Twist extrusion forming die and twist extrusion forming method

A technology for forming molds and mold cavities, which is applied in the fields of twisting and extrusion forming molds and their forming, twisting and extrusion forming molds and forming, can solve the problems of high performance requirements of extrusion rods and high equipment requirements, and achieve the elimination of internal organizational defects and improve Overall performance, the effect of improving the stress-strain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Example: Twisted extrusion mould and forming method

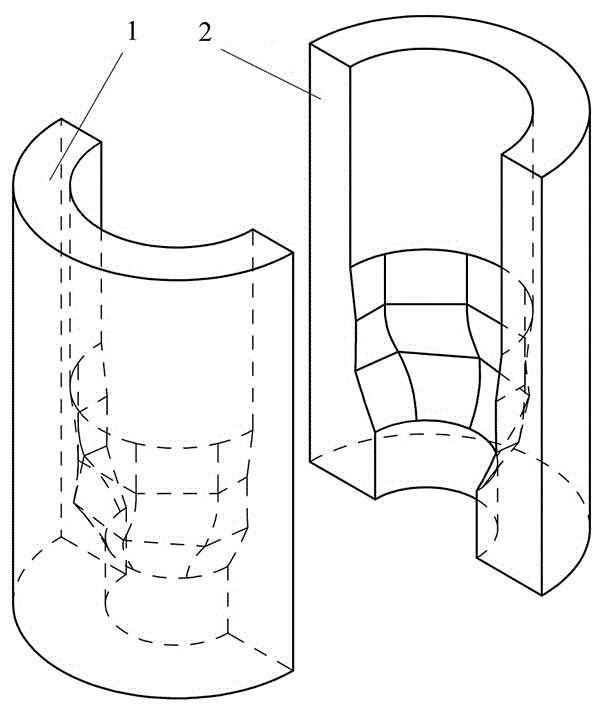

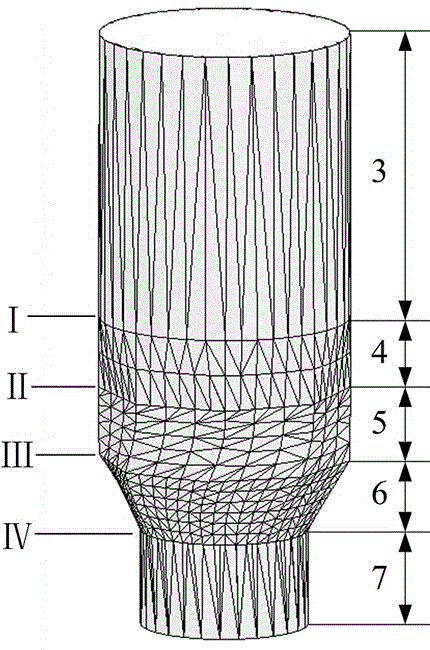

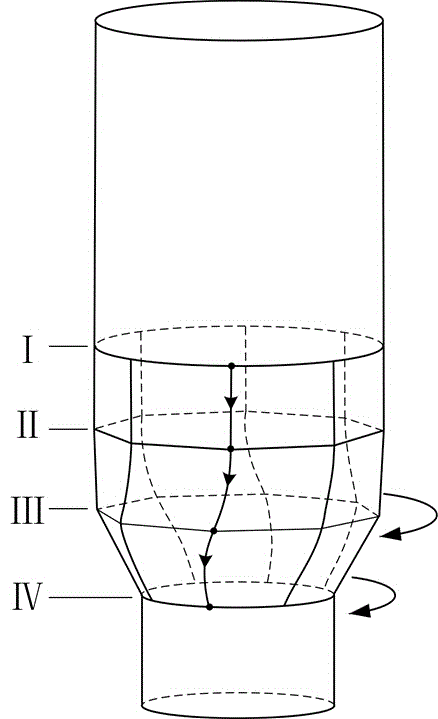

[0028] Figure 1~3 Shows the structure of the twist-extrusion mold, including the first half mold 1 and the second half mold 2. The first half mold 1 and the second half mold 2 are fastened by bolts to form a cylinder, and the inside of the cylinder is extrusion The mold cavity, and the parting surfaces of the first half mold 1 and the second half mold 2 are aligned and flush; the extrusion mold cavity descends from the extrusion inlet to the guide section 3, and the large round-octagonal transition section 4 , Regular octagonal torsion section 5, regular octagon-small circular torsion transition section 6, exit section 7;

[0029] The guide section 3 is an equal-diameter channel, the cross-sectional shape and size are the same as the shape and size of the extruded bar, the cross-section is a large circle, the diameter is 50 mm, and the length of the guide section is 225 mm;

[0030] The large circle-regular octagonal tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com