Microbial ferment fermentation device

An enzyme fermentation and microbial technology, applied in the field of microbial culture and fermentation devices, can solve the problems of lack of comprehensive and complete functions, microbial contamination volume, microbial injury, etc., to improve growth and productivity, improve quality, and solve the effect of large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

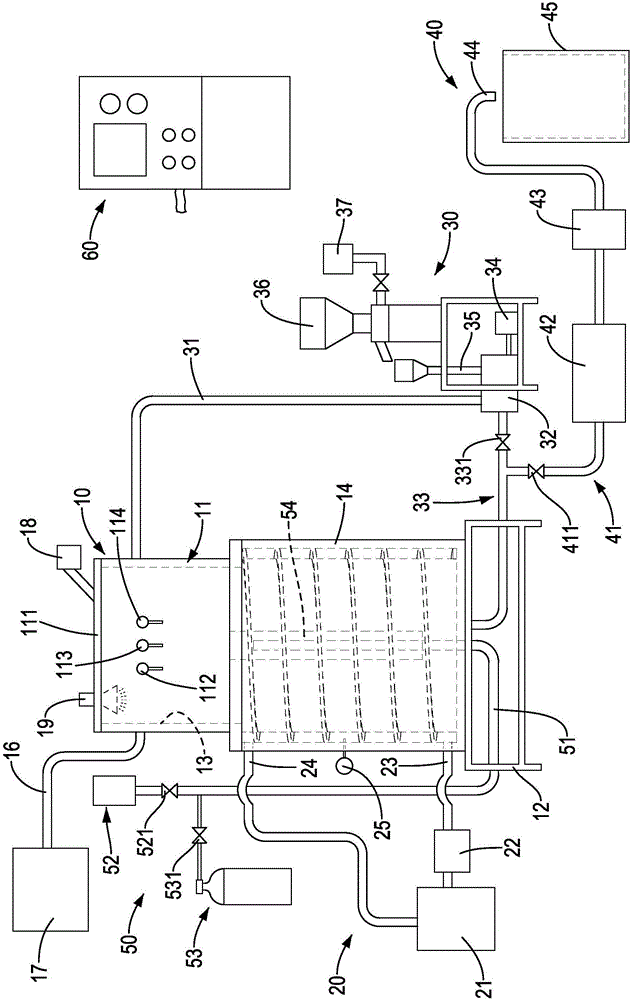

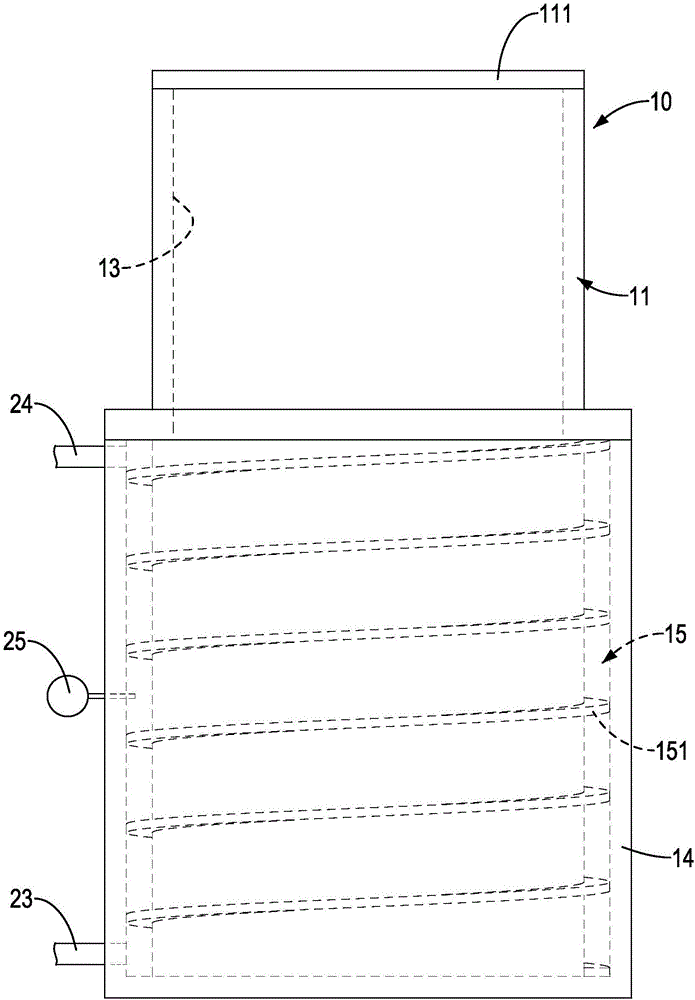

[0036] The preferred embodiment of the microbial ferment fermentation device that the present invention proposes is for example figure 1 and figure 2 As shown, it includes units such as a fermentation tank unit 10, a heat exchange unit 20, a feed unit 30, an output unit 40, an air supply unit 50 and a control unit 60, wherein:

[0037] The fermenter unit 10 is provided with an upright barrel-shaped hollow tank 11 and a base 12 positioned below the tank 11 and supported to raise the tank 11. The top of the tank 11 is provided with an opening and a closed cover The top cover 111 of the opening, the hollow interior of the tank body 11 forms a fermentation space 13 for accommodating the fermentation liquid, and a ring wall 14 is provided around the middle section and the lower section of the tank body of the tank body 11, so that the ring A thermal insulation layer 15 is formed between the wall 14 and the tank body of the tank body 11 for the circulating flow of heat medium oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com