Desulfurizing tower

A desulfurization tower and desulfurization liquid technology, applied in the field of desulfurization tower, can solve the problems of desulfurization reaction, large solution circulation volume, large sulfur paste resistance, etc., and can adjust the liquid level and circulation volume, increase the contact area, and operate with great flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

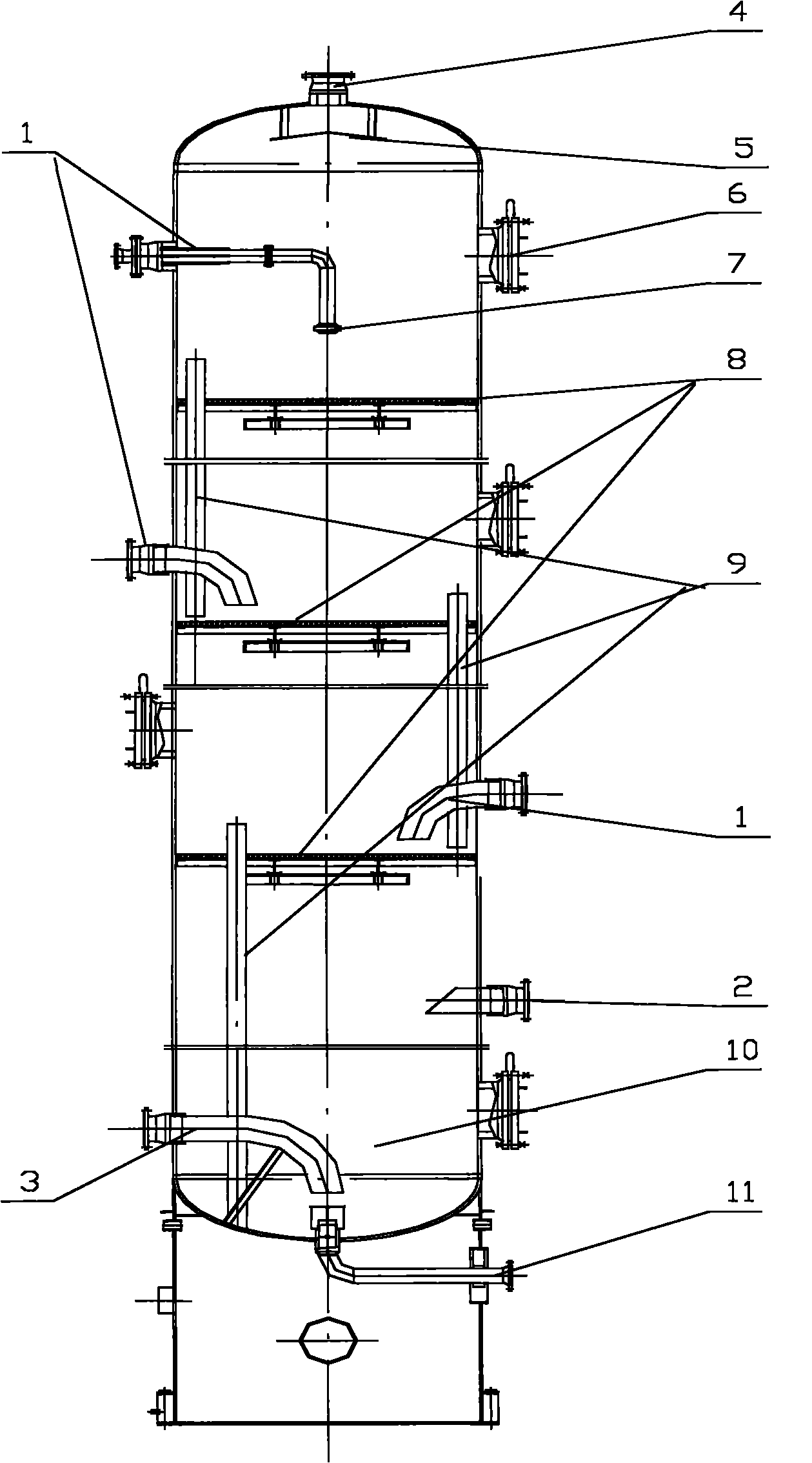

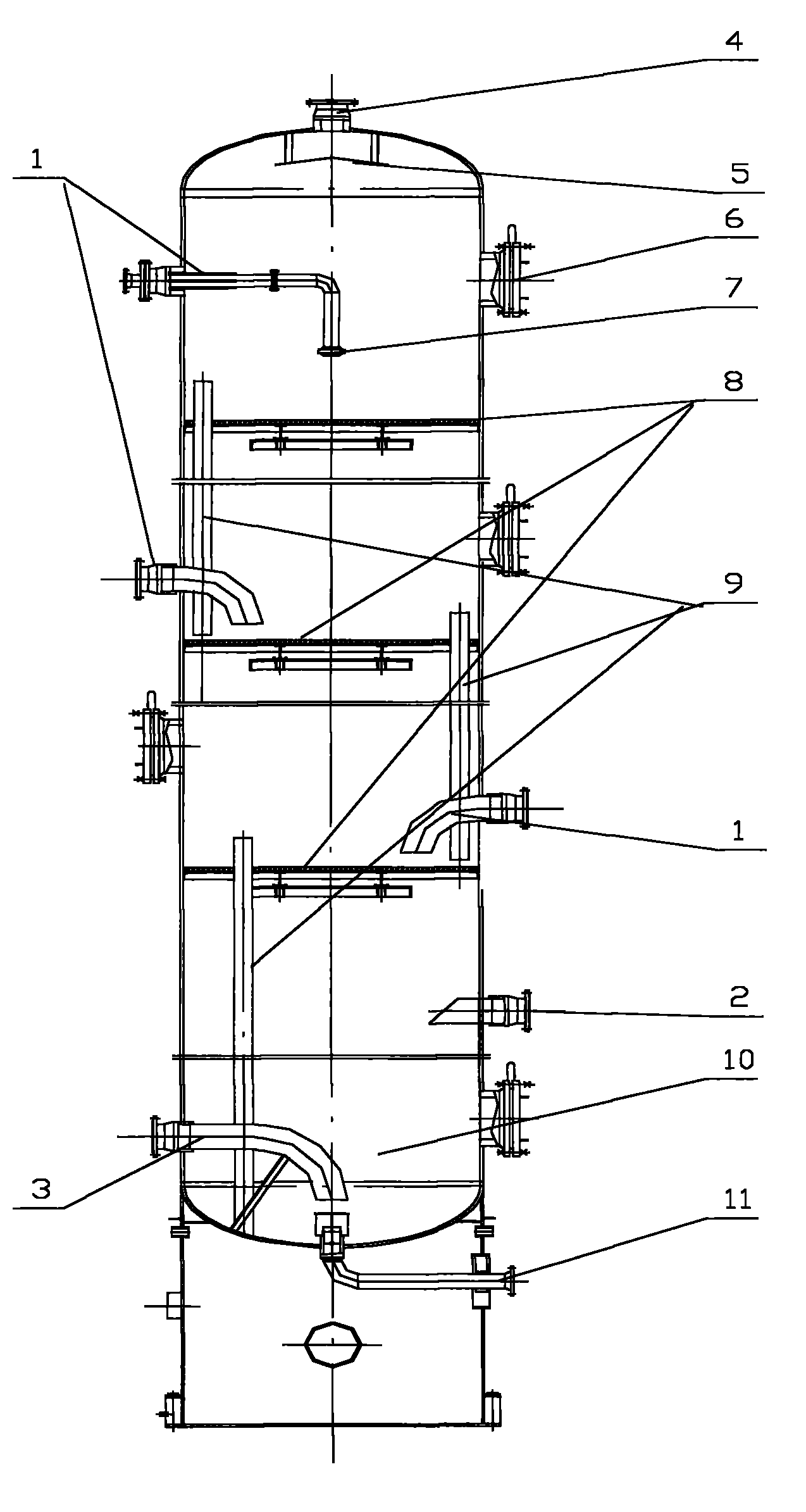

[0027] Such as figure 1 As shown, the desulfurization tower of the present invention includes a tower body, the top of the tower body is provided with an air outlet, the upper part of the tower body is provided with a feed inlet, the lower part of the tower body is provided with an air inlet, and the lower part of the tower body is also provided with a liquid outlet. The liquid outlet is arranged below the air inlet, and a gas-liquid contact plate 8 that can accumulate desulfurization liquid is provided between the inlet and the air inlet. The gas-liquid contact plate 8 is provided with a plurality of The air inlet enters the small hole through which the mixed gas in the tower body passes.

[0028] In this embodiment, the gas-liquid contact plate 8 adopts three layers, and the liquid descending channel adopts a downcomer 9.

[0029] The tower body is provided with a foam barrier 5, a liquid distributor 7 and a three-layer gas-liquid contact plate 8 from top to bottom. The three-la...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that in this example, only two layers of gas-liquid contact plates 8 are used, and two downcomers 9 are also used, and the two downcomers respectively pass through the two gas-liquid contact plates. The lower port of the lower downcomer is in communication with the liquid collection chamber 10.

[0038] The other structures and uses of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com