Patents

Literature

512results about How to "Change distribution" patented technology

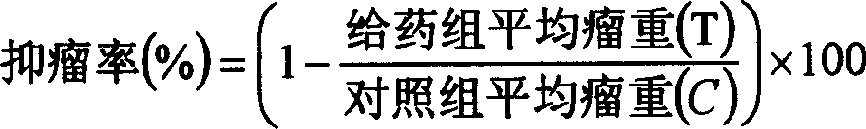

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Samarium-cobalt sintered magnet material and preparation method thereof

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

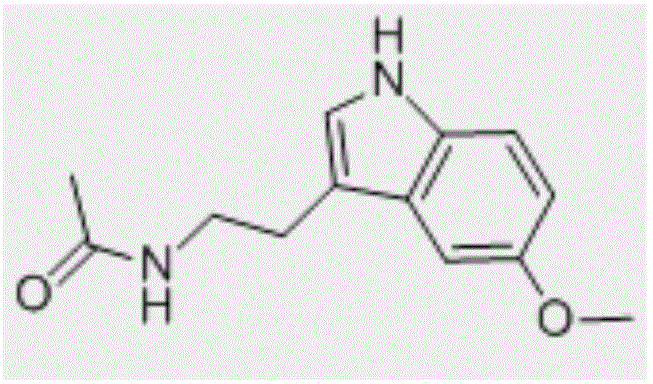

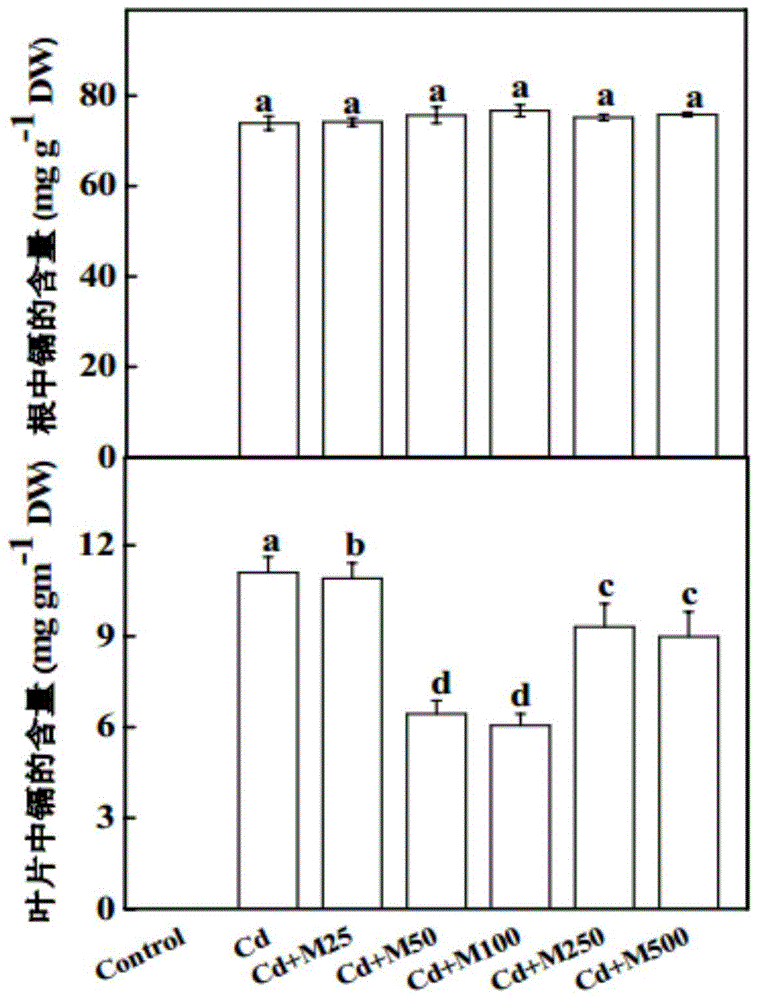

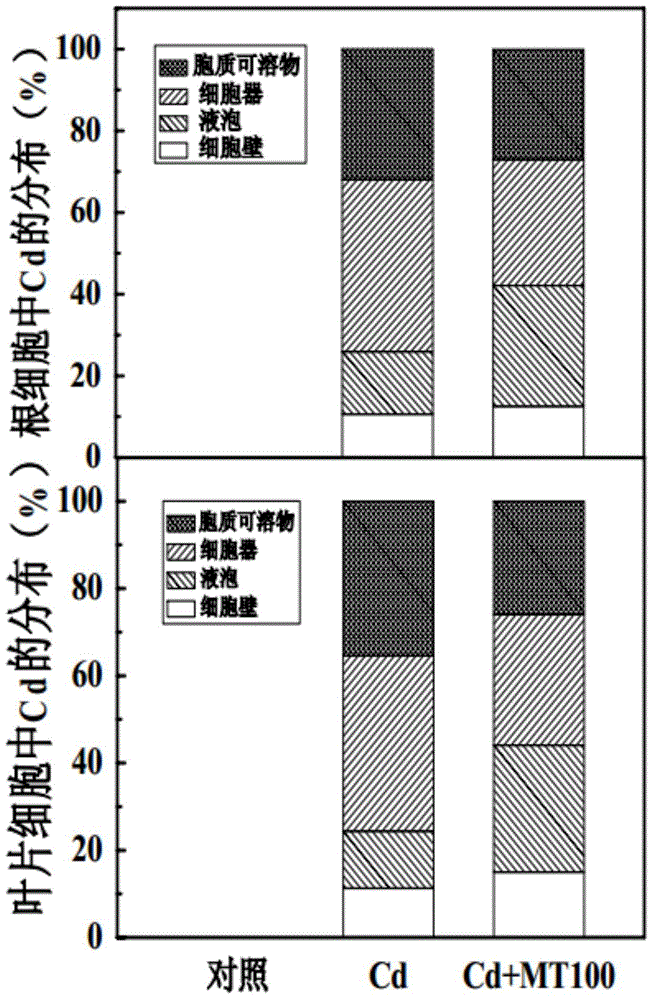

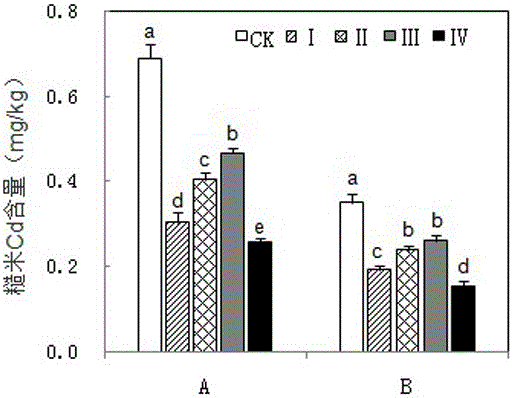

Application of melatonin in reducing cadmium accumulation in plants

ActiveCN104823738AReduce cadmium contentChange distributionPlant growth regulatorsBiocidePhytotoxicityLowering plants

The invention discloses an application of melatonin in reducing cadmium accumulation in plants. The application includes the following steps: (1) mixing melatonin and additives to form aqueous solution; (2) spraying the aqueous solution on plant leaf surfaces under cadmium stress or filling the aqueous solution in nutrient solution or soil where plants grow. The melatonin can quickly and efficiently reduce cadmium content in plant leaves, change distribution of cadmium ions in plant cells, and relieve damage of cadmium to cells; in addition, the melatonin is simple to prepare and convenient to use, does not cause product and environment pollution, does not generate phytotoxicity easily and has a wide application prospect.

Owner:ZHEJIANG UNIV

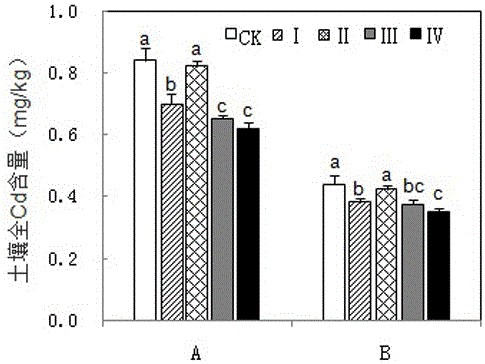

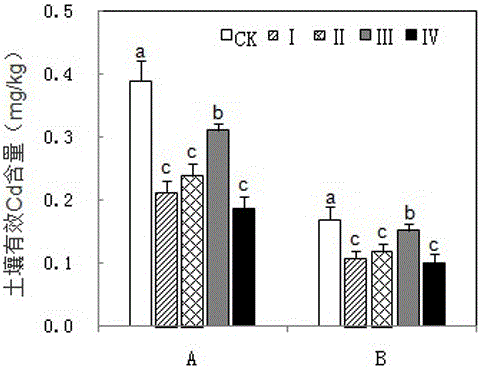

Method for reducing content of cadmium in middle rice

InactiveCN106069429AEfficient use ofHigh in nutrientsHorticulture methodsRice cultivationResource utilizationSoil heavy metals

The invention discloses a method for reducing the content of cadmium in middle rice. The method includes the following steps that after middle rice of the first year is harvested, middle rice straw is returned to the field directly, and tillage is conducted so that the middle rice straw can be evenly mixed with soil; hyperaccumulation plants are planted in a paddy; after the hyperaccumulation plants are removed from March to May in the second year, soil heavy metal passivator is scattered on the surface of soil of the paddy; tillage is conducted, and base fertilizer is applied 3-5 days later; tillage is conducted, and rice is transplanted; during planting of rice, a foliar resistance control agent is sprayed in the later tillering stage and the booting stage of rice respectively, wherein spraying time interval is 5-10 days; field drying is conducted in the later tillering stage, natural drying is conducted in the maturation stage, and flooding irrigation is conducted in other development stages. According to the method, crop production and straw resource utilization are not affected, the dual targets of reducing the paddy soil cadmium content and reducing the rice cadmium content are achieved under the combined action of plant extraction, soil passivation, foliar resistance control and water management, and effects are more remarkable compared with other combination technologies.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

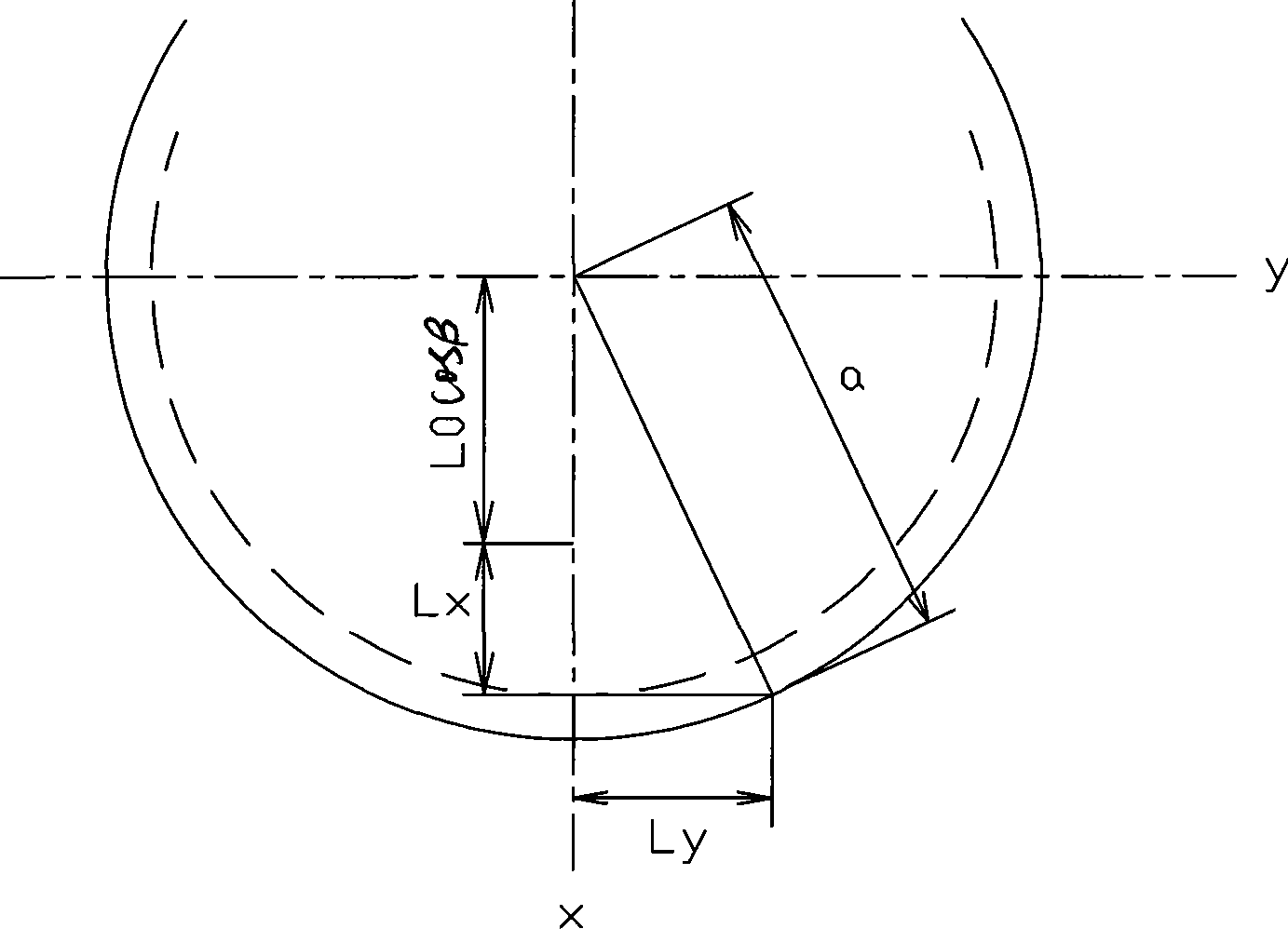

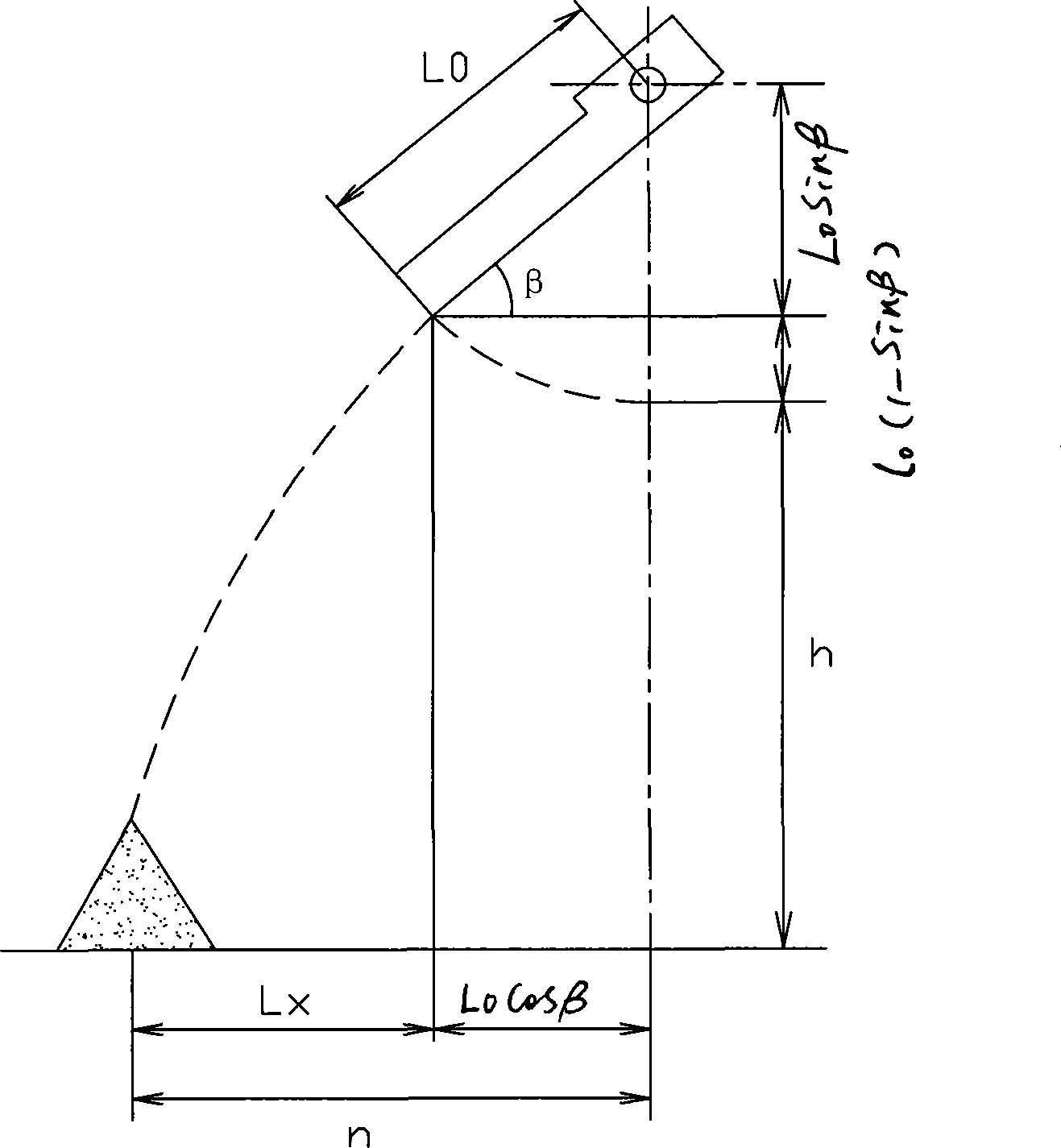

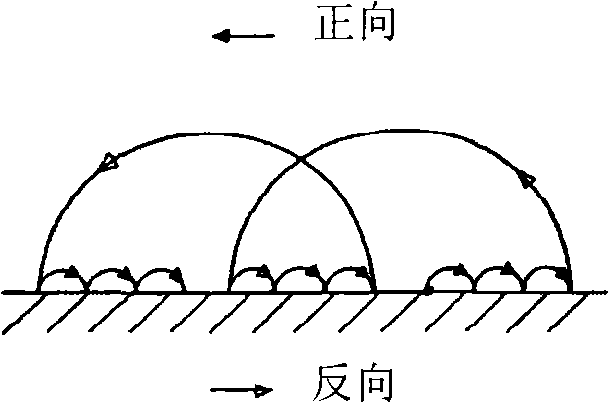

Blast furnace chute polycyclic distributing method

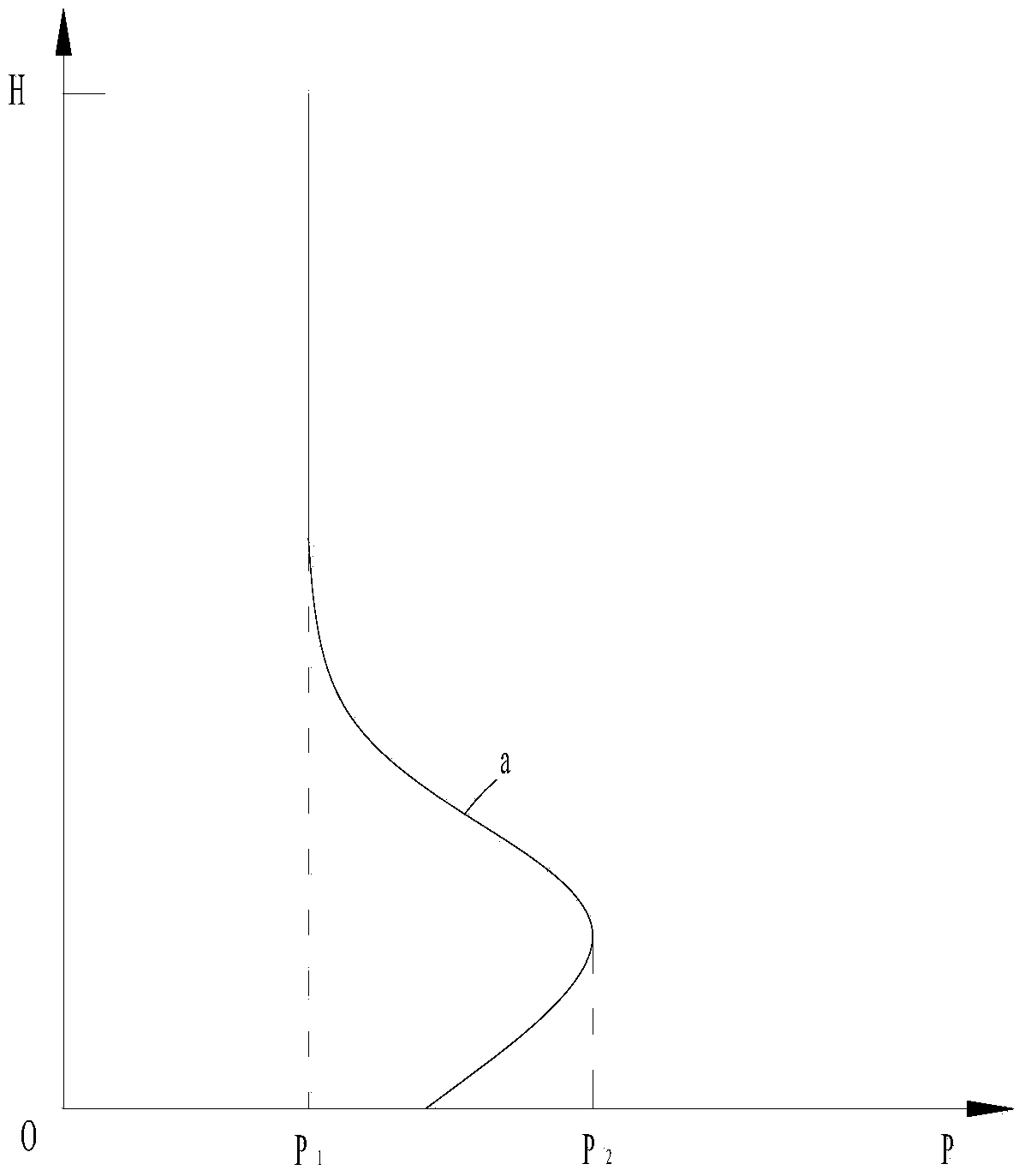

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

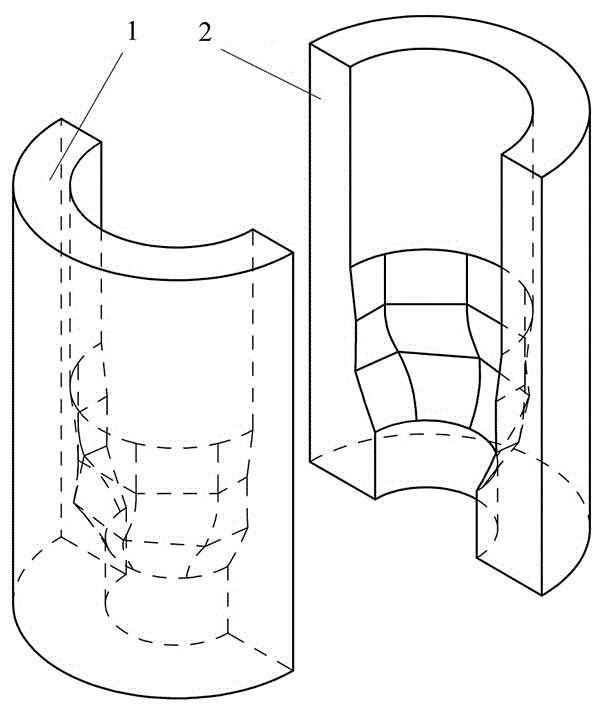

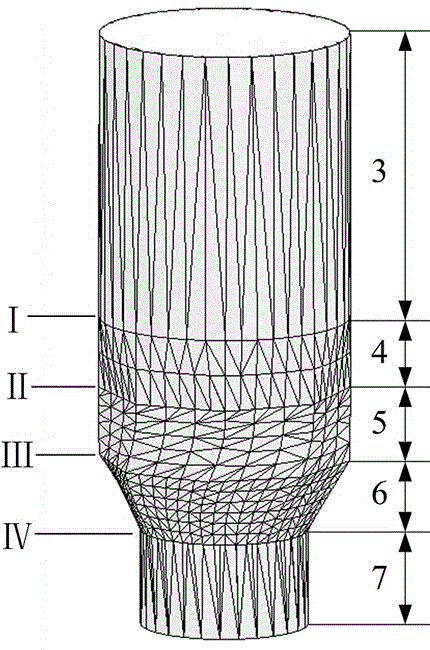

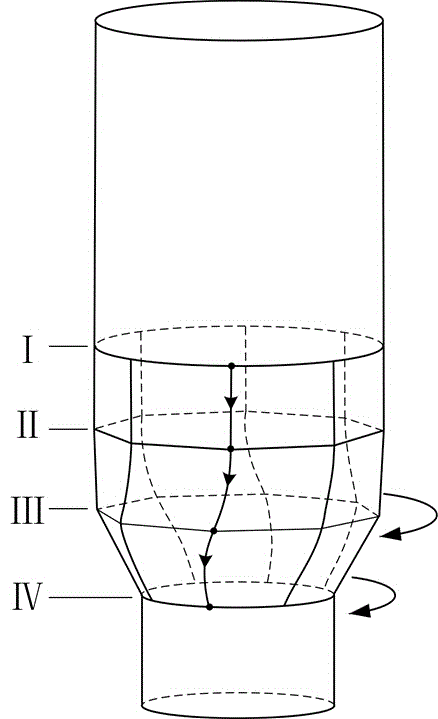

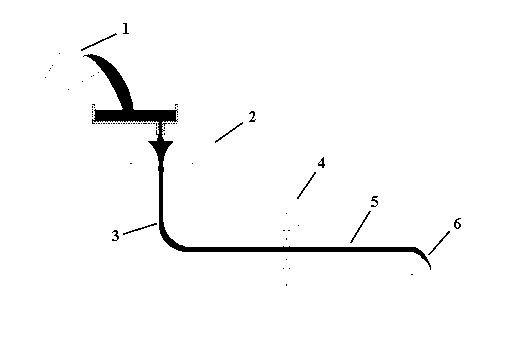

Twist extrusion forming die and twist extrusion forming method

The invention discloses a twist extrusion forming die and a twist extrusion forming method. The forming die comprises a first half die and a second half die, wherein the first half die and the second half die are tightly buckled through a bolt to form a cylinder, an extrusion die cavity is formed inside the cylinder, and a die joint of the first half die is fit and level with a die joint of the second half die; the extrusion die cavity is sequentially formed by a guide section, a large circular-regular octagonal transitional section, a regular octagonal twist section, an octagonal-small circular twist transitional section and an outlet section from an extrusion inlet to the lower side. The twist extrusion forming die has the advantages of good transformation effect, high speed and high efficiency, the weaknesses of the prior art such as non-uniformity in transformation and existence of transformation dead corner can be overcome, the stress distribution inside a material can be greatly improved, and the comprehensive performance of the material also can be improved.

Owner:TAIYUAN UNIV OF TECH

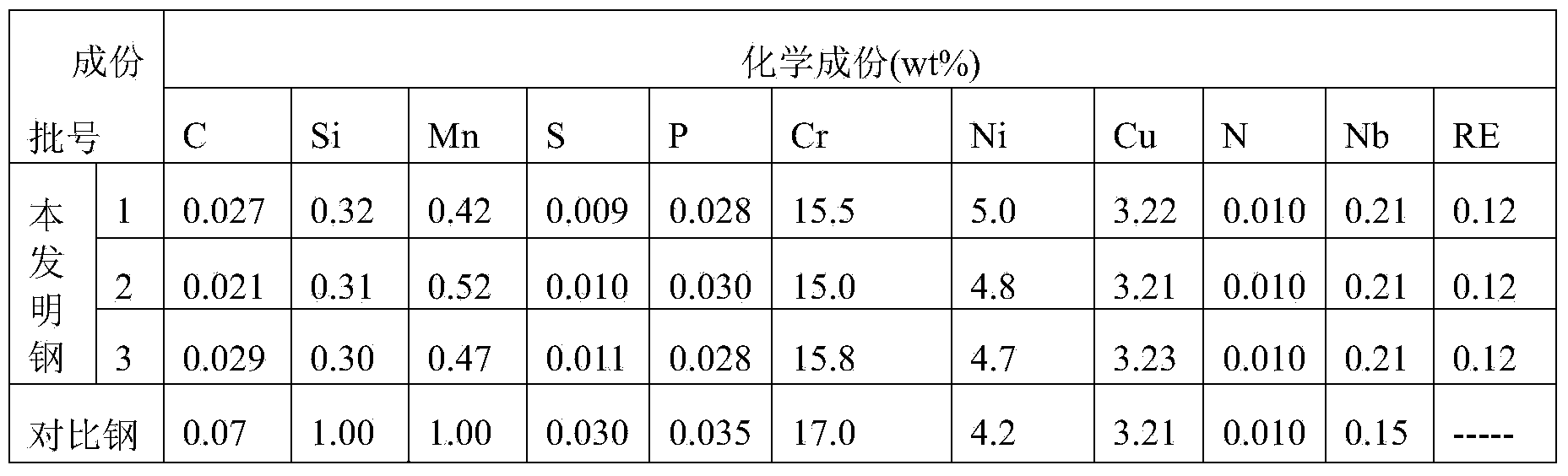

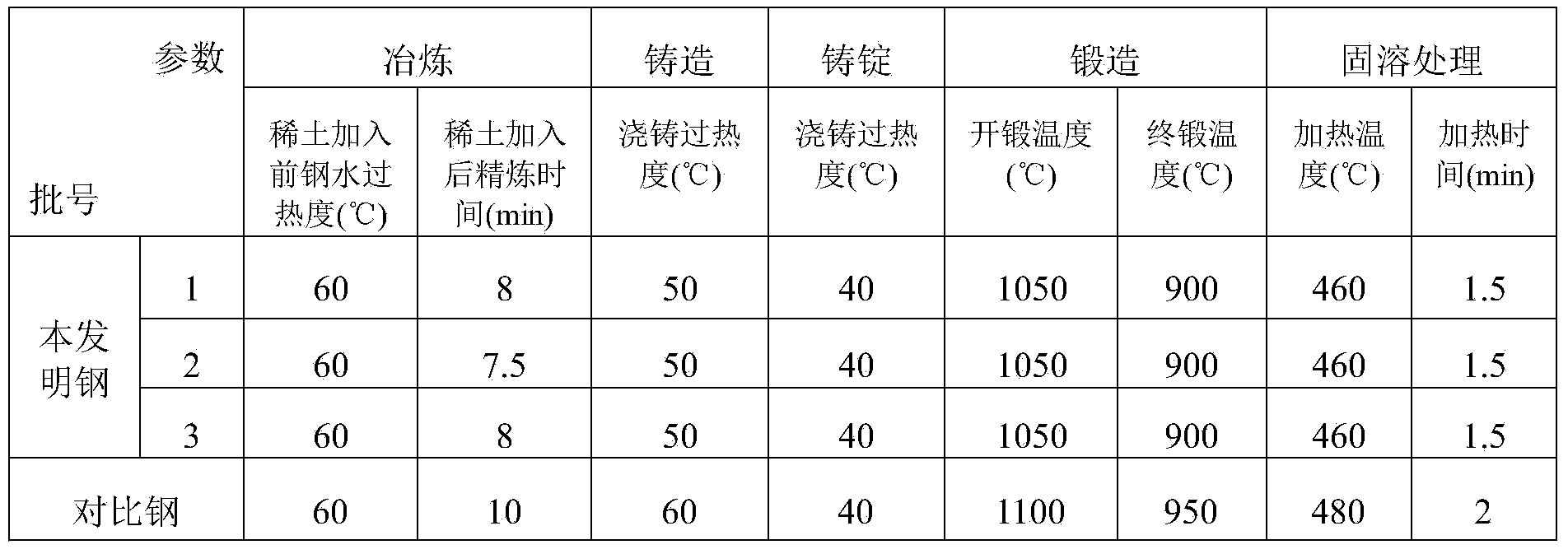

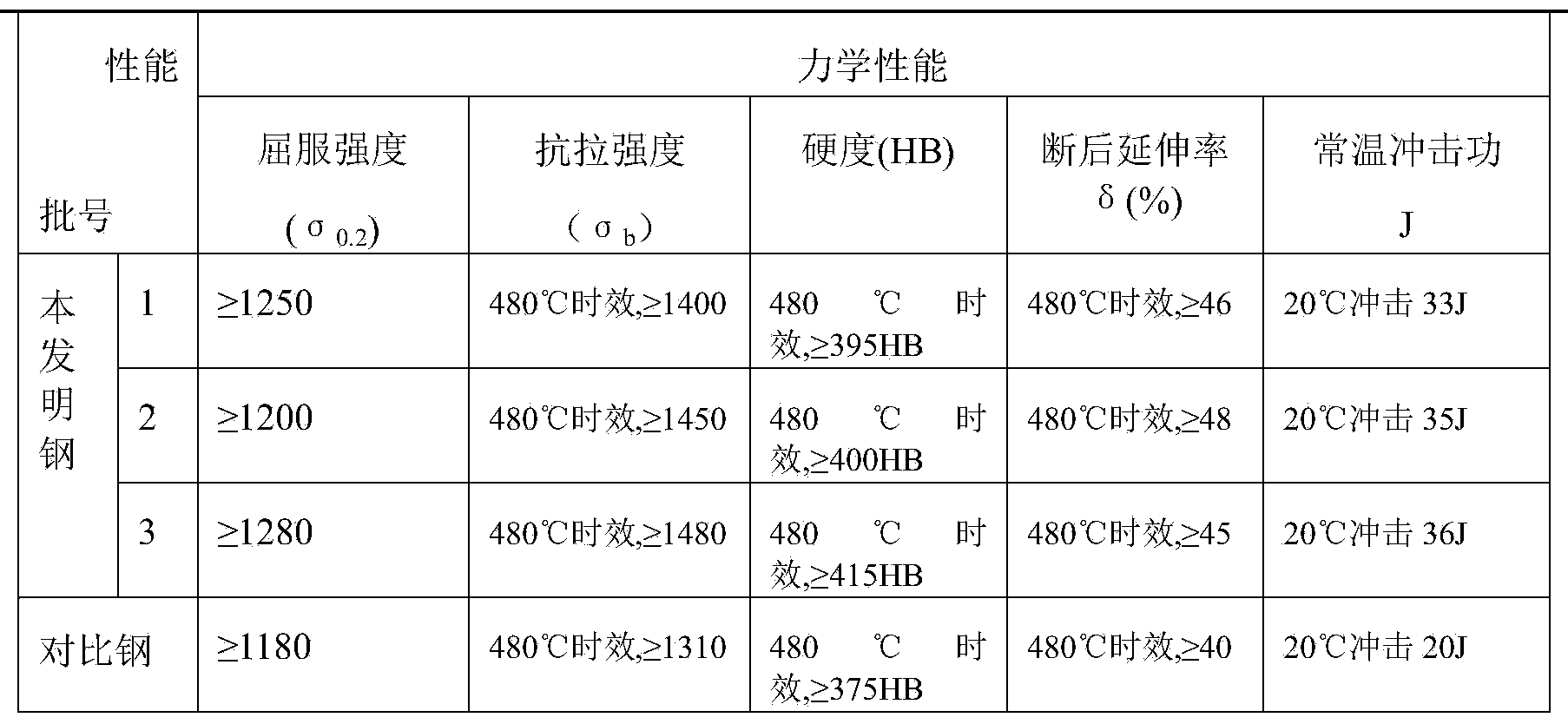

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

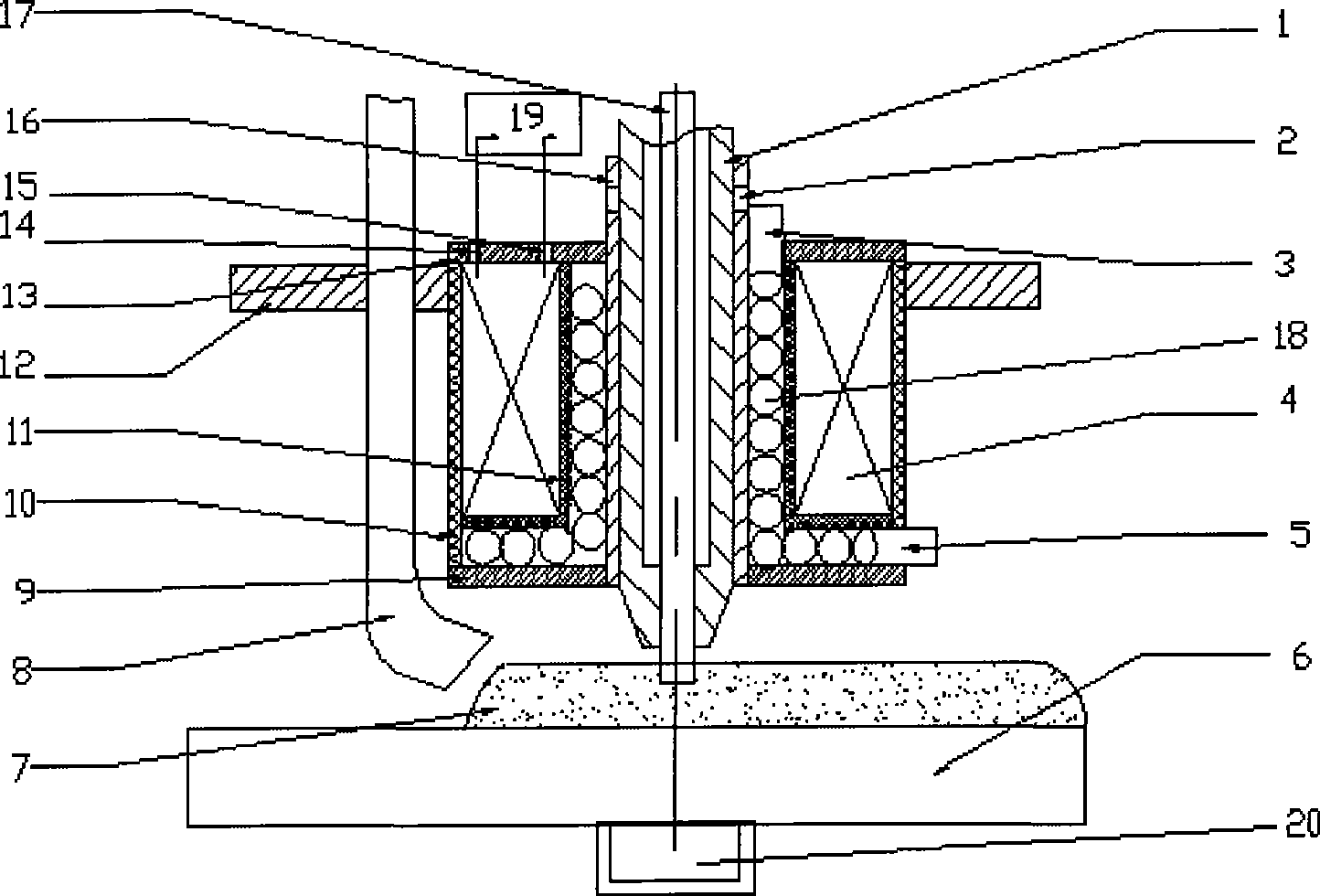

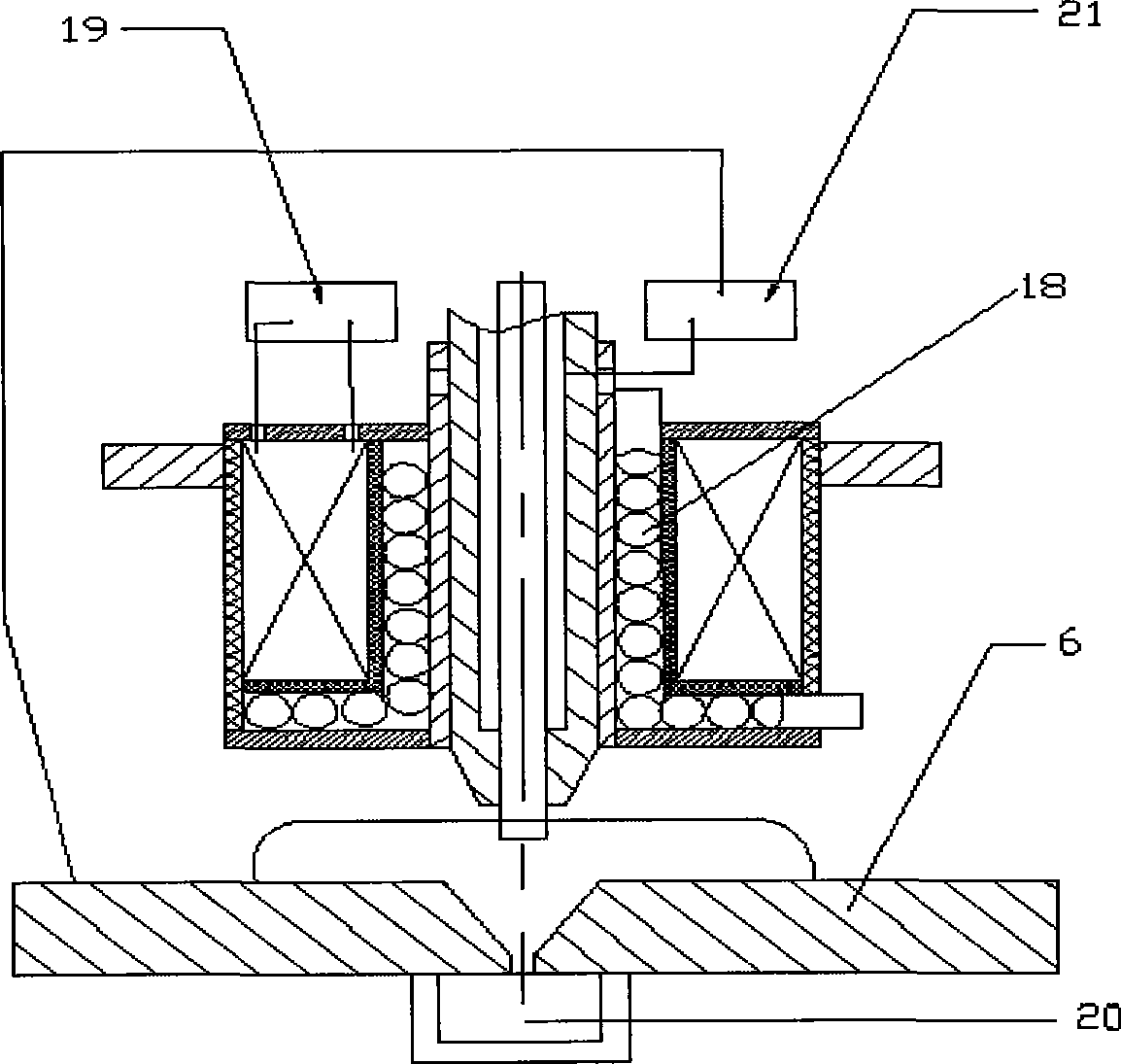

Method and equipment for electromagnetic composite double-face submerged arc welding of diphase stainless steel thick plate

InactiveCN101462196AImprove crystallizationReduce sensitivityArc welding apparatusChemical industryWelding power supply

The invention discloses a method for welding a dual-phase stainless steel and a device thereof. The method comprises: dual-side surfacing of heavy current submerged arc is controlled by an electromagnetic-composite field of the dual phase stainless steel of heavy plates without a grooveb; excitation current is provided by an excitation power supply to generate an additional longitudinal electromagnetic field; and a submerged arc welding process of the dual-phase stainless steel of the heavy plates without the groove is comprehensively controlled and realized by the electromagnetic field. The welding device is provided with the excitation power supply, a welding power supply, an excitation welding device, a device of an auxiliary electric field and a water cooling system. The excitation device consists of excitation coils, is fixed on a welding torch, and generates the additional longitudinal electromagnetic field which is coaxial with the welding torch, and the water cooling system is arranged in a bracket of the excitation coils. The device can realize the submerged arc welding of the dual-phase stainless steel of the heavy plates without the groove, with high efficiency, high quality and low cost through the electromagnetic-complex submerged arc welding; meanwhile, the device can be used for welding the dual-phase stainless steel of the heavy plates in industries, such as shipbuilding, chemical industry and so on.

Owner:CHONGQING UNIV

RE-containing Si-base partially-synthesized hydrocarbon converting catalyst

The RE-containing Si-base semi-synthesized hydrocarbon converting catalyst features are that it is prepared with silicon sol binder containing RE salt 0.1-20 % (by REO), natural aluminum silicate clay and artificially synthesized molecular sieve. With RE activated silica, the catalyst of the present invention has high heavy oil cracking activity, high heavy metal contamination resistance, low content of olefin and S in catalytically cracked gasoline.

Owner:吉林省嘉孚化学工业股份有限公司

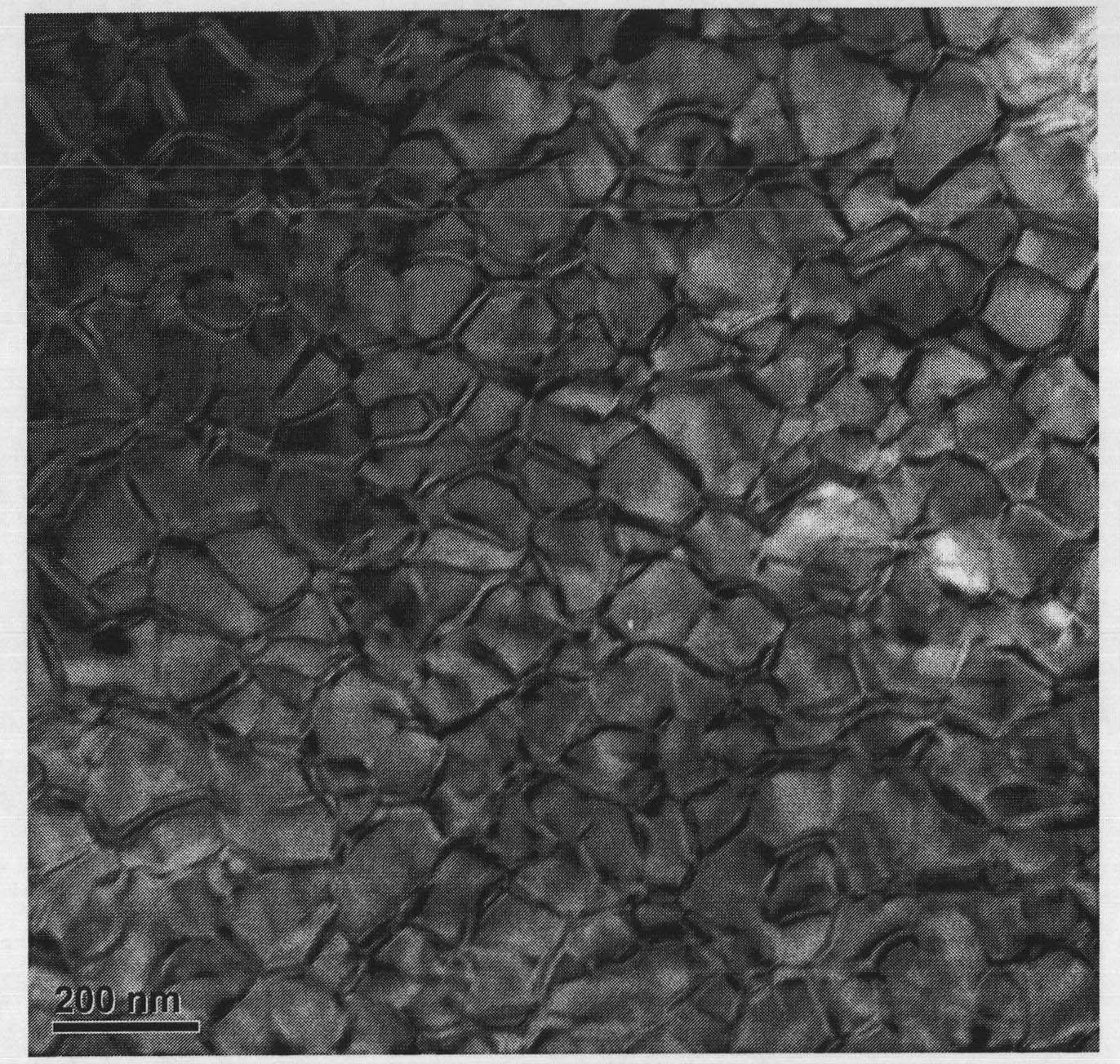

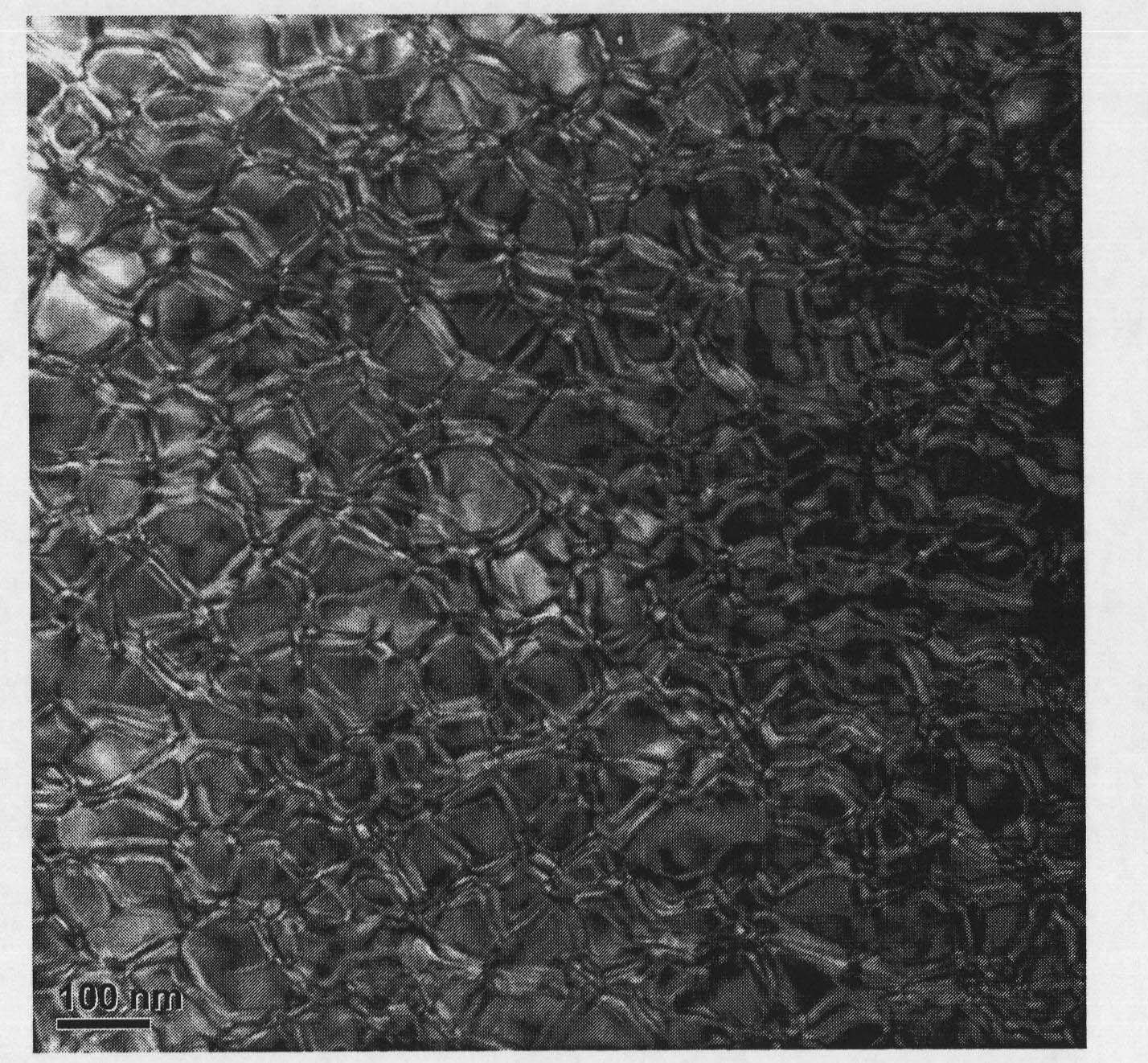

Hydrophilic polyethene microporous membrane and preparation method thereof

The invention provides a hydrophilic polyethene microporous membrane and a preparation method thereof, belonging to a polyethene microporous membrane containing blending compatilizer with a polar group, calcium carbonate and thinner and a preparation method thereof. In the preparation method of the microporous membrane, polyethene, blending compatilizer, calcium carbonate and thinner are taken as raw materials; and hydrophilic polyethene microporous membrane is finally prepared by blending processing, membrane pressing by a flat bed presser, quenching by water bath in constant temperature, extracting by extracting agent, acid cleaning, washing and drying. The invention is characterized in that the blended compatilizer with a polar group is selected to react with the calcium carbonate particles, calcium carbonate particles are evenly filled into polyurethane base body through blending processing; and porous structures are formed by the thermal induced phase separation method and the method for removing fillings by acid cleaning. As for the hydrophilic polyethene microporous membrane prepared by the method, the range of the internal average aperture is 0.1-10mu m, the aperture rate is greater than 50% and the contact angle is less than 80 degrees.

Owner:PETROCHINA CO LTD

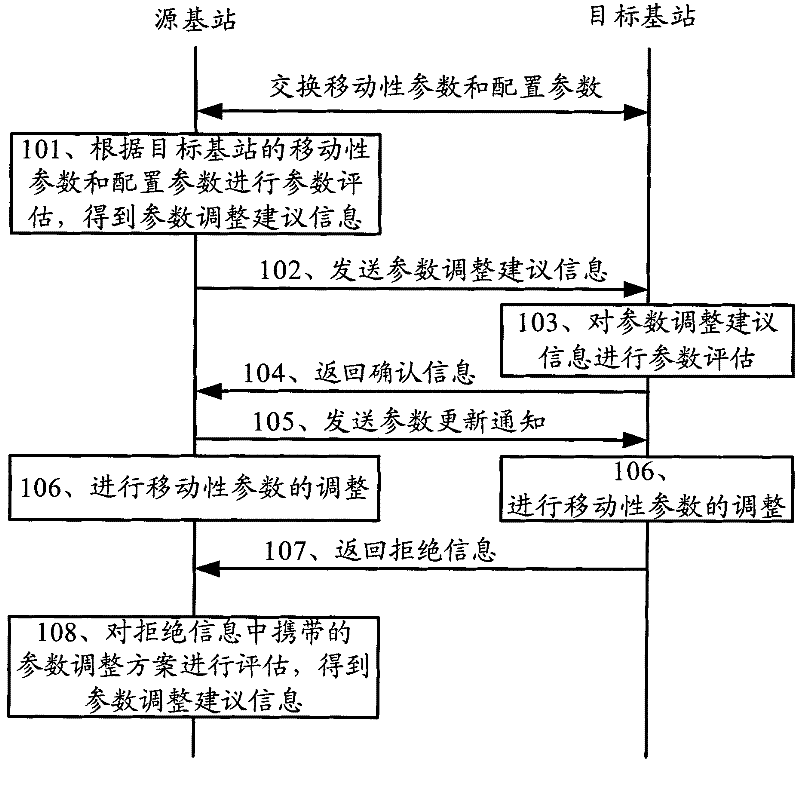

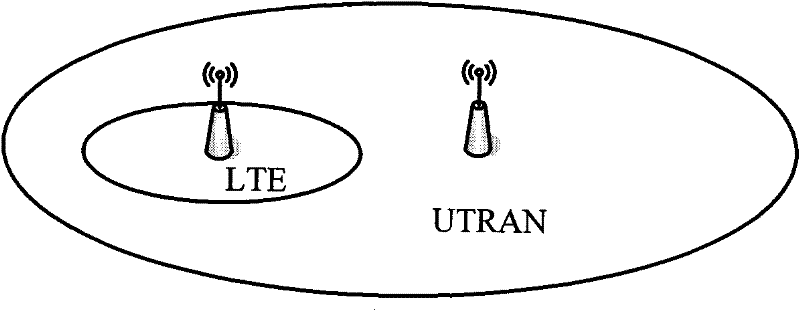

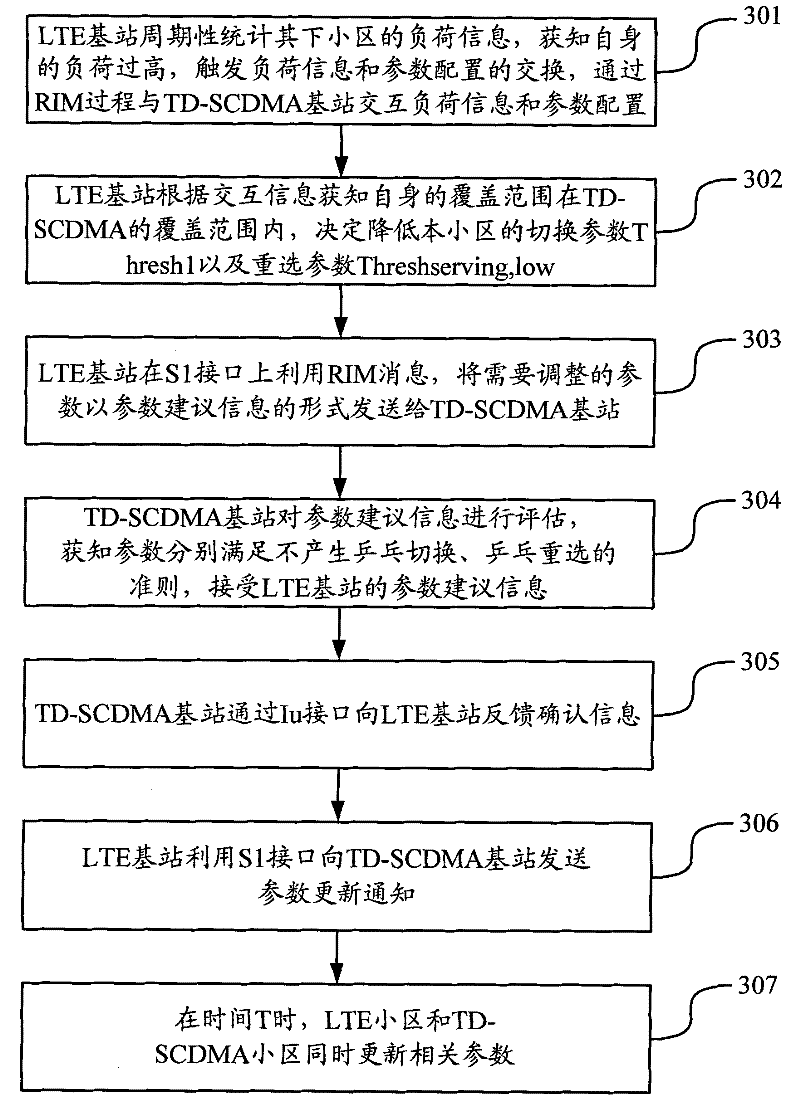

Method and device for adjusting mobility parameters

ActiveCN102264108AIncrease success rateChange distributionNetwork traffic/resource managementBase station

The embodiment of the invention discloses a method and equipment for adjusting mobility parameters. The method comprises the following steps that: a source base station evaluates parameters according to the mobility parameters and configuration parameters of a target base station to acquire parameter adjustment suggestion information, and sends the parameter adjustment suggestion information to the target base station; and the source base station sends a parameter updating notice to the target base station and adjusts the mobility parameters after confirmation information from the target base station is received. By the embodiment of the invention, the success rate of parameter consultation and the convergence of load balancing can be improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

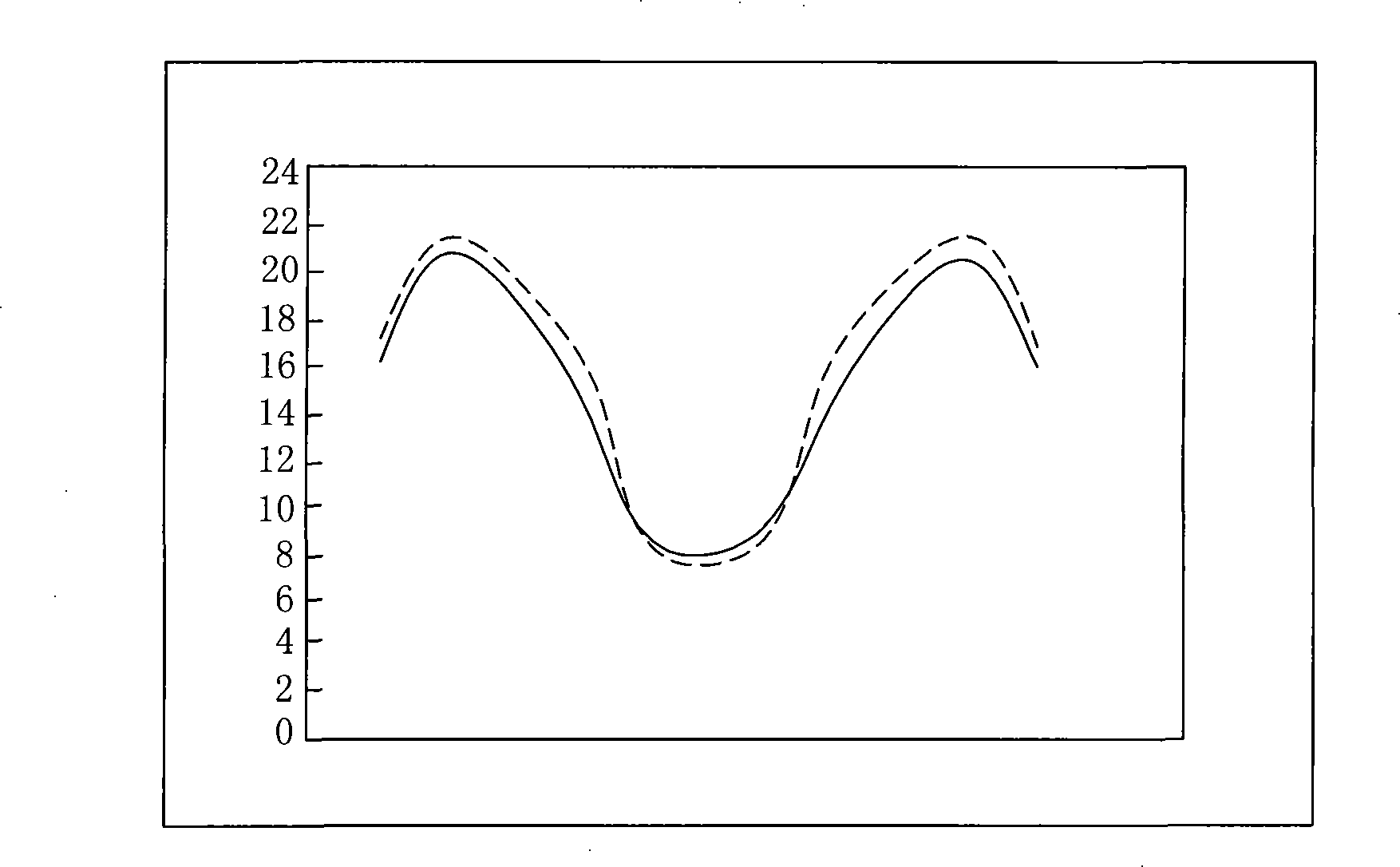

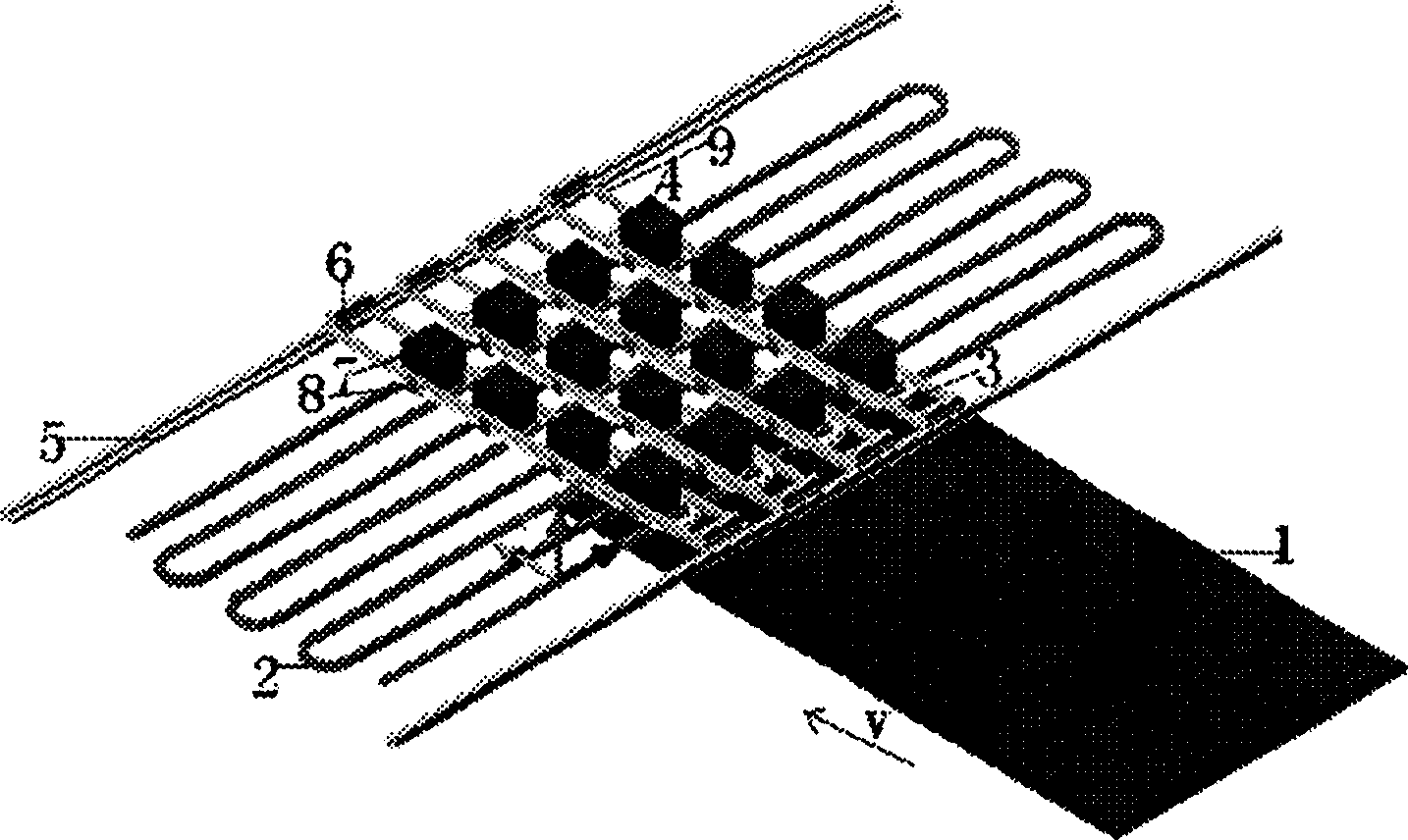

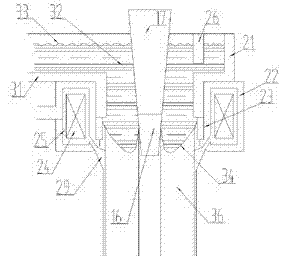

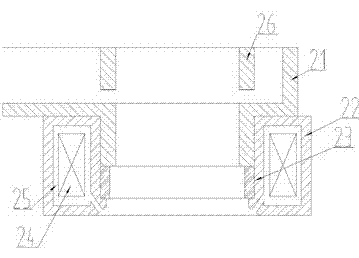

Width adjustable and temperature controllable transverse magnetic flux induction heating apparatus

InactiveCN1802044AUniform temperatureUniform and fine distributionCoil arrangementsIncreasing energy efficiencyMagnetic fluxTransverse magnetic

Present invention relates to a width adjustable and temperature controllable transverse direction magnetic flux induction heating apparatus. It contains belt material, fixed coil, mobile loop, yoke iron, guide way, travel mechanism, tank shape structure, fixed structure, and supporting rack, wherein fixed coil parallel to belt material surface, fixed coil long edge perpendicular to belt material direction of motion, removable loop parallel to belt material surface and located fixed coil outside it long edge parallel to belt material direction of motion mobile fixation to supporting rack, interior fixing several groove shape structure, yoke iron inserted in groove and fixed by fixing structure, each traveling loop can sliding in two ends guide way, supporting rack. Present invention is width and temperature controllable, can adapt belt material width variation in larger range and get more uniform temperature distribution, greatly raise production efficiency and save cost.

Owner:HEBEI UNIV OF TECH

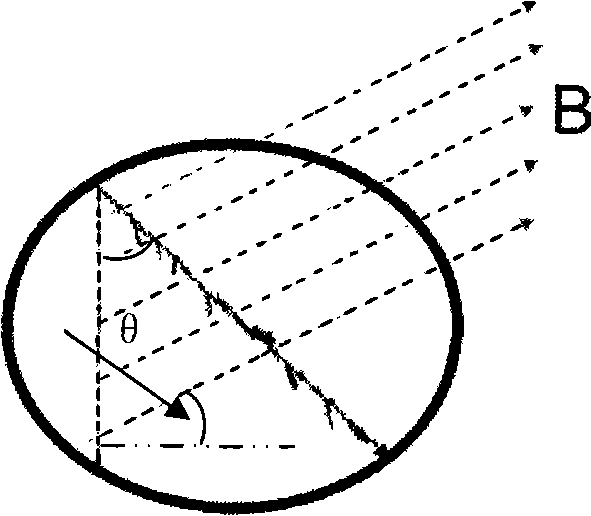

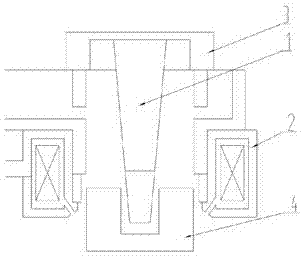

Arc source of dynamic controlled arc ion plating

InactiveCN101358328AImprove discharge formImprove job stabilityVacuum evaporation coatingSputtering coatingTarget surfaceIon plating

The invention relates to the field of film preparation, in particular to an arc ion plating arc source which controls the movement of arc pit with dynamic magnetic field. The dynamic controlled arc ion plating arc source is provided with a dynamic control magnetic field generator, a target and a target base; the target is arranged on the target base; the dynamic control magnetic field generator consists of a main control magnetic field generator and an auxiliary magnetic field generator; the main control magnetic field generator is arranged behind the target and is coaxial with the target; the auxiliary magnetic field generator is arranged around the main control magnetic field generator. In the invention, arc-shaped magnetic fields which are dynamically distributed are formed on the target surface with the help of the cooperation of the two magnetic field generators, so as to improve the discharge form and work stability of the arc pit, control the movement track of the arc pit, improve the erosion evenness and target utility rate of the target, reduce the emission of large target particles and prepare high-quality film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

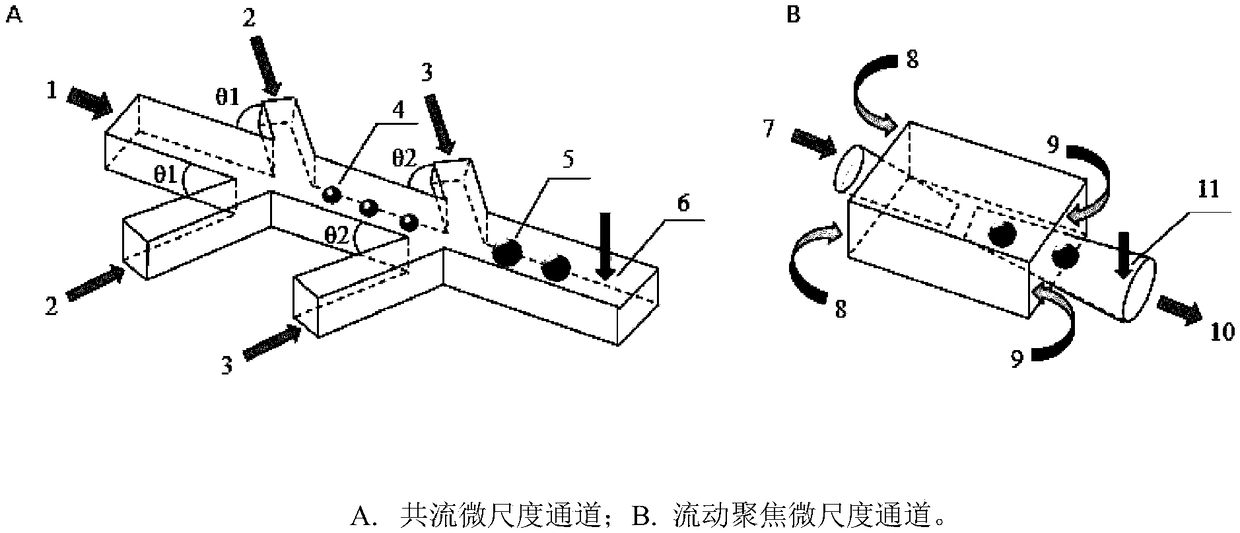

Core-shell type pre-charged chemotherapy medicine embolization microsphere and preparation method thereof

InactiveCN108721684ATargetedWith controlled releaseSurgical adhesivesTissue regenerationEmulsionArterial Embolization

The invention provides a core-shell type pre-charged chemotherapy medicine embolization microsphere and a preparation method thereof. The method comprises the following steps of using water / oil / water(W / O / W) complex emulsion type or oil / water / oil (O / W / O) complex emulsion type emulsified micro liquid drips as templates; coating tiny liquid drips containing medicine into outer layer liquid drips; high molecular polymers in the inner and outer layer liquid drips are converted through measures such as physical measures and chemical measures to form an inner layer core and an outer layer shell. Theformed core-shell structure medicine microsphere is formed by polymers of two-layer structures; the inner core contains medicine; the outer shell is favorable for maintaining the activity of the inner core medicine; the stable medicine release is realized; the sudden release is prevented; the safety is enhanced. The medicine carried microsphere prepared by the method has the advantages that the particle diameter range is 10 to 1000 micrometers; the sphere degree is good; the particle diameter is uniform; (the dimension deviation is 5 percent); the medicine encapsulation rate is high; the structure / carried medicine is controllable; meanwhile, the preparation method of the pre-charged chemotherapy medicine embolization microsphere can provide a novel idea for the clinic application study ofthe transcatheter arterial embolization.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Hydroxy camptothecin emulsion and its preparation method

InactiveCN1493289AChange distributionTissue-targetedOrganic active ingredientsEmulsion deliveryCurative effectTG - Triglyceride

A hydroxycamptothecin emulsion is prepared from hydroxycamptothecin 0.01-2.2 %, emulsifier 0.3-8%, triglyceride 2-30%, glycerine for injection 2.0-3.0 % and water for injection through dissolving the 10-hydroxycamptothecin in the oil phase containing triglyceride and emulsifier, adding water phase, mixing, and ultrasonic or homogeneous emulsifying. Its advantages are high curative effect and stability, and good target to tissue.

Owner:曹永强 +1

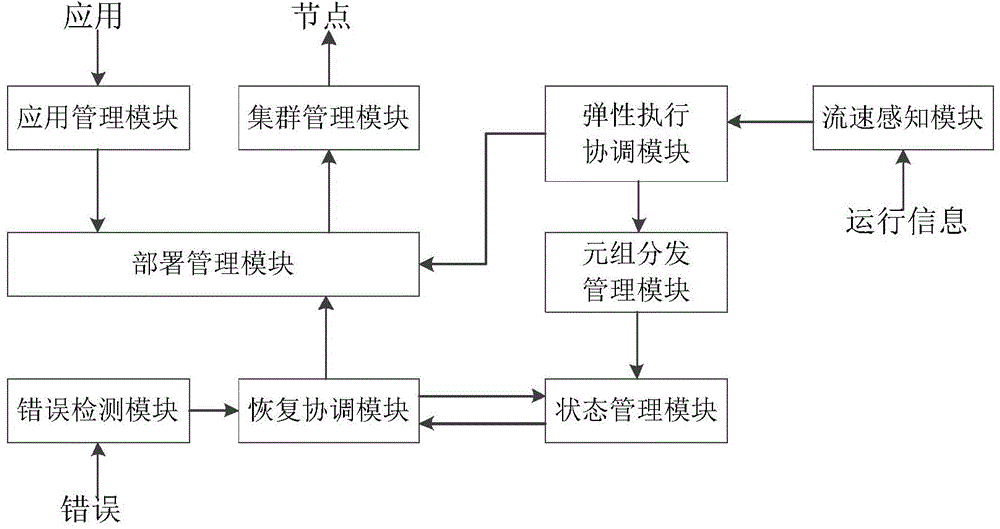

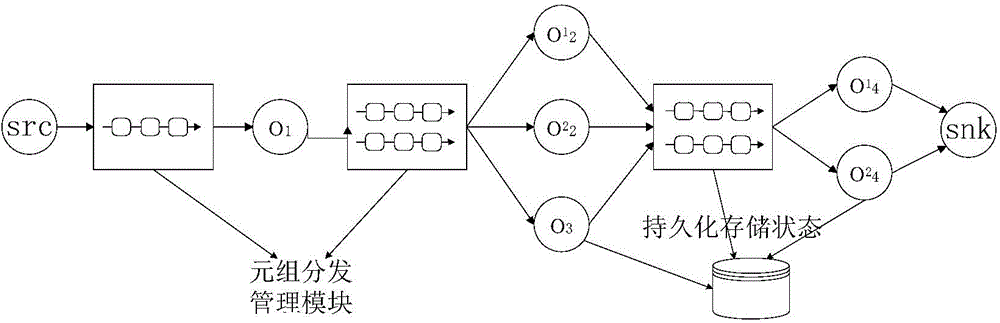

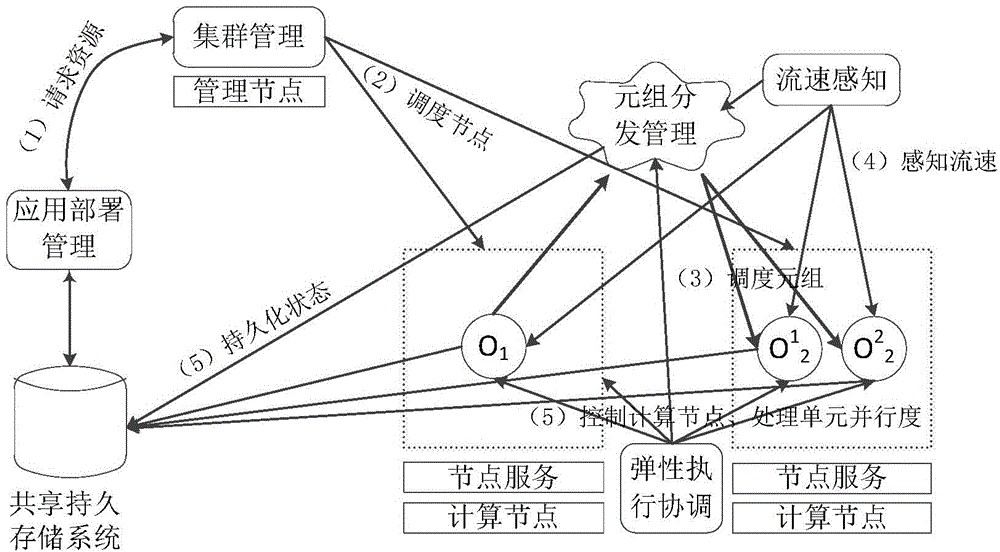

Real-time streaming computing flow speed perceiving elastic execution tolerant system

ActiveCN104794015AReduce recovery calculationsLong-term stable application operating environmentFault responseResource consumptionModularity

The invention discloses a real-time streaming computing flow speed perceiving elastic execution tolerant system. According to the system, a tight coupling relation of tuple transmitting, computing, state maintaining and processing units in a traditional streaming computing frame is changed into a modular and specialized loose coupling relation, in combination with a flow speed perceiving module, an elastic execution module, a state management module and the like, the system can control the processing time of all stages precisely, and thus display of a whole application is guaranteed. The system can conduct quick response to input steam changes or available resource changes quickly through flow speed perceiving. A distribution module can change the distribution relation flexibly and send tuples in batches timely, and resource consumption and sending delay are further reduced. The system can adjust the parallel numbers of processing units and nodes transparently through elastic execution so as to keep the application stable and guarantee delay. The system is made to have the unbelievable tolerant capacity through state management and persistent storage. The proper numbers of tuples are stored, the application recovery is accelerated, and the failure recovery speed is further increased in combination with parallel recovery of elastic execution.

Owner:HUAZHONG UNIV OF SCI & TECH

Process for synthesizing benzaldehyde by selective oxidation of toluene

InactiveCN1663941AChange distributionChange pHOrganic compound preparationCarbonyl compound preparationBenzaldehydeReaction temperature

Disclosed is a process for synthesizing benzaldehyde by selective oxidation of toluene, wherein the catalyst mainly comprises manganese, copper, cobalt, ferrum, nickel, zirconium, zinc, Argentine or / and halides of sodium, calcium, potassium, nitrates, sulfates, acetates, benzoates. The preparing process comprises letting in oxygen at the presence of the catalyst. When the conversion rate of toluene is 10%, the selectivity of benzaldehyde is 62%, the selectivity of benzoic alcohol is 14%, the selectivity of benzene carbonic acid is 22%, when the conversion rate of toluene is 39%, the selectivity of benzaldehyde is 20%, the selectivity of benzoic alcohol is 5%, the selectivity of benzene carbonic acid is 73%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

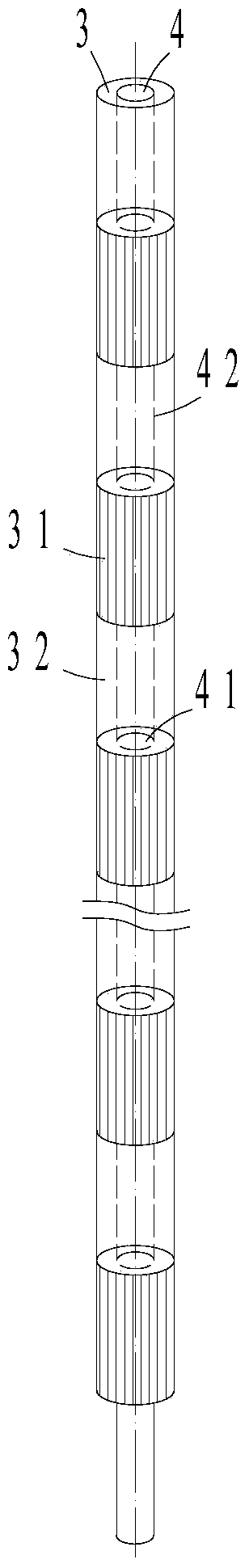

Control rod capable of flattening axial power distribution of reactor core and control rod assembly

InactiveCN103985420AIncrease powerWill not cause a reductionNuclear energy generationNuclear reaction controlControl powerNuclear engineering

The invention discloses a control rod capable of flattening the axial power distribution of a reactor core. The control rod comprises an inner layer and an outer layer, wherein the inner layer is capable of axially sliding relative to the outer layer, the outer layer comprises a plurality of neutron absorbers and non-neutron absorbers which are axially distributed at intervals, the inner layer comprises a plurality of neutron absorbers and non-neutron absorbers which are axially distributed at intervals, all the neutron absorbers and non-neutron absorbers of the outer layer and the inner layer are equal in lengths, and the number of the neutron absorbers / non-neutron absorbers in the inner layer is greater than that of the neutron absorbers / non-neutron absorbers of the outer layer by one. The invention further discloses a control rod assembly capable of flatting the axial power distribution of the reactor core. The control rod assembly comprises a plurality of control rod pairs, wherein each control rod pair comprises an A-type control rod and a B-type control rod. The control rod is applied to the power control on the reactor core of a reactor; the constitution of a control rod system and lifting and inserting procedures of the control rod are simplified; an axial power distorted peak of the reactor core can be reduced, the axial power distribution of the reactor core is improved, and further the problems of economy and safety, caused by inhomogeneous distribution of the axial power of the reactor core, are reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

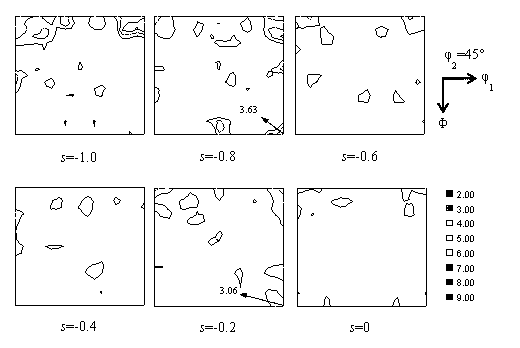

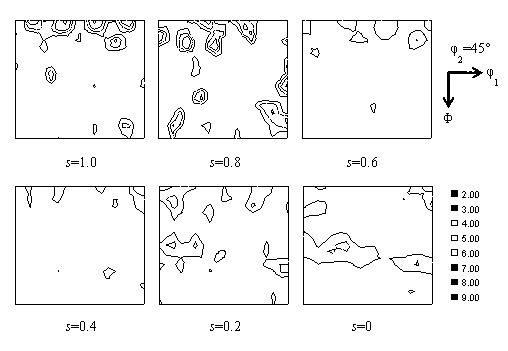

Method for enhancing hot-rolled Gaussian texture of double-roller ribbon continuous casting oriented silicon steel

InactiveCN103255338AEnhanced Hot Rolled Gaussian TextureSimple processMetal rolling arrangementsMetallurgyMolten steel

The invention belongs to the field of oriented silicon steel manufacturing, and in particular relates to a method for enhancing a hot-rolled Gaussian texture of double-roller ribbon continuous casting oriented silicon steel. Steel liquid is smelted by adopting a medium-frequency vacuum induction furnace and forms an oriented silicon steel ribbon which is 1-10 mm thick through double-roller continuous casting; the ribbon is cooled by air to the temperature of 850-1,200 DEG C for performing asynchronous rolling; the differentiate speed ratio is 1.10-1.50; the ribbon is rolled by one gate or two gates; the total press-down rate is controlled to be 10-50 percent; a hot-rolled plate is cooled to the temperature of 500-700 DEG C and then is coiled; and therefore, an oriented silicon steel hot-rolled plate with the enhanced Gaussian texture is obtained. By the method, the hot-rolled Gaussian texture of the double-roller ribbon continuous casting oriented silicon steel can be obviously enhanced by effectively controlling three technical parameters, namely the rolling temperature, the differentiate speed ratio and the total press-down rate. The technology adopted by the invention is simple and stable and can be used for a production flow of the double-roller ribbon continuous casting oriented silicon steel.

Owner:NORTHEASTERN UNIV

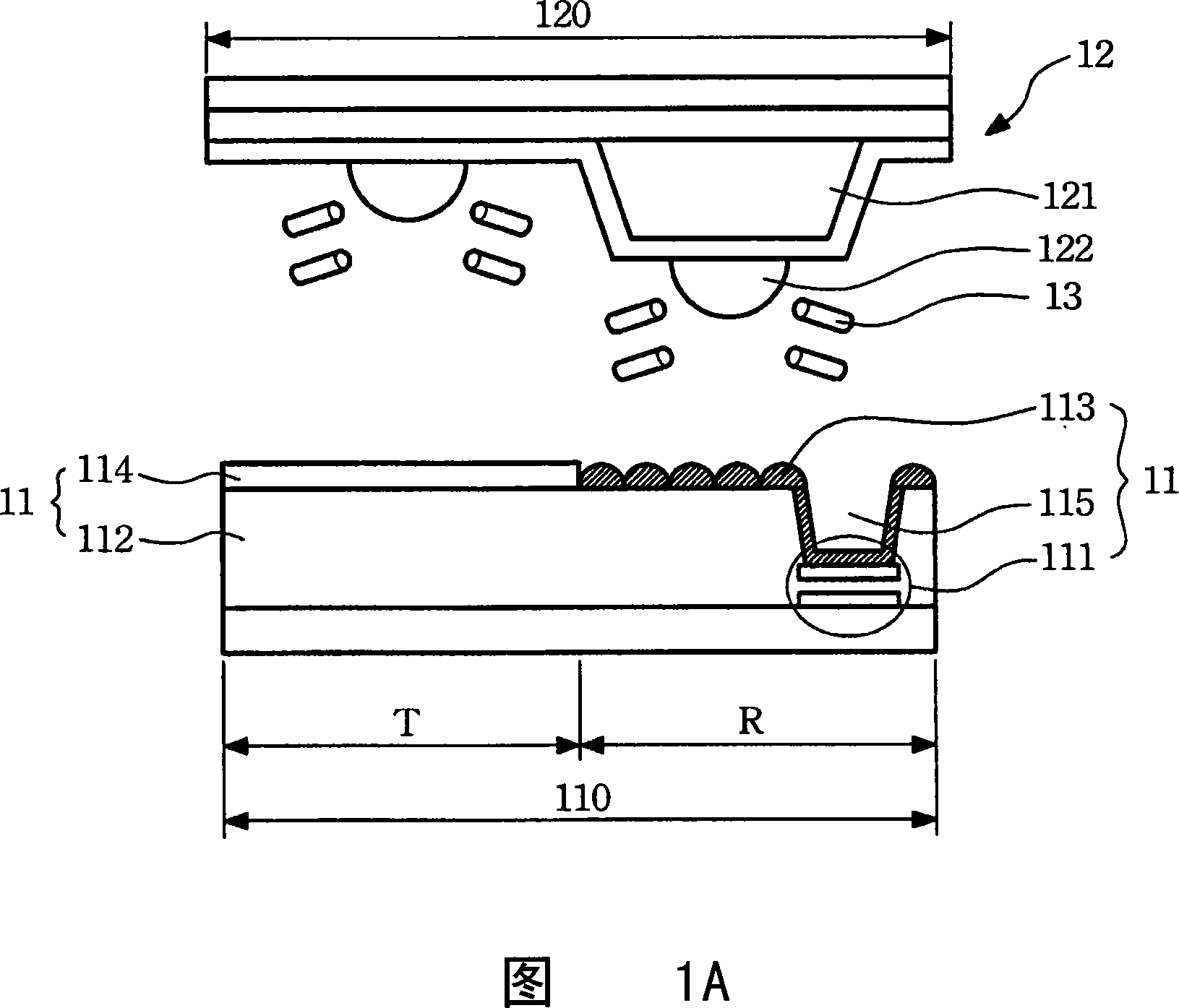

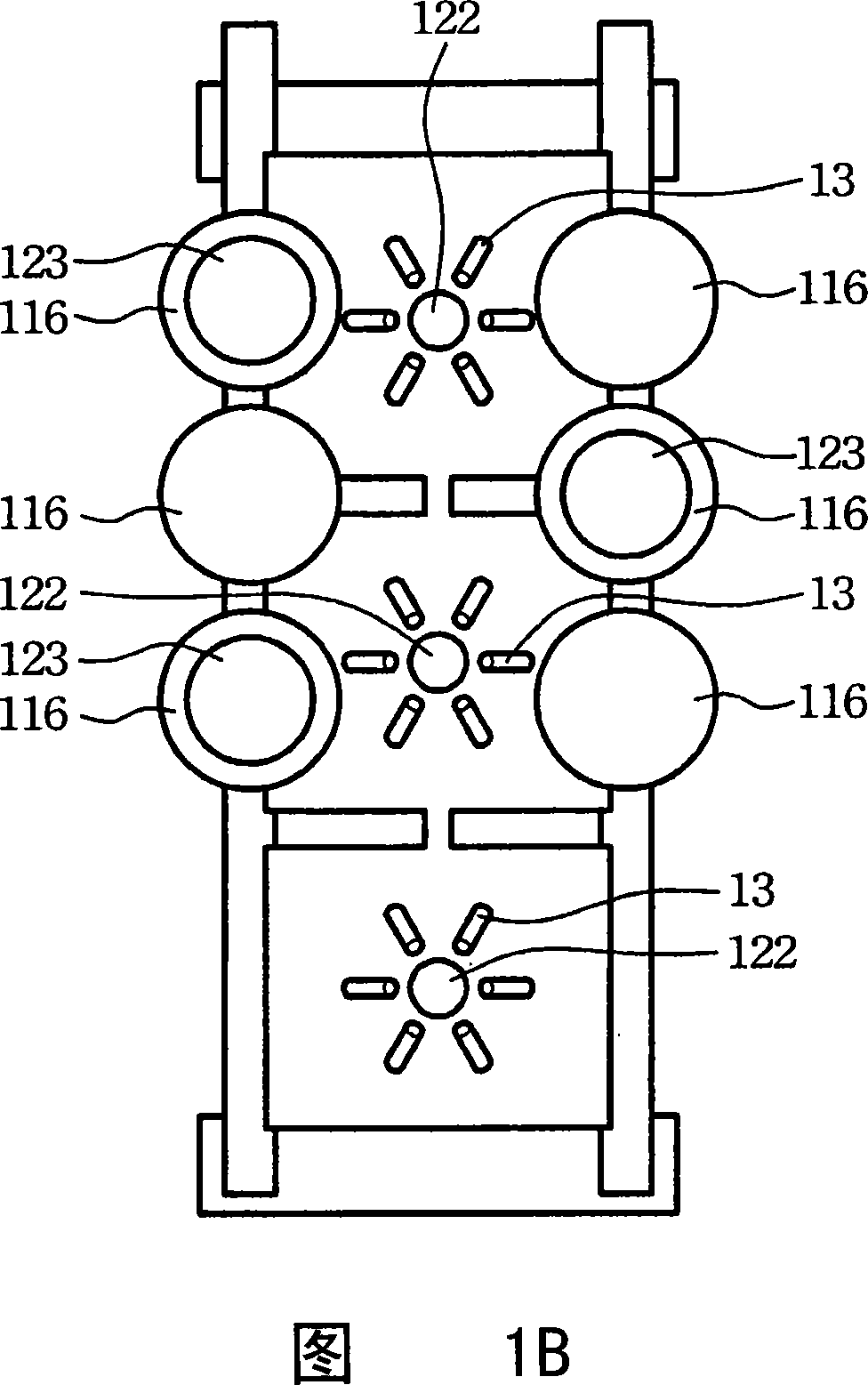

Liquid crystal panel and its producing method

ActiveCN101051160AIncrease opening ratioImprove image contrastStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal face plate is prepared for forming the first base plate with a numbers of sub-pixels by the first substrate, switch element array set on the first substrate, UHA on switch element array, contact hole and a reflection electrode set on UHA and electric-connected to on switch element of switch element array through said contact hole; arranging a packing component between the first and the second base plates and filling said packing component full of contact hole then setting a liquid crystal layer between the first and the second base plates.

Owner:AU OPTRONICS CORP

High-efficiency cleaning device for turbo multi-duct blower

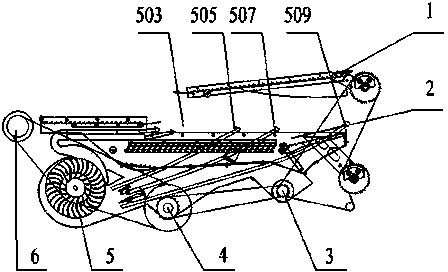

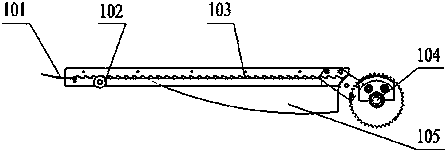

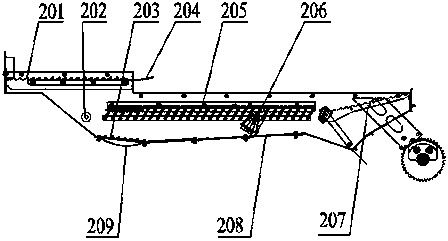

InactiveCN104226598AReduce energy lossAvoid generatingSievingGas current separationAir velocityAgricultural engineering

The invention discloses a high-efficiency cleaning device for a turbo multi-duct blower. The device mainly comprises a material conveying uniform distribution device, a grain and impurity conveyer device, a cleaning device and a transmission device, and meets the requirement on high-efficiency cleaning of crops in a large feed quantity; the turbo multi-duct blower is large in flow, uniform in air speed at an air outlet, stable in airflow, high in anti-attenuation capacity, compact in structure and high in energy efficiency ratio; through the vibration of a material vibrating screen and multiple winnowing of the turbo multi-duct blower, clean grains fall into a grain auger and enter a grain box, and partial impurities fall into a secondary impurity auger, are uniformly distributed by a return plate and enter a screen surface to realize recleaning. The high-efficiency cleaning device can meet the requirement on high-efficiency high-performance cleaning operation of wheat, rice, rape, corn, soybean and other crops in the feed quantity of 5-8kg / s, and is small in cleaning loss, low in impurity rate, high in operating efficiency and compact in structure.

Owner:JIANGSU UNIV

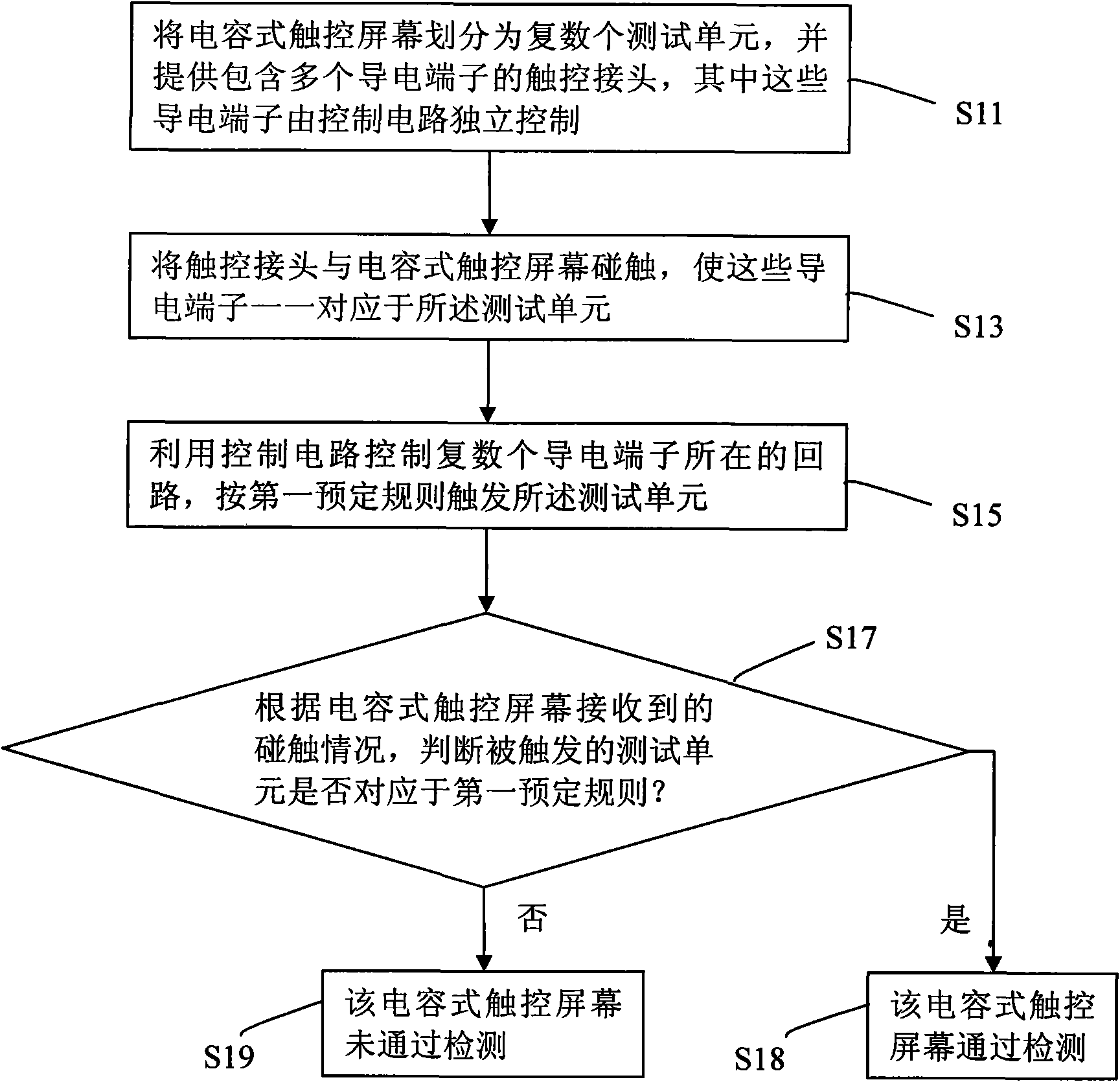

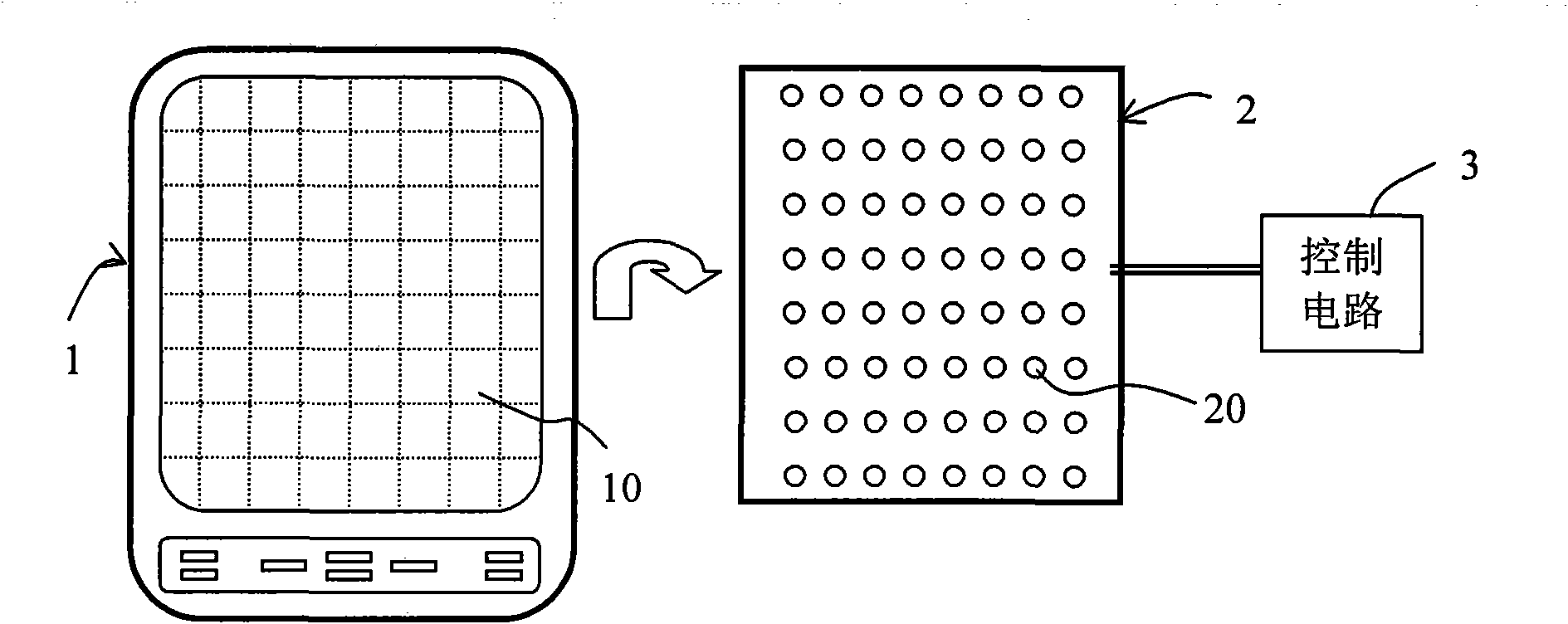

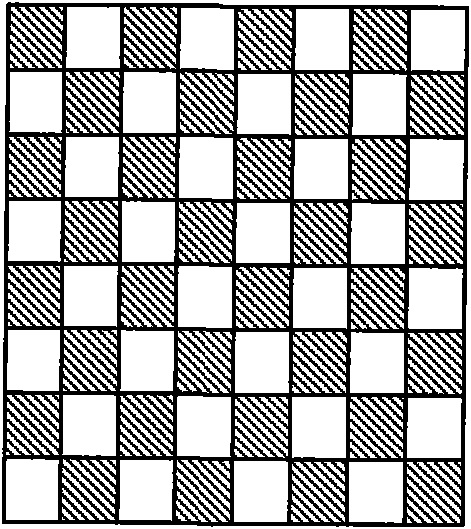

Detection method and system of capacitance-type touch screen

The invention provides a detection method and system of a capacitance-type touch screen. The detection method comprises the following steps of: dividing the capacitance-type touch screen into a plurality of test units, and providing a touch joint comprising a plurality of conductive terminals; then enabling the touch joint to be in contact with the capacitance-type touch screen; then controlling a loop with the plurality of conductive terminals by utilizing a control circuit; triggering the test units according to predetermined rules; and finally judging whether the triggered test units correspond to the predetermined rules or not according to touch conditions received by the capacitance-type touch screen so as to confirm whether the capacitance-type touch screen passes detection or not. The detection method and system provided by the invention can be used for fast finding the defect of touch ineffectiveness caused by assembly, simplifying the test process and increasing the test speed.

Owner:QISDA SUZHOU +1

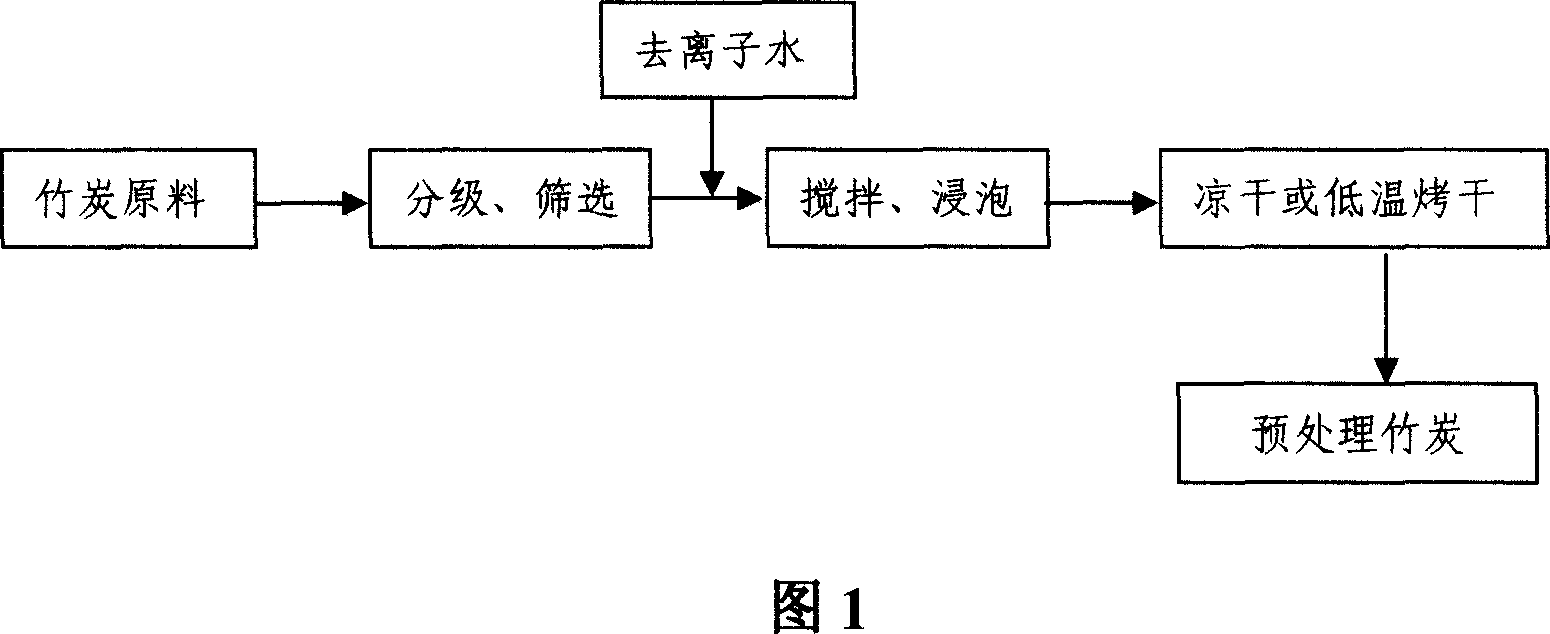

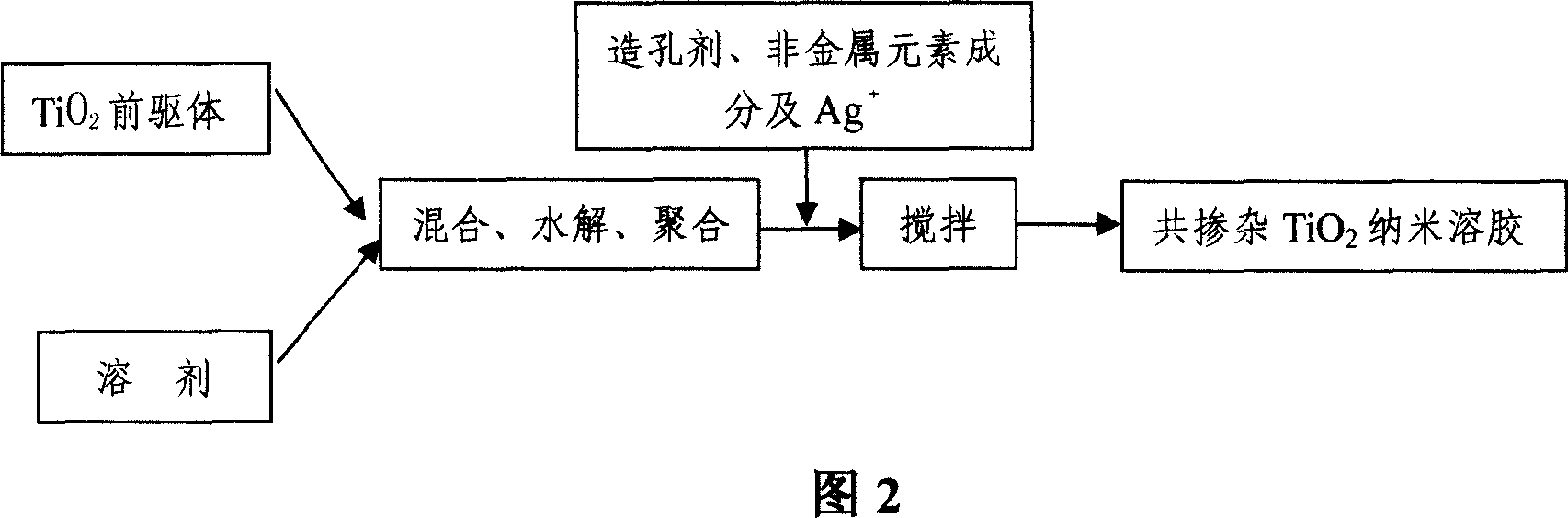

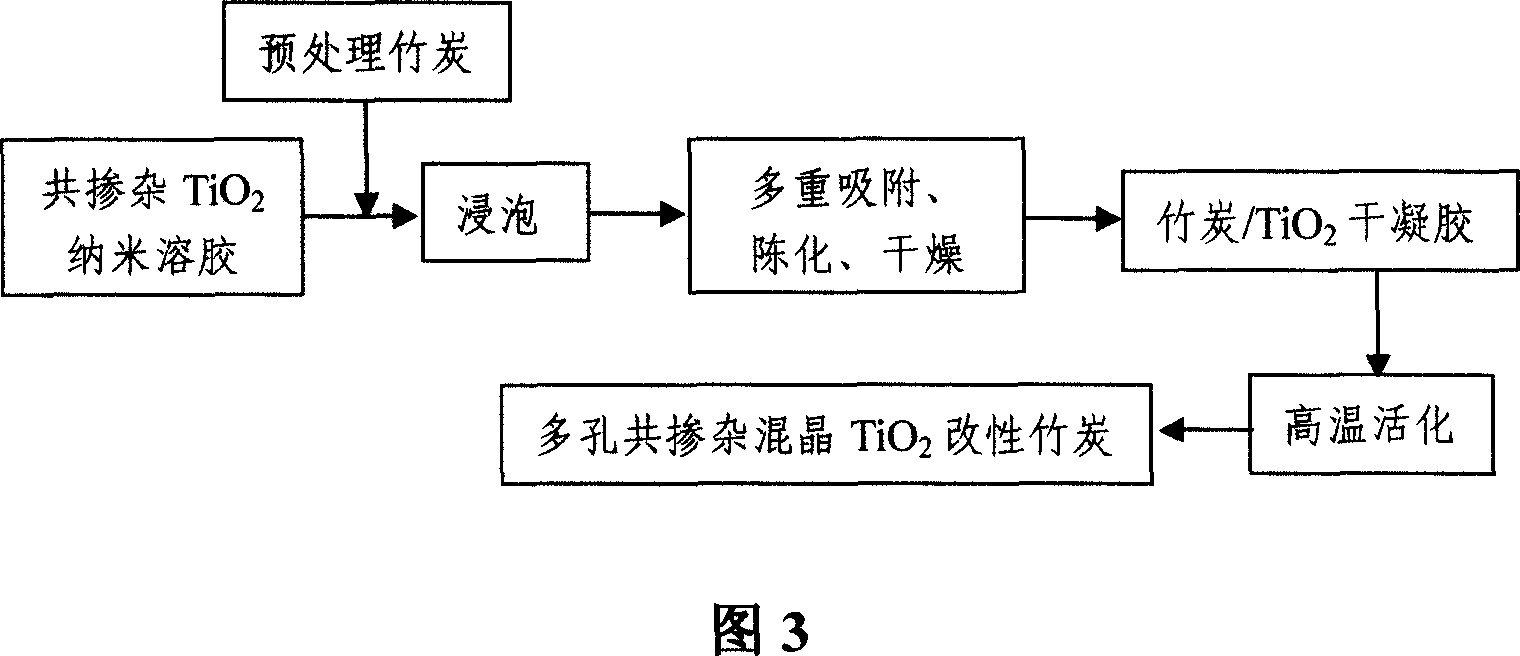

Modification bamboo charcoal having Ag and multihole TiO2 and the preparing method

InactiveCN101041134AIncrease the concentration of negative ionsSolve the blockageMetal/metal-oxides/metal-hydroxide catalystsChemicalsPhotocatalysisLight source

The invention relates to a modified bamboo-carbon product and the manufacturing method. In detail, it is the porous TiO2 bamboo-carbon product with Ag on the surface and high specific surface area, notable photocatalysis and antibacterial performances and the manufacturing method. The porous TiO2 modified bamboo-carbon with Ag on the surface comprises pretreated bamboo-carbon material and TiO2 nanometer sol doped pore-making agent Ag / N filled in bamboo-carbon duct or vascular bundle. The TiO2 nanometer sol doped pore-making agent Ag / N comprises TiO2 sol particle, pore-making agent, nitrogen doped component and Ag+. No only the invention changes the distribution of pore channels but also pore channels can not be jammed. So it can improve bamboo-carbon specific surface area in effect and increases absorption and the concentration of anion. At the same time, when there is no light source, the abundant Ag on the surface is made use of so that the bamboo-carbon is provided with permanent antibacterial performance. The invention provides important bamboo-carbon material with high quality for develop the bamboo-carbon application area.

Owner:ZHEJIANG GREEN ROCK ENVIRONMENTAL PROTECTION MATERIAL SHARE

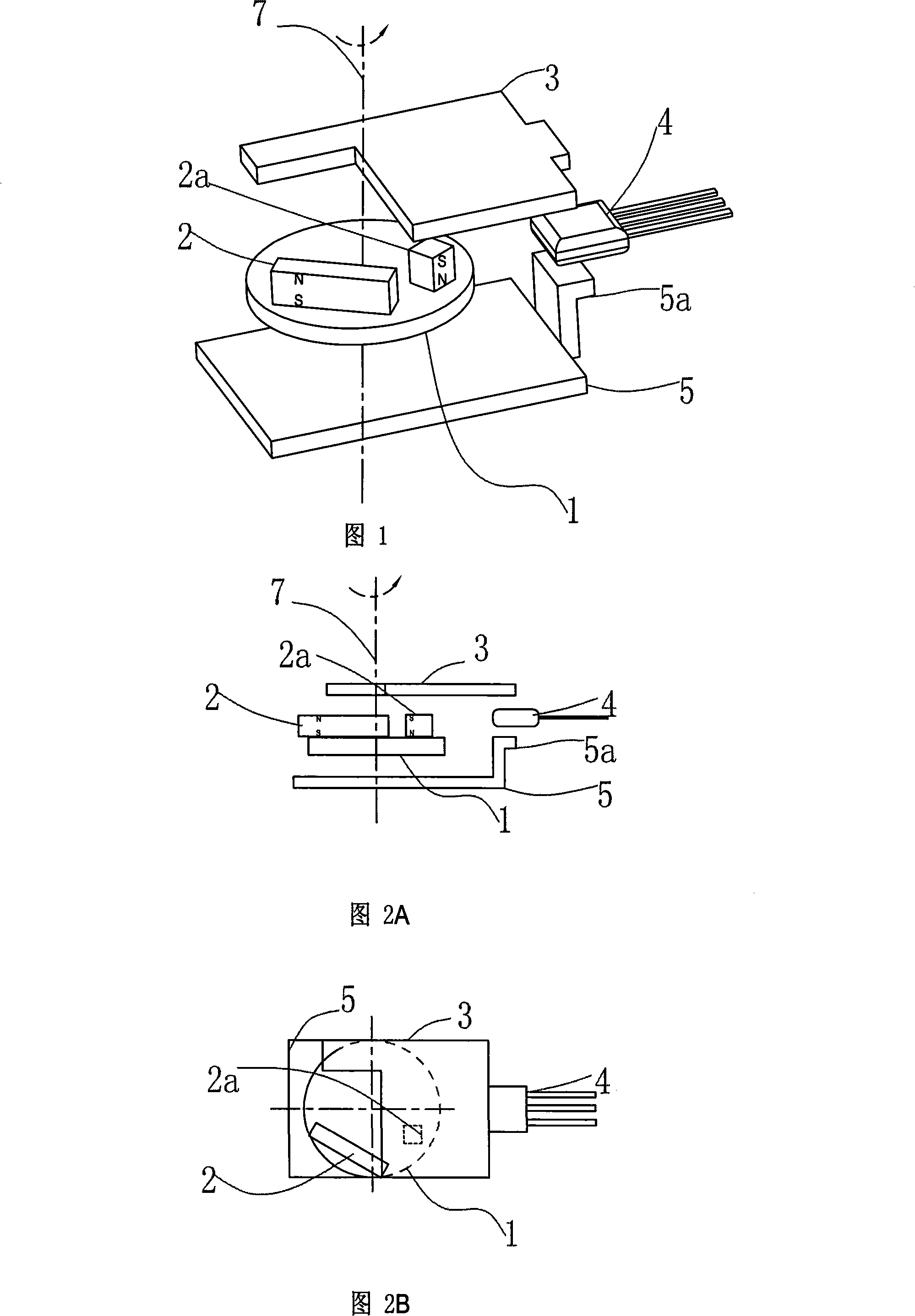

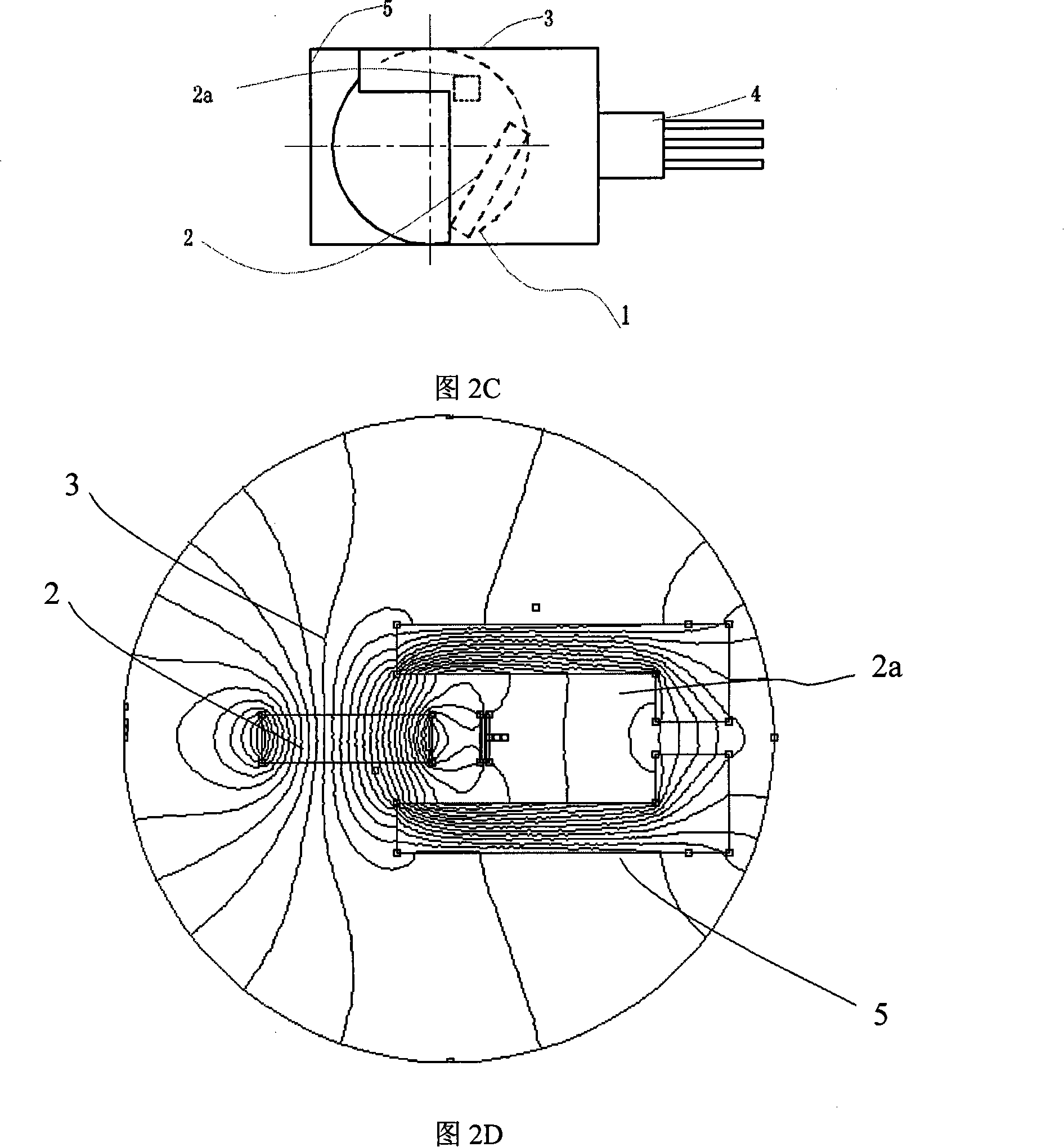

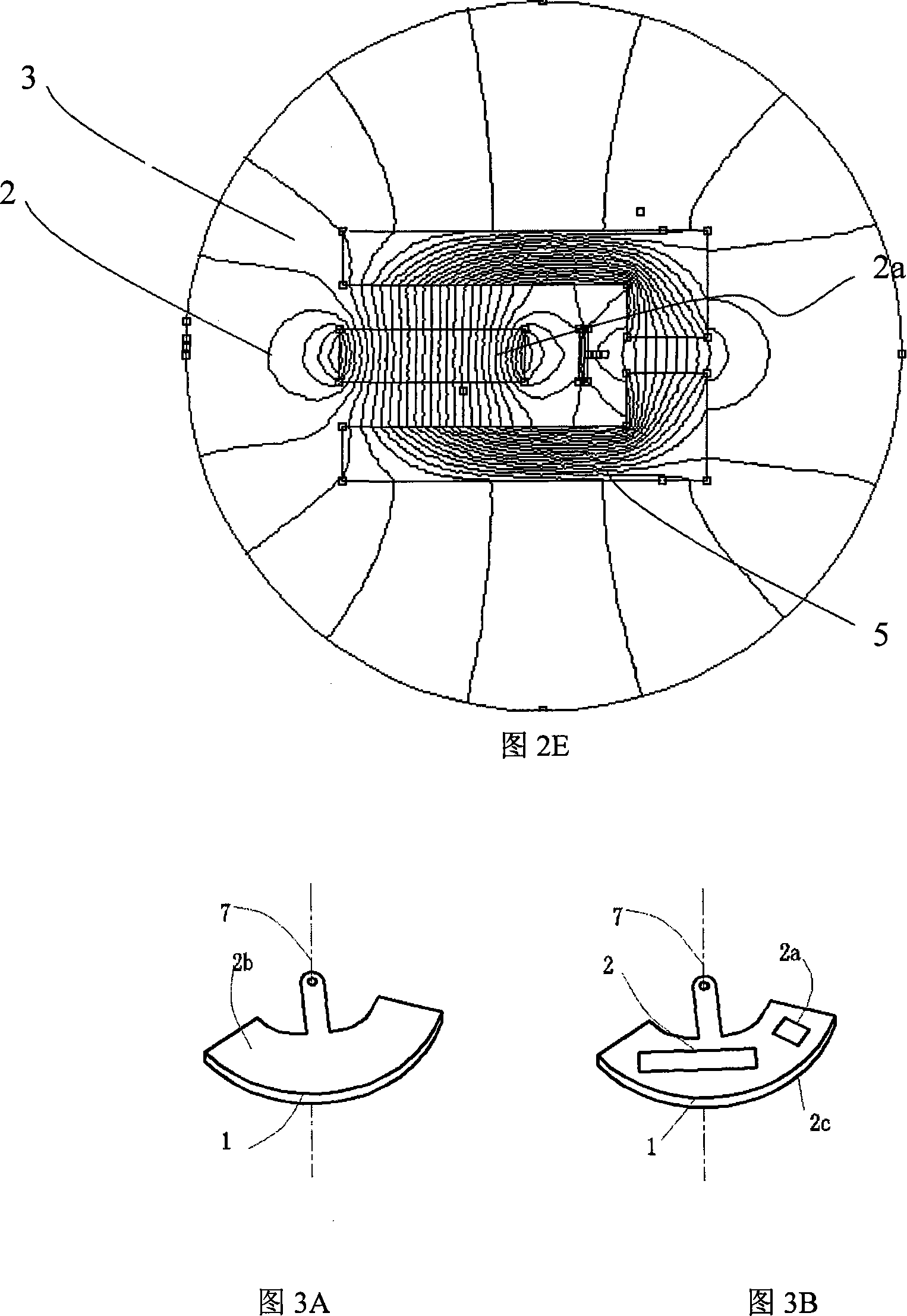

Angular displacement sensor

InactiveCN101216324AEliminate distractionsReduce distractionsConverting sensor output electrically/magneticallySignal conditioningUltimate tensile strength

The invention relates to an angular displacement sensor, belonging to the technical field of magnetoelectric sensors. The sensor comprises a rotating member (1), wherein the rotating member (1) comprises a magnetic element (2) with magnetizing direction substantially parallel to the axial direction of the rotating member (1) thereof. The magnetic field generated by the rotating member (1) forms parallel and uniform magnetic field in the magnetic flux induction surface of a Hall sensor (4). When the rotating member (1) rotates, the increment of the magnetic intensity detected by the Hall sensor (4) is proportional to the angular increment in a wide angular region, so as to realize the measurement to the angular displacement. The inventive angular displacement sensor has the advantages of simple structure, low production cost, good signal stability, and highly linear and controllable signal conditioning.

Owner:塞尔福(厦门)工业有限公司

Nano emulsion of containing ginsenoside, preparation method and usage

InactiveCN1626101AChange distributionImprove bioavailabilityOrganic active ingredientsEmulsion deliverySide effectClinical efficacy

The invention provides a nanoemulsion of ginsenoside, its preparation method and application. The ginsenoside emulsion provided by the invention contains ginsenoside, water, oil, an isotonic agent and a surfactant, and may also contain a stabilizer. The emulsion provided by the invention does not contain organic solvents and solubilizers with toxic and side effects, so it is non-allergic and has small side effects; and the content of active ingredients in the oil phase of the nanoemulsion provided by the invention is relatively high, which meets the high clinical efficacy requirements. At the same time, the emulsion can also change the distribution of saponins in the human body, improve the bioavailability of the drug, and can make the ginsenosides concentrate in the tumor site in the body, so as to improve the antitumor effect of the compound.

Owner:SHANDONG LUYE PHARMA CO LTD

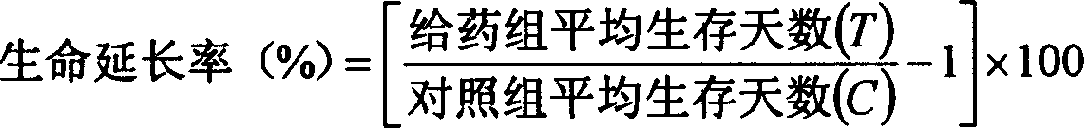

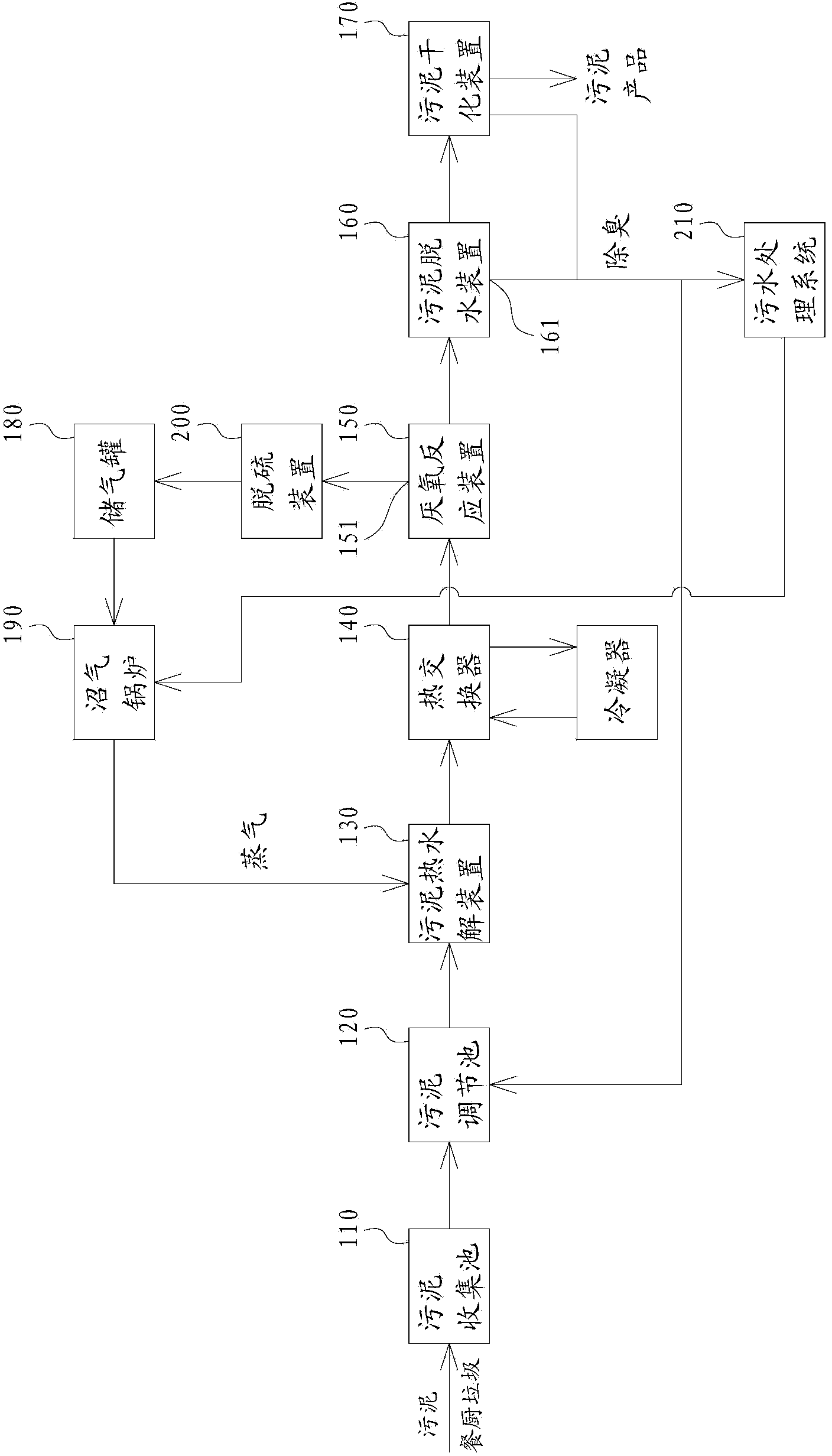

Sludge treatment system and sludge treatment method

InactiveCN104030537AIncrease in sizeSmall particlesSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEngineeringThermal water

The invention discloses a sludge treatment system, comprising a sludge collecting tank, a sludge regulating pool, a sludge thermal hydrolysis device, a heat exchanger, an anaerobic reaction device, a sludge dewatering device and a sludge drying device, which are sequentially connected. The sludge treatment system also comprises a gas storage tank and a biogas boiler, wherein the input end of the gas storage tank is connected with the exhaust end of the anaerobic reaction device; the fuel input end of the biogas boiler is connected with the output end of the gas storage tank; the output end of the biogas boiler is connected with the sludge thermal hydrolysis device; the discharge end of the sludge dewatering device is connected with the input end of the sludge regulating pool. The invention also discloses a sludge treatment method. The sludge treatment method comprises the following steps: 1) collecting a sludge material and diluting by water; 2) hydrolyzing the diluted sludge material at high temperature; 3) carrying out anaerobic digestion on the sludge subjected to thermal hydrolysis to obtain biogas and digested sludge; 4) collecting the biogas; 5) dewatering and drying the digested sludge to obtain a sludge product. Reclamation, harmlessness, minimization and stabilization of sludge treatment are achieved by the steps and method.

Owner:王胜初

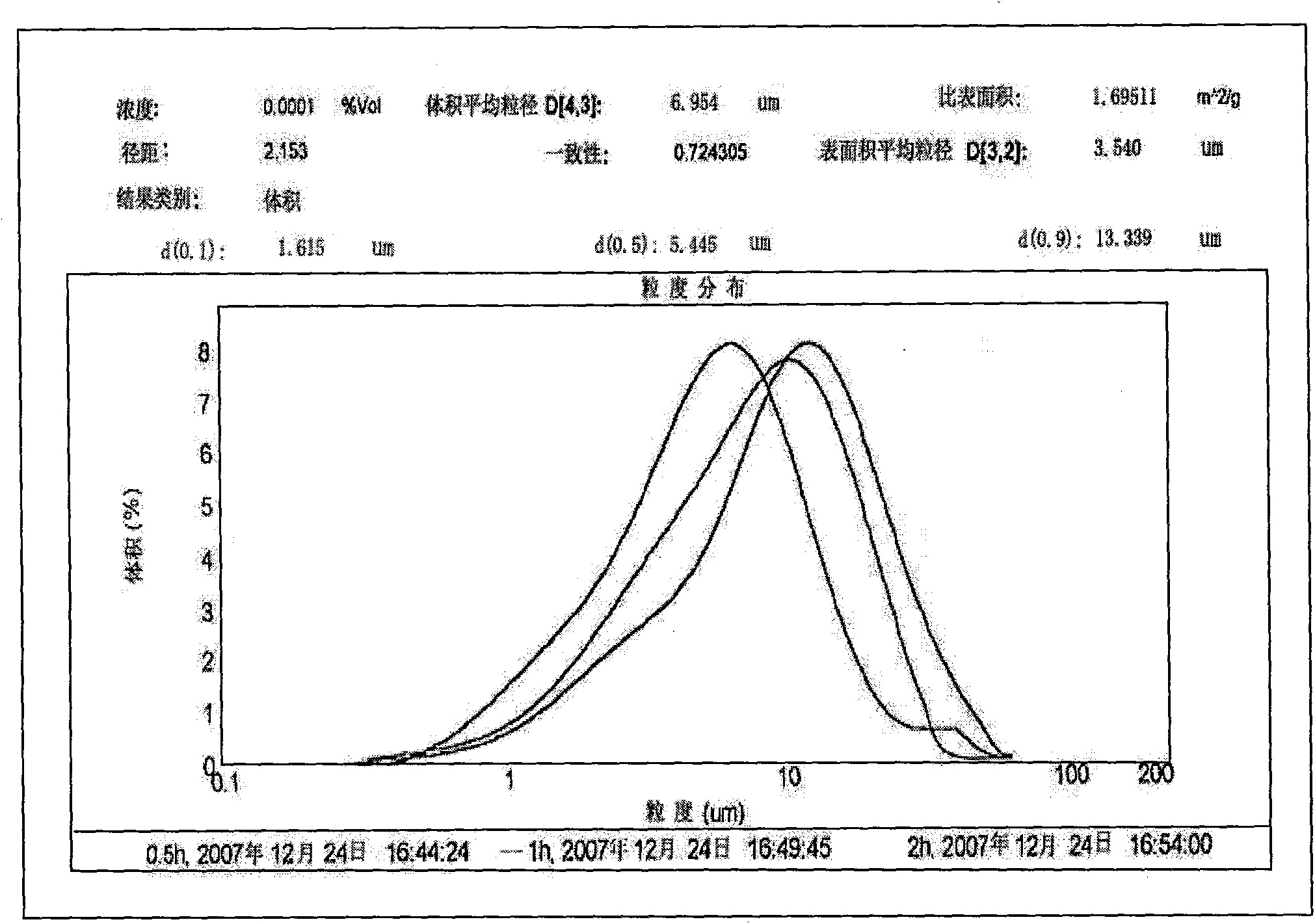

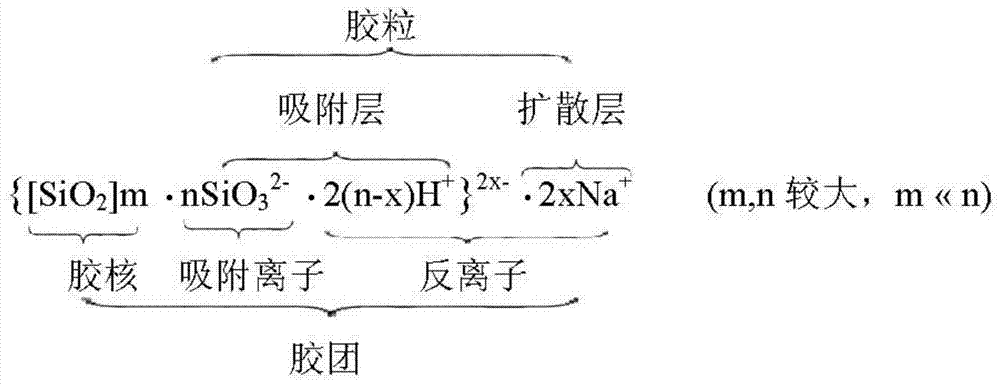

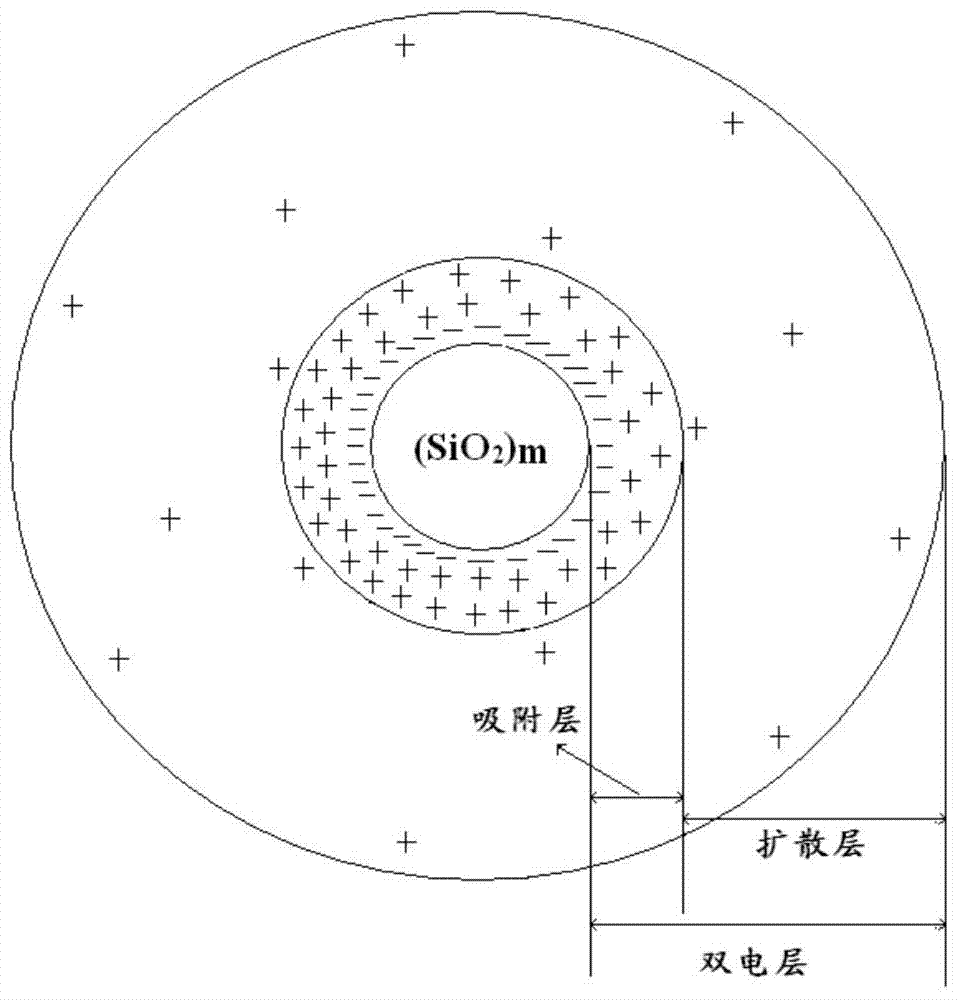

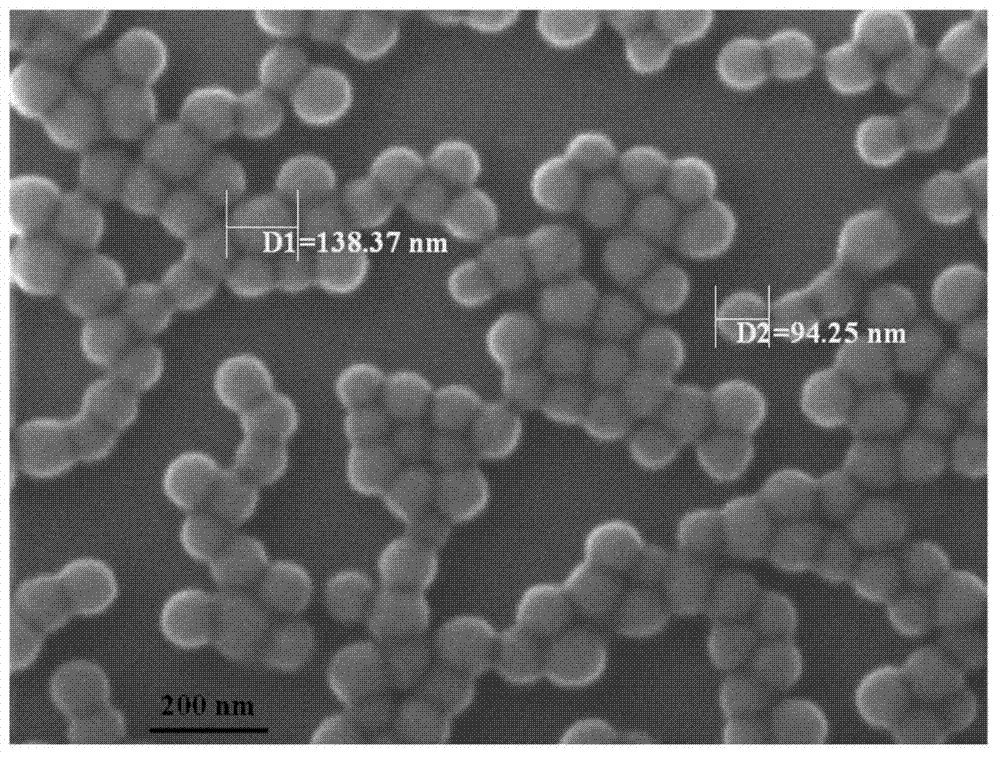

Method for rapidly preparing large-particle-size silica sol

The invention discloses a method for rapidly preparing large-particle-size silica sol, belongs to the field of inorganic application materials and in particular relates to an ion exchange method for rapidly preparing the large-particle-size silica sol. High-purity sodium silicate prepared by fumed silica is selected as a raw material, activated silica acid and silica mother solution are prepared by virtue of an ion exchange method, the pH value of the silica mother solution is regulated so as to compress a double electrode layer of silica sol particles, and the distance among the nanoparticles is further shortened so as to increase the silica particle size increase rate. Therefore, rapid formation of particle size of large-particle-size silica sol is promoted, narrow particle size distribution can be obtained, and the production efficiency and quality are greatly improved. According to the addition of a stabilizer and a polymerization inhibitor, the effects of preventing aggregation of silica sol and ending the reaction can be respectively achieved, and nanometer silica sol with uniform dispersion and controllable particle size is finally obtained. Compared with the traditional ion exchange method, the method disclosed by the invention has the advantages that the prepared silica sol is high in purity, the particle size distribution is narrow, and the production efficiency is doubled.

Owner:SHENZHEN LEAGUER MATERIAL +2

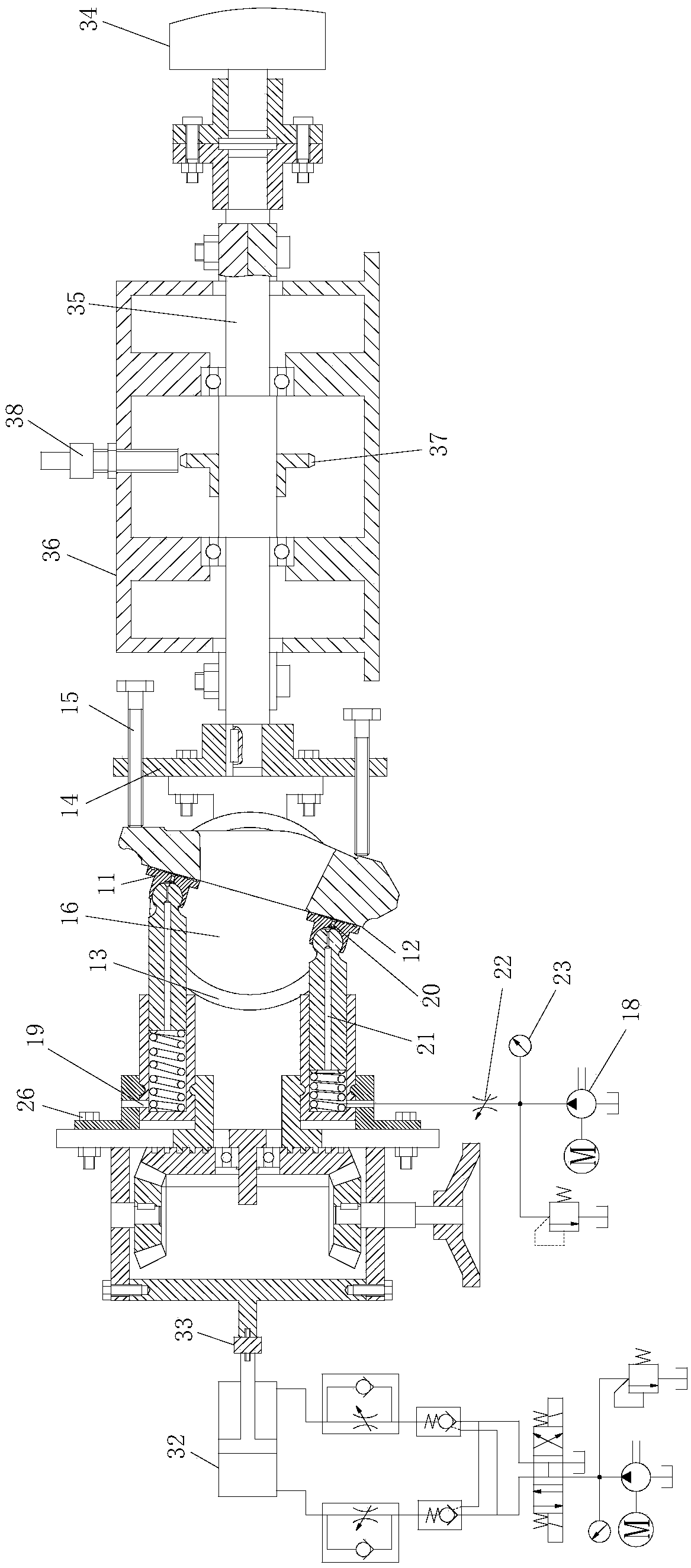

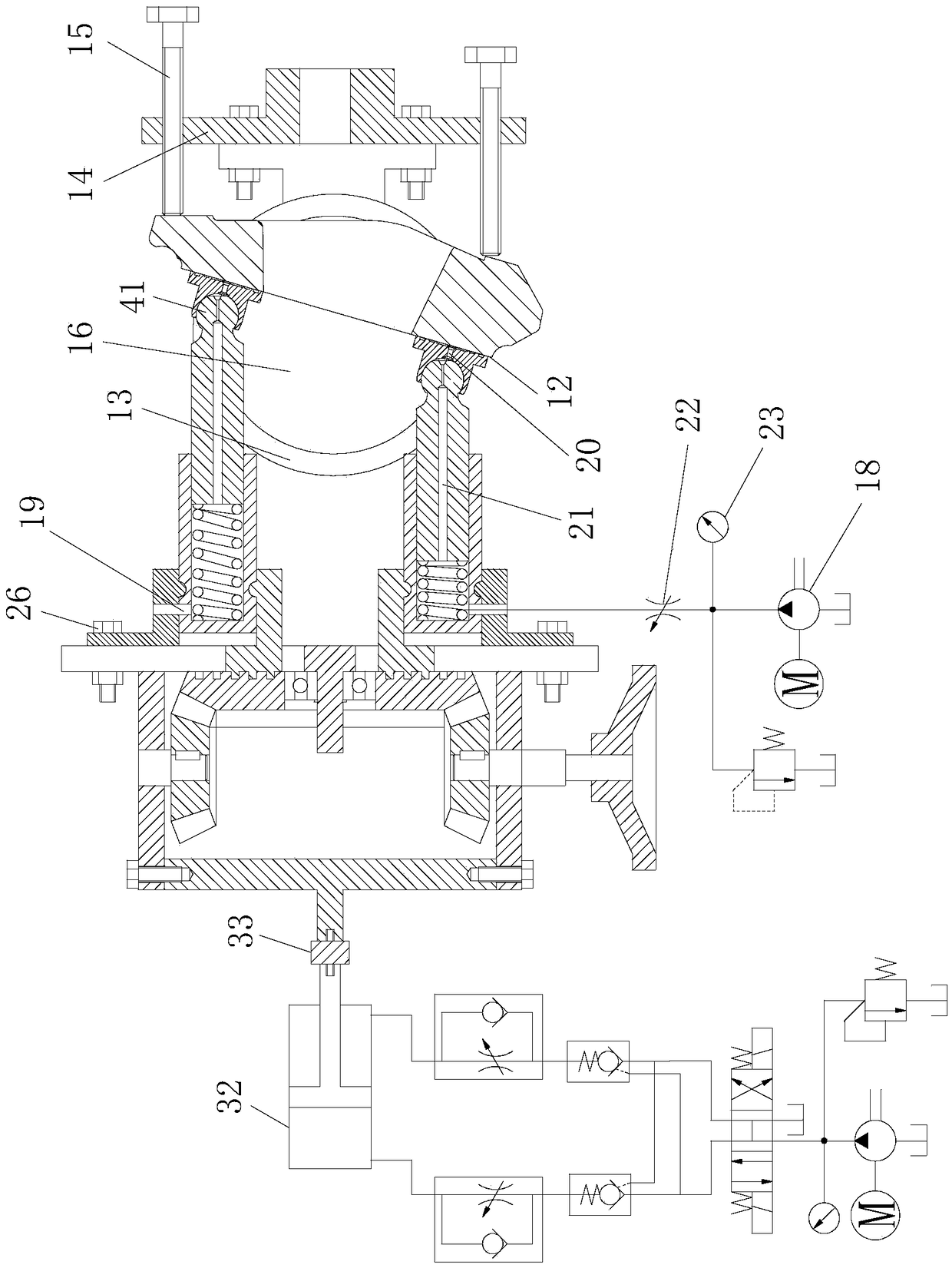

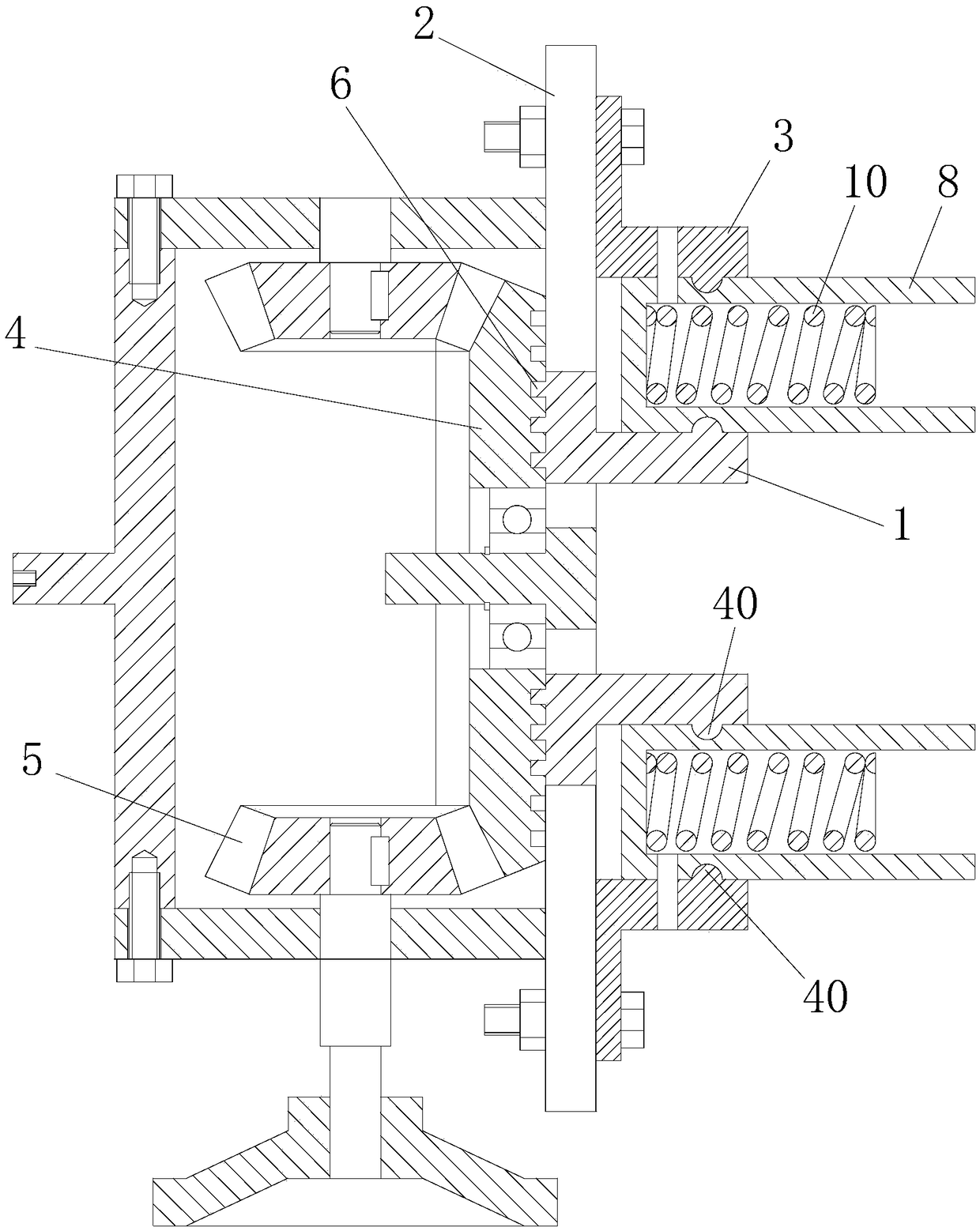

Axial plunger pump swash plate-piston shoe friction pair abrasion test device and test method thereof

PendingCN109026650ASolve complexityEnables evaluation of wear characteristicsPump testingPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses an axial plunger pump swash plate-piston shoe friction pair abrasion test device and a test method thereof. The axial plunger pump swash plate-piston shoe friction pair abrasion test device comprises a loading mechanism, a driving mechanism, a swash plate angle adjusting device and a piston shoe positioning and clamping mechanism. The loading mechanism and the piston shoe positioning and clamping mechanism are connected. The swash plate angle adjusting device is mounted on the driving mechanism. By means of the axial plunger pump swash plate-piston shoe friction pair abrasion test device and the test method thereof, the problems that axial plunger pump overall rack experiments and practical engine comprehensive investigation are long in period and complex are solved, the abrasion characteristic evaluation on a swash plate-piston shoe friction pair can be completed in a short experiment period, and a reliable basis is provided for practical production.

Owner:SOUTH CHINA UNIV OF TECH

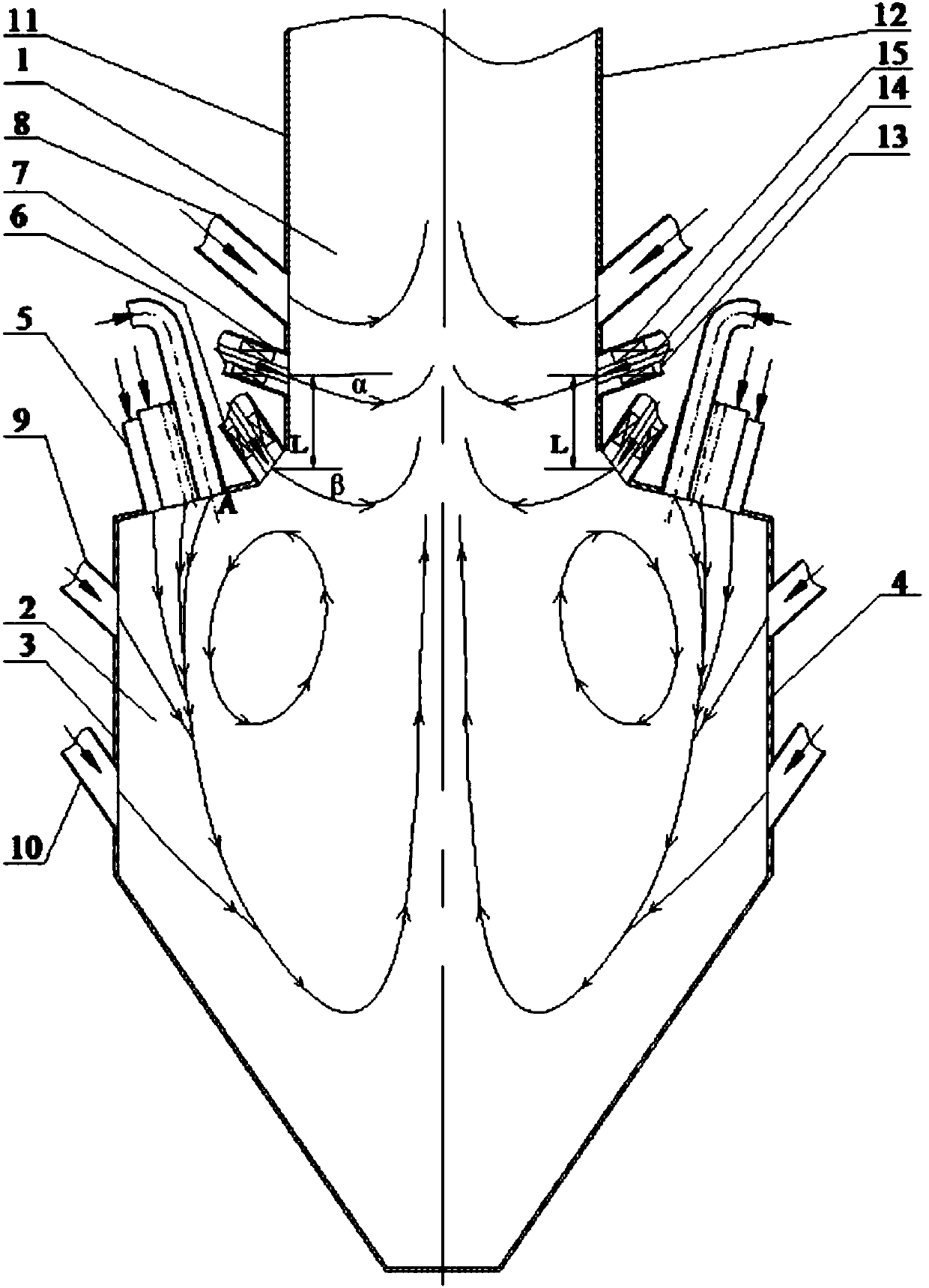

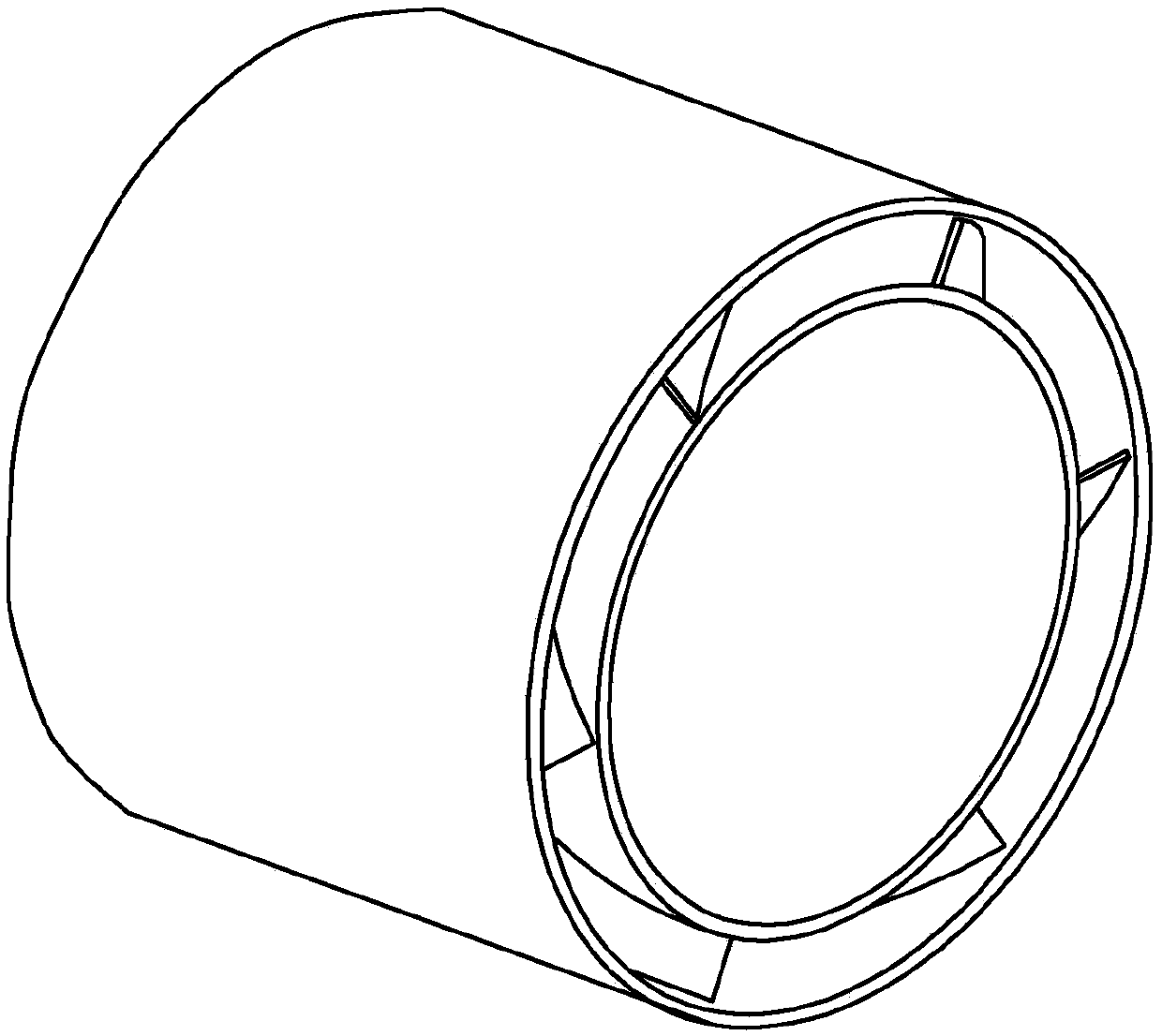

W flame boiler of turbulent burner with inner direct flow and outer turbulent flow ammonia spraying device

ActiveCN107559858AReduce NOxIncrease the degree of mixingDispersed particle separationCombustion apparatusNH3 compoundNozzle

The invention provides a W flame boiler of a turbulent burner with an inner direct flow and outer turbulent flow ammonia spraying device and relates to the W flame boiler. The W flame boiler solves the problems that an existing W flame boiler of the turbulent burner is high in NOx discharge amount and low in denitrifying efficiency. The center of a first stage ammonia spraying device is placed atthe upper edge of a front furnace arch or a back furnace arch, the distance L from the center line of a second stage ammonia spraying device to the upper edge of the front furnace arch or the back furnace arch is 1-2m, the center of the first stage ammonia spraying device is located in a same horizontal plane, and the center of the second stage ammonia spraying device is located on a same horizontal plane; the first stage ammonia spraying device and the second stage ammonia spraying device comprise inner tubes, outer rubes and a plurality of turbulent blades, the inner tubes and the outer tubes are arranged coaxially, the plurality of turbulent blades are uniformly distributed between the inner tubes and the outer tubes, the inner tubes are direct flow nozzles, and the plurality of turbulent blades arranged between the outer tubes and the inner tubes are turbulent nozzles which form the ammonia spraying device with an inner direct flow and an outer turbulent flow. The W flame boiler provided by the invention belongs to the technical field of NOx emission reduction.

Owner:HARBIN INST OF TECH

Equipment for producing aluminum alloy hollow casting ingot and method of equipment

The invention relates to the technical field of aluminum alloys, in particular to equipment for producing an aluminum alloy hollow casting ingot and a method of the equipment. The equipment for producing the aluminum alloy hollow casting ingot comprises a core die, a crystallizer, a bracket and a dummy ingot, wherein the core die is positioned at the center of the crystallizer and is concentric with the crystallizer; the bracket arranged on the crystallizer is used for supporting the core die; the dummy ingot is arranged at the lower part of the core die; a space between the core die and the crystallizer is a die cavity; the core die is designed into a taper with a large upper part and a small lower part; and the size of the taper is 1-30 degrees; a cooling system and a lubricating system are arranged in the core die; a coil is arranged in a water chamber of an aluminum sleeve of the crystallizer; and a shunt and a stop block are arranged on the crystallizer. According to the equipment for producing the aluminum alloy hollow casting ingot and the method for the equipment disclosed by the invention, a friction force between the casting ingot and the die core in the hollow casting process of the aluminum alloy is reduced and the core locking and breakout are avoided.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com