Conveyor system for the transport of passengers/goods

a conveyor system and passenger technology, applied in the direction of conveyors, escalators, transportation and packaging, etc., can solve the problems of inability to reduce the dimensions of the conveyor system, the contact between the chain link of the linear actuation system and the chain link connected to the steps or pallets is not easy, and the conveyor system is not easy to operate. the effect of reducing the height of the upper and lower end sections, improving the comfort and safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]The invention will be described as being applied to a moving walkway. However, it must be understood that the concepts described in this specification can also be applied to other types of conveyor systems. It must also be indicated that the system of the invention can operate in both directions of transport of a load / people.

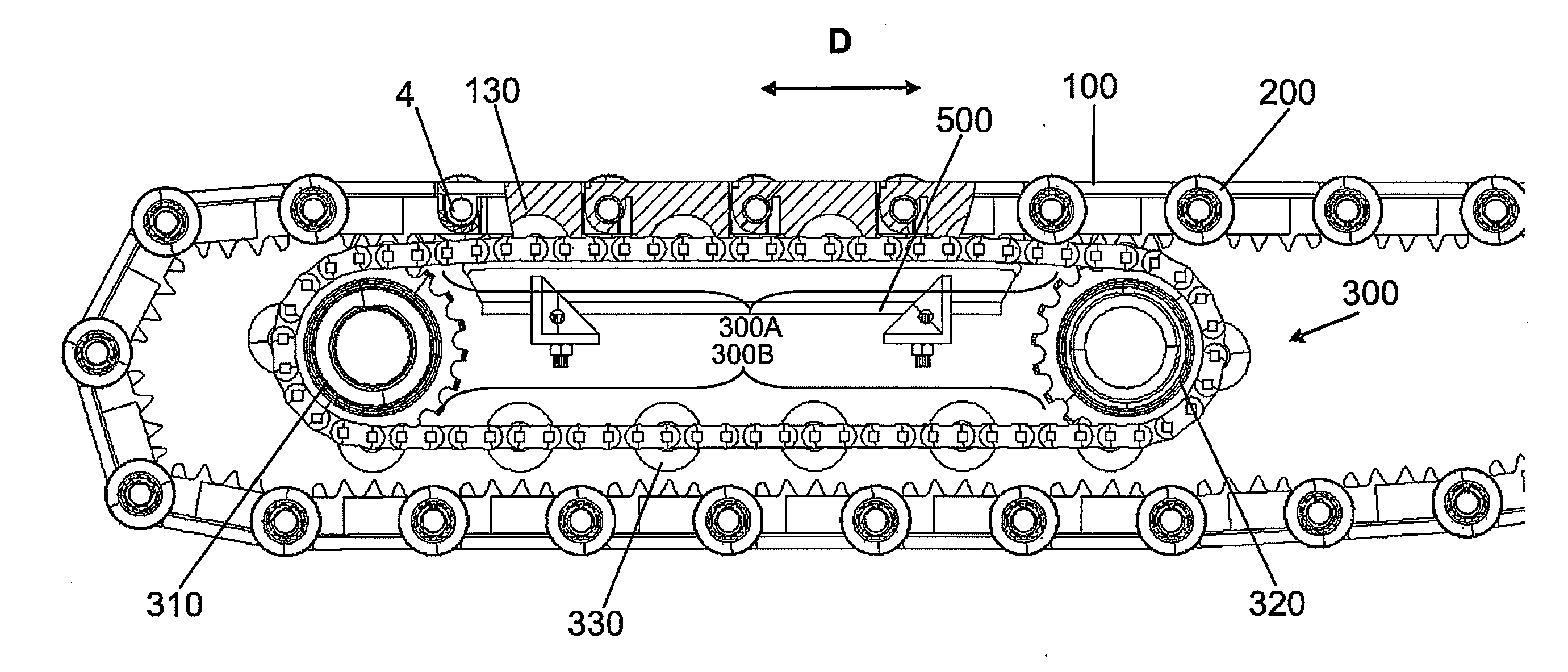

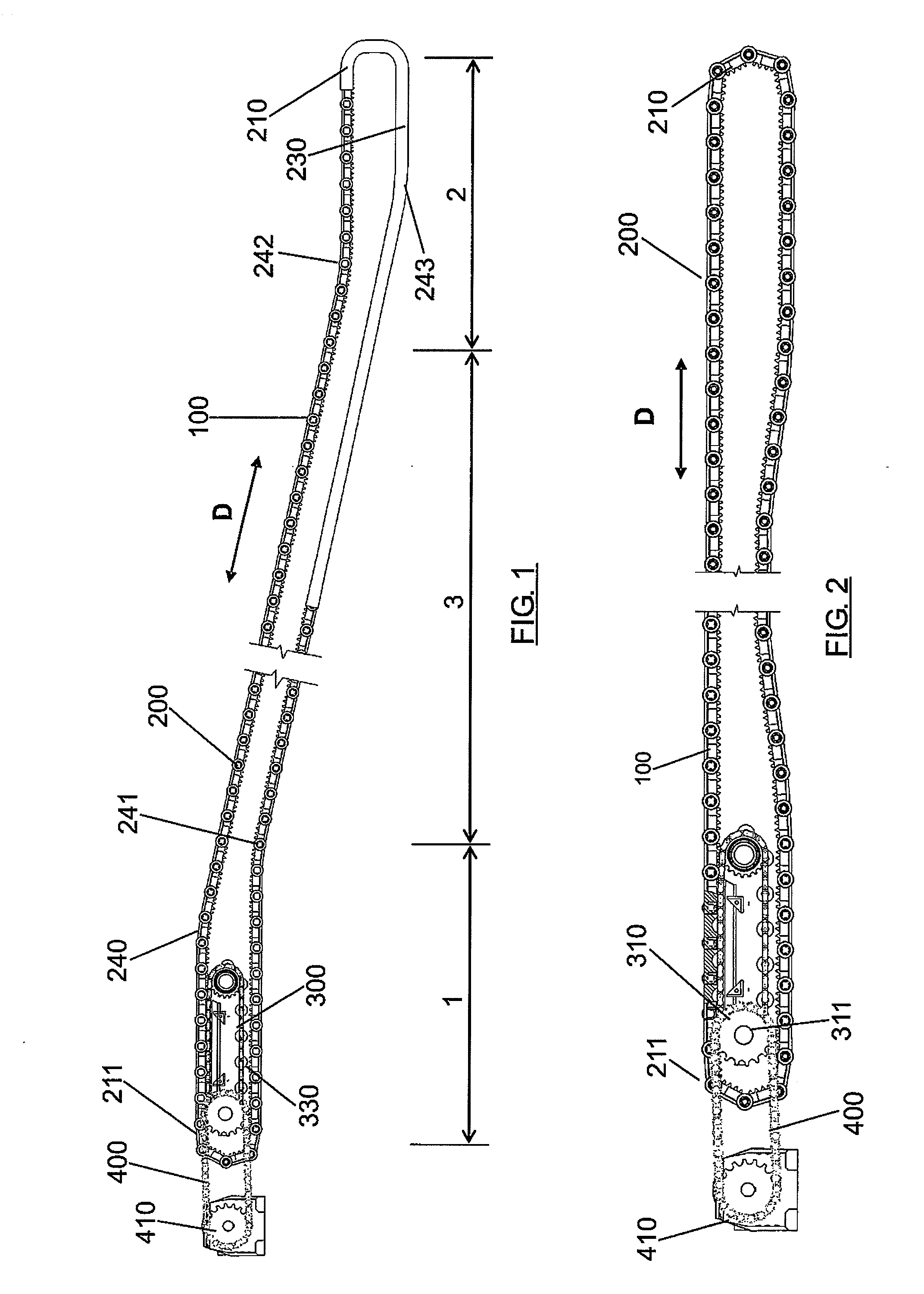

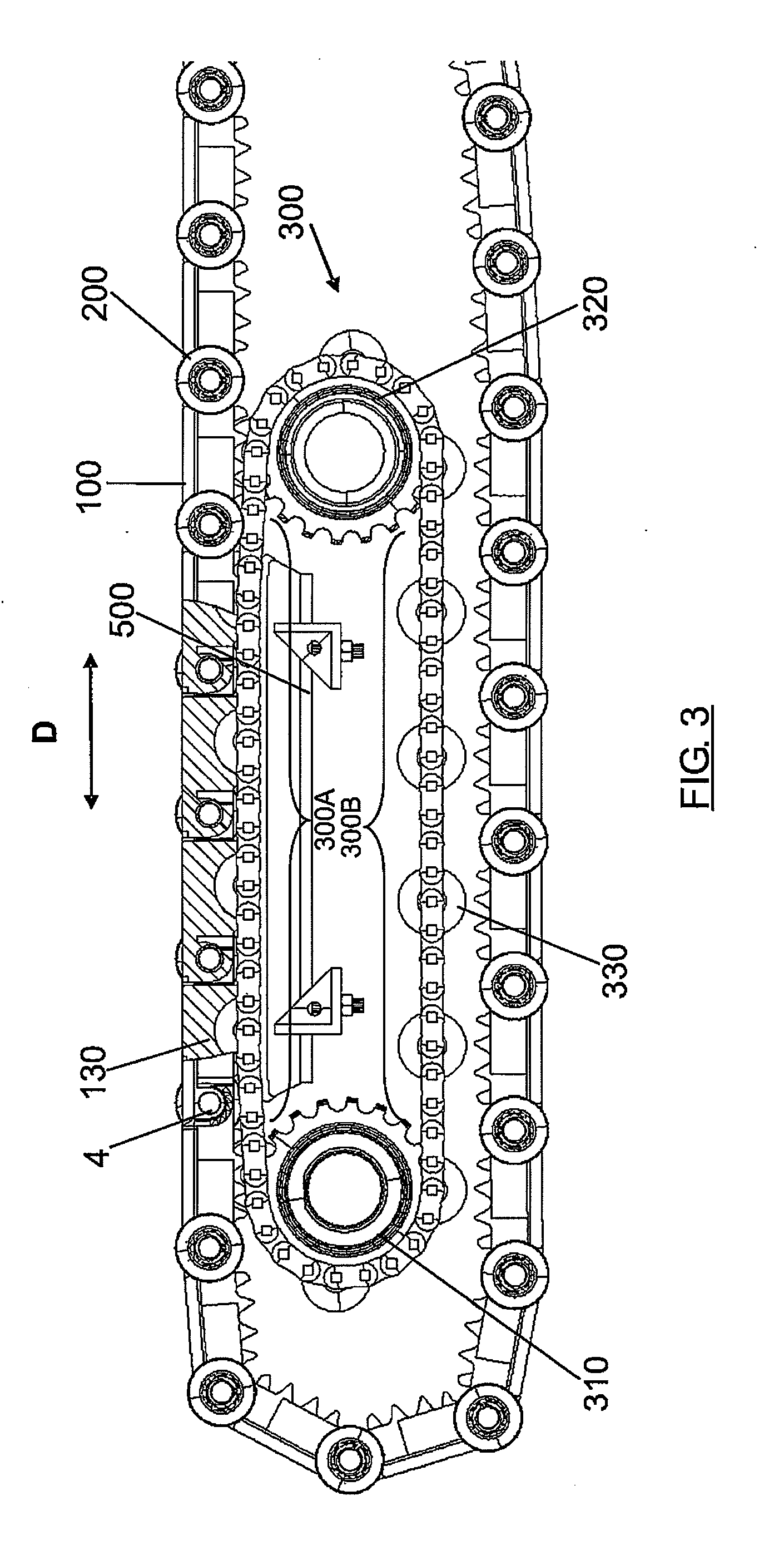

[0065]FIG. 1 shows a moving walkway having a supporting structure comprising an upper end section or head (1), a lower end section or head (2) and an intermediate section (3). A worm belt is made up of a series of links (100) which are connected by shafts-pins (4). These links (100) are held by bearing rollers (200) which are led by means of guides (230) designed in the bearing profile of the moving walkway. The guides (230) comprise an upper return section (211) and a lower return section (210) leading the links (100) at both ends of the system. The radiuses of the upper return section (211) and of the lower return section (210) can be small, greatly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com