8-13 parts of asbestos wool, 15-20 parts of pumice, 5-10 parts of kaolin, 2-5 parts of iron-doped titanium dioxide, 4-7 parts of sodium silicate, 5-10 parts of phenol-formaldehyde resin, 0.5-1 part of rare-earth additive, 2-5 parts of assistants and 60-80 parts of water. The invention further provides a preparation method for the rare-earth fireproof heat-insulating material. The rare-earth fireproof heat-insulating material prepared by the preparation method has good hydrophobicity and air permeability and excellent fire-proof and heat-insulating properties, thereby being suitable for being industrially produced on a large scale.

Owner:内蒙古宜龙节能环保科技股份有限公司

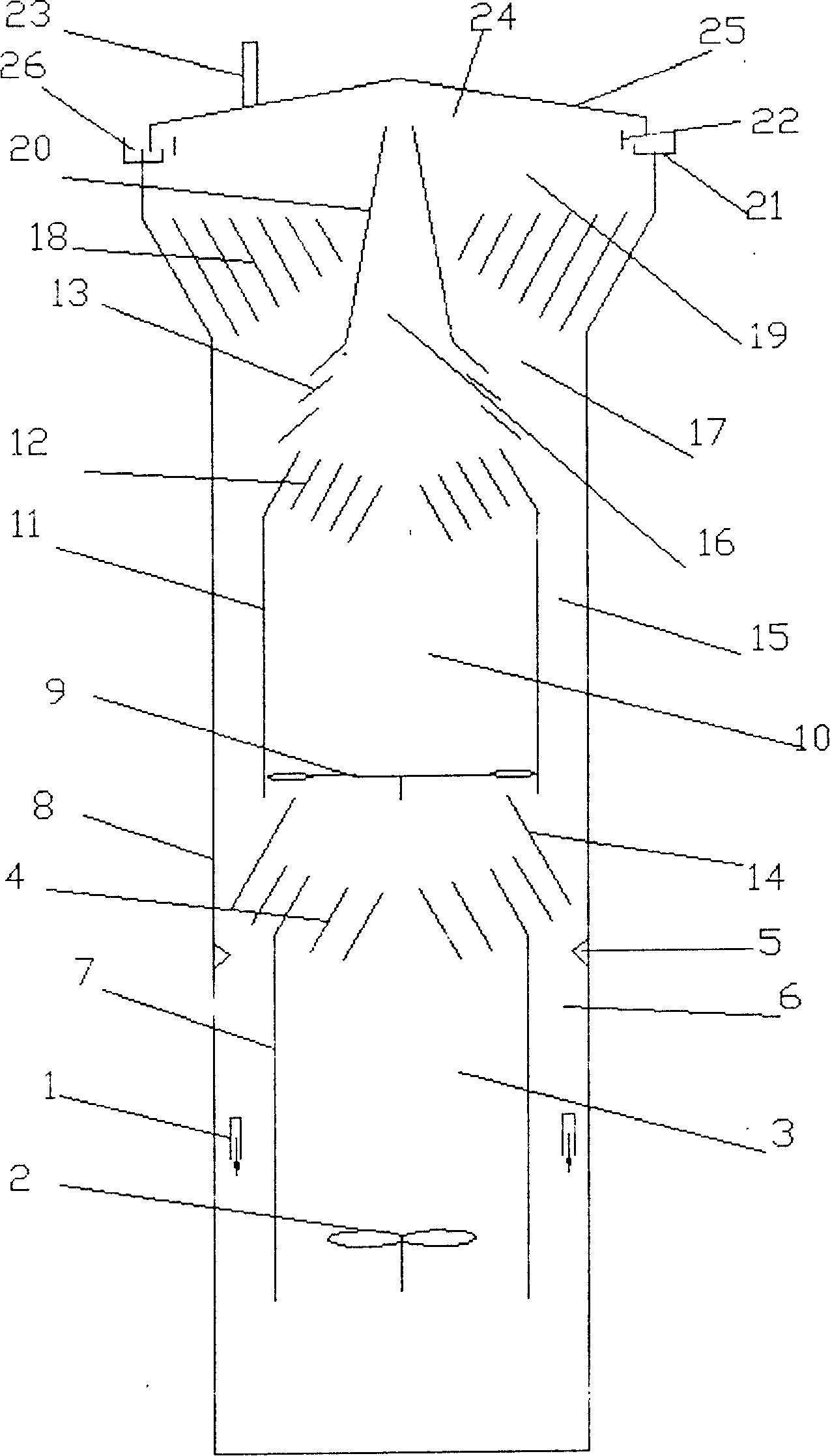

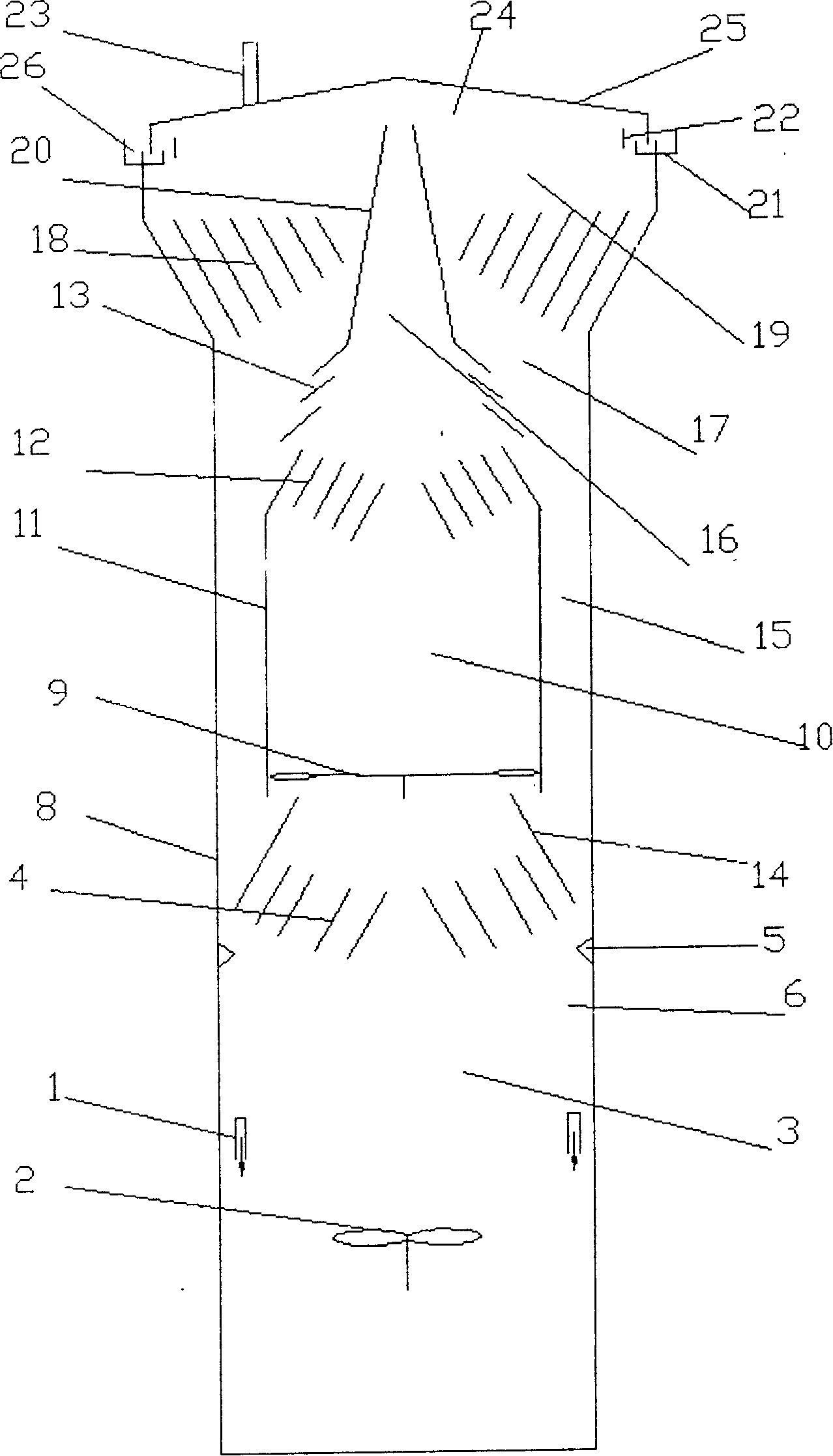

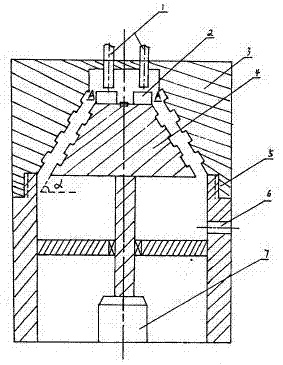

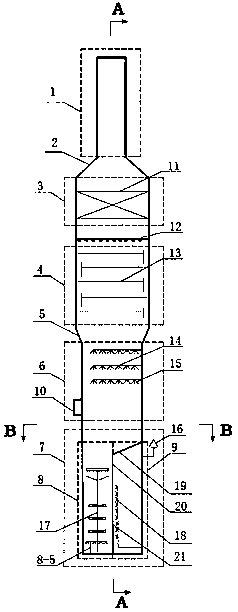

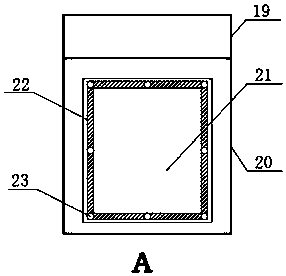

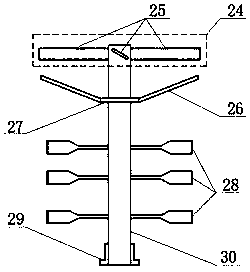

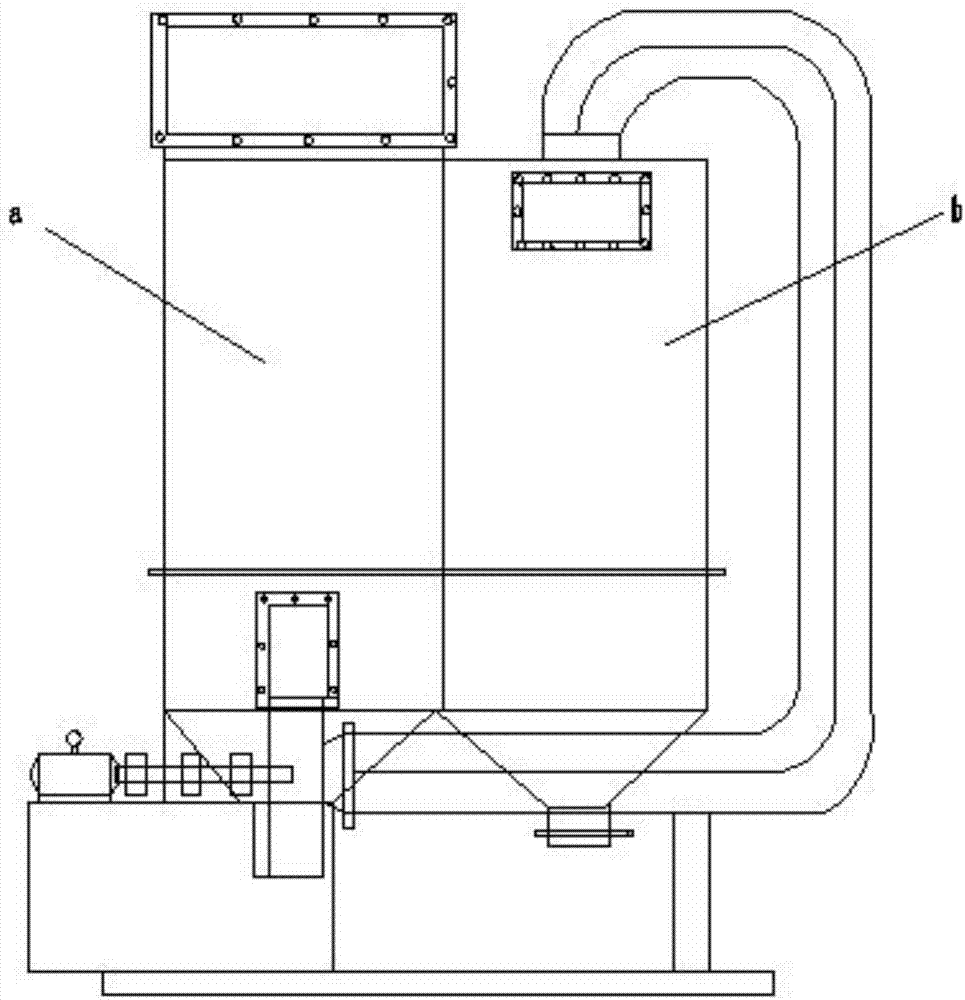

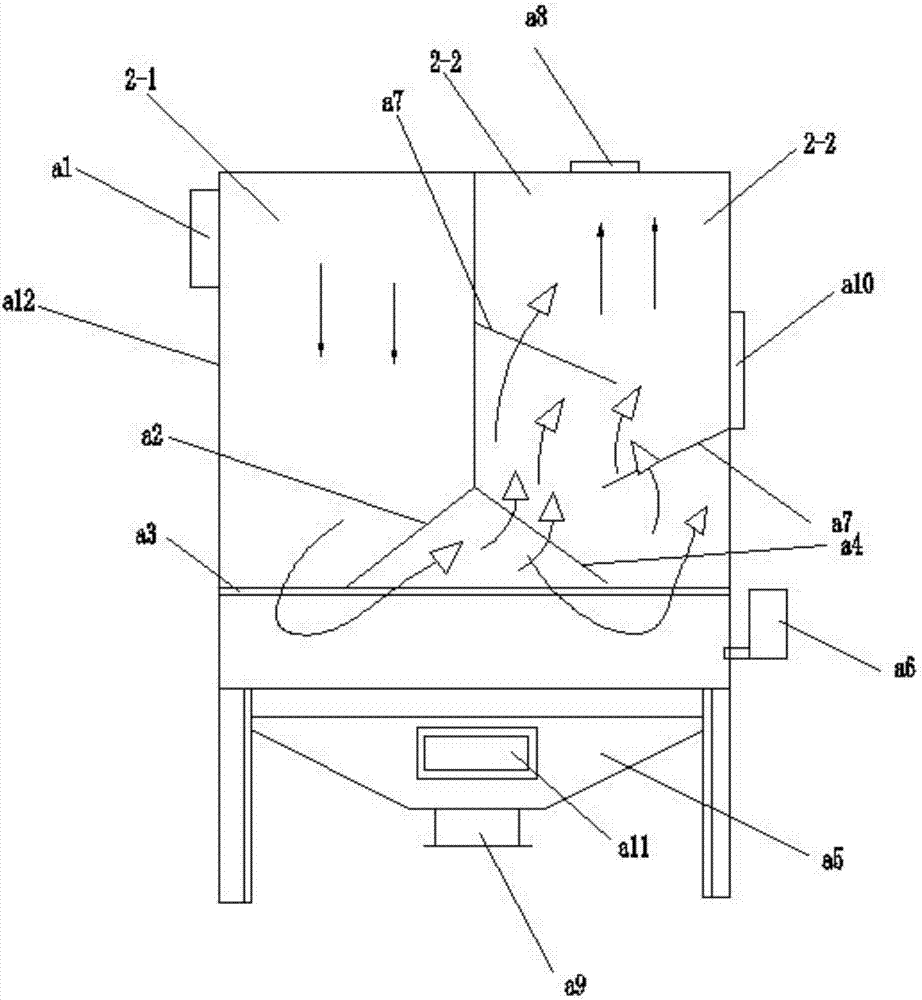

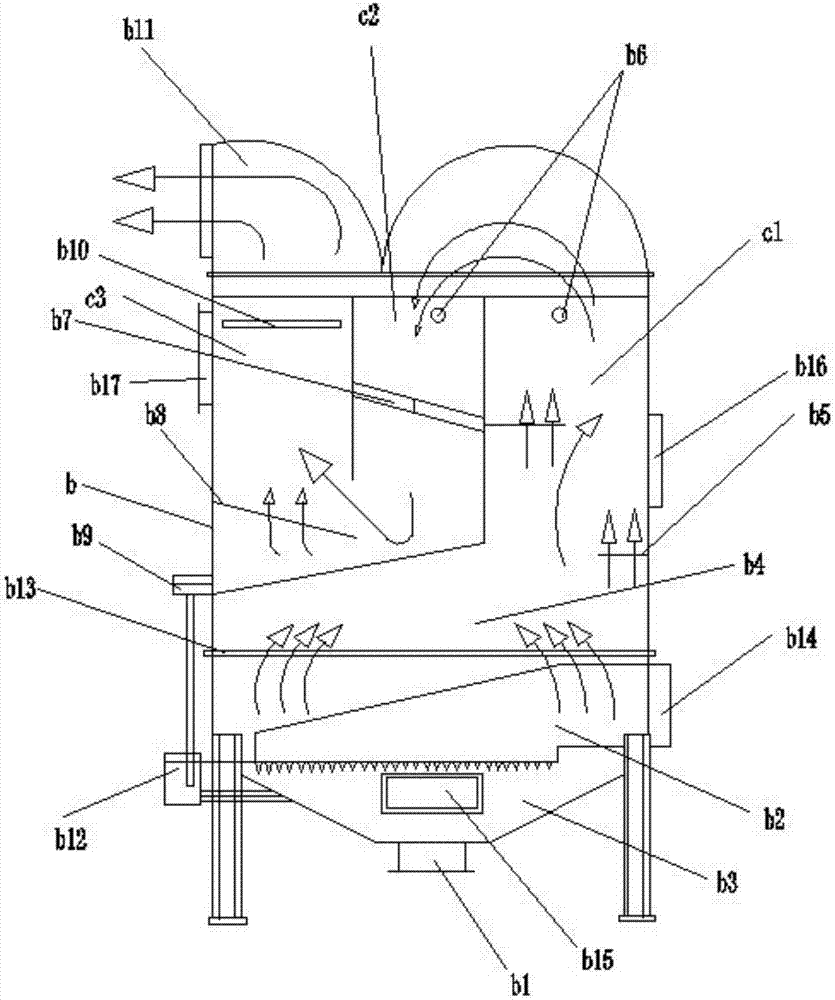

Diphase integrated multi-gradation internal circulation anaerobic bioreactor

InactiveCN101164915AThorough treatmentEasy to handleTreatment with anaerobic digestion processesHigh resistanceSmall footprint

This invention relates to a two-phase integrated, multi-layered and internal-circulation anaerobic biological reactor. It is composed of: an upper inner casing, a middle inner casing and alower inner casing, a 1st gas-liquid separation reflecting plate, a 2nd reflecting plate, a 1st gas-isolation guiding plate, a 2nd gas-isolation guiding plate, an upper agitator, a lower agitator, liquid distributor and solid-liquid separator. Due to the equipped multiple inner circulation it makes the liquid being of fluidization condition, the anaerobic reaction is better than that of prior art method. This invention has advantages of: low area occupation, high load rate, high resistance of shock load, high efficiency, stable treatment, convenient operation, low operation cost, full sealed system of reactor, no bad odour, quick starting, short period of establishment, being suitable for the treatment of waste-water, waste-matter and waste-sludge in size of large, medium or small scale.

Owner:林仁吉

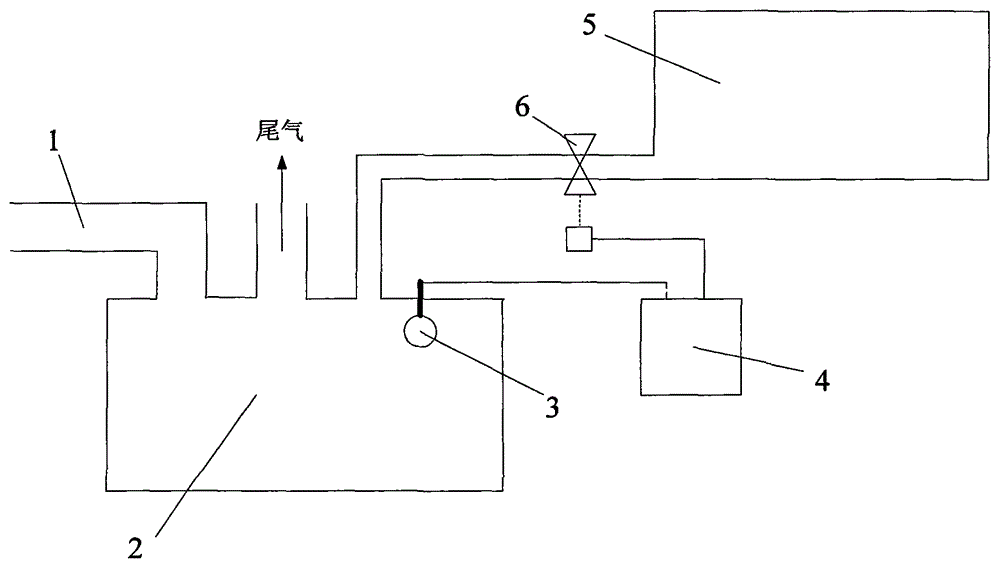

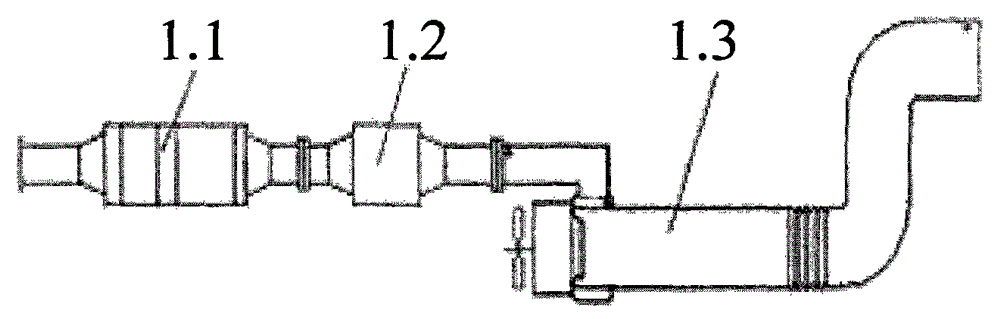

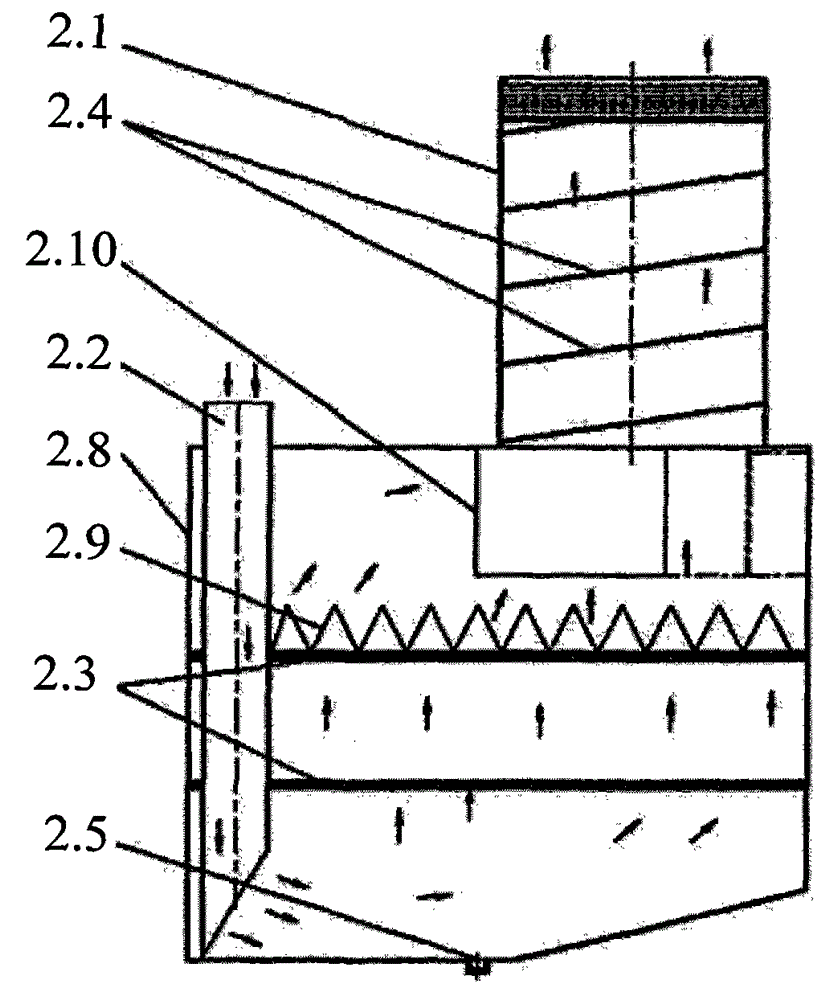

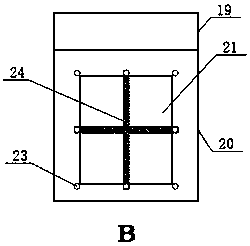

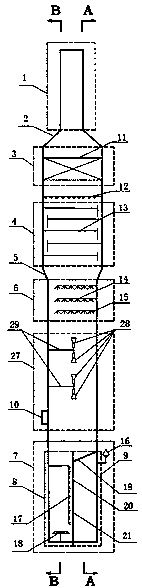

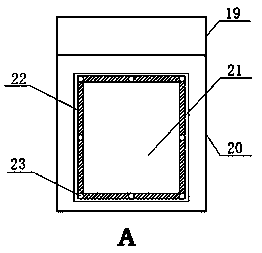

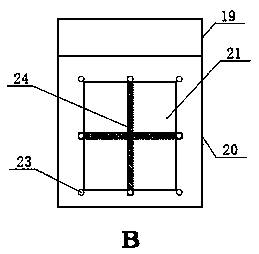

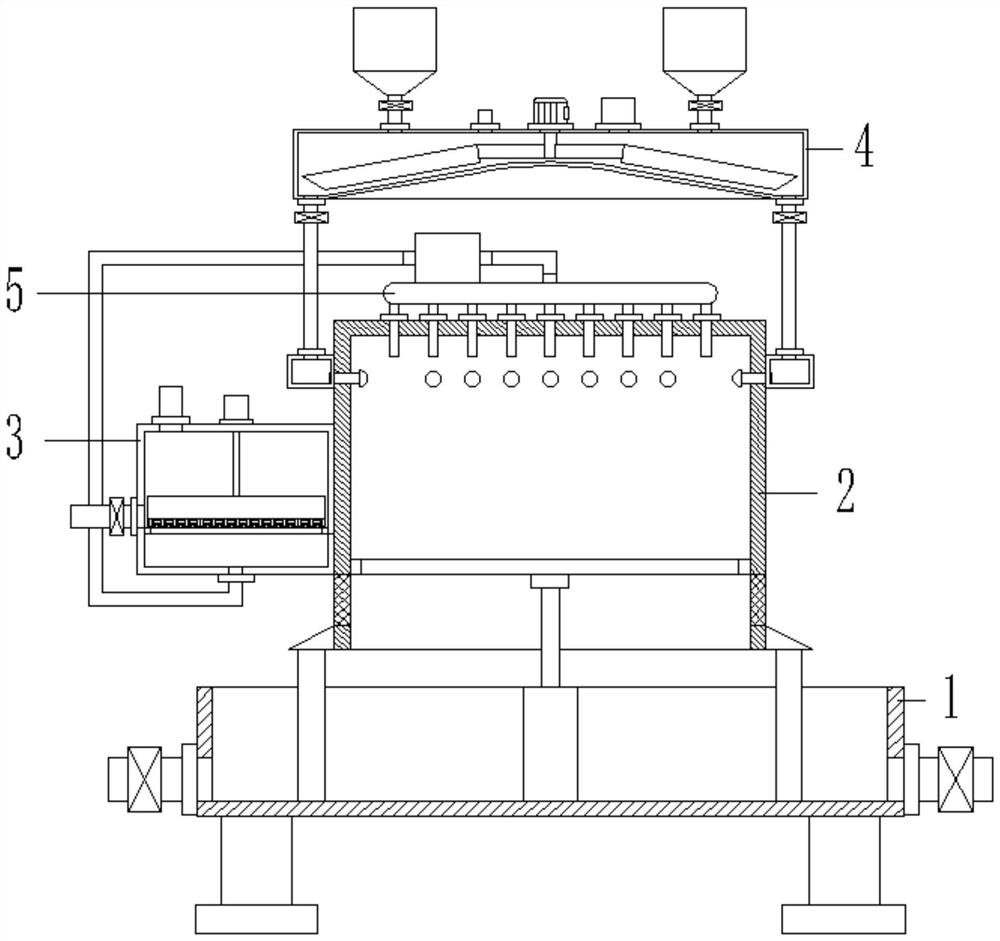

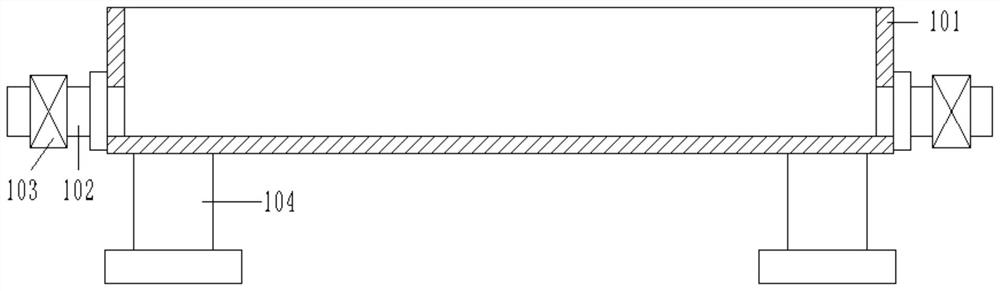

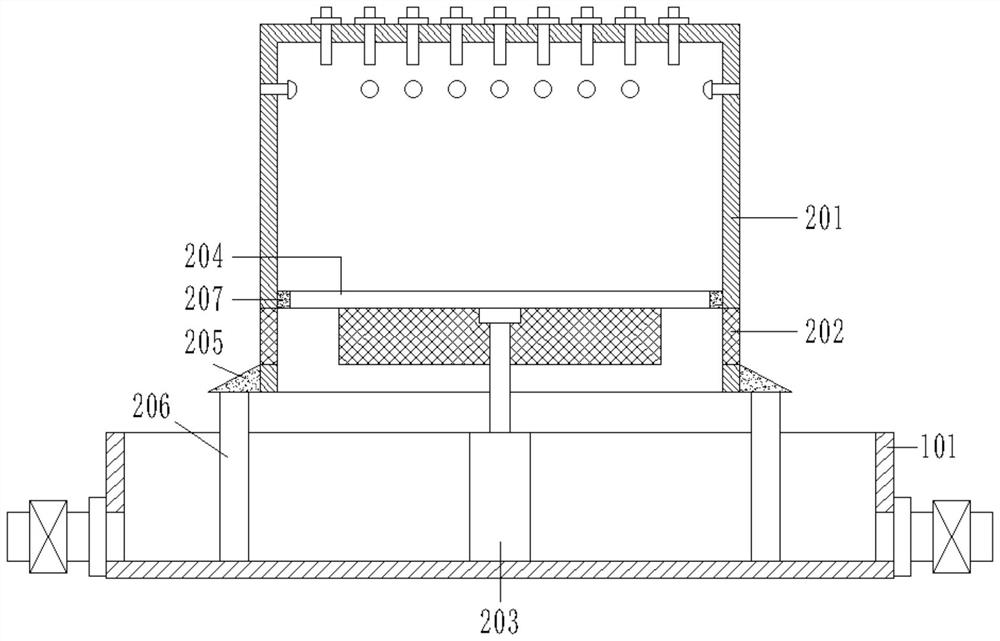

Control system for water adding tank of explosion-proof diesel engine

InactiveCN105275556AReduce consumptionSimple structureInternal combustion piston enginesExhaust apparatusControl systemWater level

The invention discloses a control system for a water adding tank of an explosion-proof diesel engine. The control system for the water adding tank of the explosion-proof diesel engine comprises an exhaust manifold (1), a washing tank (2), the water adding tank (5) and an electronic control unit (ECU) (4). The exhaust manifold (1) is connected with the washing tank (2), and the water adding tank (5) adds water into the washing tank (2) through a pipeline. An electronic liquid level sensor (3) is arranged in the washing tank (2), and the ECU (4) is connected with the liquid level sensor (3) and an electromagnetic valve (6). The electronic liquid level sensor (3) is used for obtaining water level information of the washing tank (2), and the ECU (4) is used for controlling opening or closing of the electromagnetic valve (6) according to the water level information and a preset water level threshold value. By means of the control system, the tail gas disposal effect of the explosion-proof diesel engine is greatly improved.

Owner:无锡国煤重工机械有限公司

Preparation method of farmland heavy metal contaminated soil repairing mineralizer

InactiveCN107312543AReduce manufacturing costSmall particle sizeOrganic fertilisersSoil conditioning compositionsAluminateCalcium hydroxide

The invention relates to a preparation method of a farmland heavy metal contaminated soil repairing mineralizer. Calcium chloride, calcium aluminate, aluminum oxide, calcium hydroxide and water are simultaneously added into a fully backmixing liquid film reactor for liquid-liquid two-phase co-precipitation reaction according to certain ratios, then are dispersed by a liquid distributor, and are fully mixed in a gap between a rotor and a stator, and a mixture is discharged through a material outlet to a crystallizing kettle for crystallization, so that mineralizer powder with the particle size being 20 nm to 5 [mu]m and the purity being 99.9 percent or above. The preparation method has the advantages that the mineralizer prepared with the preparation method can adsorb heavy metal ions in soil of a farmland, and the heavy metal ions are stabilized and solidified in the mineralizer and are inactivated; meanwhile, all raw materials, such as the calcium chloride, the calcium aluminate, the aluminum oxide and the calcium hydroxide, are common raw materials, so that the raw materials are readily available, and the preparation cost of the mineralizer is greatly reduced.

Owner:JIANGSU LONGCHANG CHEM

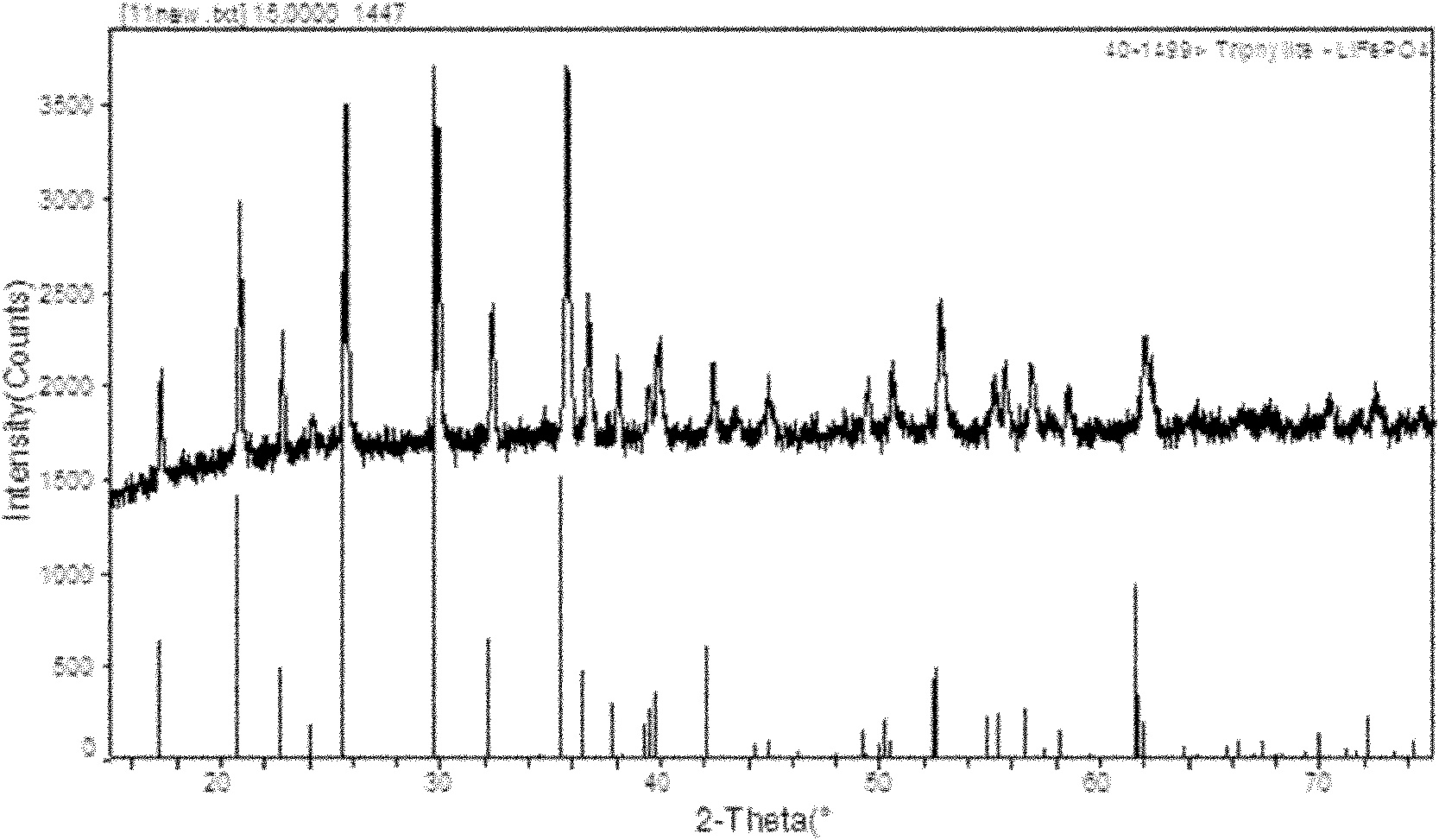

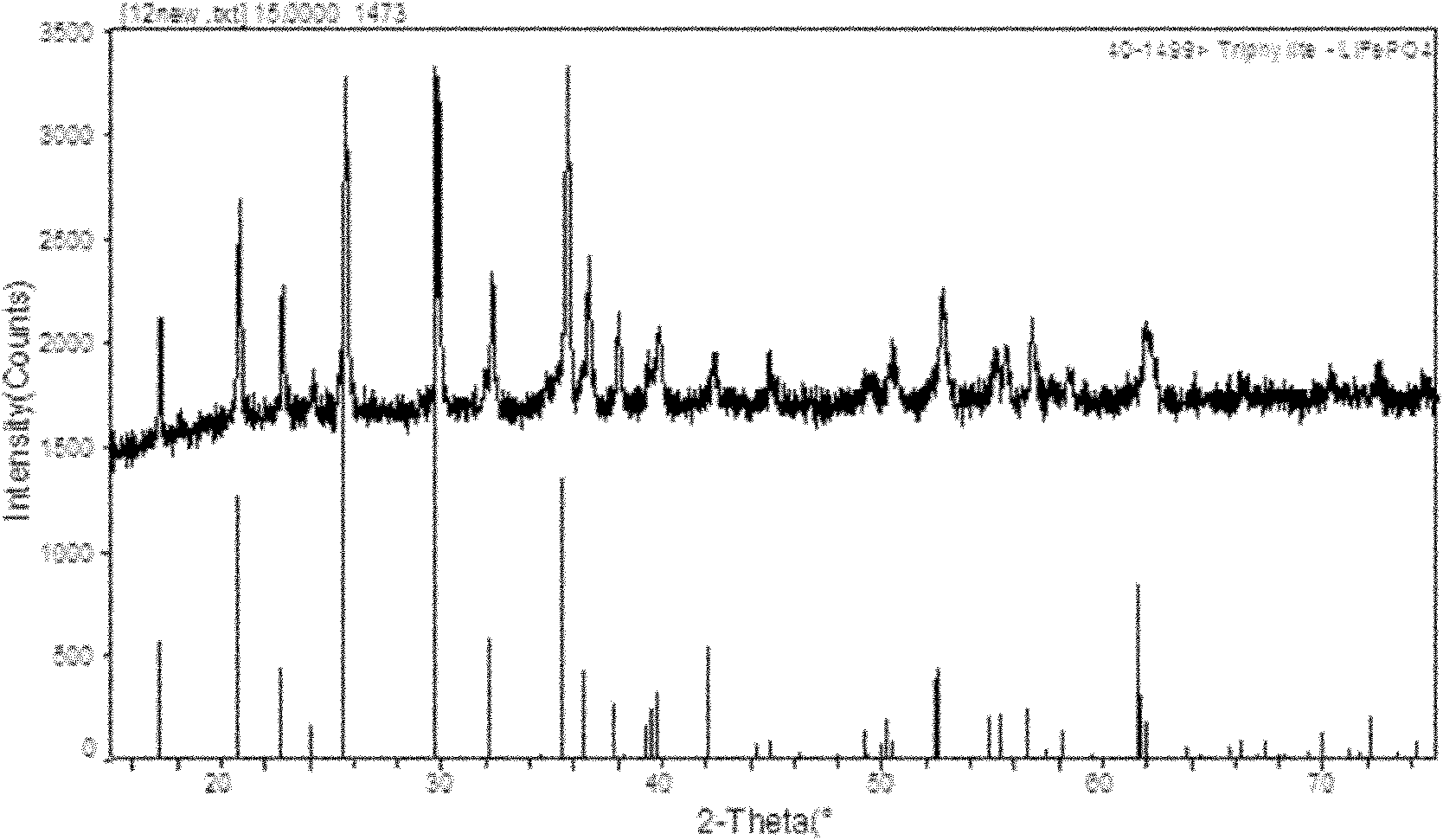

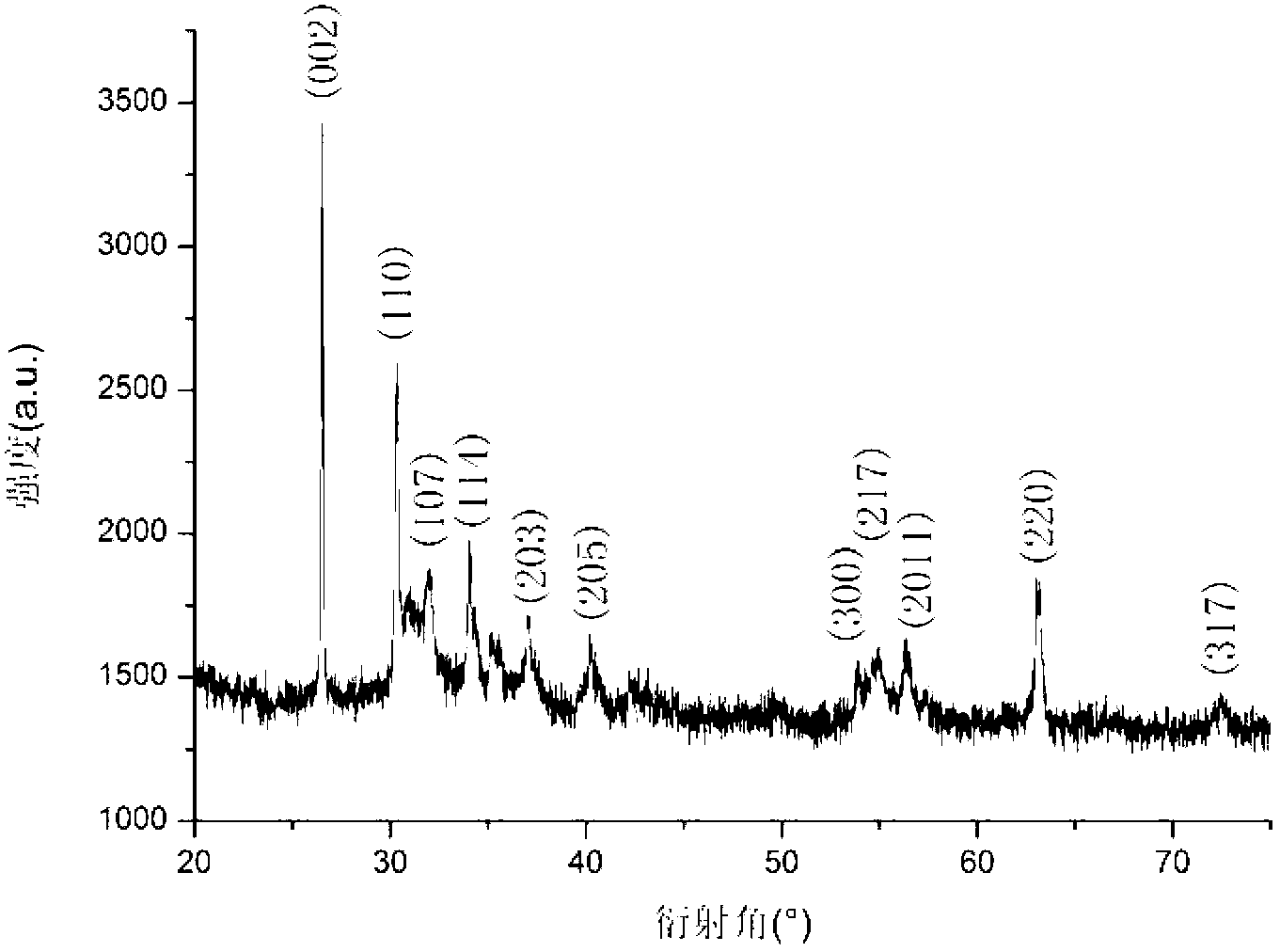

Method for preparing ferrous phosphate radical lithium salt of lithium ion battery

The invention provides a method for preparing ferrous phosphate radical lithium salt of a lithium ion battery, which comprises the following steps of: mixing Li3PO4 and Fe3(PO4)2 into a mixture; mixing uniformly by adopting a grinding or atomizing mode; transferring the uniformly mixed mixture into a high temperature furnace, pretreating under the protection of mixed nitrogen and hydrogen, wherein the volume ratio of the nitrogen to the hydrogen is 9.5:0.5; the pressure of the furnace chamber is 1.5*105Pa, the temperature is 600 to 700 and the time is 10 to 20 hours; after the temperature is reduced to room temperature, taking the material out, and adding carbon black and alcohol for uniform mixing; transferring the uniformly mixed material into the high temperature furnace, and performing high temperature treatment under the protection of nitrogen, wherein the pressure of the furnace chamber is 1.2*105Pa, the temperature is 700 to 900 DEG C and the time is 10 to 20 hours; and finally, reducing the temperature to room temperature. The lithium iron phosphate prepared by the method has good conductivity and electron mobility; and the process is simple.

Owner:IRICO

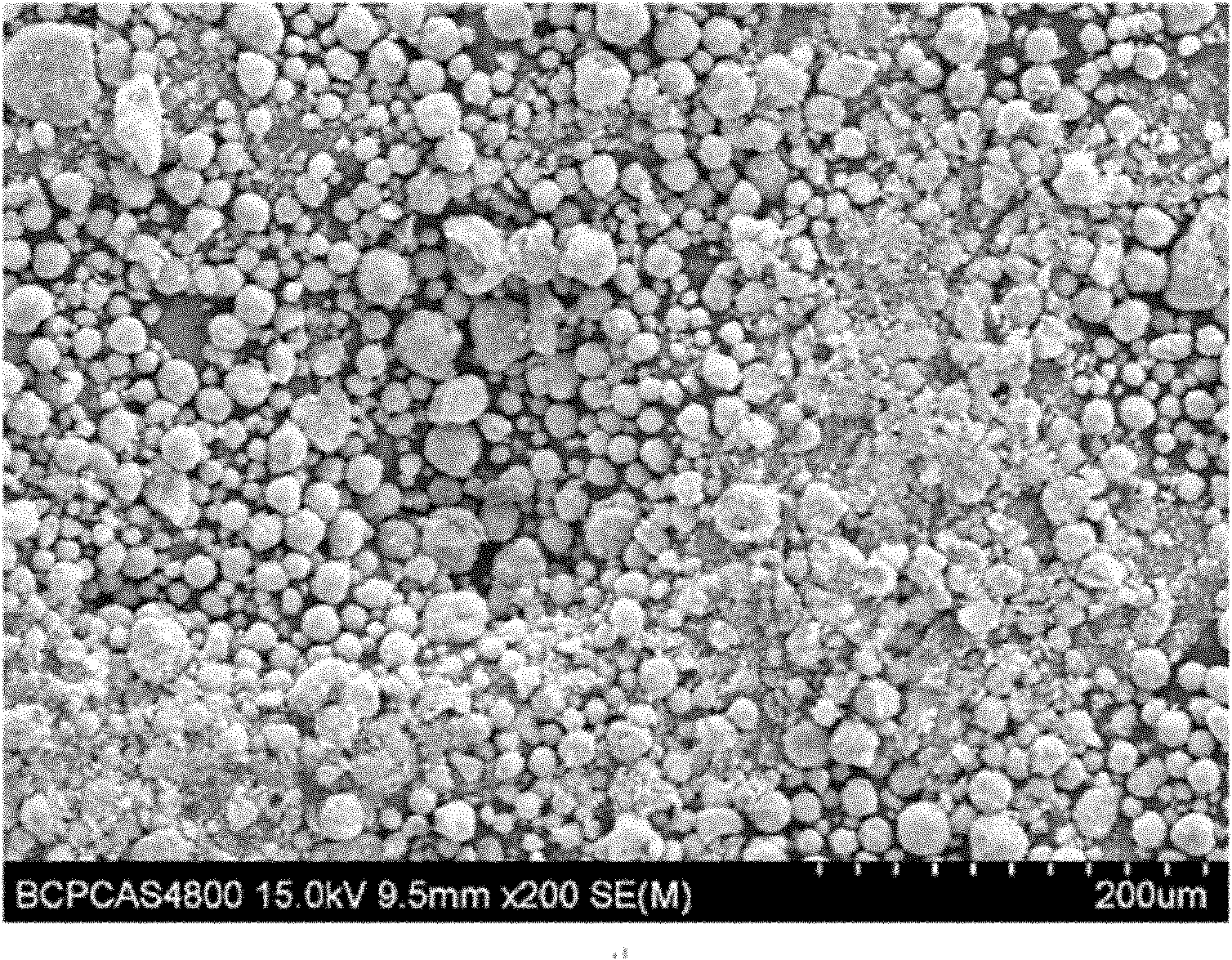

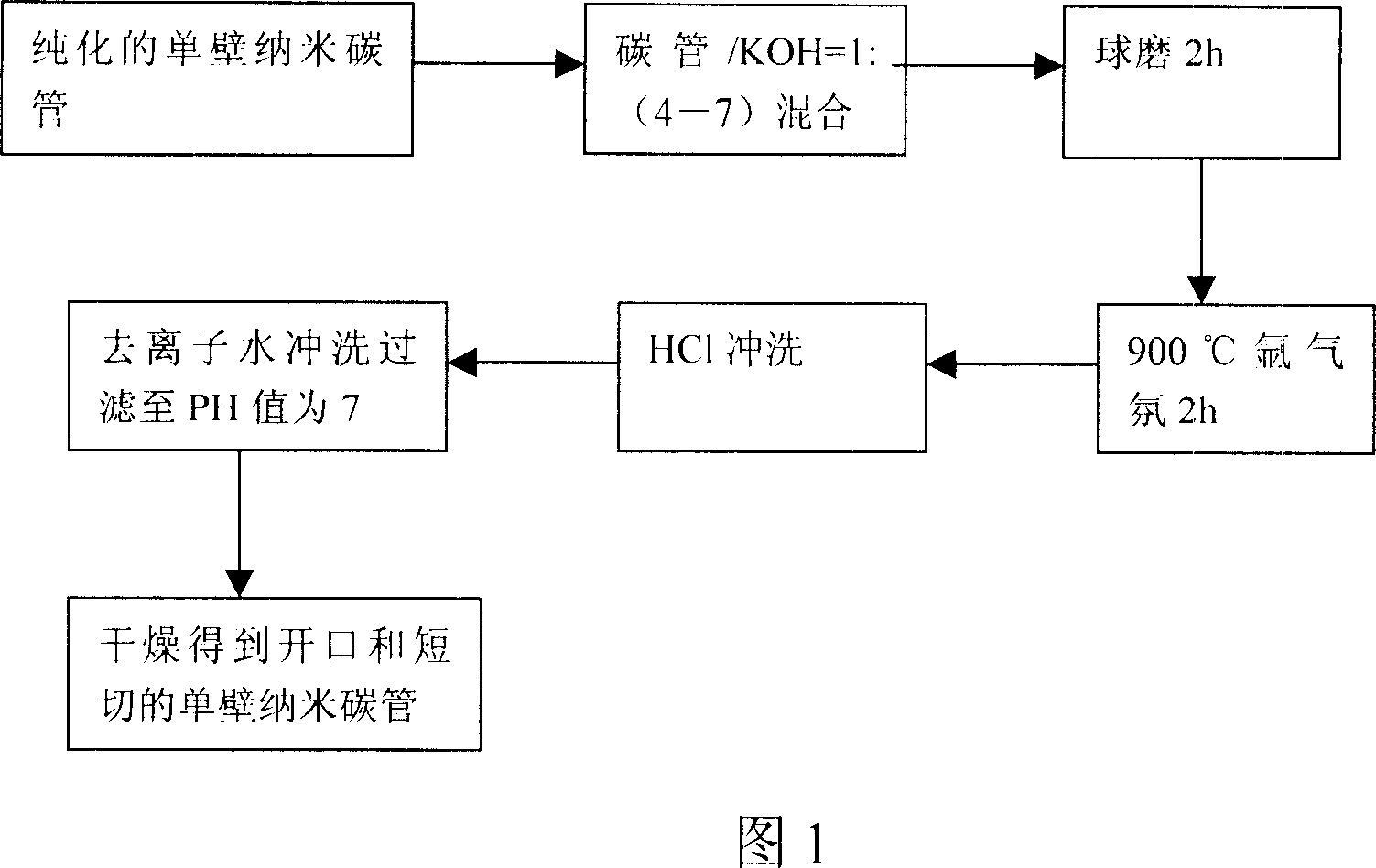

Method for making opening and short cutting on single wall Nano carbon tube

This invention relates to a method for opening and cutting single-walled carbon nanotubs with a high efficiency. The method comprises: mixing single-walled carbon nanotubs and KOH at a ratio of 1 :( 4-7), ball-milling in a planetary ball mill under 500 rpm for 1-3 h, treating at 900 deg.C in Ar for 1-3 h, washing with HCl, and rinsing with deionized water to obtain purified, opened and cut single-walled carbon nanotubs. The method avoids strong acid refluxing and oxygen-containing atmosphere oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

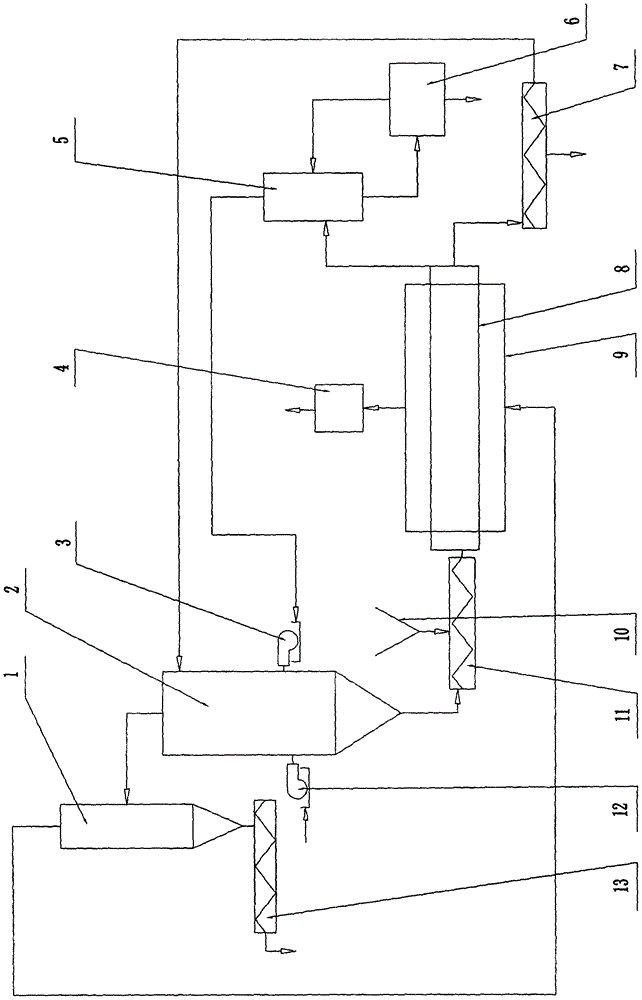

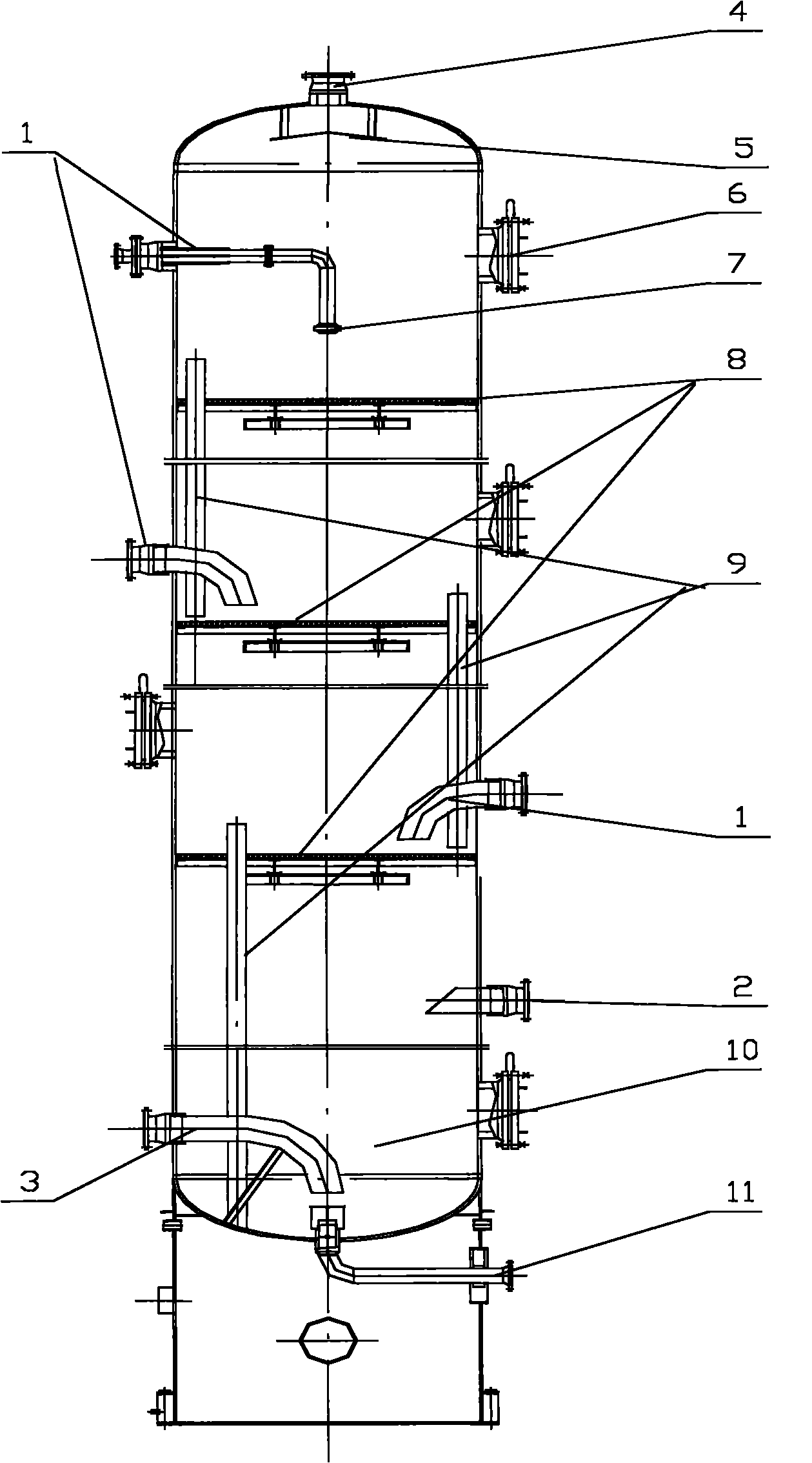

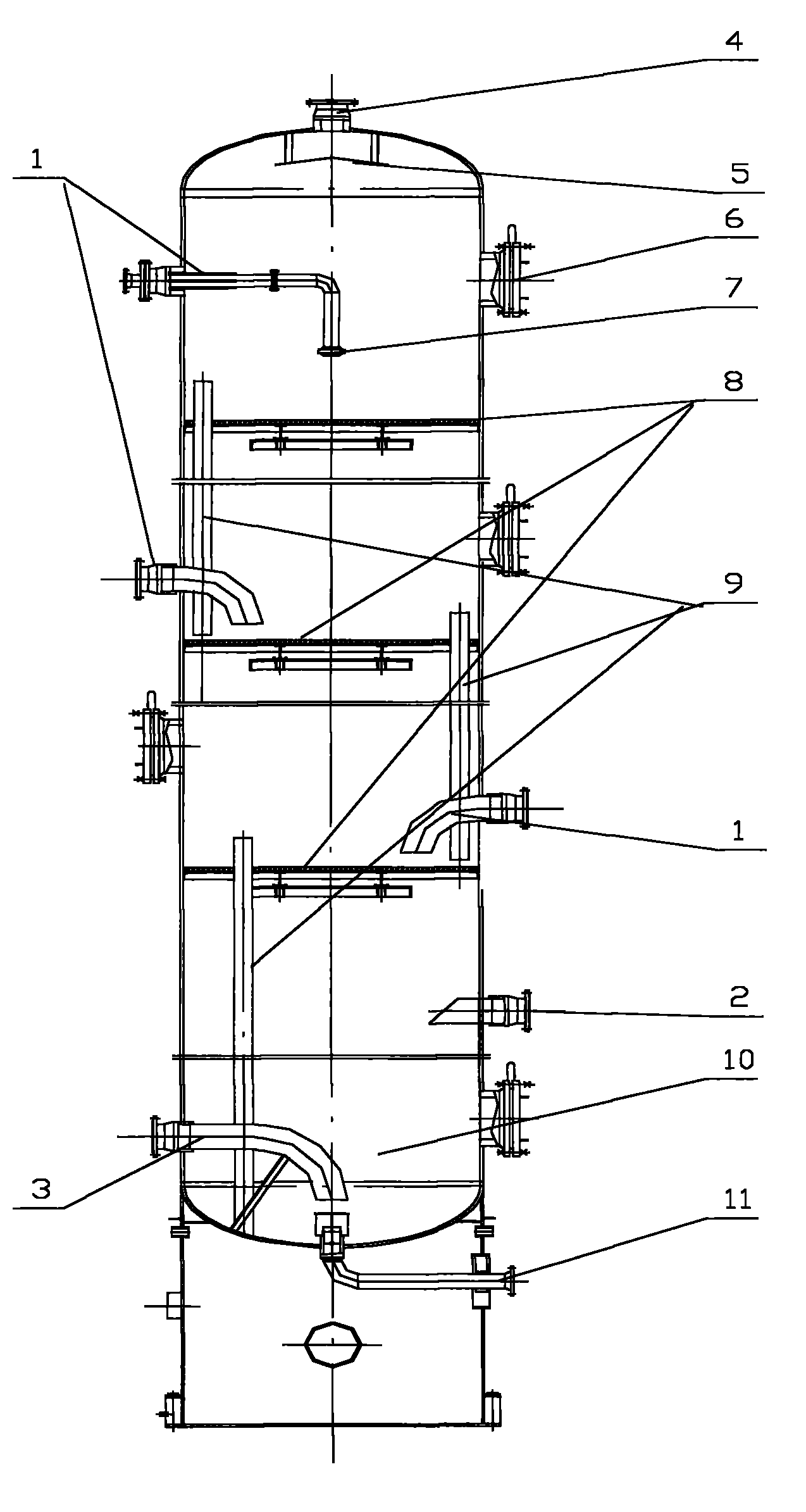

Flue gas desulfurizing tower and flue gas desulfurization and wastewater treatment method

ActiveCN108619872AWell mixed contactReduce energy consumptionUsing liquid separation agentWaste water treatment from gaseous effluentsFlocculationFlue gas

The invention discloses a flue gas desulfurizing tower and a flue gas desulfurization and wastewater treatment method. The flue gas desulfurizing tower sequentially comprises a flue gas exhaust area,a demist area, a tower tray area, a spraying area and a wastewater treatment area from top to bottom; the flue gas exhaust area and the demist area are connected through a cone deformation diameter, the tower tray area and the spraying area are connected through an inverted cone deformation diameter; the wastewater treatment area is divided by a vertical partition plat I from the center into an oxidation flocculation area and a circulation clear liquid area, the circulation clear liquid area is completely separated from the oxidation flocculation area and the spraying area through a partitionplate II from the top part of the circulation clear liquid area; the oxidation flocculation area is provided with a stirring device; and the vertical partition plate I is provided with a filter medium. The flue gas is subjected to dust removal, desulfurization and wastewater treatment in one tower, the flue gas is used to stir the wastewater to implement the operations of oxidation flocculation and concentration, the difference of the liquid levels of the two sides of the vertical partition plate is used as a driving force to filter the desulfurization wastewater, the occupied area is greatlyreduced, and the costs for the construction and transformation of the device and the operation cost of the device are obviously lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Transparent primer dipped with unsaturated polyester and preparation method thereof

InactiveCN106833309AImprove fullnessUniform molecular weight distributionEpoxy resin coatingsPolyester coatingsPolyesterAcrylic resin

The invention discloses a transparent primer dipped with unsaturated polyester. The transparent primer is composed of the following components at a weight ratio: primary paint: a diluent: an initiator: an accelerator=100:150:(1-2):(1.2-2.5); the primary paint is composed of the following components: 70-80% of unsaturated polyester resin, 5% of epoxy acrylic resin, 0.3-0.5% of a defoamer, 0.3-0.5% of a dispersant, 0.5-0.8% of an anti-settling agent, 0.2-0.4% of a flatting agent, 0.1-0.3% of a polymerization inhibitor, 4-6% of a polishing agent and 7-18% of an active solvent. The unsaturated polyester resin is allyl ether modified unsaturated polyester resin, the solid content of which is 72-78% and the viscosity of which is 2000-3000mpa.s; the active solvent is a mixture of styrene and a polyester transparent primer; and the diluent is composed of acetic ether, styrene, methylbenzene and acetone. The transparent primer dipped with unsaturated polyester disclosed by the invention has relatively good defoaming property and sag prevention, and is strong in seepage force, excellent in fillibility, and the sealing effect is obviously superior to that of a PU sealing primer in the market, so that the problem that the film collapses is effectively solved. The transparent primer for firstly dipping woodware is labor-saving and material-saving, energy-saving and environment-friendly, high in construction efficiency and suitable for flow line production.

Owner:CHENGDU YOUPIN CHEM CO LTD

Efficient wet multistage desulfurization dust remover

InactiveCN107158919AImprove efficiencyNo emission pollutionCombination devicesVena contracta diameterFlue gas

The invention discloses an efficient wet multistage desulfurization dust remover, and relates to the technical field of dust removers. The efficient wet multistage desulfurization dust remover comprises a primary desulfurization dust removal device and a secondary and tertiary desulfurization dust removal device. The primary desulfurization dust removal device is separated from the secondary and tertiary desulfurization dust removal device by sealing partition plates, the upper portion of a primary desulfurization dust removal tank is divided into a first flue chamber and a second flue chamber, a Y-shaped flue flat plate is arranged on the lower side of the first flue chamber, a Y-shaped flue orifice plate is arranged on the lower side of the second flue chamber, an alkali liquor sedimentation pond is arranged at the bottom of the primary desulfurization dust removal tank, a blow-down opening is formed in the bottom of the alkali liquor sedimentation pond, a second dust cleaning inspection opening is formed in a side wall of the alkali liquor sedimentation pond, an automatic water replenishing tank is connected with a side edge of the alkali liquor sedimentation pond, and two layers of turbulence dehydration plates are oppositely mounted on the upper side and the lower side of the inside of the second flue chamber. The efficient wet multistage desulfurization dust remover has the advantages that the efficient wet multistage desulfurization dust remover has efficient desulfurization and dust removal double-effect functions and is small in occupied area and convenient to mount; flue gas pollutant emission values of the efficient wet multistage desulfurization dust remover are lower than pollutant emission limit values in national environmental protection standards for important regions.

Owner:叶宏

Extracting method for rice-bran-oil phytosterol

The invention discloses an extracting method for rice-bran-oil phytosterol. The extracting method includes the steps that rice bran oil and an adsorbing agent are jointly put into a ball mill and subjected to ball milling, and the obtained ball-milling liquid is filtered; a filter cake is eluted with a solvent to obtain a phytosterol crude product solution, the phytosterol crude product solution is concentrated, and a phytosterol crude product is obtained; a rice-bran-oil phytosterol product is obtained through ethyl alcohol recrystallization. The adsorbing agent is one or more of attapulgite,silica gel, activated carbon, beta-cyclodextrin, hydroxypropyl-beta-cyclodextrin, sepiolite and alkaline aluminum oxide. According to the extracting method, the extracting efficiency of the rice-bran-oil phytosterol is high, the rice bran oil and the adsorbing agent are fully mixed and are in contact with each other through repeated mechanical stress, and the phytosterol is more easily separatedout. The extracting method has the advantages of being high in phytosterol extraction rate, simple in technology, convenient to operate and the like.

Owner:ZHEJIANG UNIV OF TECH

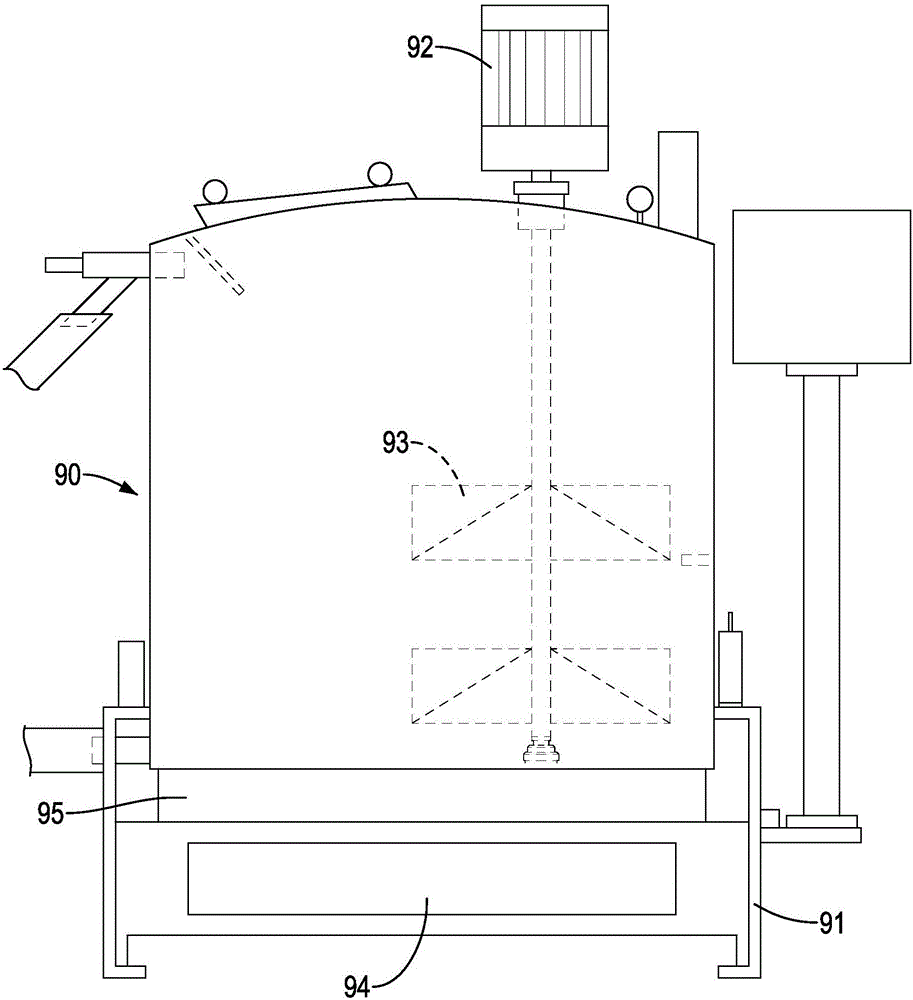

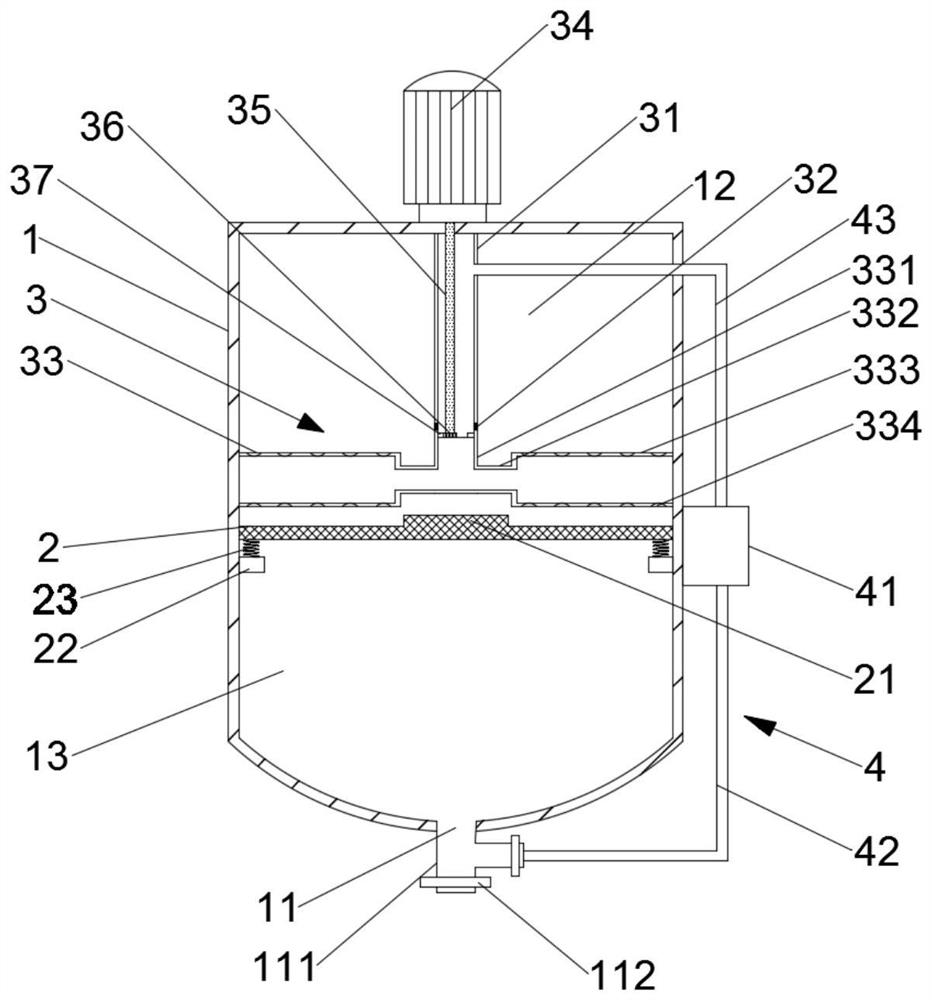

Microbial ferment fermentation device

InactiveCN105936875ADeep industrial valuePromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

The invention discloses a microbial ferment fermentation device. The device comprises a fermentation tank unit, a heat exchange unit, a material supply unit adopting pure water as a medium and realizing cycle blending, an output unit, a gas supply unit provided with a nanometer filter screen and a molecular film gas explosion tube, and a control unit for controlling all above units. The microbial ferment fermentation device has comprehensive complete functions, the gas supply unit cooperates with the drain and gas discharge effect of a vacuum machine to stir a fermentation liquid in a gas explosion manner in order to realize flowing cycle mixing, so damages to microbial strains are avoided, a gas is fully mixed with and is in full contact with the fermentation liquid and microbes, the growth and the yield of the microbes are greatly improved, and the microbes can be used to produce the high quality ferments, peptides or products, and can be flexibly applied to biological edible ferments, plant foliar ferments and soil improvers.

Owner:四川省广绿农业科技有限公司

Desulfurizing tower

InactiveCN102008879AIncrease contact areaImprove the degree of purificationDispersed particle separationEngineeringSmall hole

The invention provides a desulfurizing tower which comprises a tower body, wherein an air outlet is arranged at the top of the tower body; a feed inlet is arranged at the upper part of the tower body; and an air inlet is arranged at the lower part of the tower body. In the tower body, a gas-liquid contact plate (8) is arranged between the feed inlet and the air inlet and provided with a plurality of small holes. The desulfurizing tower solves the problem of tower plugging due to fillers in the desulfurizing tower, and has simple and reliable structure and efficient and quick gas-liquid reaction process.

Owner:SINOFERT HOLDINGS +1

Alkylation reactor and alkylation reaction method

ActiveCN109382050AReduce investmentReduced footprintLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical stationary reactorsAlkyl transferReaction zone

The invention relates to an alkylation reactor and an alkylation reaction method. The alkylation reactor comprises a mixing-reaction element of a specific structure; in the mixing-reaction element, aliquid catalyst and a reaction feed enter a reaction zone in a second liquid channel in an opposed jetting manner respectively through a first opening and a second opening arranged face to face and then undergo a mixing reaction, so the reaction feed and the liquid catalyst are fully mixed and contacted in the reaction zone; and thus, mixing and reaction efficiency is high, and selectivity and product quality are improved. The alkylation reactor of the invention may be provided with a plurality of mixing-reaction modules containing the mixing-reaction element, so a multistage reactor capable of realizing feeding stage by stage is formed. The alkylation reactor and the method for performing the alkylation reaction therewith may realize multi-stage reactions in one reactor, so an alkane-alkene ratio is optimized, reaction efficiency is enhanced, and the investment and the floor space of the reactor are reduced.

Owner:SINOPEC ENG +1

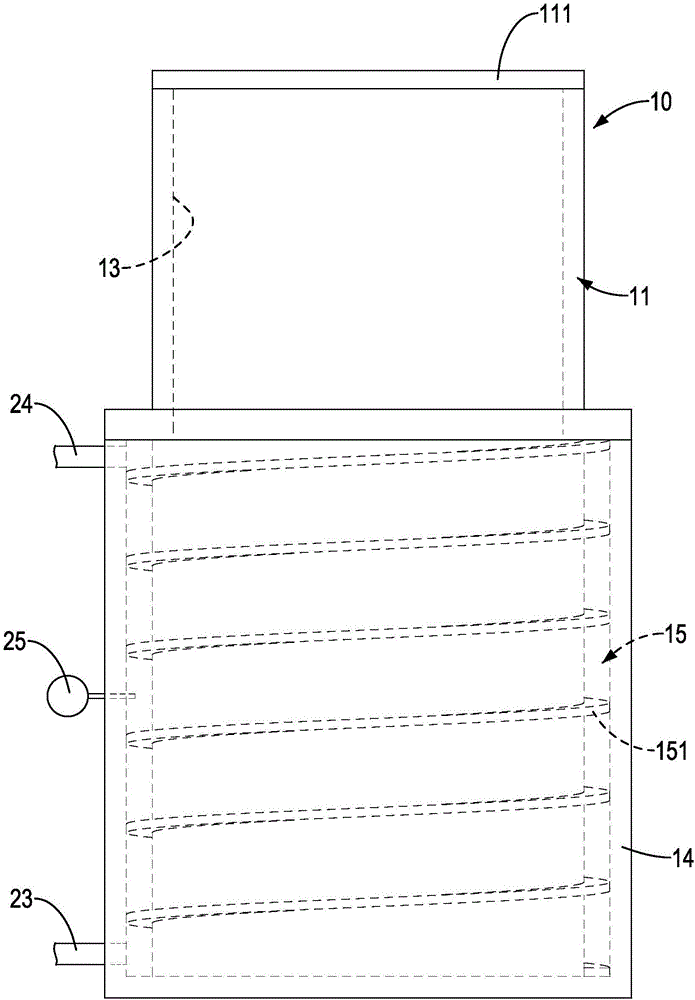

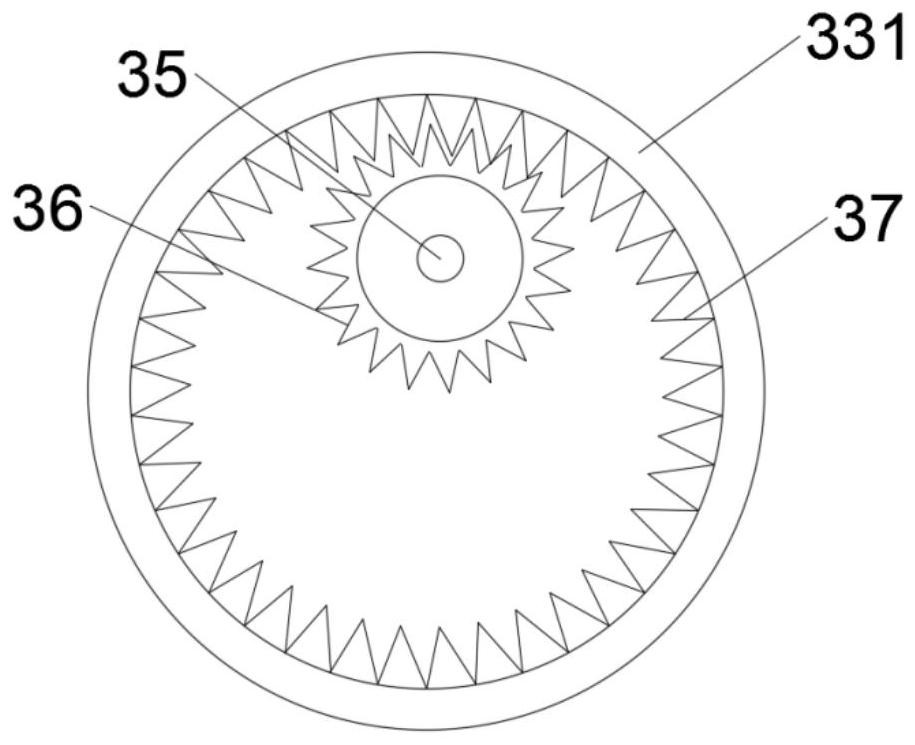

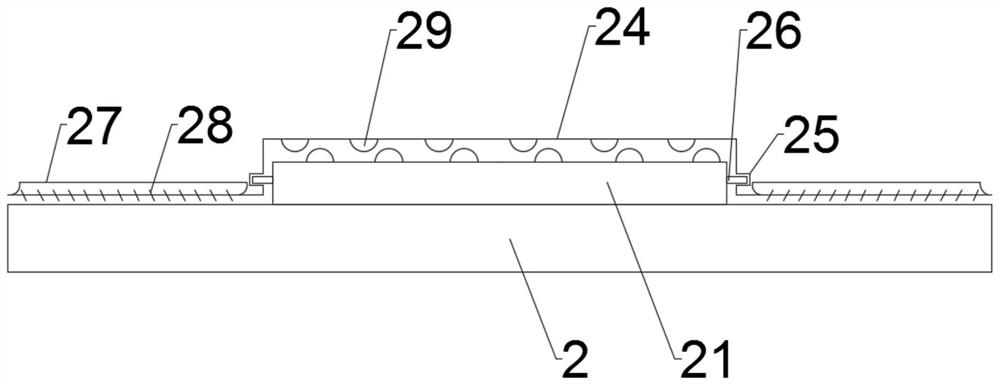

Enzymolysis device for extracting bitter gourd polypeptide skin care product

ActiveCN112029661AWell mixed contactImprove the effect of enzymatic hydrolysisBioreactor/fermenter combinationsBiological substance pretreatmentsBitter gourdEngineering

The embodiment of the invention discloses an enzymolysis device for extracting a bitter gourd polypeptide skin care product. The enzymolysis device comprises an enzymolysis tank main body and a discharging hole formed in the bottom of the enzymolysis tank main body, wherein an enzymolysis filter screen for intercepting a raw material to be subjected to enzymolysis is transversely connected to theinner wall of the enzymolysis tank main body; the enzymolysis filter screen divides the inside of the enzymolysis tank main body into an upper enzymolysis cavity and a lower filter cavity; a rolling device for rolling and flatly paving the raw material to be subjected to enzymolysis on the enzymolysis filter screen is arranged in the enzymolysis cavity; a spraying pipeline is also arranged in theenzymolysis cavity; one end of the spraying pipeline is connected with the rolling device and is used for spraying the flatly paved raw material to be subjected to enzymolysis; and the other end of the spraying pipeline extends out of the top of the enzymolysis tank main body and is connected with the discharging hole. According to the embodiment of the invention, the raw material to be subjectedto enzymolysis is flatly paved by utilizing the rolling device, and enzymolysis liquid is sprayed to the flatly paved raw material to be subjected to enzymolysis through the spraying pipeline, so thatthe raw material to be subjected to enzymolysis and the enzymolysis liquid are fully mixed and contacted, and the enzymolysis reaction efficiency is improved.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

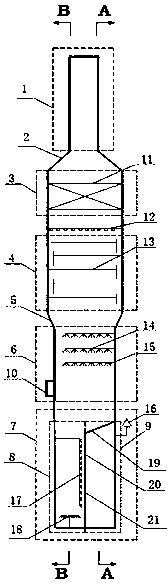

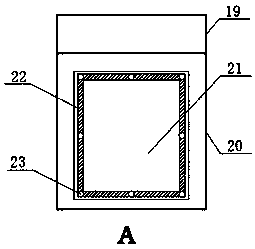

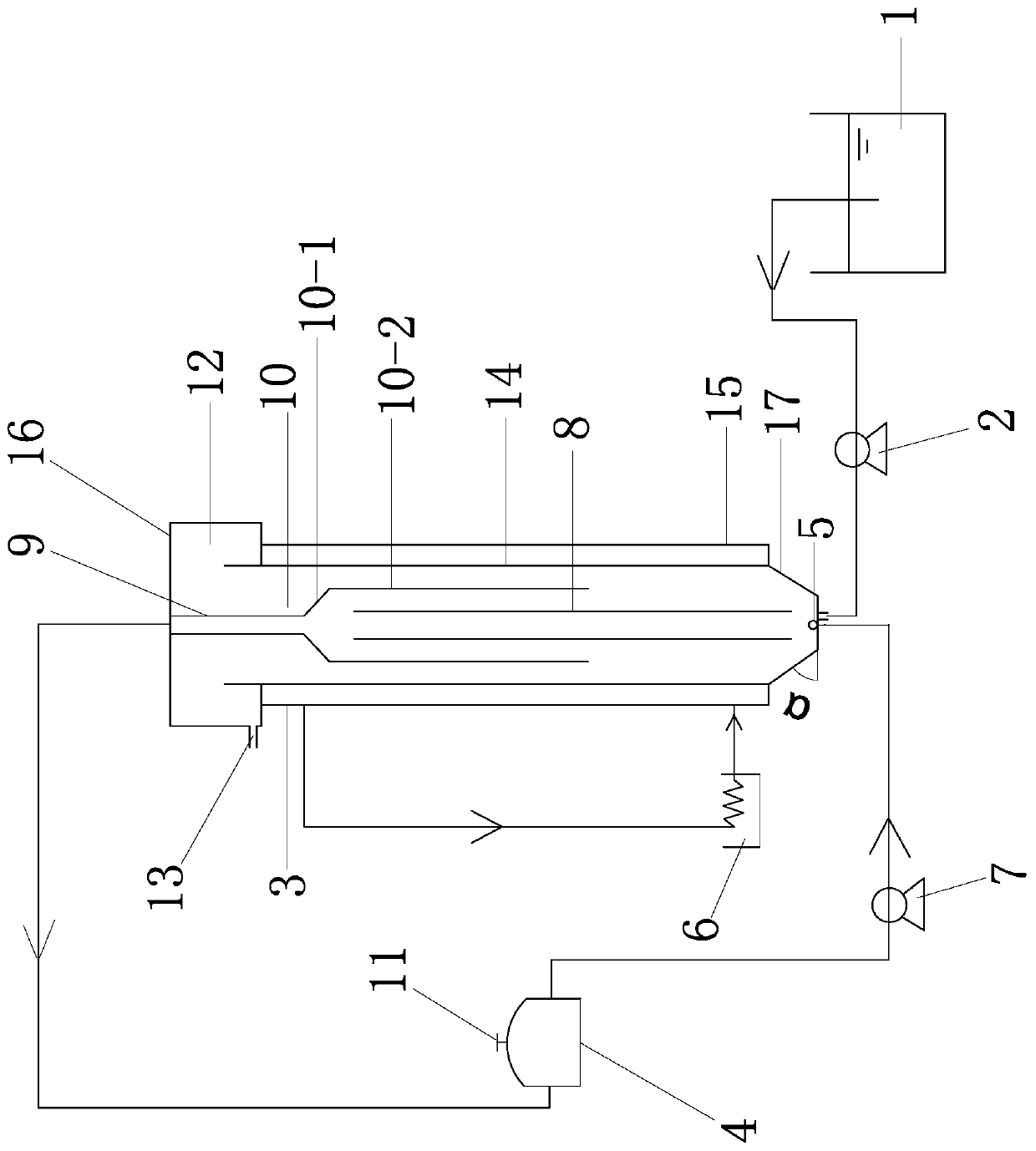

Flue gas desulfurizing tower and flue gas dust removal, desulfurization and wastewater treatment method

ActiveCN108619885AWell mixed contactPromote absorptionCombination devicesGas treatmentFlocculationFlue gas

The invention discloses a flue gas desulfurizing tower and a flue gas dust removal, desulfurization and wastewater treatment method. The flue gas desulfurizing tower sequentially comprises a flue gasexhaust area, a demist area, a tower tray area, a spraying area and a wastewater treatment area from top to bottom; the flue gas exhaust area and the demist area are connected through a cone deformation diameter, the tower tray area and the spraying area are connected through an inverted cone deformation diameter; the wastewater treatment area is divided by a vertical partition plat I from the center into an oxidation flocculation area and a circulation clear liquid area, the circulation clear liquid area is completely separated from the oxidation flocculation area and the spraying area through a partition plate II from the top part of the circulation clear liquid area; and the vertical partition plate I is provided with a filter medium. The flue gas is subjected to dust removal, desulfurization and wastewater treatment in one tower, the flue gas is used to stir the wastewater to implement the operations of oxidation flocculation and concentration, the difference of the liquid levels of the two sides of the vertical partition plate is used as a driving force to filter the desulfurization wastewater, the occupied area is greatly reduced, the costs for the construction and transformation of the device and the operation cost of the device are obviously lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flue gas desulfurization tower and flue gas dust removal, desulfurization and wastewater treatment process

ActiveCN110559817AWell mixed contactPromote absorptionUsing liquid separation agentTreatment involving filtrationFlocculationFlue gas

The invention discloses a flue gas desulfurization tower and a flue gas dust removal, desulfurization and wastewater treatment process. The flue gas desulfurization tower sequentially comprises a fluegas discharge area, a demisting area, a tray area, a spraying area, a quenching area and a wastewater treatment area from top to bottom; the flue gas discharge area is connected with the demisting area through a cone in a reducing manner, and the tray area is connected with the spraying area through an inverted cone in a reducing manner; the wastewater treatment area is divided into an oxidationflocculation area and a circulating clear liquid area through a vertical partition plate I in the center of the wastewater treatment area; the top of the circulating clear liquid area is completely isolated from the oxidation flocculation area and the spraying area by a partition plate II; and the vertical partition plate I is provided with a filter medium. Flue gas dust removal, desulfurization,desalting and wastewater treatment are carried out in one tower, so that the occupied area is greatly reduced, and the cost required by construction and transformation of the device and the operatingcost of the device are remarkably reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

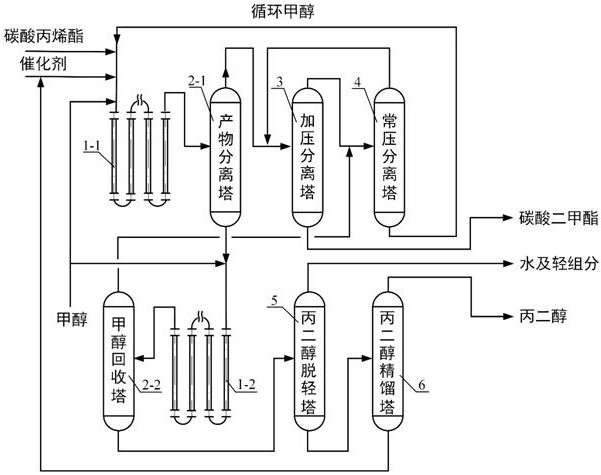

Device for producing dimethyl carbonate by transesterification method and using method thereof

PendingCN112479883AFully contactedThe interface updates quicklyOrganic compound preparationChemical industryProcess engineeringTrans esterification

The ester exchange method dimethyl carbonate production device provided by the invention is provided with two tubular ester exchange reactors which are connected in series for use, and a product separation tower is arranged between the two ester exchange reactors; a fresh raw material propylene (ethylene) carbonate enters the first transesterification reactor, a fresh raw material methanol entersthe second transesterification reactor, and the two transesterification reactors have high reaction driving force. The reaction effect far exceeding the equilibrium conversion rate can be obtained byusing the total feed composition close to the theoretical molar ratio, and the unconverted propylene (ethylene) carbonate and methanol are separated and recycled. The problems of overhigh energy consumption and complex operation control caused by pursuit of excessive methanol in the propylene (ethylene) carbonate conversion rate in the dimethyl carbonate production operation of the traditional reactive distillation column transesterification method are solved. The device is high in production efficiency, good in product quality, low in energy consumption and high in operation flexibility, andthe production process is easy to control.

Owner:吴剑华

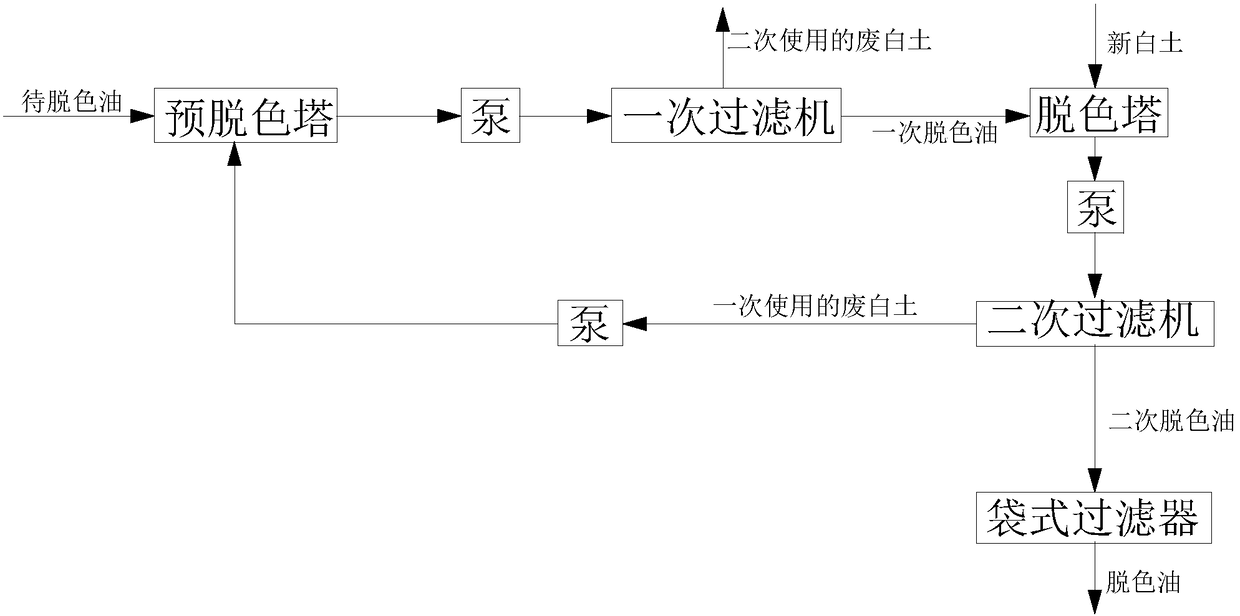

Secondary decoloring method of animal and vegetable oil

ActiveCN108251208AImprove secondary utilizationWell mixed contactFatty-oils/fats refiningRefluxVegetable oil

The invention relates to a secondary decoloring method of animal and vegetable oil. The secondary decoloring method comprises the following steps of a, mixing oil to be decolored and primarily used waste clay, and enabling a mixture to enter a decoloring tower for decoloring treatment; b, treating a material discharged in the step 1 with a primary filter to obtain primarily decolored oil and secondarily used waste clay, and treating the collected secondarily used waste clay according to a conventional waste treatment technology; c, mixing the primarily decolored oil obtained in the step b andnew clay, and enabling a mixture to enter the decoloring tower for decoloring treatment; d, treating a material discharged in the step c with a secondary filter to obtain secondarily decolored oil andprimarily used waste clay, enabling the primarily used waste clay to reflux to the step a for use; and e, treating the secondarily decolored oil obtained in the step d with a bag filter to obtain decolored oil. The secondary decoloring method of the animal and vegetable oil enables the secondary utilization ratio of waste clay to be increased, the waste clay and oil to be more fully mixed and theuse ratio of fresh clay to be lowered and belongs to the technical field of animal and vegetable oil decoloring.

Owner:立钢贝纳德工程设备(广州)有限公司

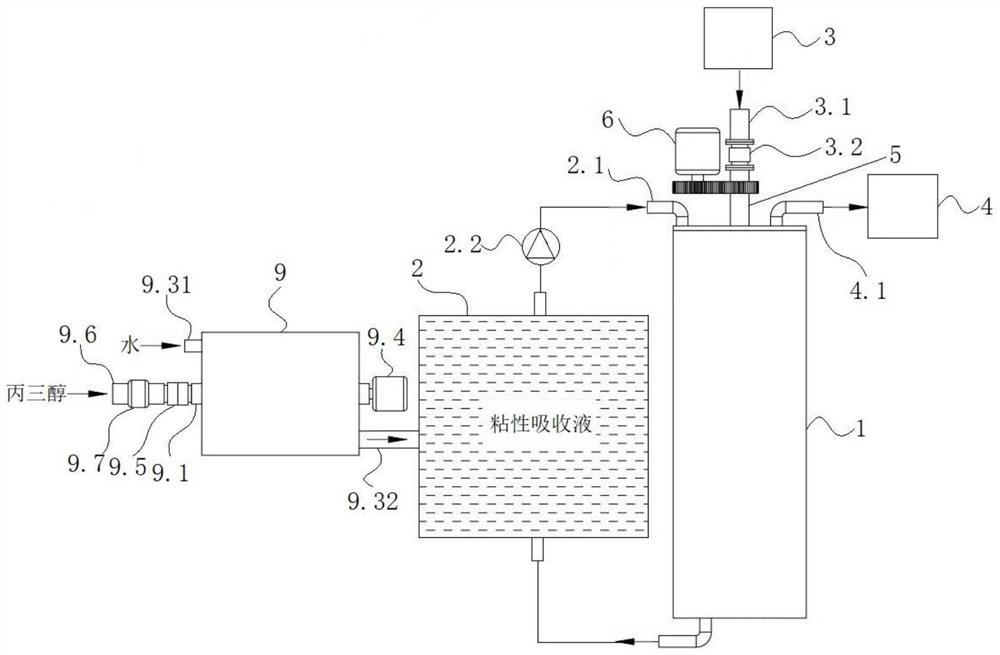

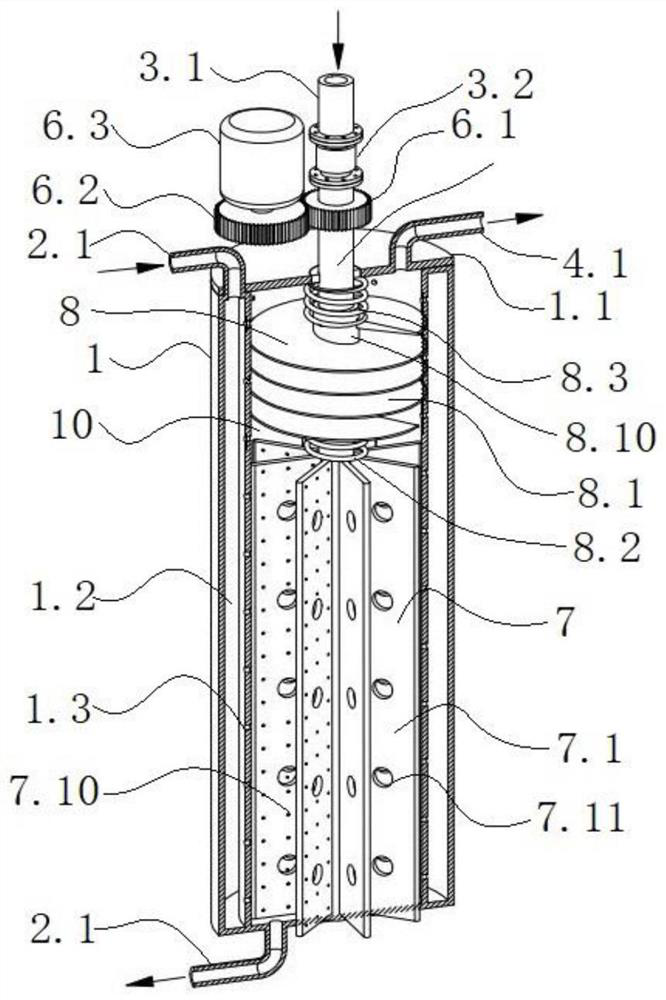

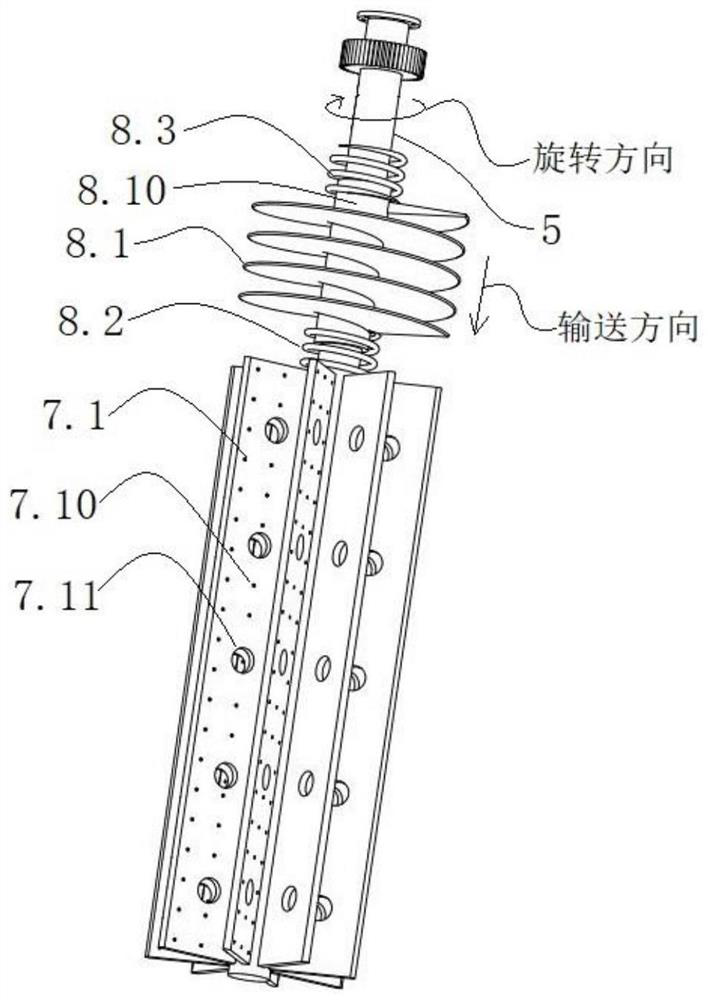

Dust removal and desulfurizing system for treating industrial waste gas by using viscous absorption liquid and treatment method

InactiveCN112452115AExtended flow timeImprove liquidityTransportation and packagingMixing methodsThermodynamicsExhaust fumes

The invention discloses a dust removal and desulfurizing system for treating industrial waste gas by using viscous absorption liquid and a treatment method. The dust removal and desulfurizing system comprises a dust removal and desulfurizing container, a viscous absorption liquid circulating tower, an industrial waste gas source and a gas receiving tower, the viscous absorption liquid circulatingtower circularly supplies the viscous absorption liquid to the dust removal and desulfurizing container, the industrial waste gas source conveys industrial waste gas to the dust removal and desulfurizing container, and the industrial waste gas subjected to dust removal and desulfurizing is received by the gas receiving tower; the dust removal and desulfurizing container is provided with a cylindrical dust removal and desulfurizing cavity and an annular liquid distribution cavity from inside to outside, the cylindrical dust removal and desulfurizing cavity is inserted into a vertical pipe, thevertical pipe is provided with a gas distribution stirring assembly and an elastic spiral choked flow blade assembly from top to bottom, and viscous absorption liquid is stirred while the gas distribution stirring assembly distributes gas; and the elastic spiral choked flow blade assembly conveys the viscous absorption liquid downwards to chock flow of industrial waste gas and generates vertical elastic vibration under flow impact of the viscous absorption liquid at the same time. The dust removal and desulfurizing system integrates industrial waste gas dedusting and desulfurizing, and dedusting and desulfurizing are thorough and efficient.

Owner:崔小勤

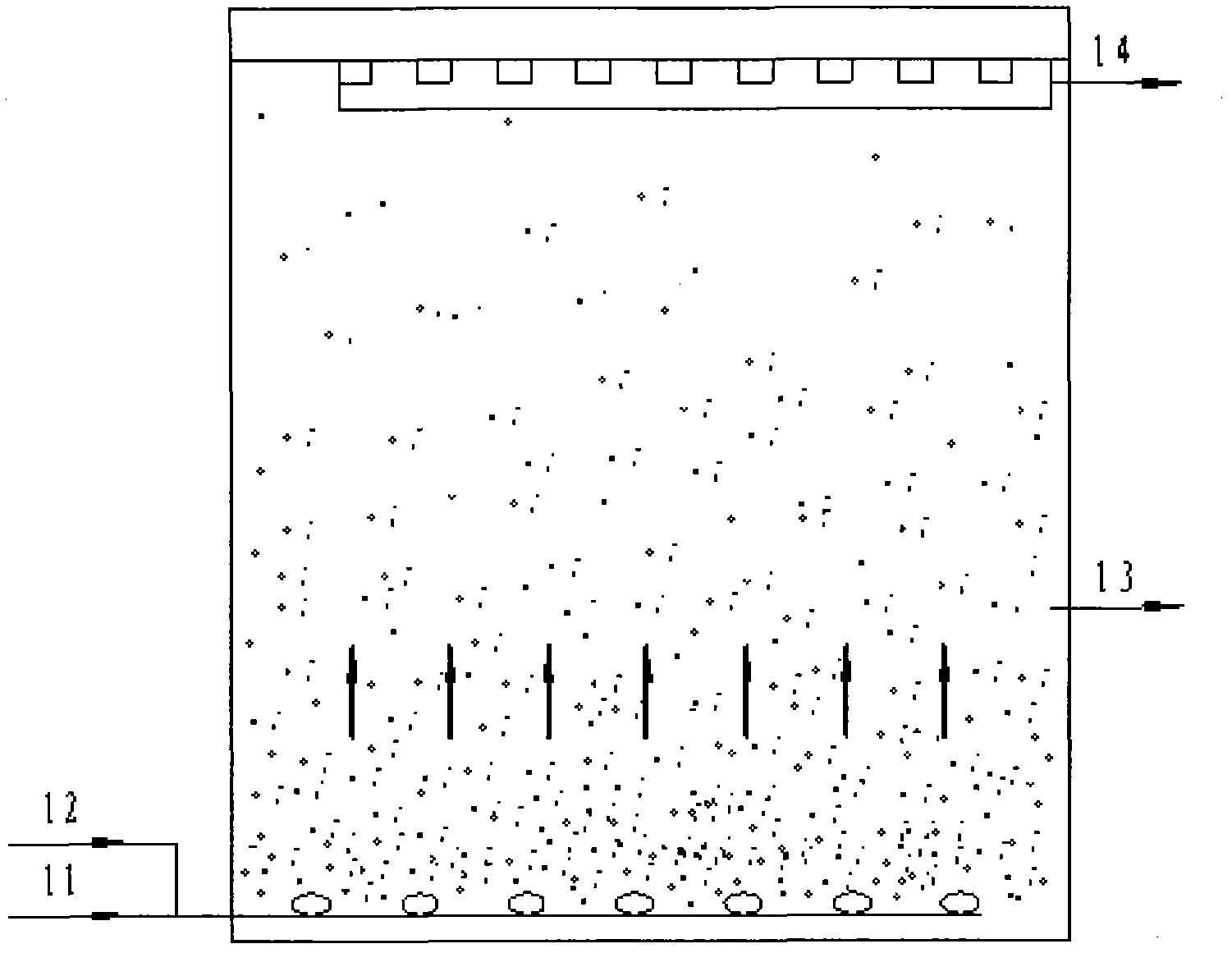

Internal-loop air-lift anaerobic ammonia oxidation-autotrophic nitrogen removal plant and operating method thereof

PendingCN110304722AWell mixed contactReduce floatingWater contaminantsBiological treatment apparatusActivated sludgeHigh concentration

An internal-loop air-lift anaerobic ammonia oxidation-autotrophic nitrogen removal plant and an operating method thereof belong to the technical field of nitrogen removal of water treatment by an activated sludge process. Nitrogen is pre-charged into a gas collecting device, and a closed-loop nitrogen circulating system is employed for aerating an anaerobic ammonia oxidation reactor to produce anair-lift effect; internal circulation is formed in the reactor under the action of air-lift, so that sludge and water are fully mixed and contacted, thereby accelerating the conversion of flocculent sludge to granular sludge while enhancing the internal mass transfer effect; an aeration rate is regulated so as to change the internal hydraulic shear force, optimize the particle size distribution ofanaerobic ammonia oxidation granular sludge in the plant and improve the anaerobic ammonia oxidation nitrogen removal performance of the plant; and when high-concentration nitrogen-containing wastewater is treated in the reaction plant, a feed water dilution effect generated by reflux in the mixed liquid can significantly improve the impact load resisting capability of the system, avoid inhibition of nitrite nitrogen and facilitate stable and efficient operation of the plant.

Owner:YANGZHOU UNIV

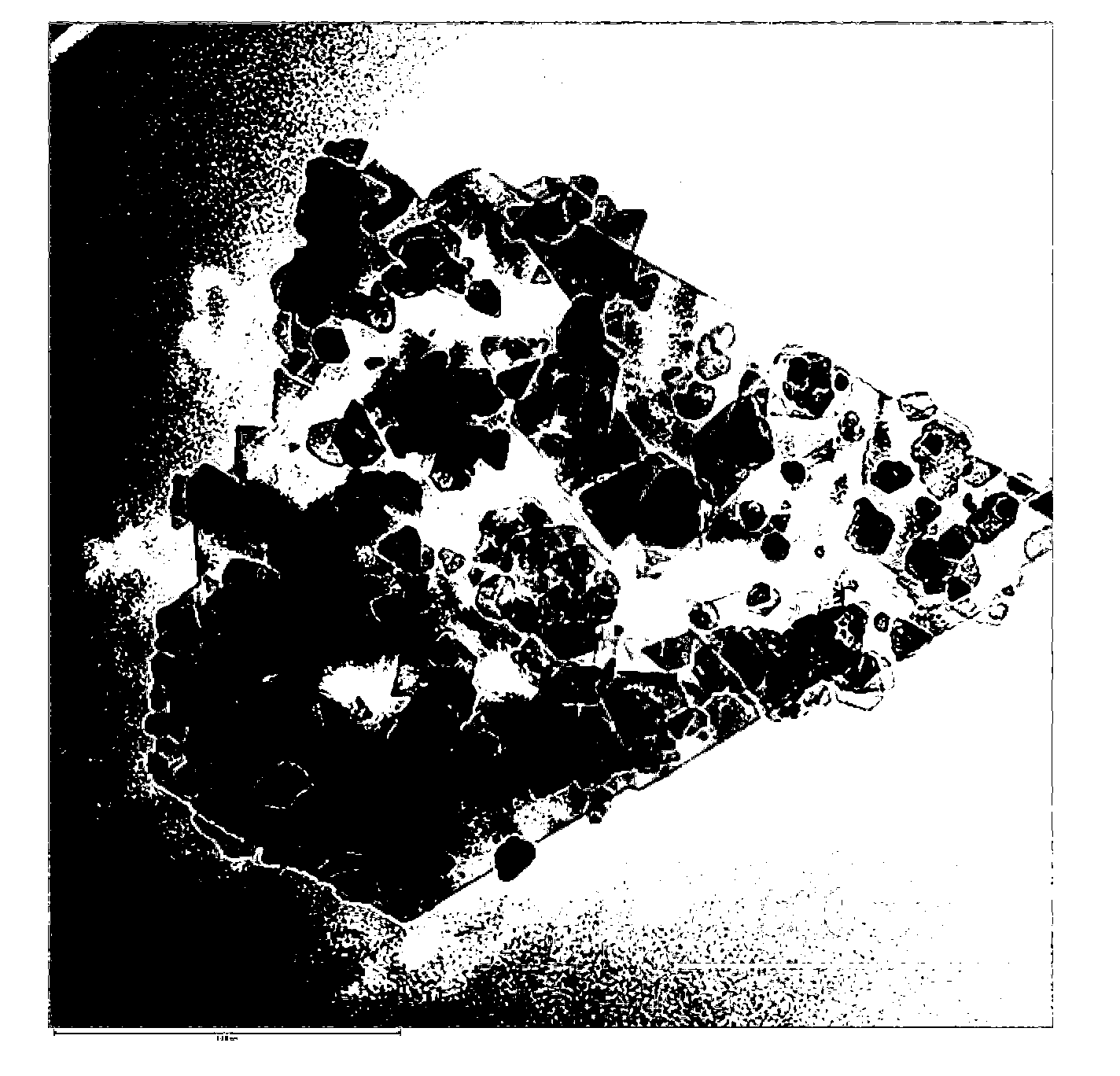

Preparation method of composite material of graphite flake-load barium ferrite nanoparticles

InactiveCN102938280AReduce chemical reaction energySynthesis temperature is lowInorganic material magnetismNanoparticlePollution

The invention provides a preparation method of a composite material of graphite flake-load barium ferrite nanoparticles, which comprises the following steps of: firstly adding barium acetate to ferric hydroxide sediment prepared by using FeCl3.6H2O and stronger ammonia water; then adding sodium hydroxide and absolute ethyl alcohol solutions, uniformly stirring, and then adding natural graphite activated by concentrated nitric acid and concentrated hydrochloric acid; uniformly stirring again, then introducing argon, and then carrying out ultrasonic treatment for 5 hours; finally placing a mixed solution subjected to the ultrasonic treatment into a high-temperature reaction kettle, carrying out heat preservation at 180-200 DEG C for 18-24 hours, repeatedly washing by using deionized water after cooling, then acid-washing by using an 0.1 mol / L HCl solution and finally diluting the solution to be neutral and then drying at 70 DEG C, thus obtaining the composite material of the graphite flake-loading barium ferrite nanoparticles. The obtained graphite flake-loading barium ferrite nanoparticles have high loading quantity, good dispersity and stable structure. The preparation method provided by the invention is simple in preparation process, low in equipment cost and environment-friendly without pollution and provides a new way for the preparation of composite magnetic materials.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Zero-discharge recycling treatment device and process for electroplating heavy metal wastewater

PendingCN113929237AEasy to recycleWell mixed contactWater contaminantsTreatment involving filtrationTreatment unitEffluent

The invention discloses a zero-discharge recycling treatment device and process for electroplating heavy metal wastewater, and relates to the technical field of electroplating heavy metal wastewater zero-discharge recycling treatment. The device comprises a collecting unit, a treatment unit is arranged at the top of the collecting unit, an aqueous solution mixing unit is arranged at the upper end of the exterior of the treatment unit, a conveying unit is arranged at the top of the treatment unit, a filtering unit is arranged beside the treatment unit, and the filtering unit is connected with the conveying unit. Through cooperation of the collecting unit, the treatment unit, the filtering unit, the aqueous solution mixing unit and the conveying unit, a used flocculating agent can be fully mixed and contacted with wastewater, and the contact area of the flocculating agent and the wastewater is increased, so that the removal efficiency of heavy metals in the wastewater is improved, zero discharge of electroplating heavy metal wastewater is facilitated, and recycling is facilitated.

Owner:科腾环保科技(嘉兴)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com