Method for preparing ferrous phosphate radical lithium salt of lithium ion battery

A lithium-ion battery, ferrous phosphate-based technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as limited application and poor conductivity, and achieve improved conductivity, good carbon-encapsulation effect, and improved electronic The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

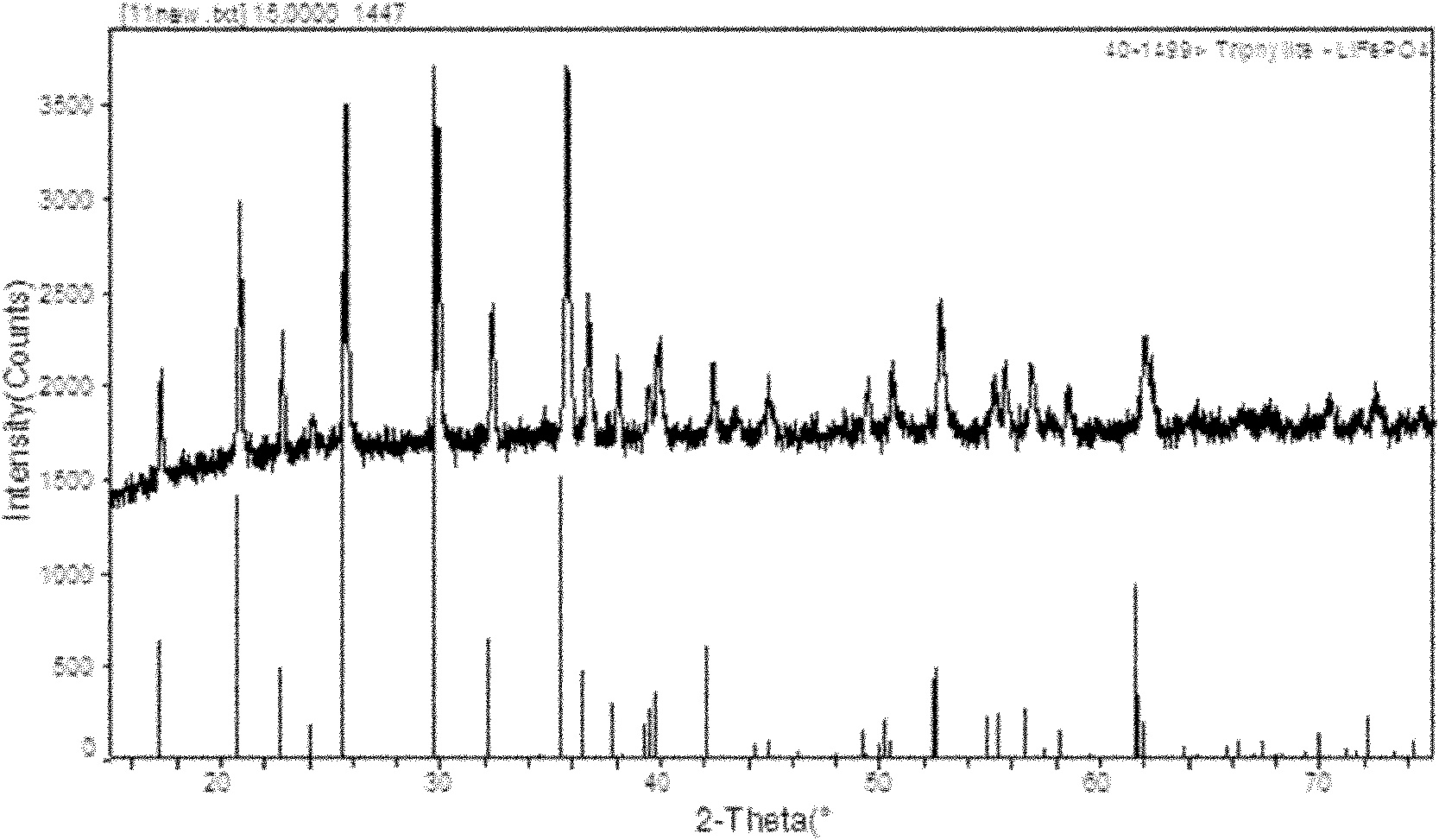

[0027] Lithium iron phosphate is prepared by grinding and mixing, and the preparation process is as follows:

[0028] 1) will Li 3 PO 4 and Fe 3 (PO 4 ) 2 Mixed into a mixture with a molar ratio of 1:1;

[0029] 2) Grind the mixture obtained in step 1) with a ball mill for 1-2 hours, and add an appropriate amount of alcohol during grinding for better grinding;

[0030] 3) Put the milled mixture into a high-temperature furnace, and heat it for pretreatment under a protective atmosphere of nitrogen and hydrogen, wherein the volume ratio of nitrogen and hydrogen is 9.5:0.5, and the furnace chamber pressure is 1.5×10 5 Pa, the temperature is 600 ℃ ~ 700 ℃, pretreatment 10 ~ 20 hours;

[0031] 4) Cool down to room temperature after the pretreatment, take out the material, add alcohol and carbon black and re-grind evenly, where carbon black accounts for carbon black and LiFePO 4 5-15% of the total weight, the carbon black can also be replaced by organic carbon, acetylene blac...

Embodiment 2

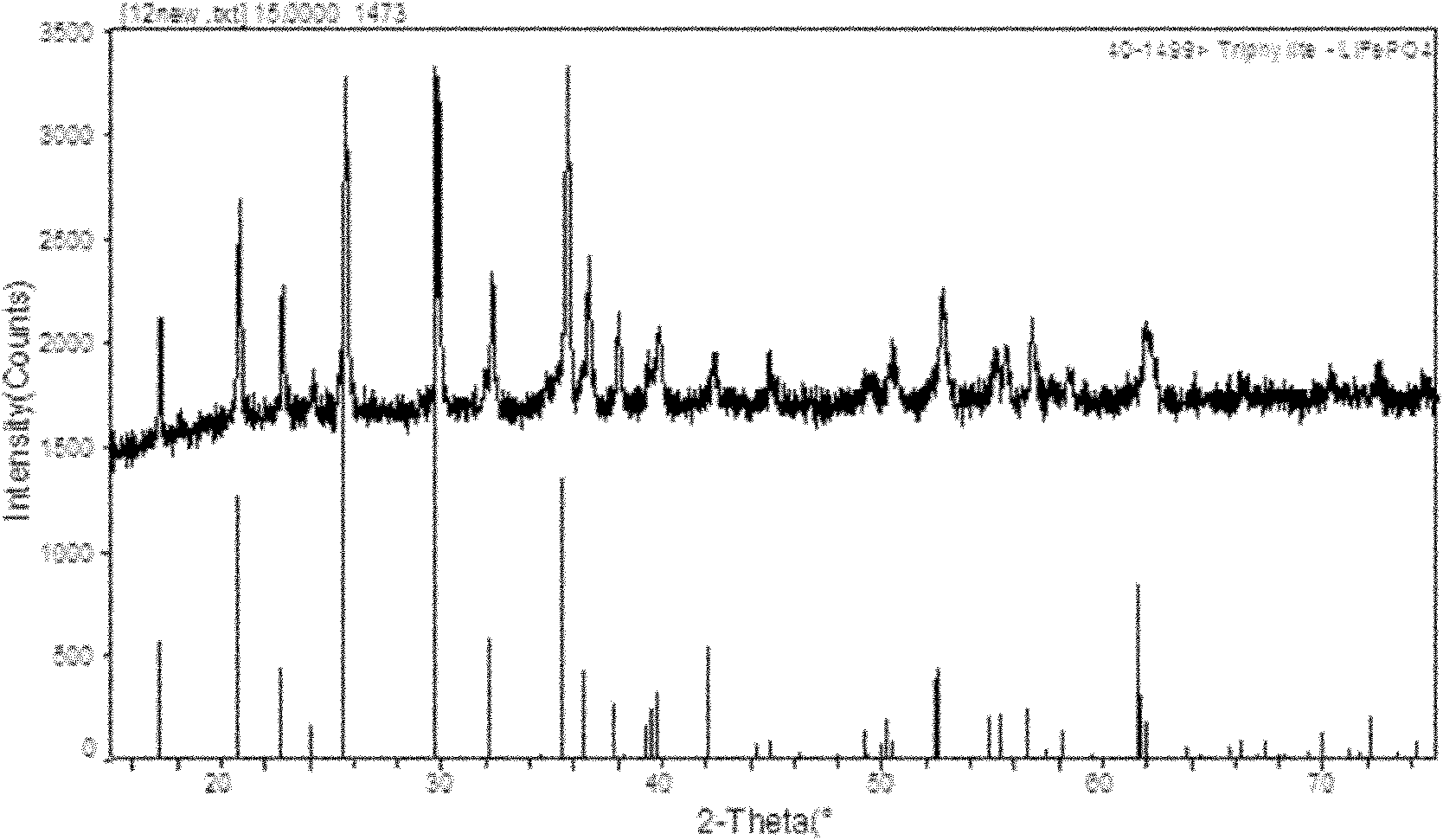

[0035] Prepare doped lithium iron phosphate by grinding and mixing, the preparation process is as follows:

[0036] 1) will Li 3 PO 4 , Fe 3 (PO 4 ) 2 , Mg 3 (PO 4 ) 2 mixed to form a mixture, in which, Li 3 PO 4 and Fe 3 (PO 4 ) 2 The molar ratio of Li is 1:0.5, Li 3 PO 4 and Mg 3 (PO 4 ) 2 The molar ratio of 1:0.5;

[0037] 2) Grind the mixture formed in step 1) with a ball mill for 1-2 hours, and add an appropriate amount of alcohol during the grinding for better grinding;

[0038] 3) Put the material obtained after grinding into a high-temperature furnace, and heat it under a protective atmosphere of nitrogen and hydrogen for pretreatment. The volume ratio of nitrogen and hydrogen is 9.5:0.5, and the pressure of the furnace chamber is 1.5×10 5 Pa, the temperature is 600℃~700℃, and the pretreatment is 10~20 hours;

[0039] 4) After the pretreatment is completed, it is lowered to room temperature, the material is taken out, and alcohol and carbon black are...

Embodiment 3

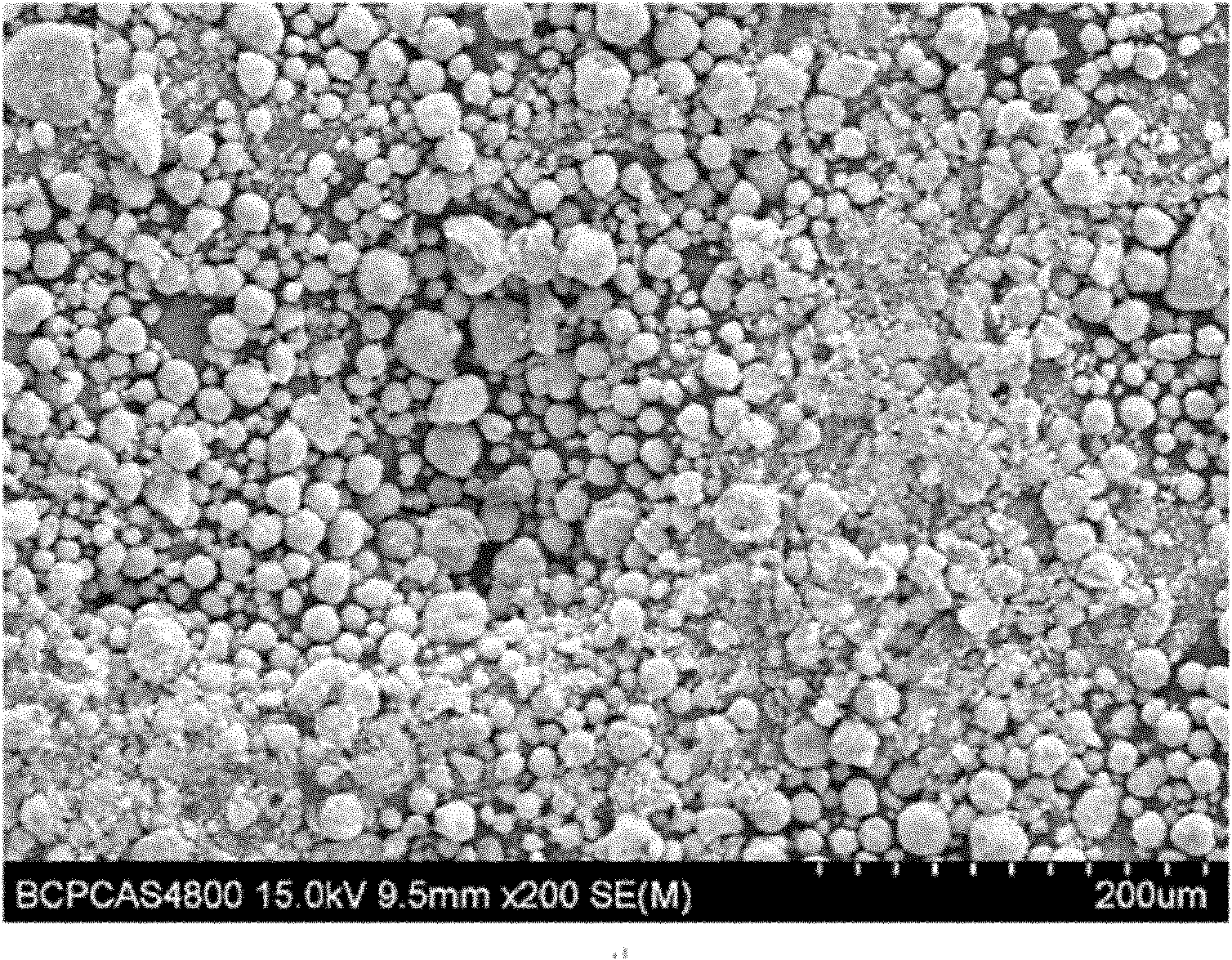

[0043] Lithium iron phosphate is prepared by spray-drying the mixture, and this method can obtain nano-sized LiFePO 4 Powder, its preparation process is as follows:

[0044] 1) will Li 3 PO 4 and Fe 3 (PO 4 ) 2 Mix at a molar ratio of 1:1 to form a mixture;

[0045] 2) Add deionized water to the above mixture to form a solution A of 1.5-2 mol / L, and then add a polymer compound as a thickener to form a solution B, wherein the thickener accounts for 30% by mass of the solution B ~40%, the thickener is one of polyethylene glycol, polyacrylic acid or polyvinyl alcohol;

[0046] 3) Spray drying: Dry the solution B formed in step 2) into a mixed powder in an air-flow spray dryer, wherein the feed solution is injected with a peristaltic pump at a sampling speed of 20-25ml / min, and the gas flow rate of the nozzle is Controlled by the pressure of compressed air, atomization is generated at about 0.15MPa, the air inlet temperature is 400-500°C, the air outlet temperature is 200-300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com