Back light module unit having high uniform brilliance

A backlight module, uniform technology, applied in optics, nonlinear optics, mirrors, etc., can solve the problems of difficult manufacturing of light guide plates, troublesome and time-consuming assembly, increased weight and volume, etc., to improve light source efficiency and uniform brightness, improve Variation and variety, easy to process and produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

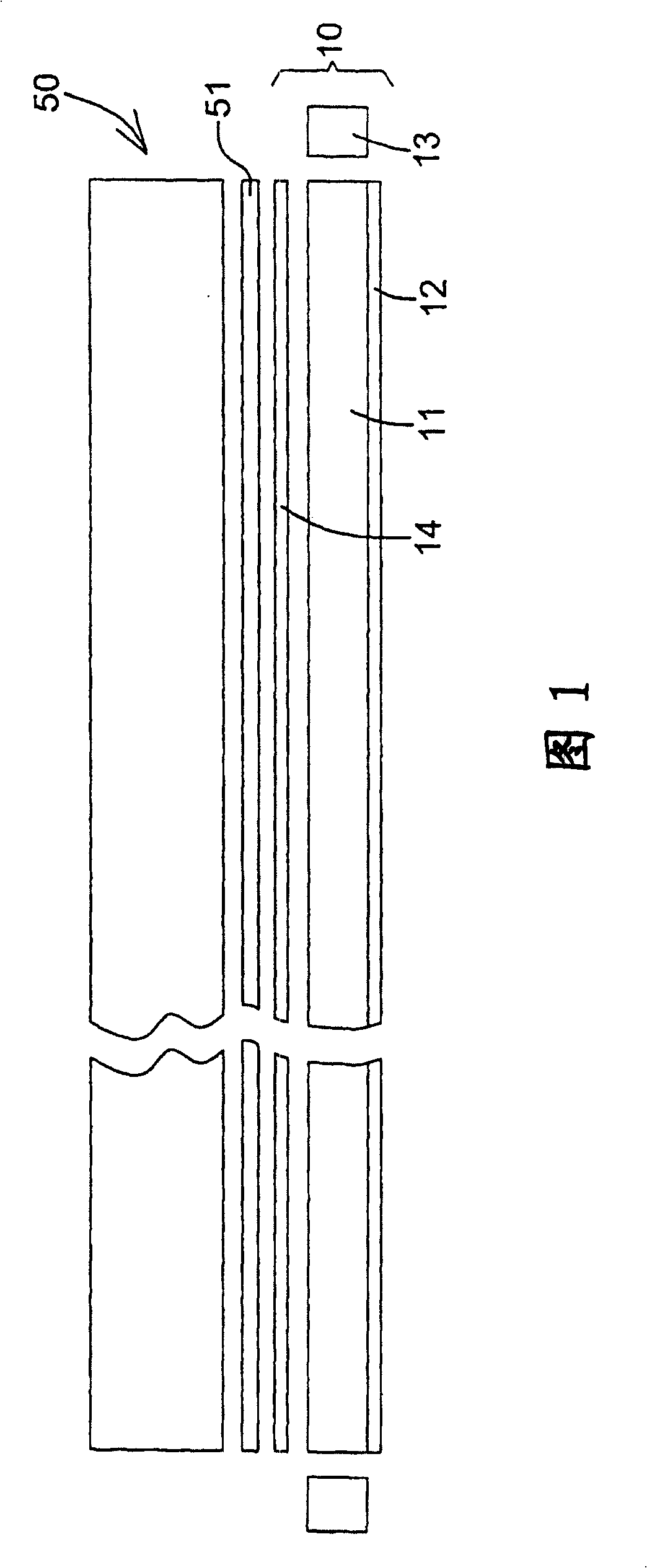

[0035] A preferred embodiment of the backlight module with high uniform luminance provided by the present invention is shown in FIG. Light source devices 13 at the ends of both sides of the light guide plate 11 are constructed, and an optical film 14 can be further arranged above the light guide plate 11; wherein:

[0036] The light guide plate 11 is a light-permeable plate with the equivalent performance of conducting and scattering uniform light;

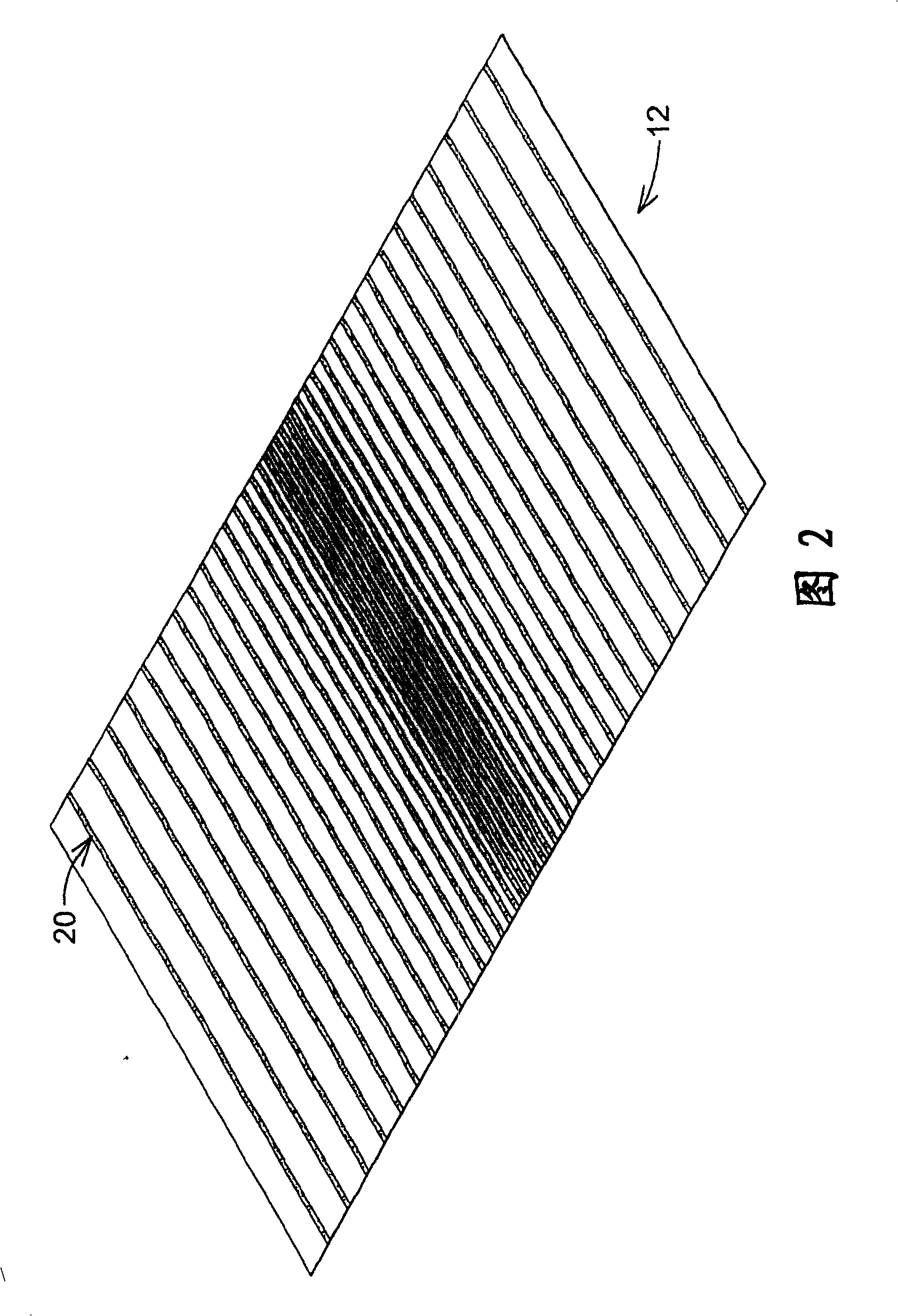

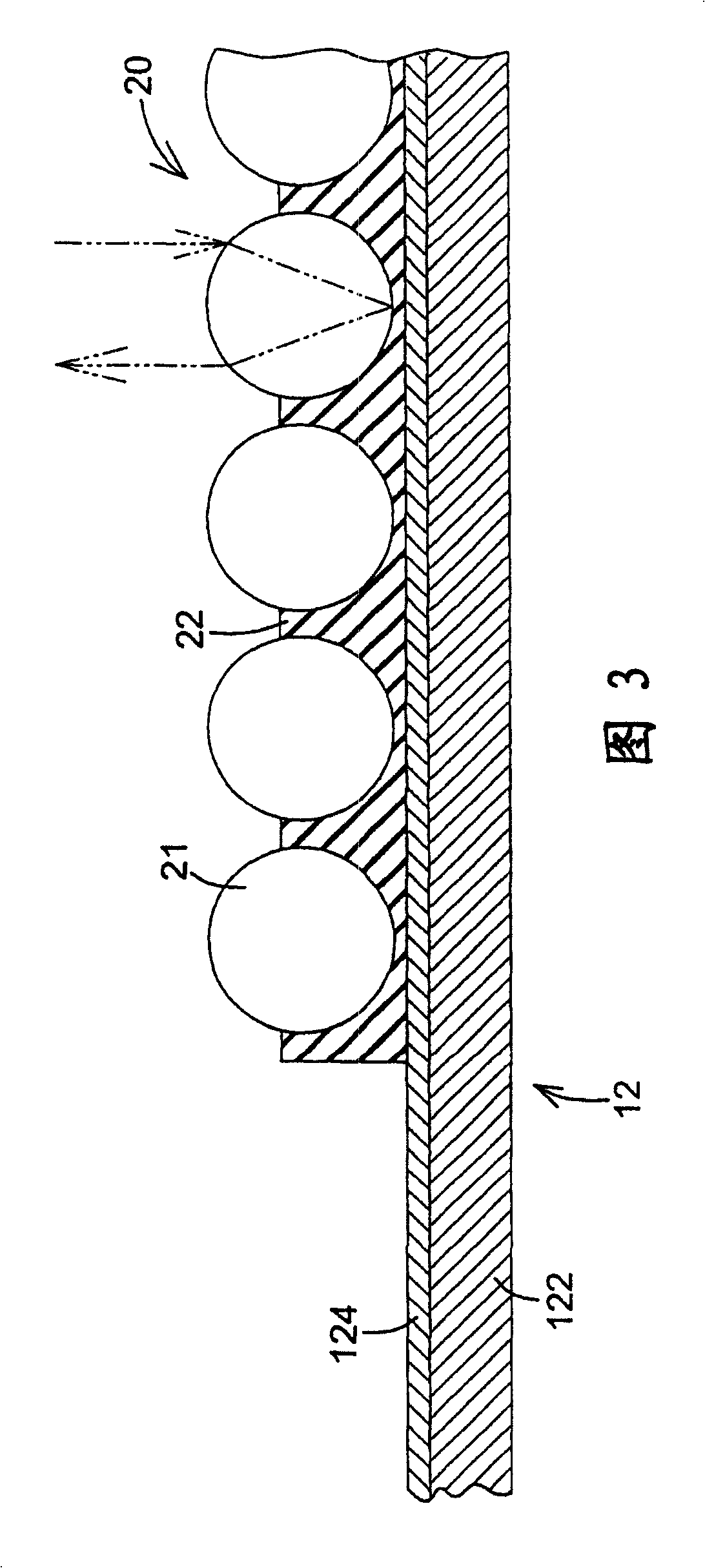

[0037] The reflector 12 is arranged under the light guide plate 11 to reflect the light exposed on the bottom surface of the light guide plate 11 back to the light guide plate 11, as shown in Figure 2 and Figure 3, the reflector 12 is provided with a rigid or flexible The base material 122 is coated with a reflective layer 124 made of diffuse reflective material on the surface of the base material 122 facing the direction of the light guide plate 11, and according to the needs of product design and the position of each light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com