Device for producing dimethyl carbonate by transesterification method and using method thereof

A technology for producing dimethyl carbonate and production equipment, which is applied in the field of production equipment for the production of dimethyl carbonate by transesterification, which can solve the problems of high energy consumption in methanol recovery, complicated operation control, and low production efficiency of the equipment, and reduce energy consumption , The interface is updated quickly and the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

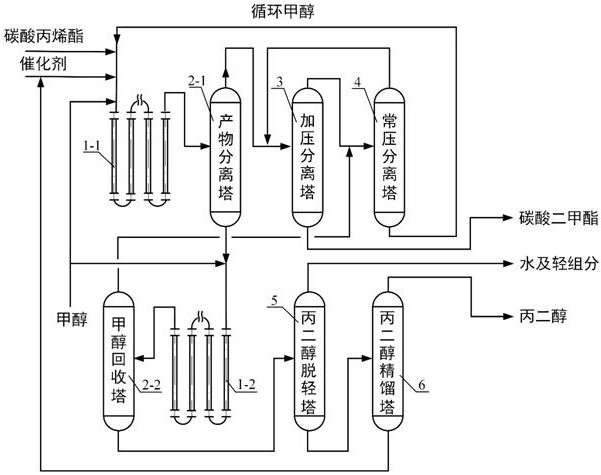

[0034] The production device of a kind of transesterification method dimethyl carbonate used in the present embodiment comprises the first transesterification reactor 1-1, product separation tower 2-1, the second transesterification reactor 1-2, methanol recovery tower 2 -2. Pressurized separation tower 3, atmospheric pressure separation tower 4, propylene glycol light removal tower 5, propylene glycol rectification tower 6 and auxiliary raw material tanks, product tanks, intermediate tanks, condensers, reboilers, material conveying devices, and equipment rooms Connect pipelines, control and display instruments and accessories. The first transesterification reactor 1-1 and the second transesterification reactor 1-2 are tubular reactors with or without a jacket, and the reaction tubes are equipped with or without dynamic and static turbulence elements for mixing the medium .

[0035]The first transesterification reactor 1-1 is equipped with material propylene carbonate, circul...

Embodiment 2

[0047] Example 2 is basically the same as Example 1, except that the first transesterification reactor 1-1 and the second transesterification reactor 1-2 are commercially available static mixers.

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1, except that the device is not provided with the second transesterification reactor 1-2, the product separation tower 2-1 tower bottom material goes to the methanol recovery tower 2-2, and methanol is recovered at the top of the tower and residual dimethyl carbonate go to atmospheric separation tower 4 or go to pressurized separation tower 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com